Multiplexed Readout for an Experiment with a Large Number of Channels Using Single-Electron Sensitivity Skipper-CCDs

Abstract

:1. Introduction

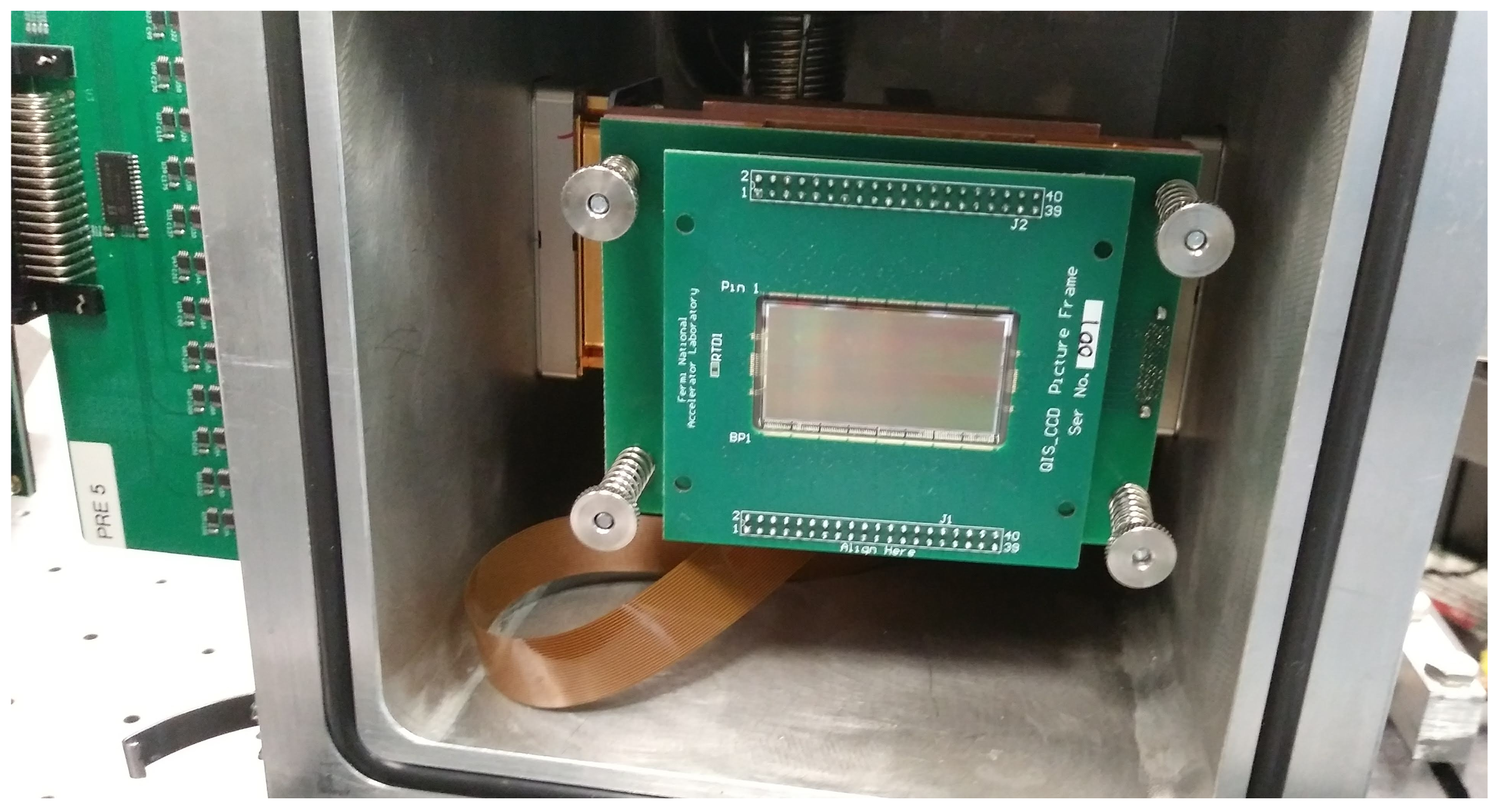

Skipper CCD and LTA Electronics

2. OSCURA Experiment

- Sensors R&D: Skipper-CCDs require a special fabrication process due to their relatively high operation voltage and the silicon thickness required to increase the sensitive mass of the sensor. New sensors developed at Microchip Inc. are currently being tested and characterized.

- Background Radiation R&D: the scientific goal of the OSCURA project requires an extremely low background radiation. This implies a detailed understanding and mitigation of all the radioactive sources near the detectors, including fabrication materials in the electronic components, flex cables, etc. Background radiation is a problem in the sense that particles emerging from contaminated materials can mask in many ways the events with the characteristics of DM signals.

- Readout Electronics R&D: Given the standard dimensions of a Skipper-CCD pixel (15 µm × 15 µm) and considering the thickness (≈650 µm) of silicon wafers for thick CCDs, a detector with a sensitive mass of 10 kg will require 28 gigapixels. The number of output channels depends on the exact size chosen for individual sensors. For one of the candidates, a sensor with a size of 1058 × 1278 pixels, the number of video (output) channels needed is 24,000. The total readout time is also a key point, since a very long readout time results in an increased dark current count, which could mimic the DM signal. There is a trade-off between the readout time required by the experiment and the number of readout channels.

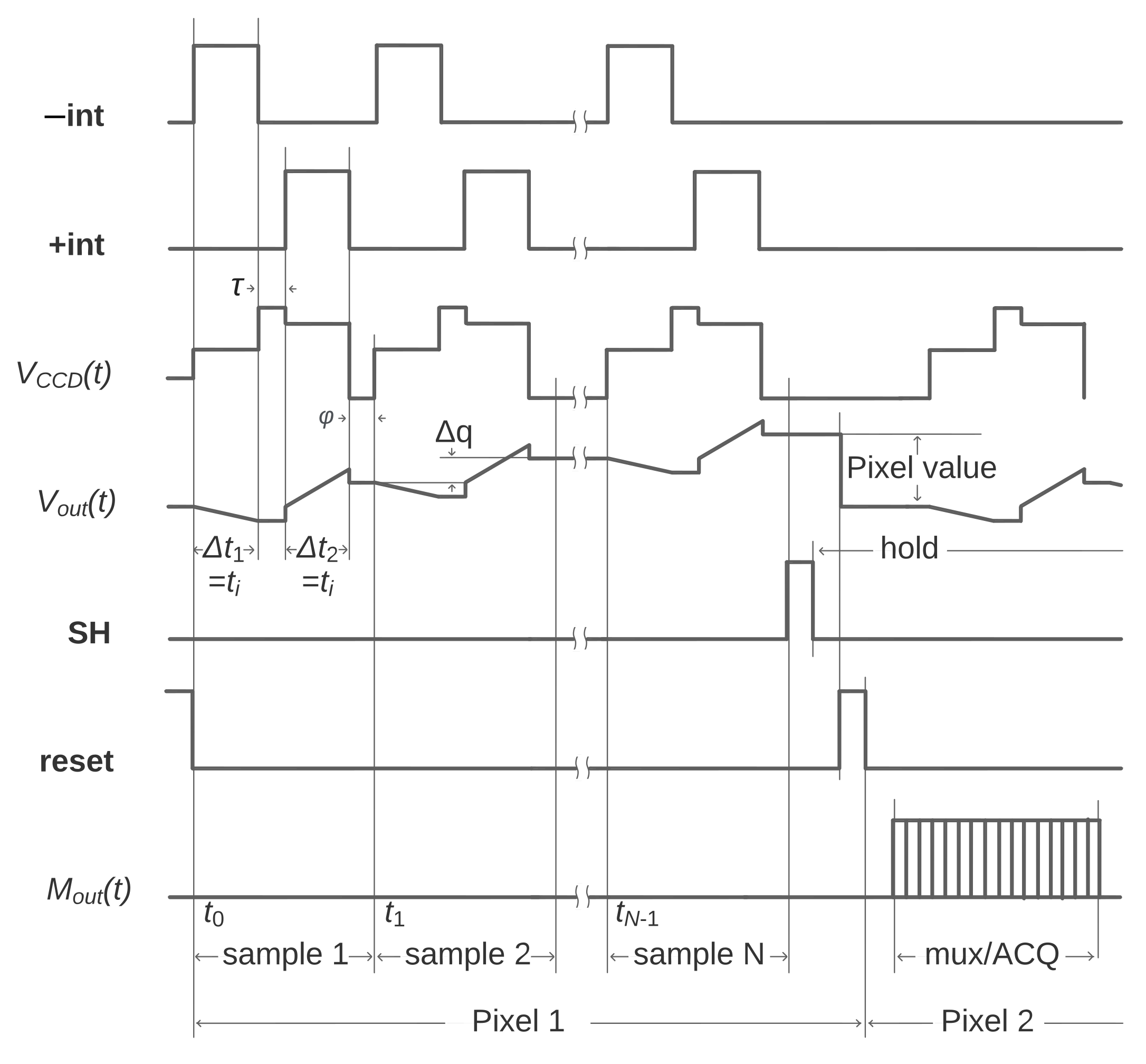

3. Description and Analysis of the Proposed Front-End Electronics

3.1. Analog Processing Chain

3.2. Sample and Hold Circuit (S&H)

3.3. First-Stage Multiplexer

3.4. Analog Pile-Up Advantages Analysis

- Fully digital signal processing: uses only a pre-amplifier and then a high-speed ADC. The pixels are calculated digitally with a microprocessor or a Field-Programmable Gate Array (FPGA) and the N pixel samples are averaged digitally either in the electronics or in a computer.

- Mixed analog/digital DSI (double slope integration): this is the most common method for scientific CCDs, where each pixel is calculated using an analog DSI circuit and then an ADC digitizes the value. The pile-up is done digitally so each pixel sample must be sent and stored during readout.

- DSI + fully analog pile-up: the circuit proposed in [17] falls into this type and is used in this proposal with the added S&H and multiplexing. The whole DSI and analog pile-up is done by the analog circuit and the final pixel value is only digitized at the end of the last pixel sample. Data transfer and storage have the lowest requirement among the three methods described.

4. Experimental Verification

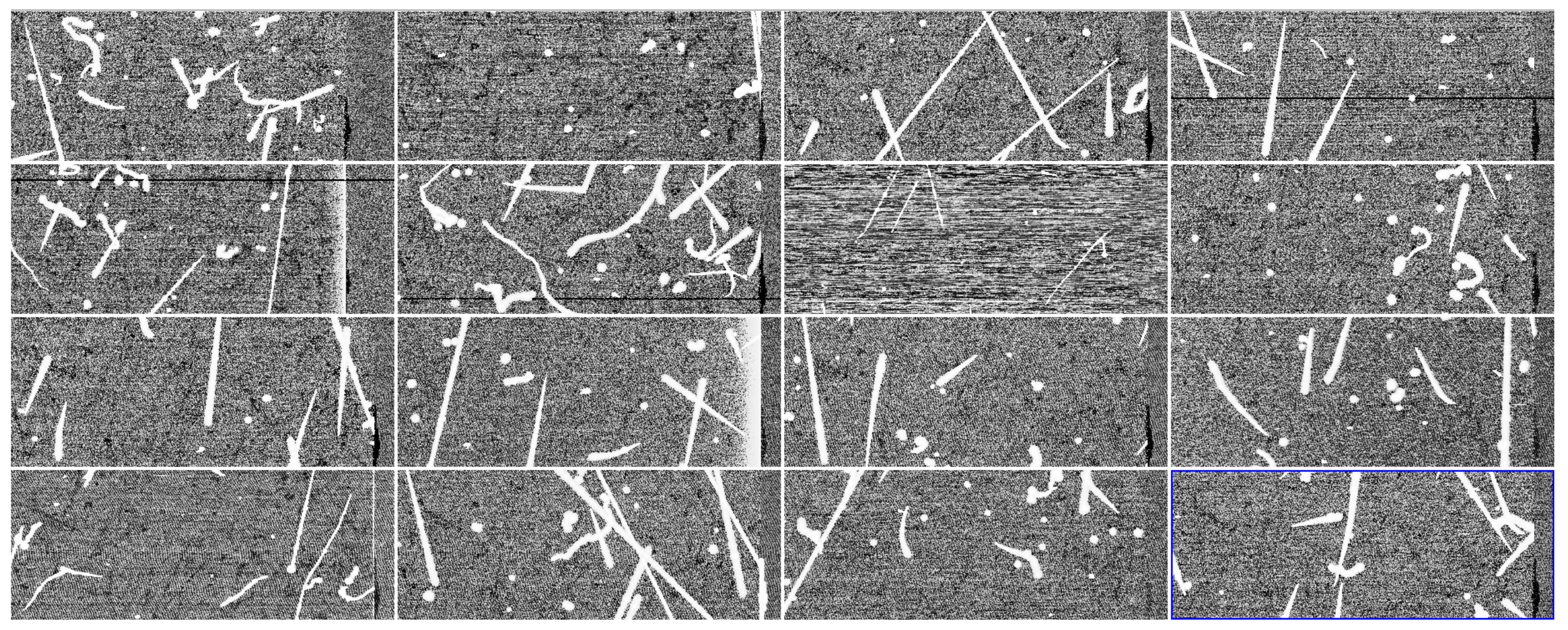

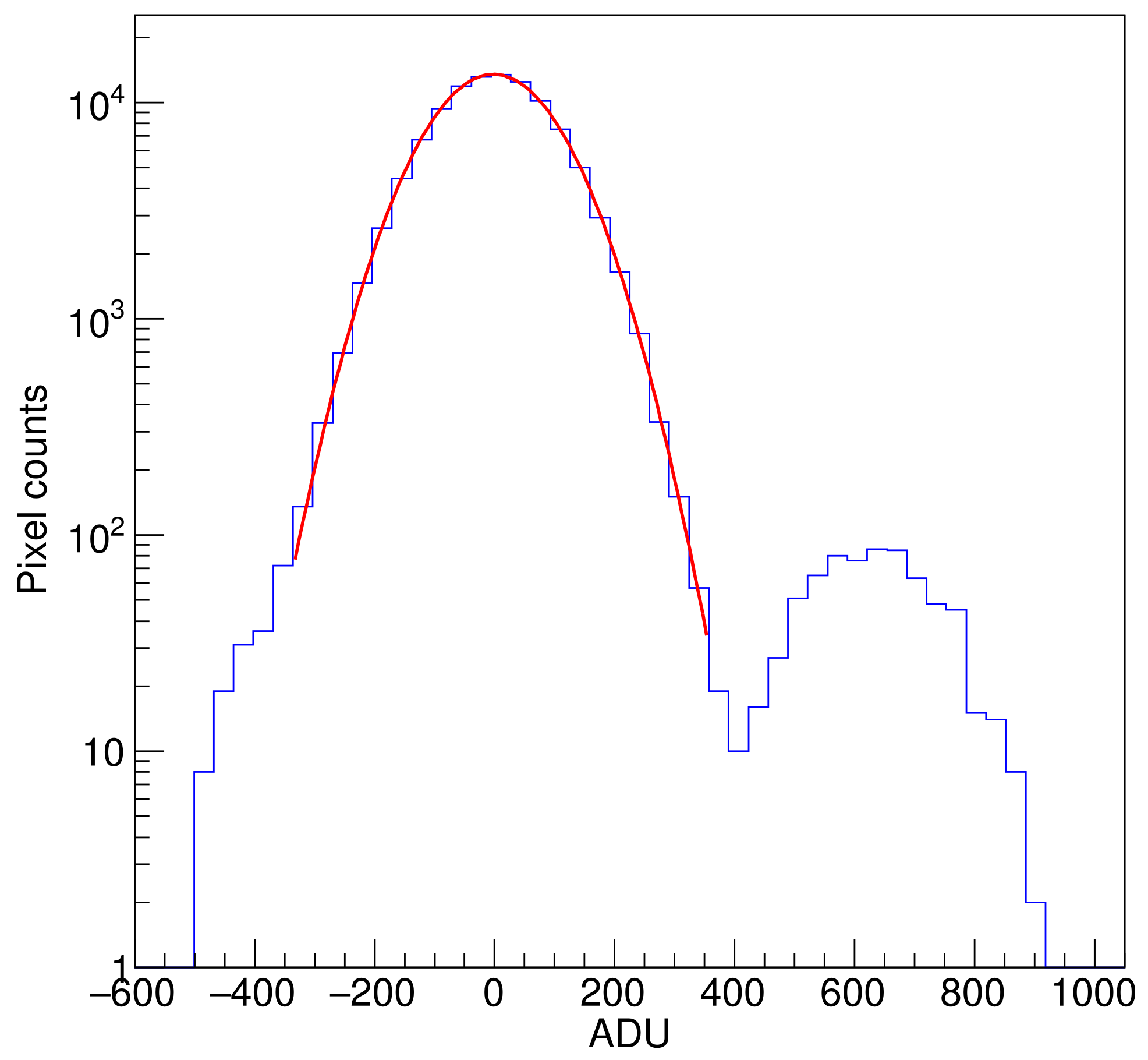

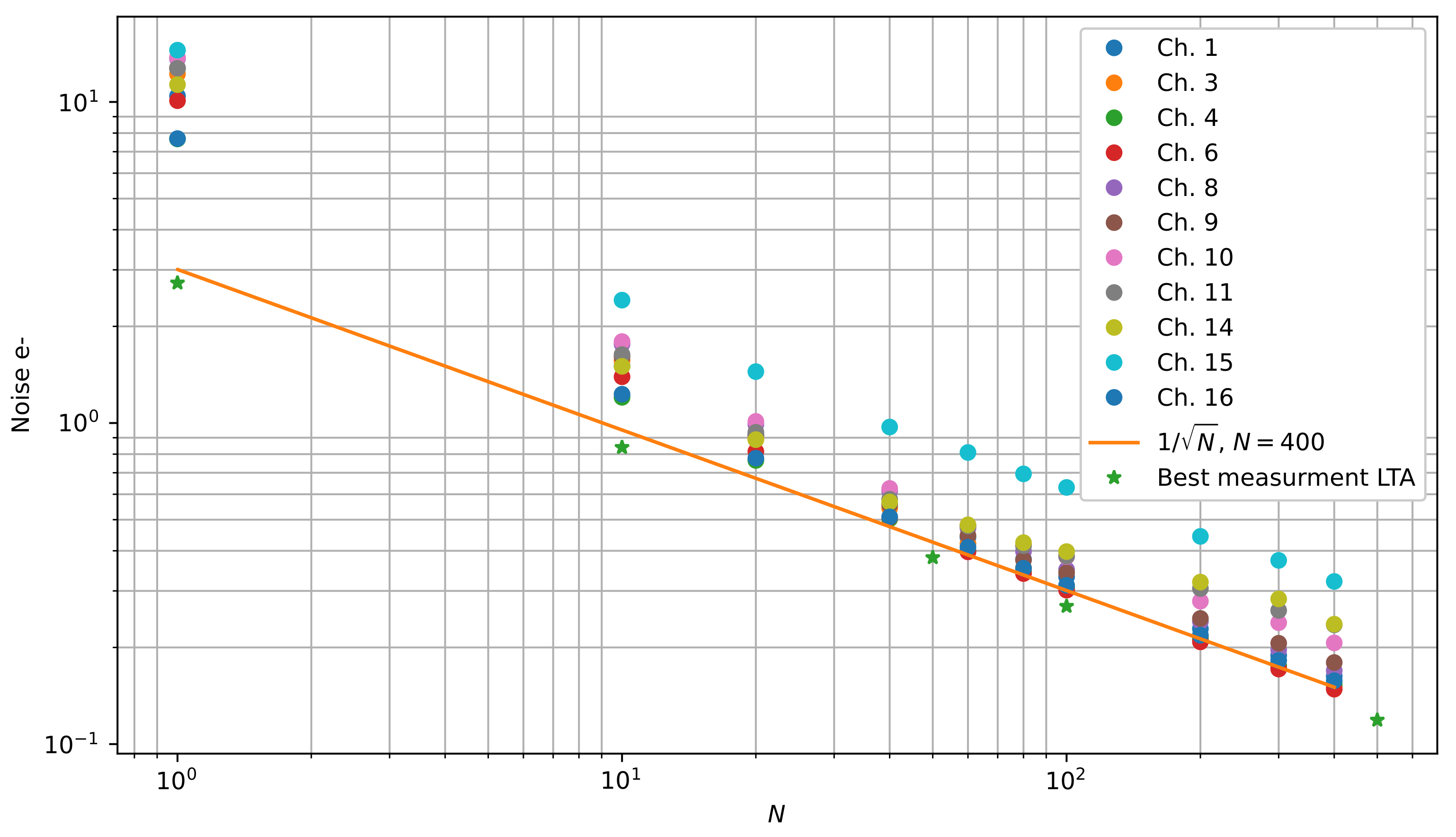

4.1. Sub-Electron Noise Measurements

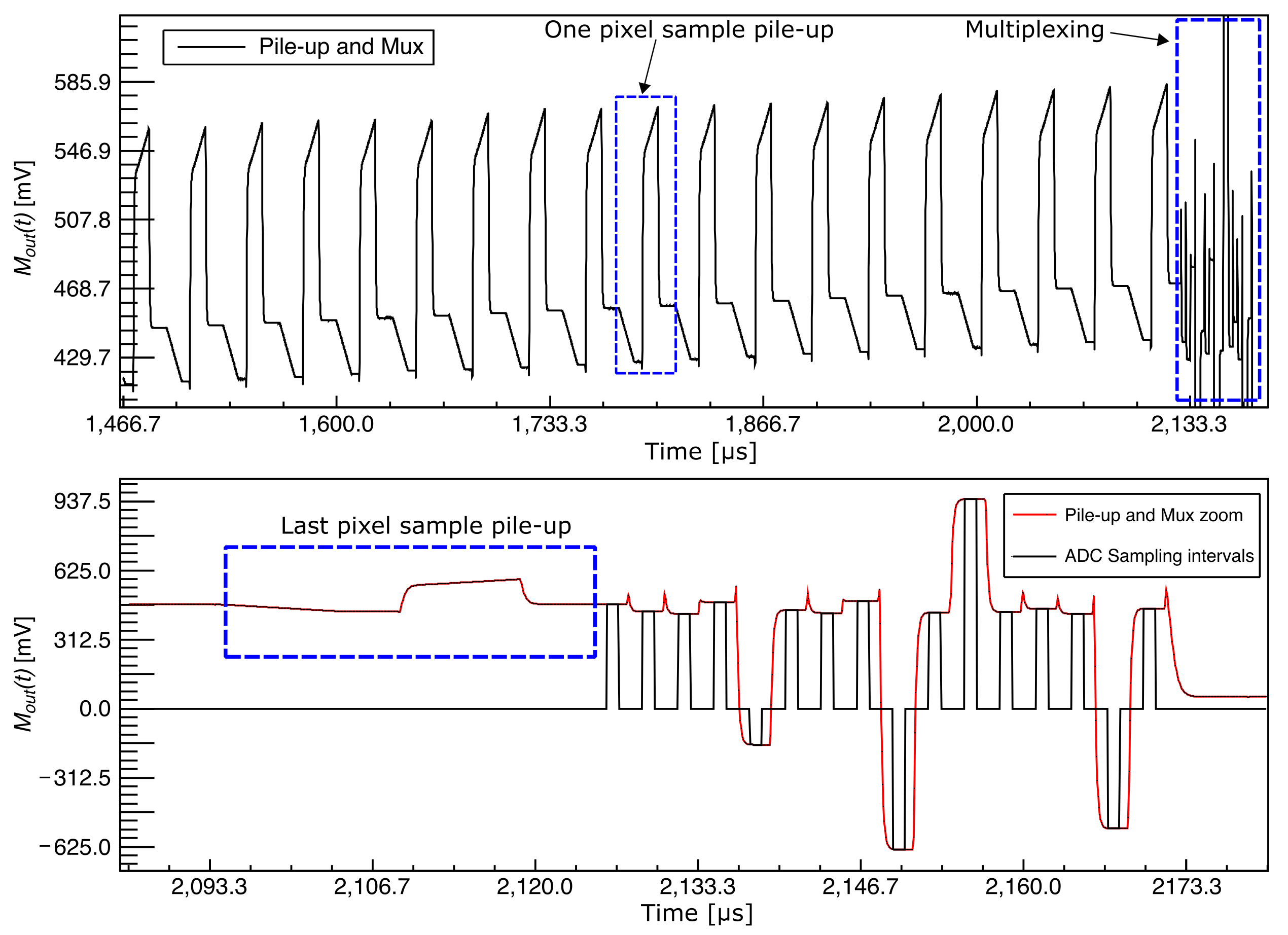

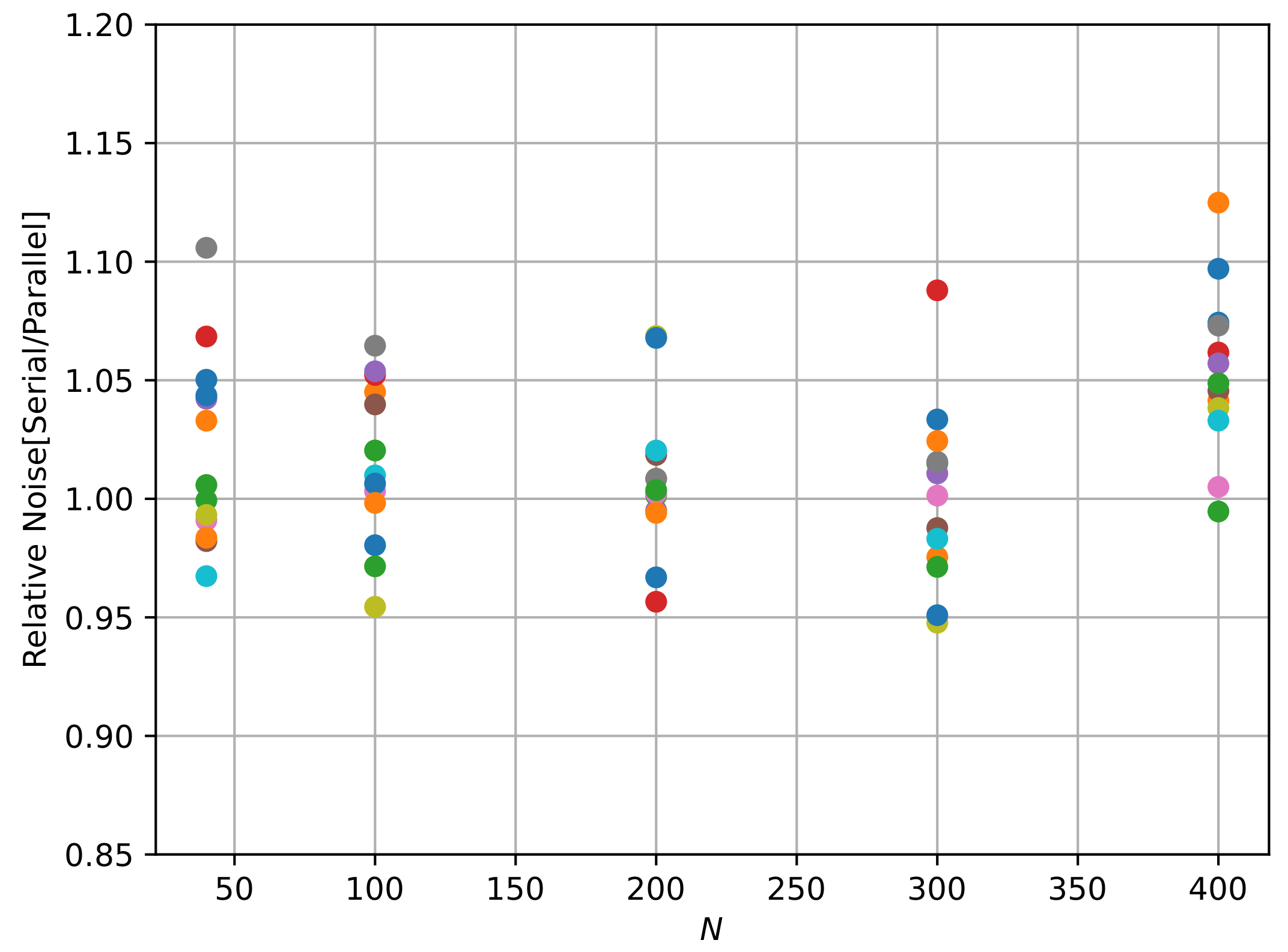

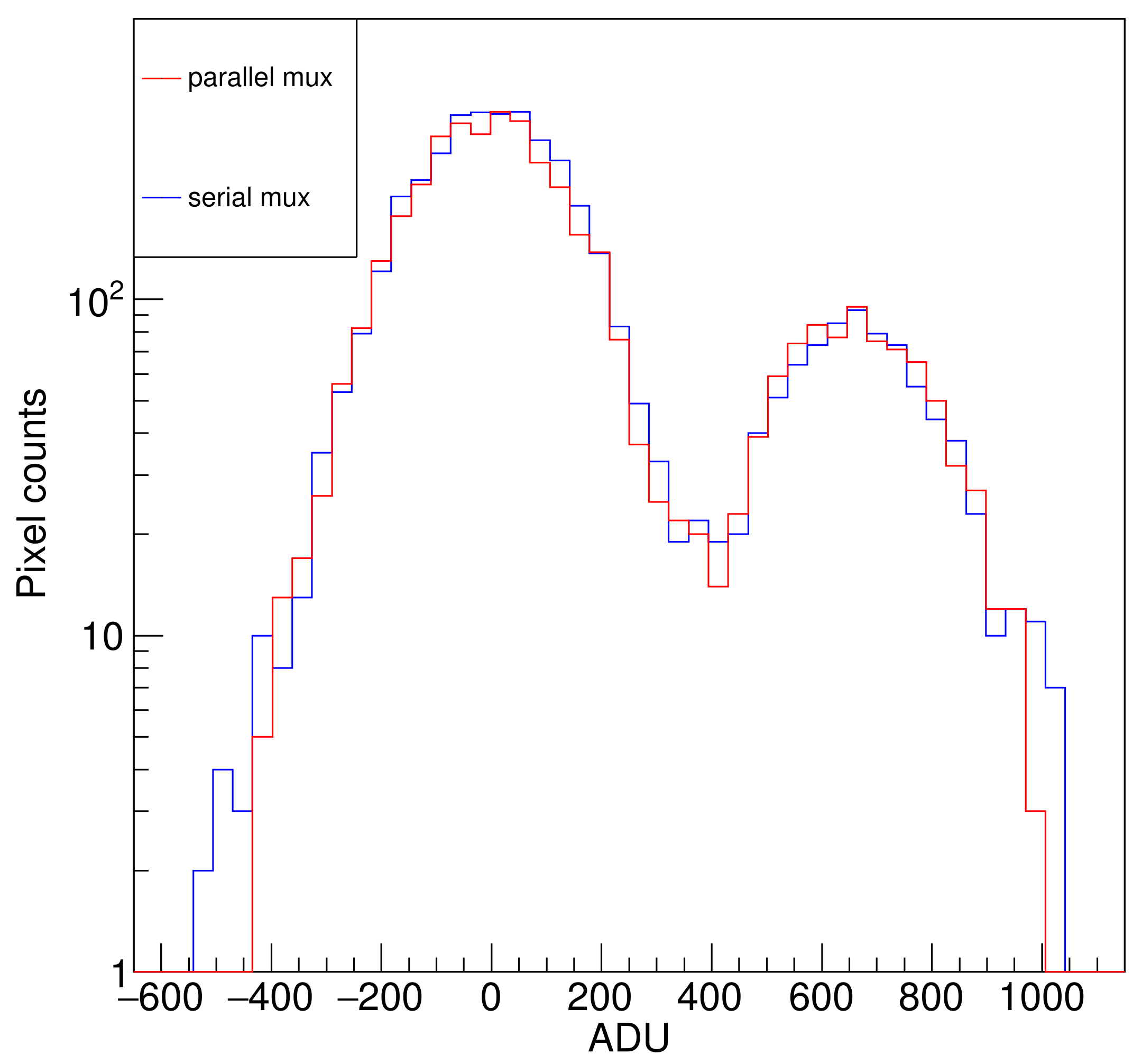

4.2. Parallel Multiplexing while Reading the Next Pixel

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| ACQ | Acquisition |

| ADC | Analog-to-digital converter |

| ADU | ADC units |

| CCD | Charge-coupled device |

| CONNIE | Coherent Neutrino-Nucleus Interaction Experiment |

| DAQ | Data acquisition |

| DM | Dark matter |

| DSI | Double slope integration |

| LTA | Low-threshold acquisition |

| OSCURA | Observatory of Skipper-CCDs Unveiling Recoiling Atoms |

| PCB | Printed circuit board |

| RMS | Root median square |

| SENSEI | Sub-Electron-Noise Skipper-CCD Experimental Instrument |

| S&H | Sample and hold |

| IOLETA | Neutrino Interaction Observation with a Low 40 Energy Threshold Array |

References

- Hartmann, F. Evolution of Silicon Sensor Technology in Particle Physics; Springer: Berlin/Heidelberg, Germany, 2009; Volume 43. [Google Scholar]

- Seidel, S. Silicon strip and pixel detectors for particle physics experiments. Phys. Rep. 2019, 828, 3. [Google Scholar] [CrossRef]

- Janesick, J.R. Scientific Charge-Coupled Devices; SPIE Press: Bellingham, WA, USA, 2001; Volume 83. [Google Scholar]

- Fernandez Moroni, G.; Estrada, J.; Cancelo, G.; Holland, S.; Paolini, E.; Diehl, H. Sub-electron readout noise in a Skipper CCD fabricated on high resistivity silicon. Exp. Astron. 2012, 34, 43–64. [Google Scholar] [CrossRef] [Green Version]

- Tiffenberg, J.; Sofo-Haro, M.; Drlica-Wagner, A.; Essig, R.; Guardincerri, Y.; Holland, S.; Volansky, T.; Yu, T.T. Single-electron and single-photon sensitivity with a silicon Skipper CCD. Phys. Rev. Lett. 2017, 119, 131802. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Stefanov, K.D.; Prest, M.J.; Downing, M.; George, E.; Bezawada, N.; Holland, A.D. Simulations and Design of a Single-Photon CMOS Imaging Pixel Using Multiple Non-Destructive Signal Sampling. Sensors 2020, 20, 2031. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chattopadhyay, T.; Herrmann, S.; Burke, B.; Donlon, K.; Prigozhin, G.; Morris, R.G.; Orel, P.; Cooper, M.; Malonis, A.; Wilkins, D.; et al. First results on SiSeRO (Single electron Sensitive Read Out) devices–a new X-ray detector for scientific instrumentation. arXiv 2021, arXiv:2112.05033. [Google Scholar]

- Chierchie, F.; Moroni, G.F.; Simbeni, P.Q.; Stefanazzi, L.; Paolini, E.; Haro, M.S.; Cancelo, G.; Estrada, J. Detailed modeling of the video signal and optimal readout of charge-coupled devices. Int. J. Circuit Theory Appl. 2020, 48, 1001–1016. [Google Scholar] [CrossRef]

- Moroni, G.F.; Chierchie, F.; Stefanazzi, L.; Paolini, E.E.; Haroy, M.S.; Cancelo, G.; Tiffenberg, J.; Estrada, J. Interleaved Readout of Charge Coupled Devices (CCDs) for Correlated Noise Reduction. IEEE Trans. Instrum. Meas. 2020, 69, 7580–7587. [Google Scholar] [CrossRef]

- Cancelo, G.I.; Chavez, C.; Chierchie, F.; Estrada, J.; Fernandez-Moroni, G.; Paolini, E.E.; Haro, M.S.; Soto, A.; Stefanazzi, L.; Tiffenberg, J.; et al. Low threshold acquisition controller for Skipper charge-coupled devices. J. Astron. Telesc. Instrum. Syst. 2021, 7, 86–91. [Google Scholar] [CrossRef]

- Aguilar-Arevalo, A.; Bertou, X.; Bonifazi, C.; Cancelo, G.; Castañeda, A.; Cervantes Vergara, B.; Chavez, C.; D’Olivo, J.C.; dos Anjos, J.a.C.; Estrada, J.; et al. Exploring low-energy neutrino physics with the Coherent Neutrino Nucleus Interaction Experiment. Phys. Rev. D 2019, 100, 092005. [Google Scholar] [CrossRef] [Green Version]

- Nasteva, I. Low-energy reactor neutrino physics with the CONNIE experiment. arXiv 2021, arXiv:2110.13620. [Google Scholar] [CrossRef]

- D’Olivo, J.C.; Bonifazi, C.; Rodrigues, D.; Moroni, G.F. vIOLETA: Neutrino Interaction Observation with a Low Energy Threshold Array. In Proceedings of the XXIX International Conference in Neutrino Physics, Chicago, IL, USA, 22 June–2 July 2020. [Google Scholar]

- Barak, L.; Bloch, I.M.; Cababie, M.; Cancelo, G.; Chaplinsky, L.; Chierchie, F.; Crisler, M.; Drlica-Wagner, A.; Essig, R.; Estrada, J.; et al. SENSEI: Direct-Detection Results on sub-GeV Dark Matter from a New Skipper CCD. Phys. Rev. Lett. 2020, 125, 171802. [Google Scholar] [CrossRef] [PubMed]

- Aguilar-Arevalo, A.; Amidei, D.; Baxter, D.; Cancelo, G.; Cervantes Vergara, B.A.; Chavarria, A.E.; Darragh-Ford, E.; de Mello Neto, J.R.T.; D’Olivo, J.C.; Estrada, J.; et al. Constraints on Light Dark Matter Particles Interacting with Electrons from DAMIC at SNOLAB. Phys. Rev. Lett. 2019, 123, 181802. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Aguilar-Arevalo, A.; Bessia, F.A.; Avalos, N.; Baxter, D.; Bertou, X.; Bonifazi, C.; Botti, A.; Cababie, M.; Cancelo, G.; Cervantes-Vergara, B.A.; et al. The Oscura Experiment. arXiv 2022, arXiv:2202.10518. [Google Scholar]

- Sofo-Haro, M.; Chavez, C.; Lipovetzky, J.; Bessia, F.A.; Cancelo, G.; Chierchie, F.; Estrada, J.; Moroni, G.F.; Stefanazzi, L.; Tiffenberg, J.; et al. Analog pile-up circuit technique using a single capacitor for the readout of Skipper-CCD detectors. J. Instrum. 2021, 16, P11012. [Google Scholar] [CrossRef]

- Leach, R.W.; Low, F.J. CCD and IR array controllers. Optical and IR Telescope Instrumentation and Detectors. In International Society for Optics and Photonics; Iye, M., Moorwood, A.F.M., Eds.; SPIE: Munich, Germany, 2000; Volume 4008, pp. 337–343. [Google Scholar] [CrossRef]

- Starr, B.M.; Buchholz, N.; Rahmer, G.; Penegor, J.; Schmidt, R.; Warner, M.; Merrill, K.M.; Claver, C.F.; Ho, Y.; Chopra, K.; et al. MONSOON Image Acquisition System. In Scientific Detectors for Astronomy; Amico, P., Beletic, J.W., Beletic, J.E., Eds.; Springer: Dordrecht, The Netherlands, 2004; pp. 269–276. [Google Scholar]

| Method | Throughput at ADC Output | Data to Transfer |

|---|---|---|

| Fully digital at 15 MSps | 270 mbps/channel | 858 MB/MPix |

| Mixed analog/digital DSI | 900 kbps/channel | 858 MB/MPix |

| DSI + analog pile-up | 2.25 kbps/channel | 2.15 MB/MPix |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chavez, C.R.; Chierchie, F.; Sofo-Haro, M.; Lipovetzky, J.; Fernandez-Moroni, G.; Estrada, J. Multiplexed Readout for an Experiment with a Large Number of Channels Using Single-Electron Sensitivity Skipper-CCDs. Sensors 2022, 22, 4308. https://doi.org/10.3390/s22114308

Chavez CR, Chierchie F, Sofo-Haro M, Lipovetzky J, Fernandez-Moroni G, Estrada J. Multiplexed Readout for an Experiment with a Large Number of Channels Using Single-Electron Sensitivity Skipper-CCDs. Sensors. 2022; 22(11):4308. https://doi.org/10.3390/s22114308

Chicago/Turabian StyleChavez, Claudio R., Fernando Chierchie, Miguel Sofo-Haro, Jose Lipovetzky, Guillermo Fernandez-Moroni, and Juan Estrada. 2022. "Multiplexed Readout for an Experiment with a Large Number of Channels Using Single-Electron Sensitivity Skipper-CCDs" Sensors 22, no. 11: 4308. https://doi.org/10.3390/s22114308

APA StyleChavez, C. R., Chierchie, F., Sofo-Haro, M., Lipovetzky, J., Fernandez-Moroni, G., & Estrada, J. (2022). Multiplexed Readout for an Experiment with a Large Number of Channels Using Single-Electron Sensitivity Skipper-CCDs. Sensors, 22(11), 4308. https://doi.org/10.3390/s22114308