Tdnn-Based Engine In-Cylinder Pressure Estimation from Shaft Velocity Spectral Representation

Abstract

1. Introduction

2. Methods

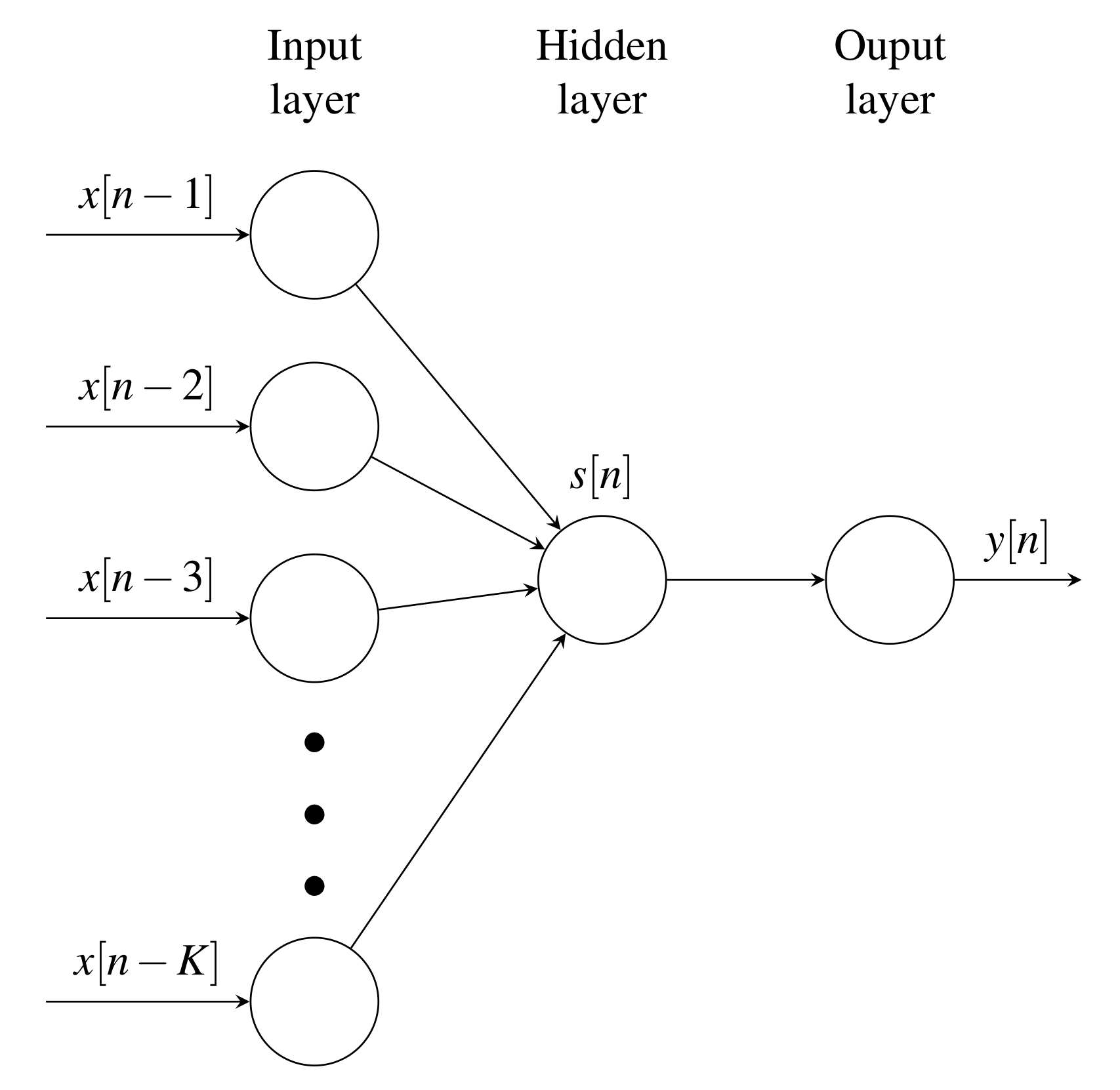

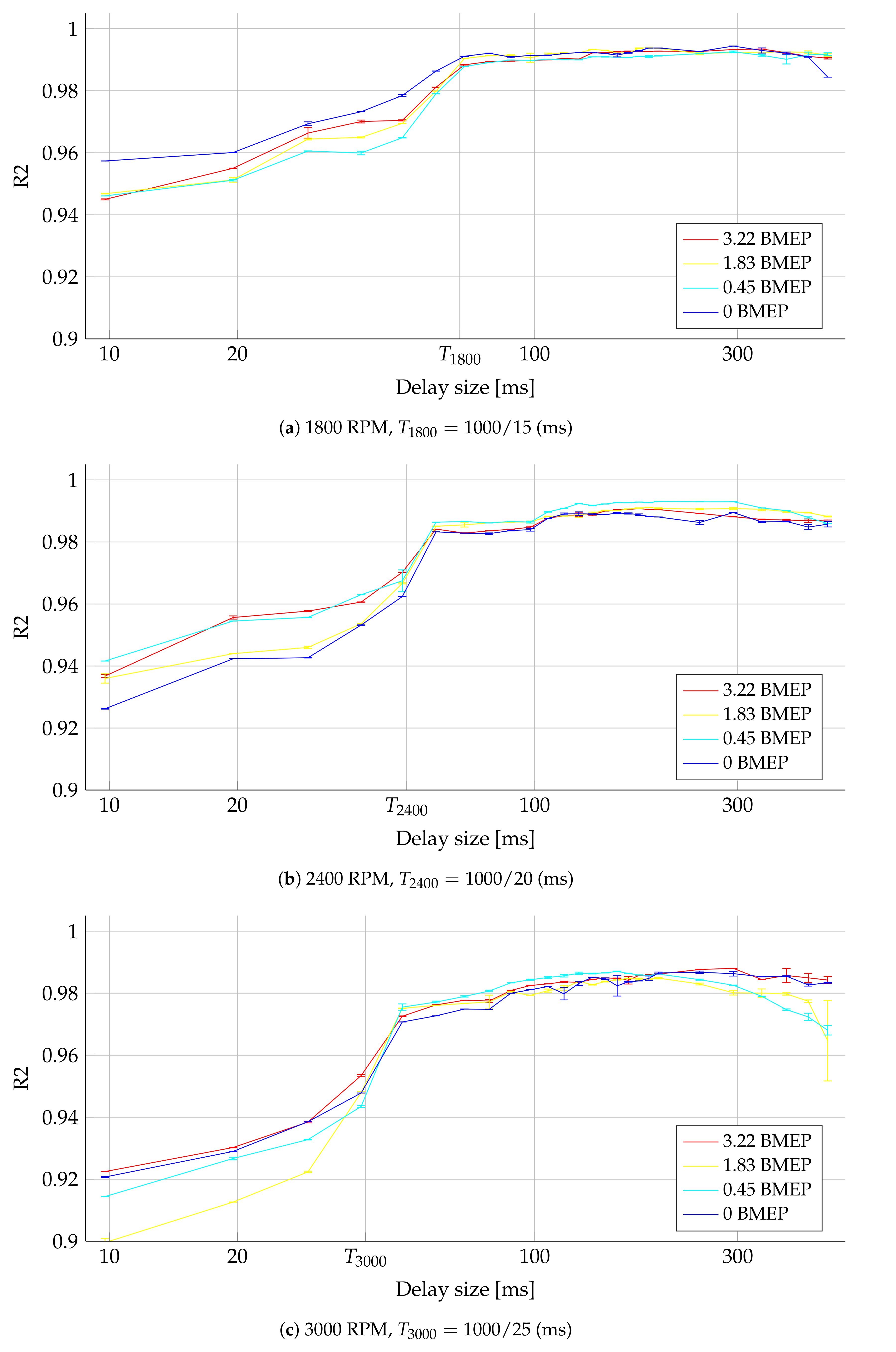

2.1. Time Delay Neural Network Fundamentals

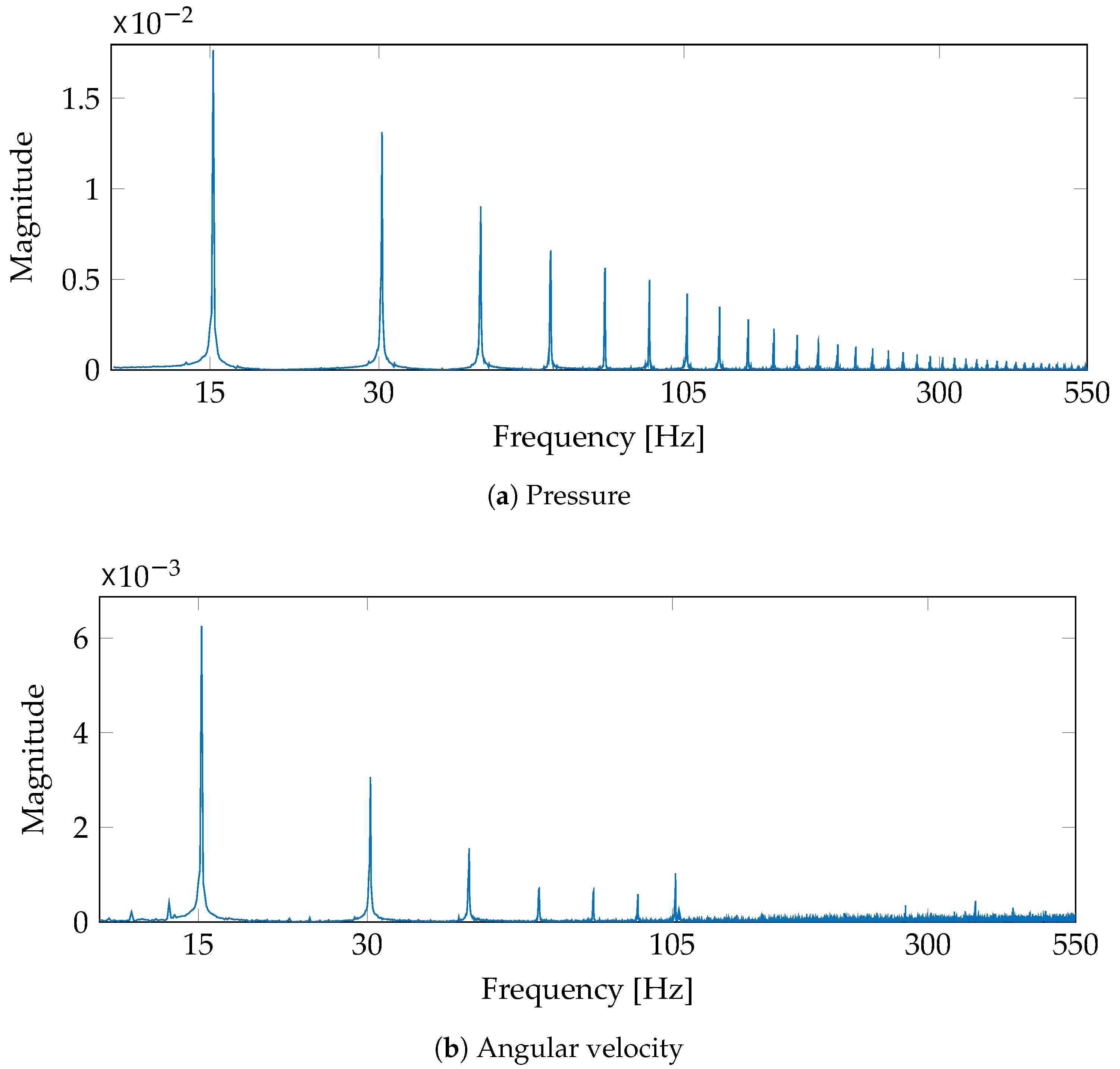

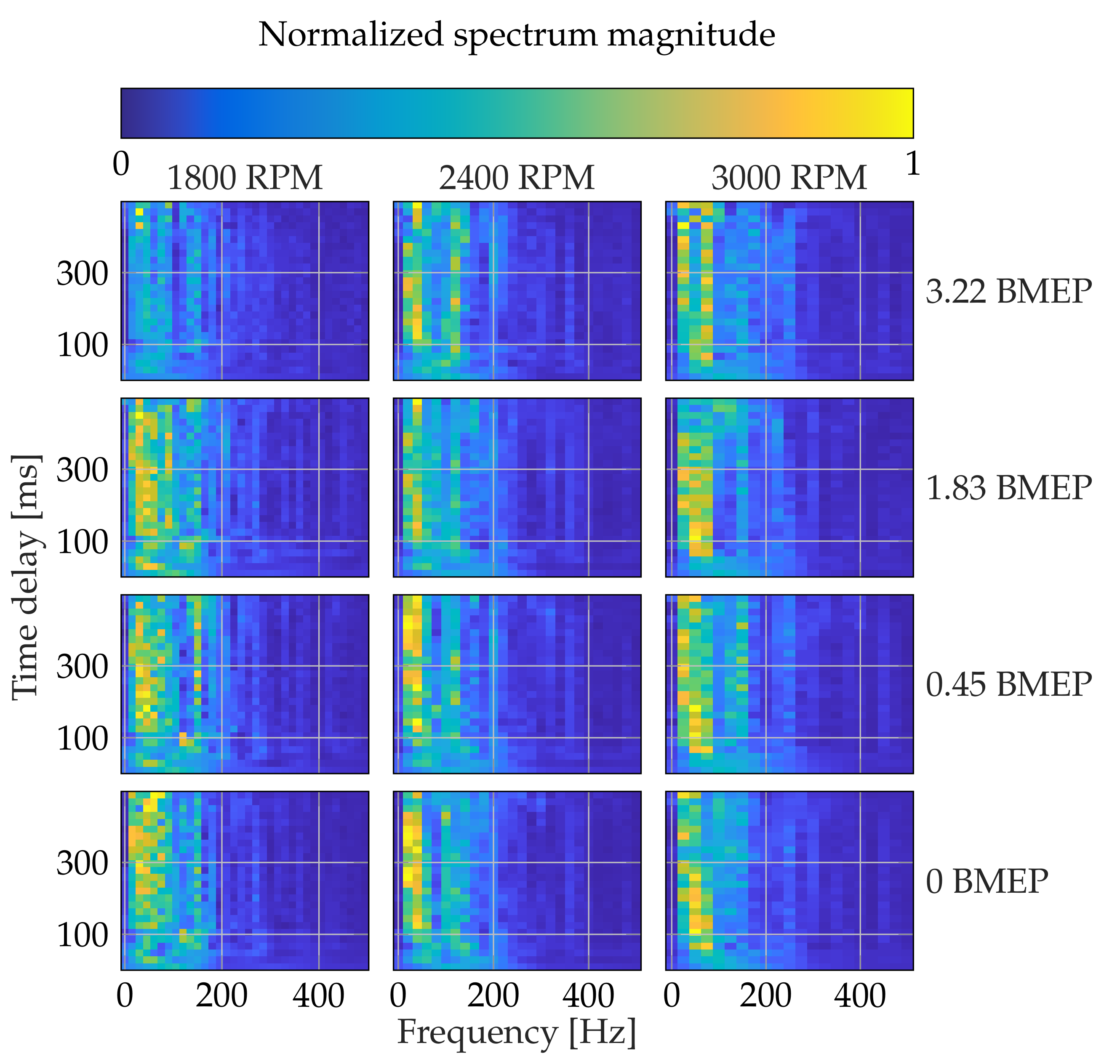

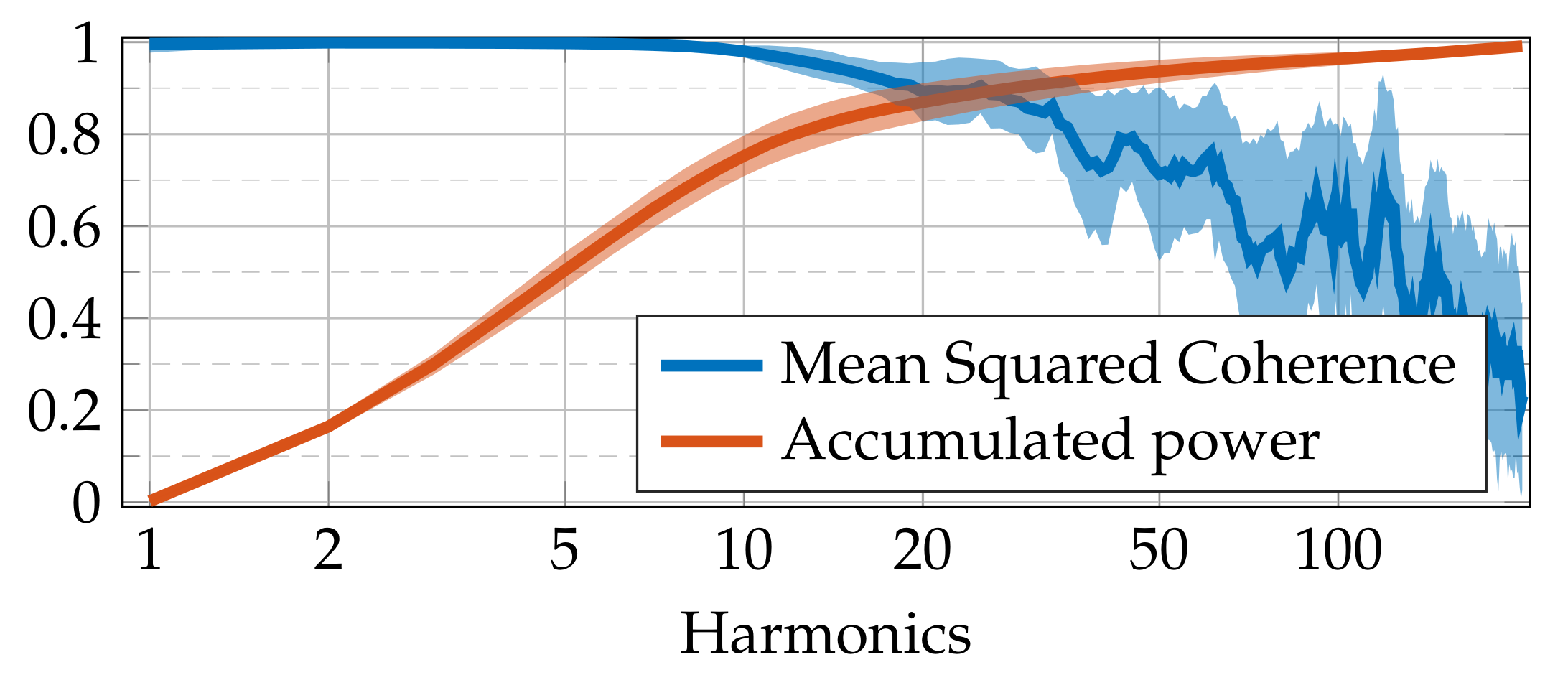

2.2. Harmonic Prediction Performance Based on Magnitude-Squared Coherence

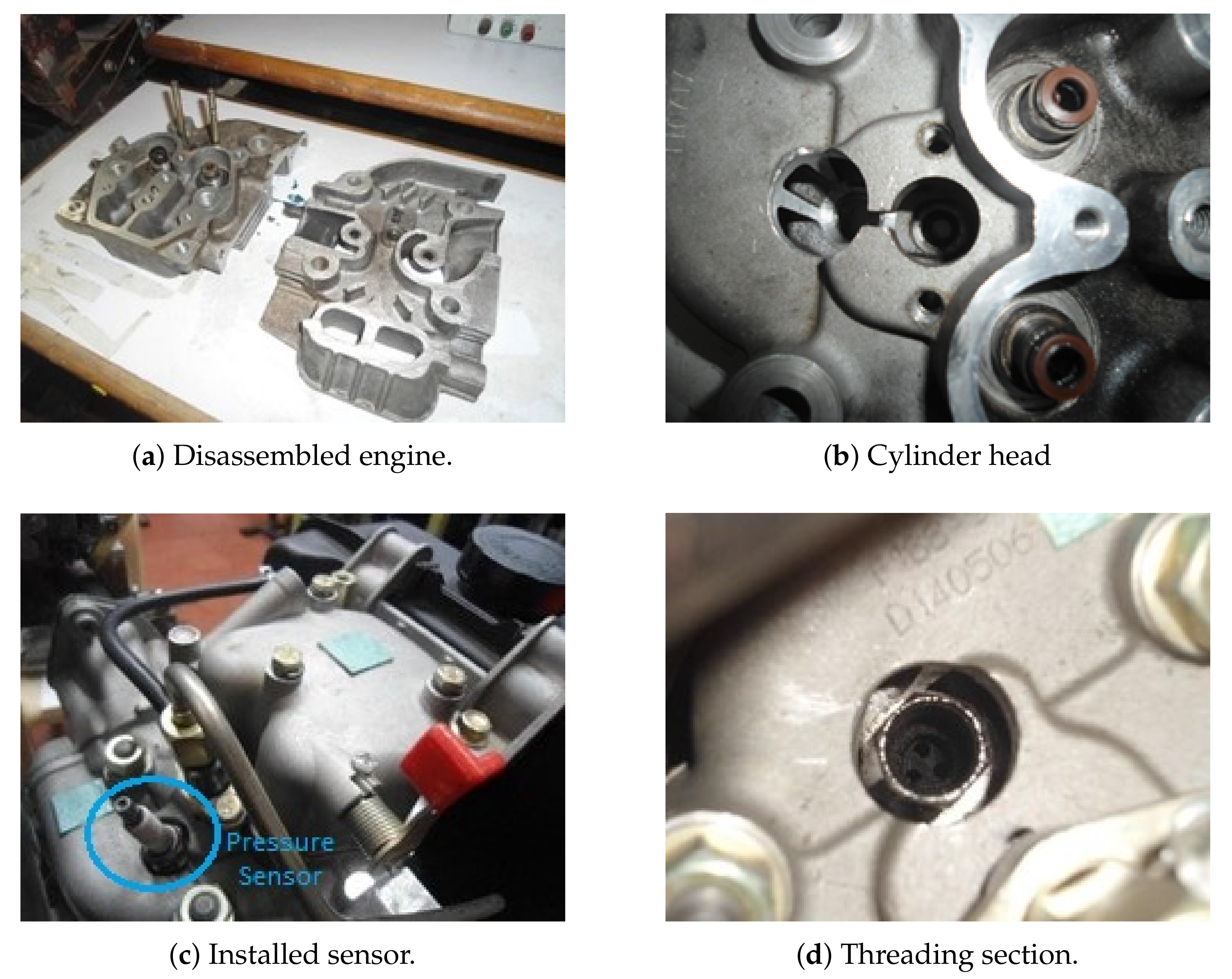

3. Experimental Setup

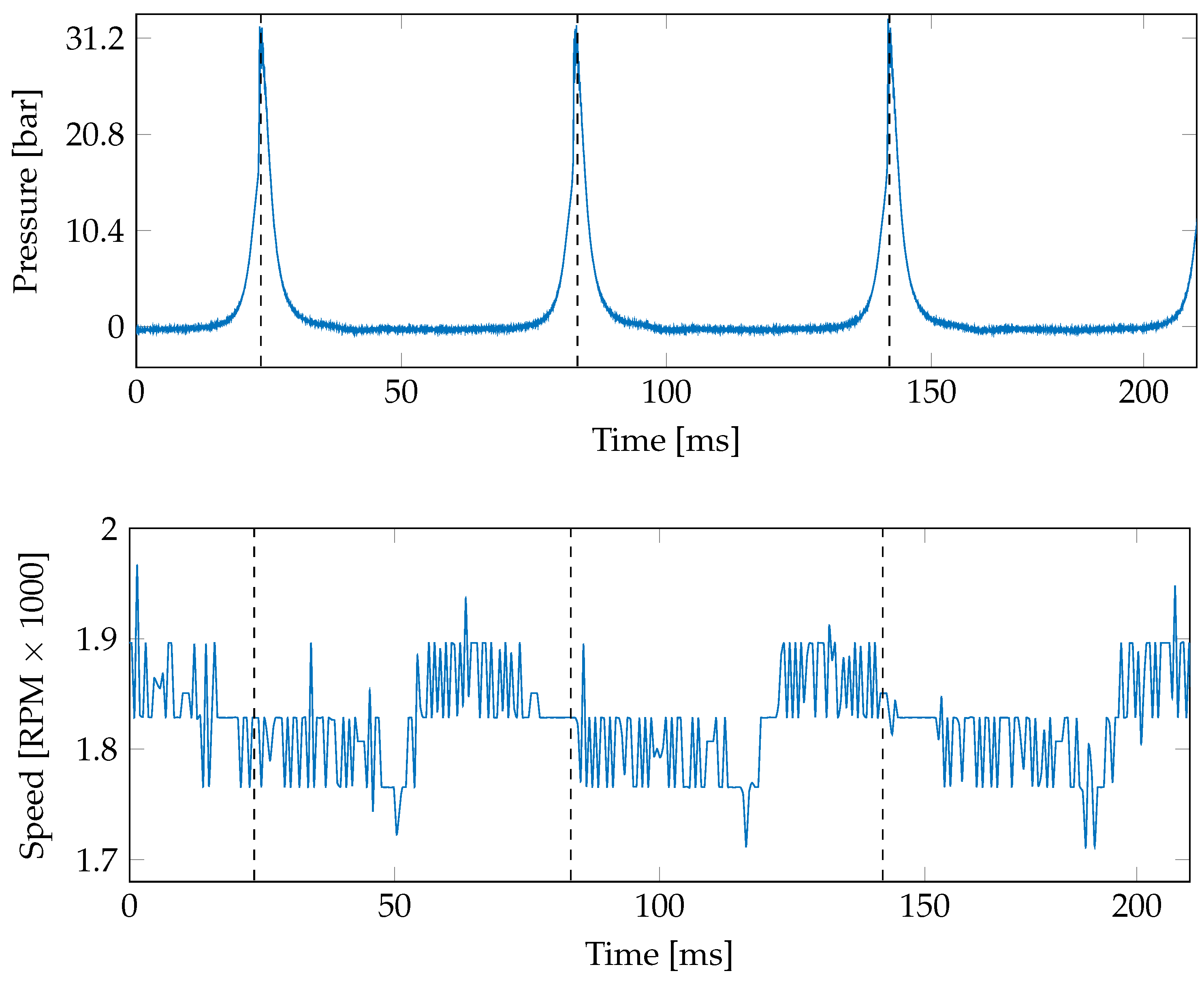

3.1. Engine Measurements, Data Acquisition, and Preprocessing

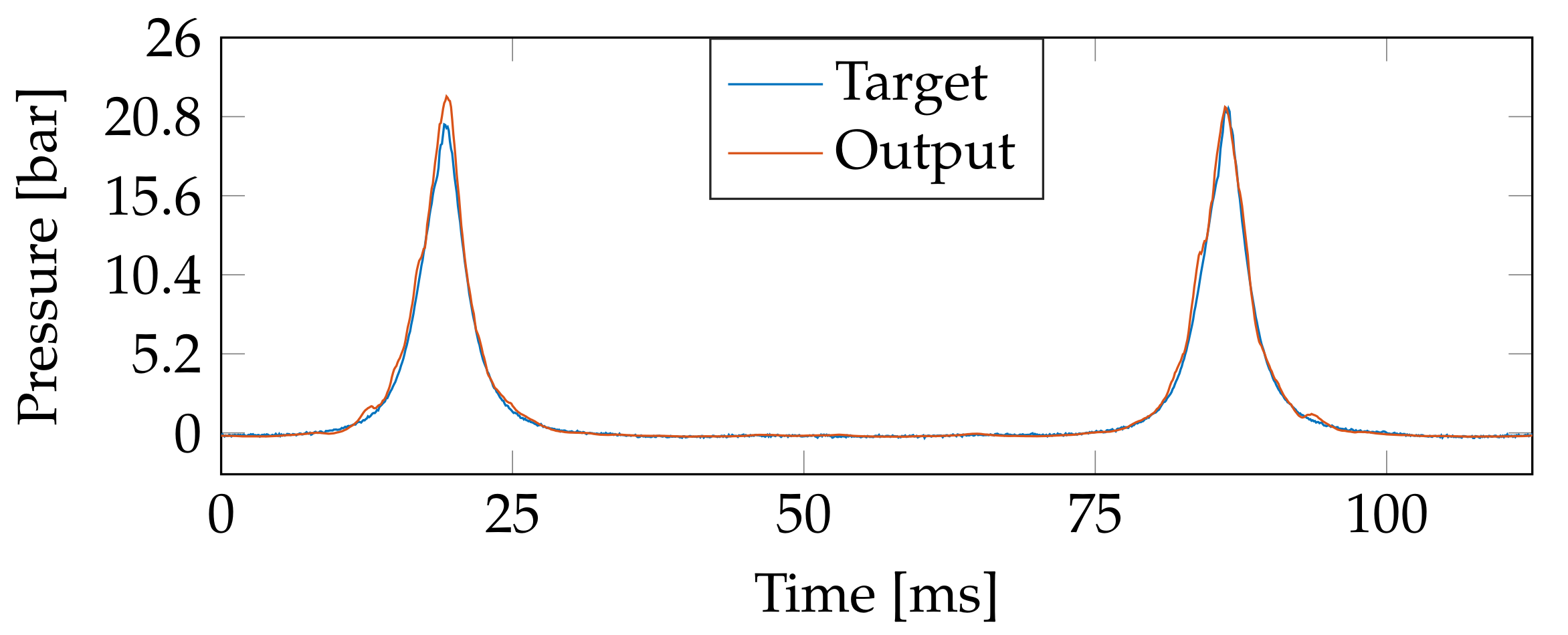

3.2. Pressure Signal Estimation

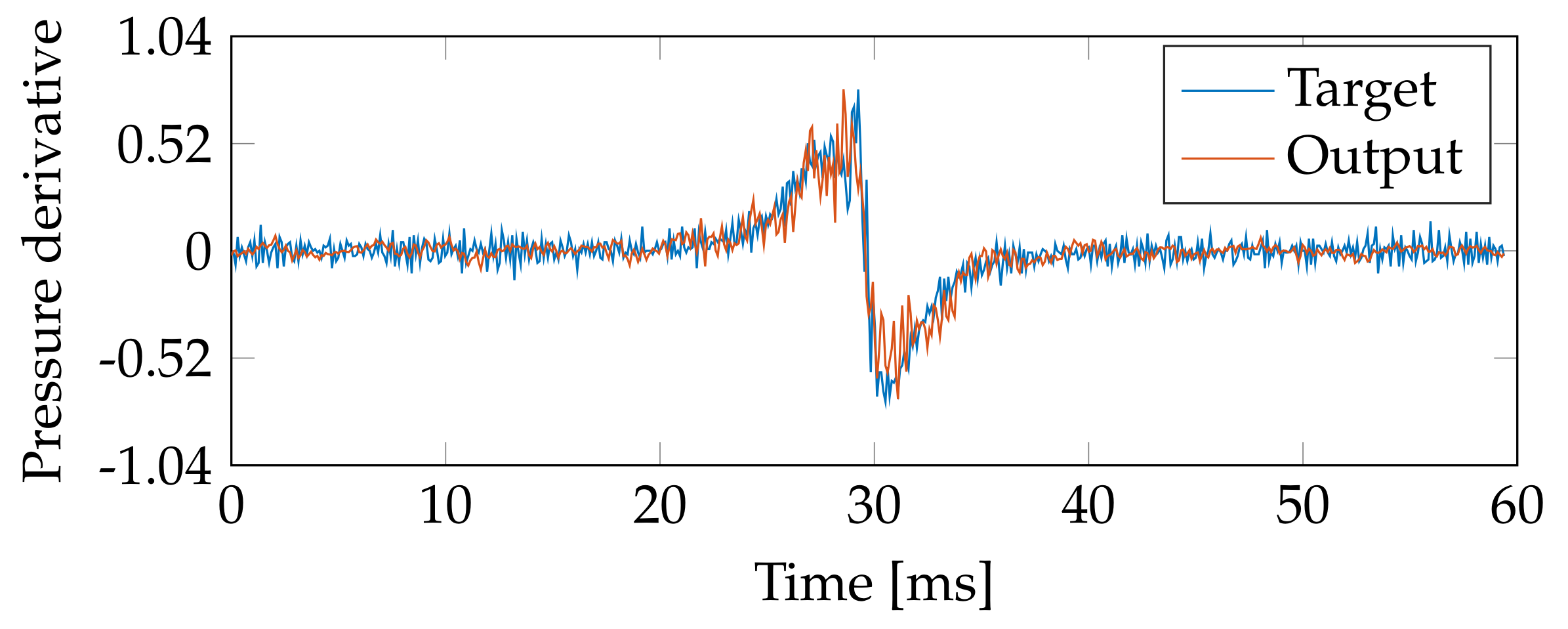

4. Results and Discussion

5. Conclusions and Future Work

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Vossoughi, G.; Rezazadeh, S. Optimization of the calibration for an internal combustion engine management system using multi-objective genetic algorithms. In Proceedings of the 2005 IEEE Congress on Evolutionary Computation, Scotland, UK, 2–5 September 2005; Volume 2, pp. 1254–1261. [Google Scholar]

- Guezennec, Y.G.; Gyan, P. A Novel Approach to Real-Time Estimation of the Individual Cylinder Combustion Pressure for SI Engine Control; Technical Report; SAE Technical Paper: Warrendale, PA, USA, 1999. [Google Scholar]

- Zhao, H. HCCI and CAI Engines for the Automotive Industry; Elsevier: Amsterdam, The Netherlands, 2007. [Google Scholar]

- Saxena, S.; Bedoya, I.D. Fundamental phenomena affecting low temperature combustion and HCCI engines, high load limits and strategies for extending these limits. Prog. Energy Combust. Sci. 2013, 39, 457–488. [Google Scholar] [CrossRef]

- Wick, M.; Bedei, J.; Gordon, D.; Wouters, C.; Lehrheuer, B.; Nuss, E.; Andert, J.; Koch, C.R. In-cycle control for stabilization of homogeneous charge compression ignition combustion using direct water injection. Appl. Energy 2019, 240, 1061–1074. [Google Scholar] [CrossRef]

- Venu, H.; Raju, V.D.; Lingesan, S.; Soudagar, M.E.M. Influence of Al2O3nano additives in ternary fuel (diesel-biodiesel-ethanol) blends operated in a single cylinder diesel engine: Performance, Combustion and Emission Characteristics. Energy 2020, 215, 119091. [Google Scholar] [CrossRef]

- Emiroğlu, A.O. Effect of fuel injection pressure on the characteristics of single cylinder diesel engine powered by butanol-diesel blend. Fuel 2019, 256, 115928. [Google Scholar] [CrossRef]

- Sudarmanta, B.; Setiyawan, A.; Bachtiar, K.A.; Yuvenda, D.; da Silva, J. Effects of Advancing the Pilot Injection Timing on The Engine Performance, Combustion and Emissions on Diesel dual fuel Engine at High Load. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: East Java, Indonesia, 2019; Volume 588, p. 012020. [Google Scholar]

- Gordon, D.; Wouters, C.; Wick, M.; Xia, F.; Lehrheuer, B.; Andert, J.; Koch, C.R.; Pischinger, S. Development and experimental validation of a real-time capable field programmable gate array–based gas exchange model for negative valve overlap. Int. J. Engine Res. 2020, 21, 421–436. [Google Scholar] [CrossRef]

- Bennett, C.; Dunne, J.; Trimby, S.; Richardson, D. Engine cylinder pressure reconstruction using crank kinematics and recurrently-trained neural networks. Mech. Syst. Signal Process. 2017, 85, 126–145. [Google Scholar] [CrossRef]

- Grajales, J.A.; Quintero, H.F.; Romero, C.A.; Henao, E.; Lopez, J.F.; Torres, D. Combustion pressure estimation method of a spark ignited combustion engine based on vibration signal processing. J. Vibroengineering 2016, 18, 4237–4247. [Google Scholar]

- Bizon, K.; Continillo, G.; Mancaruso, E.; Vaglieco, B.M. Towards On-Line Prediction of the In-Cylinder Pressure in Diesel Engines from Engine Vibration using Artificial Neural Networks; Technical Report; SAE Technical Paper: Warrendale, PA, USA, 2013. [Google Scholar]

- Bizon, K.; Continillo, G.; Mancaruso, E.; Vaglieco, B.M. Reconstruction of In-Cylinder Pressure in a Diesel Engine from Vibration Signal using a RBF Neural Network Model; Technical Report; SAE Technical Paper: Warrendale, PA, USA, 2011. [Google Scholar]

- Barelli, L.; Bidini, G.; Buratti, C.; Mariani, R. Diagnosis of internal combustion engine through vibration and acoustic pressure non-intrusive measurements. Appl. Therm. Eng. 2009, 29, 1707–1713. [Google Scholar] [CrossRef]

- Ali, S.A.; Saraswati, S. Reconstruction of cylinder pressure using crankshaft speed fluctuations. In Proceedings of the 2015 International Conference on Industrial Instrumentation and Control (ICIC), Piscataway, NJ, USA, 28–30 May 2015; pp. 456–461. [Google Scholar]

- Huang, X.; Kang, L.; Kassa, M.; Hall, C. Cylinder Specific Pressure Predictions for Advanced Dual Fuel Compression Ignition Engines Utilizing a Two-Stage Functional Data Analysis. J. Dyn. Syst. Meas. Control. 2019, 141, 051006. [Google Scholar] [CrossRef]

- Chiatti, G.; Chiavola, O.; Recco, E.; Magno, A.; Mancaruso, E.; Vaglieco, B.M. Accelerometer measurement for MFB evaluation in multi-cylinder diesel engine. Energy 2017, 133, 843–850. [Google Scholar] [CrossRef]

- Narayan, S.; Milojevic, S.; Gupta, V. Combustion monitoring in engines using accelerometer signals. J. Vibroengineering 2019, 21, 1552–1563. [Google Scholar] [CrossRef]

- Chiatti, G.; Chiavola, O.; Conti, E.; Recco, E. Automotive turbocharger speed estimation via vibration analysis for combustion optimization. Int. J. Mech. Eng. Technol. 2017, 8, 153–163. [Google Scholar]

- Lee, Y.; Lee, S.; Han, K.; Min, K. Prediction of In-Cylinder Pressure for Light-Duty Diesel Engines; Technical Report; SAE Technical Paper: Warrendale, PA, USA, 2019. [Google Scholar]

- Wu, J.; Jacoby, A.; Llamocca, D.; Sangeorzan, B. A Model for Crank-Angle-Resolved Engine Cylinder Pressure Estimation; Technical Report; SAE Technical Paper: Warrendale, PA, USA, 2018. [Google Scholar]

- Evlampiev, A.; Somers, L.; Baert, R.; De Goey, L. On the impact of the ideal gas assumption to high-pressure combustion phenomena in engines. Combust. Sci. Technol. 2007, 180, 371–390. [Google Scholar] [CrossRef]

- Yue, Z.; Hessel, R.; Reitz, R.D. Investigation of real gas effects on combustion and emissions in internal combustion engines and implications for development of chemical kinetics mechanisms. Int. J. Engine Res. 2018, 19, 269–281. [Google Scholar] [CrossRef]

- Yeliana, Y.; Cooney, C.; Worm, J.; Michalek, D.; Naber, J. Estimation of double-Wiebe function parameters using least square method for burn durations of ethanol-gasoline blends in spark ignition engine over variable compression ratios and EGR levels. Appl. Therm. Eng. 2011, 31, 2213–2220. [Google Scholar] [CrossRef]

- Liu, F.; Amaratunga, G.A.; Collings, N.; Soliman, A. An Experimental Study on Engine Dynamics Model Based In-Cylinder Pressure Estimation; Technical Report; SAE Technical Paper: Warrendale, PA, USA, 2012. [Google Scholar]

- Mariani, V.C.; Och, S.H.; dos Santos Coelho, L.; Domingues, E. Pressure prediction of a spark ignition single cylinder engine using optimized extreme learning machine models. Appl. Energy 2019, 249, 204–221. [Google Scholar] [CrossRef]

- Polat, S.; Özdilli, Ö.; Cizmeci, H. An estimation of incylinder pressure based on lambda and engine speed in hcci engine using artificial neural networks. Fresenius Environ. Bull. 2019, 28, 3568–3576. [Google Scholar]

- Trimby, S.; Dunne, J.F.; Bennett, C.; Richardson, D. Unified approach to engine cylinder pressure reconstruction using time-delay neural networks with crank kinematics or block vibration measurements. Int. J. Engine Res. 2017, 18, 256–272. [Google Scholar] [CrossRef]

- Han, R.; Bohn, C.; Bauer, G. Recursive engine in-cylinder pressure estimation using Kalman filter and structural vibration signal. IFAC-PapersOnLine 2018, 51, 700–705. [Google Scholar] [CrossRef]

- Payri, F.; Luján, J.; Martín, J.; Abbad, A. Digital signal processing of in-cylinder pressure for combustion diagnosis of internal combustion engines. Mech. Syst. Signal Process. 2010, 24, 1767–1784. [Google Scholar] [CrossRef]

- Boussaada, Z.; Curea, O.; Remaci, A.; Camblong, H.; Mrabet Bellaaj, N. A nonlinear autoregressive exogenous (NARX) neural network model for the prediction of the daily direct solar radiation. Energies 2018, 11, 620. [Google Scholar] [CrossRef]

- Kaiser, M. Time-delay neural networks for control. IFAC Proc. Vol. 1994, 27, 967–972. [Google Scholar] [CrossRef]

- Derakhshani, R.; Schuckers, S.A. Continuous time delay neural networks for detection of temporal patterns in signals. In Proceedings of the 2004 IEEE International Joint Conference on Neural Networks (IEEE Cat. No. 04CH37541), Budapest, Hungary, 25–29 July 2004; Volume 4, pp. 2723–2728. [Google Scholar]

- Bodisco, T.; Brown, R.J. Inter-cycle variability of in-cylinder pressure parameters in an ethanol fumigated common rail diesel engine. Energy 2013, 52, 55–65. [Google Scholar] [CrossRef]

- Burrus, C.S.; Parks, T. Convolution Algorithms; Citeseer: New York, NY, USA, 1985. [Google Scholar]

- Chen, H.; Zhang, P.; Liu, Y. Investigation on combustion and emission performance of a common rail diesel engine fueled with diesel-ethylene glycol dual fuel. Appl. Therm. Eng. 2018, 142, 43–55. [Google Scholar] [CrossRef]

- Larsson, S.; Schagerberg, S. SI-Engine Cylinder Pressure Estimation Using Torque Sensors; Technical Report; SAE Technical Paper: Warrendale, PA, USA, 2004. [Google Scholar]

| Type | 4-Stroke Vertical |

|---|---|

| Cylinders | 1 |

| Fuel | Diesel |

| Compression ratio | 19:1 |

| Fuel feed system | Direct injection |

| Fuel injection angle | 20 before TDC |

| Fuel pump | Positive displacement |

| Engine-Cooling System | Forced air |

| Bore × Stroke | 86 mm × 70 mm |

| Lubricant | SAE 10W30 |

| Max power | 7.30 kW( 10.0 HP) 3600 RPM |

| Max torque | 27 Nm 1500 RPM |

| Application Range (GVW) (t/lb) | 15–18/33,000–39,500 | |

|---|---|---|

| Maximum braking torque | 12 V | 1650 Nm/1218 lb-ft |

| 24 V | 2000 Nm/1476 lb-ft | |

| Weight | Complete | 232 Kg/511 lb |

| Stator | 154 Kg/339 lb | |

| Rotors | 78 Kg/172 lb | |

| Rotors Inertia | 2.69 Kgm/64 lb-ft2 | |

| Maximum transmissible torque | 31,600 Nm/23,321 lb-ft | |

| Max. admissible R.P.M. | Constant | 2600 |

| Periodic | 3600 | |

| Air-gap regulation (±0.1 mm/0.0039 inch.) | 1.4 mm/0.0551 inch | |

| Model | Optrand D822J6-SP |

|---|---|

| Pressure Range [bar] | 0–100 |

| Input Voltage [V] | 9–18 DC |

| Output Voltage [V] | 0.5–4.5 DC |

| Sensitivity [bar/V] | 26.02 |

| Frequency Range [Hz] | 0.1–20,000 |

| Temperature Range [°C] | 0–390 |

| Cable Length [m] | 1.5 |

| Load level | Current [A] | Torque [Nm] | BMEP [bar] |

|---|---|---|---|

| 0 | 0 | 0 | 0 |

| 1 | 0.5 | 1.5 | 0.45 |

| 2 | 1 | 6.1 | 1.83 |

| 3 | 1.5 | 10.7 | 3.22 |

| Speed [RPM]/Load [BMEP] | 0 | 0.45 | 1.83 | 3.22 |

|---|---|---|---|---|

| 1200 | 1.158 | 2.258 | −0.163|1.303 | 2.222|1.718 | −4.991|1.165 |

| 1500 | 2.001|2.086 | 4.193|2.588 | −0.054|2.143 | 2.867|1.948 |

| 1800 | 4.681|2.503 | 6.228|2.875 | 7.233|1.479 | 2.619|1.469 |

| Method | #Cylinders | #Predictors | #States | Ploc Error (°) | Pmax Error (%) | R2 |

|---|---|---|---|---|---|---|

| ELM [26] | 1 | 3 | 5 | - | - | 0.993 |

| ANN [27] | 1 | 3 | 5 | - | - | 0.998 |

| ANN [28] | 3 | 2 | 9 | 1.55–3.08 | 1.52–2.86 | - |

| Kalman Filter [29] | 4 | 1 | 9 | −2.11–2.30 | −17.74–12.00 | - |

| Ours | 1 | 1 | 12 | 1.30–2.59 | −4.99–7.23 | 0.994 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Valencia-Duque, A.F.; Cárdenas-Peña, D.A.; Álvarez-Meza, A.M.; Orozco-Gutiérrez, Á.A.; Quintero-Riaza, H.F. Tdnn-Based Engine In-Cylinder Pressure Estimation from Shaft Velocity Spectral Representation. Sensors 2021, 21, 2186. https://doi.org/10.3390/s21062186

Valencia-Duque AF, Cárdenas-Peña DA, Álvarez-Meza AM, Orozco-Gutiérrez ÁA, Quintero-Riaza HF. Tdnn-Based Engine In-Cylinder Pressure Estimation from Shaft Velocity Spectral Representation. Sensors. 2021; 21(6):2186. https://doi.org/10.3390/s21062186

Chicago/Turabian StyleValencia-Duque, Andrés F., David A. Cárdenas-Peña, Andrés M. Álvarez-Meza, Álvaro A. Orozco-Gutiérrez, and Héctor F. Quintero-Riaza. 2021. "Tdnn-Based Engine In-Cylinder Pressure Estimation from Shaft Velocity Spectral Representation" Sensors 21, no. 6: 2186. https://doi.org/10.3390/s21062186

APA StyleValencia-Duque, A. F., Cárdenas-Peña, D. A., Álvarez-Meza, A. M., Orozco-Gutiérrez, Á. A., & Quintero-Riaza, H. F. (2021). Tdnn-Based Engine In-Cylinder Pressure Estimation from Shaft Velocity Spectral Representation. Sensors, 21(6), 2186. https://doi.org/10.3390/s21062186