Micromagnetic and Microstructural Characterization of Ferromagnetic Steels in Different Heat Treatment Conditions

Abstract

:1. Introduction

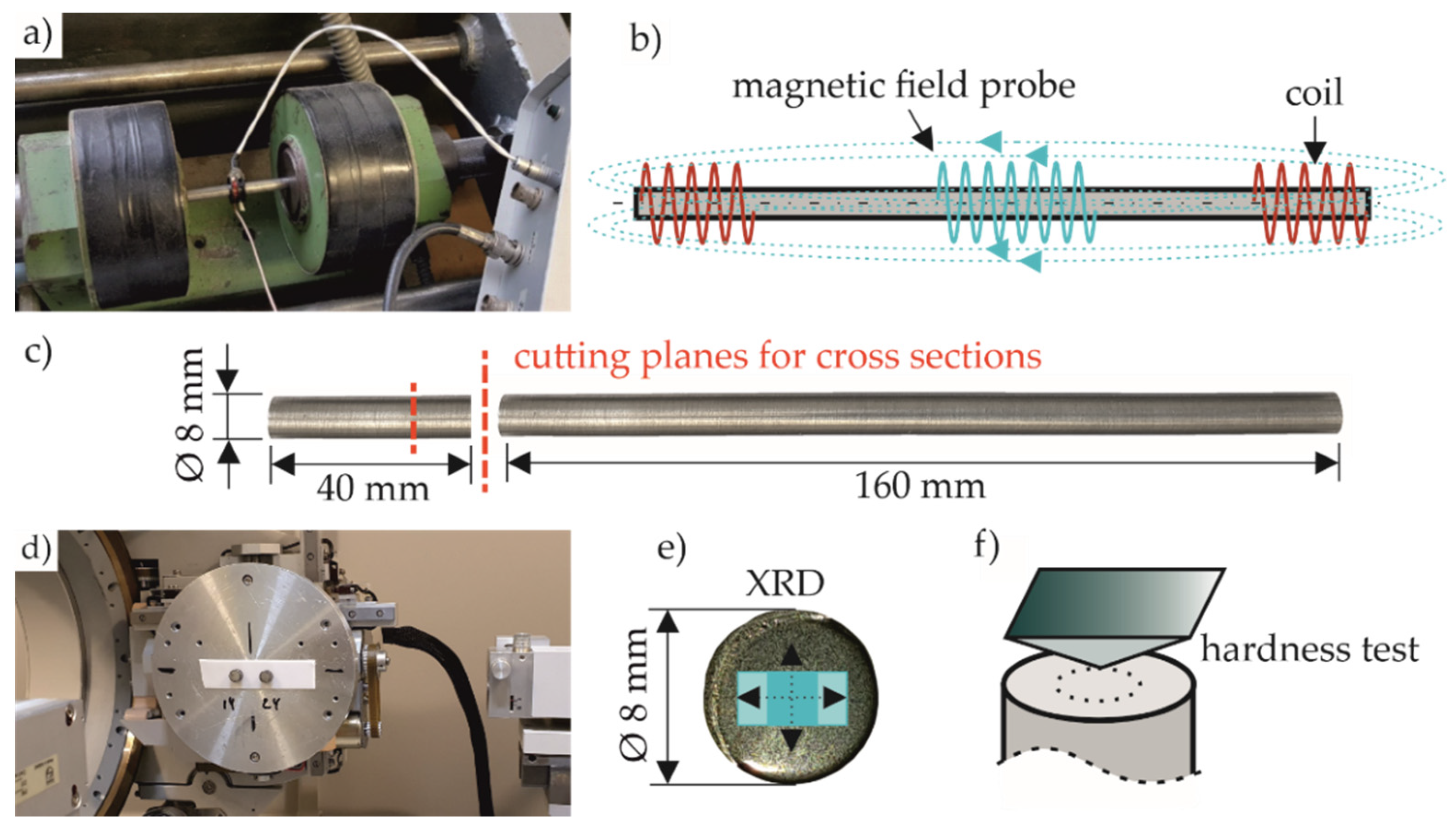

2. Materials and Methods

Experimental Setup

3. Results

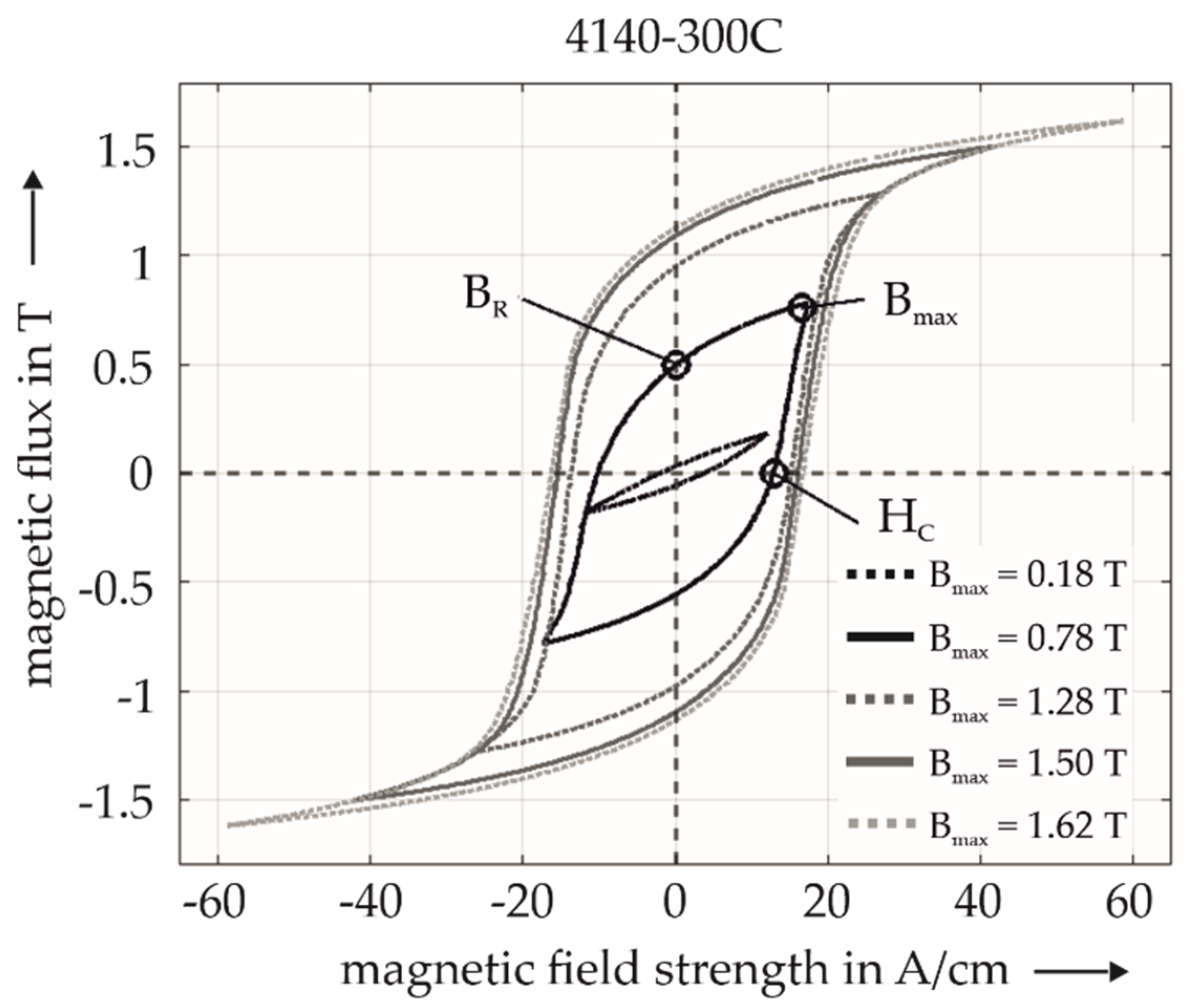

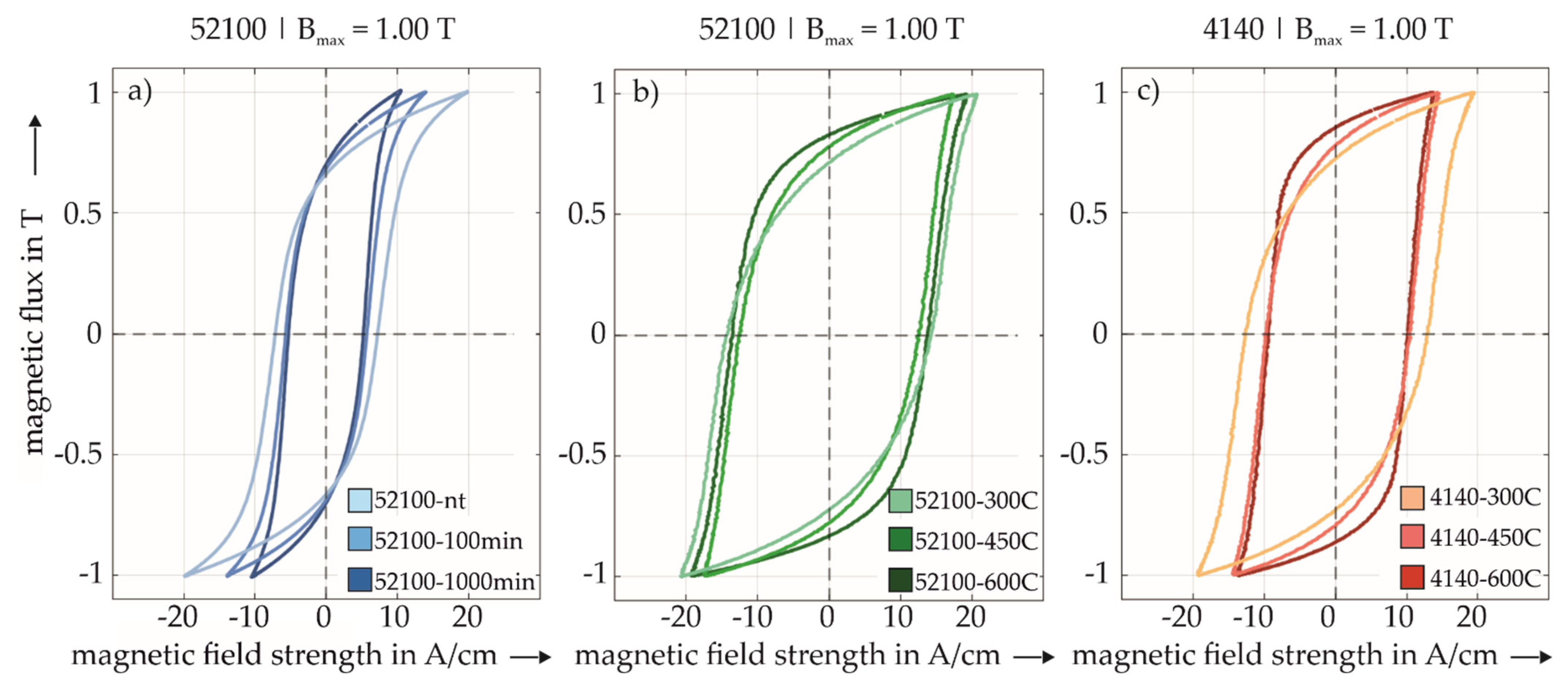

3.1. Micromagnetic Characterization at Fixed Level of Induction

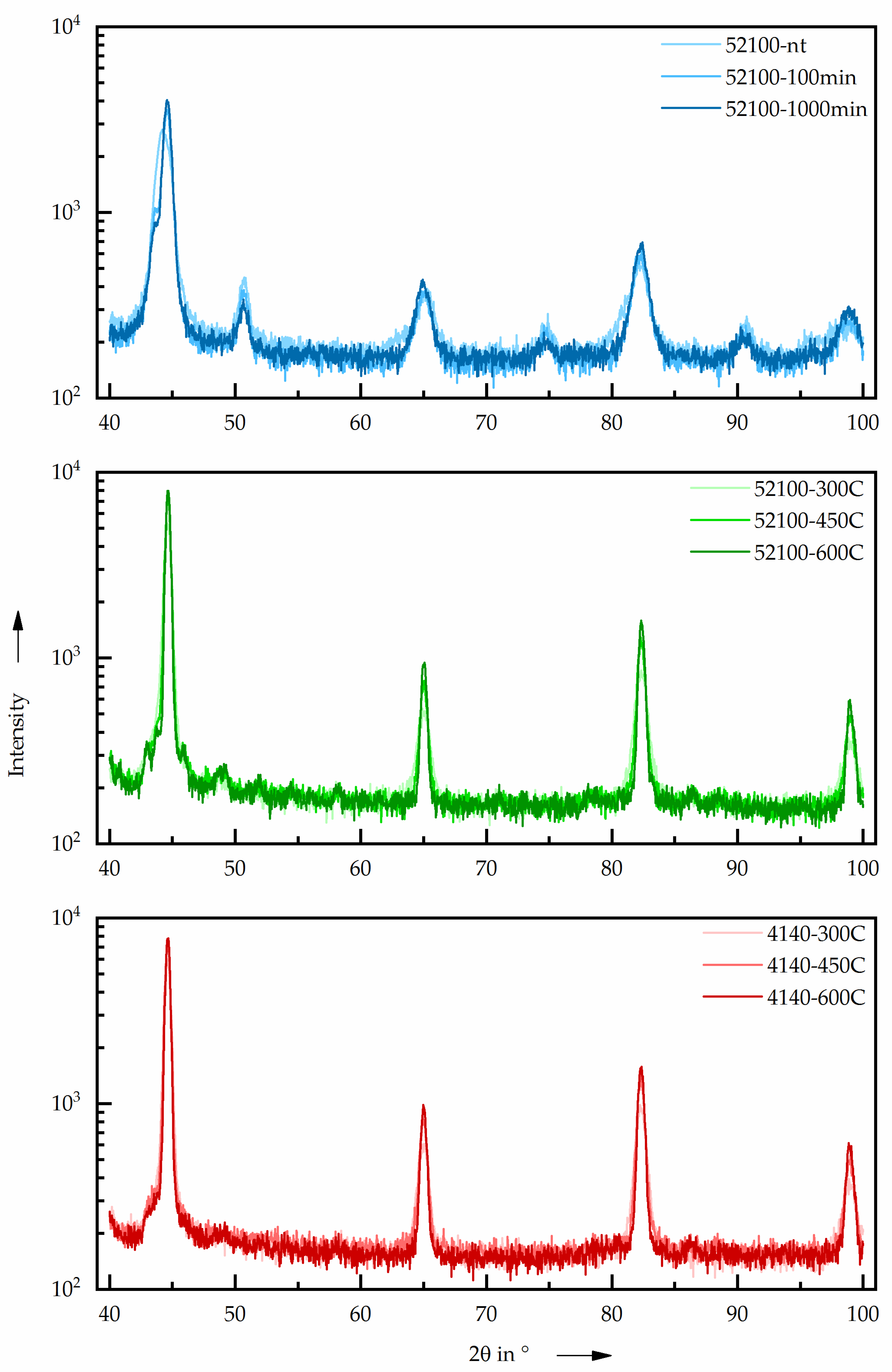

3.2. Microstructural and Micromagnetic Characterization at Fixed Magnetization Amplitude and Frequency

4. Discussion

5. Conclusions

- The investigated specimens can be consistently characterized in their technical and physical properties in terms of micromagnetic, X-ray, and mechanical hardness.

- The correlation of hardness to BR as well as HC and Bmax to RA content shows the relationship between mechanical and micromagnetic properties, where BR increases almost proportionally with decreasing hardness and Bmax increases while HC decreases with decreasing RA content.

- The use of the two different investigation methods (constant field strength or constant flux) shows a comparable characteristic behavior of the magnetic hysteresis and allows the transferability to comparable measurement systems.

- The physically-based characteristic values HC, BR, and Bmax used for the quantification of the magnetic hysteresis profile are to be evaluated as lower limits of information for the precise description of the hysteresis profile.

- Due to the almost residual stress-free state of the specimens, the observed micromagnetic effects, in particular, can be attributed to the different RA contents as well as the discernible change in the microstructure.

- The described quantitative correlations between micromagnetic and microstructural, resp. mechanical properties of the specifically manufactured specimens allow a comparison of similar micromagnetic measuring systems since the reference ability to the respective material conditions of the specimens is ensured. This comparison will take place among multiple institutes within the context of the priority program 2086. These actions will be the first steps for a generalization and standardization of different micromagnetic measurement techniques and thus will allow an instrument-independent calibration on defined calibration specimens.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| Specimen | Specimen No. | RA Content in vol.% | Hardness HV 30 | std. HV 30 | Microhardness HV 0.1 | std. HV 0.1 | Mean Residual Stress in MPa | std. Residual Stress |

|---|---|---|---|---|---|---|---|---|

| 52100-100 min | 02 | 17.2 | 786.7 | 8.3 | 9734 | 1102 | 22.3 | 39.35 |

| 52100-1000 min | 04 | 13 | 754.7 | 1.9 | 8963 | 198 | 15.3 | 31.7 |

| 52100-nt | 06 | 18.1 | 908.0 | 1.4 | 10846 | 143 | 37.45 | 59.8 |

| 52100-300C | 08 | 2.3 | 680.7 | 8.2 | 8060 | 319 | −3.6 | 18.6 |

| 52100-450C | 10 | 1.8 | 525.7 | 6.3 | 6153 | 195 | −4.2 | 12.2 |

| 52100-600C | 12 | 2 | 370.3 | 2.4 | 4326 | 363 | −4.75 | 6.45 |

| 4140-300C | 14 | 0 | 524.3 | 2.5 | 5944 | 131 | −1.85 | 12.5 |

| - | 16 | 0.1 | 516.3 | 1.2 | 5964 | 165 | 17.05 | 15.3 |

| 4140-450C | 18 | 0 | 431.3 | 2.1 | 5036 | 208 | 0.85 | 7.1 |

| - | 20 | 0 | 432.7 | 1.7 | 4826 | 100 | 15.8 | 10.8 |

| 4140-600C | 22 | 0 | 326.3 | 2.1 | 3725 | 152 | 11.9 | 8.3 |

| - | 24 | 0 | 329.3 | 1.2 | 3766 | 324 | 7 | 9.55 |

| Data Acquired with Fixed Magnetization Parameters | Data Acquired with Fixed Maximum Flux | |||

|---|---|---|---|---|

| Specimen | Specimen No. | Remanence in T | Saturation in T | Coercivity in A/cm |

| 52100-100 min | 01 | 17.2 | 1.06 | 28.6 |

| 52100-1000 min | 03 | 13 | 1.21 | 26.1 |

| 52100-nt | 05 | 18.1 | 0.90 | 36.3 |

| 52100-300C | 07 | 2.3 | 1.71 | 14.3 |

| 52100-450C | 09 | 1.8 | 1.72 | 12.6 |

| 52100-600C | 11 | 2 | 1.61 | 13.8 |

| 4140-300C | 13 | 0 | 1.70 | 12.8 |

| - | 15 | 0.1 | 1.70 | - |

| 4140-450C | 17 | 0 | 1.78 | 10.3 |

| - | 19 | 0 | 1.77 | - |

| 4140-600C | 21 | 0 | 1.76 | 10.1 |

| - | 23 | 0 | 1.76 | - |

Appendix B

References

- Dwivedi, S.K.; Vishwakarma, M.; Soni, P. Advances and Researches on Non Destructive Testing: A Review. Mater. Today Proc. 2018, 5, 3690–3698. [Google Scholar] [CrossRef]

- Wolter, B.; Dobmann, G.; Boller, C. NDT Based Process Monitoring and Control. SV-JME 2011, 2011, 218–226. [Google Scholar] [CrossRef]

- Uebel, J.; Ankener, W.; Basten, S.; Smaga, M.; Kirsch, B.; Seewig, J.; Beck, T.; Aurich, J.C. In-process and ex-situ measurement techniques for the characterization of surface conditions during cryogenic hard turning of AISI 52100. Tm—Tech. Mess. 2020, 87, 694–703. [Google Scholar] [CrossRef]

- Sackmann, D.; Heinzel, J.; Karpuschewski, B. An approach for a reliable detection of grinding burn using the Barkhausen noise multi-parameter analysis. Procedia CIRP 2020, 87, 415–419. [Google Scholar] [CrossRef]

- Jedamski, R.; Epp, J. Non-Destructive Micromagnetic Determination of Hardness and Case Hardening Depth Using Linear Regression Analysis and Artificial Neural Networks. Metals 2021, 11, 18. [Google Scholar] [CrossRef]

- Fricke, L.V.; Nguyen, H.N.; Breidenstein, B.; Zaremba, D.; Maier, H.J. Eddy Current Detection of the Martensitic Transformation in AISI304 Induced upon Cryogenic Cutting. Steel Res. Int. 2021, 92, 2000299. [Google Scholar] [CrossRef]

- Böttger, D.; Stampfer, B.; Gauder, D.; Straß, B.; Häfner, B.; Lanza, G.; Schulze, V.; Wolter, B. Concept for soft sensor structure for turning processes of AISI4140. Tm—Tech. Mess. 2020, 87, 745–756. [Google Scholar] [CrossRef]

- Stampfer, B.; González, G.; Gerstenmeyer, M.; Schulze, V. The Present State of Surface Conditioning in Cutting and Grinding. JMMP 2021, 5, 92. [Google Scholar] [CrossRef]

- Wolter, B.; Gabi, Y.; Conrad, C. Nondestructive Testing with 3MA—An Overview of Principles and Applications. Appl. Sci. 2019, 9, 1068. [Google Scholar] [CrossRef] [Green Version]

- Heinzel, J.; Jedamski, R.; Epp, J.; Karpuschewski, B. In-process measurement of Barkhausen noise and resulting productivity increase potential in grinding of case hardened steel. CIRP J. Manuf. Sci. Technol. 2021, 32, 37–45. [Google Scholar] [CrossRef]

- Szielasko, K.; Wolter, B.; Tschuncky, R.; Youssef, S. Micromagnetic materials characterization using machine learning. Tm—Tech. Mess. 2020, 87, 428–437. [Google Scholar] [CrossRef]

- Bayrak, M.; Ozturk, F.; Demirezen, M.; Evis, Z. Analysis of Tempering Treatment on Material Properties of DIN 41Cr4 and DIN 42CrMo4 Steels. J. Mater. Eng Perform. 2007, 16, 597–600. [Google Scholar] [CrossRef]

- Anoop, A.D.; Sekhar, A.S.; Kamaraj, M.; Gopinath, K. Modelling the mechanical behaviour of heat-treated AISI 52100 bearing steel with retained austenite. Proceedings of the Institution of Mechanical Engineers. Part L J. Mater. Des. Appl. 2018, 232, 44–57. [Google Scholar] [CrossRef]

- Suresh, R.; Basavarajappa, S.; Gaitonde, V.N.; Samuel, G.L.; Davim, J.P. State-of-the-art research in machinability of hardened steels. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2013, 227, 191–209. [Google Scholar] [CrossRef]

- Akujärvi, V.; Cedell, T.; Gutnichenko, O.; Jaskari, M.; Andersson, M. Evolution of magnetic properties during tempering. Int. J. Adv. Manuf. Technol. 2021, 119, 2329–2339. [Google Scholar] [CrossRef]

- Davut, K.; Hakan Gür, C. Monitoring the Microstructural Changes During Tempering of Quenched SAE 5140 steel by Magnetic Barkhausen Noise. J. Nondestruct. Eval. 2007, 26, 107–113. [Google Scholar] [CrossRef]

- Kashefi, M.; Rafsanjani, A.; Kahrobaee, S.; Alaee, M. Magnetic nondestructive technology for detection of tempered martensite embrittlement. J. Magn. Magn. Mater. 2012, 324, 4090–4093. [Google Scholar] [CrossRef]

- Stratton, P.; Shedletsky, I.; Lee, M. Gas Quenching with Helium. SSP 2006, 118, 221–226. [Google Scholar] [CrossRef]

- Lior, N. The cooling process in gas quenching. J. Mater. Processing Technol. 2004, 155–156, 1881–1888. [Google Scholar] [CrossRef]

- Schajer, G.S. Practical Residual Stress Measurement Methods; Wiley: Chichester, UK, 2013; ISBN 9781118342374. [Google Scholar]

- Moderne Röntgenbeugung: Röntgendiffraktometrie für Materialwissenschaftler, Physiker und Chemiker; 2., überarb. und erw. Aufl.; Vieweg + Teubner: Wiesbaden, Germany, 2009; ISBN 978-3-8351-0166-1.

- Dinnebier, R.E.; Evans, J.S.O.; Leineweber, A. Rietveld Refinement: Practical Powder Diffraction Pattern Analysis Using TOPAS; De Gruyter: Berlin, Germany; Boston, MA, USA, 2019; ISBN 978-3-11-045621-9. [Google Scholar]

- Chulkina, A.A.; Ul’yanov, A.I. Effect of the magnetic properties of cementite on the coercive force of high-carbon steels after quenching and tempering. Phys. Metals Metallogr. 2009, 108, 548–555. [Google Scholar] [CrossRef]

- Läpple, V. Wärmebehandlung des Stahls: Grundlagen, Verfahren und Werkstoffe; 8., völlig überarb. und erw. Aufl.; Verl. Europa-Lehrmittel: Haan-Gruiten, Germany, 2003; ISBN 3-8085-1308-X. [Google Scholar]

- Anglada-Rivera, J.; Padovese, L.; Capó-Sánchez, J. Magnetic Barkhausen Noise and hysteresis loop in commercial carbon steel: Influence of applied tensile stress and grain size. J. Magn. Magn. Mater. 2001, 231, 299–306. [Google Scholar] [CrossRef]

| Alloying Element in wt.% | C | Si | Mn | P | S | Cr | Ni | Al | N | Mo | Co | Fe |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| AISI 4140 | 0.39 | 0.24 | 0.72 | 0.008 | 0.026 | 1.07 | 0.16 | 0.027 | 0.006 | 0.208 | 0.014 | 96.92 |

| AISI 52100 | 0.94 | 0.32 | 0.37 | 0.005 | 0.003 | 1.43 | 0.02 | 0.001 | 0.007 | 0.002 | N/A | 96.84 |

| Specimen | Material AISI | Austenitization | Quenching | Tempering |

|---|---|---|---|---|

| 52100-nt | 52100 | 850 °C/120 min | helium gas quenching | Non-tempered |

| 52100-100 min | 52100 | 850 °C/120 min | 180 °C/100 min | |

| 52100-1000 min | 52100 | 850 °C/120 min | 180 °C/1000 min | |

| 52100-300C | 52100 | 850 °C/120 min | 300 °C/60 min | |

| 52100-450C | 52100 | 850 °C/120 min | 450 °C/60 min | |

| 52100-600C | 52100 | 850 °C/120 min | 600 °C/60 min | |

| 4140-300C | 4140 | 850 °C/30 min | 300 °C/60 min | |

| 4140-450C | 4140 | 850 °C/30 min | 450 °C/60 min | |

| 4140-600C | 4140 | 850 °C/30 min | 600 °C/60 min |

| AISI4140 | Mean (HC) | Std (HC) | Var (HC) | Mean (BR) | Std (BR) | Var (BR) |

|---|---|---|---|---|---|---|

| 300C | 12.82 A/cm | 0.05 A/cm | 0.00 A/cm | 0.73 T | 0.00 T | 0.00 T |

| 450C | 10.19 A/cm | 0.06 A/cm | 0.00 A/cm | 0.79 T | 0.00 T | 0.00 T |

| 600C | 9.84 A/cm | 0.06 A/cm | 0.00 A/cm | 0.86 T | 0.01 T | 0.00 T |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ankener, W.; Böttger, D.; Smaga, M.; Gabi, Y.; Strass, B.; Wolter, B.; Beck, T. Micromagnetic and Microstructural Characterization of Ferromagnetic Steels in Different Heat Treatment Conditions. Sensors 2022, 22, 4428. https://doi.org/10.3390/s22124428

Ankener W, Böttger D, Smaga M, Gabi Y, Strass B, Wolter B, Beck T. Micromagnetic and Microstructural Characterization of Ferromagnetic Steels in Different Heat Treatment Conditions. Sensors. 2022; 22(12):4428. https://doi.org/10.3390/s22124428

Chicago/Turabian StyleAnkener, Werner, David Böttger, Marek Smaga, Yasmine Gabi, Benjamin Strass, Bernd Wolter, and Tilmann Beck. 2022. "Micromagnetic and Microstructural Characterization of Ferromagnetic Steels in Different Heat Treatment Conditions" Sensors 22, no. 12: 4428. https://doi.org/10.3390/s22124428

APA StyleAnkener, W., Böttger, D., Smaga, M., Gabi, Y., Strass, B., Wolter, B., & Beck, T. (2022). Micromagnetic and Microstructural Characterization of Ferromagnetic Steels in Different Heat Treatment Conditions. Sensors, 22(12), 4428. https://doi.org/10.3390/s22124428