1. Introduction

To cope with the problem of individual energy shortages and environmental pollution, developing new energy vehicles (NEVs) is an inevitable choice for the global automotive industry in the 21st century [

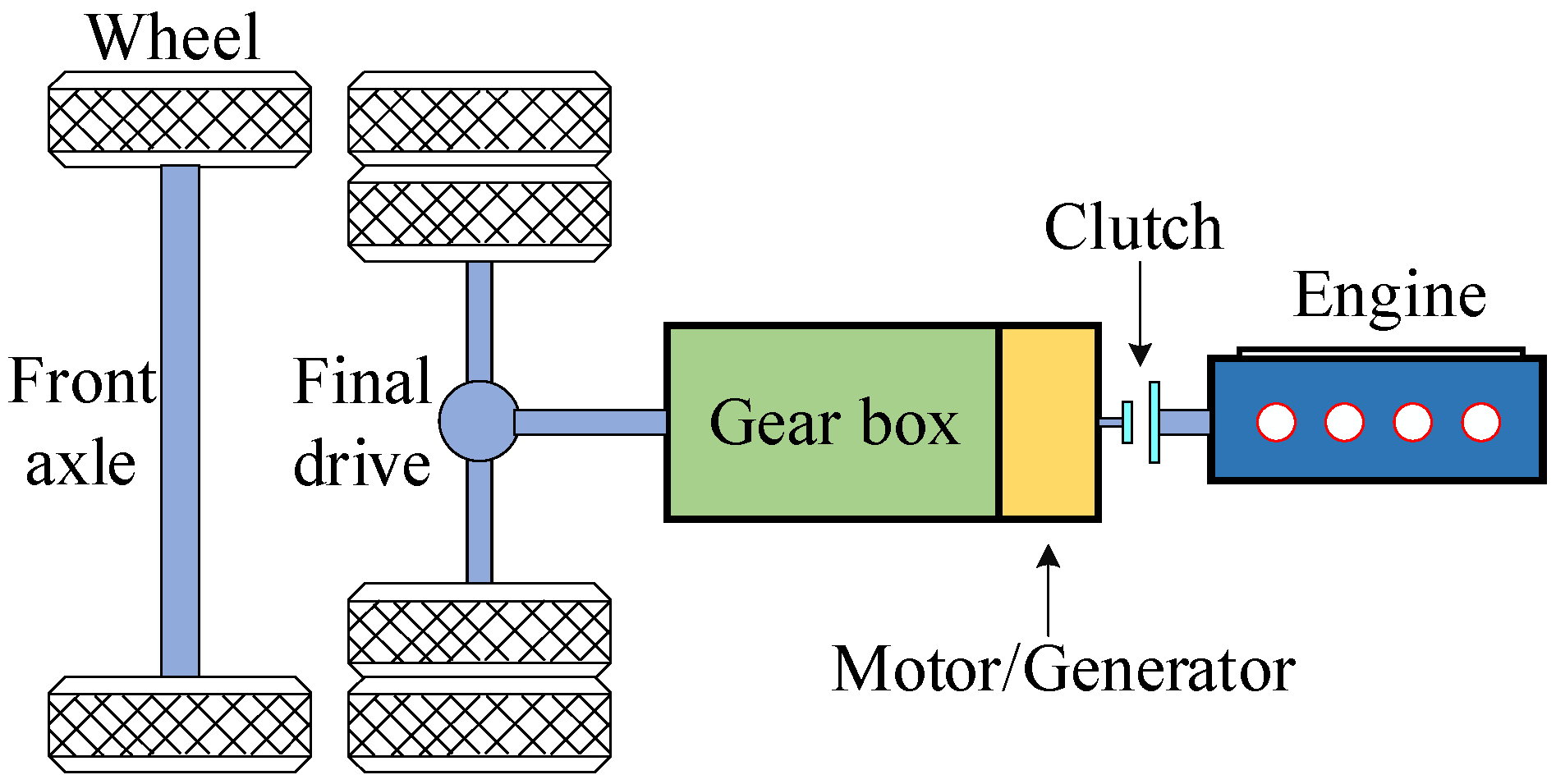

1]. Plug-in hybrid elective vehicles (PHEVs) combine the advantages of traditional vehicles with pure electric vehicles (EVs), which is a conducive method to achieve energy security and carbon neutral goals. Structurally, the non-uniformity of energy sources makes hybrid vehicles more diverse in energy distribution when the power demand is the same. Thus, rationally, energy distribution is the key to researching the energy management of multi-energy source vehicles (MEVs).

At present, energy management control strategies for MEVs mainly divide into three categories: rule-based [

2,

3], optimization-based [

4,

5] and data-driven [

6]. Reference [

7] proposes a driving strategy based on fuzzy logic. Based on the logic threshold control, the predefined control rules are fuzzified by adding expert experience. The rule-based control strategy has been widely applied due to its simplicity and ease of implementation; however, it cannot obtain good fuel economy and realize the self-adaptation of driving conditions. To maximize fuel economy, global optimization control strategies have been developed, such as Pontryagin’s minimum principle (PMP) [

8] and dynamic programming (DP) [

9,

10].

The dynamic programming strategy, as the representative global optimization method, can obtain the theoretical optimal fuel economy. Based on the dynamic programming algorithm, the trajectory of gears and engine on/off states are optimized in reference [

11] to minimize the fuel consumption of vehicles driving on hilly roads. However, a DP-based strategy needs to acquire the whole driving information in advance. To overcome the difficulties of being put in to practice, it is essential to overcome the reliance on deterministic trip information and improve the computational efficiency.

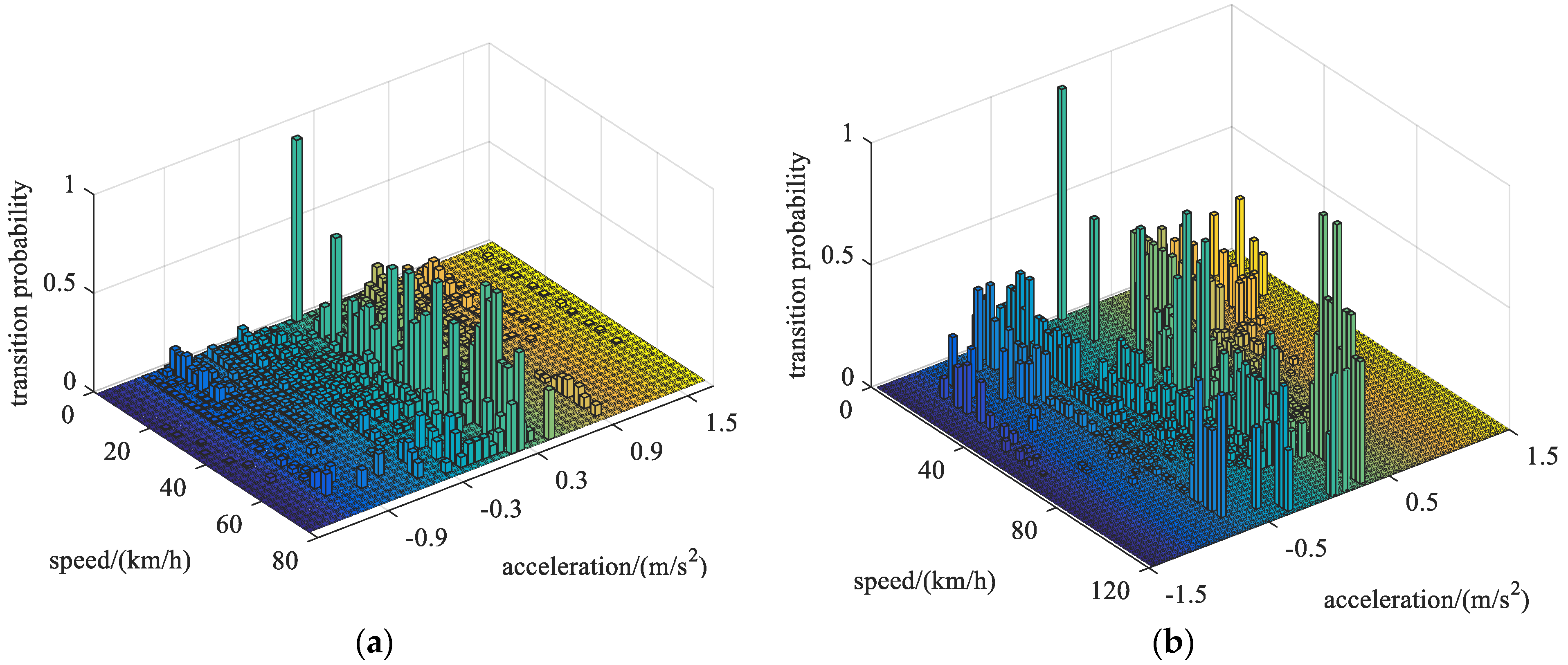

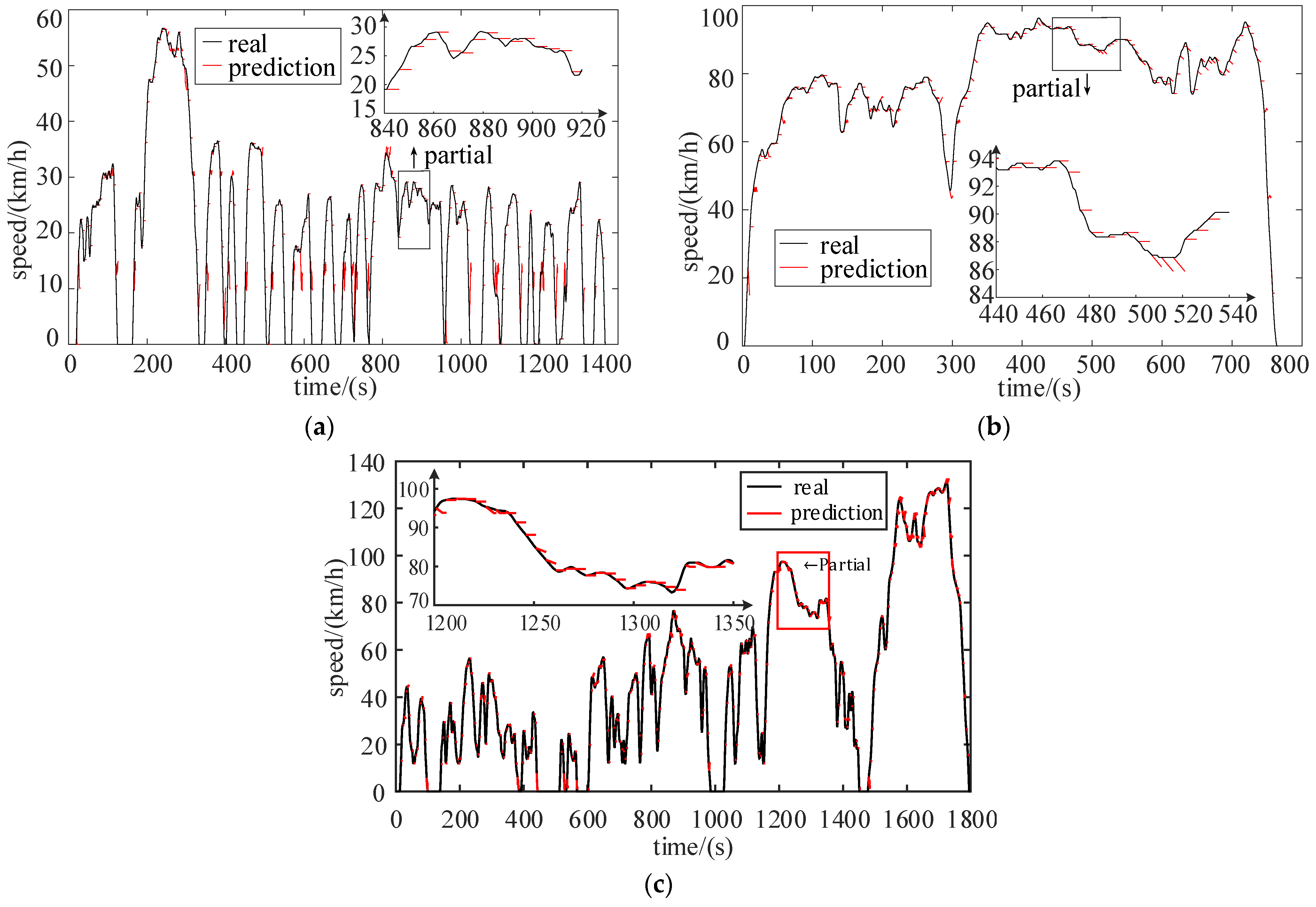

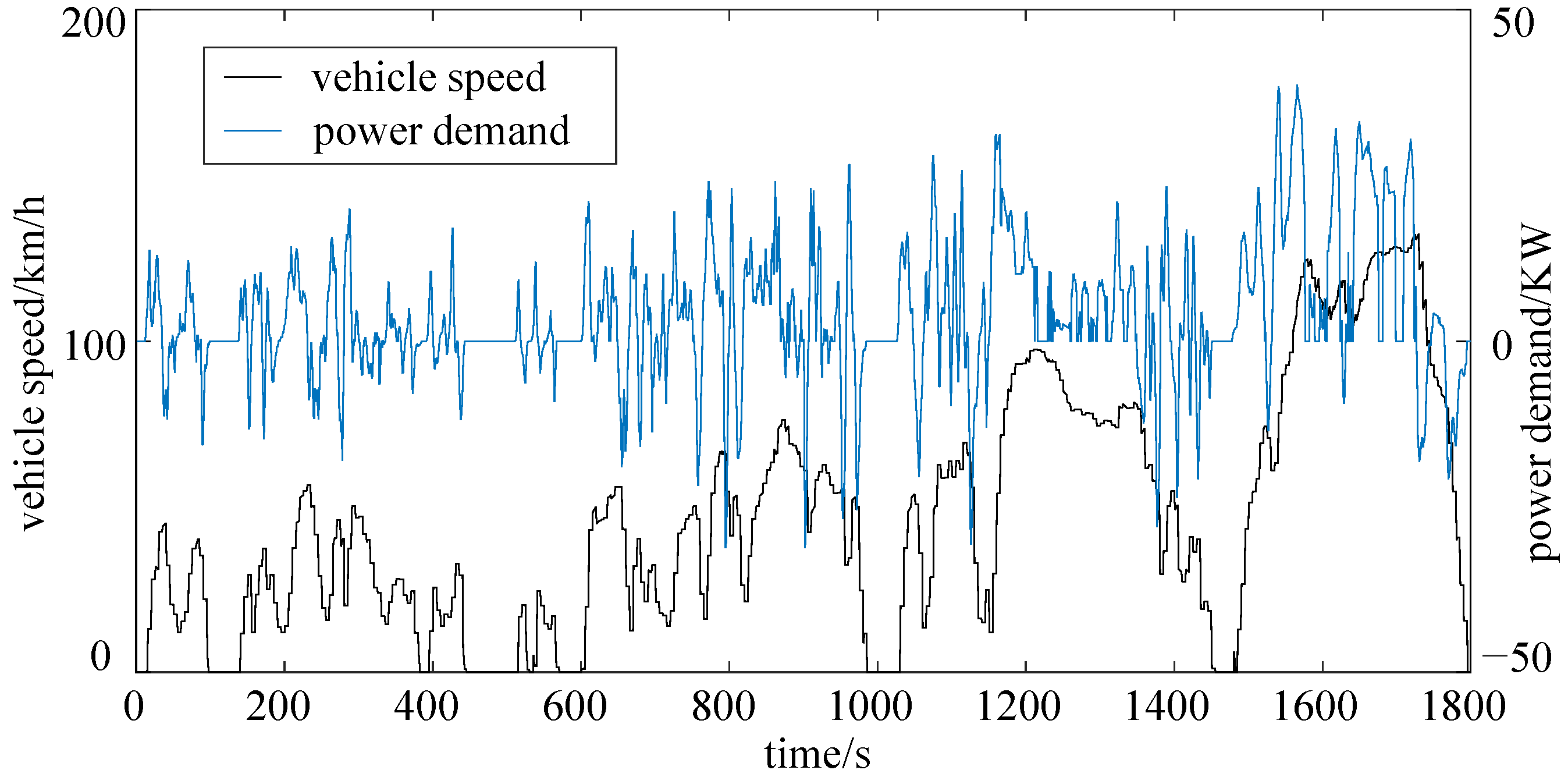

The implementation of a DP strategy requires deterministic trip information in advance. Vehicle speed and slope, as the main trip information, has a significant impact on global optimization energy management. Under the Chinese Standard Urban Driving Cycle (CSUDC), reference [

12] systematically studied the fuel-saving potential of the DP-based method. When we cannot obtain the speed information of the entire driving cycle in advance, the prediction of speed is necessary. There exist three methods to predict the vehicle speed, a Markov chain [

13,

14], artificial neural networks (NNs) [

15,

16] and exponentially varying prediction [

17,

18]. Whether it is a Markov chain velocity predictor or an NN-based velocity predictor, once there exists low similarity between real road conditions and training samples or history data, the prediction accuracy will significantly reduce.

Slope also has a significant impact on global optimization for energy management. Thanks to geographical information systems (GISs) and global positioning systems (GPSs) [

19], the slope on a regular route is available. By considering the impact of road gradient on the driving demand of the vehicle, a plug-in hybrid electric vehicle energy management strategy based on road gradient information is proposed in reference [

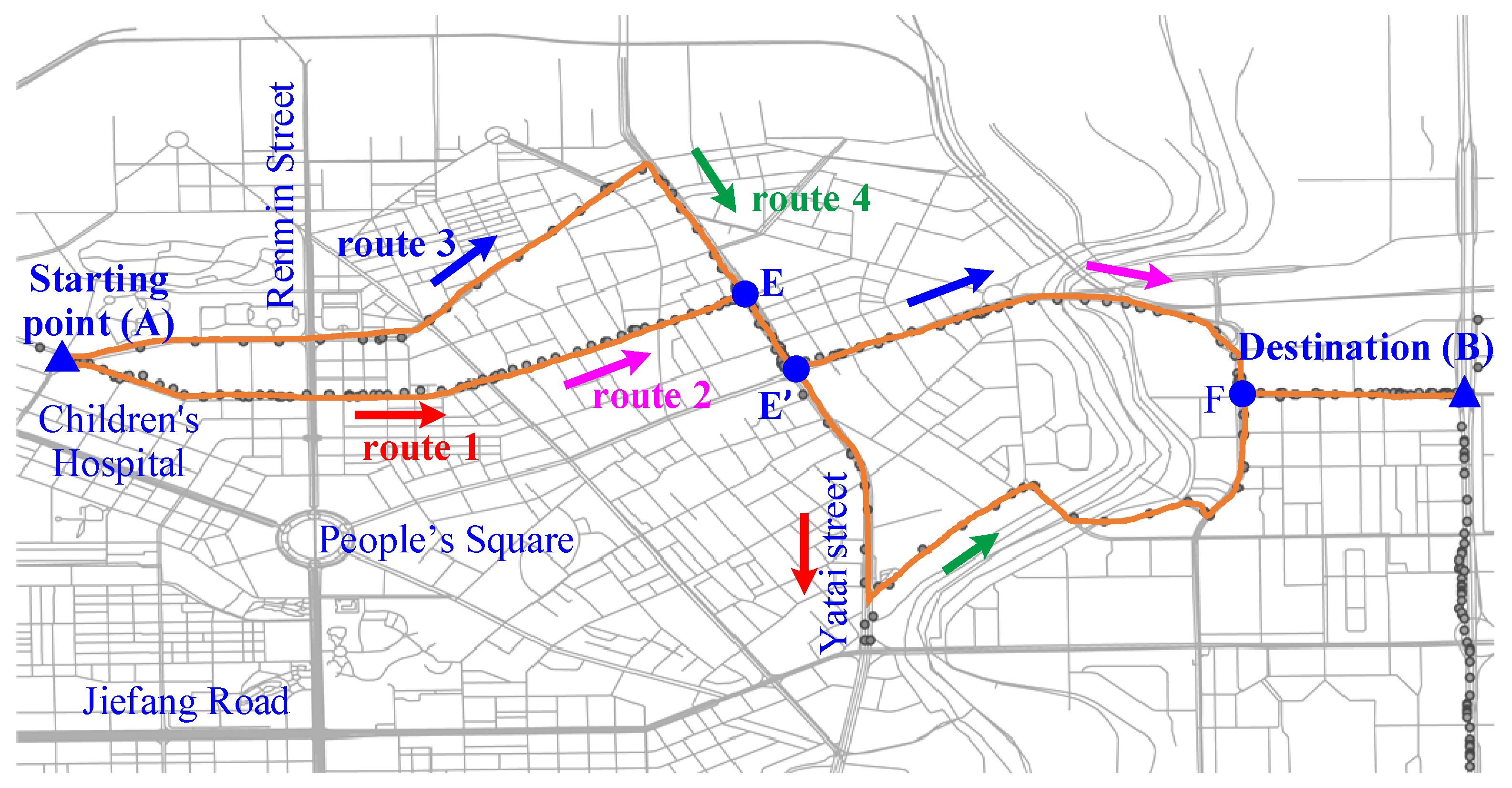

20]. However, the route to the destination is not unique for a flexible vehicle. During real driving, due to some unexpected situations, such as road congestion, traffic lights, etc., the driver will choose other routes. When the driver encounters multi-junction roads (such as crossroads or roundabouts), the driver’s motivation will affect the direction of the vehicle, that is, the slope cannot be directly obtained. In reference [

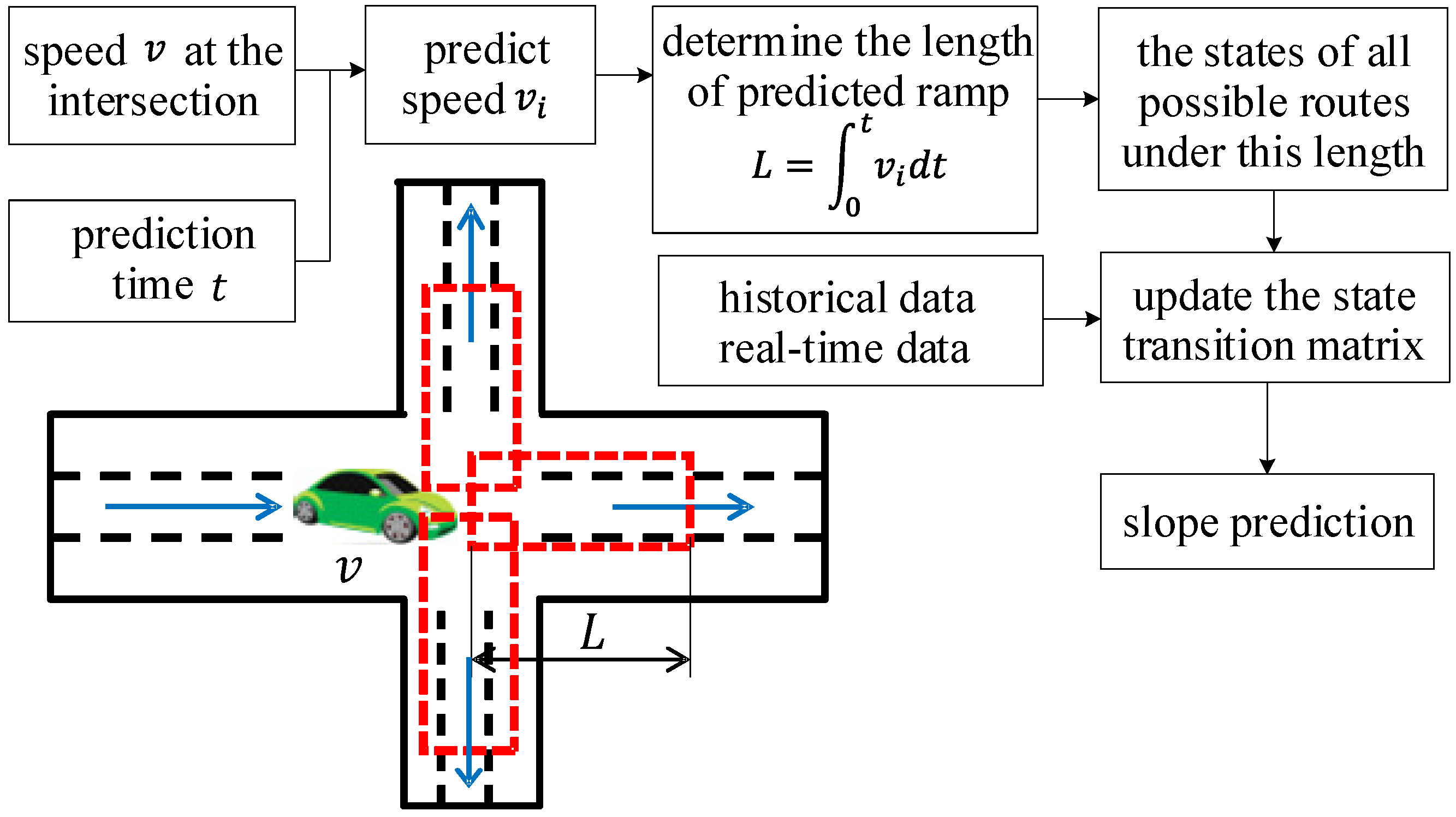

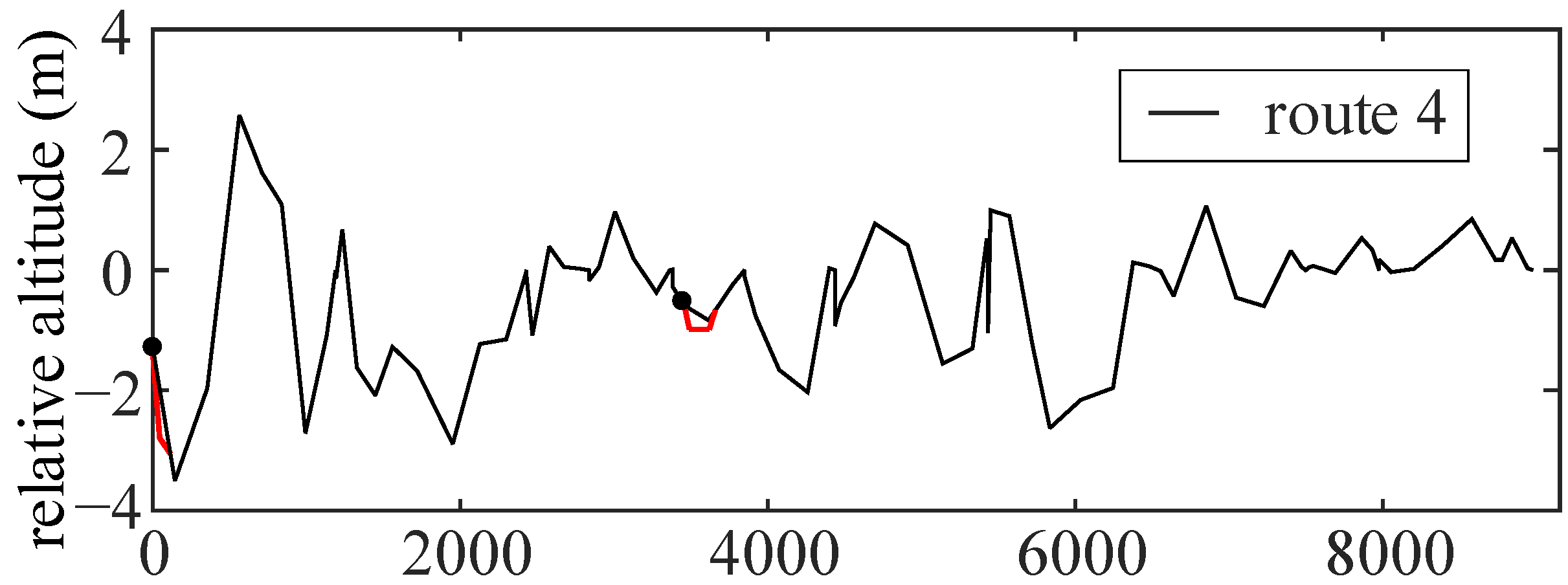

21], the possible future routes, as well as their probabilities, are obtained using GPS information and historical driving data. Regarding the unknown future route, how to acquire the slope is the key to determining accurate power demand.

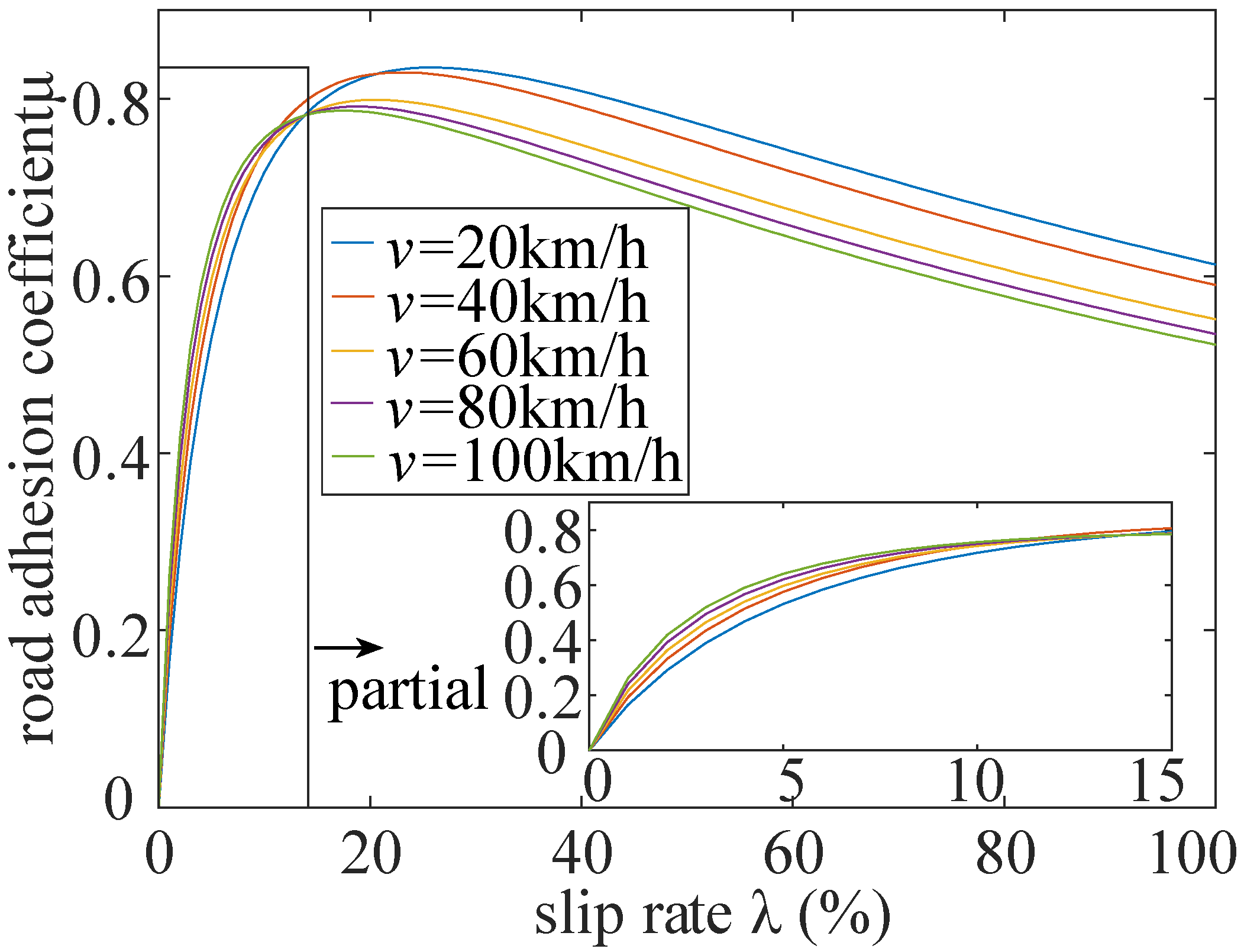

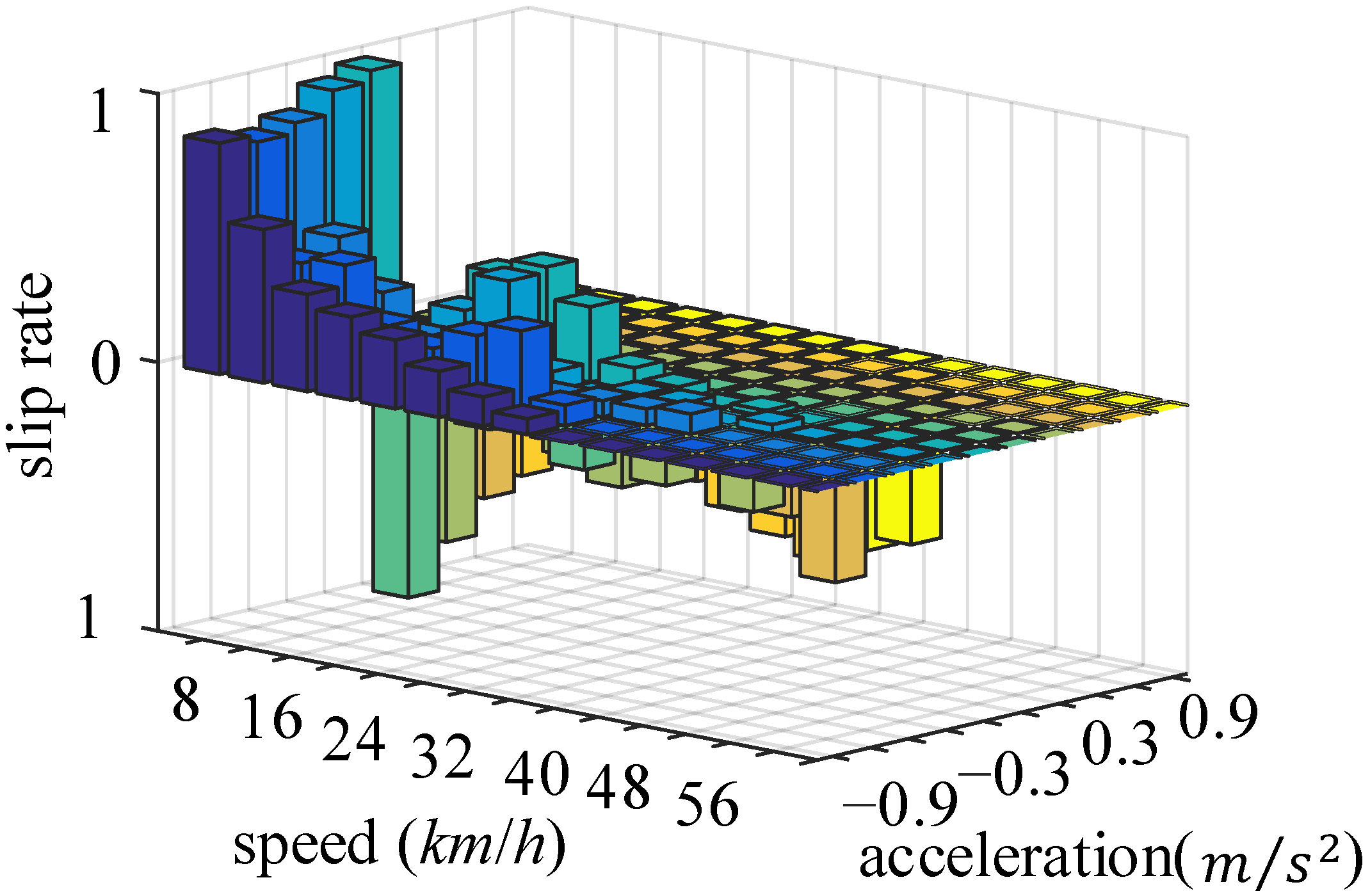

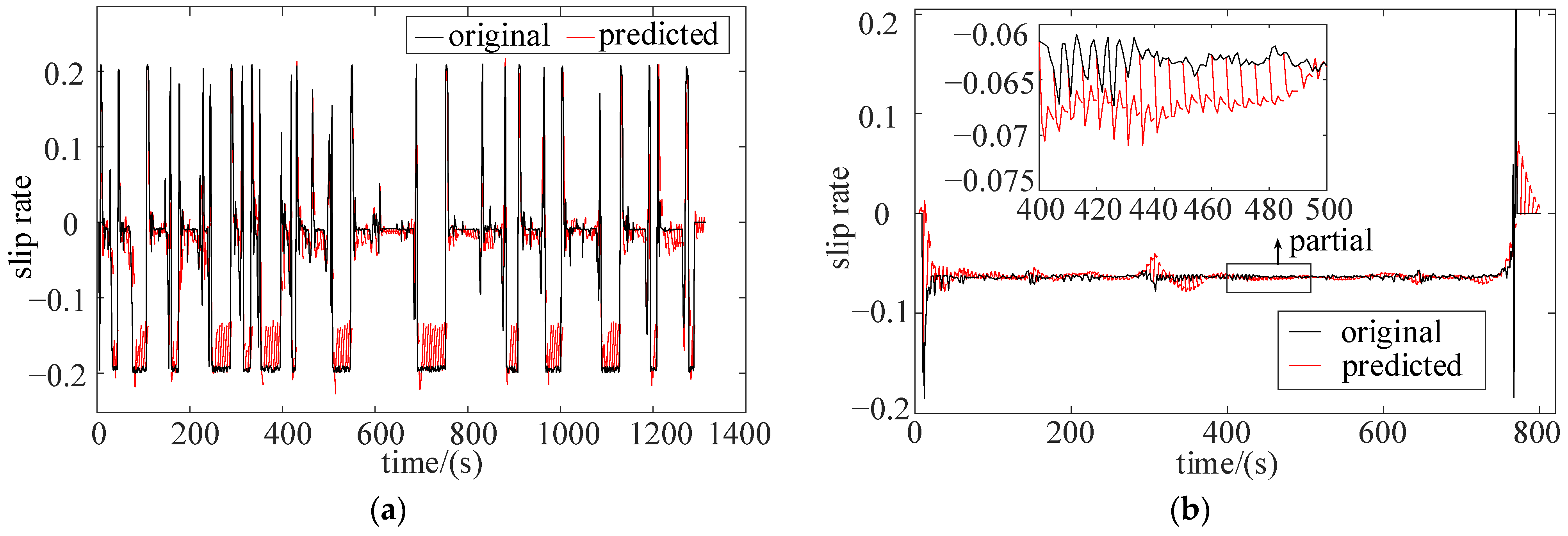

In addition, the trip information in the previous literature mainly involves the vehicle’s speed and slope, without considering the slip ratio. The slip ratio is related to wheel speed, which affects the calculation accuracy of power demand. In summary, comprehensive and accurate trip information should be acquired to provide an information foundation for global optimization energy management.

With the development of artificial intelligence (AI) and big data technology, data-driven strategy [

22] has emerged on the basis of optimal controls, such as reinforcement learning (RL) [

23,

24] and adaptive dynamic programming (ADP) [

25,

26]. The core is to deeply mine DP behavior to achieve self-learning energy management; however, this is restricted by high device configuration and complex algorithms. Based on the predictive trip information, optimization in a short-term horizon can be achieved, which can significantly improve the real-time performance of the DP strategy. However, a reference state of charge (

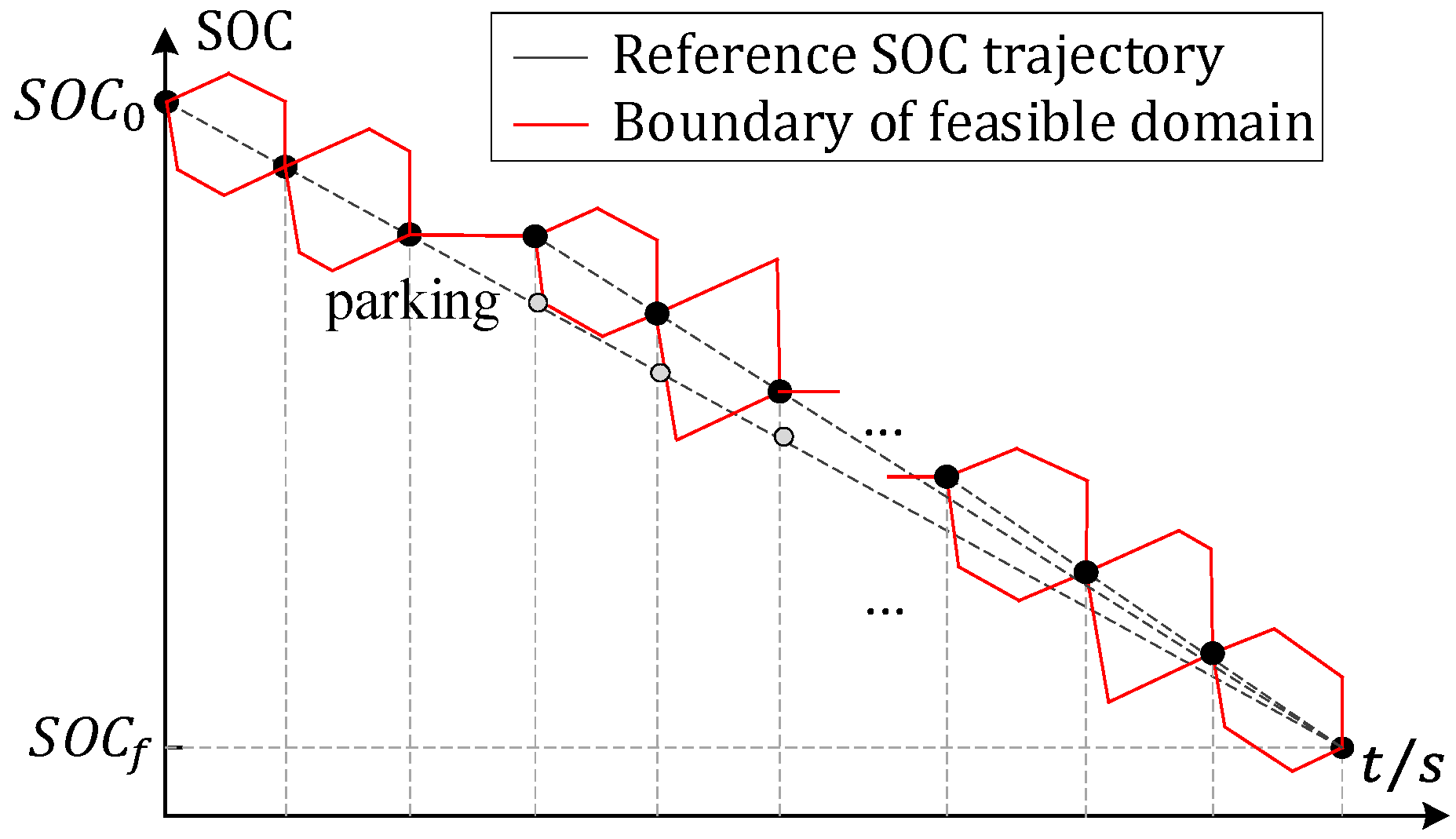

) trajectory should be pre-planned to ensure global optimality. Thence, how to generate an approximate reference SOC trajectory is crucial for predictive energy management.

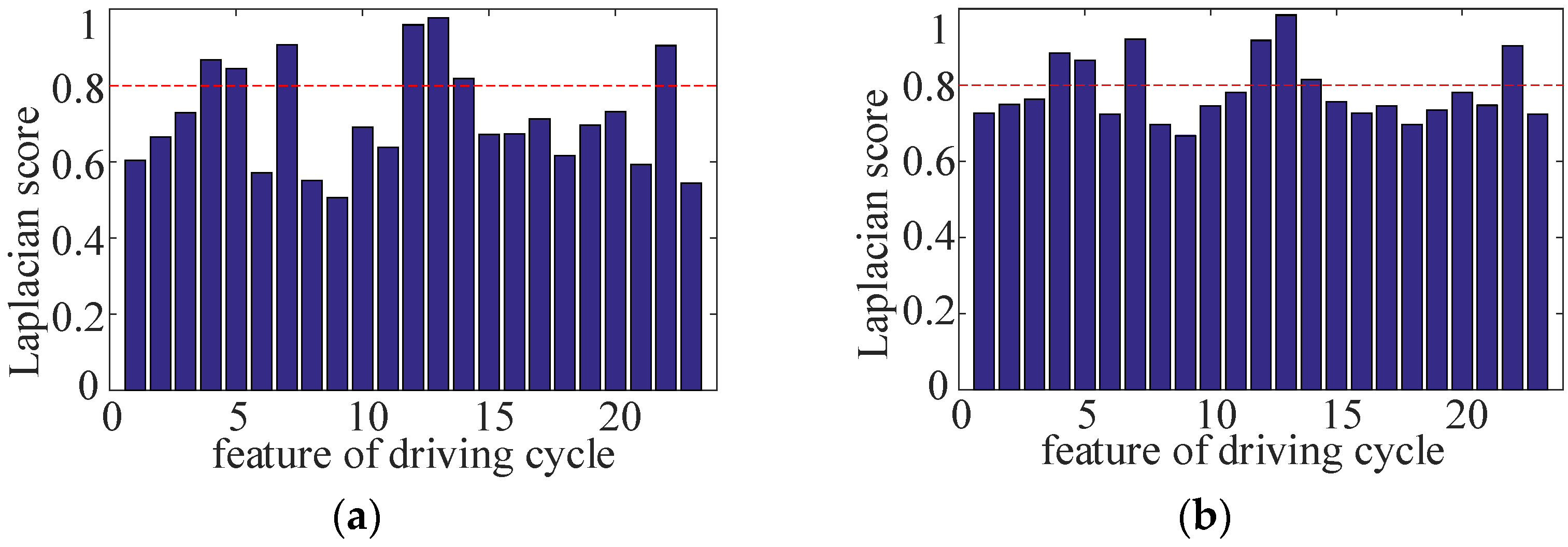

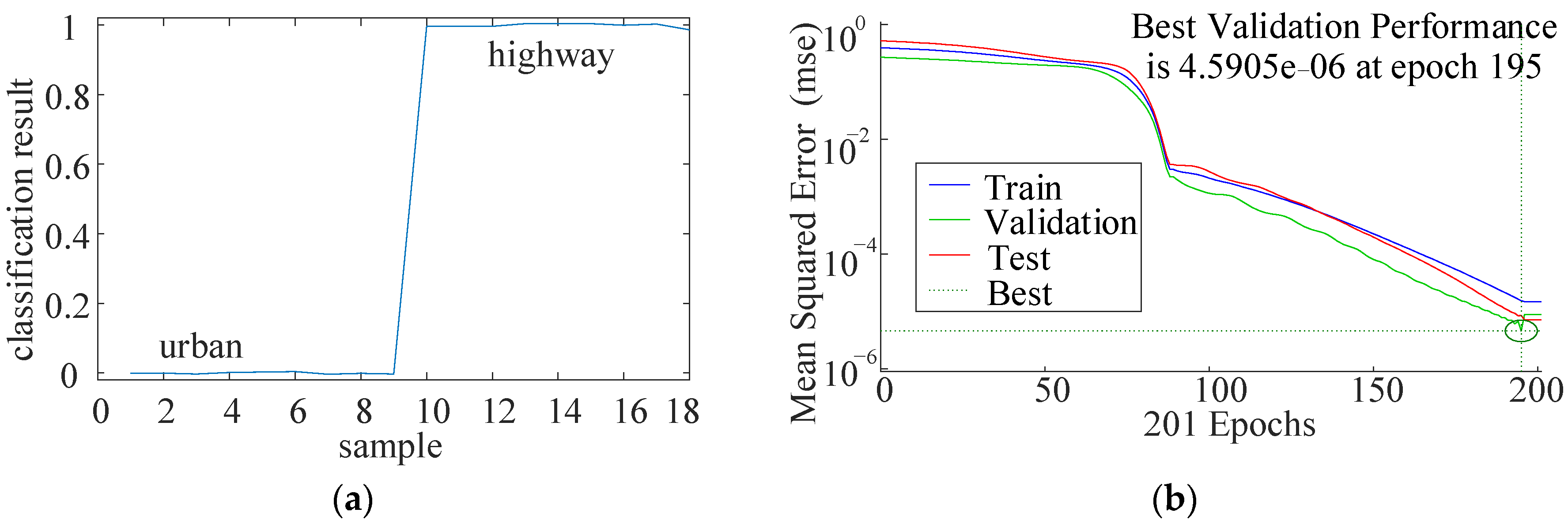

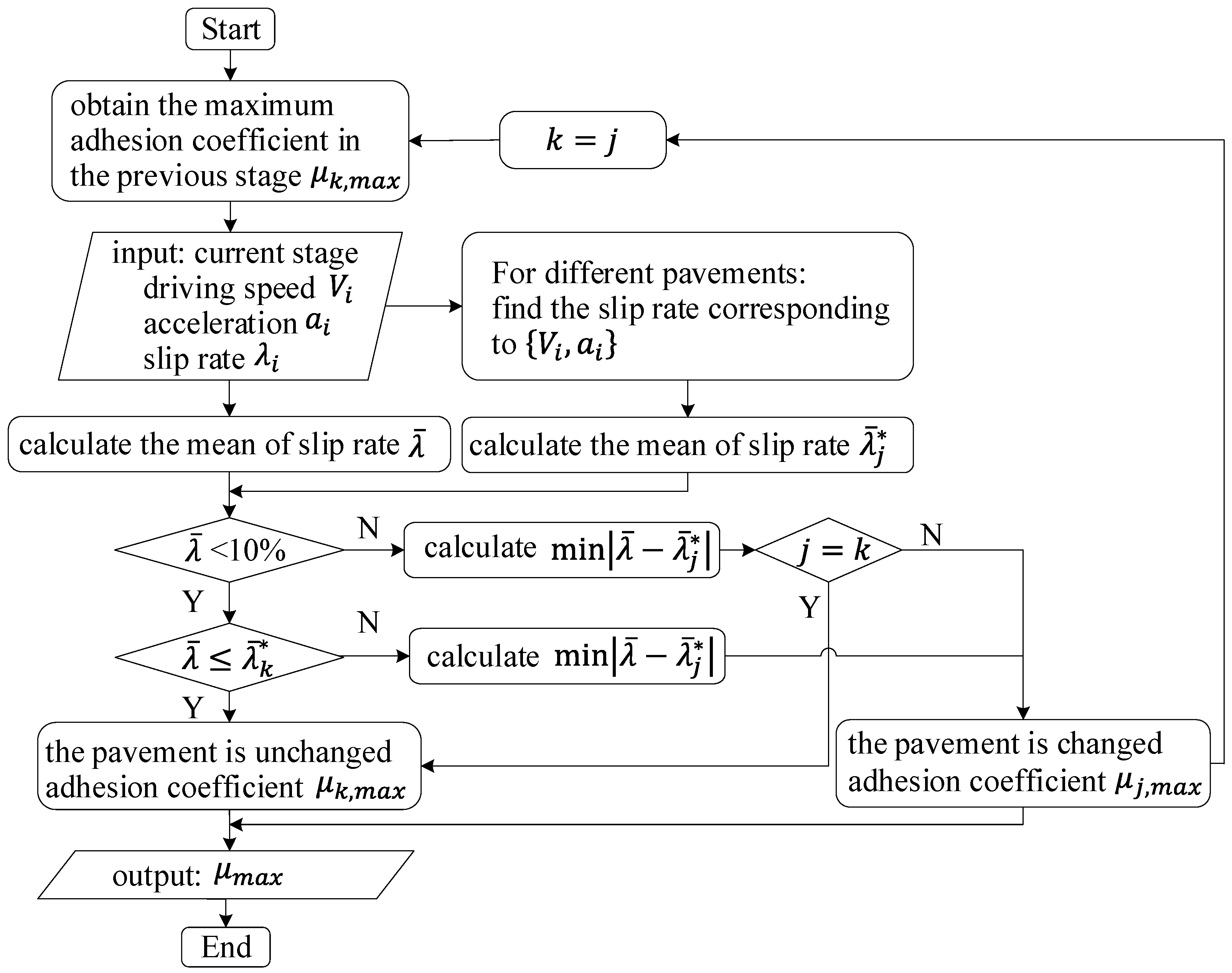

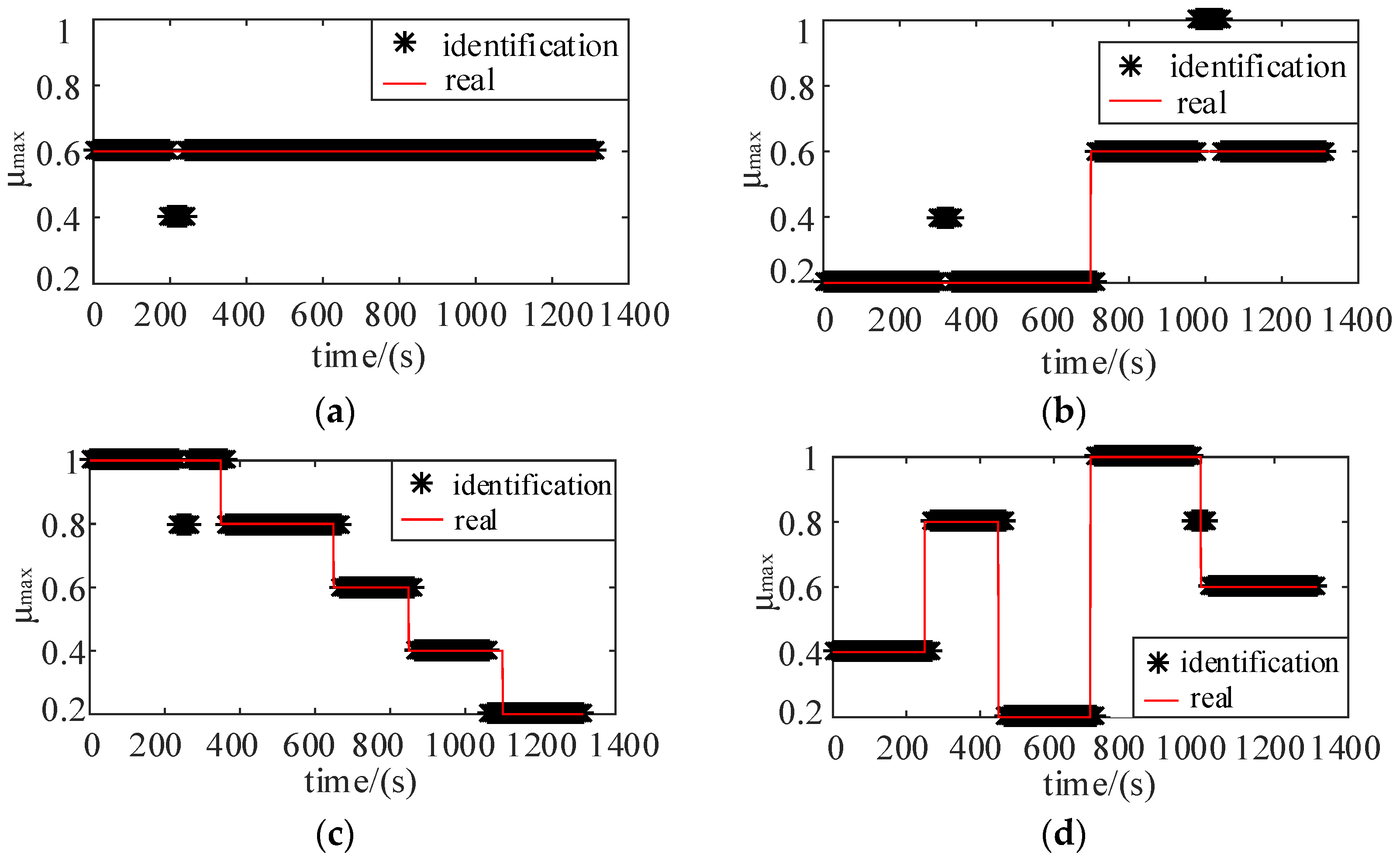

The target of this paper is to develop a predictive energy management strategy (PEMS) based on full-factor trip information, including vehicle speed, slope and slip ratio. First, the prediction model of the full-factor trip information is established. In particular, on the basis of the maximum adhesion coefficient identification model, the slip ratio is determined by the certain recurrent jump state network. Then, a predictive energy management strategy (PEMS) is developed, which generates a reference SOC trajectory to ensure global optimality. Finally, the influence of prediction time on prediction accuracy of the full-factor trip information is analyzed, which lays a foundation for determining the optimal prediction time to balance vehicle fuel economy and prediction accuracy.

The rest of this paper is organized as follows. The system architecture and powertrain modelling of PHEV is introduced in

Section 2. The prediction model of the full-factor trip information is established in

Section 3. Then, in

Section 4, a predictive energy management strategy is developed. Two case studies (UDDS and WLTC) are performed to verify the effectiveness of the proposed strategy. Several conclusions are drawn in

Section 5.

5. Conclusions

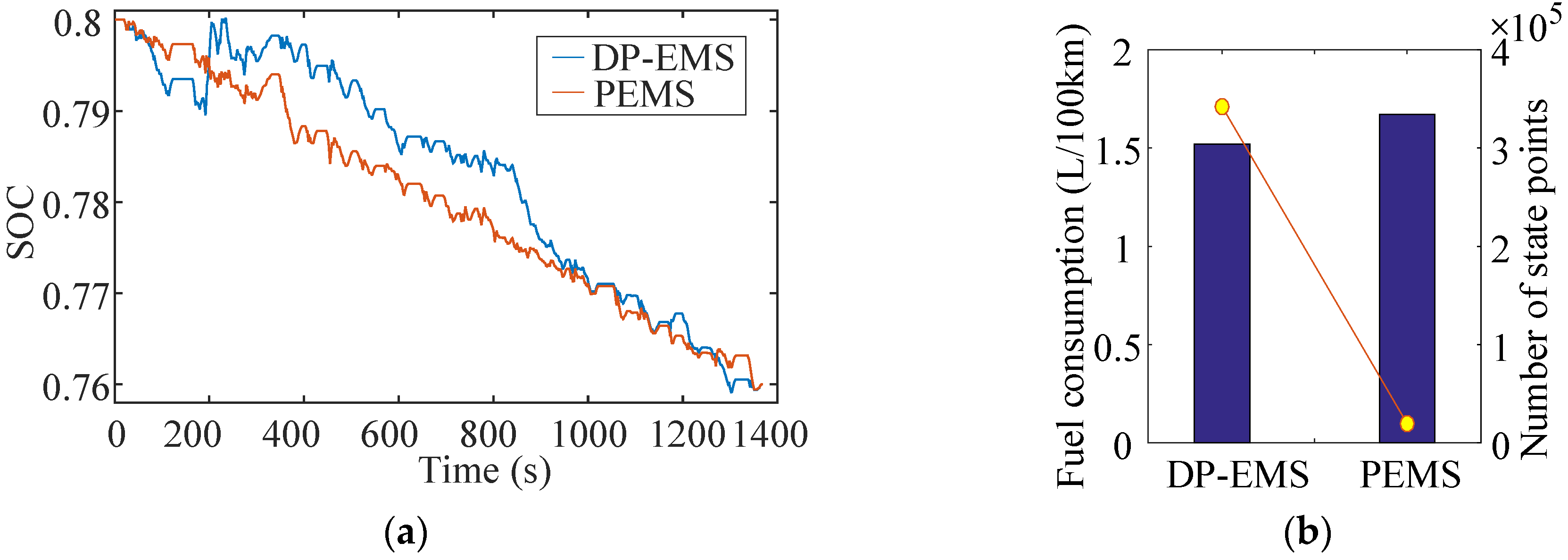

Dynamic programming (DP), as a typical global optimization method, can obtain the theoretical optimal fuel economy of multi-energy source vehicles (MEVs). To overcome the difficulties in the practical application of a traditional DP control strategy, a predictive energy management strategy (PEMS) is proposed based on the predictive trip information.

With the Intelligent Connected Vehicle (ICV) and Intelligent Transportation System (ITS), the data from the “drives–vehicles–roads” system are available. Based on the basic information, the prediction model of full-factor trip information is established. To be specific, combined with driving condition recognition, the vehicle speed is predicted based on the state transition probability matrix. Similarly, the slope at intersections is predicted based on the Markov model. On the basis of the above, the slip ratio is determined based on the identified maximum adhesion coefficient. Then, a predictive energy management strategy is developed, which pre-plans the terminal SOC of each prediction horizon to ensure the optimality. The reference SOC is determined by exploring the trend of the optimal SOC trajectories under multiple standard driving cycles.

To verify the effectiveness of the proposed model, two case studies (UDDS and WLTC) are given. The simulation results verify that the proposed strategy improves the vehicle economy while improving the global optimality as much as possible.