Monitoring and Visualization of Crystallization Processes Using Electrical Resistance Tomography: CaCO3 and Sucrose Crystallization Case Studies

Abstract

:1. Introduction

2. ERT System and Methods

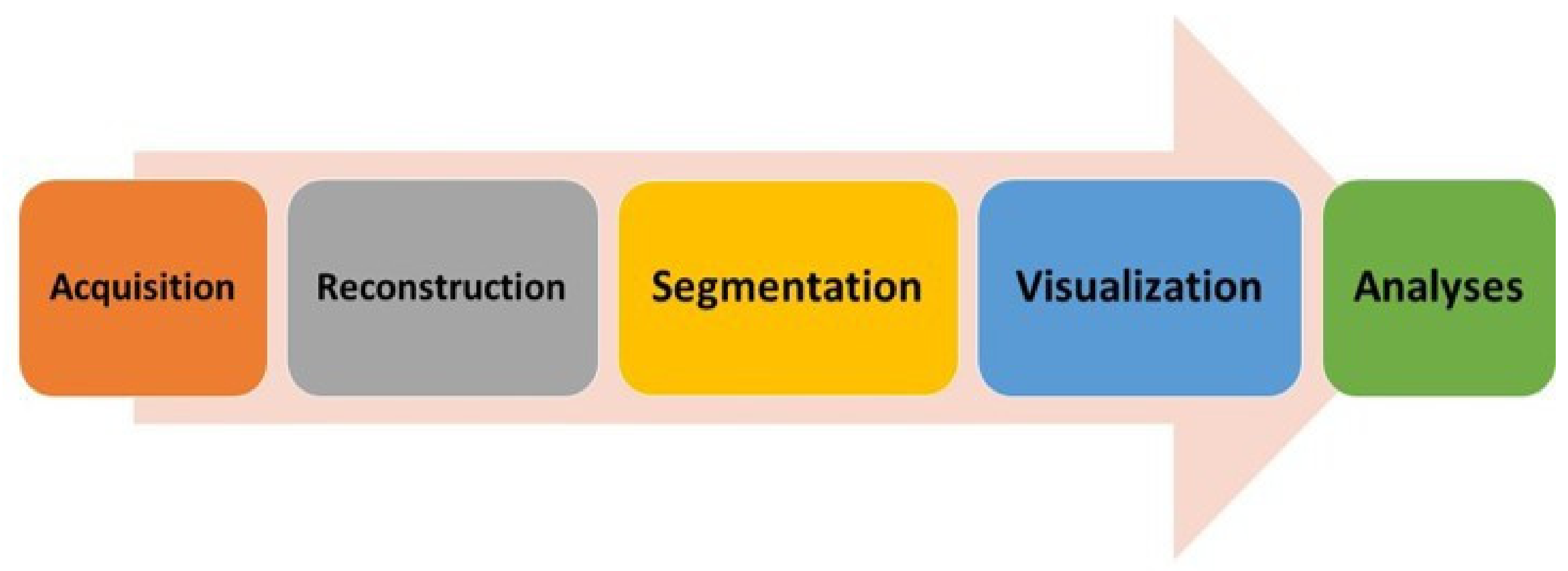

2.1. Process Engineering Workflow Using ERT

2.2. General ERT System

2.3. Related Works for ERT Software Development

3. Experimental Setup and Crystallization Process Description

3.1. Process Description of CaCO3 Reactive Crystallization

3.2. Process Description for Sucrose Crystallization

4. Development of the Software ERT-Vis

4.1. Development of the Application Modules and GUI

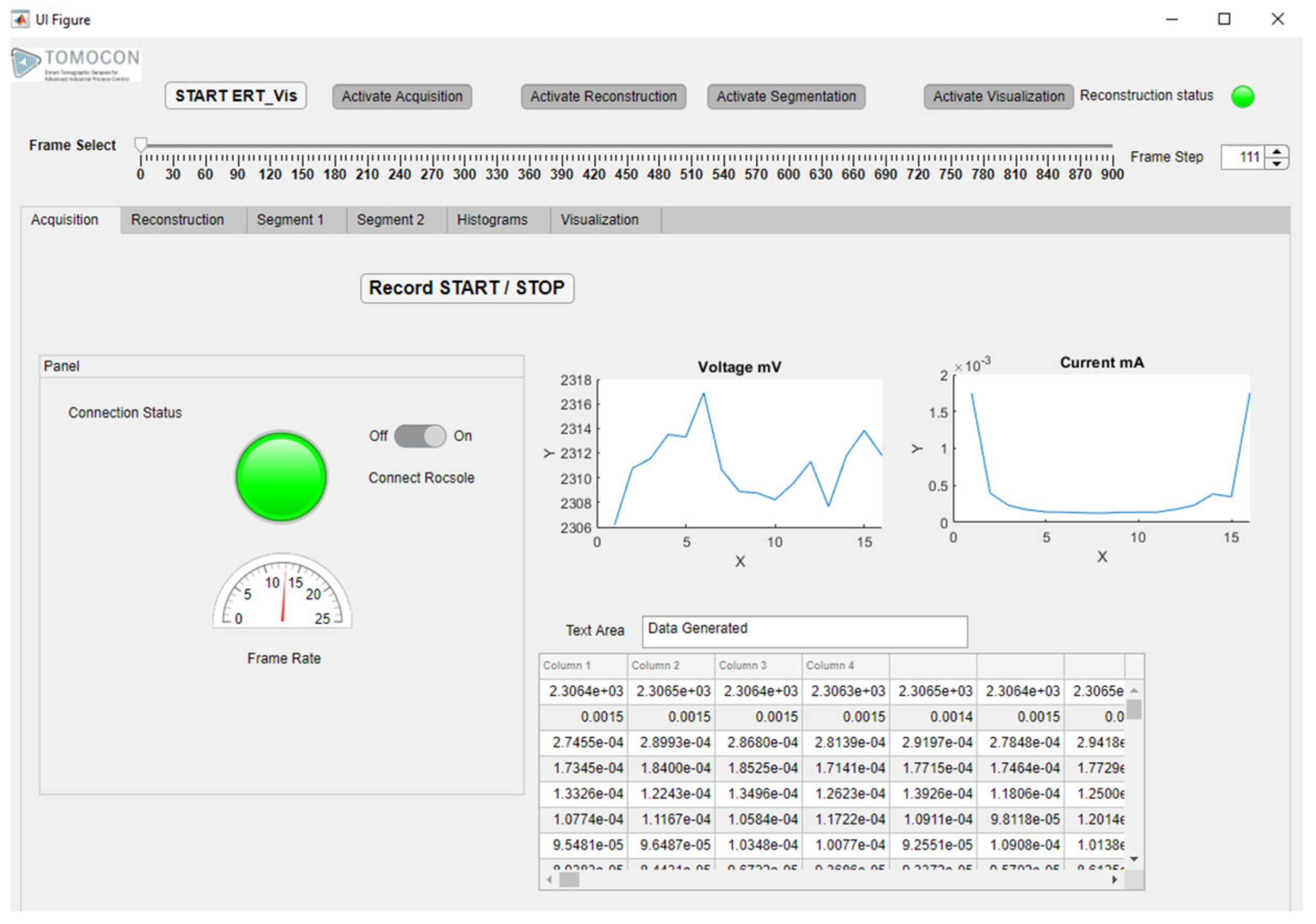

4.2. Module 1: Data Acquisition

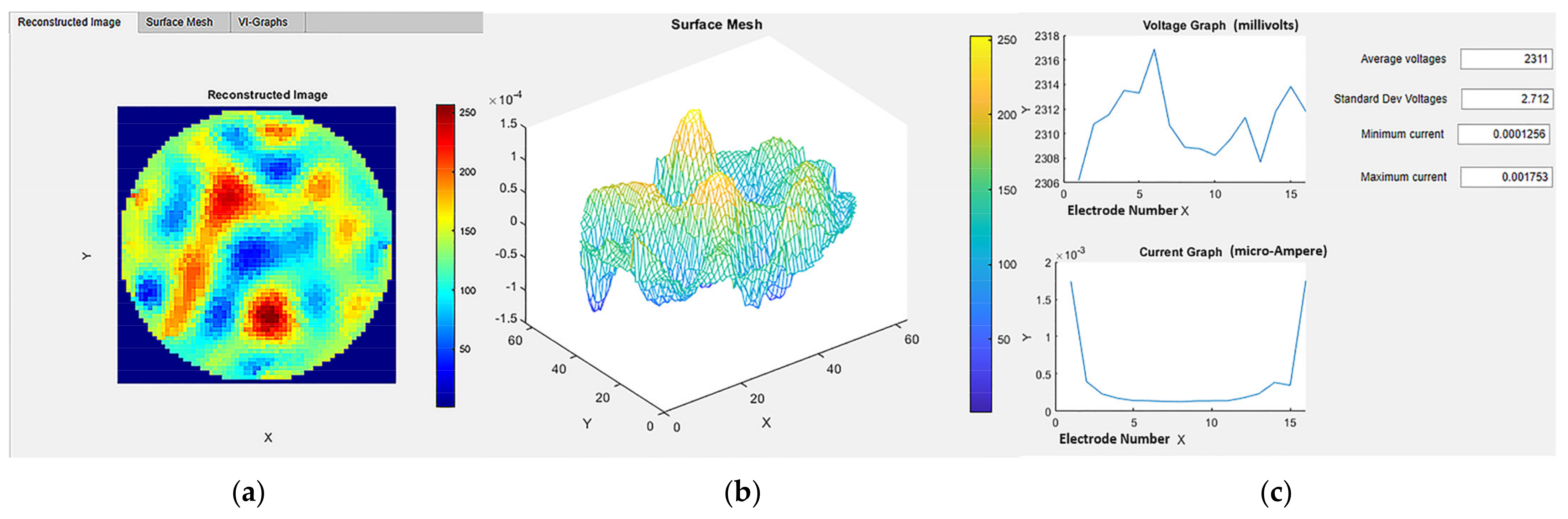

4.3. Module 2: Reconstruction

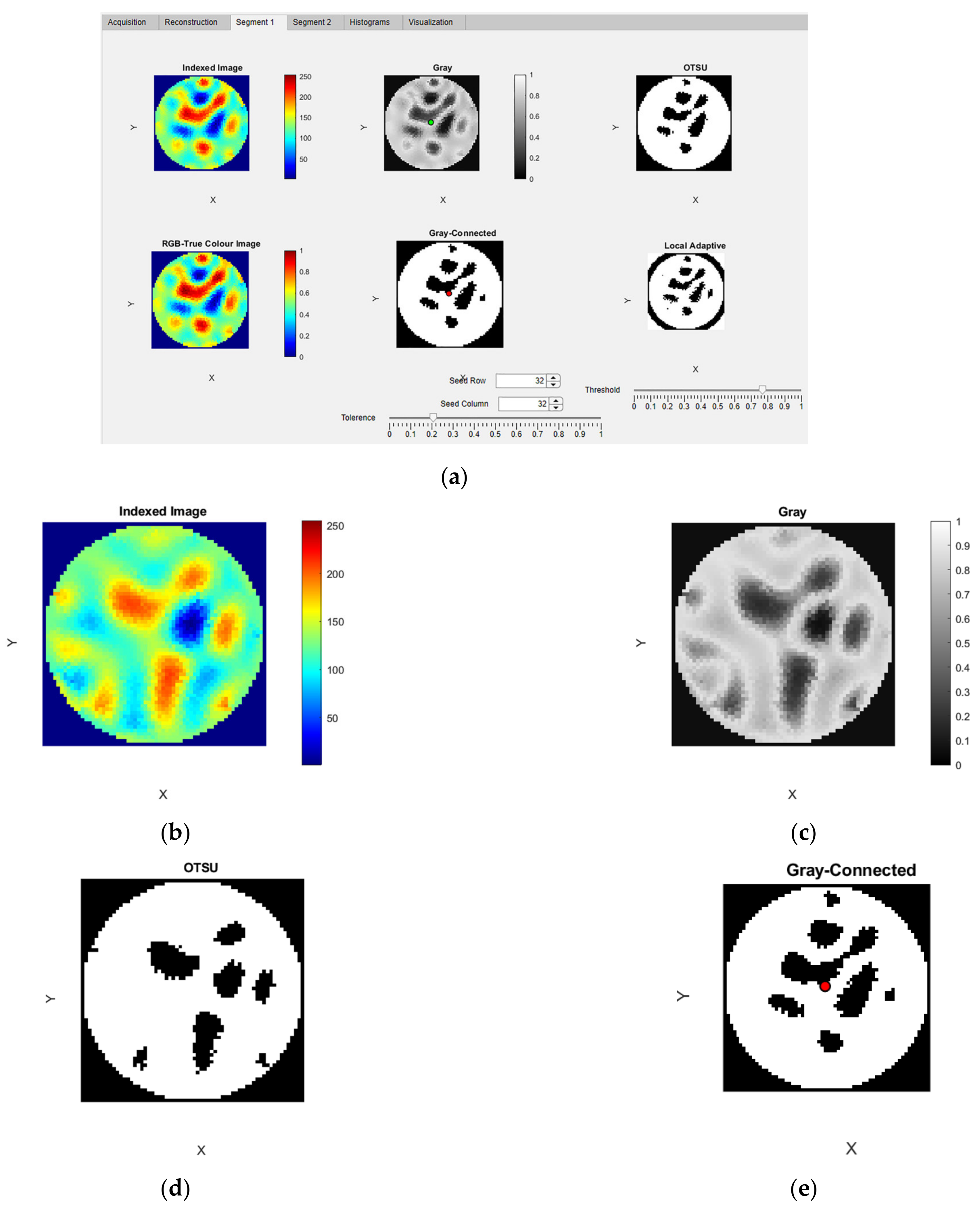

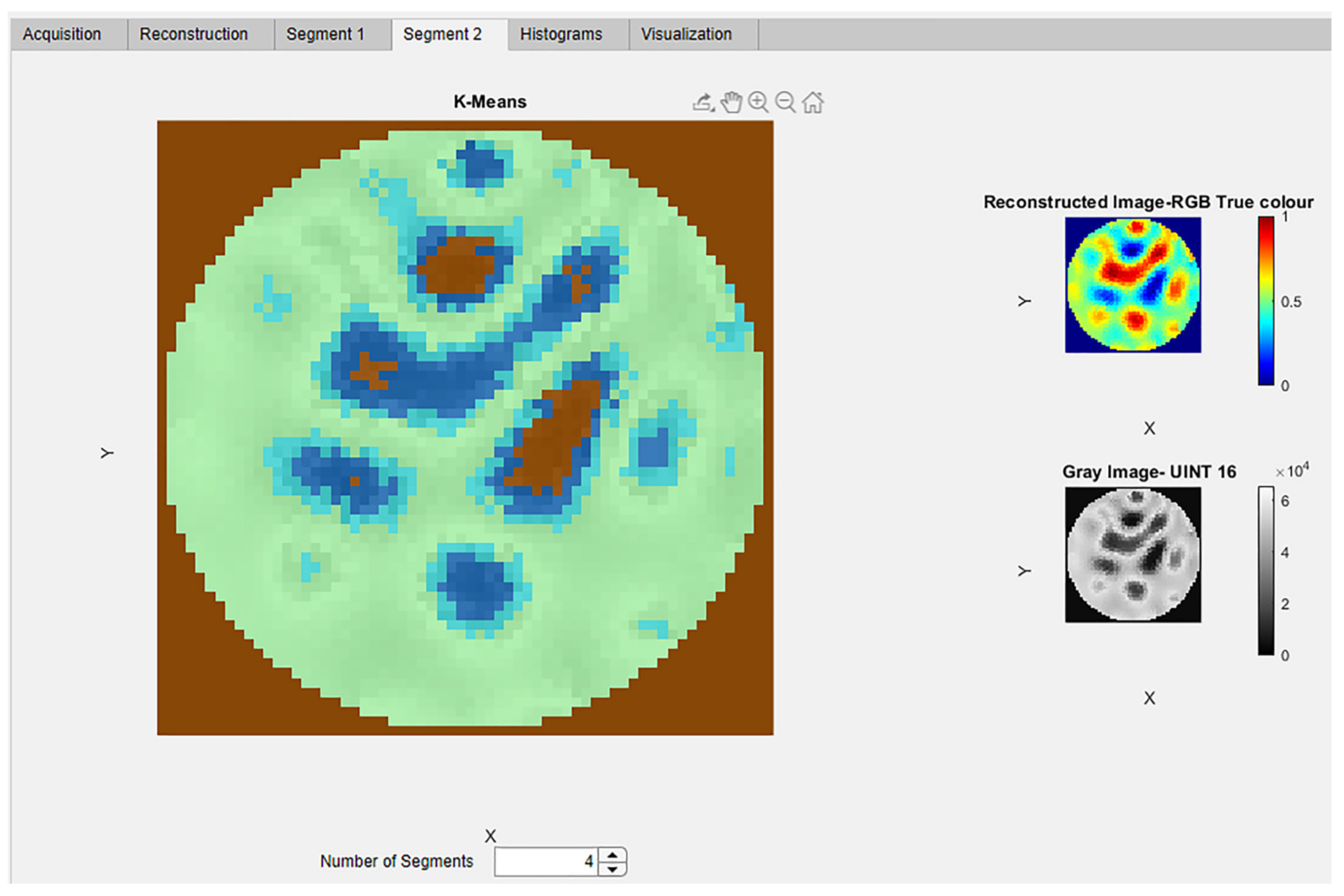

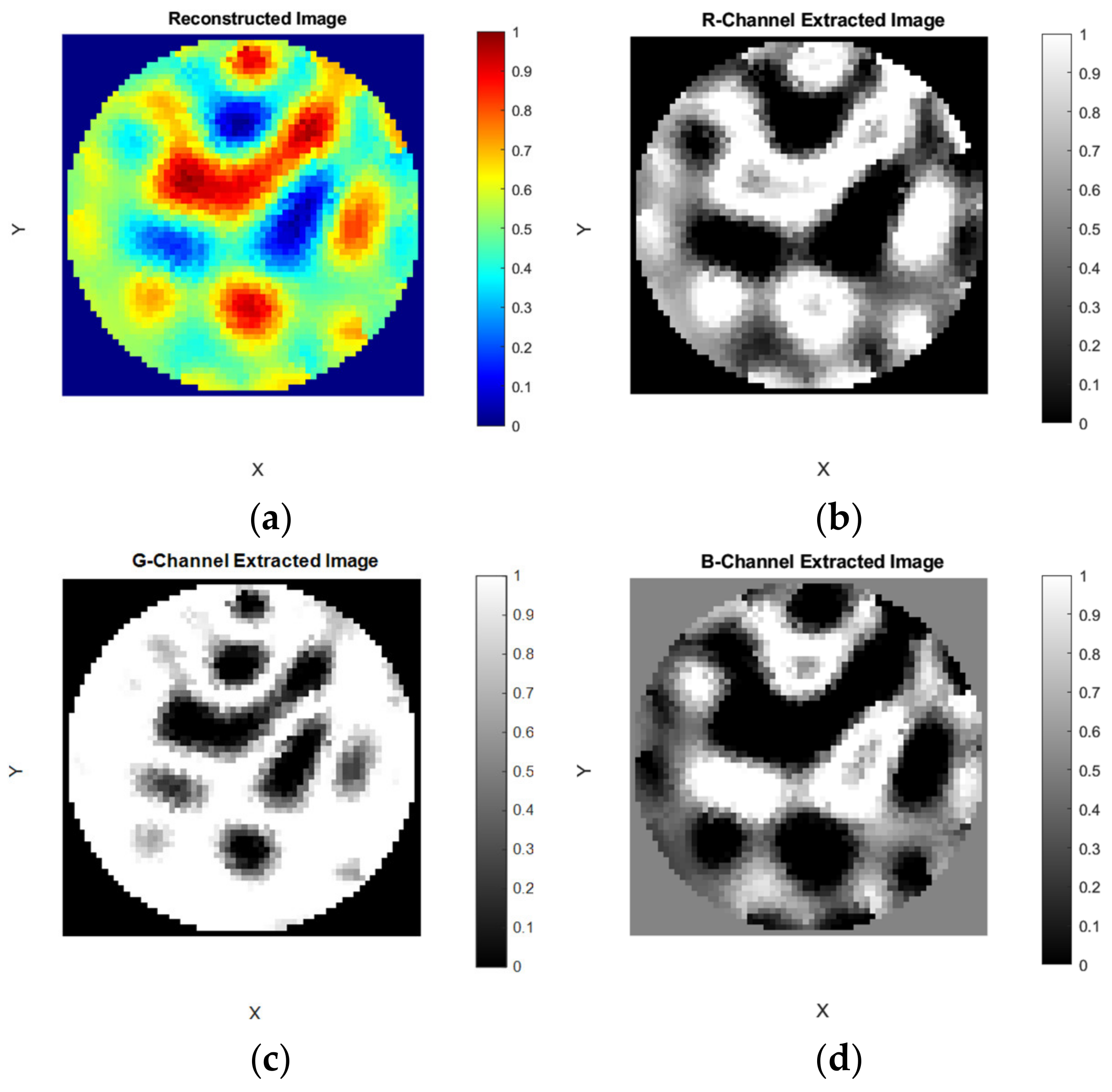

4.4. Module 3: Segmentation

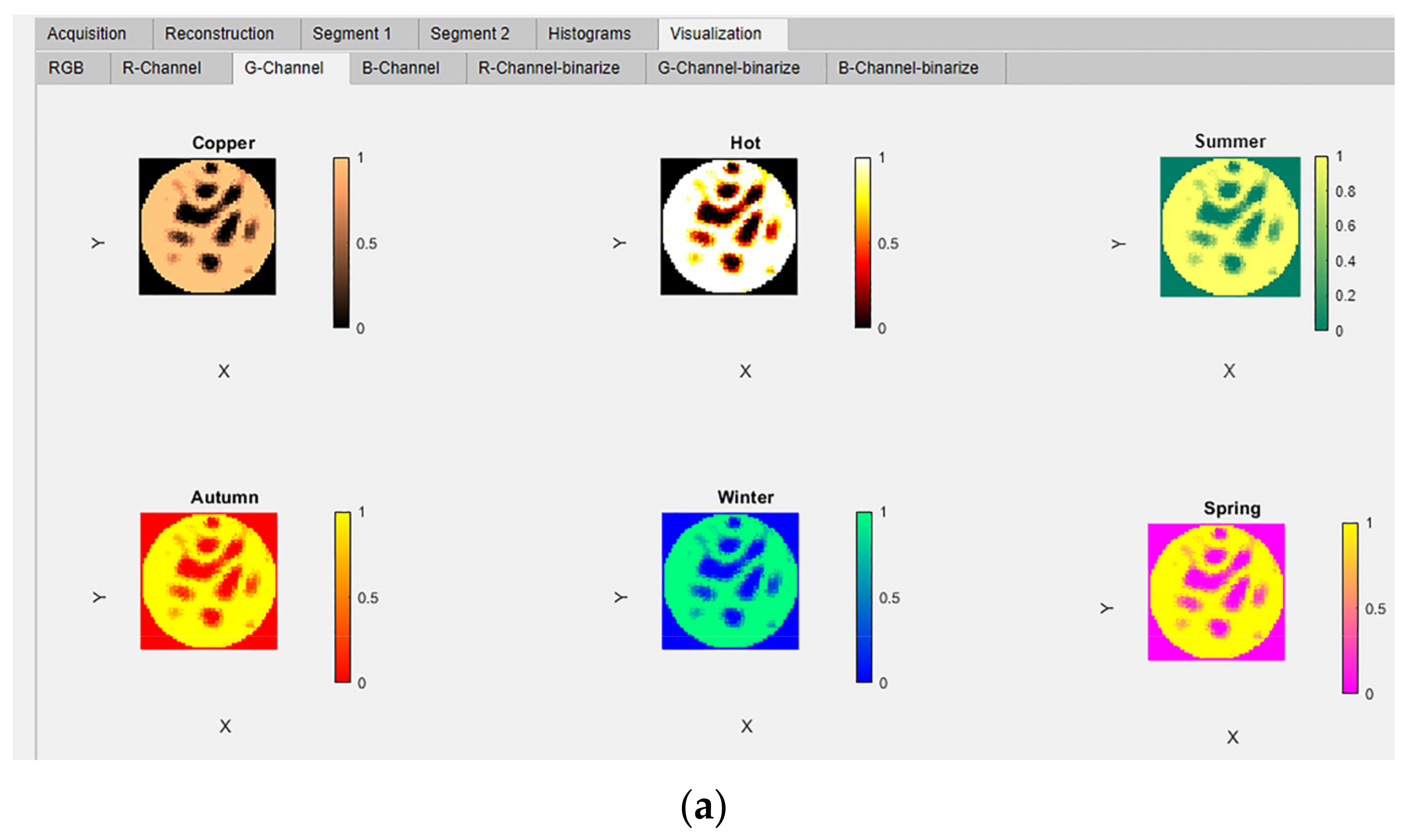

4.5. Module 4: Visualization

5. Results

5.1. Software Evaluation Case Study

5.1.1. Case Study

- P1: PhD student who has been working with ERT for three years.

- P2: Associate professor with over 15 years of experience in ERT technology.

- P3: Professor with more than 20 years of experience in tomography.

- P4: PhD student with almost three years of hands-on tomographic experience.

5.1.2. The ERT Visual Analytics Task

- Task-1: Load the reference data, then load the experimental data.

- Task-2: Choose the frame number X using the slider.

- Task-3: Check various image reconstructions. Check the 2D images and 3D meshes-V-I numerical data in different tabs.

- Task-4: Observe the segmentation results. Switch to any other segmentation methods.

- Task-5: Observe the histograms of the images.

- Task-6: Observe the separated R, G, and B channels of ERT images.

- Task-7: Select and change the colormaps of the extracted R, G, and B channels.

- Task-8 (optional): Conduct binarization using the threshold and visualization for the gray-connected seed row/column.

5.1.3. Insights

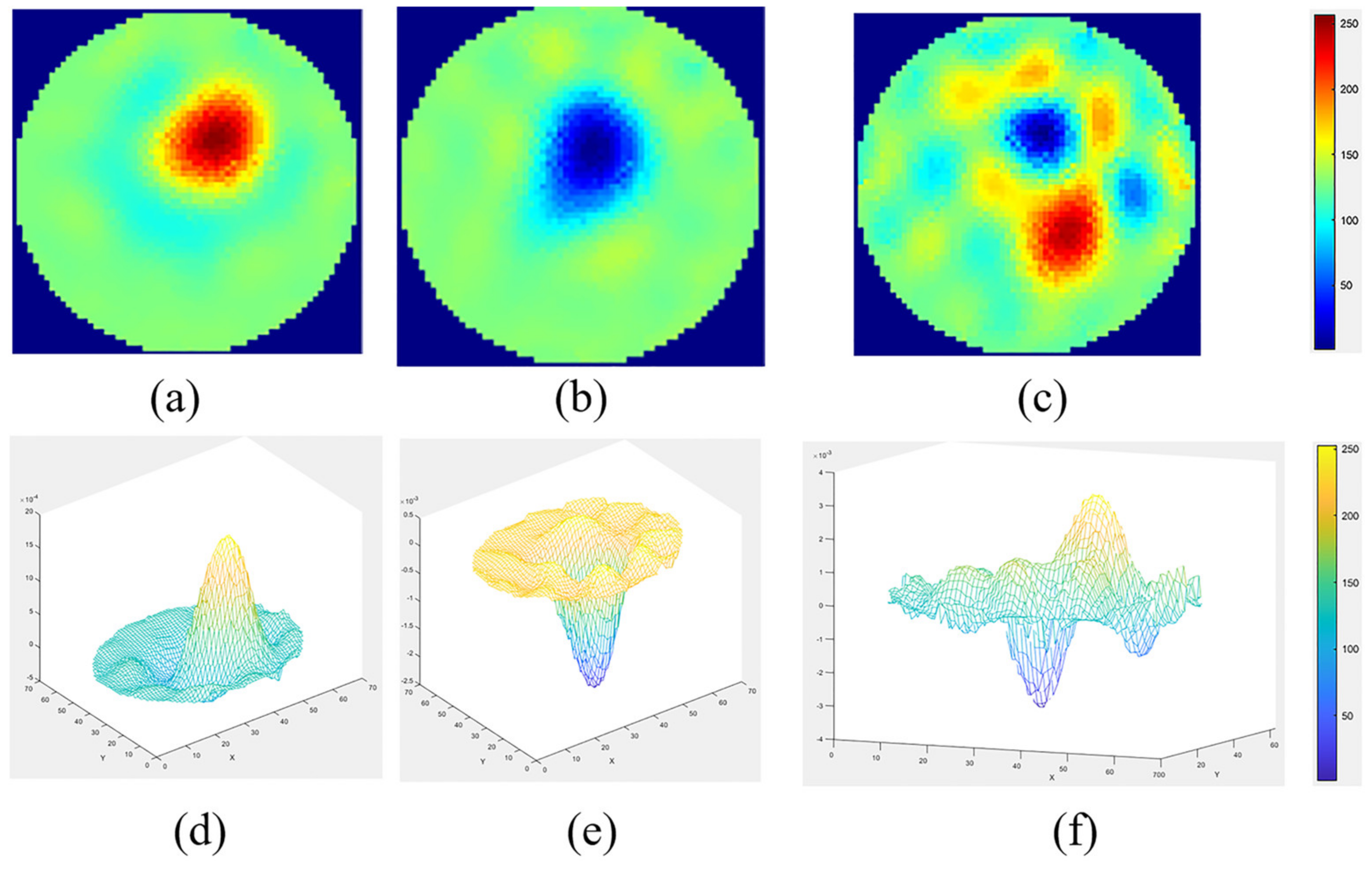

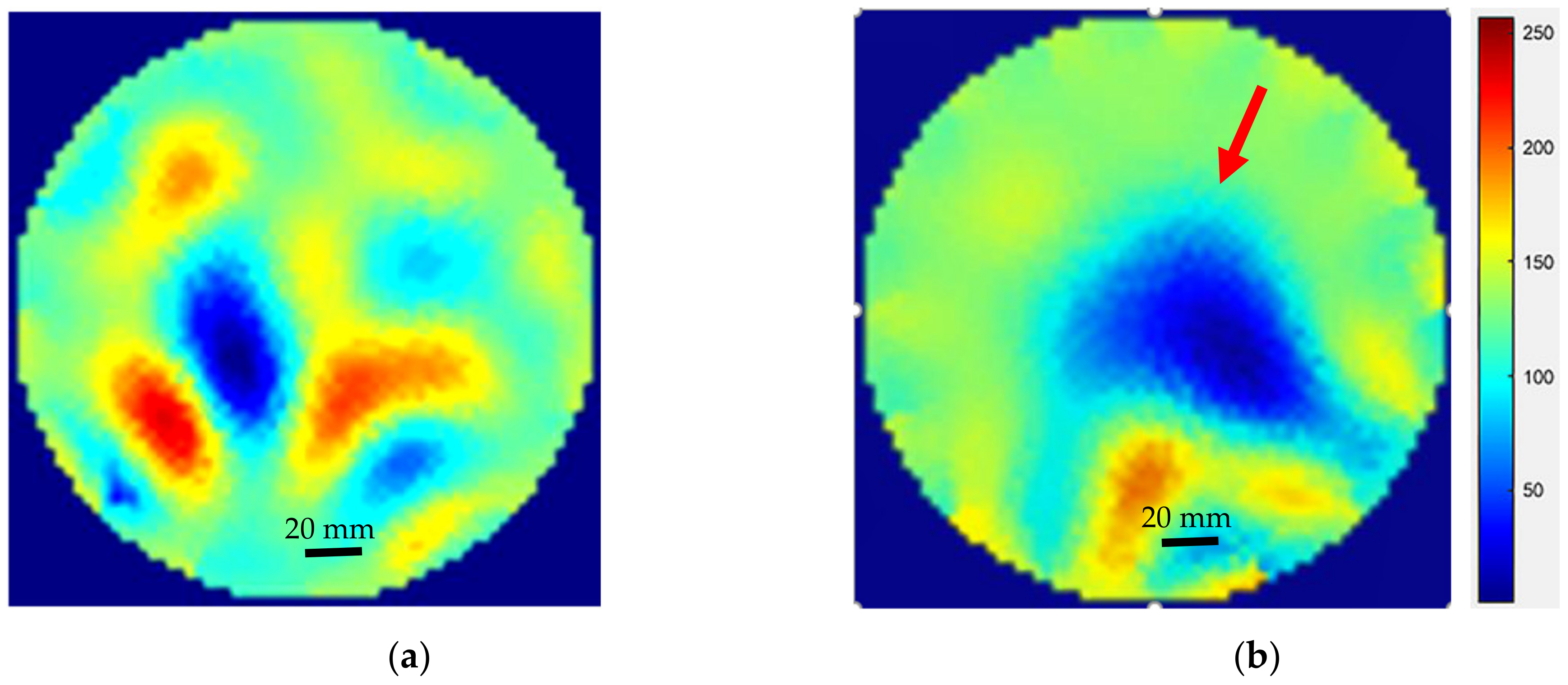

5.2. Results for CaCO3 Precipitative Crystallization Using ERT-Vis

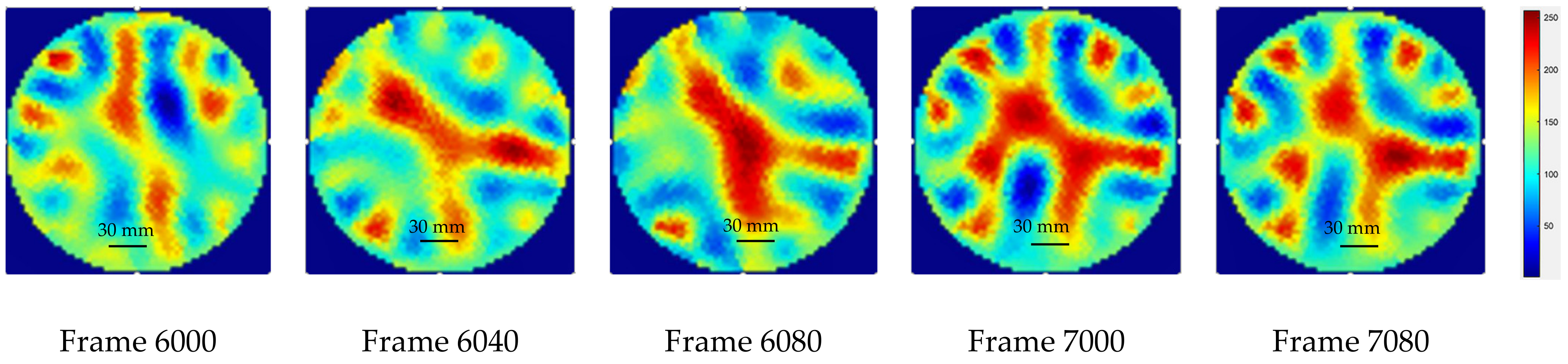

5.3. Results for Sucrose Crystallization Using ERT-Vis

6. Discussion

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Larsen, P.A.; Patience, D.B.; Rawlings, J.B. Industrial crystallization process control. IEEE Control Syst. 2006, 26, 70–80. [Google Scholar] [CrossRef]

- Lewis, A.; Seckler, M.; Kramer, H.; Van Rosmalen, G. Industrial Crystallization: Fundamentals and Applications; Cambridge University Press: Cambridge, UK, 2015. [Google Scholar]

- McDonald, M.A.; Salami, H.; Harris, P.R.; Lagerman, C.E.; Yang, X.; Bommarius, A.S.; Grover, M.A.; Rousseau, R.W. Reactive Crystallization: A Review. React. Chem. Eng. 2021, 6, 364–400. [Google Scholar] [CrossRef]

- Karpiński, P.; Bałdyga, J. Precipitation Processes. In Handbook of Industrial Crystallization; Cambridge University Press: Cambridge, UK, 2019. [Google Scholar] [CrossRef]

- Bowler, A.; Bakalis, S.; Watson, N.J. A review of in-line and on-line measurement techniques to monitor industrial mixing processes. Chem. Eng. Res. Des. 2019, 153, 463–495. [Google Scholar] [CrossRef]

- Scott, D.M. Recent advances in in-process characterization of suspensions and slurries. Powder Technol. 2022, 399, 117159. [Google Scholar] [CrossRef]

- Simon, L.L.; Simone, E.; Oucherif, K.A. Crystallization process monitoring and control using process analytical technology. In Computer Aided Chemical Engineering; Elsevier: Cham, Switzerland, 2018; pp. 215–242. [Google Scholar]

- Myerson, A. Handbook of Industrial Crystallization; Butterworth-Heinemann: Boston, MA, USA, 2002; ISBN 0-08-053351-5. [Google Scholar]

- Gao, Y.; Zhang, T.; Ma, Y.; Xue, F.; Gao, Z.; Hou, B.; Gong, J. Application of PAT-Based Feedback Control Approaches in Pharmaceutical Crystallization. Crystals 2021, 11, 221. [Google Scholar] [CrossRef]

- Lawrence, X.Y.; Lionberger, R.A.; Raw, A.S.; D’costa, R.; Wu, H.; Hussain, A.S. Applications of Process Analytical Technology to Crystallization Processes. Adv. Drug Deliv. Rev. 2004, 56, 349–369. [Google Scholar]

- Singh, M.; Chakraborty, J.; Nere, N.; Tung, H.-H.; Bordawekar, S.; Ramkrishna, D. Image-Analysis-Based Method for 3D Crystal Morphology Measurement and Polymorph Identification Using Confocal Microscopy. Cryst. Growth Des. 2012, 12, 3735–3748. [Google Scholar] [CrossRef]

- Cardona, J.; Ferreira, C.; McGinty, J.; Hamilton, A.; Agimelen, O.; Cleary, A.; Atkinson, R.; Michie, C.; Marshall, S.; Chen, Y.-C.; et al. Image analysis framework with focus evaluation for in situ characterisation of particle size and shape attributes. Chem. Eng. Sci. 2018, 191, 208–231. [Google Scholar] [CrossRef]

- Simone, E.; Saleemi, A.N.; Nagy, Z.K. Raman, UV, NIR, and Mid-IR Spectroscopy with Focused Beam Reflectance Measurement in Monitoring Polymorphic Transformations. Chem. Eng. Technol. 2014, 37, 1305–1313. [Google Scholar] [CrossRef]

- Zhao, Y.; Wang, M.; Hammond, R.B. Characterization of crystallisation processes with electrical impedance spectroscopy. Nucl. Eng. Des. 2011, 241, 1938–1944. [Google Scholar] [CrossRef]

- Eder, C.; Briesen, H. Impedance spectroscopy as a process analytical technology (PAT) tool for online monitoring of sucrose crystallization. Food Control 2019, 101, 251–260. [Google Scholar] [CrossRef]

- Al Nasser, W.N.; Al Salhi, F.H. Kinetics determination of calcium carbonate precipitation behavior by inline techniques. Powder Technol. 2015, 270, 548–560. [Google Scholar] [CrossRef]

- Han, B.; Haq, R.A.U.; Louhi-Kultanen, M. Lithium carbonate precipitation by homogeneous and heterogeneous reactive crystallization. Hydrometallurgy 2020, 195, 105386. [Google Scholar] [CrossRef]

- Gao, Z.; Wu, Y.; Bao, Y.; Gong, J.; Wang, J.; Rohani, S. Image Analysis for In-line Measurement of Multidimensional Size, Shape, and Polymorphic Transformation of l-Glutamic Acid Using Deep Learning-Based Image Segmentation and Classification. Cryst. Growth Des. 2018, 18, 4275–4281. [Google Scholar] [CrossRef]

- Hampel, U.; Babout, L.; Banasiak, R.; Schleicher, E.; Soleimani, M.; Wondrak, T.; Vauhkonen, M.; Lähivaara, T.; Tan, C.; Hoyle, B.; et al. A Review on Fast Tomographic Imaging Techniques and Their Potential Application in Industrial Process Control. Sensors 2022, 22, 2309. [Google Scholar] [CrossRef]

- Merrifield, D.R.; Ramachandran, V.; Roberts, K.J.; Armour, W.; Axford, D.; Basham, M.; Connolley, T.; Evans, G.; McAuley, K.E.; Owen, R.L.; et al. A novel technique combining high-resolution synchrotron x-ray microtomography and x-ray diffraction for characterization of micro particulates. Meas. Sci. Technol. 2011, 22, 115703. [Google Scholar] [CrossRef]

- Polacci, M.; Arzilli, F.; La Spina, G.; Le Gall, N.; Cai, B.; Hartley, M.E.; Di Genova, D.; Vo, N.T.; Nonni, S.; Atwood, R.C.; et al. Crystallisation in basaltic magmas revealed via in situ 4D synchrotron X-ray microtomography. Sci. Rep. 2018, 8, 8377. [Google Scholar] [CrossRef]

- Koulountzios, P.; Aghajanian, S.; Rymarczyk, T.; Koiranen, T.; Soleimani, M. An Ultrasound Tomography Method for Monitoring CO2 Capture Process Involving Stirring and CaCO3 Precipitation. Sensors 2021, 21, 6995. [Google Scholar] [CrossRef]

- Wajman, R. The concept of 3D ECT system with increased border area sensitivity for crystallization processes diagnosis. Sens. Rev. 2021, 41, 35–45. [Google Scholar] [CrossRef]

- Rao, G.; Aghajanian, S.; Koiranen, T.; Wajman, R.; Jackowska-Strumiłło, L. Process Monitoring of Antisolvent Based Crystallization in Low Conductivity Solutions Using Electrical Impedance Spectroscopy and 2-D Electrical Resistance Tomography. Appl. Sci. 2020, 10, 3903. [Google Scholar] [CrossRef]

- Rao, G.; Sattar, M.; Wajman, R.; Jackowska-Strumiłło, L. Quantitative Evaluations with 2d Electrical Resistance Tomography in the Low-Conductivity Solutions Using 3d-Printed Phantoms and Sucrose Crystal Agglomerate Assessments. Sensors 2021, 21, 564. [Google Scholar] [CrossRef]

- Aghajanian, S.; Rao, G.; Ruuskanen, V.; Wajman, R.; Jackowska-Strumillo, L.; Koiranen, T. Real-Time Fault Detection and Diagnosis of CaCO3 Reactive Crystallization Process by Electrical Resistance Tomography Measurements. Sensors 2021, 21, 6958. [Google Scholar] [CrossRef]

- Zhang, Y.; Fjeld, M.; Said, A.; Fratarcangeli, M. Task-Based Colormap Design Supporting Visual Comprehension in Process Tomography. In Proceedings of the EuroVis 2020—Short Papers, Norköpping, Sweden, 25–29 May 2020; Kerren, A., Garth, C., Marai, G.E., Eds.; The Eurographics Association: Norköpping, Sweden, 2020. [Google Scholar]

- Zhang, Y.; Fjeld, M.; Fratarcangeli, M.; Said, A.; Zhao, S. Affective Colormap Design for Accurate Visual Comprehension in Industrial Tomography. Sensors 2021, 21, 4766. [Google Scholar] [CrossRef]

- Hampel, U.; Wondrak, T.; Bieberle, M.; Lecrivain, G.; Schubert, M.; Eckert, K.; Reinecke, S. Smart Tomographic Sensors for Advanced Industrial Process Control TOMOCON. Chem. Ing. Tech. 2018, 90, 1238–1239. [Google Scholar] [CrossRef] [Green Version]

- Liu, B.; Yang, B.; Xu, C.; Xia, J.; Dai, M.; Ji, Z.; You, F.; Dong, X.; Shi, X.; Fu, F. pyEIT: A python based framework for Electrical Impedance Tomography. SoftwareX 2018, 7, 304–308. [Google Scholar] [CrossRef]

- Grychtol, B.; Müller, B.; Adler, A. 3D EIT image reconstruction with GREIT. Physiol. Meas. 2016, 37, 785–800. [Google Scholar] [CrossRef]

- Wei, K.; Qiu, C.; Soleimani, M.; Primrose, K. ITS Reconstruction Tool-Suite: An inverse algorithm package for industrial process tomography. Flow Meas. Instrum. 2015, 46, 292–302. [Google Scholar] [CrossRef] [Green Version]

- Ye, L.; Yang, W. Real-Time 3D Visualisation in Electrical Capacitance Tomography. In Proceedings of the 2012 IEEE International Conference on Imaging Systems and Techniques, Manchester, UK, 16–17 July 2012; pp. 40–44. [Google Scholar]

- Banasiak, R.; Jaworski, T.; Wajman, R. Aplikacja Dla Potrzeb Kompleksowego Przetwarzania Tomograficznych Danych Pomiarowych-TomoKIS Studio. Zeszyty Naukowe Politechniki Lodzkiej. 2010. Available online: http://repozytorium.p.lodz.pl/handle/11652/386 (accessed on 30 April 2022).

- Vauhkonen, M.; Lionheart, W.; Heikkinen, L.M.; Vauhkonen, P.J.; Kaipio, J. A MATLAB package for the EIDORS project to reconstruct two-dimensional EIT images. Physiol. Meas. 2001, 22, 107–111. [Google Scholar] [CrossRef]

- Adler, A.; Lionheart, W. Uses and abuses of EIDORS: An extensible software base for EIT. Physiol. Meas. 2006, 27, S25–S42. [Google Scholar] [CrossRef] [Green Version]

- Adler, A.; Lionheart, W.R.B. EIDORS: Towards a Community-Based Extensible Software Base for EIT. In Proceedings of the 6th Conference on Biomedical Applications of Electrical Impedance Tomography, London, UK, 22–24 June 2005; pp. 1–4. [Google Scholar]

- Lionheart, W.R.B.; Arridge, S.R.; Schweiger, M.; Vauhkonen, M.; Kaipio, J.P. Electrical Impedance and Diffuse Optical Tomography Reconstruction Software. In Proceedings of the 1st World Congress on Industrial Process Tomography, Buxton, UK, 14–17 April 1999; pp. 474–477. [Google Scholar]

- Aghajanian, S.; Nieminen, H.; Laari, A.; Koiranen, T. Integration of a calcium carbonate crystallization process and membrane contactor–based CO2 capture. Sep. Purif. Technol. 2021, 274, 119043. [Google Scholar] [CrossRef]

- Honig, P. Principles of Sugar Technology; Elsevier: Amsterdam, The Netherlands, 2013. [Google Scholar]

- Crestani, C.E.; Bernardo, A.; Costa, C.B.; Giulietti, M. Experimental data and estimation of sucrose solubility in impure solutions. J. Food Eng. 2018, 218, 14–23. [Google Scholar] [CrossRef]

- Jackson, R.F.; Silsbee, C.G. Saturation relations in mixtures of sucrose, dextrose, and levulose. J. Frankl. Inst. 1924, 198, 546–547. [Google Scholar] [CrossRef]

- Adler, A. EIDORS, Version 3.10; Carleton University: Ottawa, ON, Canada, 2019. Available online: http://eidors3d.sourceforge.net/(accessed on 30 April 2022).

- Polydorides, N.; Lionheart, W.R.B. A Matlab toolkit for three-dimensional electrical impedance tomography: A contribution to the Electrical Impedance and Diffuse Optical Reconstruction Software project. Meas. Sci. Technol. 2002, 13, 1871–1883. [Google Scholar] [CrossRef]

- Campbell, R. Mat2im. 2020. Available online: https://www.mathworks.com/matlabcentral/fileexchange/26322-mat2im (accessed on 30 April 2022).

| Software | Acquisition | Reconstruction | Segmentation | Visualization | Researcher’s Open Access |

|---|---|---|---|---|---|

| pyEIT | No | Yes | No | Limited | Yes |

| GREIT | No | Yes | No | Limited | Yes |

| ITS Reconstruction Tool-Suite | Yes | Yes | Limited | Limited | No |

| Real-time 3D ECT | Limited | Yes | No | No | No |

| TomoKIS Studio | Yes | Yes | No | Limited | No |

| EIDORS | No | Yes | No | Limited | Yes |

| ERT-Vis | Limited | Yes (EIDORS) | Yes | Yes | Yes |

| Parameter | CaCO3 Reactive Crystallization | Sucrose Cooling Crystallization |

|---|---|---|

| Size of Reactor | 200 mm diameter | 63 mm internal diameter |

| Number of Electrodes | 16 | 16 |

| Type of Reactor | polypropylene | Glass jacketed |

| Acquisition Frame Rate | 16 Hz | 12 Hz |

| Reconstruction Algorithm | Gauss-Newton | Gauss-Newton |

| Total Time for Experiment | 10 min | 15–20 min |

| Type of Crystallization | Reactive crystallization | Cooling crystallization |

| Stirrer Speed | 100 rpm | No stirrer |

| Input Induced Voltage | 3 V | 3 V |

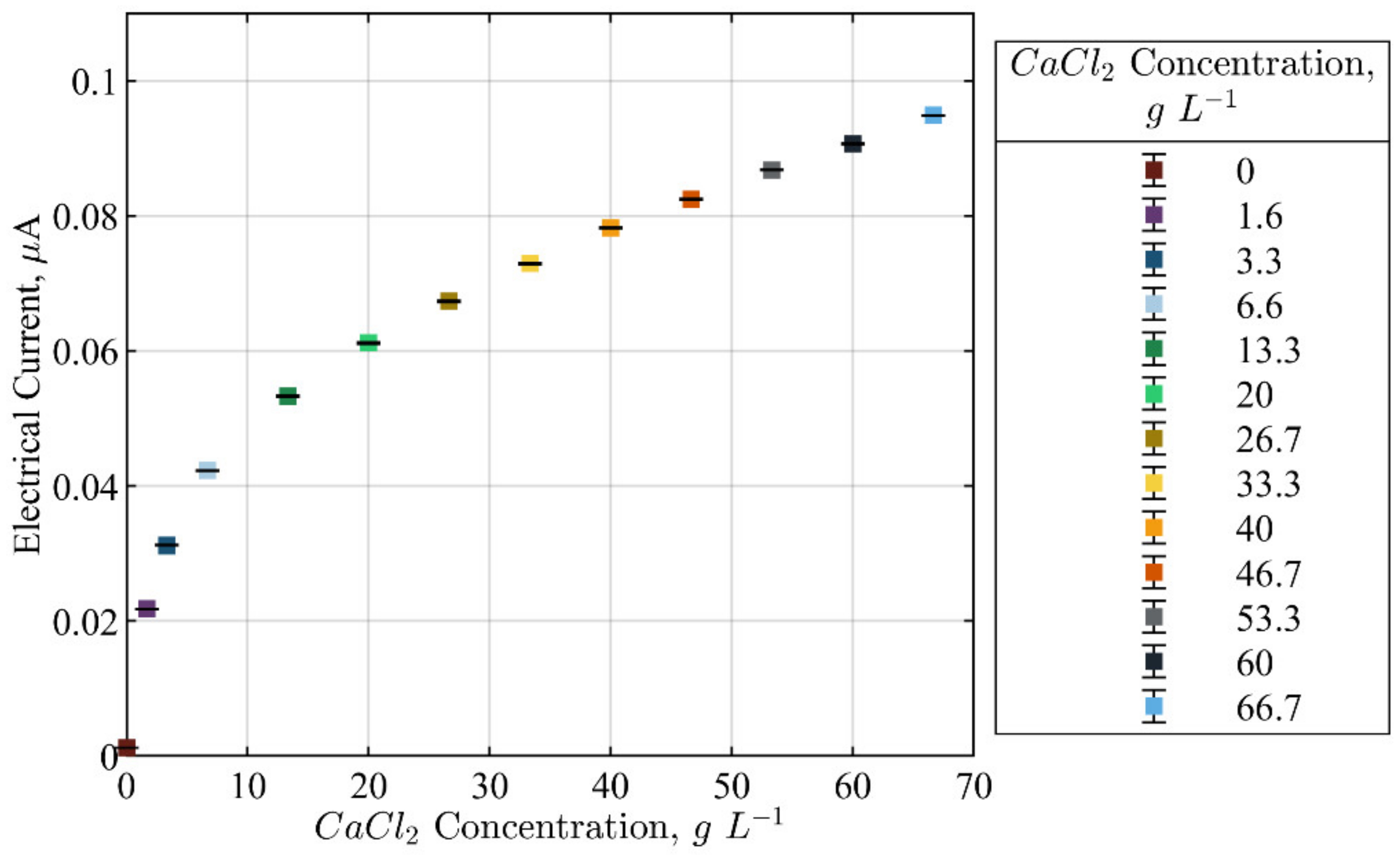

| Range of Currents detected | 0–0.1 µA | 0.1–1.75 mA |

| Transducers Frequency | 156 KHz | 156 KHz |

| Expert | Task | Comment |

|---|---|---|

| P1 | Task-1 | Loading files is very immediate, which is not common in the similar tools I used before. |

| P2 | Task-3 | It is straightforward for users to have an overview of the whole application. |

| P4 | Task-3 | It is considerably more convenient to simultaneously check both 2D and 3D visualizations in the same panel. Putting reconstruction as the first module is valuable for domain users to better understand the problems. |

| P2, P3 | Task-4 | The segmentation methods are diverse, and selection is easy. |

| P1 | Task-5 | It’s very time-saving to observe the histograms of the images as they took only a short time to be displayed. |

| P2 | Task-7 | ERT-Vis possesses a consistent and coherent workflow which makes it comfortable for users to follow. It was advisable to implement it in real time experiments. |

| P3 | Task-8 | Amazed by the content contained in a single application as it supports multi-modal visual analysis. |

| P1 | Task-1 | Loading files is very immediate, which is not common in the similar tools I used before. |

| P2 | Task-3 | It is straightforward for users to have an overview of the whole application. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rao, G.; Aghajanian, S.; Zhang, Y.; Jackowska-Strumiłło, L.; Koiranen, T.; Fjeld, M. Monitoring and Visualization of Crystallization Processes Using Electrical Resistance Tomography: CaCO3 and Sucrose Crystallization Case Studies. Sensors 2022, 22, 4431. https://doi.org/10.3390/s22124431

Rao G, Aghajanian S, Zhang Y, Jackowska-Strumiłło L, Koiranen T, Fjeld M. Monitoring and Visualization of Crystallization Processes Using Electrical Resistance Tomography: CaCO3 and Sucrose Crystallization Case Studies. Sensors. 2022; 22(12):4431. https://doi.org/10.3390/s22124431

Chicago/Turabian StyleRao, Guruprasad, Soheil Aghajanian, Yuchong Zhang, Lidia Jackowska-Strumiłło, Tuomas Koiranen, and Morten Fjeld. 2022. "Monitoring and Visualization of Crystallization Processes Using Electrical Resistance Tomography: CaCO3 and Sucrose Crystallization Case Studies" Sensors 22, no. 12: 4431. https://doi.org/10.3390/s22124431

APA StyleRao, G., Aghajanian, S., Zhang, Y., Jackowska-Strumiłło, L., Koiranen, T., & Fjeld, M. (2022). Monitoring and Visualization of Crystallization Processes Using Electrical Resistance Tomography: CaCO3 and Sucrose Crystallization Case Studies. Sensors, 22(12), 4431. https://doi.org/10.3390/s22124431