1. Introduction

Mapping, navigation, and path planning have been one of the major research focus areas in robotics and auto industries in the past two decades [

1,

2,

3,

4,

5,

6,

7]. Major contributions have been introduced, particularly to increasing the perception and understanding of the robots’ surrounding environment. Perception of the environment is greatly affected by the types of sensors used. Laser scanners are becoming common in many industries besides driverless vehicles, including rescue operations, medicine, robotics, and unmanned air vehicles. LiDAR (light detection and ranging) is the favoured laser sensor due to its high accuracy, wide and long scanning range, and high stability [

8]. However, LiDAR is expensive and has major drawbacks when scanning in a transparent or specular reflective surface, such as glasses and mirrors. Hence, LiDAR sensors only account for diffuse objects [

9]. However, most modern environments contain glass or other specular surface architectural features. Glass dividers, panned doors, and full-height windows are an example of such features [

10].

Precision in localisation and mapping algorithms for robotics and driverless platforms is very critical. Using LiDAR sensors in a transparent environment causes the sensor to report inaccurate range data, leading to a potential collision triggered by errors in the map generated by the algorithm. Data collected by LiDAR sensors in an environment with a transparent and reflective object is also subject to a significant amount of noise caused by virtual cloud points created from the reflection of objects nearby the transparent materials [

9]. Such reflected data points degrade the quality of the map. Thus, detecting glass and removing wrong range measures and point clouds generated by the reflection of objects (virtual points) in a LiDAR is critically important for laser-based grid mapping and the safety of autonomous robots.

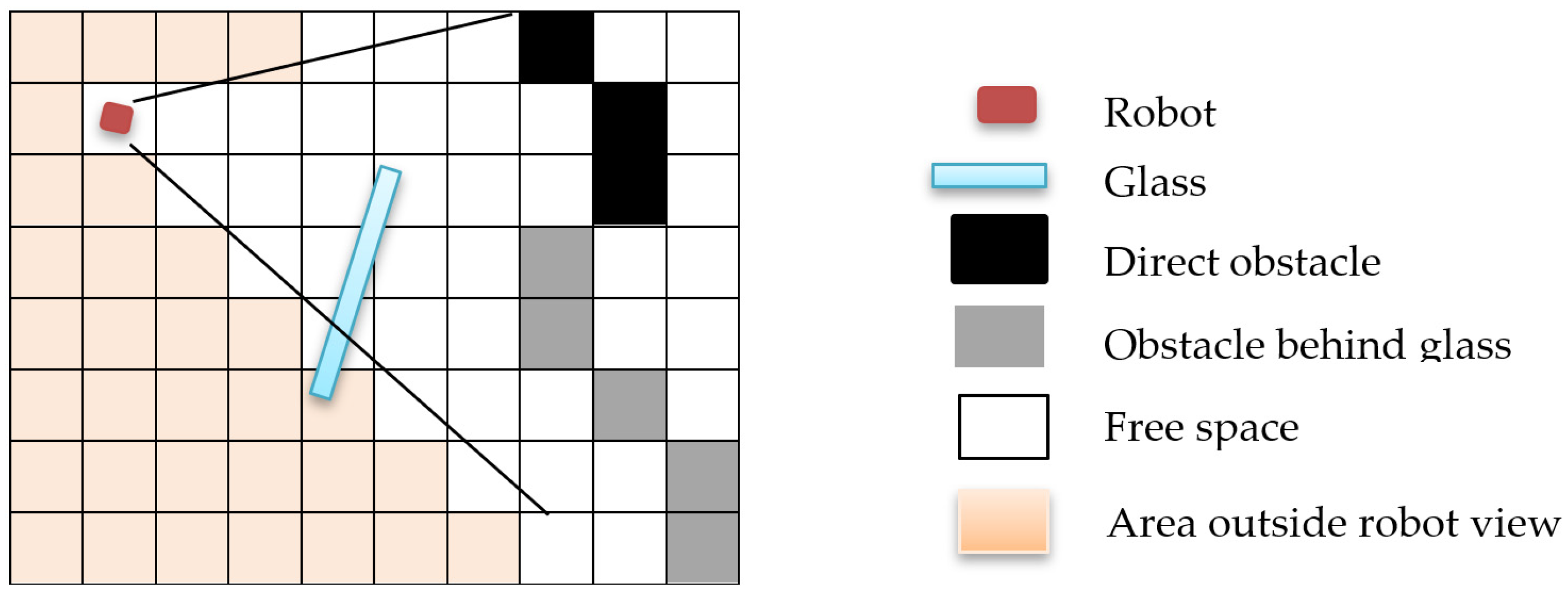

Occupancy grid mapping is a probabilistic method that maps the robot’s environment as an array of cells. Each cell holds the likelihood value that the cell is occupied. The basic assumption behind this method is that objects in the environment are detectable from any angle.

Figure 1 illustrates how conventional grid mapping algorithms work in a glass environment. The orange square represents where the robot poses, and the blue rectangle represents the presence of glass in the environment. Obstacles that are directly hit by the LiDAR lasers are represented by black boxes, whereas the grey boxes represent obstacles behind the glass. All grid areas found where the glass is located should be mapped as occupied space to obtain an accurate representation of the environment and avoid potential collisions. However, traditional occupancy grid mapping fails to detect glass and identify its location.

In this paper, we propose a novel method that uses the variation of range measurements between neighbouring LiDAR point clouds to identify and localise the presence of glass in an indoor environment. This study quantifies the disparity between successive range measurements when the pulses pass through glass and hit objects and when the pulses hit objects with no presence of glass. We use two complementary filters to compute this variational difference. The first filter computes the rolling window standard deviation to locate the presence of glass. The second filter uses the output of the first filter as its input and combines measurements of distance and intensity to determine glass width profile and location. The method has been tested using an occupancy grid mapping algorithm to quantify and analyse its performance. As autonomous agents are becoming human assistants in indoor environments, which more likely contain a glass environment, our approach will have a great significant to identify and localise the presence of glass in such environments.

3. Methods

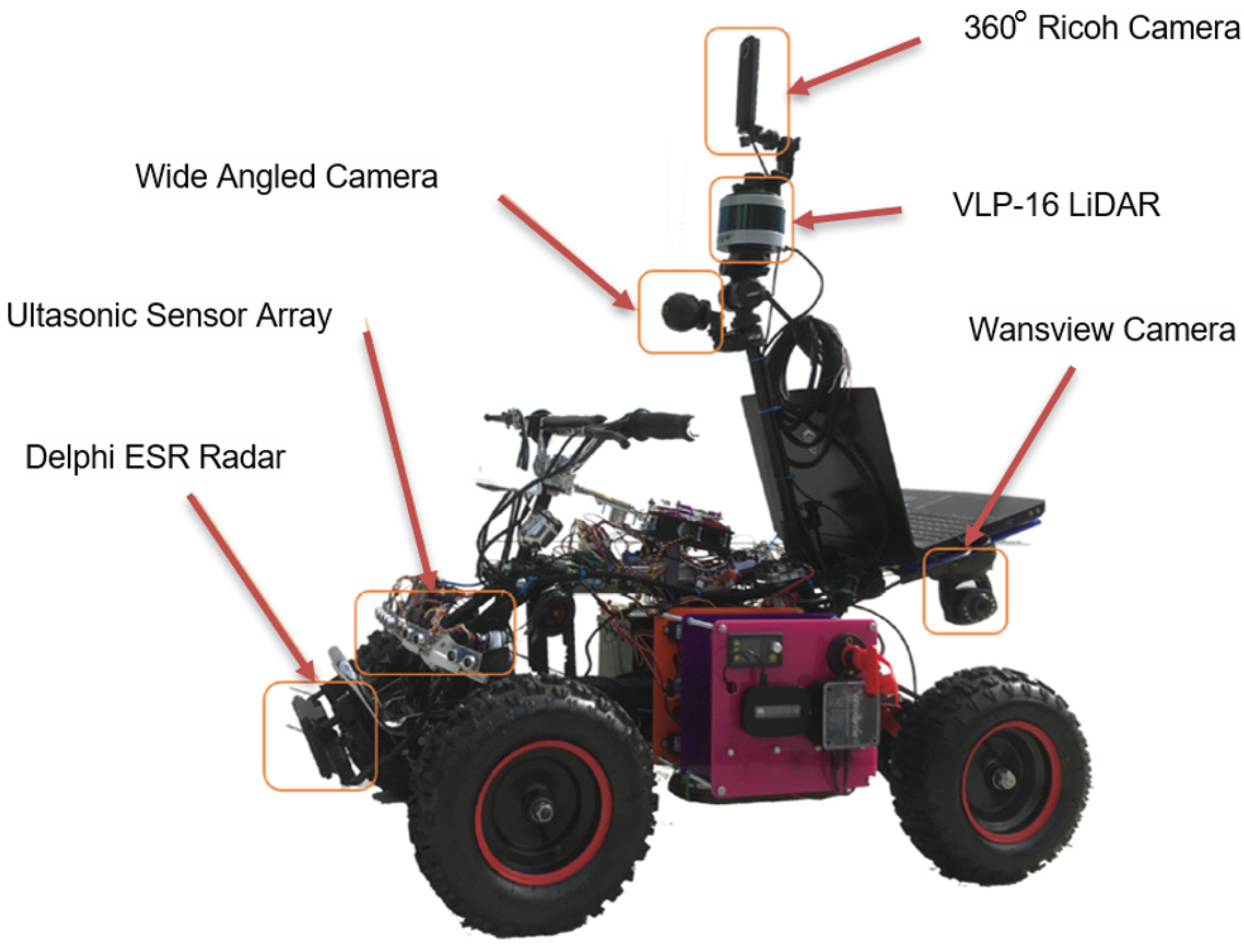

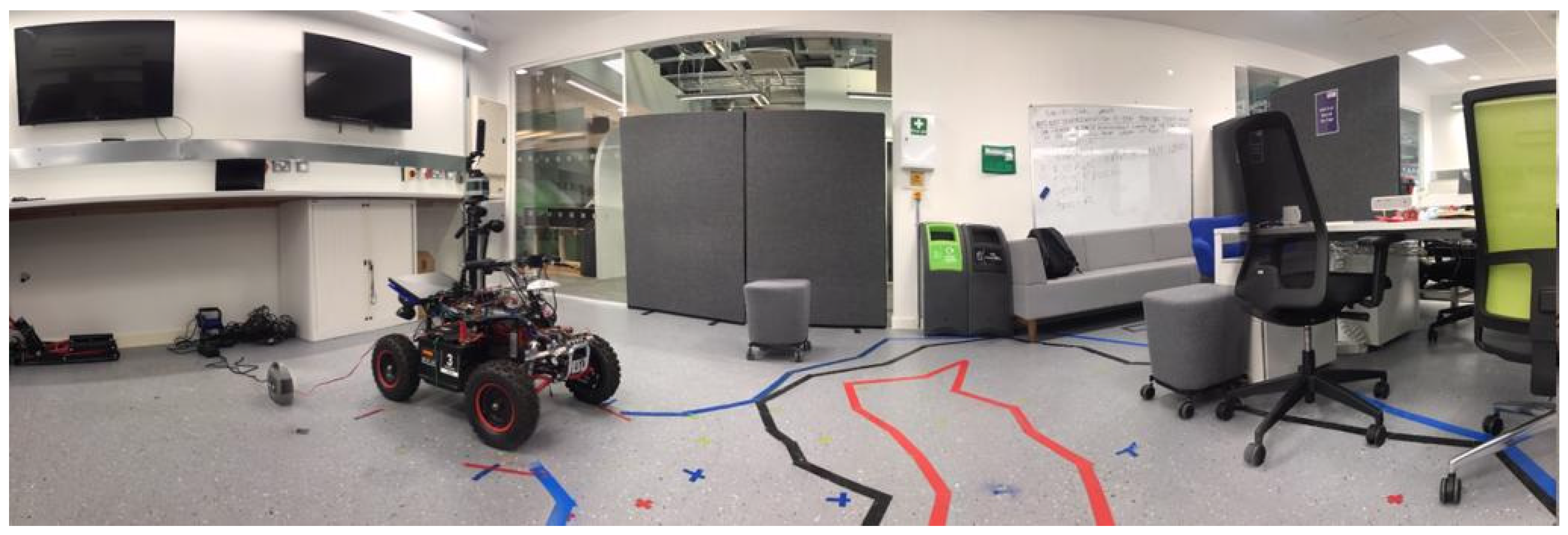

Initially, we collected data using the Loughborough University London Autonomous Testbed

Figure 2. The testbed has six different sensors installed: three cameras 360° Ricoh, Wansview, and wide-angle camera to collect visual data; an ultrasonic sensor to collect near-distance range measurements; and a Delphi ESR Radar sensor to measure the front side far-distance range measurement and speed data. The LiDAR data used in this study, which is generated from a Velodyne VLP-16 LiDAR apparatus, was collected while the car was driven autonomously by leveraging data from the sensors mounted on the testbed. This sensor has a maximum range of 100 m with 16-channels, taking a total of 300,000 measurements per second. This device captures 360° and 30° on the horizontal and vertical axis, respectively. The data are collected in different types of glass and glass installations, including single and double-glazed structures.

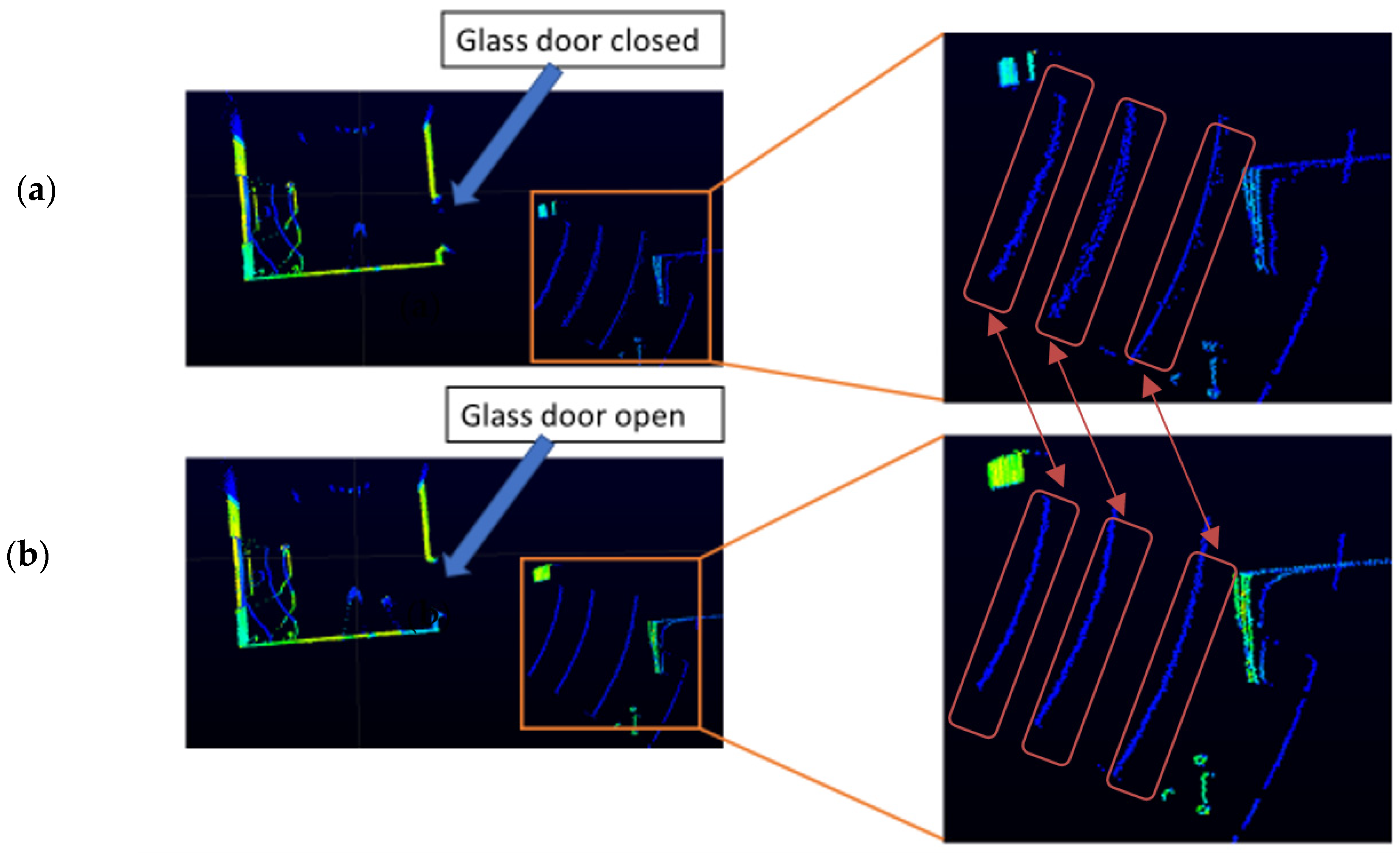

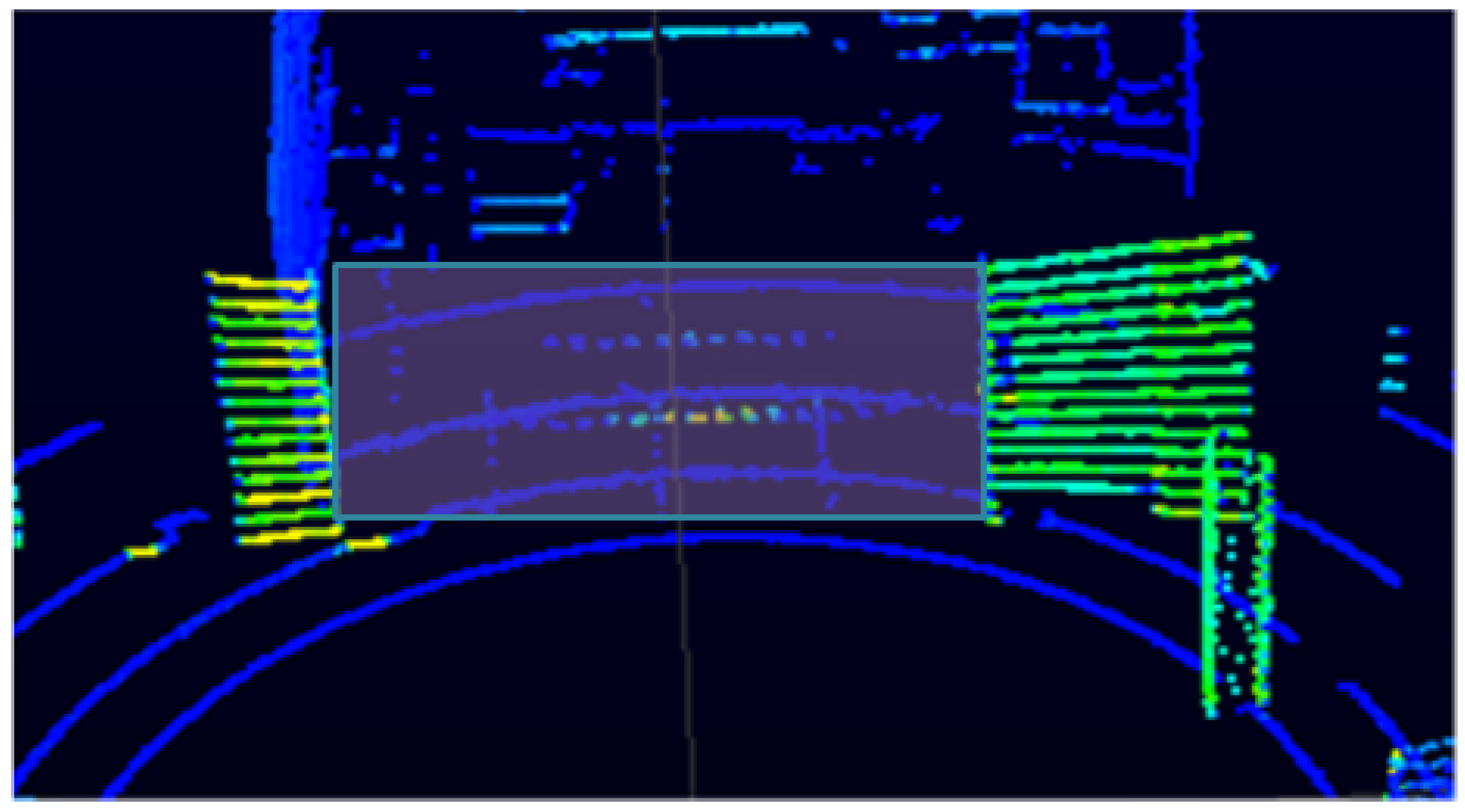

The range measurements in the orange box in

Figure 3a versus

Figure 3b have a slight difference. Although the difference is very small, it is mathematically significant. The difference in range measurements is smaller or larger depending on the height of the LiDAR from the ground and the angle of elevation of the LiDAR. The VLP-16 LiDAR sensor used in this study has an array of 16 infrared lasers, and each laser fires approximately 18,000 times per second. Each of the laser’s 16 channels are fixed at a certain elevation angle in relation to the horizontal plane of the LiDAR apparatus. Each of the 16 infrared lasers are assigned a specific laser ID number from 0 to 15 counting from the bottom to the upper channel. In this experiment, the LiDAR is mounted at 90 cm from the ground, and range difference between neighbouring pulses is largest in laser IDs 4, 6, and 8 with vertical angles −110, −90, and −70, respectively. When laser pulses pass through a glass medium, the difference in range measurement of neighbouring point clouds is higher than when lasers hit an object directly.

We conduct the experiment frame by frame because we aim to achieve our objective accurately starting from the very first scan. The experimental setup is designed in such a way to makes the proposed algorithm robust by pressing it to produce results from only one a single scan. Therefore, our algorithm does not depend on consecutive scan matching which leads to a potential gross error over time. Our experiment is set at 5 frames per second.

Figure 3a,b shows a scan of a single frame from the LiDAR.

Figure 4 classifies the point clouds in two groups by quantifying the range difference. First, we manually extracted a set of point clouds that pass through glass and classify them as

). We follow the same procedure and manually extract the point clouds, which directly hit objects and classify them as

. Then, we calculate the standard deviation of range measurements between the two groups.

represents the standard deviation,

is the mean, and

is the total number of point clouds included in each group.

We apply Equations (1) and (2) in several point cloud datasets from single- and double-glazed glass environments. Then, we compute the threshold (

) between the two groups as follows:

The result of Equation (3) is used as a threshold to compare against the new neighbouring data inputs from the LiDAR apparatus. We did not compute the standard deviation of two consecutive laser pulses to compare against the threshold, as the standard deviation different between

and

will be very small. Instead, we use a sliding window to compute the standard deviation of a group of neighbouring incoming pulses, as this simply widens up the gap between standard deviation of

and

The mathematical representation of the sliding window size (

) used in this study is declared in Equation (4).

are the number of samples included before and after the point cloud (

In other words,

is the upper limit of the sliding window for sample (

and

is the lower limit of the sliding window for the same sample (

. We ran several experiments to decide the sliding window size and found size 11 to have the highest accuracy. Hence, we use 5 samples before and after sample

In other words, both

.

Using the window stated in Equation (4), we calculate the standard deviation of the range measurement in each window.

represents the standard deviation of each window.

represents the LiDAR range measurement.

is the mean of the laser measurements inside the window.

We subsequently apply Equation (5) to classify each window as a

or as a candidate for

by comparing the result with the threshold (first filter), as presented in

Figure 4.

Equations (1)–(3) are performed on hand-labelled

and

data. In filter 1, we primarily use the standard deviation difference between the two groups to classify incoming point clouds as

and

Hence, we use the average of the hand-labelled data’s standard deviation (Equation (3)) as a threshold. Therefore, every 11 new incoming point cloud data are assigned to group (the sliding window size (Equation (4))) and the standard deviation of each of each window (Equation (5)) is compared against Equation (3). If the result is above the average, then these point clouds are labelled as potential

, and if the result is below the threshold, it is classified as

The pseudocode of Algorithm 1 is presented below.

| Algorithm 1. Filter 1 |

Input

WiH,J← rolling window

P ← the scan point clouds

Trh ← threshold

for each point clouds run a rolling window do

Calculate the STDV of window

If STDV of the window > threshold then

Store the point cloud to potential PCoG

else

store the point as PCoO

end if

end |

When lasers hit a straight object such as a wall, range measurements between neighbouring pulses either increase or decrease depending on the rotation direction of the apparatus, as illustrated in

Figure 5.

This characteristic has a significant impact on the standard deviation, as it tends to increase its value, which may lead to the wrong assignment of some point clouds hitting the straight surface as a PCoG. Hence, we run a second filter on all points clouds assigned as PCoG by filter one. The second filter is designed based on the following beliefs:

Distance increases and intensity decreases at the first point when a LiDAR pulse passes through the glass as it is expressed in (

Figure 6), and

Distance decreases and intensity increases at the last point when a LiDAR pulse passes through the glass (

Figure 6).

All point clouds that do not meet the second filter criteria are assigned as

and added together with filter one

to get the total, as illustrated in

Figure 4. We also use the second filter (Algorithm 2) to confirm point clouds assigned as

are in the correct glass width profile (within the interval of intensity fall and rise (

Figure 6)).

| Algorithm 2. Filter 2 |

Input

PCoG ← Potential glass hitting point clouds filtered by algorithm one

PCoO ← Non-glass object hitting point clouds by algorithm one

I ← Intensity

Dis ← LiDAR range measurement

for all point clouds except for those filtered as PCoO by algorithm one do

if Dis increases at the first point

Where a pulse passes through glass

AND

if I decreases at the same point, then

Store this point as beginning of window profile width

end if

end if

if Dis decreases at the end point

Where a pulse passes through glass

AND

if I increases at the same point then

Store this point as end of window profile width

end if

end if

end

for all PCoO DO

if between the beginning and end

profile width then

accept as a PCoO

else

add the point clouds to PCoO

end if

end |

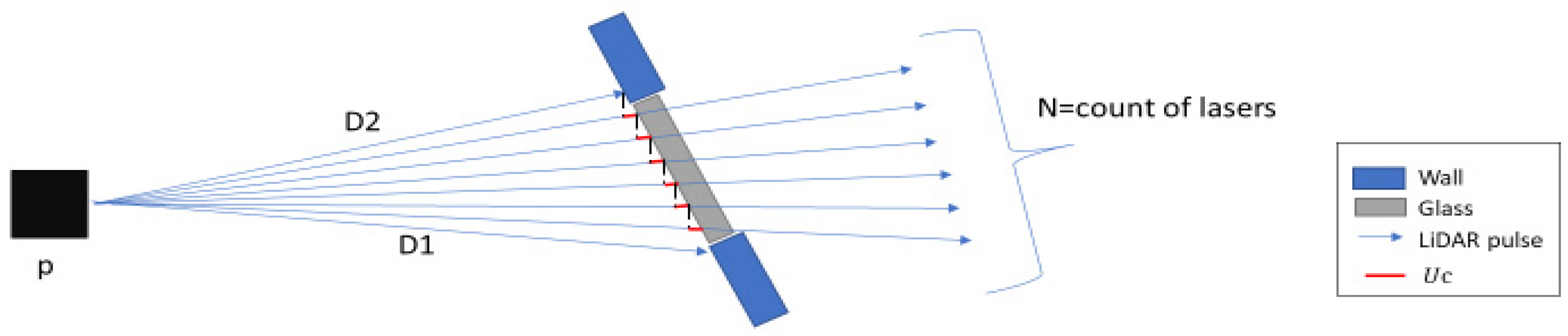

Finally, we update the cartesian coordinates and the range measurement of all the point clouds assigned as

by the second filter. Let

represent the range and cartesian coordinates measure at the end and beginning of a glass region respectively (i.e., the beginning and the end measurement of consecutive point clouds assigned as

by the second filter, illustrated in

Figure 7).

is the value-added on each consecutive point.

is the total count of consecutive lasers.

Once the glass width profile is known from Algorithm 2, then, we extract the upper and lower limit of the glass width profile’s distance measurement (D1 and D2), the cartesian coordinate at the beginning and end of the glass width profile (X1 and X2) and (Y1 and Y2) together with the total number of laser beams within the upper and the lower limit interval. We use these as the input for algorithm three to update distance and cartesian coordinates. Algorithm 3, presented below, is for updating distance measurement. Cartesian coordinates can be similarly updated by changing D1 and D2 by (X1 and X2) and (Y1 and Y2), respectively.

| Algorithm 3. Update distance (Similar method used for updating cartesian coordinates) |

Input

N ← Count of laser

D1 ← Distance measurement of the end of the glass frame

D2 ← Distance measurement of the beginning of the glass frame

for each point clouds to the length of N do

Store the result to Uc

Add Uc to the range measurement

Store the result

end |

4. Experiments and Results

This section consists of three experiments conducted to demonstrate the usability of the proposed algorithm. These experiments use single- and double-glazed glass. All the glass used in these experiments are glass walls. In the rooms where experiments 1 and 2 were conducted, one wall was partially glass. In the room where experiment 3 was conducted, one wall consisted of two separate glass panes.

Initially, we present the finding that in all the experiments, there is a marginal difference in the rolling window standard deviation (rolling stdev) of the laser range measurements between point clouds that pass-through glass and those that do not.

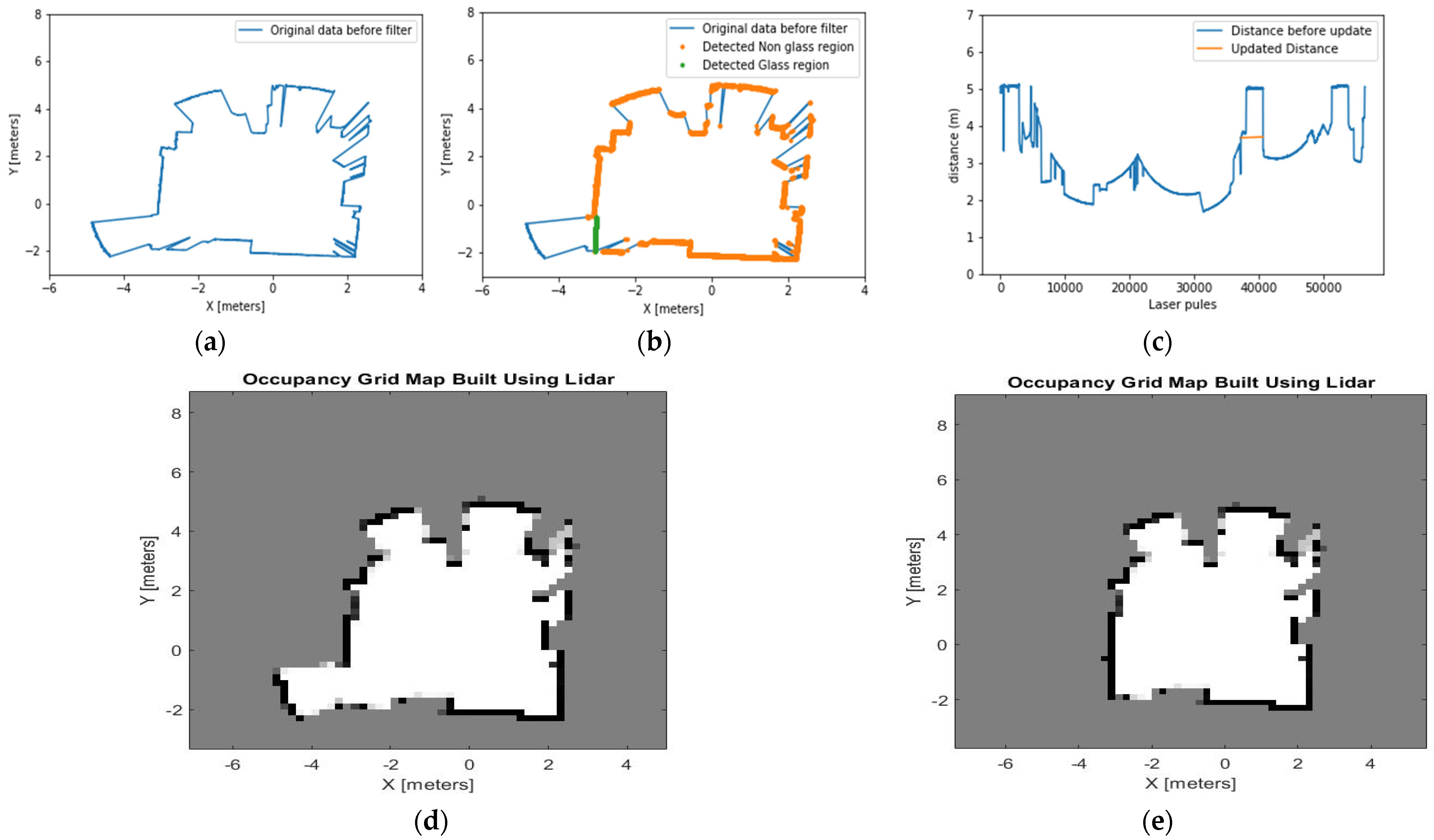

Figure 8 illustrates this margin.

The experiments presented hereafter have two primary aims: firstly, to identify and locate the presence of glass in the three experimental setups and, secondly, if there is a presence of glass, to update the lasers pules distance by recalculating the distance between the LiDAR apparatus and the identified glass.

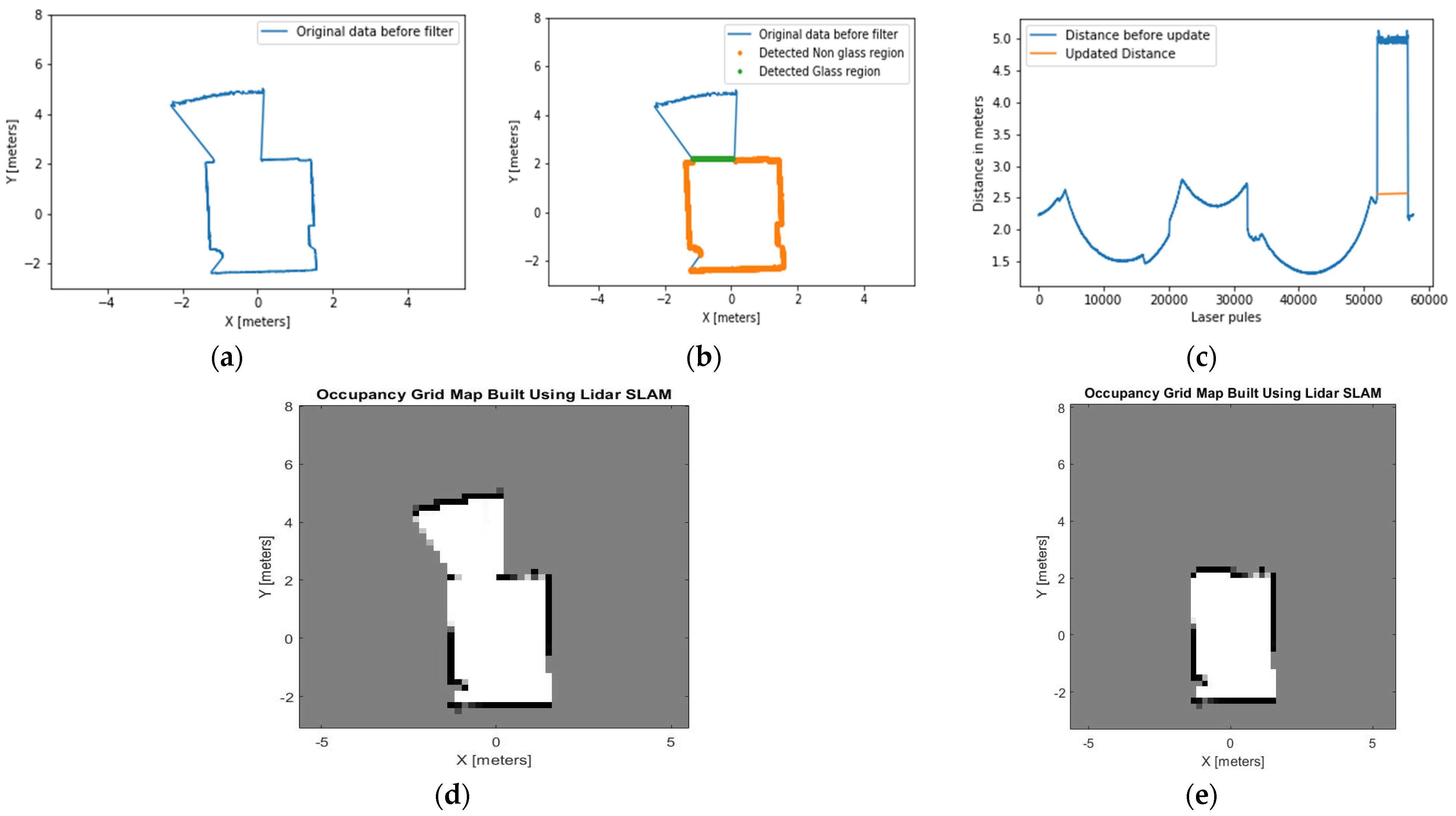

4.1. Experiment 1: Office-Like Environment

This experiment room is conducted in an office-like room. The room has a glass wall located at the corner of the left side, as seen in

Figure 9. The glass wall in experiment 1 is a single glazed glass. The height of the glass is 2.5 m, and the width is 1.5 m. Point clouds behind the glass wall are unwanted, since they represent objects beyond the glass. There was a 3-m distance between the glass wall and the LiDAR apparatus.

Using the proposed method, the point clouds that pass through glass are identified using Equation (3). The width of the glass is identified using the second filter of the proposed algorithm. Then, the distance and cartesian coordinates of the point clouds that are within the range of the identified glass are updated using Equation (4).

All maps displayed in the results sections are 2D maps presented on an XY plane. The result in green (

Figure 10b) shows the updated cartesian coordinates of the identified glass regions. In

Figure 10c, the orange line shows the updated distance measurement.

Figure 10d,e show the comparison of the traditional grid map and grid map constructed using the proposed method. The traditional method wrongly identifies the glass region and points beyond the glass region as free space. The proposed method correctly identifies the LiDAR point clouds that pass through the glass wall. This algorithm also updates the distance and cartesian coordinates to approximate the location of the glass. Finally, point clouds beyond the glass region are labelled as occupied space.

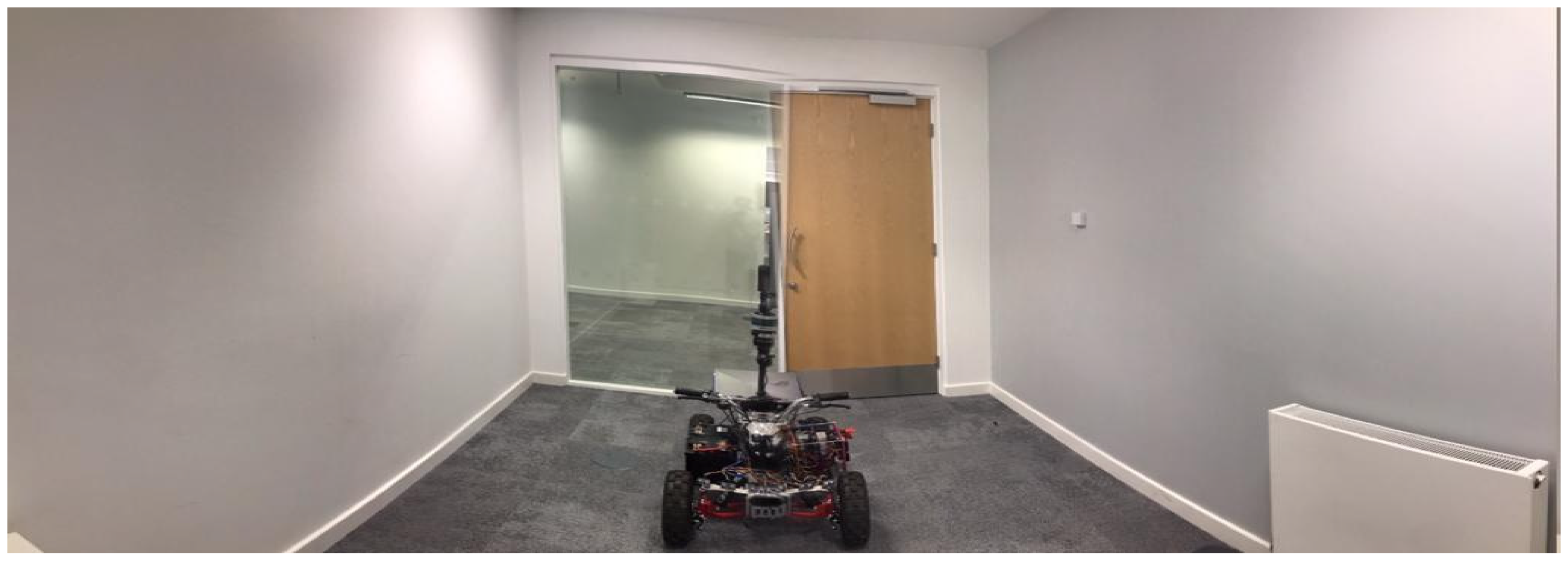

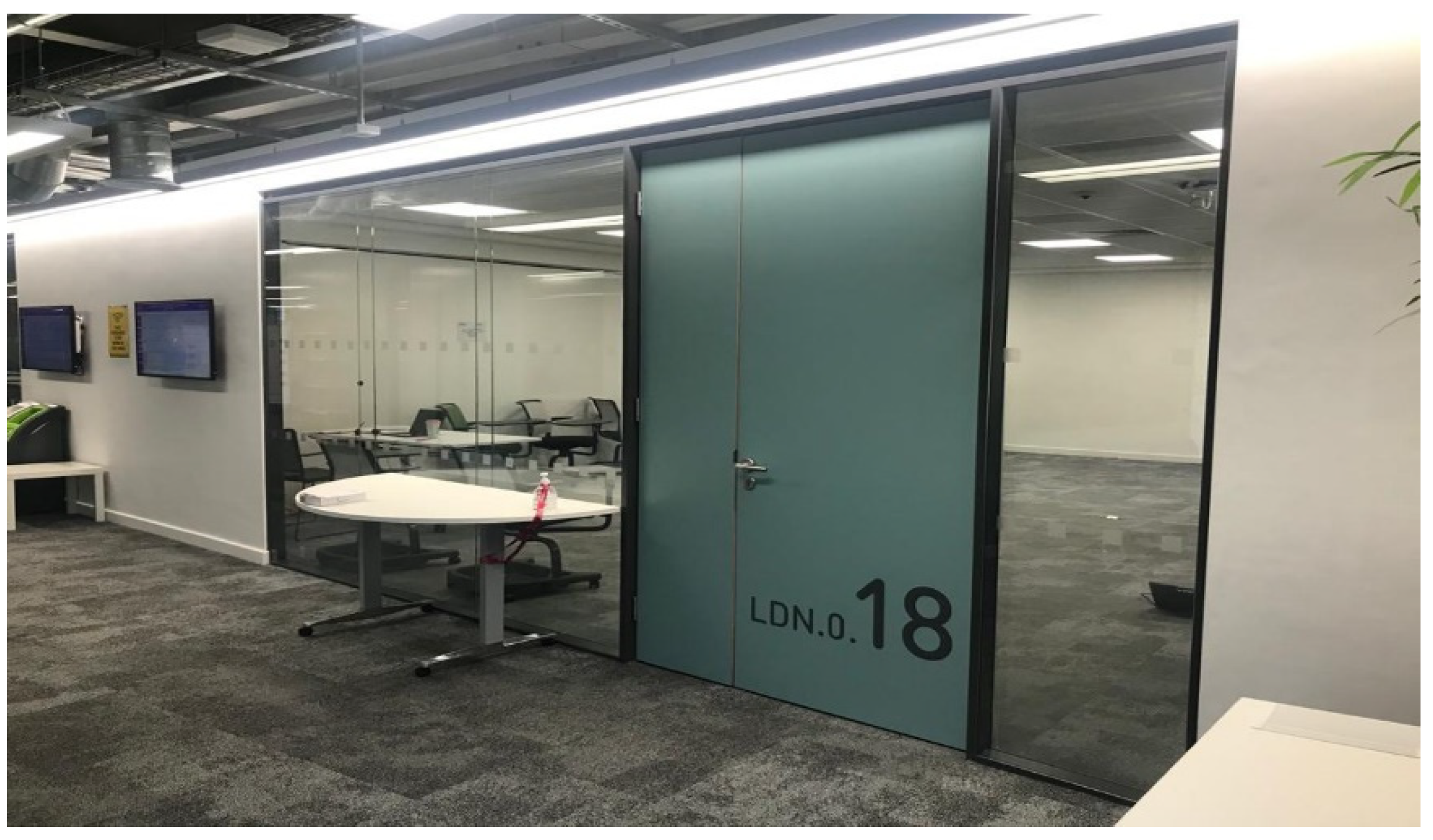

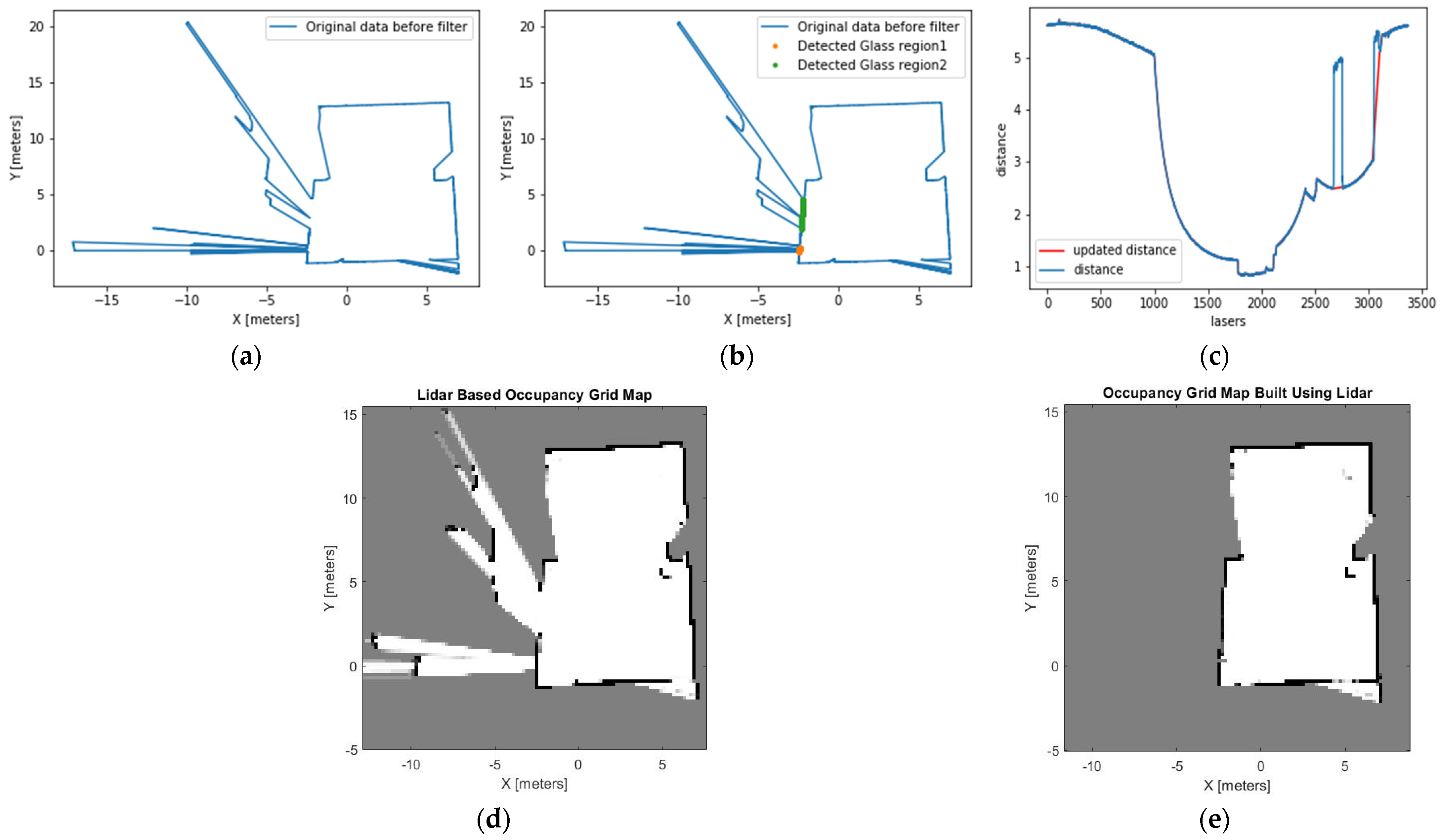

4.2. Experiment 2: Room with a Corridor in Front

The second experiment is conducted in an empty room with a double-glazed glass wall located on the front side of the room as shown in

Figure 11. There was a 2-m distance between the LiDAR apparatus and glass wall. The height of the glass wall is 2.20 m and the width is 1.5 m.

Our algorithm filters the point clouds that pass through glass and identifies the width of the glass boundary using Equation (5) and filter two, respectively. The conventional occupancy grid map (

Figure 12d) assumes there is a free space pathway between the room and the corridor.

Figure 12e presents the map produced by our method. This approach effectively identifies the glass area and estimates the glass width. It produces a correct representation of the environment by updating the cartesian coordinates and the distance measurement of the LiDAR.

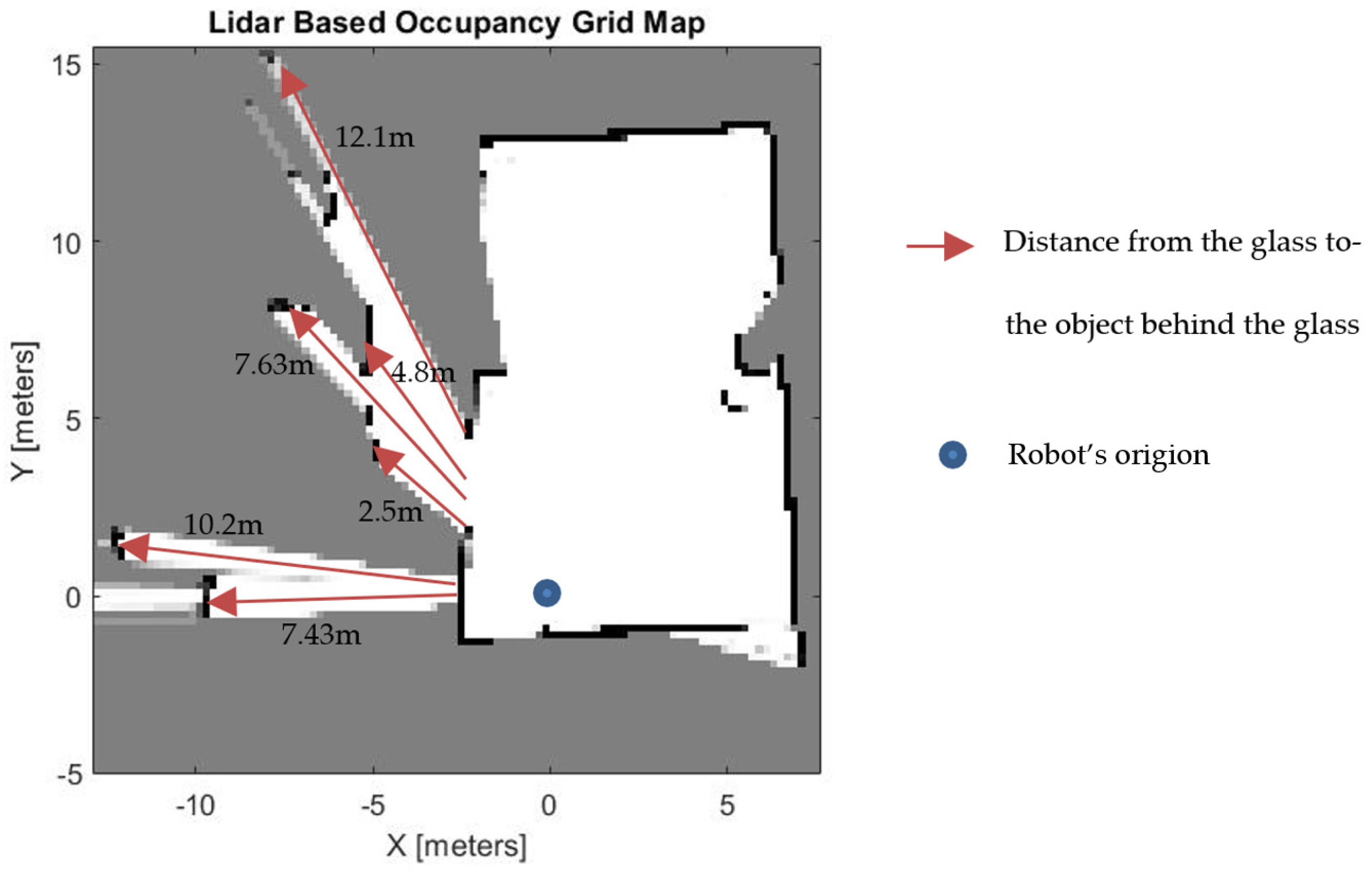

4.3. Experiment 3: Room with Two Glass Walls

The third experiment is conducted in a room that has two single glaze glass walls, as shown in

Figure 13. The first glass was put in a 2-m distance from the LiDAR apparatus and had an area of 0.75 m × 2.20 m. The far side of the second glass has a 4-m distance from the LiDAR apparatus and has an area of 2.5 m × 2.20 m. A 1-m wide wall separates the two glass planes.

Both glass walls in this experiment are identified and located. The identified width of the glass in this experiment is a little greater than the dimension of the glass because we applied a higher window size to filter the point clouds. As a result, non-glass walls near the glass end and start points are labelled as a glass. Nevertheless, this does not affect the map produced (

Figure 14e), as the purpose of the algorithm is to identify glass and to assign the glass as occupied space.

Using the proposed method, in all three experiments, glass walls are displayed as occupied regions on the respective occupancy grid map cell.

We conducted experiment 3 in an environment where objects, which are behind the glass, are placed at different distances from the location of the glass. Such an environment makes it viable to see the performance of the proposed algorithm with respect to the distance of objects behind the glass. While the closest object to the glass is placed 2.5 m away, the farthest is located 12.1 m from the glass.

Figure 15 shows that our algorithm effectively works despite the difference in distance of objects behind the glass. However, theoretically, it will be difficult for our algorithm to detect glass if an object is placed right behind the glass. This is due to the overlap between

PCoO’s and

PCoG’s rolling standard deviation. However, since we are proposing this algorithm to improve occupancy gride mapping, such case has no effect. If objects are placed right behind the glass, then we can assume that there will be no free space to be detected between the object and the glass.

The quantitative performance evaluation of the proposed algorithm is challenging since it is hard to obtain a ground truth point cloud with glass areas detected [

25]. Hence, we compare the proposed method result with ground truth data generated by hand labelling each point cloud as

and

The method’s accuracy is quantified based on methods by Zhao et al. [

9] and Foster et al. [

10]. Point clouds passing through glass were considered accurate if the point cloud is in the subset of hand-labelled

. If the point cloud is not in the subset, it will counted as false positive.

Table 1 shows the experiment results compared to the hand-labelled ground truth. The mean accuracy of glass correctly detected in the proposed method is 96.2%.

We also evaluate the proposed method’s accuracy of the updated distance. A sticker was attached to selected places on the glass during data collection. The ground truth for the true position of the glass (the true distance from the robot’s pose to the glass) is collected by using these stickers attached to the glass. The cloud points that hit the sticker are extracted, and their respective range measurement is used as the ground truth distance. Then, the updated distance results from the proposed algorithm are compared against the ground truth distance. Then, we calculated the Root Mean Square Deviation (RMSD) and compared against the approach of Zhao et al. [

9]. As shown in

Table 2, this method gives a better estimation of the glass location.

5. Conclusions

This paper presents a novel methodology to perform occupancy grid mapping in the presence of glass. Existing reflection detection algorithms perform poorly in the presence of glass. Therefore, in this paper, we focus on glass detection by itself.

The proposed method is based on the variation of neighbouring LiDAR point clouds when the LiDAR pulses pass through glass. Results show that there is a variation of neighbouring pulses’ distance measurement when the pulses pass through glass versus when the pulses directly hit objects. We classify LiDAR pulses into two groups: those that pass through glass and those that directly hit objects. Then, we apply two filters using intensity and range discrepancy to identify the boundary of the glass. Finally, we update the cartesian coordinates and the distance measurement of the LiDAR. Then, we show the usability of this method using occupancy grid maps that demonstrate improved map quality with a single scan. This approach effectively identifies and localises glass and improves indoor mapping quality using LiDAR sensors.

The key findings and contributions of this paper can be summarised as follows:

LiDAR range measurements exhibit a different character when the pulses pass through glass

We proposed a novel method to detect and localise glass using LiDAR

We proposed a new approach to update distance and cartesian coordinates measurement from a LiDAR apparatus to compensate the incorrect reading due to the presence of glass.

Our approach effectively improves traditional occupancy grid mapping by eliminating a false positive free space.

In the future, this approach can be integrated with a camera sensor to investigate the algorithms robustness for indoor and outdoor dynamic environment in real time.