Fatigue Crack Monitoring of T-Type Joints in Steel Offshore Oil and Gas Jacket Platform

Abstract

1. Introduction

2. Fatigue Test

2.1. Selection of Joints

2.2. Experimental Process

2.3. Experimental Results

- (1)

- Due to the difference in welding quality, the welding strength of each specimen is different. The differences in the quality of the tested joints is mainly dependent on the welding quality.

- (2)

- The crack damage location is different. Some are in the weld area, and some are outside the weld area.

- (3)

- Due to the existence and influence of the initial defects of the specimen, the experimental results have a certain degree of uncertainty.

- (4)

- The fatigue crack damage observed in the experiment may be at different stages.

- (5)

- In the current study, the cracks were mainly detected in the heat-affected zone.

- (1)

- When making fatigue specimen, the welding conditions and quality of the specimens should be strictly controlled to ensure the consistency of the specimen performance.

- (2)

- Different types and positions of structural damage may have an impact on the fatigue results.

- (3)

- The impact of initial defects on the structure should be reduced as low as possible.

- (4)

- High-precision and sensitive fatigue crack observation devices are suggested to be applied in order to improve the accuracy of observations.

2.3.1. T-Type Plate Joint

2.3.2. T-Type Tube-Plate Joint

2.3.3. T-Type Tube Joint

3. Finite Element Analysis

3.1. Modelling

3.2. Mesh

3.3. Boundary Conditions and Applied Load

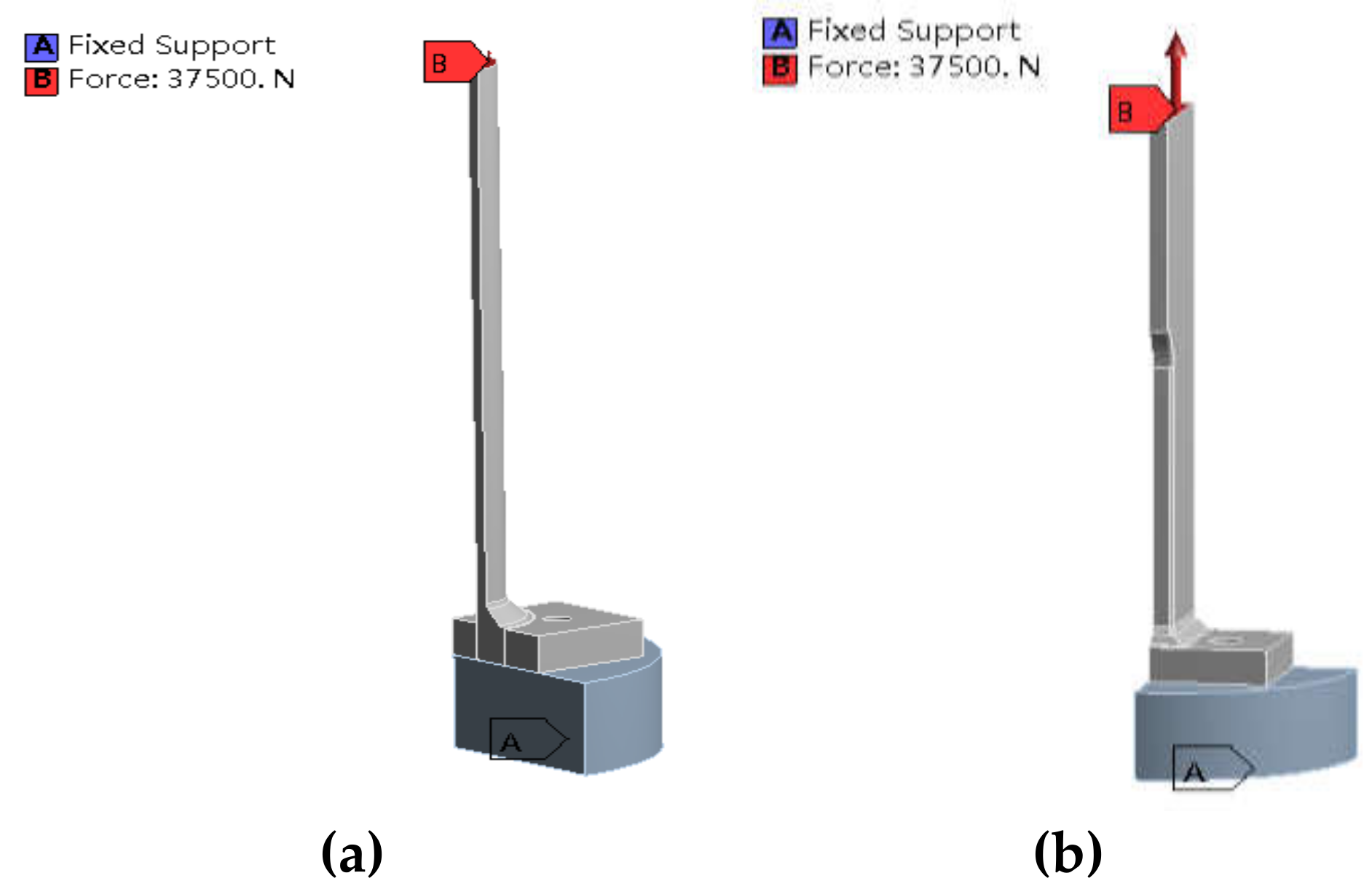

- (1)

- T-type plate joint: the boundary conditions are set as shown in Figure 13a. The A end is fixed and the B end is loaded.

- (2)

- T-type tube-plate joint: the boundary conditions are set as shown in Figure 13b. The A end is fixed, and the B end is loaded.

- (3)

- T-type tube joint: The boundary conditions are set as shown in Figure 13c. Both sides of the lower pipe are fixed to simulate clamping, and the B end is loaded.

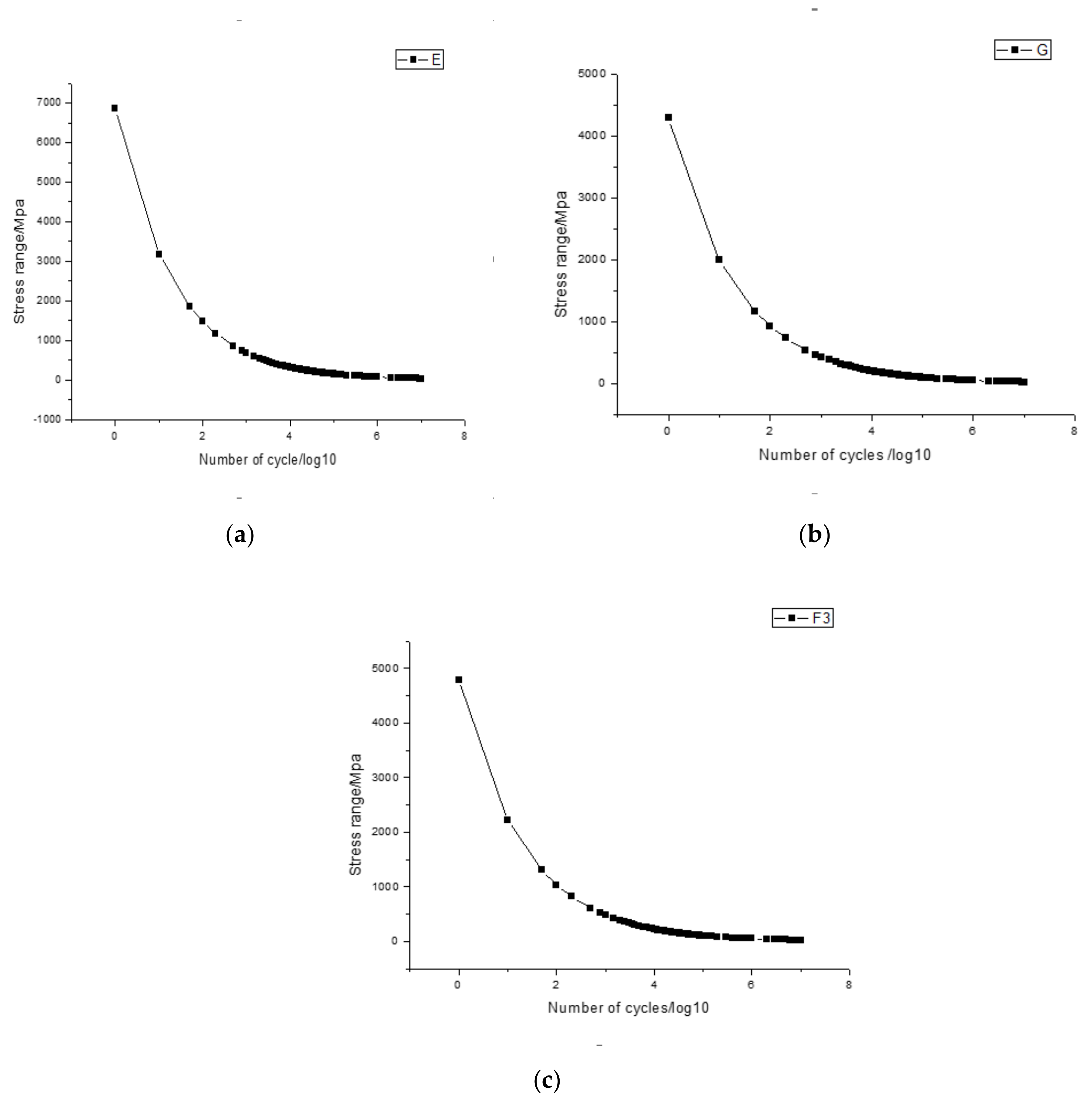

3.4. S-N Curve

3.5. Discussion

3.5.1. Fatigue Damage Location

- (1)

- T-type plate joint

- (2)

- T-type tube-plate joint

- (3)

- T-type tube joint

3.5.2. Fatigue Life

4. Conclusions

- (1)

- In the fatigue test, the fatigue crack damage can be located relatively accurately through the stained flaw detection method, combined with the digital microscope to observe the crack damage of the specimen, which can detect micro scale cracks more effectively. A crack of the size 0.463 mm is detected in the current study.

- (2)

- In the early stage of fatigue crack development of joints, fatigue damage is often linear small-scale cracks (crack lengths between 0.463 mm and 14.640 mm are detected in the current study), and the propagation direction often expands along the welding direction. Early cracks when grows more are changed in a broken line shape, and slowly change after reaching a certain size, then other new cracks are also formed.

- (3)

- The fatigue cracks of the three types of joints are the first to appear at the weld toe and its vicinity, and they spread along the welding direction. The fatigue damage location of T-type plate joint and T-type tube-plate joint is more concentrated in the upper weld toe area, and the fatigue damage location of the T-type tube joint is closer to the lower weld toe area. In engineering practice, the above-mentioned fatigue damage areas should be taken into consideration.

- (4)

- Through finite element analysis, the high stress and strain areas of the three types of typical joints are determined. The dangerous areas appear in the weld area of the joint connection. After comparing the sensitive areas of the above joints. The test results are basically consistent, which proves the reliability of the finite element method in analyzing the fatigue damage location.

- (5)

- The finite element calculation results and the test results are compared and analyzed. The results of the T-type tube joint are closer, and the results of T-type plate joint and T-type tube-plate joint are relatively small and still have a relatively large safety margin, which proves that the use of finite element analysis to predict fatigue life will provide large safety margin and thus it is more safe to predict the fatigue life of the joints by finite element method in engineering applications.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Madsen, H.O.; Skjong, R.K.; Tallin, A.G. Probabilistic fatigue crack growth analysis of offshore structures, with reliability updating through inspection. Proceedings of Marine Structural Symposium, Arlington, VA, USA, 5–6 October 1987; pp. 45–55. [Google Scholar]

- Melchers, R.E. Structural Reliability Analysis and Prediction; John Wiley: Hoboken, NJ, USA, 1999. [Google Scholar]

- Moan, T. Reliability and risk analysis for design and operations planning of offshore structures. Proceedings of 6th ICOSSAR, Structural Safety and Reliability, Balkema, Rotterdam, The Netherlands, 9–13 August 1994; Volume I, pp. 21–43. [Google Scholar]

- Hirdaris, S.; Bai, W.; Dessi, D.; Ergin, A.; Gu, X.; Hermundstad, O.; Huijsmans, R.; Iijima, K.; Nielsen, U.; Parunov, J.; et al. Loads for use in the design of ships and offshore structures. Ocean. Eng. 2014, 78, 131–174. [Google Scholar] [CrossRef]

- Pinheiro, B.D.C.; Pasqualino, I.P. Fatigue analysis of damaged steel pipelines under cyclic internal pressure. Int. J. Fatigue 2009, 31, 962–973. [Google Scholar] [CrossRef]

- Song, X.; Wang, S. A novel spectral moments equivalence based lumping block method for efficient estimation of offshore structural fatigue damage. Int. J. Fatigue 2019, 118, 162–175. [Google Scholar] [CrossRef]

- Wisch, D.J. Fixed steel offshore structure design-past, present & future. In Proceedings of the offshore technology conference, Houston, TX, USA, 4–7 May 1998; pp. 317–323. [Google Scholar]

- Waegter, J.; Vissing-Jorgensen, C.; Thesbjerg, L.; Krenk, S. Pushover analysis of framed offshore structures. In Proceedings of the 17th international conference on offshore mechanics and arctic engineering, Lisbon, Portugal, 5–9 July 1998; pp. 1–6. [Google Scholar]

- Rodrigues, P.F.N.; Jacob, B.P. Collapse analysis of steel jacket structures for offshore oil exploitation. J. Constr. Steel Res. 2005, 61, 1147–1171. [Google Scholar] [CrossRef]

- Lee, M.M.K.; Llewelyn-Parry, A. Strength prediction for ring-stiffened DT-joints in offshore jacket structures. Eng. Struct. 2005, 27, 421–430. [Google Scholar] [CrossRef]

- Dong, W.; Moan, T.; Gao, Z. Fatigue reliability analysis of the jacket support structure for offshore wind turbine considering the effect of corrosion and inspection. Reliab. Eng. Syst. Saf. 2012, 106, 11–27. [Google Scholar] [CrossRef]

- Paik, J.K.; Thayamballi, A.K. Ultimate Strength of Ageing Ships. Proceedings of the Institution of Mechanical Engineers, Part M: Journal of Engineering for the Maritime Environment; Sage Publications: London, UK, 2002; pp. 57–77. [Google Scholar]

- Akpan, U.O.; Koko, T.S.; Ayyub, B.; Dunbar, T.E. Risk assessment of ageing ship hull structures in the presence of corrosion and fatigue. Mar. Struct. 2002, 15, 211–231. [Google Scholar] [CrossRef]

- Soares, C.G.; Garbatov, Y. Reliability of maintained ship hull girders subjected to corrosion and fatigue. Struct. Saf. 1998, 20, 201–219. [Google Scholar] [CrossRef]

- Paik, J.; Wang, G.; Thayamballi, K.; Lee, J.; Park, Y. Time-dependent risk assessment of aging ships accounting for general/pit corrosion, fatigue cracking and local denting damage. Trans. Soc. Nav. Architects Mar. Eng. 2003, 111, 159–197. [Google Scholar]

- Paik, J.K.; Lee, J.M.; Ko, M.J. Ultimate shear strength of plate elements with pit corrosion wastage. Thin-Wall Struct. 2004, 42, 1161–1176. [Google Scholar] [CrossRef]

- Paik, J.K.; Kumar, Y.S.; Lee, J.M. Ultimate strength of cracked plate elements under axial compression or tension. Thin-Wall Struct. 2005, 43, 237–272. [Google Scholar] [CrossRef]

- Saad-Eldeen, S.; Garbatov, Y.; Soares, C.G. Experimental assessment of the ultimate strength of a box girder subjected to severe corrosion. Mar. Struct. 2011, 24, 338–357. [Google Scholar]

- Saad-Eldeen, S.; Garbatov, Y.; Soares, C.G. Ultimate strength assessment of corroded box girders. Ocean Eng. 2013, 58, 35–47. [Google Scholar] [CrossRef]

- Correia, J.A.; Ferradosa, T.; Castro, J.M.; Fantuzzi, N.; De Jesus, A.M. Editorial: Renewable Energy and Oceanic Structures: Part I. In Proceedings of the Institution of Civil Engineers—Maritime Engineering; Thomas Telford Ltd.: London, UK, 2019; Volume 172, pp. 1–2. [Google Scholar] [CrossRef]

- Correia, J.A.; Ferradosa, T.; Castro, J.M.; Pavlou, D.G.; De Jesus, A.M. Editorial: Renewable Energy and Oceanic Structures: Part II. In Proceedings of the Proceedings of the Institution of Civil Engineers—Maritime Engineering; Thomas Telford Ltd.: London, UK, 2019; Volume 172, pp. 71–72. [Google Scholar]

- Rebelo, C.; Correia, J.; Baniotopoulos, C.; De Jesus, A. Wind energy technology (WINERCOST). Wind. Eng. 2018, 42, 267. [Google Scholar] [CrossRef]

- Jimenez-Martinez, M. Fatigue of offshore structures: A review of statistical fatigue damage assessment for stochastic loadings. Int. J. Fatigue 2020, 132, 105327. [Google Scholar] [CrossRef]

- Moghaddam, B.T.; Hamedany, A.M.; Mehmanparast, A.; Brennan, F.; Nikbin, K.; Davies, C.M. Numerical analysis of pitting corrosion fatigue in floating offshore wind turbine foundations. Procedia Struct. Integr. 2019, 17, 64–71. [Google Scholar] [CrossRef]

- Toft, H.S.; Svenningsen, L.; Sørensen, J.D.; Moser, W.; Thøgersen, M.L. Uncertainty in wind climate parameters and their influence on wind turbine fatigue loads. Renew. Energy 2016, 90, 352–361. [Google Scholar] [CrossRef]

- Velarde, J.; Kramhøft, C.; Sørensen, J.D. Global sensitivity analysis of offshore wind turbine foundation fatigue loads. Renew. Energy 2019, 140, 177–189. [Google Scholar] [CrossRef]

- Zhu, S.-P.; Liao, D.; Liu, Q.; Correia, J.A.; De Jesus, A.M. Nonlinear fatigue damage accumulation: Isodamage curve-based model and life prediction aspects. Int. J. Fatigue 2019, 128, 105185. [Google Scholar] [CrossRef]

- Farhan, M.; Mohammadi, M.R.S.; Correia, J.A.; Rebelo, C. Transition piece design for an onshore hybrid wind turbine with multiaxial fatigue life estimation. Wind. Eng. 2018, 42, 286–303. [Google Scholar] [CrossRef]

- Shabakhty, N.; Khansari, A. Fatigue Analysis of a Jacket Structure to Linear and Weakly Nonlinear Random Waves. J. Offshore Mech. Arct. Eng. 2019, 141, 1–29. [Google Scholar] [CrossRef]

- Meng, D.; Hu, Z.; Wu, P.; Zhu, S.-P.; Correia, J.A.F.O.; De Jesus, A.M.P. Reliability-based optimisation for offshore structures using saddlepoint approximation. Proc. Inst. Civ. Eng. Marit. Eng. 2020, 173, 33–42. [Google Scholar] [CrossRef]

- Zhang, M.; Wu, Q.; Wu, Y.; Du, J.; Xu, Y.; Xu, X. Fatigue damage analysis for offshore wind turbine considering coupled loads effects. In Proceedings of the 28th International Ocean and Polar Engineering Conference., Sapporo, Japan, 10–15 June 2018. [Google Scholar]

- Fan, T.Y.; Huang, C.C.; Chu, T.L. Fatigue analysis for jacket type support structure of offshore wind turbine under local environmental conditions in Taiwan. In Proceedings of the 27th International Ocean and Polar Engineering Conference, San Francisco, CA, USA, 25–30 June 2017. [Google Scholar]

- Yeter, B.; Garbatov, Y.; Soares, C.G. Fatigue damage assessment of fixed offshore wind turbine tripod support structures. Eng. Struct. 2015, 101, 518–528. [Google Scholar] [CrossRef]

- Mendes, P.; Correia, J.A.F.O.; Mourão, A.; Pereira, R.; Fantuzzi, N.; De Jesus, A.; Calçada, R. Fatigue Assessments of a Jacket-Type Offshore Structure Based on Static and Dynamic Analyses. Pract. Period. Struct. Des. Constr. 2021, 26, 04020054. [Google Scholar] [CrossRef]

- Abd Alhusein, T.A.; Kadim, J.A. Fatigue Analysis of fixed jacket platform using FEM. Inter. J. Scie. Eng. Res. 2020, 11, 2229–5518. [Google Scholar]

- Lin, T.-Y.; Zhao, Y.-Q.; Huang, H.-H. Representative Environmental Condition for Fatigue Analysis of Offshore Jacket Substructure. Energies 2020, 13, 5494. [Google Scholar] [CrossRef]

- Sam, M.-T. Offshore Heavy Lift Rigging Analysis Using Spreadsheet. Pract. Period. Struct. Des. Constr. 2009, 14, 63–69. [Google Scholar] [CrossRef]

- Dawood, N.; Marzouk, H. Design Guidelines for the Cracking Control of Thick High-Strength Concrete Members. Pract. Period. Struct. Des. Constr. 2013, 18, 122–130. [Google Scholar] [CrossRef]

- Reddy, D.V.; Bolivar, J.C.; Sobhan, K. Durability-Based Ranking of Typical Structural Repairs for Corrosion-Damaged Marine Piles. Pract. Period. Struct. Des. Constr. 2013, 18, 225–237. [Google Scholar] [CrossRef]

- Tang, P.; Bittner, R.B. Use of Value Engineering to Develop Creative Design Solutions for Marine Construction Projects. Pract. Period. Struct. Des. Constr. 2014, 19, 129–136. [Google Scholar] [CrossRef]

- Gaidai, O.; Naess, A. Nonlinear Effects on Fatigue Analysis for Fixed Offshore Structures. J. Offshore Mech. Arct. Eng. 2008, 130, 031009. [Google Scholar] [CrossRef]

- Fan, T.-Y.; Lin, C.-Y.; Huang, C.-C.; Chu, T.-L. Time-Domain Fatigue Analysis of Multi-planar Tubular Joints for a Jacket-Type Substructure of Offshore Wind Turbines. Int. J. Offshore Polar Eng. 2020, 30, 112–119. [Google Scholar] [CrossRef]

- Liao, D.; Zhu, S.; Correia, J.A.; De Jesus, A.M.; Berto, F. Recent advances on notch effects in metal fatigue: A review. Fatigue Fract. Eng. Mater. Struct. 2020, 43, 637–659. [Google Scholar] [CrossRef]

- Ahmadi, H.; Lotfollahi-Yaghin, M.A. Effect of SCFs on S–N based fatigue reliability of multi-planar tubular DKT-joints of offshore jacket-type structures. Ships Offshore Struct. 2013, 8, 55–72. [Google Scholar] [CrossRef]

- Ahmadi, H.; Lotfollahi-Yaghin, M.A.; Aminfar, M.H. The development of fatigue design formulas for the outer brace SCFs in offshore three-planar tubular KT-joints. Thin-Walled Struct. 2012, 58, 67–78. [Google Scholar] [CrossRef]

- Barbosa, J.F.; Correia, J.A.; Júnior, R.F.; Zhu, S.-P.; De Jesus, A.M. Probabilistic S-N fields based on statistical distributions applied to metallic and composite materials: State of the art. Adv. Mech. Eng. 2019, 11, 168781401987039. [Google Scholar] [CrossRef]

- Correia, J.A.F.O.; Correia, M.; Holm, M.; Ekeborg, J.; Lesiuk, G.; Castro, J.M.; De Jesus, A.M.P.; Calçada, R. Evaluation of Fatigue Design Curves for a Double-Side Welded Connection Used in Offshore Applications. Mater. Fabr. 2018, 6A. [Google Scholar] [CrossRef]

- Dong, P.; Hong, J.K. Fatigue of Tubular Joints: Hot Spot Stress Method Revisited. J. Offshore Mech. Arct. Eng. 2012, 134, 031602. [Google Scholar] [CrossRef]

- Khalili, H.; Oterkus, S.; Barltrop, N.; Bharadwaj, U. Updating the Distributions of Uncertain Parameters Involved in Fatigue Analysis. J. Mar. Sci. Eng. 2020, 8, 778. [Google Scholar] [CrossRef]

- Chryssanthopoulos, M.; Righiniotis, T. Fatigue reliability of welded steel structures. J. Constr. Steel Res. 2006, 62, 1199–1209. [Google Scholar] [CrossRef]

- Wirsching, P.H.; Chen, Y.-N. Considerations of probability-based fatigue design for marine structures. Mar. Struct. 1988, 1, 23–45. [Google Scholar] [CrossRef]

- Zhao, Z.; Haldar, A.; Breen, F.L. Fatigue?Reliability Updating through Inspections of Steel Bridges. J. Struct. Eng. 1994, 120, 1624–1642. [Google Scholar] [CrossRef]

- Soares, C.G.; Garbatov, Y. Fatigue reliability of the ship hull girder accounting for inspection and repair. Reliab. Eng. Syst. Saf. 1996, 51, 341–351. [Google Scholar] [CrossRef]

- Rajasankar, J.; Iyer, N.R.; Rao, T.A. Structural integrity assessment of offshore tubular joints based on reliability analysis. Int. J. Fatigue 2003, 25, 609–619. [Google Scholar] [CrossRef]

- Na, W.S.; Baek, J. A Review of the Piezoelectric Electromechanical Impedance Based Structural Health Monitoring Technique for Engineering Structures. Sensors 2018, 18, 1307. [Google Scholar] [CrossRef]

- Liang, C.; Sun, F.P.; Rogers, C.A. Coupled Electro-Mechanical Analysis of Adaptive Material Systems—Determination of the Actuator Power Consumption and System Energy Transfer. J. Intell. Mater. Syst. Struct. 1994, 5, 12–20. [Google Scholar] [CrossRef]

- Grabulov, V.; Blačić, I.; Radović, A.; Sedmak, S. Tough ness and ductility of high strength steels welded joints. Struct. Integrity Life 2008, 8, 181–190. [Google Scholar]

- Tawengi, A.S.; Sedmak, A.; Grabulov, V. Cold weld cracking susceptibility of high strength low alloyed HSLA steel Nionikral 70. Metalurgija 2014, 53, 624–626. [Google Scholar]

- Qiang, X.; Bijlaard, F.S.; Kolstein, H. Elevated-temperature mechanical properties of high strength structural steel S460N: Experimental study and recommendations for fire-resistance design. Fire Saf. J. 2013, 55, 15–21. [Google Scholar] [CrossRef]

- Topaç, M.; Günal, H.; Kuralay, N. Fatigue failure prediction of a rear axle housing prototype by using finite element analysis. Eng. Fail. Anal. 2009, 16, 1474–1482. [Google Scholar] [CrossRef]

- Omajane, J.; Martikainen, J.; Kah, P. Weldability of thermo-mechanically rolled steels used in oil and gas offshore structures. Int. J. Eng. Sci. 2014, 3, 62–69. [Google Scholar]

- Skowrońska, B.; Szulc, J.; Chmielewski, T.; Sałaciński, T.; Świercz, R. Properties and microstructure of hybride Plasma+MAG welded joints of thermomechanically treated S700MC steel. In Proceedings of the 27th Anniversary International Conference on Metallurgy and Materials (METAL), Brno, Czech Republic, 23–25 May 2018. [Google Scholar]

- Pańcikiewicz, K.; Tuz, L.; Żurek, Z.; Rakoczy, Ł. Optimization of Filler Metals Consumption in the Production of Welded Steel Structures. Adv. Mater. Sci. 2016, 16, 27–34. [Google Scholar] [CrossRef][Green Version]

- Sajek, A.; Nowacki, J. Comparative evaluation of various experimental and numerical simulation methods for determination of t 8/5 cooling times in HPAW process weldments. Arch. Civ. Mech. Eng. 2018, 18, 583–591. [Google Scholar]

- Górka, J. Assessment of Steel Subjected to the Thermomechanical Control Process with Respect to Weldability. Metals 2018, 8, 169. [Google Scholar] [CrossRef]

- Łabanowski, J.; Prokop-Strzelczyńska, K.; Rogalski, G.; Fydrych, D. The Effect of Wet Underwater Welding on Cold Cracking Susceptibility of Duplex Stainless Steel. Adv. Mater. Sci. 2016, 16, 68–77. [Google Scholar] [CrossRef]

- Li, H.; Liu, D.; Guo, N.; Chen, H.; Du, Y.; Feng, J. The effect of alumino-thermic addition on underwater wet welding process stability. J. Mater. Process. Technol. 2017, 245, 149–156. [Google Scholar] [CrossRef]

- Purnama, D.; Winarto, W.; Susilo, F.H. Human-dedicated sustainable product and process design: Materials, resources, and energy. In Proceedings of the 4th International Conference on Engineering, Technology, and Industrial Application (ICETIA), Surakarta, Indonesia, 13 December 2017; Volume 1977, p. 030015. [Google Scholar] [CrossRef]

- Tomków, J.; Fydrych, D.; Rogalski, G.; Łabanowski, J. Temper Bead Welding of S460N Steel in Wet Welding Conditions. Adv. Mater. Sci. 2018, 18, 5–14. [Google Scholar] [CrossRef]

- Tomków, J.; Fydrych, D.; Rogalski, G. Dissimilar underwater wet welding of HSLA steels. Int. J. Adv. Manuf. Technol. 2020, 109, 717–725. [Google Scholar] [CrossRef]

- Yin, Y.; Yang, X.; Cui, L.; Cao, J.; Xu, W. Microstructure and mechanical properties of underwater friction taper plug weld on X65 steel with carbon and stainless steel plugs. Sci. Technol. Weld. Join. 2016, 21, 259–266. [Google Scholar] [CrossRef]

- Heirani, F.; Abbasi, A.; Ardestani, M. Effects of processing parameters on microstructure and mechanical behaviors of underwater friction stir welding of Al5083 alloy. J. Manuf. Process. 2017, 25, 77–84. [Google Scholar] [CrossRef]

- Rogalski, G.; Fydrych, D.; Łabanowski, J. Underwater Wet Repair Welding of API 5L X65M Pipeline Steel. Pol. Marit. Res. 2017, 24, 188–194. [Google Scholar] [CrossRef]

- Chen, H.; Guo, N.; Shi, X.; Du, Y.; Feng, J.; Wang, G. Effect of water flow on the arc stability and metal transfer in underwater flux-cored wet welding. J. Manuf. Process. 2018, 31, 103–115. [Google Scholar] [CrossRef]

- Shi, Y.; Lin, S.; Hu, Y.; Yi, Y.; Li, Z. Porosity and Microstructure of Underwater Wet FCAW of Duplex Stainless Steel. Met. Microstruct. Anal. 2017, 6, 383–389. [Google Scholar] [CrossRef]

- Fydrych, D.; Łabanowski, J.; Tomków, J.; Rogalski, G. Cold Cracking Of Underwater Wet Welded S355G10+N High Strength Steel. Adv. Mater. Sci. 2015, 15, 48–56. [Google Scholar] [CrossRef]

- Maksimov, S. Underwater arc welding of higher strength low-alloy steels. Weld. Int. 2010, 24, 449–454. [Google Scholar] [CrossRef]

- Hart, P.H.M. Weld metal hydrogen cracking in pipeline Girth welds. In Proceedings of the 1st International Conference, Wollongong, NSW, Australia, 1–2 March 1999. [Google Scholar]

- Wilhelmsen Ships Service. Defects - Hydrogen Cracks in Steels - Prevention and Best Practice. Available online: https://www.twi-global.com/technical-knowledge/job-knowledge/defects-hydrogen-cracks-in-steels-prevention-and-best-practice-046 (accessed on 4 May 2021).

- Hydrogen Embrittlement an Over View from a Mecha Nical Fastenings Aspect, FERA 17 Nothwick Crescent Solihull West Midlands B91 3TU. 2000. Available online: https://www.diva-portal.org/smash/get/diva2:1024622/FULLTEXT01.pdf (accessed on 4 May 2021).

- Urbikain, G.; Perez, J.M.; López de Lacalle, L.N.; Andueza, A. Combination of friction drilling and form tapping processes on dissimilar materials for making nutless joints. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2018, 232, 1007–1020. [Google Scholar] [CrossRef]

- Dixit, U.; Joshi, S.; Davim, J. Incorporation of material behavior in modeling of metal forming and machining processes: A review. Mater. Des. 2011, 32, 3655–3670. [Google Scholar] [CrossRef]

- Silva, C.A.; Rosa, P.A.R.; Martins, P.A.F. Innovative testing machines and methodologies for the mechanical characterization of materials. Exp. Tech. 2016, 40, 569–581. [Google Scholar] [CrossRef]

- Krahmer, D.M.; Polvorosa, R.; De Lacalle, L.N.L.; Alonso-Pinillos, U.; Abate, G.; Riu, F. Alternatives for Specimen Manufacturing in Tensile Testing of Steel Plates. Exp. Tech. 2016, 40, 1555–1565. [Google Scholar] [CrossRef]

- Khan, S.; Al-Shuhail, A.A.; Khulief, Y.A. Numerical modeling of the geomechanical behavior of Ghawar Arab-D carbonate petroleum reservoir undergoing CO2 injection. Environ. Earth Sci. 2016, 75, 1–15. [Google Scholar] [CrossRef]

- Israf, U.D.; Usman, M.; Khan, S.; Aasif, H.; Alotaibi, M.A.; Alharthi, A.I.; Centi, G. Prospects for a green methanol thermo-catalytic process from CO2 by using MOFs based materials: A mini-review. J. CO2 Util. 2020. [Google Scholar] [CrossRef]

- Khan, S.; Khulief, Y.A.; Al-Shuhail, A.A. The effect of injection well arrangement on CO2 injection into carbonate petroleum reservoir. Int. J. Glob. Warm. 2018, 14. [Google Scholar] [CrossRef]

- Garba, M.D.; Muhammad, U.; Khan, S.; Farrukh, K.; Ahmad, S.; Muhamad, G.; Akram, F.E.; Muhammad, H. CO2 towards fuels: A review of catalytic conversion of carbon dioxide to hydrocarbons. J. Environ. Chem. Eng. 2020. [Google Scholar] [CrossRef]

- Khan, S.; Khulief, Y.A.; Al-Shuhail, A.A. Numerical modeling of the geomechanical behavior of Biyadh Reservoir undergoing CO2 injection. Int. J. Geomech. 2017, 17, 1–12. [Google Scholar] [CrossRef]

- Khan, S.; Khulief, Y.A.; Al-Shuhail, A.A. Alleviation of pore pressure buildup and ground uplift during carbon dioxide injection into Ghawar Arab-D carbonate naturally fractured reservoir. Environ. Earth Sci. 2018, 77. [Google Scholar] [CrossRef]

- Hamad, H.; Bai, Y.; Ali, L. A risk-based inspection planning methodology for integrity management of subsea oil and gas pipelines. Ships Offshore Struct. 2020. [Google Scholar] [CrossRef]

- Ali, L.; Bai, Y.; Jin, S. Risk Assessment and reliability analysis of subsea production Systems. In Proceedings of the ASME 2020 39th International Conference on Ocean, Offshore and Arctic Engineering, Virtual Conference, 3–7 August 2020. [Google Scholar] [CrossRef]

- Ali, L.; Bai, Y.; Xu, Y. A methodology to derive design metocean internal wave current for submarine structures. Ships Offshore Struct. 2020. [Google Scholar] [CrossRef]

- Ali, L.; Nawaz, A.; Bai, Y. Numerical simulations of GFRP-Reinforced columns having polypropylene and polyvinyl alcohol fibers. Hindawi Complex. 2020. [Google Scholar] [CrossRef]

- Jimenez, M. DURABILITY TESTS: Statistical analysIs for variable amplitude loads. Trans. Can. Soc. Mech. Eng. 2017, 41, 910–921. [Google Scholar] [CrossRef]

- ISO 12107, Metallic materials—Fatigue Testing—Statistical Planning and Analysis of Data. Available online: https://www.iso.org/standard/50242.html (accessed on 4 May 2021).

- Department of Energy, Background to New Fatigue Design UKOSRP II/PSC/P85-2T, from 16/9/84 to 5/1/85. guidance for steel welded joints in offshore structures, Report of the Department of Energy Guidance Notes Revision Draft Panel. HMSO, 1984. Available online: https://www.amazon.com/Background-fatigue-guidance-offshore-structures/dp/0114114560 (accessed on 4 May 2021).

- Guidance on Design, Construction and Certification, 4th ed.; HMSO, Department of Energy: London, UK, 1990; (including amendment No. 3 published in February 1995).

- Wylde, J.G. Fatigue Tests on Welded Tubular Joints in Air and Sea Water, TWI Research Report 251/1984, 1984 (Confidential to Industrial Members of TWI). Available online: https://www.twi-global.com/what-we-do/research-and-technology/research-reports/industrial-member-reports/fatigue-tests-on-welded-tubular-joints-in-air-and-sea-water-251-1984 (accessed on 4 May 2021).

- Wylde, J.G. Seawater Corrosion Fatigue Tests on Steel Tubular Joints, Internal TWI Report 7921.01/87/589.2. 1988. Available online: https://www.twi-global.com/technical-knowledge/published-papers/review-and-assessment-of-fatigue-data-for-offshore-structural-components-containing-through-thickness-cracks-june-2008 (accessed on 4 May 2021).

- Eide, O.I.; Berge, S. Fatigue capacity of stiffened tubular joints. In Proceedings of the 9th International Conference on Offshore Mechanics and Arctic Engineering, Houston, TX, USA, 18–23 February 1990; Volume 3, p. 209. [Google Scholar]

- Macdonald, A.; Brown, C.M.; Thomson, J.F.; Kerr, J. Strain Distribution Measurement and Fatigue Tests on Welded Tubular Joints, Report No. B12 in United Kingdom Offshore Steels Research Project—Phase I Research Contract Reports, Department of Energy, OTI 89 540,1988. Available online: https://www.twi-global.com/technical-knowledge/published-papers/straindistributionmeasurementandfatiguetestsonweldedtubularjoints (accessed on 4 May 2021).

- Fatigue Analysis of Unbonded Flexible Pipe. In Y.B Qiang Bai Flexible Pipes (P.225) Hoboken, NJ, USA Martian Srivencer. Available online: https://onepetro.org/OTCONF/proceedings-abstract/07OTC/All-07OTC/OTC-18905-MS/37377 (accessed on 4 May 2021).

| Property | Value |

|---|---|

| Material types Tensile strength (MPa) | Steel (Q345B) 490–675 |

| Yield strength (MPa) | ≥345 |

| Elongation after fracture | ≥21% |

| Specimen No | Welding Current [A] 50–100 | Welding Voltage [V] 18–21 | Welding Speed [mm/s] 5–20 | Heat Input [kJ/mm] |

|---|---|---|---|---|

| 1 | 90 | 20.0 | 6.5 | 0.28 |

| 75 | 19.0 | 5.0 | 0.29 | |

| 2 | 85 | 19.5 | 5.35 | 0.31 |

| 94 | 20.5 | 6.5 | 0.30 | |

| 3 | 98 | 18.5 | 5.0 | 0.37 |

| 88 | 21.0 | 6.18 | 0.30 |

| Elements | Content |

|---|---|

| C≤ Mn | 0.2 1.0–1.6 |

| Si≤ | 0.035 |

| Al≥ | 0.02–0.15 |

| Nb | 0.015–0.06 |

| Specimens | Load (kN) | Fatigue Life (Times) | Damage Position | Crack Length (mm) |

|---|---|---|---|---|

| G01 | 150 | 9409 | Weld toe | 13.500 |

| G02 | 150 | 6666 | Weld toe | 9.760 |

| G03 | 150 | 5361 | Weld seam | Large crack |

| G04 | 150 | 976 | Weld seam | Large crack |

| G05 | 150 | 4714 | Weld toe | 1.360 |

| G06 | 150 | 10,017 | Weld toe | 2.816 |

| G07 | 150 | 6937 | Weld toe | 5.390 |

| G08 | 150 | 2894 | Bolt | Large crack |

| G09 | 150 | 3450 | Weld toe | 2.254 |

| G10 | 150 | 17,114 | Weld toe | 0.463 |

| G11 | 150 | 24,202 | Weld toe | 8.386 |

| G12 | 150 | 43,279 | Weld toe | 6.850 |

| G13 | 150 | 62,441 | Weld toe | Large crack |

| G14 | 150 | 32,177 | Weld toe | 1.038 |

| Specimens | Load (kN) | Fatigue Life (Times) | Damage Position | Crack Length (mm) |

|---|---|---|---|---|

| H01 | 150 | 3553 | Near weld seam | 9.940 |

| H02 | 150 | 1400 | Bolt cracked | 12.680 |

| H03 | 150 | 2350 | Weld seam cracked | Snapped |

| H04 | 150 | 5491 | Weld seam | 13.000 |

| H05 | 150 | 12,446 | Weld toe | 4.200 |

| H06 | 150 | 8393 | Weld toe | 1.050 |

| H07 | 150 | 10,758 | Weld toe | 3.468 |

| H08 | 150 | 2465 | Weld toe | 0.920 |

| H09 | 150 | 17,167 | Weld toe | 14.640 |

| H10 | 150 | 5429 | Weld toe | 0.559 |

| H11 | 150 | 15,491 | Weld seam cracked | Snapped |

| H12 | 150 | 28,841 | Weld toe | 2.480 |

| H13 | 150 | 21,810 | Weld toe | 10.129 |

| H14 | 150 | 30,391 | Snaped | Large crack |

| Specimens | Load (kN) | Fatigue Life (Times) | Damage Position | Crack Length (mm) |

|---|---|---|---|---|

| T01 | 180 | 638 | Outside weld toe | 12.470 |

| T02 | 180 | 337 | Weld toe | 8.984 |

| T03 | 180 | 794 | Weld toe | 4.247 |

| T04 | 180 | 618 | Weld toe | 0.864 |

| T05 | 180 | 529 | Weld toe | 3.766 |

| T06 | 180 | 224 | Weld toe | 2.443 |

| T07 | 180 | 321 | Weld toe | 4.596 |

| T08 | 180 | 132 | Weld toe | 0.947 |

| Material | Young’s Modulus (GPa) | Poisson Ratio | Tensile Strength (MPa) | Yield Point (MPa) |

|---|---|---|---|---|

| Q345 | 206 | 0.28 | 550 | 320 |

| Type | Grid Size (mm) | Number of Grid Elements | Number of Grid Nodes |

|---|---|---|---|

| T-type plate joint | 2 | 60148 | 266232 |

| T-type tube-plate joint | 2 | 69457 | 307746 |

| T-type tube joint | 2 | 43546 | 211881 |

| Type | Finite Element Model | Test Load (N) | Simulative Load (N) |

|---|---|---|---|

| T-type plate joint | 1/4 model | 150,000 | 37,500 |

| T-type tube-plate joint | 1/4 model | 150,000 | 37,500 |

| T-type tube joint | 1/4 model | 180,000 | 47,500 |

| The Type of Connection Node | S-N Curve Category | The Thickness Factor Is Corrected |

|---|---|---|

| T-type plate joint | E | Without |

| T-type tube-plate joint | G | Without |

| T-type tube joint | F3 | Without |

| Type | Test Results (Times) | FE Results (Times) | Fatigue Standard Deviation | Ratio of Finite Element Life to Test Life |

|---|---|---|---|---|

| T-type plate joint | 16402 | 9113 | 18157.62 | 55.56% |

| T-type tube-plate joint | 11856 | 5581 | 8400.58 | 47.07% |

| T-type tube joint | 449 | 377 | 295.11 | 83.96% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ali, L.; Khan, S.; Bashmal, S.; Iqbal, N.; Dai, W.; Bai, Y. Fatigue Crack Monitoring of T-Type Joints in Steel Offshore Oil and Gas Jacket Platform. Sensors 2021, 21, 3294. https://doi.org/10.3390/s21093294

Ali L, Khan S, Bashmal S, Iqbal N, Dai W, Bai Y. Fatigue Crack Monitoring of T-Type Joints in Steel Offshore Oil and Gas Jacket Platform. Sensors. 2021; 21(9):3294. https://doi.org/10.3390/s21093294

Chicago/Turabian StyleAli, Liaqat, Sikandar Khan, Salem Bashmal, Naveed Iqbal, Weishun Dai, and Yong Bai. 2021. "Fatigue Crack Monitoring of T-Type Joints in Steel Offshore Oil and Gas Jacket Platform" Sensors 21, no. 9: 3294. https://doi.org/10.3390/s21093294

APA StyleAli, L., Khan, S., Bashmal, S., Iqbal, N., Dai, W., & Bai, Y. (2021). Fatigue Crack Monitoring of T-Type Joints in Steel Offshore Oil and Gas Jacket Platform. Sensors, 21(9), 3294. https://doi.org/10.3390/s21093294