Research on Dynamic Characteristics of the RBBH System Based on Dynamics Model and Vibration Data Fusion

Abstract

1. Introduction

2. Nonlinear Dynamic Models of the RBBH System

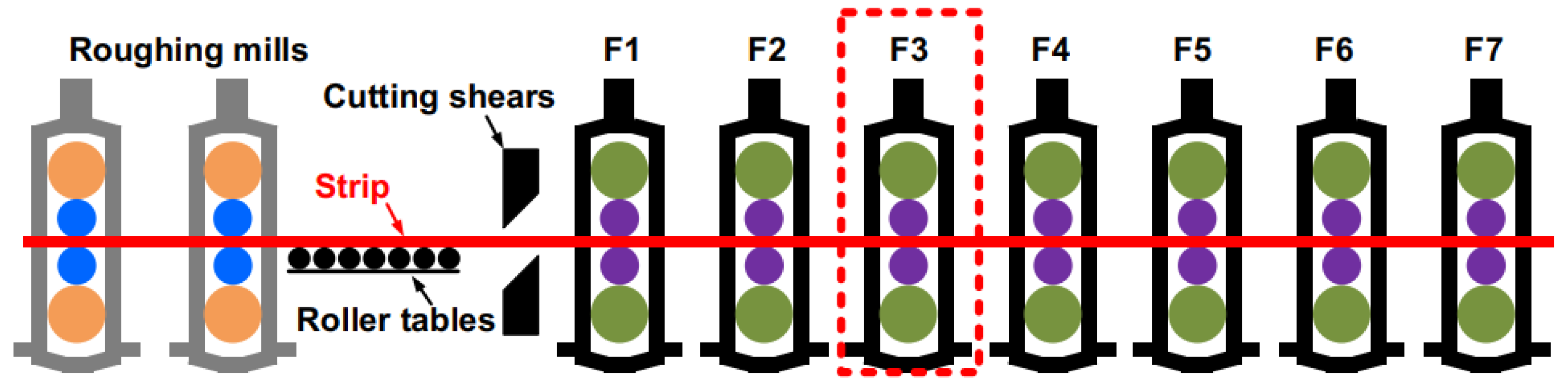

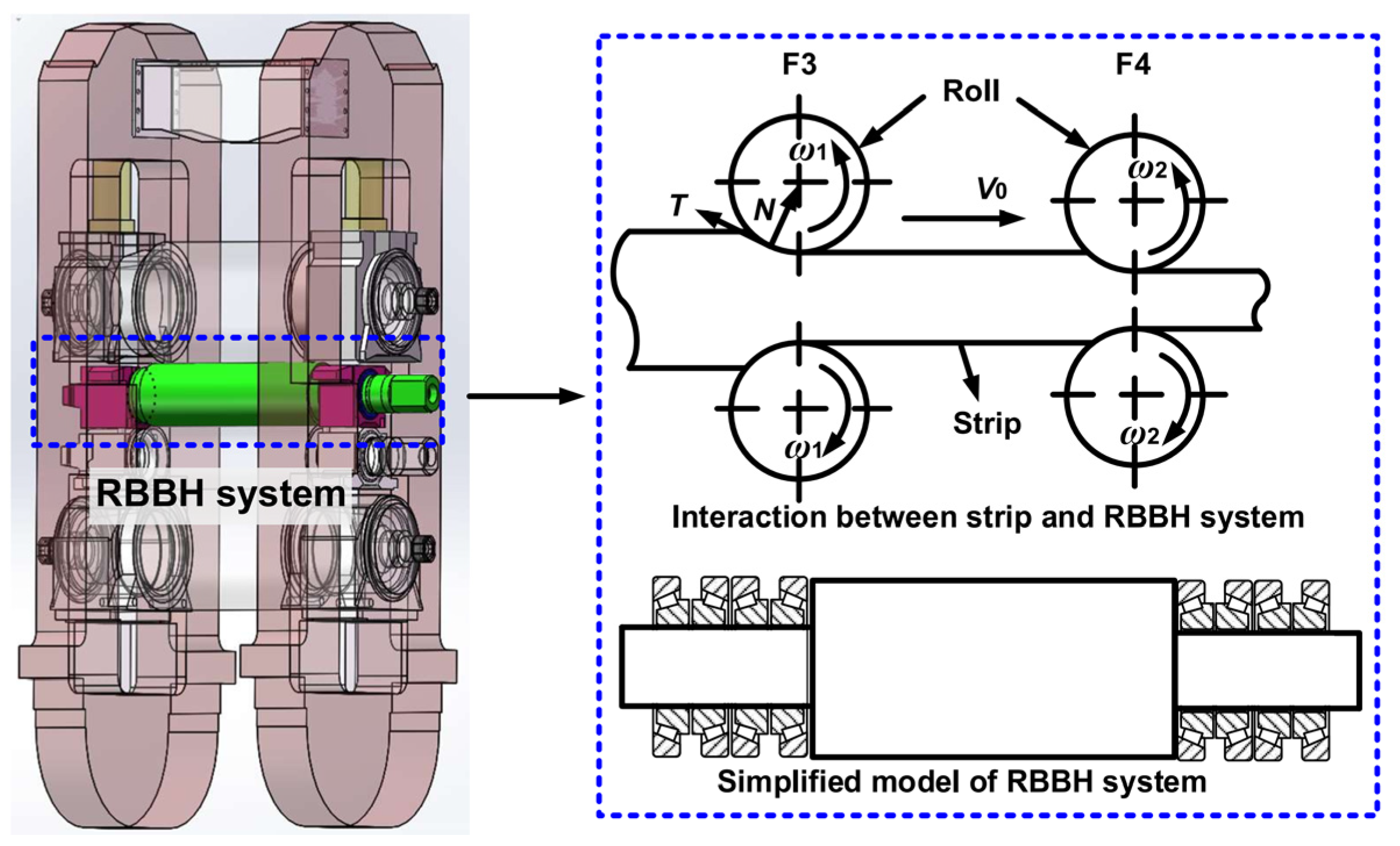

2.1. Engineering Background

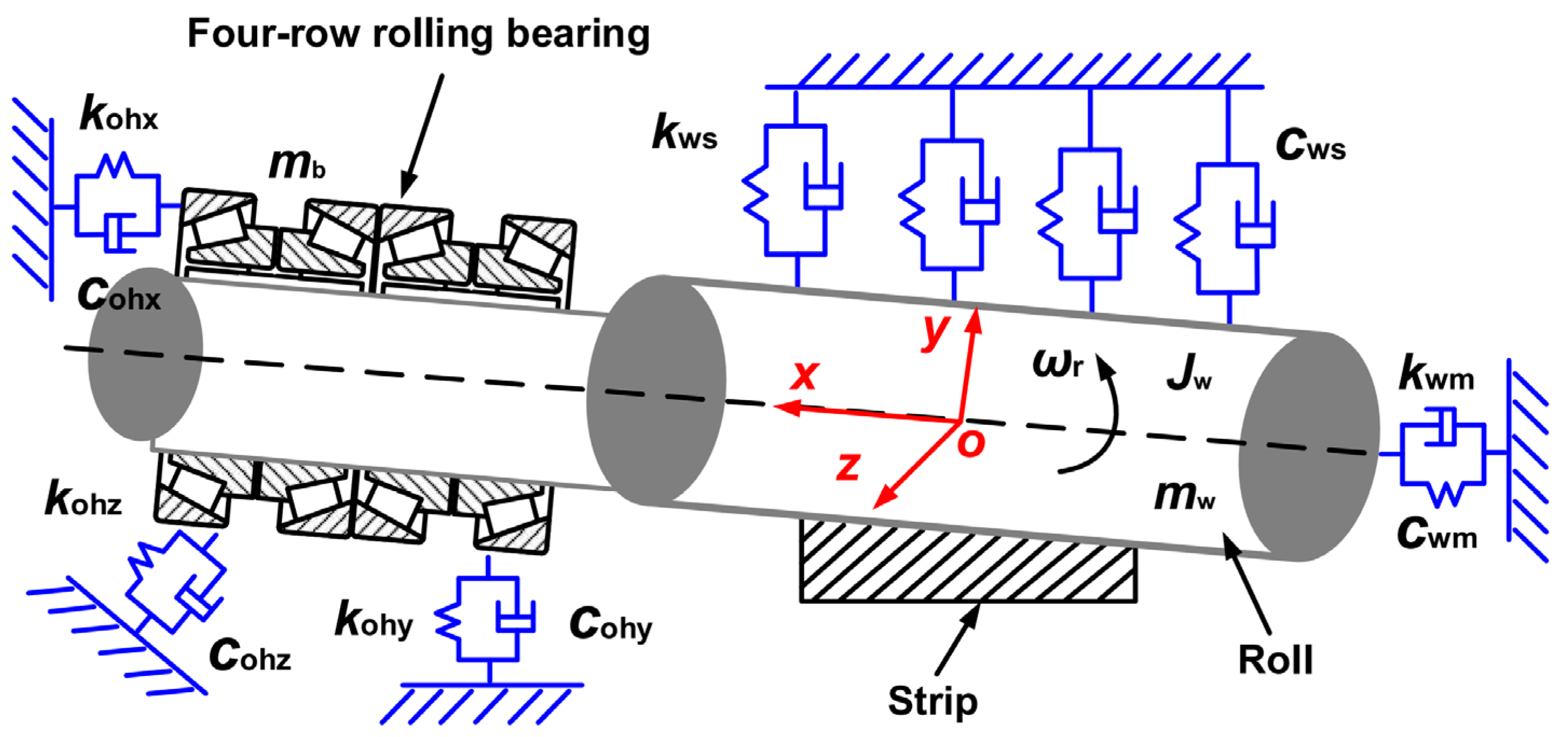

- (1)

- The roll is an isotropic beam of equal cross-section; the longitudinal displacement along the axis of the roll and the elastic deformation of the roll along the rolling line caused by the horizontal load are ignored.

- (2)

- The influence of roll moment of inertia and shear deformation are ignored.

- (3)

- The contact between the work roll and the support roll is elastic contact.

2.2. The RBBH System Modeling

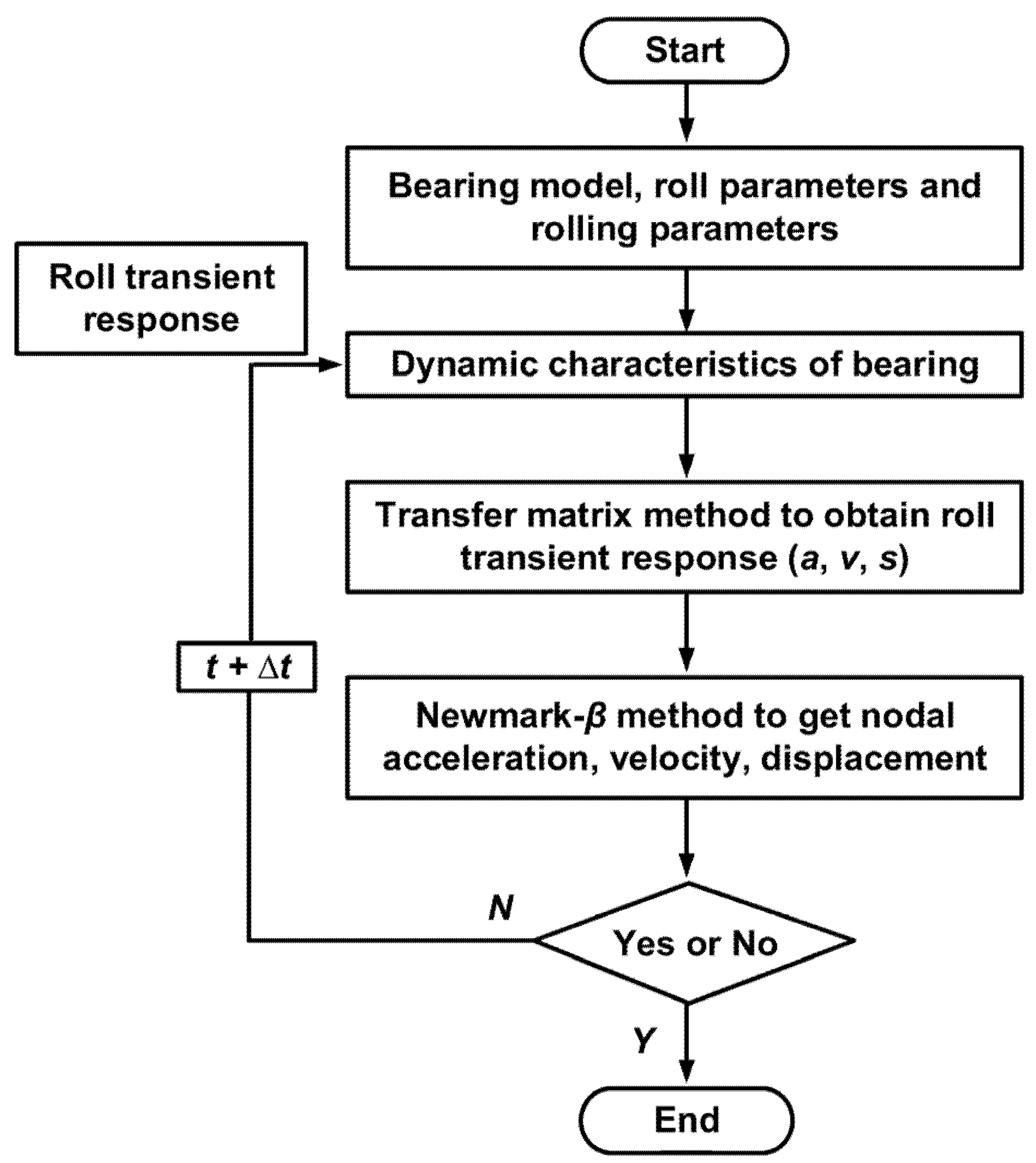

2.3. Methodology

3. Numerical Results and Discussion

3.1. Model Parameters

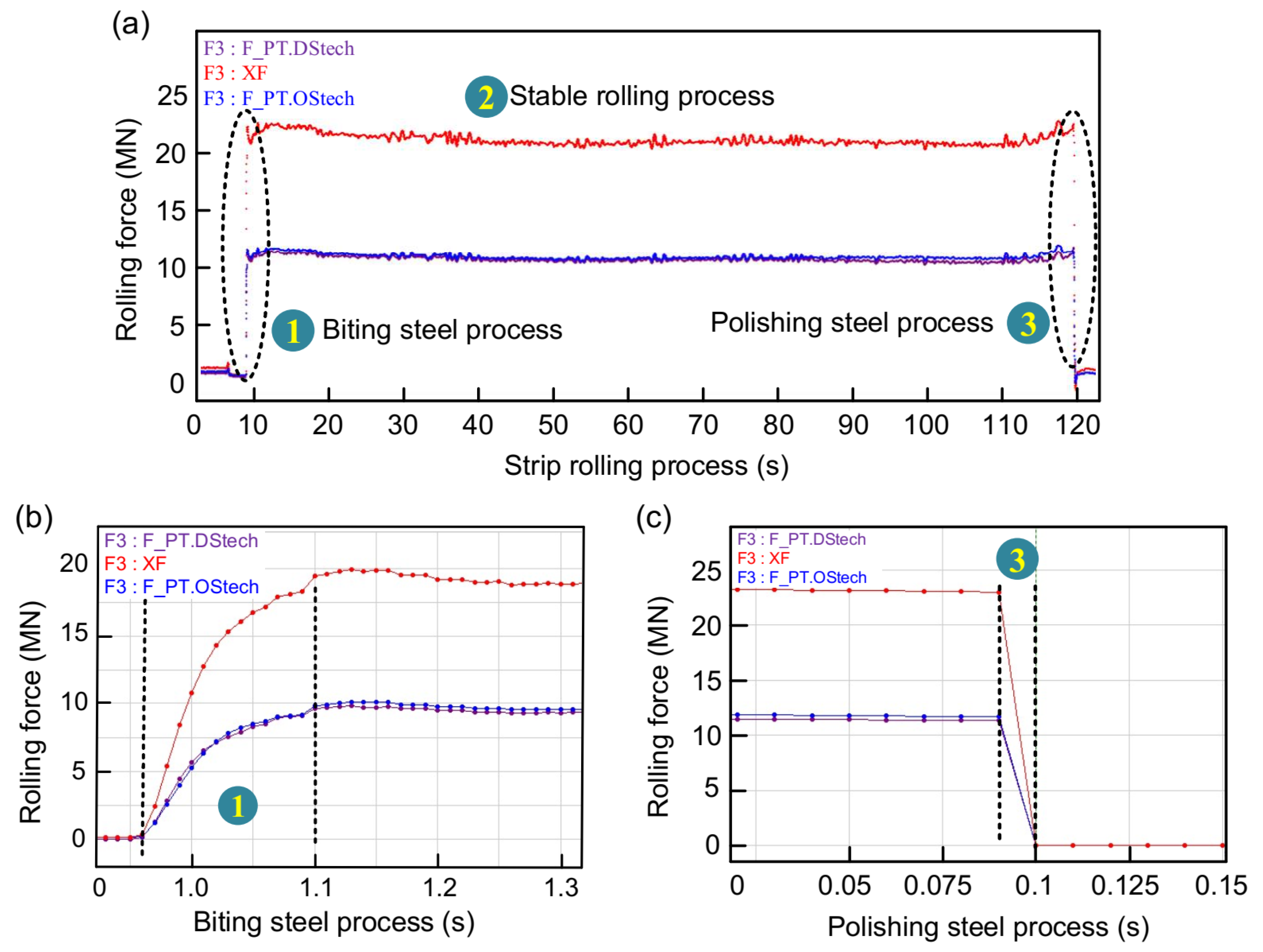

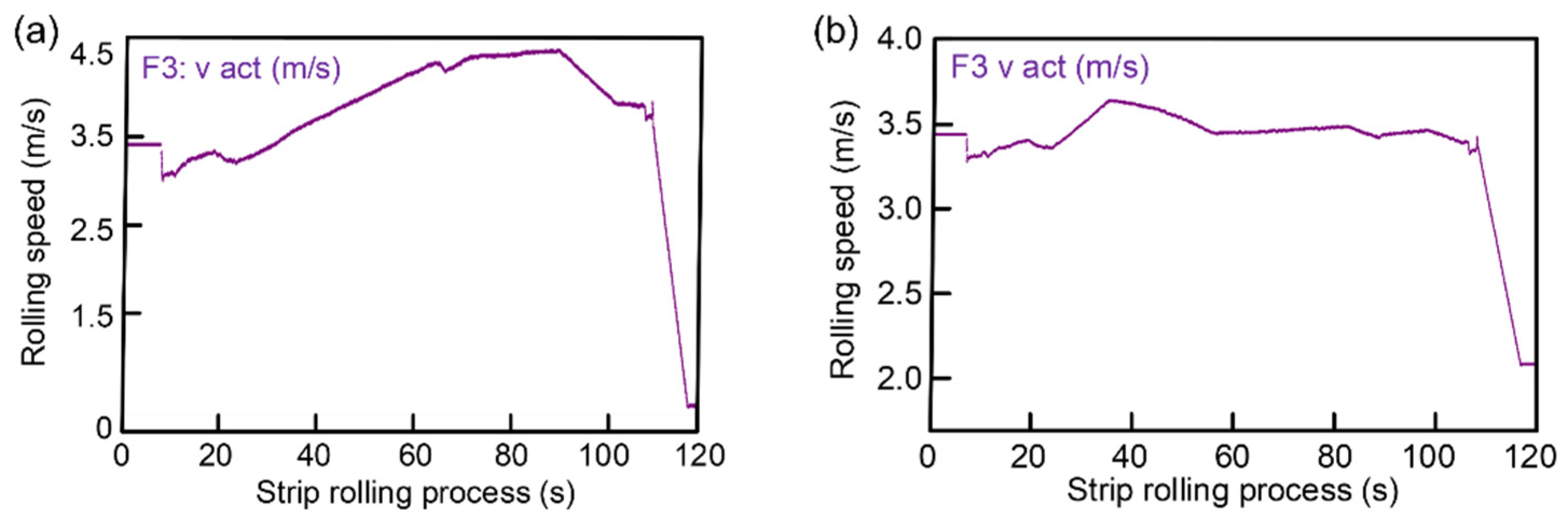

3.2. Rolling Process Parameters

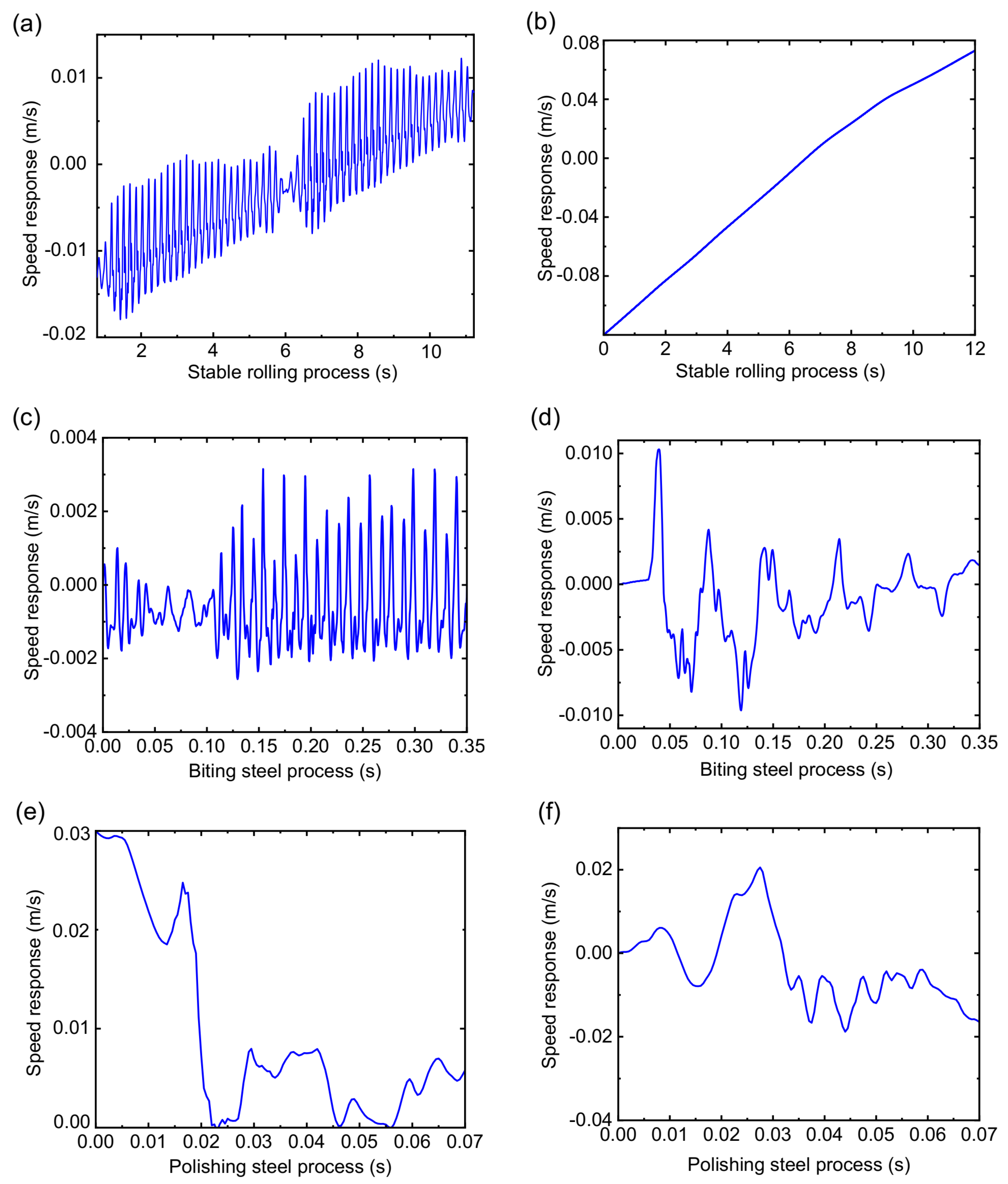

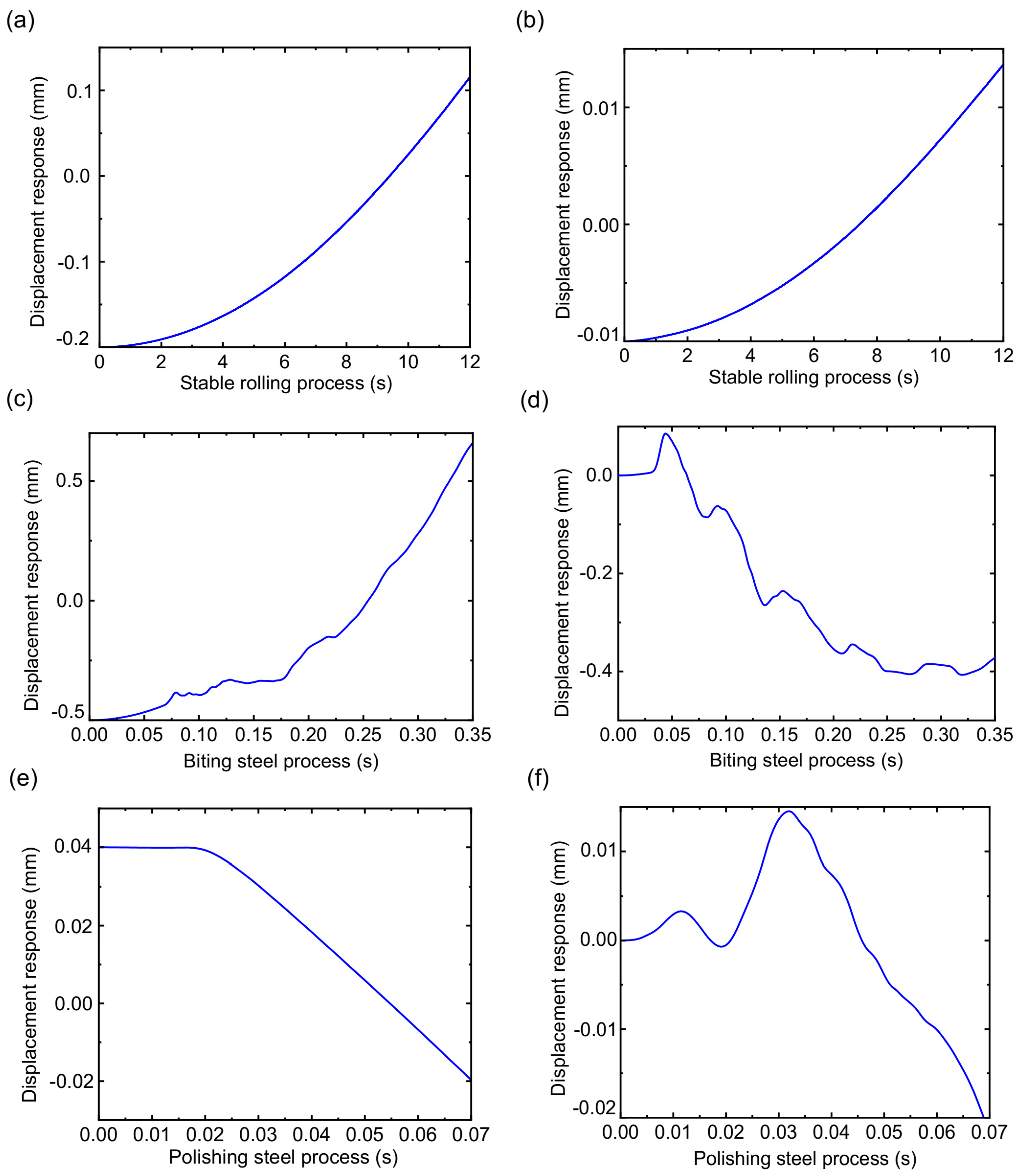

3.3. Numerical Results and Discussion

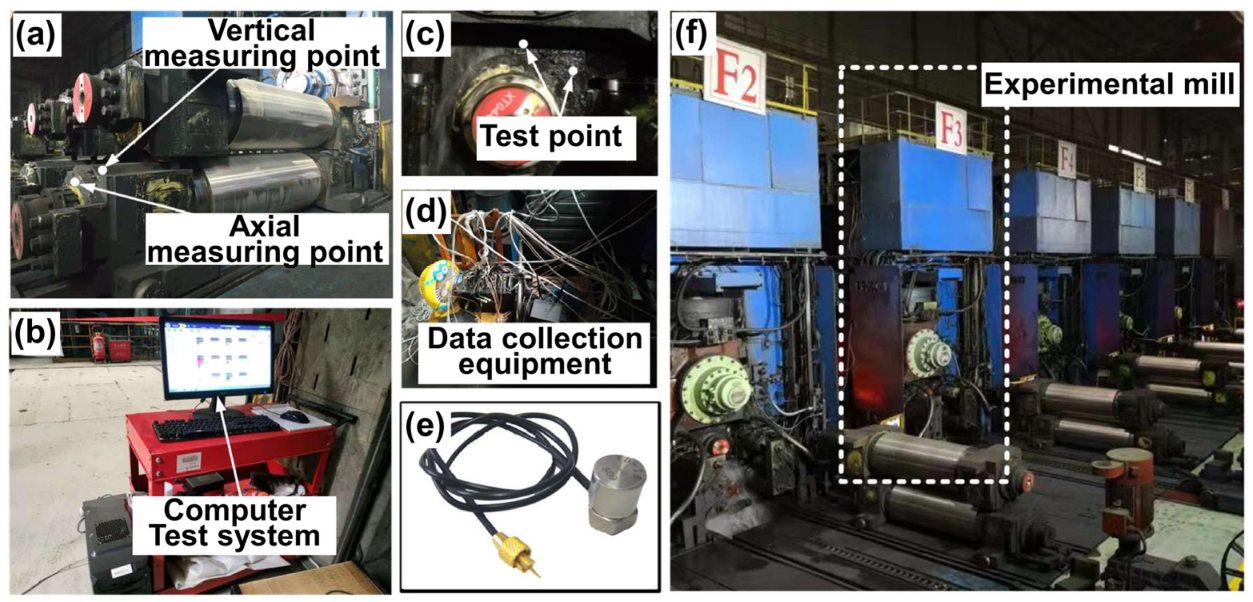

4. Experimental Validation

4.1. Model Parameters

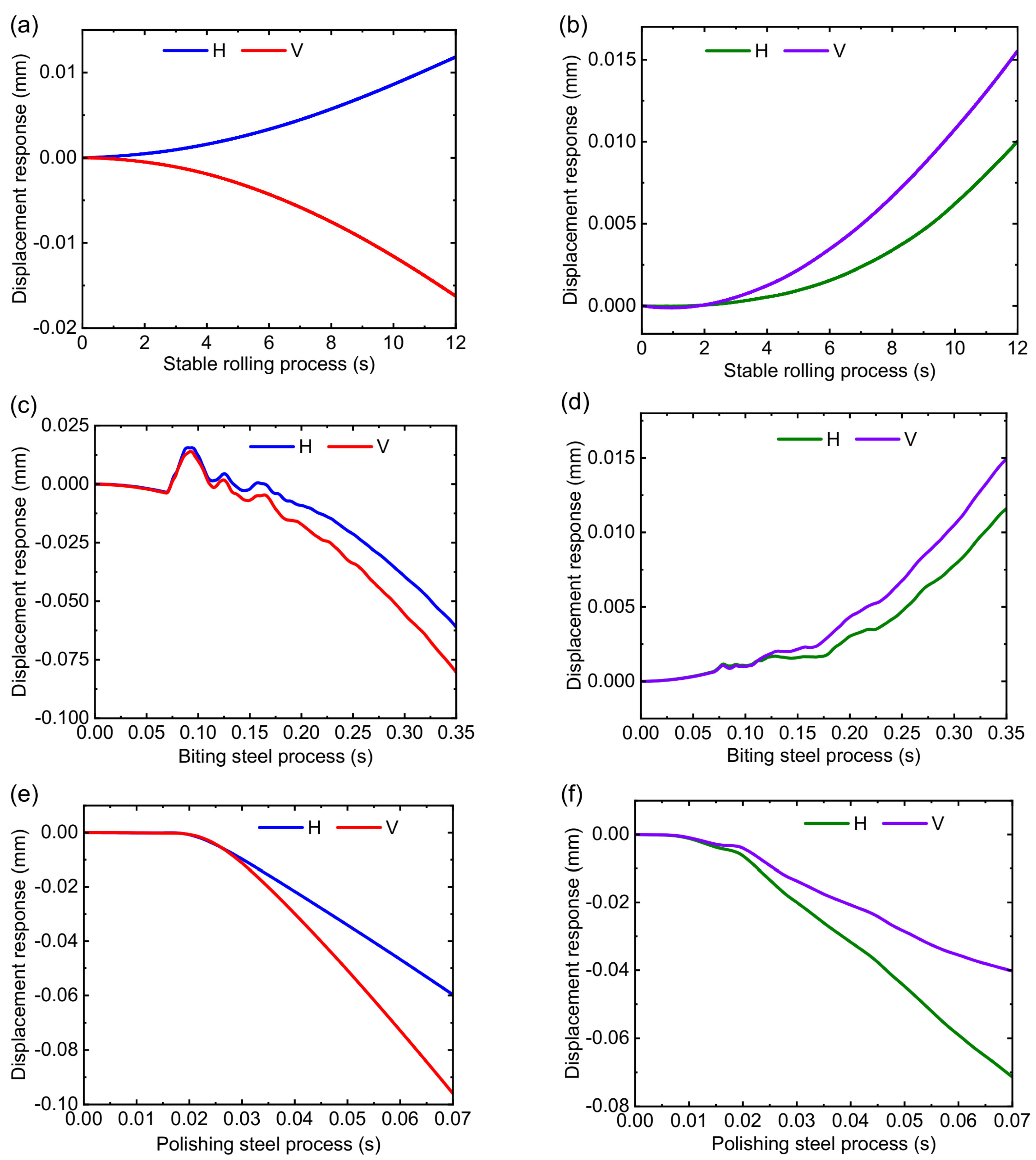

4.2. Results and Discussion

5. Conclusions

- (1)

- The dynamic characteristics of the RBBH system are controlled by the dynamic model during the rolling period, including acceleration response, velocity response, and displacement response.

- (2)

- A coupling nonlinear dynamic model and a general dynamic equation of the RBBH system supported by four-row rolling element bearings are proposed under high speed and heavy load.

- (3)

- When the SPA-H of 1.6 mm is rolled, the dynamic response of the RBBH system is much greater than that of the 3.2 mm. The stability of the RBBH system varies with strip thickness.

- (4)

- The dynamic characteristic of the RBBH system is a coupling dynamic result which contains the motion characteristic of multiple directions.

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Peng, R.; Zhang, X.; Shi, P. Vertical–Horizontal Coupling Vibration of Hot Rolling Mill Rolls under Multi-Piecewise Nonlinear Constraints. Metals 2021, 11, 170. [Google Scholar] [CrossRef]

- Zhao, C.; Sun, J.; Lin, S.; Peng, Y. Fault Diagnosis Method for Rolling Mill Multi Row Bearings Based on AMVMD-MC1DCNN under Unbalanced Dataset. Sensors 2021, 21, 5494. [Google Scholar] [CrossRef]

- Cao, H.; Niu, L.; Xi, S.; Chen, X. Mechanical model development of rolling bearing-rotor systems: A review. Mech. Syst. Signal Process. 2018, 102, 37–58. [Google Scholar] [CrossRef]

- Yang, Y.; Yang, W.; Jiang, D. Simulation and experimental analysis of rolling element bearing fault in rotor-bearing-casing system. Eng. Fail. Anal. 2018, 92, 205–221. [Google Scholar] [CrossRef]

- Rusnak, J.; Malega, P.; Svetlik, J.; Rudy, V.; Smajda, N. The Research of the Rolling Speed Influence on the Mechanism of Strip Breaks in the Steel Rolling Process. Materials 2020, 13, 3509. [Google Scholar] [CrossRef]

- Liu, S.; Wang, Z.; Wang, J.; Li, H. Sliding bifurcation research of a horizontal–torsional coupled main drive system of rolling mill. Nonlinear Dyn. 2015, 83, 441–455. [Google Scholar] [CrossRef]

- Liu, S.; Ai, H.; Pang, Z.; Lin, Z.; Zhao, D. Hopf bifurcation control of nonlinear electromechanical coupling main drive system of rolling mill. Eur. Phys. J. Plus 2020, 135, 365. [Google Scholar] [CrossRef]

- Peng, Y.; Zhang, Y.; Sun, J.; Zang, Y. Tandem strip mill’s multi-parameter coupling dynamic modeling based on the thickness control. Chin. J. Mech. Eng. 2015, 28, 353–362. [Google Scholar] [CrossRef]

- Liu, H.; Liu, B.; Jiang, J.; Liu, F.; Li, P. Nonlinear vibration characteristic of strip mill under the coupling effect of roll-rolled piece. J. Vibroeng. 2016, 18, 5492–5504. [Google Scholar] [CrossRef]

- Liu, J.; Xu, Y.; Shao, Y. Dynamic modelling of a rotor-bearing-housing system including a localized fault. Proc. Inst. Mech. Eng. Part K J. Multi-Body Dyn. 2017, 232, 385–397. [Google Scholar] [CrossRef]

- Wang, Q.; Jiang, Z.; Zhao, J.; Fang, M. Multi-factor coupling system characteristic of the dynamic roll gap in the high-speed rolling mill during the unsteady lubrication process. Tribol. Int. 2013, 67, 174–181. [Google Scholar] [CrossRef]

- Xu, H.; Cui, L.-L.; Shang, D.-G. A study of nonlinear coupling dynamic characteristics of the cold rolling mill system under different rolling parameters. Adv. Mech. Eng. 2017, 9, 85–99. [Google Scholar] [CrossRef]

- Peng, R.; Zhang, X.; Shi, P. Coupled Vibration Behavior of Hot Rolling Mill Rolls under Multinonlinear Effects. Shock. Vib. 2020, 2020, 6104028. [Google Scholar] [CrossRef]

- Zhu, Y.; Qian, P.; Tang, S.; Jiang, W.; Li, W.; Zhao, J. Amplitude-frequency characteristics analysis for vertical vibration of hydraulic AGC system under nonlinear action. AIP Adv. 2019, 9, 035019. [Google Scholar] [CrossRef]

- Sinou, J.J. Non-linear dynamics and contacts of an unbalanced flexible rotor supported on ball bearings. Mech. Mach. Theory 2009, 44, 1713–1732. [Google Scholar] [CrossRef]

- Moazen Ahmadi, A.; Petersen, D.; Howard, C. A nonlinear dynamic vibration model of defective bearings—The importance of modelling the finite size of rolling elements. Mech. Syst. Signal Process. 2015, 52–53, 309–326. [Google Scholar] [CrossRef]

- Wang, W.-Z.; Hu, L.; Zhang, S.-G.; Zhao, Z.-Q.; Ai, S. Modeling angular contact ball bearing without raceway control hypothesis. Mech. Mach. Theory 2014, 82, 154–172. [Google Scholar] [CrossRef]

- Gao, S.; Chatterton, S.; Naldi, L.; Pennacchi, P. Ball bearing skidding and over-skidding in large-scale angular contact ball bearings: Nonlinear dynamic model with thermal effects and experimental results. Mech. Syst. Signal Process. 2021, 147, 107120. [Google Scholar] [CrossRef]

- Than, V.-T.; Huang, J.H. Nonlinear thermal effects on high-speed spindle bearings subjected to preload. Tribol. Int. 2016, 96, 361–372. [Google Scholar] [CrossRef]

- Yang, Z.; Yu, T.; Zhang, Y.; Sun, Z. Influence of cage clearance on the heating characteristics of high-speed ball bearings. Tribol. Int. 2017, 105, 125–134. [Google Scholar] [CrossRef]

- Bovet, C.; Zamponi, L. An approach for predicting the internal behaviour of ball bearings under high moment load. Mech. Mach. Theory 2016, 101, 1–22. [Google Scholar] [CrossRef]

- Cao, H.; Li, Y.; Chen, X. A New Dynamic Model of Ball-Bearing Rotor Systems Based on Rigid Body Element. J. Manuf. Sci. Eng. 2016, 138, 071007. [Google Scholar] [CrossRef]

- Tu, W.; Yu, W.; Shao, Y.; Yu, Y. A nonlinear dynamic vibration model of cylindrical roller bearing considering skidding. Nonlinear Dyn. 2021, 103, 2299–2313. [Google Scholar] [CrossRef]

- Liu, Y.; Chen, Z.; Tang, L.; Zhai, W. Skidding dynamic performance of rolling bearing with cage flexibility under accelerating conditions. Mech. Syst. Signal Process. 2021, 150, 107257. [Google Scholar] [CrossRef]

- Singh, S.; Köpke, U.G.; Howard, C.Q.; Petersen, D. Analyses of contact forces and vibration response for a defective rolling element bearing using an explicit dynamics finite element model. J. Sound Vib. 2014, 333, 5356–5377. [Google Scholar] [CrossRef]

- Adeniyi, A.A.; Morvan, H.; Simmons, K. A Computational Fluid Dynamics Simulation of Oil–Air Flow between the Cage and Inner Race of an Aero-engine Bearing. J. Eng. Gas Turbines Power 2017, 139, 012506. [Google Scholar] [CrossRef]

| Parameters | Values |

|---|---|

| Bearing width B (mm) | 298.4 |

| Inner ring diameter Di (mm) | 288.9 |

| Outer ring diameter Do (mm) | 406.4 |

| Rolling element small diameter Dr1 (mm) | 26.2 |

| Rolling element big diameterDr2 (mm) | 27.9 |

| rolling element length lr (mm) | 54 |

| Load ratings Cr (KN) | 2627 |

| Radial clearance Pd1 (mm) | 0.12–0.18 |

| Axial clearance Pd2 (mm) | 0.54–0.79 |

| Total length of roll L (mm) | 5250 |

| Barrel length Lb (mm) | 2080 |

| Barrel diameter Db (mm) | 760 |

| Component | Material Properties | Density (kg/m3) | Elastic Modulus (GPa) | Poisson’s Ratio |

|---|---|---|---|---|

| Spacer | SAE1045 | 7850 | 210 | 0.31 |

| Cage | 08Al | 7800 | 210 | 0.3 |

| Rolling element | G20Cr2Ni4 | 7810 | 209 | 0.32 |

| Inner ring | G20Cr2Ni4 | 7810 | 209 | 0.32 |

| Outer ring | G20Cr2Ni4 | 7810 | 209 | 0.32 |

| Bearing housing | ZG230 | 7800 | 202 | 0.3 |

| Roll | 60CrMnMo | 7870 | 207 | 0.25 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lin, S.; Sun, J.; Zhao, C.; Peng, Y. Research on Dynamic Characteristics of the RBBH System Based on Dynamics Model and Vibration Data Fusion. Sensors 2022, 22, 3806. https://doi.org/10.3390/s22103806

Lin S, Sun J, Zhao C, Peng Y. Research on Dynamic Characteristics of the RBBH System Based on Dynamics Model and Vibration Data Fusion. Sensors. 2022; 22(10):3806. https://doi.org/10.3390/s22103806

Chicago/Turabian StyleLin, Shuilin, Jianliang Sun, Chen Zhao, and Yan Peng. 2022. "Research on Dynamic Characteristics of the RBBH System Based on Dynamics Model and Vibration Data Fusion" Sensors 22, no. 10: 3806. https://doi.org/10.3390/s22103806

APA StyleLin, S., Sun, J., Zhao, C., & Peng, Y. (2022). Research on Dynamic Characteristics of the RBBH System Based on Dynamics Model and Vibration Data Fusion. Sensors, 22(10), 3806. https://doi.org/10.3390/s22103806