Industry 4.0 and Precision Livestock Farming (PLF): An up to Date Overview across Animal Productions

Abstract

:1. Introduction

2. The Rise of Technology and Gaps in Current Farming Systems: Core Concepts for Automatic, Non-Invasive, Real Time Data Storing and Sharing

2.1. Industrial Revolution: From Industry 1.0 to 4.0

2.2. Industry 4.0

2.3. Internet of Things (IoT)

2.4. Big Data

2.5. 5G

2.6. Agriculture 4.0

2.7. Precision Livestock Farming (PLF)

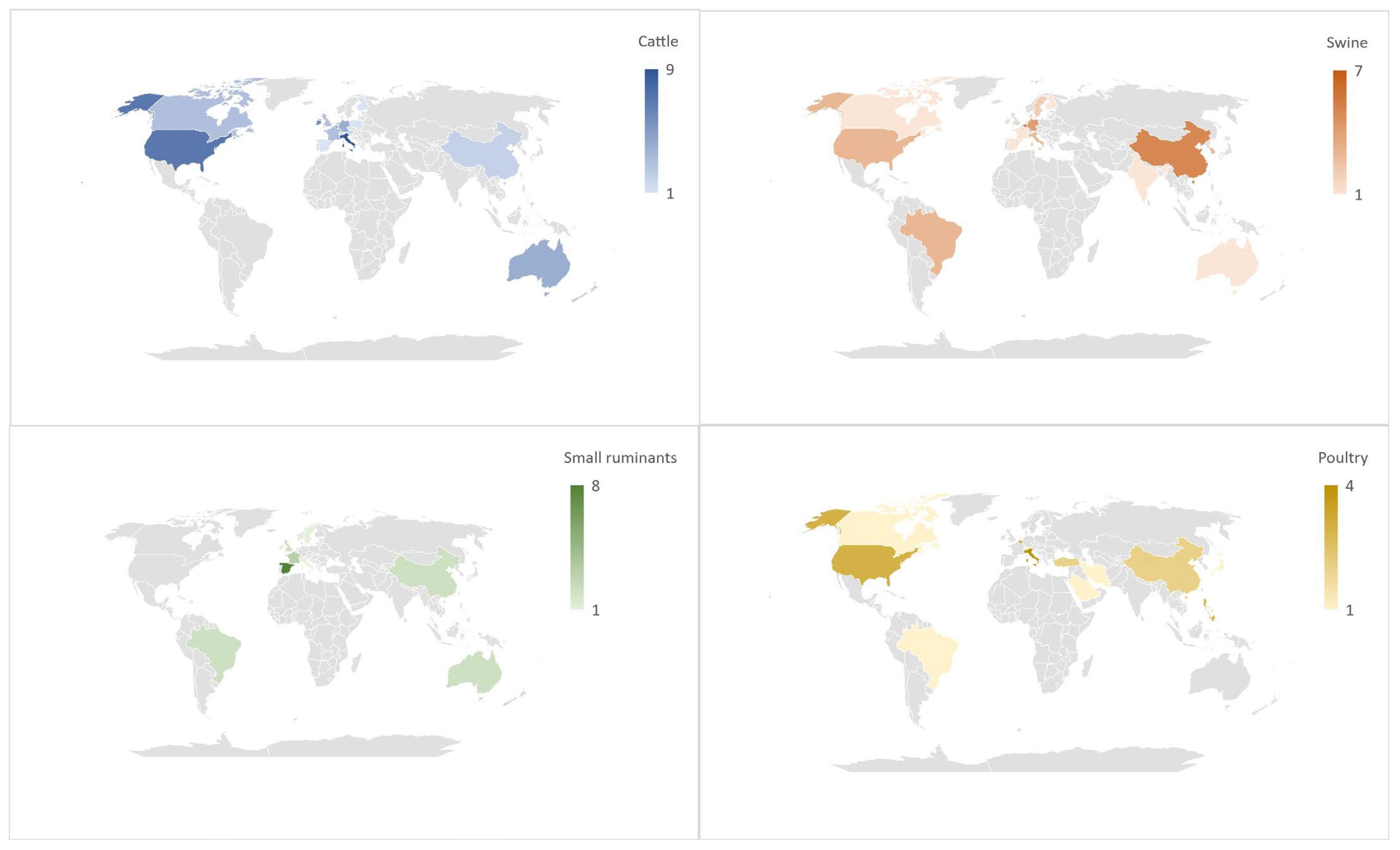

3. Animal Productions and Farming Systems

3.1. Cattle

3.1.1. Identification and Tracking Systems

3.1.2. Automatic Milking Systems

3.1.3. Oestrus Detection

3.1.4. Diseases Detection

3.1.5. Animal Performances and Feed Monitoring

3.1.6. Animal Behaviour

3.2. Small Ruminants

3.2.1. Animal Identification and Automatic Tracking

3.2.2. Automatic Milking Systems

3.2.3. Diseases and Oestrus Detection

3.2.4. Animal Performances, Feed Monitoring and Animal Behaviour

3.3. Swine

3.3.1. Animal Identification and Automatic Tracking

3.3.2. Diseases Detection

3.3.3. Animal Performances and Feed Monitoring

3.3.4. Animal Behaviour

3.4. Poultry

3.4.1. Diseases Detection

3.4.2. Animal Performances and Feed Monitoring

3.4.3. Animal Behaviour

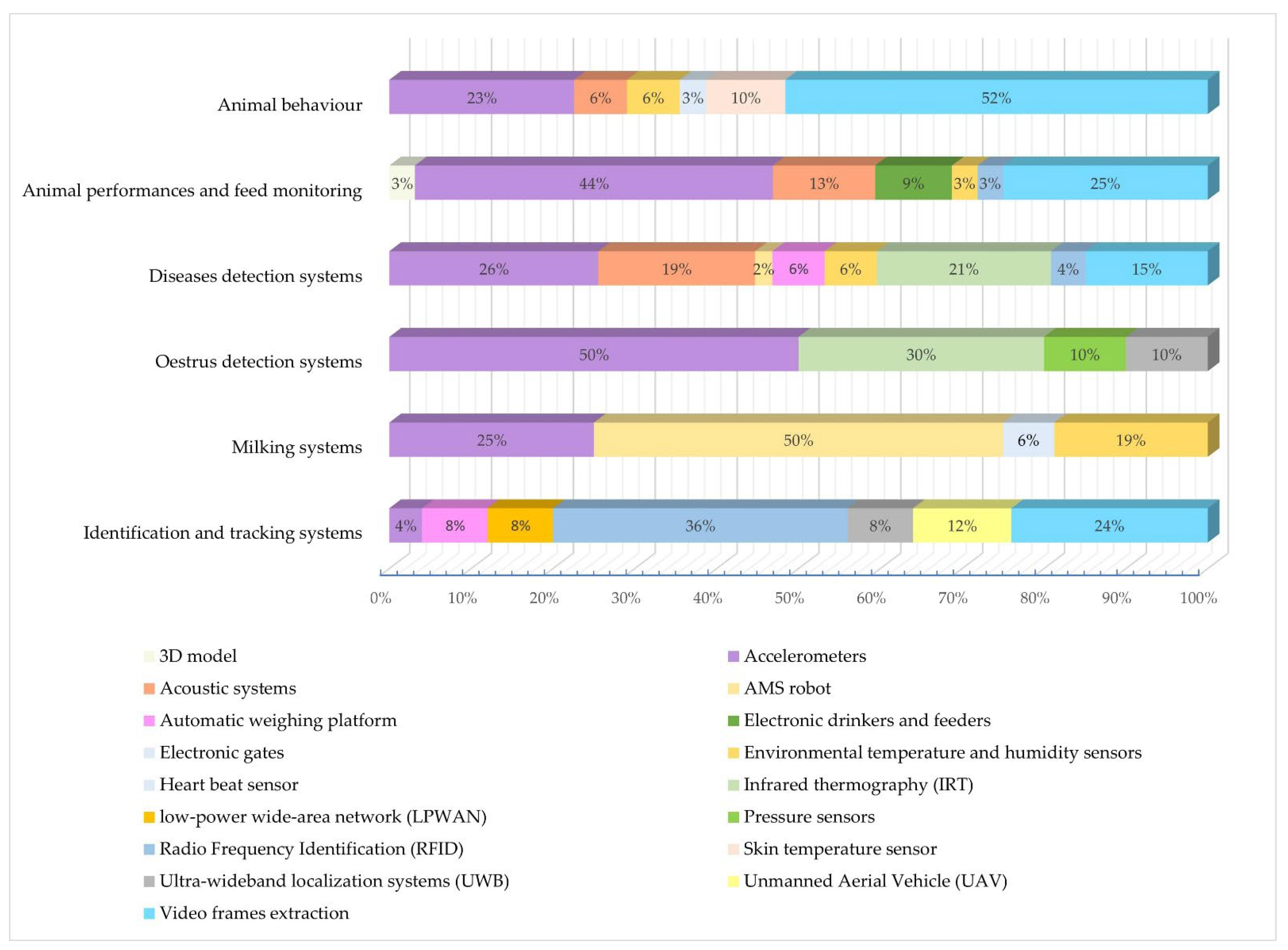

| Areas of Interest | Technologies | Cattle | Small Ruminants | Swine | Poultry |

|---|---|---|---|---|---|

| Identification and tracking systems | Radio Frequency Identification (RFID) | [45] | [104,105,106,111] | [135,136,139,140] | |

| Video frames extraction | [46] | [137,138,141,142] | |||

| Unmanned Aerial Vehicle (UAV) | [47] | [109,110] | |||

| Ultra-wideband localization systems (UWB) | [48] | [107] | |||

| Accelerometers | [49] | ||||

| low-power wide-area network (LPWAN) | [50,51] | ||||

| Video frames extraction | [107] | ||||

| Automatic weighing platform | |||||

| Milking systems | AMS robot | [53,54,55,56] | [112,113,114,115] | ||

| Accelerometers | [53,55] | [118] | |||

| Electronic gates | [111] | ||||

| Environmental temperature and humidity sensors | [56] | ||||

| Oestrus detection systems | Accelerometers | [57,58,59,60] | [116] | ||

| Ultra-wideband localization systems (UWB) | [61] * | ||||

| Pressure sensors | [117] | ||||

| Infrared thermography (IRT) | [62] | [119,120] | |||

| Diseases detection systems | Automatic weighing platform | [63] | |||

| Accelerometers | [64,66,67,68,72] * | [180] | |||

| Infrared thermography (IRT) | [65,74] | [121,122,123,124,125] | |||

| Video frames extraction | [66,67,68,80] | [123] | [175,176,177,178,179] | ||

| Automatic weighing platform | [67] | ||||

| AMS robot | [76,78] | ||||

| Acoustic systems | [79] | [143,145,146,147,148] | [183,184] | ||

| Environmental temperature, air and humidity sensors | [181,182] | ||||

| Radio Frequency Identification (RFID) | [80] | [123] | |||

| Animal performances and feed monitoring | Accelerometers | [82,83,84,85,87,88,91,92,93] * | [127] | ||

| Video frames extraction | [84] | [153,154,155,156,157,158,159] * | [189,196] | ||

| Acoustic systems | [88] | [186,187,188] | |||

| RFID | [94] | ||||

| 3D model | [94] | ||||

| Environmental temperature and humidity sensors | [150] | ||||

| Electronic drinkers and feeders | [150,152] | [190] * | |||

| Animal behaviour | Accelerometers | [97,98,99,101,102] * | [131] | ||

| Video frames extraction | [98,99,100] | [170,171,172,173,174] | [177,192,193,194,195] * | ||

| Acoustic systems | [130] | [160,161,162,163,164,165,166,167,168,169] | [189,196] | ||

| Heart beat sensor | [132] * | ||||

| Skin temperature sensor | [132] * | [160,161] | |||

| Environmental temperature and humidity sensors | [101,102] * | [197,198] * |

4. Challenges of PLF and IoT

4.1. Economic Challenges

4.2. Applicability

4.3. Ethical Issues

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Alexandratos, N.; Bruinsma, J. World Agriculture towards 2030/2050: The 2012 Revision; ESA Working Paper No. 12-03; FAO: Rome, Italy, 2012; Volume 20. [Google Scholar]

- Food and Agriculture Organization of the United Nations. How to Feed the World in 2050: High Level Expert Forum; FAO: Rome, Italy, 2009. [Google Scholar]

- Thompson, P.B. From Field to Fork; Oxford University Press: New York, NY, USA, 2015. [Google Scholar]

- Parsons, D.J.; Green, D.M.; Schofield, C.P.; Whittemore, C.T. Real-time Control of Pig Growth through an Integrated Management System. Biosyst. Eng. 2007, 96, 257–266. [Google Scholar] [CrossRef] [Green Version]

- Frost, A.R.; Parsons, D.J.; Stacey, K.F.; Robertson, A.P.; Welch, S.K.; Filmer, D.; Fothergill, A. Progress towards the development of an integrated management system for broiler chicken production. Comput. Electron. Agric. 2003, 39, 227–240. [Google Scholar] [CrossRef]

- Blokhuis, H.J.; Veissier, I.; Miele, M.; Jones, B. Safeguarding farm animal welfare. In Sustainability Certification Schemes in the Agricultural and Natural Resource Sectors; Routledge: London, UK, 2019; pp. 137–153. ISBN 0203701739. [Google Scholar]

- Buller, H.; Blokhuis, H.; Lokhorst, K.; Silberberg, M.; Veissier, I. Animal welfare management in a digital world. Animals 2020, 10, 1779. [Google Scholar] [CrossRef]

- Simitzis, P.; Tzanidakis, C.; Tzamaloukas, O.; Sossidou, E. Contribution of Precision Livestock Farming Systems to the Improvement of Welfare Status and Productivity of Dairy Animals. Dairy 2022, 3, 12–28. [Google Scholar] [CrossRef]

- Crainer, S. The management century: A critical review of 20th century thought and practice. Choice Rev. Online 2000, 38, 1645. [Google Scholar] [CrossRef]

- Smith, A. An Inquiry into the Wealth of Nations; Strahan and Cadell: London, UK, 1776. [Google Scholar]

- Taylor, F.W. The Principles of Scientific Management. In Modern Economic Classics-Evaluations Through Time; Taylor & Francis: Abingdon, UK, 2017; ISBN 9781351982399. [Google Scholar]

- Yin, Y.; Stecke, K.E.; Li, D. The evolution of production systems from Industry 2.0 through Industry 4.0. Int. J. Prod. Res. 2018, 56, 848–861. [Google Scholar] [CrossRef] [Green Version]

- Lasi, H.; Fettke, P.; Kemper, H.G.; Feld, T.; Hoffmann, M. Industry 4.0. Bus. Inf. Syst. Eng. 2014, 6, 239–242. [Google Scholar] [CrossRef]

- Maci, L. Che Cos’è l’Industria 4.0 e Perché è Importante Saperla Affrontare. Economy Up, 11 January 2022. [Google Scholar]

- Rüßmann, M.; Markus, L.; Gerbert, P.; Waldner, M.; Justus, J.; Engel, P.; Harnisch, M. Industry 4.0: The Future of Productivity and Growth in Manufacturing Industries. Bost. Consult. 2015, 9, 54–89. [Google Scholar]

- TongKe, F. Smart Agriculture Based on Cloud Computing and IOT. J. Converg. Inf. Technol. 2013, 8, 210–216. [Google Scholar] [CrossRef]

- CEMA. Digital Farming: What Does It Really Mean? European Agricultural Machinery: Brussels, Belgium, 2017; Volume 32. [Google Scholar]

- Lee, I.; Lee, K. The Internet of Things (IoT): Applications, investments, and challenges for enterprises. Bus. Horiz. 2015, 58, 431–440. [Google Scholar] [CrossRef]

- Liu, Y.; Ma, X.; Shu, L.; Hancke, G.P.; Abu-Mahfouz, A.M. From Industry 4.0 to Agriculture 4.0: Current Status, Enabling Technologies, and Research Challenges. IEEE Trans. Ind. Inform. 2020, 17, 4322–4334. [Google Scholar] [CrossRef]

- Witkowski, K. Internet of Things, Big Data, Industry 4.0—Innovative Solutions in Logistics and Supply Chains Management. Procedia Eng. 2017, 182, 763–769. [Google Scholar] [CrossRef]

- Farooq, M.S.; Riaz, S.; Abid, A.; Abid, K.; Naeem, M.A. A Survey on the Role of IoT in Agriculture for the Implementation of Smart Farming. IEEE Access 2019, 7, 156237–156271. [Google Scholar] [CrossRef]

- Başçiftçi, F.; Gündüz, K.A. Identification of Acidosis Disease in Cattle Using IoT. In Proceedings of the 2019 4th International Conference on Computer Science and Engineering (UBMK), Samsun, Turkey, 11–15 September 2019; pp. 58–62. [Google Scholar]

- Ibrahim, H.; Mostafa, N.; Halawa, H.; Elsalamouny, M.; Daoud, R.; Amer, H.; Adel, Y.; Shaarawi, A.; Khattab, A.; ElSayed, H. A layered IoT architecture for greenhouse monitoring and remote control. SN Appl. Sci. 2019, 1, 223. [Google Scholar] [CrossRef]

- Stubbs, M. Big Data in U.S. Agriculture; Congressional Research Service: Washington, DC, USA, 2016. [Google Scholar]

- Philip, L.; Cottrill, C.; Farrington, J.; Williams, F.; Ashmore, F. The digital divide: Patterns, policy and scenarios for connecting the ‘final few’ in rural communities across Great Britain. J. Rural Stud. 2017, 54, 386–398. [Google Scholar] [CrossRef] [Green Version]

- Wang, C.X.; Haider, F.; Gao, X.; You, X.H.; Yang, Y.; Yuan, D.; Aggoune, H.M.; Haas, H.; Fletcher, S.; Hepsaydir, E. Cellular architecture and key technologies for 5G wireless communication networks. IEEE Commun. Mag. 2014, 52, 122–130. [Google Scholar] [CrossRef] [Green Version]

- Tang, Y.; Dananjayan, S.; Hou, C.; Guo, Q.; Luo, S.; He, Y. A survey on the 5G network and its impact on agriculture: Challenges and opportunities. Comput. Electron. Agric. 2021, 180, 105895. [Google Scholar] [CrossRef]

- Hajlaoui, E.; Zaier, A.; Khlifi, A.; Ghodhbane, J.; Ben Hamed, M.; Sbita, L. 4G and 5G technologies: A Comparative Study. In Proceedings of the 2020 International Conference on Advanced Technologies for Signal and Image Processing, ATSIP 2020, Sousse, Tunisia, 2–5 September 2020. [Google Scholar]

- Cappai, M.G.; Rubiu, N.G.; Nieddu, G.; Bitti, M.P.L.; Pinna, W. Analysis of fieldwork activities during milk production recording in dairy ewes by means of individual ear tag (ET) alone or plus RFID based electronic identification (EID). Comput. Electron. Agric. 2018, 144, 324–328. [Google Scholar] [CrossRef]

- Cappai, M.G.; Picciau, M.; Nieddu, G.; Bitti, M.P.L.; Pinna, W. Long term performance of RFID technology in the large scale identification of small ruminants through electronic ceramic boluses: Implications for animal welfare and regulation compliance. Small Rumin. Res. 2014, 117, 169–175. [Google Scholar] [CrossRef]

- Borocz, M.; Szoke, L.; Horvath, B. Possible climate friendly innovation ways and technical solutions in the agricultural sector for 2030. Hung. Agric. Eng. 2016, 29, 55–59. [Google Scholar] [CrossRef]

- Kovács, I.; Husti, I. The role of digitalization in the agricultural 4.0—How to connect the industry 4.0 to agriculture? Hung. Agric. Eng. 2018, 33, 38–42. [Google Scholar] [CrossRef]

- Berckmans, D. Automatic on-line monitoring of animals by precision livestock farming. In Livestock Production and Society; Wageningen Academic Publishers: Wageningen, The Netherlands, 2006. [Google Scholar]

- Werkheiser, I. Technology and responsibility: A discussion of underexamined risks and concerns in precision livestock farming. Anim. Front. 2020, 10, 51–57. [Google Scholar] [CrossRef]

- Wathes, C.M.; Kristensen, H.H.; Aerts, J.M.; Berckmans, D. Is precision livestock farming an engineer’s daydream or nightmare, an animal’s friend or foe, and a farmer’s panacea or pitfall? Comput. Electron. Agric. 2008, 64, 2–10. [Google Scholar] [CrossRef]

- Berckmans, D. Precision livestock farming technologies for welfare management in intensive livestock systems. OIE Rev. Sci. Tech. 2014, 33, 189–196. [Google Scholar] [CrossRef]

- Rutter, S.M. A “smart” future for ruminant livestock production? Cattle Pract. 2012, 20, 186–193. [Google Scholar]

- Føre, M.; Frank, K.; Norton, T.; Svendsen, E.; Alfredsen, J.A.; Dempster, T.; Eguiraun, H.; Watson, W.; Stahl, A.; Sunde, L.M.; et al. Precision fish farming: A new framework to improve production in aquaculture. Biosyst. Eng. 2018, 173, 176–193. [Google Scholar] [CrossRef]

- Costa, A.; Mentasti, T.; Guarino, M.; Leroy, T.; Berckmans, D. Real time monitoring of pig activity: Practical difficulties in pigs’ behaviour labelling. In Proceedings of the Precision Livestock Farming 2007—Papers Presented at the 3rd European Conference on Precision Livestock Farming; Wageningen Academic Publishers: Wageningen, The Netherlands, 2007. [Google Scholar]

- Dominiak, K.N.; Kristensen, A.R. Prioritizing alarms from sensor-based detection models in livestock production—A review on model performance and alarm reducing methods. Comput. Electron. Agric. 2017, 133, 46–67. [Google Scholar] [CrossRef]

- King, A. Technology: The Future of Agriculture. Nature 2017, 544, S21–S23. [Google Scholar] [CrossRef] [Green Version]

- Norton, T.; Chen, C.; Larsen, M.L.V.; Berckmans, D. Review: Precision livestock farming: Building “digital representations” to bring the animals closer to the farmer. Animal 2019, 13, 3009–3017. [Google Scholar] [CrossRef] [Green Version]

- Halachmi, I.; Guarino, M.; Bewley, J.; Pastell, M. Smart Animal Agriculture: Application of Real-Time Sensors to Improve Animal Well-Being and Production. Annu. Rev. Anim. Biosci. 2019, 7, 403–425. [Google Scholar] [CrossRef]

- Trivelli, L.; Apicella, A.; Chiarello, F.; Rana, R.; Fantoni, G.; Tarabella, A. From precision agriculture to Industry 4.0: Unveiling technological connections in the agrifood sector. Br. Food J. 2019, 121, 1730–1743. [Google Scholar] [CrossRef]

- Mun, L.N.; Kin, S.; Hall, D.M.; Cole, P.H. A small passive UHF RFID tag for livestock identification. In Proceedings of the MAPE2005: IEEE 2005 International Symposium on Microwave, Antenna, Propagation and EMC Technologies for Wireless Communications, Beijing, China, 8–12 August 2005. [Google Scholar]

- Qiao, Y.; Su, D.; Kong, H.; Sukkarieh, S.; Lomax, S.; Clark, C. BiLSTM-based Individual Cattle Identification for Automated Precision Livestock Farming. In Proceedings of the IEEE International Conference on Automation Science and Engineering, Hong Kong, China, 20–21 August 2020. [Google Scholar]

- Andrew, W.; Greatwood, C.; Burghardt, T. Fusing animal biometrics with autonomous robotics: Drone-based search and individual id of friesian cattle. In Proceedings of the IEEE/CVF Winter Conference on Applications of Computer Vision Workshops, Snowmass Village, CO, USA, 2–5 March 2022; pp. 38–43. [Google Scholar]

- Meunier, B.; Pradel, P.; Sloth, K.H.; Cirié, C.; Delval, E.; Mialon, M.M.; Veissier, I. Image analysis to refine measurements of dairy cow behaviour from a real-time location system. Biosyst. Eng. 2018, 173, 32–44. [Google Scholar] [CrossRef]

- Terrasson, G.; Llaria, A.; Marra, A.; Voaden, S. Accelerometer based solution for precision livestock farming: Geolocation enhancement and animal activity identification. IOP Conf. Ser. Mater. Sci. Eng. 2016, 38, 012004. [Google Scholar] [CrossRef] [Green Version]

- Llaria, A.; Terrasson, G.; Arregui, H.; Hacala, A. Geolocation and monitoring platform for extensive farming in mountain pastures. In Proceedings of the IEEE International Conference on Industrial Technology, Seville, Spain, 17–19 March 2015. [Google Scholar]

- Casas, R.; Hermosa, A.; Marco, Á.; Blanco, T.; Zarazaga-Soria, F.J. Real-Time Extensive Livestock Monitoring Using LPWAN Smart Wearable and Infrastructure. Appl. Sci. 2021, 11, 1240. [Google Scholar] [CrossRef]

- John, A.J.; Clark, C.E.F.; Freeman, M.J.; Kerrisk, K.L.; Garcia, S.C.; Halachmi, I. Review: Milking robot utilization, a successful precision livestock farming evolution. Animal 2016, 10, 1484–1492. [Google Scholar] [CrossRef]

- Benni, S.; Pastell, M.; Bonora, F.; Tassinari, P.; Torreggiani, D. A generalised additive model to characterise dairy cows’ responses to heat stress. Animal 2020, 14, 418–424. [Google Scholar] [CrossRef]

- Bonora, F.; Pastell, M.; Benni, S.; Tassinari, P.; Torreggiani, D. ICT Monitoring and Mathematical Modelling of Dairy Cows Performances in Hot Climate Conditions: A study Case in Po Valley (Italy). 2018. Available online: https://cigrjournal.org/index.php/Ejounral/article/view/4679 (accessed on 3 May 2022).

- Bonora, F.; Benni, S.; Barbaresi, A.; Tassinari, P.; Torreggiani, D. A cluster-graph model for herd characterisation in dairy farms equipped with an automatic milking system. Biosyst. Eng. 2018, 167, 1–7. [Google Scholar] [CrossRef]

- Bovo, M.; Agrusti, M.; Benni, S.; Torreggiani, D.; Tassinari, P. Random forest modelling of milk yield of dairy cows under heat stress conditions. Animals 2021, 11, 1305. [Google Scholar] [CrossRef]

- Valenza, A.; Giordano, J.O.; Lopes, G.; Vincenti, L.; Amundson, M.C.; Fricke, P.M. Assessment of an accelerometer system for detection of estrus and treatment with gonadotropin-releasing hormone at the time of insemination in lactating dairy cows. J. Dairy Sci. 2012, 95, 7115–7127. [Google Scholar] [CrossRef]

- Aungier, S.P.M.; Roche, J.F.; Sheehy, M.; Crowe, M.A. Effects of management and health on the use of activity monitoring for estrus detection in dairy cows. J. Dairy Sci. 2012, 95, 2452–2466. [Google Scholar] [CrossRef]

- LeRoy, C.N.S.; Walton, J.S.; LeBlanc, S.J. Estrous detection intensity and accuracy and optimal timing of insemination with automated activity monitors for dairy cows. J. Dairy Sci. 2018, 101, 1638–1647. [Google Scholar] [CrossRef]

- Roelofs, J.B.; Van Eerdenburg, F.J.C.M.; Soede, N.M.; Kemp, B. Pedometer readings for estrous detection and as predictor for time of ovulation in dairy cattle. Theriogenology 2005, 64, 1690–1703. [Google Scholar] [CrossRef]

- Arcidiacono, C.; Porto, S.M.C.; Mancino, M.; Cascone, G. A software tool for the automatic and real-time analysis of cow velocity data in free-stall barns: The case study of oestrus detection from Ultra-Wide-Band data. Biosyst. Eng. 2018, 173, 157–165. [Google Scholar] [CrossRef]

- Marquez, H.J.P.; Ambrose, D.J.; Schaefer, A.L.; Cook, N.J.; Bench, C.J. Infrared thermography and behavioral biometrics associated with estrus indicators and ovulation in estrus-synchronized dairy cows housed in tiestalls. J. Dairy Sci. 2019, 102, 4427–4440. [Google Scholar] [CrossRef] [Green Version]

- Dunthorn, J.; Dyer, R.M.; Neerchal, N.K.; Mchenry, J.S.; Rajkondawar, P.G.; Steingraber, G.; Tasch, U. Predictive models of lameness in dairy cows achieve high sensitivity and specificity with force measurements in three dimensions. J. Dairy Res. 2015, 82, 391–399. [Google Scholar] [CrossRef]

- Kokin, E.; Praks, J.; Veermäe, I.; Poikalainen, V.; Vallas, M. IceTag3DTM accelerometric device in cattle lameness detection. Agron. Res. 2014, 12, 223–230. [Google Scholar]

- Alsaaod, M.; Büscher, W. Detection of hoof lesions using digital infrared thermography in dairy cows. J. Dairy Sci. 2012, 95, 735–742. [Google Scholar] [CrossRef]

- Mandel, R.; Harazy, H.; Gygax, L.; Nicol, C.J.; Ben-David, A.; Whay, H.R.; Klement, E. Short communication: Detection of lameness in dairy cows using a grooming device. J. Dairy Sci. 2018, 101, 1511–1517. [Google Scholar] [CrossRef]

- Chapinal, N.; de Passillé, A.M.; Rushen, J.; Wagner, S. Automated methods for detecting lameness and measuring analgesia in dairy cattle. J. Dairy Sci. 2010, 93, 2007–2013. [Google Scholar] [CrossRef] [Green Version]

- Van Hertem, T.; Bahr, C.; Tello, A.S.; Viazzi, S.; Steensels, M.; Romanini, C.E.B.; Lokhorst, C.; Maltz, E.; Halachmi, I.; Berckmans, D. Lameness detection in dairy cattle: Single predictor v. multivariate analysis of image-based posture processing and behaviour and performance sensing. Animal 2016, 10, 1525–1532. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Warner, D.; Vasseur, E.; Lefebvre, D.M.; Lacroix, R. A machine learning based decision aid for lameness in dairy herds using farm-based records. Comput. Electron. Agric. 2020, 169, 105193. [Google Scholar] [CrossRef]

- Taneja, M.; Byabazaire, J.; Jalodia, N.; Davy, A.; Olariu, C.; Malone, P. Machine learning based fog computing assisted data-driven approach for early lameness detection in dairy cattle. Comput. Electron. Agric. 2020, 171, 105286. [Google Scholar] [CrossRef]

- Taneja, M.; Jalodia, N.; Malone, P.; Byabazaire, J.; Davy, A.; Olariu, C. Connected Cows: Utilizing Fog and Cloud Analytics toward Data-Driven Decisions for Smart Dairy Farming. IEEE Internet Things Mag. 2020, 2, 32–37. [Google Scholar] [CrossRef] [Green Version]

- Steensels, M.; Maltz, E.; Bahr, C.; Berckmans, D.; Antler, A.; Halachmi, I. Towards practical application of sensors for monitoring animal health; design and validation of a model to detect ketosis. J. Dairy Res. 2017, 84, 139–145. [Google Scholar] [CrossRef]

- Krieger, S.; Sattlecker, G.; Kickinger, F.; Auer, W.; Drillich, M.; Iwersen, M. Prediction of calving in dairy cows using a tail-mounted tri-axial accelerometer: A pilot study. Biosyst. Eng. 2018, 173, 79–84. [Google Scholar] [CrossRef]

- Steensels, M.; Antler, A.; Bahr, C.; Berckmans, D.; Maltz, E.; Halachmi, I. A decision-tree model to detect post-calving diseases based on rumination, activity, milk yield, BW and voluntary visits to the milking robot. Animal 2016, 10, 1493–1500. [Google Scholar] [CrossRef] [Green Version]

- Steensels, M.; Bahr, C.; Berckmans, D.; Halachmi, I.; Antler, A.; Maltz, E. Lying patterns of high producing healthy dairy cows after calving in commercial herds as affected by age, environmental conditions and production. Appl. Anim. Behav. Sci. 2012, 136, 88–95. [Google Scholar] [CrossRef]

- Steensels, M.; Maltz, E.; Bahr, C.; Berckmans, D.; Antler, A.; Halachmi, I. Towards practical application of sensors for monitoring animal health: The effect of post-calving health problems on rumination duration, activity and milk yield. J. Dairy Res. 2017, 84, 132–138. [Google Scholar] [CrossRef]

- Ghang, X.; Kang, X.; Feng, N.; Liu, G. Automatic recognition of dairy cow mastitis from thermal images by a deep learning detector. Comput. Electron. Agric. 2020, 178, 105754. [Google Scholar] [CrossRef]

- González, L.A.; Tolkamp, B.J.; Coffey, M.P.; Ferret, A.; Kyriazakis, I. Changes in feeding behavior as possible indicators for the automatic monitoring of health disorders in dairy cows. J. Dairy Sci. 2008, 91, 1017–1028. [Google Scholar] [CrossRef] [Green Version]

- Carpentier, L.; Berckmans, D.; Youssef, A.; Berckmans, D.; van Waterschoot, T.; Johnston, D.; Ferguson, N.; Earley, B.; Fontana, I.; Tullo, E.; et al. Automatic cough detection for bovine respiratory disease in a calf house. Biosyst. Eng. 2018, 173, 45–56. [Google Scholar] [CrossRef]

- Lowe, G.; Sutherland, M.; Waas, J.; Schaefer, A.; Cox, N.; Stewart, M. Infrared thermography—A non-invasive method of measuring respiration rate in calves. Animals 2019, 9, 535. [Google Scholar] [CrossRef] [Green Version]

- Cheng, L.; Al-Marashdeh, O.; McCormick, J.; Guo, X.; Chen, A.; Logan, C.; Tao, J.Z.; Carr, H.; Edwards, G. Live weight gain, animal behaviour and urinary nitrogen excretion of dairy heifers grazing ryegrass–white clover pasture, chicory or plantain. N. Z. J. Agric. Res. 2018, 61, 454–467. [Google Scholar] [CrossRef]

- Pereira, G.M.; Sharpe, K.T.; Heins, B.J. Evaluation of the RumiWatch system as a benchmark to monitor feeding and locomotion behaviors of grazing dairy cows. J. Dairy Sci. 2021, 104, 3736–3750. [Google Scholar] [CrossRef] [PubMed]

- Rombach, M.; Münger, A.; Niederhauser, J.; Südekum, K.H.; Schori, F. Evaluation and validation of an automatic jaw movement recorder (RumiWatch) for ingestive and rumination behaviors of dairy cows during grazing and supplementation. J. Dairy Sci. 2018, 101, 2463–2475. [Google Scholar] [CrossRef]

- Ruuska, S.; Kajava, S.; Mughal, M.; Zehner, N.; Mononen, J. Validation of a pressure sensor-based system for measuring eating, rumination and drinking behaviour of dairy cattle. Appl. Anim. Behav. Sci. 2016, 174, 19–23. [Google Scholar] [CrossRef]

- Steinmetz, M.; von Soosten, D.; Hummel, J.; Meyer, U.; Dänicke, S. Validation of the RumiWatch Converter V0.7.4.5 classification accuracy for the automatic monitoring of behavioural characteristics in dairy cows. Arch. Anim. Nutr. 2020, 74, 164–172. [Google Scholar] [CrossRef]

- Werner, J.; Leso, L.; Umstatter, C.; Schick, M.; O’Brien, B. Evaluation of precision technologies for measuring cows’ grazing behaviour. In Grassland Resources for Extensive Farming Systems in Marginal Lands: Major Drivers and Future Scenarios, Proceedings of the European Grassland Federation, Alghero, Italy, 7–10 May 2017; Istituto Sistema Produzione Animale Ambiente Mediterraneo: Sassari, Italy, 2017. [Google Scholar]

- Werner, J.; Viel, J.; Niederhauser, J.; O’Leary, N.; Umstatter, C.; O’Brien, B. Validation of new algorithms for the RumiWatch noseband sensor to detect grazing behaviour of dairy cows. In Sustainable Meat and Milk Production from Grasslands, Proceedings of the 27th General Meeting of the European Grassland Federation, Cork, Ireland, 17–21 June 2018; Animal and Grassland Research and Innovation Centre: Cork, Ireland, 2018. [Google Scholar]

- Werner, J.; Leso, L.; Umstatter, C.; Niederhauser, J.; Kennedy, E.; Geoghegan, A.; Shalloo, L.; Schick, M.; O’Brien, B. Evaluation of the RumiWatchSystem for measuring grazing behaviour of cows. J. Neurosci. Methods 2018, 300, 138–146. [Google Scholar] [CrossRef]

- Islas, A.; Gilbery, T.C.; Goulart, R.S.; Dahlen, C.R.; Bauer, M.L.; Swanson, K.C. Influence of supplementation with corn dried distillers grains plus solubles to growing calves fed medium-quality hay on growth performance and feeding behavior. J. Anim. Sci. 2014, 92, 705–711. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Reuter, R.R.; Moffet, C.A.; Horn, G.W.; Zimmerman, S.; Billars, M. Technical Note: Daily variation in intake of a salt-limited supplement by grazing steers. Prof. Anim. Sci. 2017, 33, 372–377. [Google Scholar] [CrossRef]

- Wolfger, B.; Timsit, E.; Pajor, E.A.; Cook, N.; Barkema, H.W.; Orsel, K. Technical note: Accuracy of an ear tag-attached accelerometer to monitor rumination and feeding behavior in feedlot cattle. J. Anim. Sci. 2015, 93, 3164–3168. [Google Scholar] [CrossRef] [Green Version]

- Giovanetti, V.; Decandia, M.; Acciaro, M.; Mameli, M.; Molle, G.; Cabiddu, A.; Manca, C.; Cossu, R.; Serra, M.G.; Rassu, S.P.G.; et al. Automatic classification of feeding behaviours in Sarda cattle using tri-axial accelerometry with different time epoch settings. In Proceedings of the Precision Livestock Farming 2017—Papers Presented at the 8th European Conference on Precision Livestock Farming, ECPLF 2017, Nantes, France, 12–14 September 2017. [Google Scholar]

- Giovanetti, V.; Decandia, M.; Molle, G.; Acciaro, M.; Mameli, M.; Cabiddu, A.; Cossu, R.; Serra, M.G.; Manca, C.; Rassu, S.P.G.; et al. Automatic classification system for grazing, ruminating and resting behaviour of dairy sheep using a tri-axial accelerometer. Livest. Sci. 2017, 196, 42–48. [Google Scholar] [CrossRef]

- Cappai, M.G.; Gambella, F.; Piccirilli, D.; Rubiu, N.G.; Dimauro, C.; Pazzona, A.L.; Pinna, W. Integrating the RFID identification system for Charolaise breeding bulls with 3D imaging for virtual archive creation. PeerJ Comput. Sci. 2019, 5, e179. [Google Scholar] [CrossRef] [Green Version]

- Bayvel, A.C.D. Science-based animal welfare standards: The international role of the Office International des Épizooties. Anim. Welf. 2004, 13, 163–169. [Google Scholar]

- Caja, G.; Castro-Costa, A.; Knight, C.H. Engineering to support wellbeing of dairy animals. J. Dairy Res. 2016, 83, 136–147. [Google Scholar] [CrossRef]

- Borchers, M.R.; Chang, Y.M.; Tsai, I.C.; Wadsworth, B.A.; Bewley, J.M. A validation of technologies monitoring dairy cow feeding, ruminating, and lying behaviors. J. Dairy Sci. 2016, 99, 7458–7466. [Google Scholar] [CrossRef]

- Carslake, C.; Vázquez-Diosdado, J.A.; Kaler, J. Machine learning algorithms to classify and quantify multiple behaviours in dairy calves using a sensor: Moving beyond classification in precision livestock. Sensors 2020, 21, 88. [Google Scholar] [CrossRef]

- Swartz, T.H.; McGilliard, M.L.; Petersson-Wolfe, C.S. The use of an accelerometer for measuring step activity and lying behaviors in dairy calves. J. Dairy Sci. 2016, 99, 9109–9113. [Google Scholar] [CrossRef] [Green Version]

- Bikker, J.P.; Van Laar, H.; Rump, P.; Doorenbos, J.; Van Meurs, K.; Griffioen, G.M.; Dijkstra, J. Evaluation of an ear-attached movement sensor to record cow feeding behavior and activity. J. Dairy Sci. 2014, 97, 2974–2979. [Google Scholar] [CrossRef]

- Carpio, F.; Jukan, A.; Sanchez, A.I.M.; Amla, N.; Kemper, N. Beyond production indicators: A novel smart farming application and system for animal welfare. In Proceedings of the Fourth International Conference on Animal-Computer Interaction, Milton Keynes, UK, 21–23 November 2017; pp. 1–11. [Google Scholar]

- Unold, O.; Nikodem, M.; Piasecki, M.; Szyc, K.; Maciejewski, H.; Bawiec, M.; Dobrowolski, P.; Zdunek, M. IoT-based cow health monitoring system. In Proceedings of the International Conference on Computational Science; Springer: Berlin/Heidelberg, Germany, 2020; pp. 344–356. [Google Scholar]

- Robinson, T.P.; Wint, G.R.W.; Conchedda, G.; Van Boeckel, T.P.; Ercoli, V.; Palamara, E.; Cinardi, G.; D’Aietti, L.; Hay, S.I.; Gilbert, M. Mapping the global distribution of livestock. PLoS ONE 2014, 9, e96084. [Google Scholar] [CrossRef] [Green Version]

- Caja, G.; Carné, S.; Salama, A.A.K.; Ait-Saidi, A.; Rojas-Olivares, M.A.; Rovai, M.; Capote, J.; Castro, N.; Argüello, A.; Ayadi, M. State-of-the-art of electronic identification techniques and applications in goats. Small Rumin. Res. 2014, 121, 42–50. [Google Scholar] [CrossRef]

- Carné, S.; Caja, G.; Ghirardi, J.J.; Salama, A.A.K. Long-term performance of visual and electronic identification devices in dairy goats. J. Dairy Sci. 2009, 92, 1500–1511. [Google Scholar] [CrossRef] [Green Version]

- Pinna, W.; Sedda, P.; Moniello, G.; Ribó, O. Electronic identification of Sarda goats under extensive conditions in the island of Sardinia. Small Rumin. Res. 2006, 66, 286–290. [Google Scholar] [CrossRef]

- Ren, K.; Karlsson, J.; Liuska, M.; Hartikainen, M.; Hansen, I.; Jørgensen, G.H.M. A sensor-fusion-system for tracking sheep location and behaviour. Int. J. Distrib. Sens. Netw. 2020, 16, 1–10. [Google Scholar] [CrossRef]

- Betteridge, K.; Hoogendoorn, C.; Costall, D.; Carter, M.; Griffiths, W. Sensors for detecting and logging spatial distribution of urine patches of grazing female sheep and cattle. Comput. Electron. Agric. 2010, 73, 66–73. [Google Scholar] [CrossRef]

- Al-Thani, N.; Albuainain, A.; Alnaimi, F.; Zorba, N. Drones for sheep livestock monitoring. In Proceedings of the 2020 IEEE 20th Mediterranean Electrotechnical Conference (MELECON), Palermo, Italy, 16–18 June 2020; pp. 672–676. [Google Scholar]

- Xu, B.; Wang, W.; Falzon, G.; Kwan, P.; Guo, L.; Sun, Z.; Li, C. Livestock classification and counting in quadcopter aerial images using Mask R-CNN. Int. J. Remote Sens. 2020, 41, 8121–8142. [Google Scholar] [CrossRef] [Green Version]

- Alejandro, M. Automation devices in sheep and goat machine milking. Small Rumin. Res. 2016, 142, 48–50. [Google Scholar] [CrossRef]

- Bueso-Ródenas, J.; Romero, G.; Arias, R.; Rodríguez, A.M.; Díaz, J.R. Effect of automatic cluster removers on milking efficiency and teat condition of Manchega ewes. J. Dairy Sci. 2015, 98, 3887–3895. [Google Scholar] [CrossRef] [Green Version]

- Romero, G.; Bueso-Ródenas, J.; Gascó, M.P.; Díaz, J.R. Effect of automatic cluster removers (ACRs) on the milking of Murciano-Granadina goats during lactation. Small Rumin. Res. 2015, 128, 54–58. [Google Scholar] [CrossRef]

- Bueso-Ródenas, J.; Arias, R.; Rodriguez, A.M.; Romero, G.; Díaz, J.R. Effect of the settings of two automatic cluster removers (ACRs) on the milking efficiency of Manchega ewes. Small Rumin. Res. 2014, 120, 224–230. [Google Scholar] [CrossRef]

- Bueso-Ródenas, J.; Romero, G.; Roca, A.; Díaz, J.R. Effect of one automatic cluster remover (ACR) setting on milking efficiency on Murciano–Granadina goats. Livest. Sci. 2014, 161, 193–200. [Google Scholar] [CrossRef]

- Alhamada, M.; Debus, N.; Lurette, A.; Bocquier, F. Validation of automated electronic oestrus detection in sheep as an alternative to visual observation. Small Rumin. Res. 2016, 134, 97–104. [Google Scholar] [CrossRef]

- Alhamada, M.; Debus, N.; Lurette, A.; Bocquier, F. Automatic oestrus detection system enables monitoring of sexual behaviour in sheep. Small Rumin. Res. 2017, 149, 105–111. [Google Scholar] [CrossRef]

- Mozo, R.; Alabart, J.L.; Rivas, E.; Folch, J. New method to automatically evaluate the sexual activity of the ram based on accelerometer records. Small Rumin. Res. 2019, 172, 16–22. [Google Scholar] [CrossRef]

- de Freitas, A.C.B.; Vega, W.H.O.; Quirino, C.R.; Junior, A.B.; David, C.M.G.; Geraldo, A.T.; Rua, M.A.S.; Rojas, L.F.C.; de Almeida Filho, J.E.; Dias, A.J.B. Surface temperature of ewes during estrous cycle measured by infrared thermography. Theriogenology 2018, 119, 245–251. [Google Scholar] [CrossRef]

- Façanha, D.A.E.; Peixoto, G.C.X.; Ferreira, J.B.; de Souza, J.E.R.; Paiva, R.D.M.; Ricarte, A.R.F. Detecting estrus in Canindé goats by two infrared thermography methods. Acta Vet. Bras. 2018, 12, 49–54. [Google Scholar] [CrossRef]

- De Diego, A.C.P.; Sánchez-Cordón, P.J.; Pedrera, M.; Martínez-López, B.; Gómez-Villamandos, J.C.; Sánchez-Vizcaíno, J.M. The use of infrared thermography as a non-invasive method for fever detection in sheep infected with bluetongue virus. Vet. J. 2013, 198, 182–186. [Google Scholar] [CrossRef] [PubMed]

- Sutherland, M.A.; Worth, G.M.; Dowling, S.K.; Lowe, G.L.; Cave, V.M.; Stewart, M. Evaluation of infrared thermography as a non-invasive method of measuring the autonomic nervous response in sheep. PLoS ONE 2020, 15, e0233558. [Google Scholar] [CrossRef]

- Stubsjøen, S.M.; Flø, A.S.; Moe, R.O.; Janczak, A.M.; Skjerve, E.; Valle, P.S.; Zanella, A.J. Exploring non-invasive methods to assess pain in sheep. Physiol. Behav. 2009, 98, 640–648. [Google Scholar] [CrossRef]

- Byrne, D.T.; Berry, D.P.; Esmonde, H.; McGovern, F.; Creighton, P.; McHugh, N. Infrared thermography as a tool to detect hoof lesions in sheep. Transl. Anim. Sci. 2019, 3, 577–588. [Google Scholar] [CrossRef]

- Gelasakis, A.I.; Kalogianni, A.I.; Moschovas, M.; Tsimpouri, E.; Pnevmatikos, T.; Bossis, I.; Arsenos, G.; Simitzis, P. Evaluation of Infrared Thermography for the Detection of Footrot and White Line Disease Lesions in Dairy Sheep. Vet. Sci. 2021, 8, 219. [Google Scholar] [CrossRef] [PubMed]

- Mansbridge, N.; Mitsch, J.; Bollard, N.; Ellis, K.; Miguel-Pacheco, G.G.; Dottorini, T.; Kaler, J. Feature selection and comparison of machine learning algorithms in classification of grazing and rumination behaviour in sheep. Sensors 2018, 18, 3532. [Google Scholar] [CrossRef] [Green Version]

- Ikurior, S.J.; Marquetoux, N.; Leu, S.T.; Corner-Thomas, R.A.; Scott, I.; Pomroy, W.E. What Are Sheep Doing? Tri-Axial Accelerometer Sensor Data Identify the Diel Activity Pattern of Ewe Lambs on Pasture. Sensors 2021, 21, 6816. [Google Scholar] [CrossRef]

- González-García, E.; Alhamada, M.; Pradel, J.; Douls, S.; Parisot, S.; Bocquier, F.; Menassol, J.-B.; Llach, I.; González, L.A. A mobile and automated walk-over-weighing system for a close and remote monitoring of liveweight in sheep. Comput. Electron. Agric. 2018, 153, 226–238. [Google Scholar] [CrossRef]

- Barwick, J.; Lamb, D.W.; Dobos, R.; Welch, M.; Trotter, M. Categorising sheep activity using a tri-axial accelerometer. Comput. Electron. Agric. 2018, 145, 289–297. [Google Scholar] [CrossRef]

- Bishop, J.; Falzon, G.; Trotter, M.; Kwan, P.; Meek, P. Sound analysis and detection, and the potential for precision livestock farming-a sheep vocalization case study. In Proceedings of the 1st Asian-Australasian Conference on Precision Pastures and Livestock Farming, Hamilton, New Zealand, 16–19 October 2017; pp. 1–7. [Google Scholar]

- Vázquez-Diosdado, J.A.; Paul, V.; Ellis, K.A.; Coates, D.; Loomba, R.; Kaler, J. A combined offline and online algorithm for real-time and long-term classification of sheep behaviour: Novel approach for precision livestock farming. Sensors 2019, 19, 3201. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Cui, Y.; Zhang, M.; Li, J.; Luo, H.; Zhang, X.; Fu, Z. WSMS: Wearable stress monitoring system based on IoT multi-sensor platform for living sheep transportation. Electronics 2019, 8, 441. [Google Scholar] [CrossRef] [Green Version]

- Leroy, T.; Mentasti, T.; Costa, A.; Guarino, M.; Aerts, J.-M.; Berckmans, D. Eyenamic: Real-time measurement of pig activity in practical conditions. In Proceedings of the Fourth Workshop on Smart Sensors in Livestock Monitoring, Gargnano, Italy, 22–23 September 2006. [Google Scholar]

- Gómez, Y.; Stygar, A.H.; Boumans, I.J.M.M.; Bokkers, E.A.M.; Pedersen, L.J.; Niemi, J.K.; Pastell, M.; Manteca, X.; Llonch, P. A systematic review on validated Precision Livestock Farming technologies for pig production and its potential to assess animal welfare. Front. Vet. Sci. 2021, 8, 660565. [Google Scholar] [CrossRef] [PubMed]

- Maselyne, J.; Saeys, W.; De Ketelaere, B.; Mertens, K.; Vangeyte, J.; Hessel, E.F.; Millet, S.; Van Nuffel, A. Validation of a high frequency radio frequency identification (HF RFID) system for registering feeding patterns of growing-finishing pigs. Comput. Electron. Agric. 2014, 102, 10–18. [Google Scholar] [CrossRef] [Green Version]

- Cappai, M.G.; Rubiu, N.G.; Pinna, W. Economic assessment of a smart traceability system (RFID+DNA) for origin and brand protection of the pork product labelled “Suinetto di Sardegna”. Comput. Electron. Agric. 2018, 145, 248–252. [Google Scholar] [CrossRef]

- Nasirahmadi, A.; Sturm, B.; Olsson, A.C.; Jeppsson, K.H.; Müller, S.; Edwards, S.; Hensel, O. Automatic scoring of lateral and sternal lying posture in grouped pigs using image processing and Support Vector Machine. Comput. Electron. Agric. 2019, 156, 475–481. [Google Scholar] [CrossRef]

- Tian, M.; Guo, H.; Chen, H.; Wang, Q.; Long, C.; Ma, Y. Automated pig counting using deep learning. Comput. Electron. Agric. 2019, 163, 104840. [Google Scholar] [CrossRef]

- Bonneau, M.; Vayssade, J.A.; Troupe, W.; Arquet, R. Outdoor animal tracking combining neural network and time-lapse cameras. Comput. Electron. Agric. 2020, 168, 105150. [Google Scholar] [CrossRef]

- Traulsen, I.; Scheel, C.; Auer, W.; Burfeind, O.; Krieter, J. Using acceleration data to automatically detect the onset of farrowing in sows. Sensors 2018, 18, 170. [Google Scholar] [CrossRef] [Green Version]

- Brünger, J.; Traulsen, I.; Koch, R. Model-based detection of pigs in images under sub-optimal conditions. Comput. Electron. Agric. 2018, 152, 59–63. [Google Scholar] [CrossRef]

- Marsot, M.; Mei, J.; Shan, X.; Ye, L.; Feng, P.; Yan, X.; Li, C.; Zhao, Y. An adaptive pig face recognition approach using Convolutional Neural Networks. Comput. Electron. Agric. 2020, 173, 105386. [Google Scholar] [CrossRef]

- Van Hirtum, A.; Berckmans, D. Fuzzy approach for improved recognition of citric acid induced piglet coughing from continuous registration. J. Sound Vib. 2003, 266, 677–686. [Google Scholar] [CrossRef]

- Nathues, H.; Spergser, J.; Rosengarten, R.; Kreienbrock, L.; Grosse Beilage, E. Value of the clinical examination in diagnosing enzootic pneumonia in fattening pigs. Vet. J. 2012, 193, 443–447. [Google Scholar] [CrossRef]

- Vandermeulen, J.; Decré, W.; Berckmans, D.; Exadaktylos, V.; Bahr, C.; Berckmans, D. The pig cough monitor: From research topic to commercial product. In Proceedings of the Precision Livestock Farming 2013—Papers Presented at the 6th European Conference on Precision Livestock Farming, ECPLF 2013, Berlin, Germany, 25–26 November 2013. [Google Scholar]

- Hemeryck, M.; Berckmans, D.; Vranken, E.; Tullo, E.; Fontana, I.; Guarino, M.; Van Waterschoot, T. The Pig Cough Monitor in the EU-PLF project: Results and multimodal data analysis in two case studies. In Proceedings of the Precision Livestock Farming 2015—Papers Presented at the 7th European Conference on Precision Livestock Farming, ECPLF 2015, Milan, Italy, 7–10 July 2015. [Google Scholar]

- Yin, Y.; Tu, D.; Shen, W.; Bao, J. Recognition of sick pig cough sounds based on convolutional neural network in field situations. Inf. Process. Agric. 2020, 8, 369–379. [Google Scholar] [CrossRef]

- Hemeryck, M.; Berckmans, D. 5.4. Pig cough monitoring in the EU-PLF project: First results. In Precision Livestock Farming Applications; Wageningen Academic Publishers: Wageningen, The Netherlands, 2015. [Google Scholar]

- Nadal-Roig, E.; Plà-Aragonès, L.M.; Alonso-Ayuso, A. Production planning of supply chains in the pig industry. Comput. Electron. Agric. 2019, 161, 72–78. [Google Scholar] [CrossRef]

- Madsen, T.N.; Kristensen, A.R. A model for monitoring the condition of young pigs by their drinking behaviour. Comput. Electron. Agric. 2005, 48, 138–154. [Google Scholar] [CrossRef]

- Yang, Q.; Xiao, D.; Lin, S. Feeding behavior recognition for group-housed pigs with the Faster R-CNN. Comput. Electron. Agric. 2018, 155, 453–460. [Google Scholar] [CrossRef]

- Wallenbeck, A.; Keeling, L.J. Using data from electronic feeders on visit frequency and feed consumption to indicate tail biting outbreaks in commercial pig production. J. Anim. Sci. 2013, 91, 2879–2884. [Google Scholar] [CrossRef] [Green Version]

- Wang, Y.; Yang, W.; Winter, P.; Walker, L. Walk-through weighing of pigs using machine vision and an artificial neural network. Biosyst. Eng. 2008, 100, 117–125. [Google Scholar] [CrossRef]

- Jun, K.; Kim, S.J.; Ji, H.W. Estimating pig weights from images without constraint on posture and illumination. Comput. Electron. Agric. 2018, 153, 169–176. [Google Scholar] [CrossRef]

- Shi, C.; Zhang, J.; Teng, G. Mobile measuring system based on LabVIEW for pig body components estimation in a large-scale farm. Comput. Electron. Agric. 2019, 156, 399–405. [Google Scholar] [CrossRef]

- Banhazi, T.M.; Tscharke, M.; Ferdous, W.M.; Saunders, C.; Lee, S.H. Improved Image Analysis Based System to Reliably Predict the Live Weight of Pigs on Farm: Preliminary Results. Aust. J. Multi-Discip. Eng. 2011, 8, 107–119. [Google Scholar] [CrossRef]

- Condotta, I.C.F.S.; Brown-Brandl, T.M.; Silva-Miranda, K.O.; Stinn, J.P. Evaluation of a depth sensor for mass estimation of growing and finishing pigs. Biosyst. Eng. 2018, 173, 11–18. [Google Scholar] [CrossRef]

- Maselyne, J.; Van Nuffel, A.; Briene, P.; Vangeyte, J.; De Ketelaere, B.; Millet, S.; Van den Hof, J.; Maes, D.; Saeys, W. Online warning systems for individual fattening pigs based on their feeding pattern. Biosyst. Eng. 2018, 173, 143–156. [Google Scholar] [CrossRef]

- Han, K.; Lee, W.; Sung, K.-Y. Development of a model to analyze the relationship between smart pig-farm environmental data and daily weight increase based on decision tree. J. Korea Inst. Inf. Commun. Eng. 2016, 20, 2348–2354. [Google Scholar] [CrossRef] [Green Version]

- Fonseca, F.N.; Abe, J.M.; Nääs, I.A.; Cordeiro, A.S.F.; Amaral, F. Automatic prediction of stress in piglets using skin temperature. In Proceedings of the 2019 ASABE Annual International Meeting, Boston, MA, USA, 7–10 July 2019. [Google Scholar]

- da Fonseca, F.N.; Abe, J.M.; de Alencar Nääs, I.; da Silva Cordeiro, A.F.; do Amaral, F.V.; Ungaro, H.C. Automatic prediction of stress in piglets (Sus Scrofa) using infrared skin temperature. Comput. Electron. Agric. 2020, 168, 105148. [Google Scholar] [CrossRef]

- Soerensen, D.D.; Pedersen, L.J. Infrared skin temperature measurements for monitoring health in pigs: A review. Acta Vet. Scand. 2015, 57, 5. [Google Scholar] [CrossRef] [Green Version]

- Flores-Peinado, S.; Mota-Rojas, D.; Guerrero-Legarreta, I.; Mora-Medina, P.; Cruz-Monterrosa, R.; Gómez-Prado, J.; Guadalupe Hernández, M.; Cruz-Playas, J.; Martínez-Burnes, J. Physiological responses of pigs to preslaughter handling: Infrared and thermal imaging applications. Int. J. Vet. Sci. Med. 2020, 8, 71–84. [Google Scholar] [CrossRef]

- Soerensen, D.D.; Clausen, S.; Mercer, J.B.; Pedersen, L.J. Determining the emissivity of pig skin for accurate infrared thermography. Comput. Electron. Agric. 2014, 109, 52–58. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, H.; Liu, T. Study on body temperature detection of pig based on infrared technology: A review. Artif. Intell. Agric. 2019, 1, 14–26. [Google Scholar] [CrossRef]

- Boileau, A.; Farish, M.; Turner, S.P.; Camerlink, I. Infrared thermography of agonistic behaviour in pigs. Physiol. Behav. 2019, 210, 112637. [Google Scholar] [CrossRef]

- Neethirajan, S.; Kemp, B. Digital livestock farming. Sens. Bio-Sens. Res. 2021, 32, 100408. [Google Scholar] [CrossRef]

- Garcia, R.; Aguilar, J.; Toro, M.; Pinto, A.; Rodriguez, P. A systematic literature review on the use of machine learning in precision livestock farming. Comput. Electron. Agric. 2020, 179, 105826. [Google Scholar] [CrossRef]

- da Silva, J.P.; de Alencar Nääs, I.; Abe, J.M.; da Silva Cordeiro, A.F. Classification of piglet (Sus Scrofa) stress conditions using vocalization pattern and applying paraconsistent logic Eτ. Comput. Electron. Agric. 2019, 166, 105020. [Google Scholar] [CrossRef]

- Oczak, M.; Ismailova, G.; Sonoda, L.T.; Fels, M.; Hartung, J.; Guarino, M.; Viazzi, S.; Berckmans, D.; Vranken, E. Identification of behaviour of weaner pigs in the early phase of aggressive interaction for the development of an automatic monitoring system of pig aggression. In Proceedings of the International Workshop on Veterinary Biosignals and Biodevices, VBB 2012, in Conjunction with BIOSTEC 2012, Porto, Portugal, 1–4 February 2012. [Google Scholar]

- Wutke, M.; Heinrich, F.; Das, P.P.; Lange, A.; Gentz, M.; Traulsen, I.; Warns, F.K.; Schmitt, A.O.; Gültas, M. Detecting Animal Contacts—A Deep Learning-Based Pig Detection and Tracking Approach for the Quantification of Social Contacts. Sensors 2021, 21, 7512. [Google Scholar] [CrossRef]

- Chen, C.; Zhu, W.; Liu, D.; Steibel, J.; Siegford, J.; Wurtz, K.; Han, J.; Norton, T. Detection of aggressive behaviours in pigs using a RealSence depth sensor. Comput. Electron. Agric. 2019, 166, 105003. [Google Scholar] [CrossRef]

- Chen, C.; Zhu, W.; Steibel, J.; Siegford, J.; Wurtz, K.; Han, J.; Norton, T. Recognition of aggressive episodes of pigs based on convolutional neural network and long short-term memory. Comput. Electron. Agric. 2020, 169, 105166. [Google Scholar] [CrossRef]

- Lee, J.; Jin, L.; Park, D.; Chung, Y. Automatic recognition of aggressive behavior in pigs using a kinect depth sensor. Sensors 2016, 16, 631. [Google Scholar] [CrossRef] [Green Version]

- Okada, H.; Suzuki, K.; Kenji, T.; Itoh, T. Applicability of wireless activity sensor network to avian influenza monitoring system in poultry farms. J. Sens. Technol. 2014, 2014, 18–23. [Google Scholar] [CrossRef] [Green Version]

- Zhuang, X.; Bi, M.; Guo, J.; Wu, S.; Zhang, T. Development of an early warning algorithm to detect sick broilers. Comput. Electron. Agric. 2018, 144, 102–113. [Google Scholar] [CrossRef]

- Peña Fernández, A.; Norton, T.; Tullo, E.; van Hertem, T.; Youssef, A.; Exadaktylos, V.; Vranken, E.; Guarino, M.; Berckmans, D. Real-time monitoring of broiler flock’s welfare status using camera-based technology. Biosyst. Eng. 2018, 173, 103–114. [Google Scholar] [CrossRef]

- Aydin, A. Development of an early detection system for lameness of broilers using computer vision. Comput. Electron. Agric. 2017, 136, 140–146. [Google Scholar] [CrossRef]

- Aydin, A. Using 3D vision camera system to automatically assess the level of inactivity in broiler chickens. Comput. Electron. Agric. 2017, 135, 4–10. [Google Scholar] [CrossRef]

- Banerjee, D.; Daigle, C.L.; Dong, B.; Wurtz, K.; Newberry, R.C.; Siegford, J.M.; Biswas, S. Detection of jumping and landing force in laying hens using wireless wearable sensors. Poult. Sci. 2014, 93, 2724–2733. [Google Scholar] [CrossRef]

- Tullo, E.; Fontana, I.; Peña Fernandez, A.; Vranken, E.; Norton, T.; Berckmans, D.; Guarino, M. Association between environmental predisposing risk factors and leg disorders in broiler chickens. J. Anim. Sci. 2017, 95, 1512. [Google Scholar] [CrossRef] [PubMed]

- Grilli, G.; Borgonovo, F.; Tullo, E.; Fontana, I.; Guarino, M.; Ferrante, V. A pilot study to detect coccidiosis in poultry farms at early stage from air analysis. Biosyst. Eng. 2018, 173, 64–70. [Google Scholar] [CrossRef]

- Mahdavian, A.; Minaei, S.; Yang, C.; Almasganj, F.; Rahimi, S.; Marchetto, P.M. Ability evaluation of a voice activity detection algorithm in bioacoustics: A case study on poultry calls. Comput. Electron. Agric. 2020, 168, 105100. [Google Scholar] [CrossRef]

- Carpentier, L.; Vranken, E.; Berckmans, D.; Paeshuyse, J.; Norton, T. Development of sound-based poultry health monitoring tool for automated sneeze detection. Comput. Electron. Agric. 2019, 162, 573–581. [Google Scholar] [CrossRef]

- Hadinia, S.H.; Carneiro, P.R.O.; Ouellette, C.A.; Zuidhof, M.J. Energy partitioning by broiler breeder pullets in skip-a-day and precision feeding systems. Poult. Sci. 2018, 97, 4279–4289. [Google Scholar] [CrossRef] [PubMed]

- Aydin, A.; Bahr, C.; Viazzi, S.; Exadaktylos, V.; Buyse, J.; Berckmans, D. A novel method to automatically measure the feed intake of broiler chickens by sound technology. Comput. Electron. Agric. 2014, 101, 17–23. [Google Scholar] [CrossRef]

- Aydin, A.; Berckmans, D. Using sound technology to automatically detect the short-term feeding behaviours of broiler chickens. Comput. Electron. Agric. 2016, 121, 25–31. [Google Scholar] [CrossRef]

- Aydin, A.; Bahr, C.; Berckmans, D. A real-time monitoring tool to automatically measure the feed intakes of multiple broiler chickens by sound analysis. Comput. Electron. Agric. 2015, 114, 1–6. [Google Scholar] [CrossRef]

- De Montis, A.; Pinna, A.; Barra, M.; Vranken, E. Analysis of poultry eating and drinking behavior by software eYeNamic. J. Agric. Eng. 2013, 44, 166–172. [Google Scholar] [CrossRef]

- Batuto, A.; Dejeron, T.B.; Dela Cruz, P.; Samonte, M.J.C. E-poultry: An IoT poultry management system for small farms. In Proceedings of the 2020 IEEE 7th International Conference on Industrial Engineering and Applications (ICIEA), Paris, France, 4–6 June 2020; pp. 738–742. [Google Scholar]

- Archer, G.S.; Shivaprasad, H.L.; Mench, J.A. Effect of providing light during incubation on the health, productivity, and behavior of broiler chickens. Poult. Sci. 2009, 88, 29–37. [Google Scholar] [CrossRef]

- Pereira, D.F.; Miyamoto, B.C.B.; Maia, G.D.N.; Tatiana Sales, G.; Magalhães, M.M.; Gates, R.S. Machine vision to identify broiler breeder behavior. Comput. Electron. Agric. 2013, 99, 194–199. [Google Scholar] [CrossRef]

- Xiao, L.; Ding, K.; Gao, Y.; Rao, X. Behavior-induced health condition monitoring of caged chickens using binocular vision. Comput. Electron. Agric. 2019, 156, 254–262. [Google Scholar] [CrossRef]

- Montalcini, C.M.; Voelkl, B.; Gómez, Y.; Gantner, M.; Toscano, M.J. Evaluation of an Active LF Tracking System and Data Processing Methods for Livestock Precision Farming in the Poultry Sector. Sensors 2022, 22, 659. [Google Scholar] [CrossRef] [PubMed]

- Ross, L.; Cressman, M.D.; Cramer, M.C.; Pairis-Garcia, M.D. Validation of alternative behavioral observation methods in young broiler chickens. Poult. Sci. 2019, 98, 6225–6231. [Google Scholar] [CrossRef]

- Abdanan Mehdizadeh, S.; Neves, D.P.; Tscharke, M.; Nääs, I.A.; Banhazi, T.M. Image analysis method to evaluate beak and head motion of broiler chickens during feeding. Comput. Electron. Agric. 2015, 114, 88–95. [Google Scholar] [CrossRef]

- Goud, K.S.; Sudharson, A. Internet based smart poultry farm. Indian J. Sci. Technol. 2015, 8, 1–5. [Google Scholar] [CrossRef]

- Ammad-Uddin, M.; Ayaz, M.; Aggoune, E.H.; Sajjad, M. Wireless sensor network: A complete solution for poultry farming. In Proceedings of the ISTT 2014—2014 IEEE 2nd International Symposium on Telecommunication Technologies, Langkawi, Malaysia, 24–26 November 2014. [Google Scholar]

- Vranken, E.; Berckmans, D. Precision livestock farming for pigs. Anim. Front. 2017, 7, 32–37. [Google Scholar] [CrossRef] [Green Version]

- Alston, J.M.; Pardey, P.G. Agriculture in the global economy. J. Econ. Perspect. 2014, 28, 121–146. [Google Scholar] [CrossRef] [Green Version]

- Bilal, M.; Oyedele, L.O.; Qadir, J.; Munir, K.; Ajayi, S.O.; Akinade, O.O.; Owolabi, H.A.; Alaka, H.A.; Pasha, M. Big Data in the construction industry: A review of present status, opportunities, and future trends. Adv. Eng. Inform. 2016, 30, 500–521. [Google Scholar] [CrossRef]

- Otles, S.; Sakalli, A. Industry 4.0: The Smart Factory of the Future in Beverage Industry. In Production and Management of Beverages; Elsevier: Amsterdam, The Netherlands, 2019. [Google Scholar]

- Villa-Henriksen, A.; Edwards, G.T.C.; Pesonen, L.A.; Green, O.; Sørensen, C.A.G. Internet of Things in arable farming: Implementation, applications, challenges and potential. Biosyst. Eng. 2020, 191, 60–84. [Google Scholar] [CrossRef]

- Akpakwu, G.A.; Silva, B.J.; Hancke, G.P.; Abu-Mahfouz, A.M. A Survey on 5G Networks for the Internet of Things: Communication Technologies and Challenges. IEEE Access 2017, 6, 3619–3647. [Google Scholar] [CrossRef]

- Banhazi, T.M.; Black, J.L. Precision Livestock Farming: A Suite of Electronic Systems to Ensure the Application of Best Practice Management on Livestock Farms. Aust. J. Multi-Discip. Eng. 2009, 7, 1–14. [Google Scholar] [CrossRef]

- Banhazi, T.M.; Lehr, H.; Black, J.L.; Crabtree, H.; Schofield, P.; Tscharke, M.; Berckmans, D. Precision Livestock Farming: An international review of scientific and commercial aspects. Int. J. Agric. Biol. Eng. 2012, 5, 1. [Google Scholar]

- Navarro, E.; Costa, N.; Pereira, A. A systematic review of iot solutions for smart farming. Sensors 2020, 20, 4231. [Google Scholar] [CrossRef] [PubMed]

- Thompson, P.B. The Agrarian Vision: Sustainability and Environmental Ethics; University Press of Kentucky: Lexington, KY, USA, 2010; ISBN 9780813125879. [Google Scholar]

- Thompson, P.B. The Spirit of the Soil: Agriculture and Environmental Ethics, 2nd ed.; Routledge: London, UK, 2017; ISBN 9781315559971. [Google Scholar]

- Cornou, C. Automation systems for farm animals: Potential impacts on the human-animal relationship and on animal welfare. Anthrozoos 2009, 22, 213–220. [Google Scholar] [CrossRef]

- Rose, D.C.; Morris, C.; Lobley, M.; Winter, M.; Sutherland, W.J.; Dicks, L.V. Exploring the spatialities of technological and user re-scripting: The case of decision support tools in UK agriculture. Geoforum 2018, 89, 11–18. [Google Scholar] [CrossRef]

- Wiseman, L.; Sanderson, J.; Zhang, A.; Jakku, E. Farmers and their data: An examination of farmers’ reluctance to share their data through the lens of the laws impacting smart farming. NJAS Wageningen J. Life Sci. 2019, 90–91, 100301. [Google Scholar] [CrossRef]

- Broom, D.M. Indicators of poor welfare. Br. Vet. J. 1986, 142, 524–526. [Google Scholar] [CrossRef]

- Siegrist, M.; Hartmann, C. Consumer acceptance of novel food technologies. Nat. Food 2020, 1, 343–350. [Google Scholar] [CrossRef]

- Krampe, C.; Serratosa, J.; Niemi, J.K.; Ingenbleek, P.T.M. Consumer Perceptions of Precision Livestock Farming—A Qualitative Study in Three European Countries. Animals 2021, 11, 1221. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Morrone, S.; Dimauro, C.; Gambella, F.; Cappai, M.G. Industry 4.0 and Precision Livestock Farming (PLF): An up to Date Overview across Animal Productions. Sensors 2022, 22, 4319. https://doi.org/10.3390/s22124319

Morrone S, Dimauro C, Gambella F, Cappai MG. Industry 4.0 and Precision Livestock Farming (PLF): An up to Date Overview across Animal Productions. Sensors. 2022; 22(12):4319. https://doi.org/10.3390/s22124319

Chicago/Turabian StyleMorrone, Sarah, Corrado Dimauro, Filippo Gambella, and Maria Grazia Cappai. 2022. "Industry 4.0 and Precision Livestock Farming (PLF): An up to Date Overview across Animal Productions" Sensors 22, no. 12: 4319. https://doi.org/10.3390/s22124319

APA StyleMorrone, S., Dimauro, C., Gambella, F., & Cappai, M. G. (2022). Industry 4.0 and Precision Livestock Farming (PLF): An up to Date Overview across Animal Productions. Sensors, 22(12), 4319. https://doi.org/10.3390/s22124319