Learned Block Iterative Shrinkage Thresholding Algorithm for Photothermal Super Resolution Imaging

Abstract

1. Introduction

- implementation of LBISTA as a method to solve the inverse problem in photothermal SR imaging for nondestructive testing without a manual choice of regularization parameters;

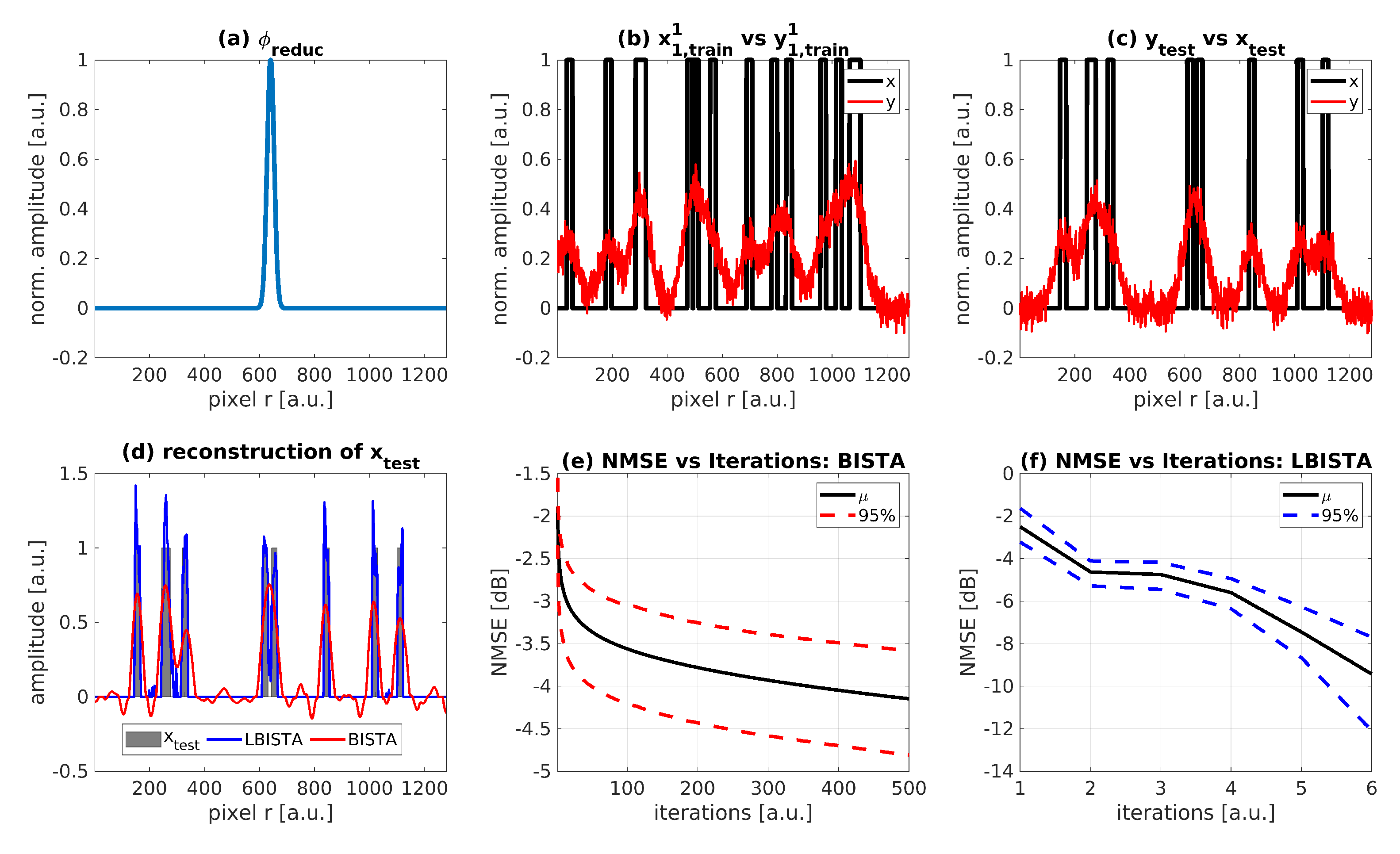

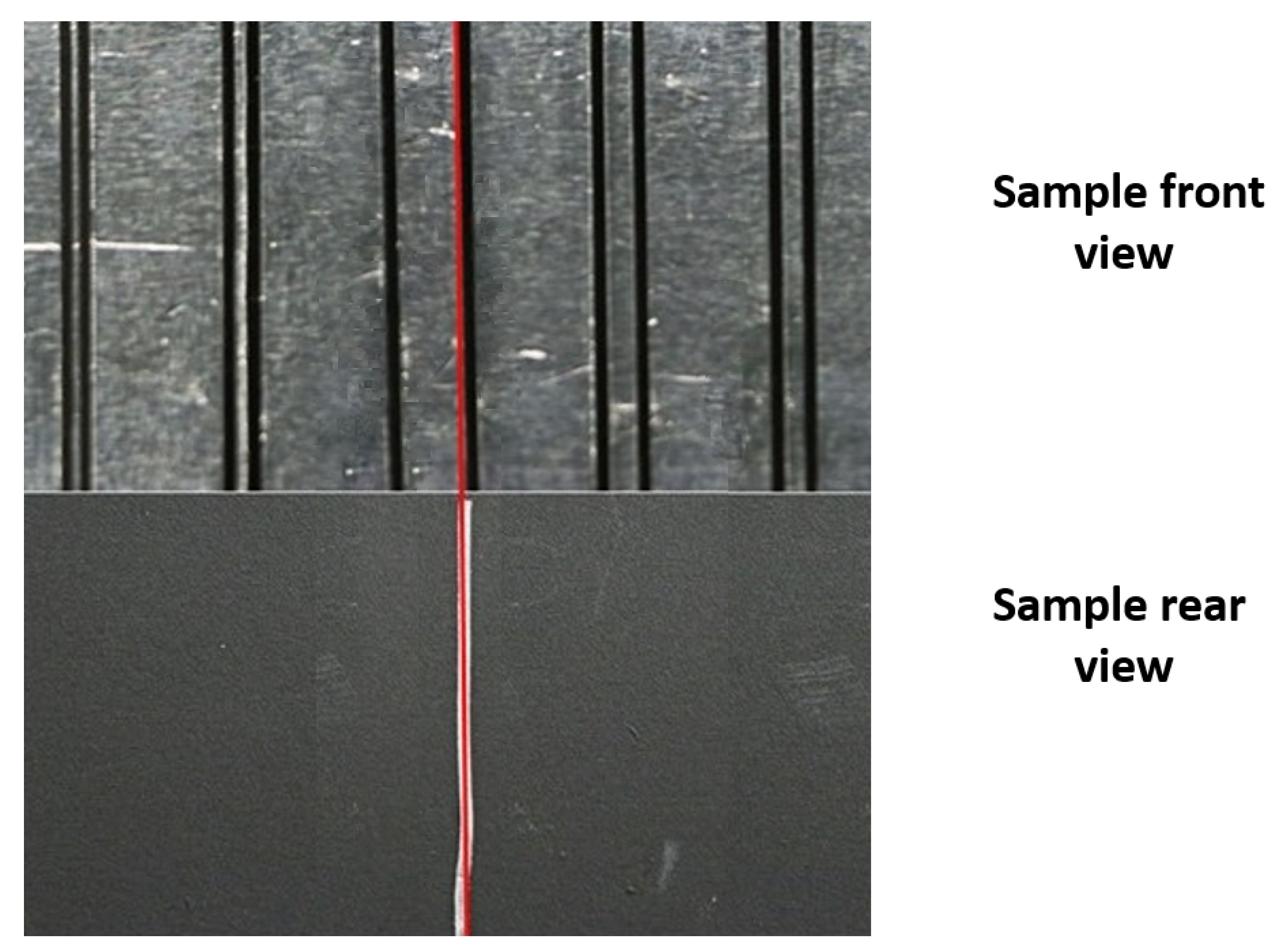

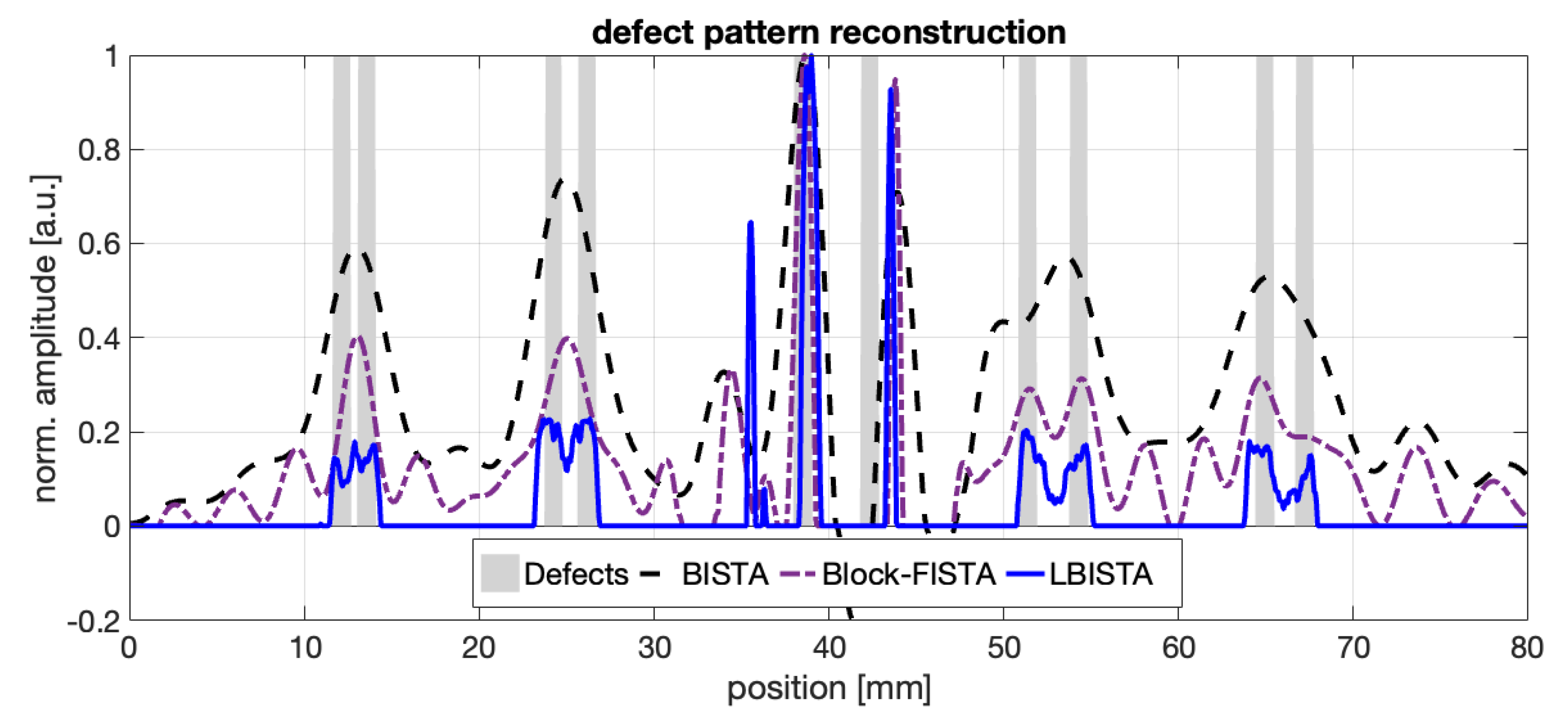

- results of applying LBISTA to synthetic and experimental test data based on experiments performed with a specimen made of steel S235JR to examine defects that are not resolvable with conventional flash thermography;

- comparison of LBISTA with state-of-the-art BISTA for photothermal SR imaging;

- parameter studies of (i) tied and (ii) untied LBISTA: (1) studies of the hyperparameters, (2) studies of the parameters set to generate the synthetic training data (forward model) for photothermal SR imaging. In the tied case we train the same particular trainable parameter for each layer and in the untied case we can train it for each layer individually.

2. Mathematical Model in Active Thermal Imaging

2.1. Defect Detection and Reconstruction

2.2. Photothermal Super Resolution

2.3. Block-Minimization Problem

3. Learned Block Iterative Shrinkage Thresholding Algorithm

3.1. Training Data

3.2. Training Implementation

| Algorithm 1: LBISTA, implementation of training |

Input :Training rate tr, refinements f, exact solution x∗,m and trainable Variables V with case = tied or case = untied |

4. Evaluation of LBISTA

4.1. Numerical Results

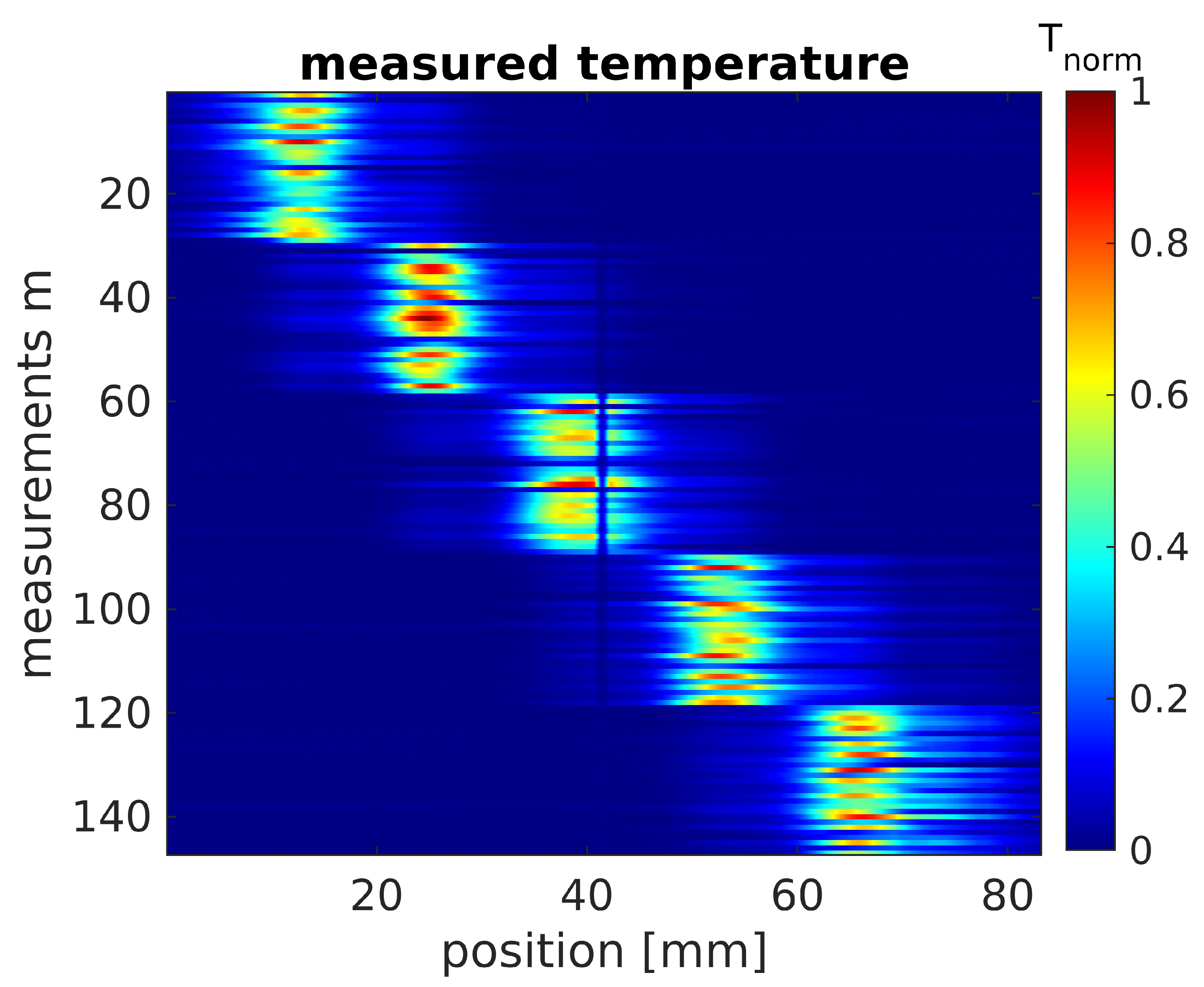

4.2. Evaluation of LBISTA with Experimental Data from Active Thermal Imaging

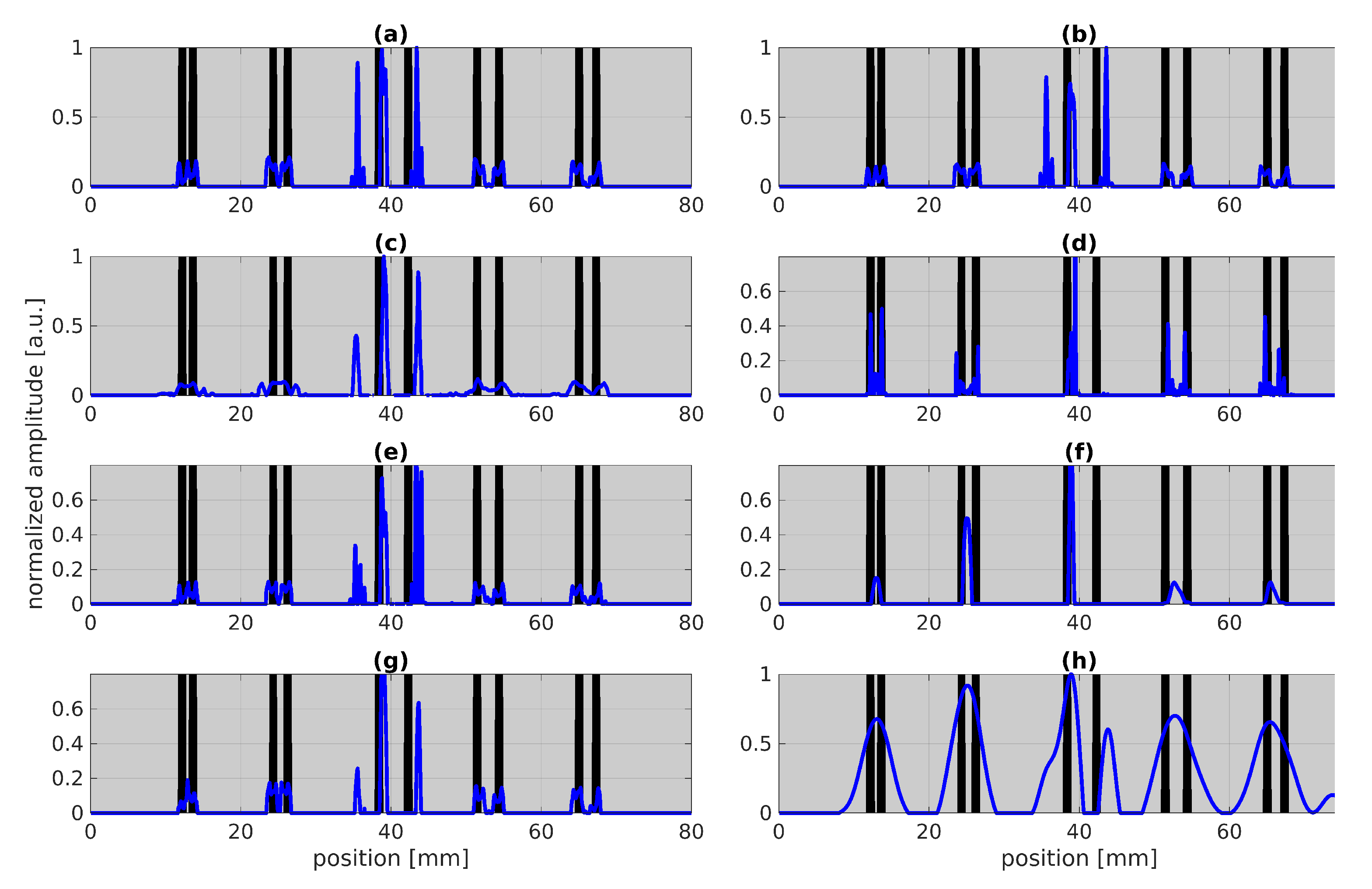

- Training batch size (a,b): Varying the number of batches between and does not really change the result.

- Defect pattern (c,d,e,f): In contrast, changing the sparsity of the defects from(c.f. (e,f)) or the defect width (see (c,d)) leads to significant changes in the results such that the result in (d) is even able to clearly detect both stripes in the first pair with the smallest distance between the stripes. In (f), obviously a too small sparsity has been used as the PNZ is quite high in comparison to the chosen PNZ in (e). Thus, it is obviously beneficial to know roughly the sparsity.

- Training rate and number of layers (g,h): In (g) we get similarly good results just by using one refinement instead of three as used in Figure 5. Only using one refinement could save a lot of time during training. In (h), a rather bad result is shown, where we used one refinement and only three layers. Thus, these parameters should be chosen high enough so that we reach convergence within training.

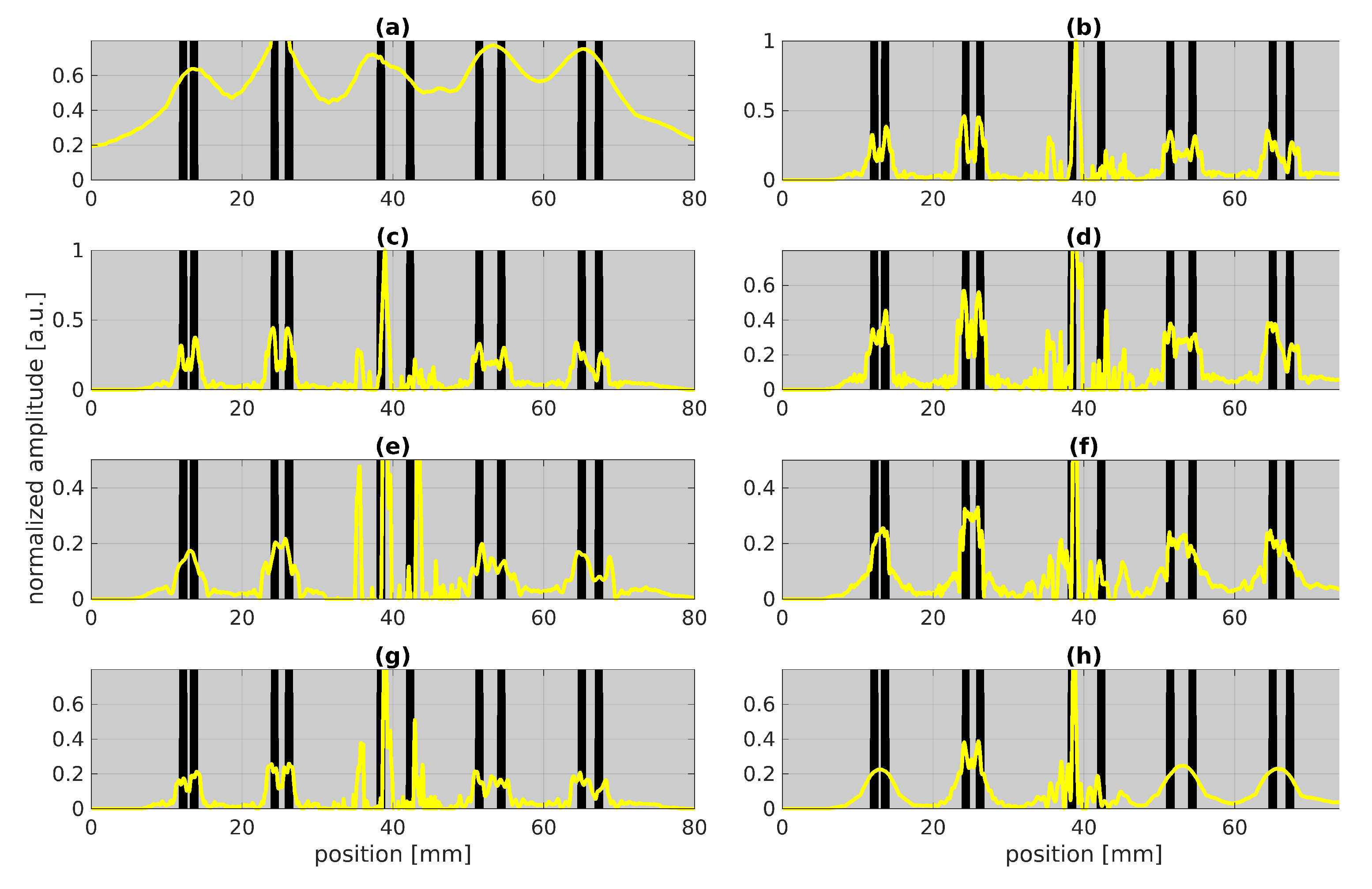

- Absorption coefficient and training iterations (a,b): In contrast to tied LBISTA, untied LBISTA exhibits significant changes by varying the absorption coefficient in training. According to our studies, an absorption coefficient of is a good choice. Further, increasing the maximum number of iterations as shown in (b) can enhance the reconstruction quality so that all stripes could be indicated very well except for the middle stripe pair (most likely due to the marker line).

- Training batch size (c,d): The result in (c) using fewer batches and iterations as in (b) shows that similarly good results can be achieved. Increasing the number of batches to as shown in (d) can further enhance the reconstruction quality as now even the middle defect pair could be clearly resolved.

- Defect width (e,f): The variation of the defect width rather degrades the reconstruction result as shown in (e,f). This means that the default choice performs best for untied LBISTA. However, with tied LBISTA (Figure 6c,d) we could see improvements by changing the parameter of the defect width.

- Defect sparsity (g,h): The variation of the sparsity in untied LBISTA in (g,h) confirms our investigations in tied LBISTA (see (e,f)), deterioration by using a too small sparsity of .

5. Conclusions and Outlook

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Vollmer, M.; Möllmann, K.-P. Infrared Thermal Imaging: Fundamentals, Research and Applications; John Wiley & Sons: Hoboken, NJ, USA, 2017. [Google Scholar]

- Ortega, J.M.; Golobic, M.; Sain, J.D.; Lenhardt, J.M.; Wu, A.S.; Fisher, S.E.; Perez, L.X.P.; Jaycox, A.W.; Smay, J.E.; Duoss, E.B.; et al. Active mixing of disparate inks for multimaterial 3D printing. Adv. Mater. Technol. 2019, 4, 1800717. [Google Scholar] [CrossRef]

- Ciampa, F.; Mahmoodi, P.; Pinto, F.; Meo, M. Recent advances in active infrared thermography for non-destructive testing of aerospace components. Sensors 2018, 18, 609. [Google Scholar] [CrossRef] [PubMed]

- Strąkowska, M.; Strąkowski, R.; Strzelecki, M.; De Mey, G.; Więcek, B. Thermal modelling and screening method for skin pathologies using active thermography. Biocybern. Biomed. Eng. 2018, 38, 602–610. [Google Scholar] [CrossRef]

- Gonzalez-Hernandez, J.L.; Recinella, A.N.; Kandlikar, S.G.; Dabydeen, D.; Medeiros, L.; Phatak, P. Technology, application and potential of dynamic breast thermography for the detection of breast cancer. Int. J. Heat Mass Transf. 2019, 131, 558–573. [Google Scholar] [CrossRef]

- Wiecek, B. Review on thermal image processing for passive and active thermography. In Proceedings of the IEEE Engineering in Medicine and Biology 27th Annual Conference, Shanghai, China, 17–18 January 2006. [Google Scholar]

- Samadi, N.; Thapa, D.; Salimi, M.; Parkhimchyk, A.; Tabatabaei, N. Low-cost active thermography using cellphone infrared cameras: From early detection of dental caries to quantification of THC in oral fluid. Sci. Rep. 2020, 10, 7857. [Google Scholar] [CrossRef]

- Almond, D.P.; Patel, P.M. Photothermal Science and Techniques; Springer Science & Business Media: Berlin/Heidelberg, Germany, 1996; Volume 10. [Google Scholar]

- Hung, Y.Y.; Chen, Y.S.; Ng, S.P.; Liu, L.; Huang, Y.H.; Luk, B.L.; Ip, R.W.L.; Wu, C.M.L.; Chung, P.S. Review and comparison of shearography and active thermography for nondestructive evaluation. Mater. Sci. Eng. R Rep. 2009, 64, 73–112. [Google Scholar] [CrossRef]

- Cole, K.; Beck, J.; Haji-Sheikh, A.; Litkouhi, B. Heat Conduction Using Greens Functions; Taylor & Francis: Abingdon, UK, 2010. [Google Scholar]

- Bryan, K.; Caudill, L.F., Jr. An inverse problem in thermal imaging. SIAM J. Appl. Math. 1996, 56, 715–735. [Google Scholar] [CrossRef][Green Version]

- Wang, J.; Zabaras, N. Hiearchical Bayesian models for inverse problems in heat conduction. Inverse Probl. 2004, 21, 183. [Google Scholar] [CrossRef]

- Kukreja, S.L.; Löfberg, J.; Brenner, M.J. A least absolute shrinkage and selection operator (LASSO) for nonlinear system identification. IFAC Proc. 2006, 39, 814–819. [Google Scholar] [CrossRef]

- Donoho, D.L. Compressed Sensing. IEEE Trans. Inf. Theory 2006, 52, 1289–1306. [Google Scholar] [CrossRef]

- Baraniuk, R.G. Compressive Sensing. IEEE Signal Process. Mag. 2007, 24, 187–229. [Google Scholar] [CrossRef]

- Beck, A.; Teboulle, M. A fast iterative shrinkage-thresholding algorithm for linear inverse problems. SIAM J. Imaging Sci. 2009, 2, 183–202. [Google Scholar] [CrossRef]

- Gregor, K.; LeCun, Y. Learning Fast Approximations of Sparse Coding. In Proceedings of the 27th International Conference on Machine Learning, Haifa, Israel, 21–24 June 2010; pp. 399–406. [Google Scholar]

- Liu, J.; Chen, X.; Wang, Z.; Yin, W. ALISTA: Analytic Weights Are As Good As Learned Weights in LISTA. In Proceedings of the International Conference on Learning Representations, New Orleans, LA, USA, 6–9 May 2019. [Google Scholar]

- Kim, D.; Park, D. Element-Wise Adaptive Thresholds for Learned Iterative Shrinkage Thresholding Algorithms. IEEE Access 2020, 8, 45874–45886. [Google Scholar] [CrossRef]

- Chun, I.Y.; Huang, Z.; Lim, H.; Fessler, J.A. Momentum-Net: Fast and convergent iterative neural network for inverse problems. IEEE Trans. Pattern Anal. Mach. Intell. 2020, 1. [Google Scholar] [CrossRef]

- Lv, X.; Bi, G.; Wan, C. The Group Lasso for Stable Recovery of Block-Sparse Signal Representations. IEEE Trans. Signal Process. 2011, 59, 1371–1382. [Google Scholar] [CrossRef]

- Eldar, Y.C.; Bolcskei, H. Block-sparsity: Coherence and efficient recovery. In Proceedings of the 2009 IEEE International Conference on Acoustics, Speech and Signal Processing, Taipei, Taiwan, 19–24 April 2009; pp. 2885–2888. [Google Scholar]

- Elhamifar, E.; Vidal, R. Block-sparse recovery via convex optimization. IEEE Trans. Signal Process. 2012, 60, 4094–4107. [Google Scholar] [CrossRef]

- Lin, J.H.; Li, S. Block sparse recovery via mixed l 2/l 1 minimization. Acta Math. Sin. Engl. Ser. 2013, 29, 1401–1412. [Google Scholar] [CrossRef]

- Boufounos, P.; Kutyniok, G.; Rauhut, H. Sparse recovery from combined fusion frame measurements. IEEE Trans. Inf. Theory 2011, 57, 3864–3876. [Google Scholar] [CrossRef]

- Ahmadi, S.; Thummerer, G.; Breitwieser, S.; Mayr, G.; Lecompagnon, J.; Burgholzer, P.; Jung, P.; Caire, G.; Ziegler, M. Multidimensional Reconstruction of Internal Defects in Additively Manufactured Steel Using Photothermal Super Resolution Combined With Virtual Wave-Based Image Processing. IEEE Trans. Ind. Inform. 2021, 17, 7368–7378. [Google Scholar] [CrossRef]

- Murray, T.W.; Haltmeier, M.; Berer, T.; Leiss-Holzinger, E.; Burgholzer, P. Super-resolution photoacoustic microscopy using blind structured illumination. Optica 2017, 4, 17–22. [Google Scholar] [CrossRef]

- Burgholzer, P.; Berer, T.; Gruber, J.; Mayr, G. Super-resolution thermographic imaging using blind structured illumination. Appl. Phys. Lett. 2017, 111, 031908. [Google Scholar] [CrossRef]

- Burgholzer, P.; Berer, T.; Ziegler, M.; Thiel, E.; Ahmadi, S.; Gruber, J.; Mayr, G.; Hendorfer, G. Blind structured illumination as excitation for super-resolution photothermal radiometry. Quant. Infrared Thermogr. J. 2020, 7, 268–278. [Google Scholar] [CrossRef]

- Ahmadi, S.; Burgholzer, P.; Mayr, G.; Jung, P.; Caire, G.; Ziegler, M. Photothermal super resolution imaging: A comparison of different thermographic reconstruction techniques. NDT E Int. J. 2020, 111, 102228. [Google Scholar] [CrossRef]

- Ahmadi, S.; Burgholzer, P.; Jung, P.; Caire, G.; Ziegler, M. Super resolution laser line scanning thermography. Opt. Lasers Eng. 2020, 134, 106279. [Google Scholar] [CrossRef]

- Ahmadi, S.; Lecompagnon, J.; Hirsch, P.D.; Burgholzer, P.; Jung, P.; Caire, G.; Ziegler, M. Laser excited super resolution thermal imaging for nondestructive inspection of internal defects. Sci. Rep. 2020, 10, 22357. [Google Scholar] [CrossRef]

- Seppala, J.E.; Migler, K.D. Infrared thermography of welding zones produced by polymer extrusion additive manufacturing. Addit. Manuf. 2016, 12, 71–76. [Google Scholar] [CrossRef]

- Mohr, G.; Altenburg, S.J.; Ulbricht, A.; Heinrich, P.; Baum, D.; Maierhofer, C.; Hilgenberg, K. In-situ defect detection in laser powder bed fusion by using thermography and optical tomography—Comparison to computed tomography. Metals 2020, 10, 103. [Google Scholar] [CrossRef]

- Altenburg, S.J.; Straße, A.; Gumenyuk, A.; Maierhofer, C. In-situ monitoring of a laser metal deposition (LMD) process: Comparison of MWIR, SWIR and high-speed NIR thermography. Quant. Infrared Thermogr. J. 2020, 19, 97–114. [Google Scholar] [CrossRef]

- Metz, C.; Franz, P.; Fischer, C.; Wachtendorfer, V. Active thermography for quality assurance of 3D-printed polymer structures. Quant. Infrared Thermogr. J. 2021, 18, 50–71. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, H.; Wang, J.; Pu, Y.; Pal, N.R. Feature Selection Using a Neural Network With Group Lasso Regularization and Controlled Redundancy. IEEE Trans. Neural Netw. Learn. Syst. 2021, 32, 1110–1123. [Google Scholar] [CrossRef]

- Wen, W.; Wu, C.; Wang, Y.; Chen, Y.; Li, H. Learning Structured Sparsity in Deep Neural Networks. In Proceedings of the Advances in Neural Information Processing Systems 29 (NIPS 2016), Barcelona, Spain, 5–10 December 2016. [Google Scholar]

- Huang, G.; Liu, S.; Van der Maaten, L.; Weinberger, K.Q. Condensenet: An efficient densenet using learned group convolutions. In Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition, Salt Lake City, UT, USA, 18–23 June 2018. [Google Scholar]

- Ahmadi, S.; Kästner, L.; Hauffen, J.C.; Jung, P.; Ziegler, M. Photothermal-SR-Net: A Customized Deep Unfolding Neural Network for Photothermal Super Resolution Imaging. IEEE Trans. Instrum. Meas. 2022, 71, 4502509. [Google Scholar] [CrossRef]

- Haltmeier, M. Block-sparse analysis regularization of ill-posed problems via L2,1-minimization. In Proceedings of the 18th International Conference on Methods & Models in Automation & Robotics (MMAR), Miedzyzdroje, Poland, 26–29 August 2013. [Google Scholar]

- Borgerding, M.; Schniter, P.; Rangan, S. AMP-Inspired Deep Networks for Sparse Linear Inverse Problems. IEEE Trans. Signal Process. 2017, 65, 4293–4308. [Google Scholar] [CrossRef]

- Chen, X.; Liu, J.; Wang, Z.; Yin, W. Theoretical linear convergence of unfolded ISTA and its practical weights and thresholds. arXiv 2018, arXiv:1808.10038. [Google Scholar]

| Gaussian Noise in | SNR = 8 dB |

| Defect pattern | defect width = mm |

| defect sparsity (PNZ) = | |

| absorption coefficient = | |

| Illumination pattern | laser line width = mm |

| illumination sparsity (PNZ) = | |

| Training parameters | refinements f: |

| training rate | |

| initial lambda | |

| number of layers | |

| step size | |

| batch number | |

| tied LBISTA | max. number of iterations |

| untied LBISTA | max. number of iterations |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hauffen, J.C.; Kästner, L.; Ahmadi, S.; Jung, P.; Caire, G.; Ziegler, M. Learned Block Iterative Shrinkage Thresholding Algorithm for Photothermal Super Resolution Imaging. Sensors 2022, 22, 5533. https://doi.org/10.3390/s22155533

Hauffen JC, Kästner L, Ahmadi S, Jung P, Caire G, Ziegler M. Learned Block Iterative Shrinkage Thresholding Algorithm for Photothermal Super Resolution Imaging. Sensors. 2022; 22(15):5533. https://doi.org/10.3390/s22155533

Chicago/Turabian StyleHauffen, Jan Christian, Linh Kästner, Samim Ahmadi, Peter Jung, Giuseppe Caire, and Mathias Ziegler. 2022. "Learned Block Iterative Shrinkage Thresholding Algorithm for Photothermal Super Resolution Imaging" Sensors 22, no. 15: 5533. https://doi.org/10.3390/s22155533

APA StyleHauffen, J. C., Kästner, L., Ahmadi, S., Jung, P., Caire, G., & Ziegler, M. (2022). Learned Block Iterative Shrinkage Thresholding Algorithm for Photothermal Super Resolution Imaging. Sensors, 22(15), 5533. https://doi.org/10.3390/s22155533