Textile Electrodes: Influence of Knitting Construction and Pressure on the Contact Impedance

Abstract

1. Introduction

2. Materials and Methods

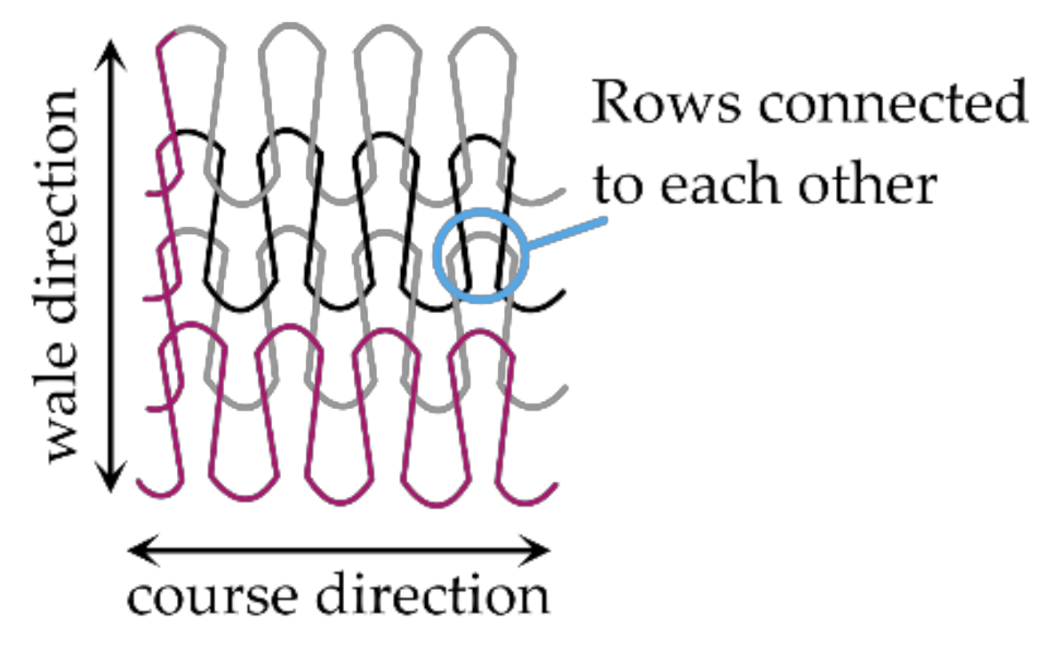

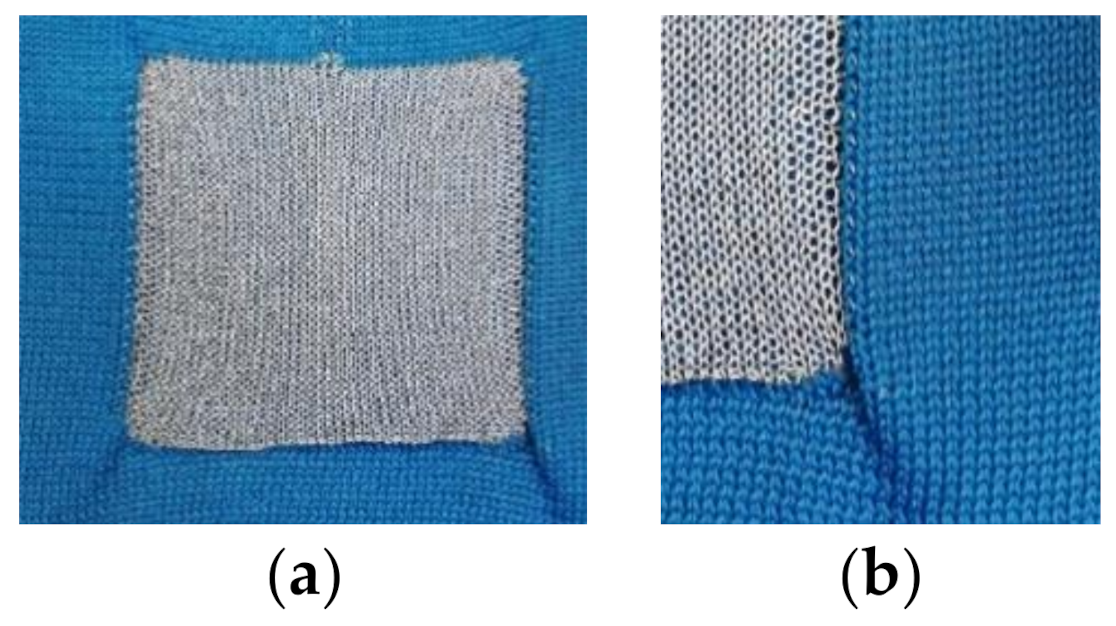

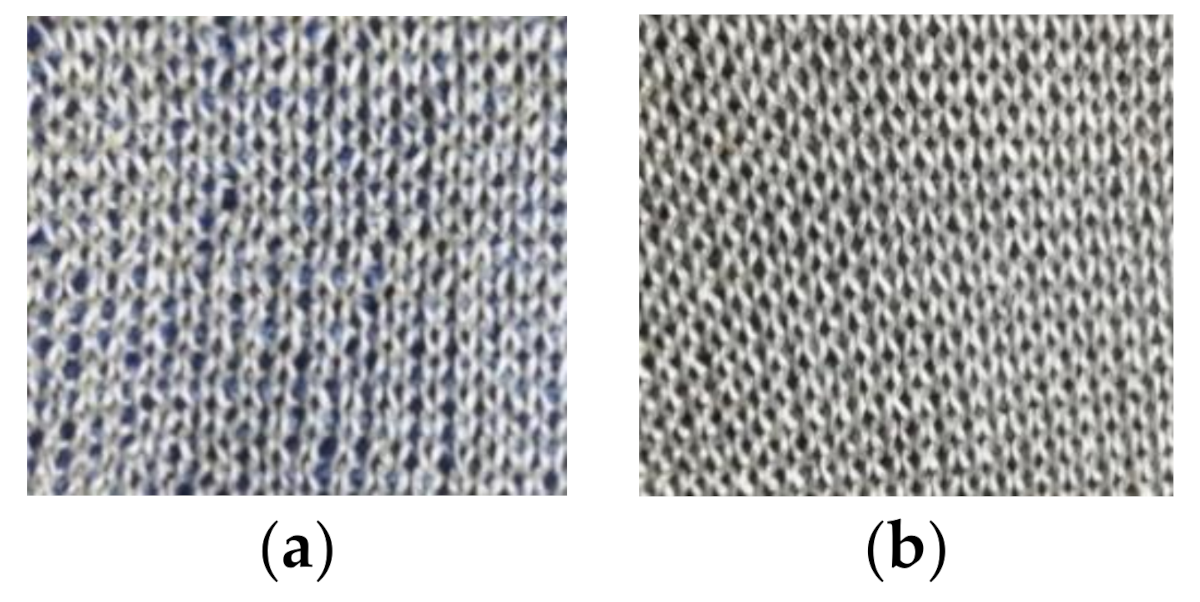

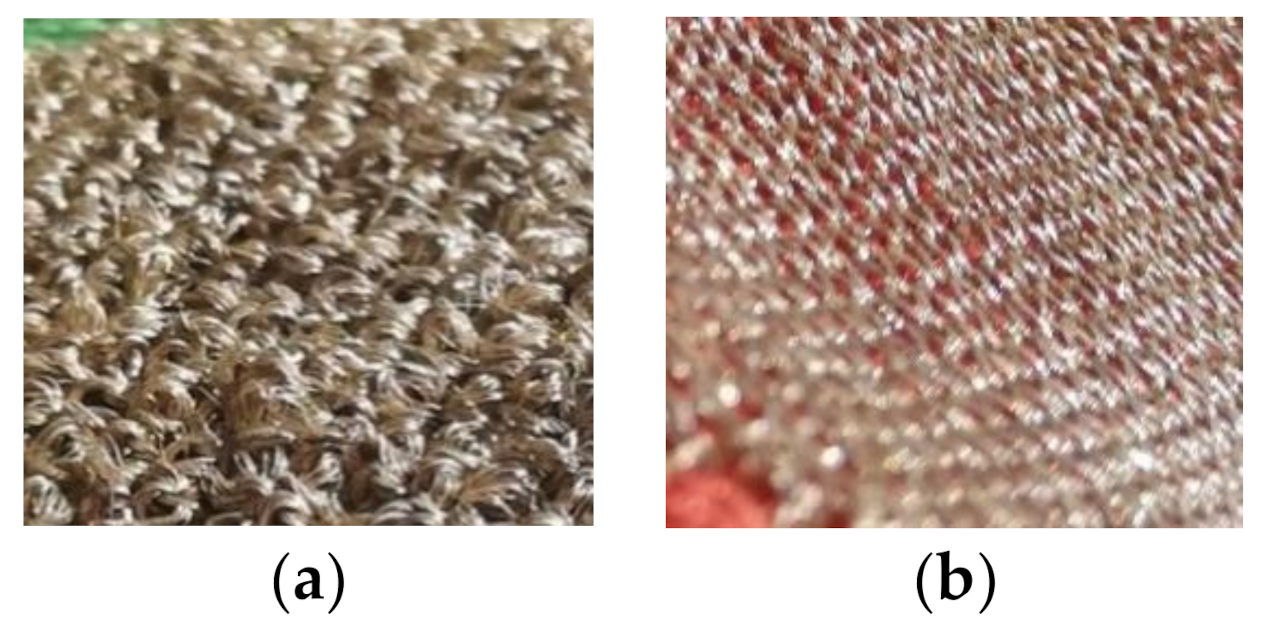

2.1. Fabrication of Knitted Electrodes

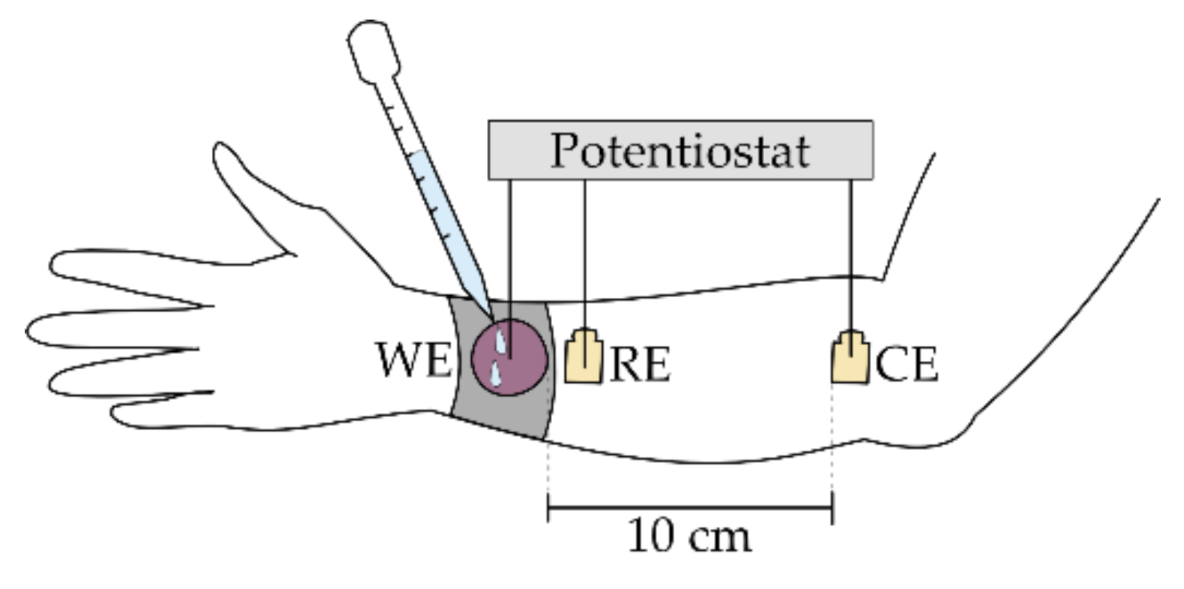

2.2. Impedance Testing Methods

2.2.1. Series I: Influence of Electrode Construction

2.2.2. Series II: Influence of Pressure

3. Results

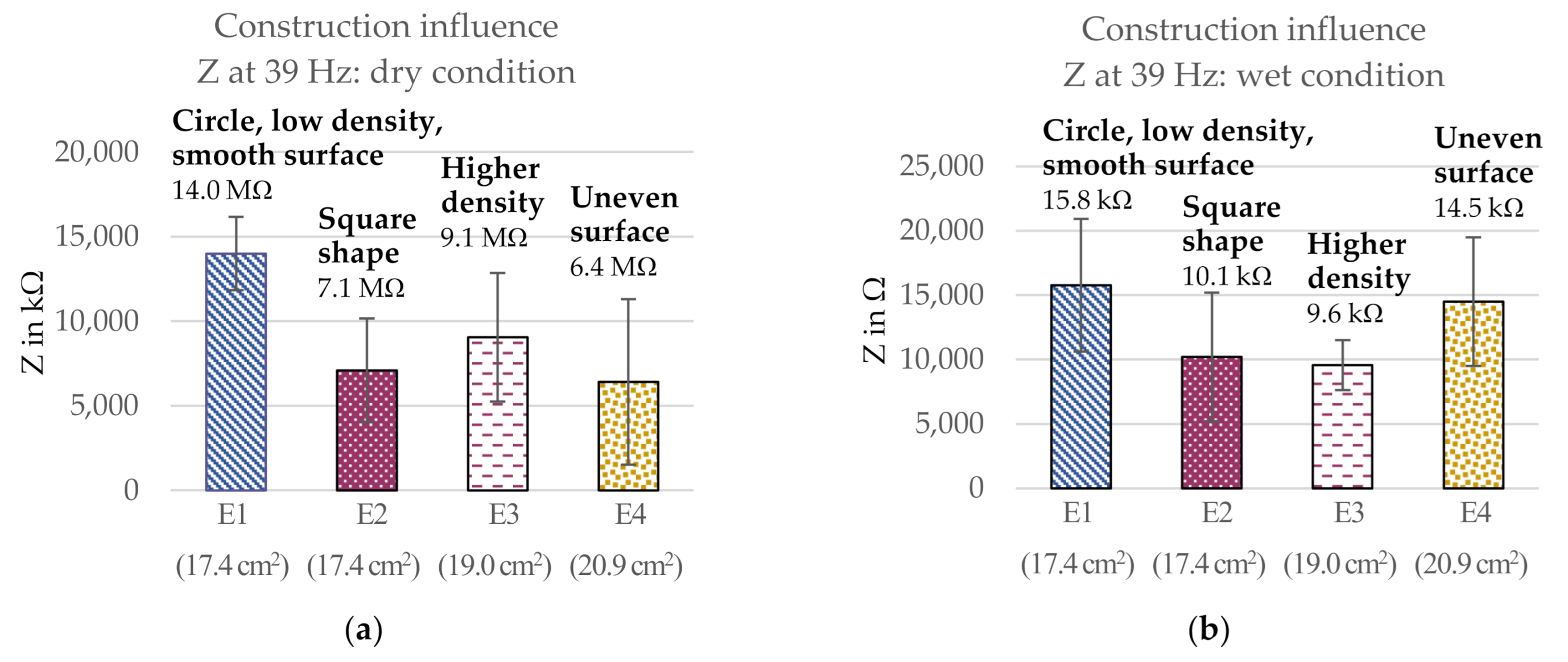

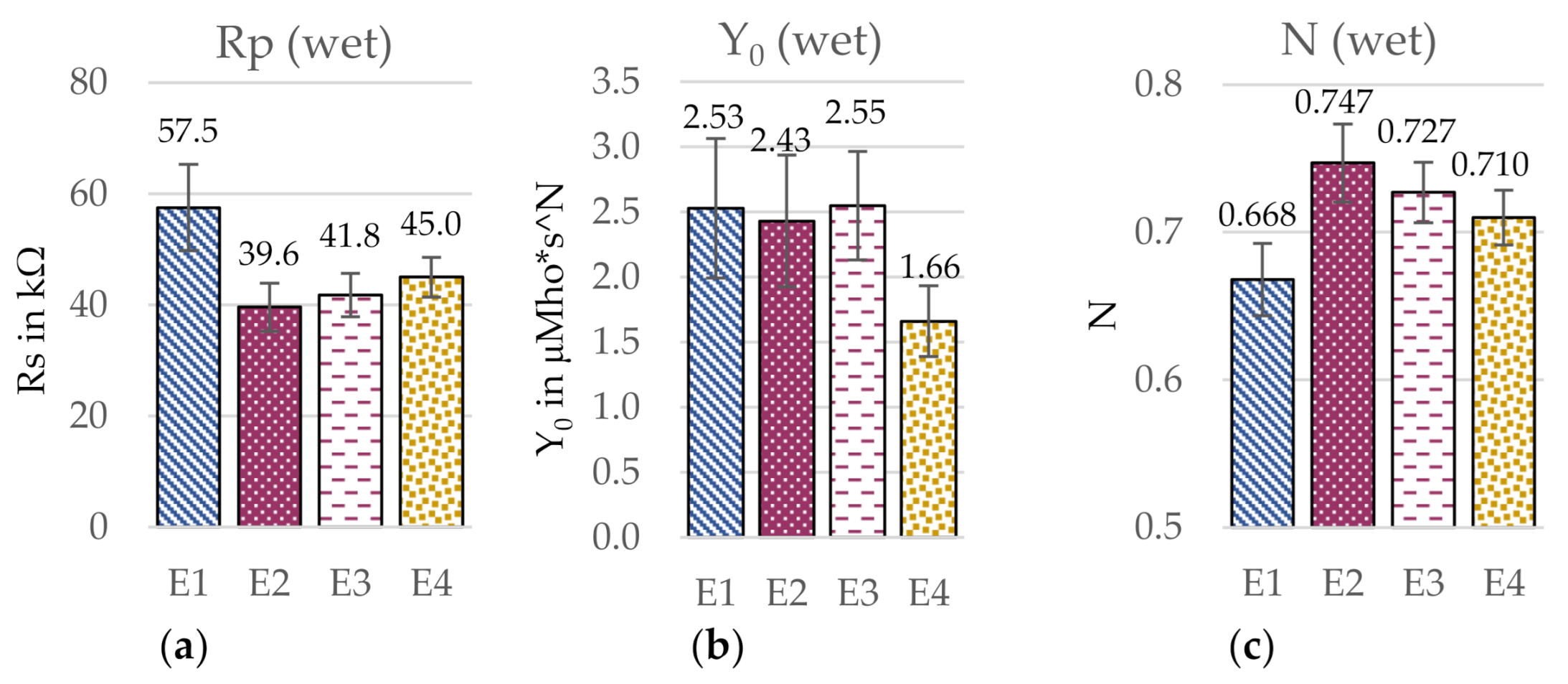

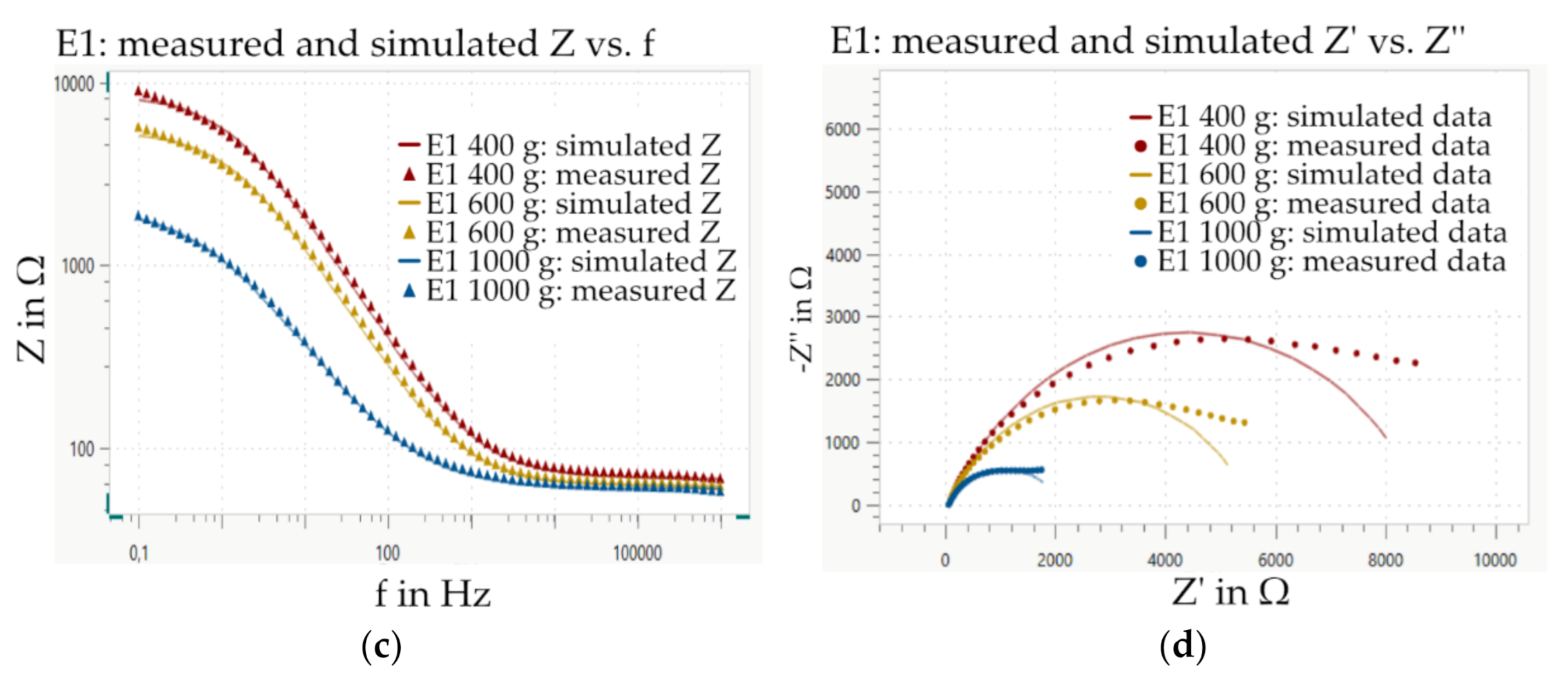

3.1. Series I: Influence of Electrode Size and Construction in Wet and Dry Condition

3.1.1. Influence of Size

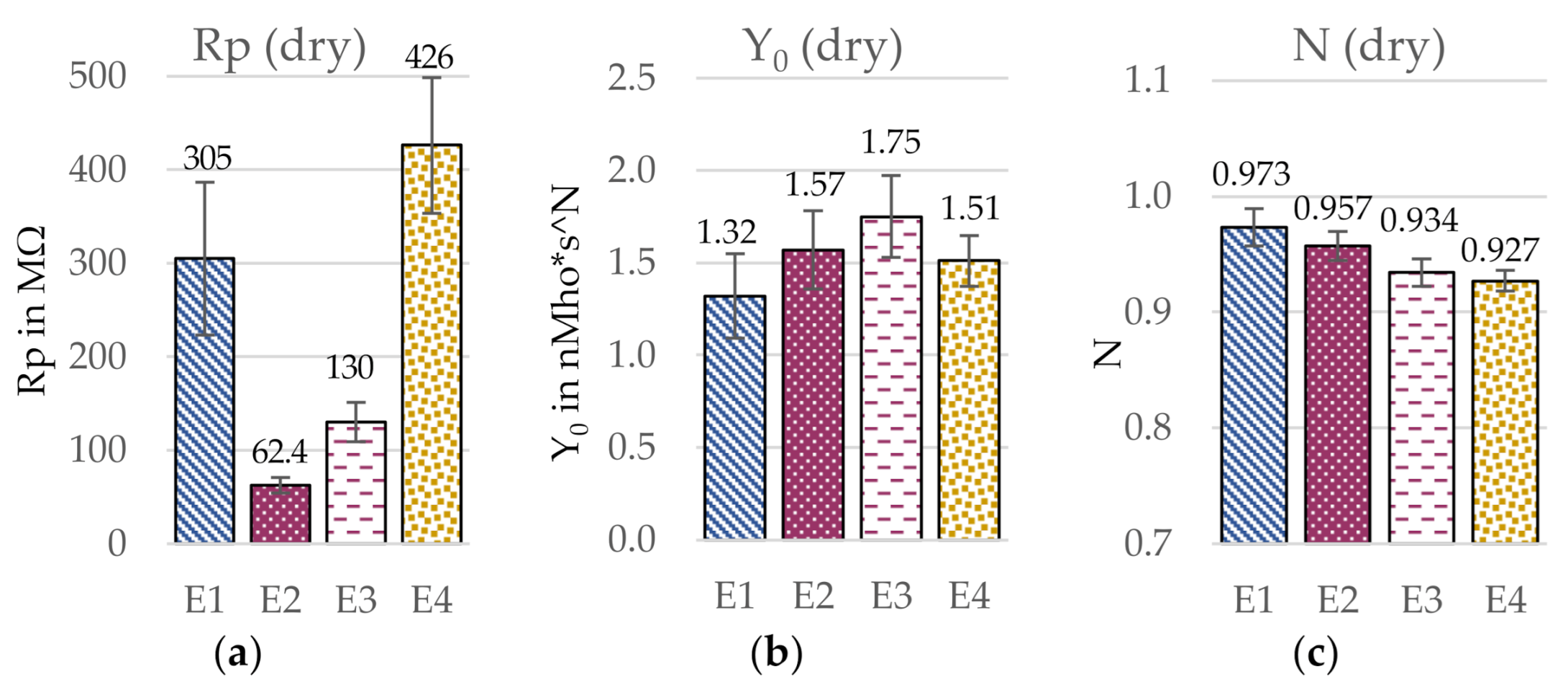

3.1.2. Influence of Electrode Construction Parameters

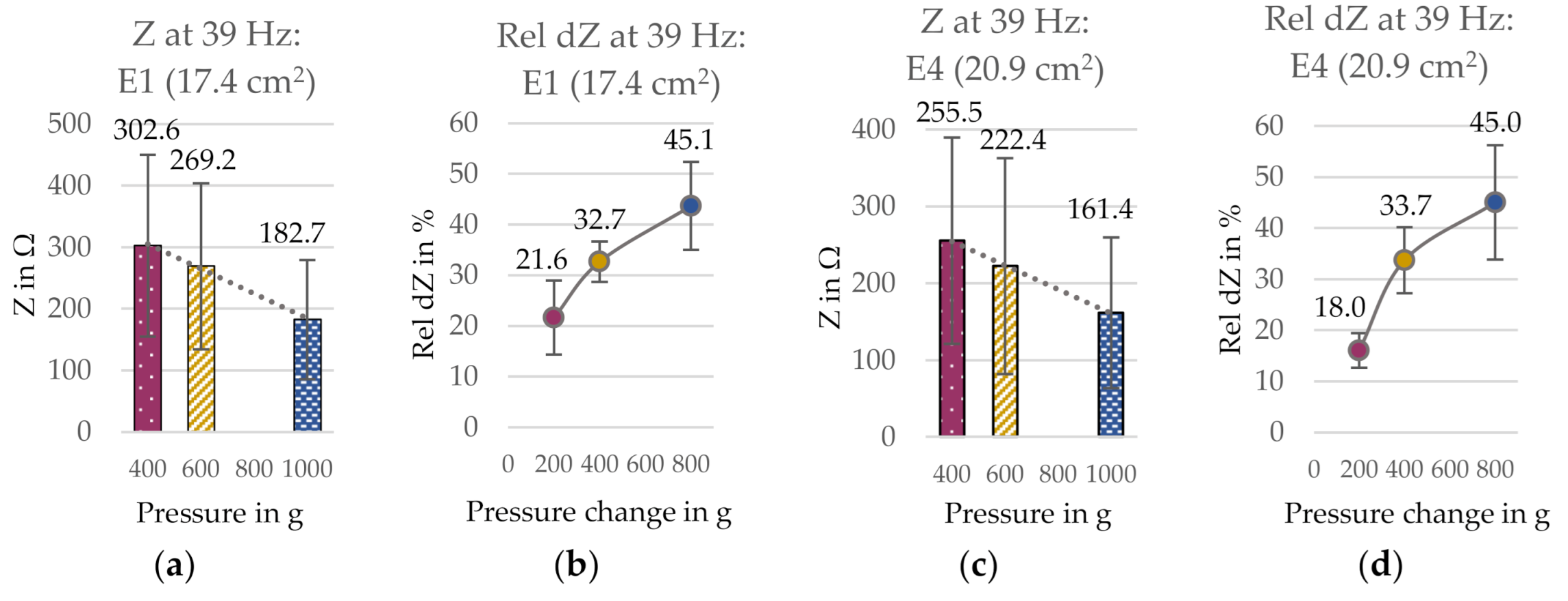

3.2. Series II: Influence of Pressure Application and Electrode Construction

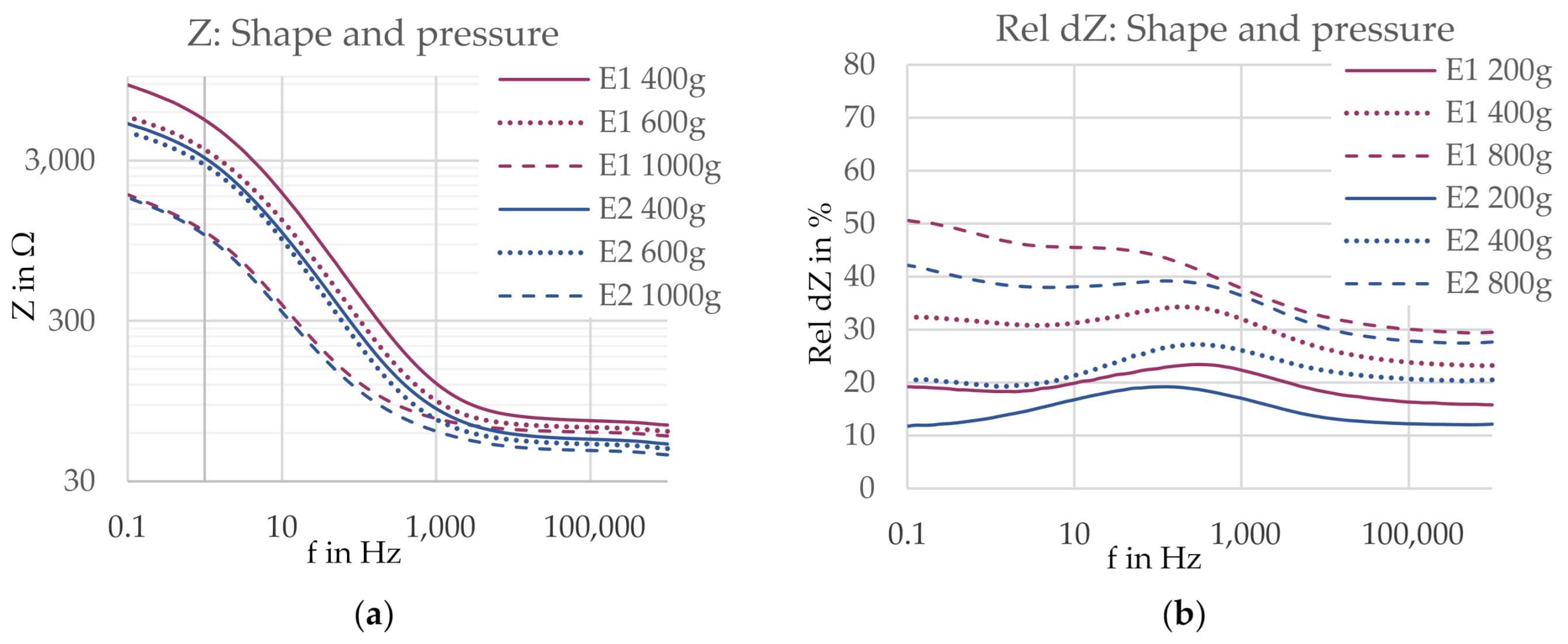

3.2.1. Shape and Pressure

3.2.2. Density and Pressure

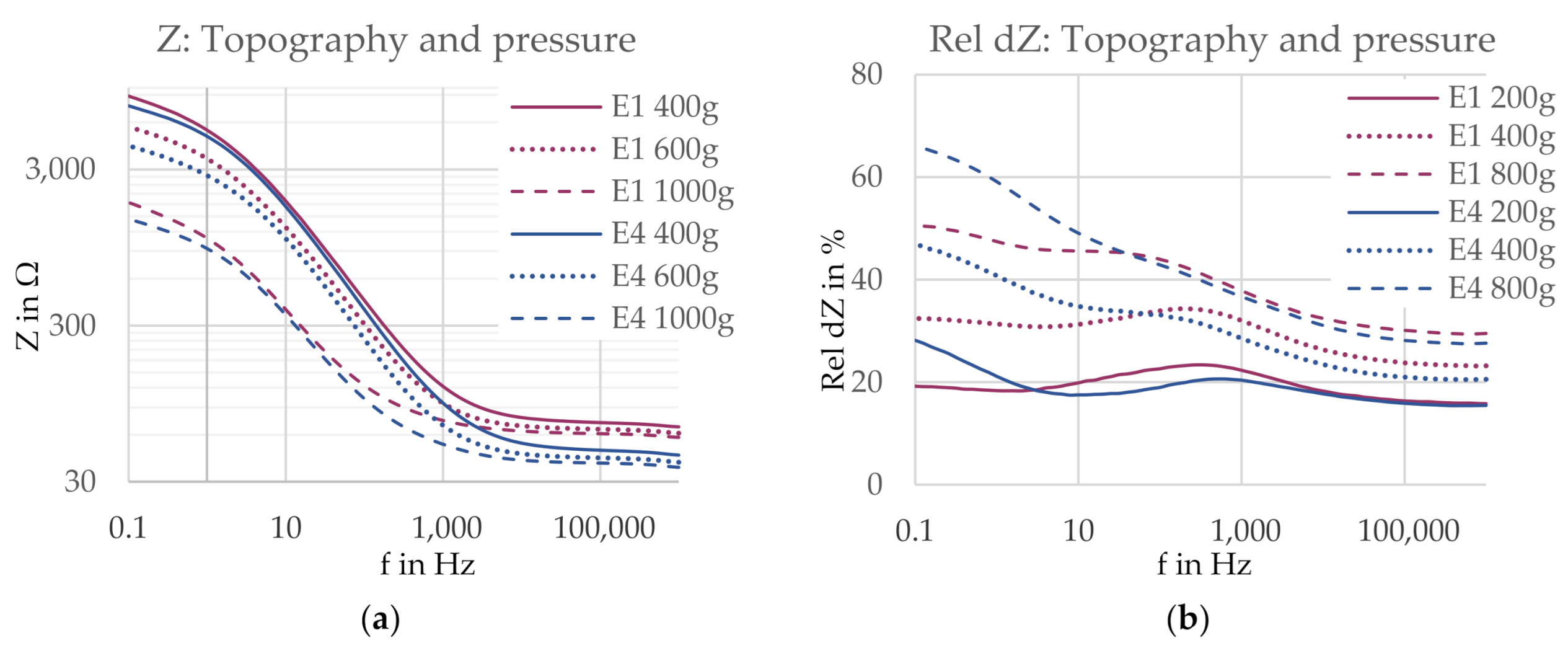

3.2.3. Topography and Pressure

4. Discussion

4.1. Factors Lowering the Contact Impedance

4.1.1. Electrode Condition

4.1.2. Electrode Size

4.1.3. Electrode Construction

4.1.4. Pressure Application

4.2. Factors Affecting the Contact Impedance Variation

4.2.1. Experimental Considerations

4.2.2. Electrode Construction

4.2.3. Pressure

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Guo, L.; Bashir, T.; Bresky, E.; Persson, N.-K. Electroconductive Textiles and Textile—Based Electromechanical Sensors—Integration In as an Approach for Smart Textiles. In Smart Textiles and Their Applications; Koncar, V., Ed.; Woodhead Publishing: Oxford, UK, 2016; pp. 657–693. [Google Scholar]

- Persson, N.-K.; Martinez, J.G.; Zhong, Y.; Maziz, A.; Jager, E.W.H. Actuating Textiles: Next Generation of Smart Textiles. Adv. Mater. Technol. 2018, 3, 1700397. [Google Scholar] [CrossRef]

- Lund, A.; van der Velden, N.M.; Persson, N.-K.; Hamedi, M.M.; Müller, C. Electrically Conducting Fibres for E-Textiles: An Open Playground for Conjugated Polymers and Carbon Nanomaterials. Mater. Sci. Eng. R 2018, 126, 1–29. [Google Scholar] [CrossRef]

- Guo, L.; Sandsjö, L.; Ortiz-Catalan, M.; Skrifvars, M. Systematic Review of Textile-Based Electrodes for Long-Term and Continuous Surface Electromyography Recording. Text. Res. J. 2020, 90, 227–244. [Google Scholar] [CrossRef]

- Popović-Bijelić, A.; Bijelić, G.; Jorgovanović, N.; Bojanić, D.; Popović, M.B.; Popović, D.B. Multi-Field Surface Electrode for Selective Electrical Stimulation. Artif. Organs 2005, 29, 448–452. [Google Scholar] [CrossRef] [PubMed]

- Crema, A.; Malesevic, N.; Furfaro, I.; Raschella, F.; Pedrocchi, A.; Micera, S. A Wearable Multi-Site System for NMES-Based Hand Function Restoration. IEEE transactions on neural systems and rehabilitation engineering. IEEE Trans. Neural Syst. Rehabil. Eng. 2018, 26, 428–440. [Google Scholar] [CrossRef] [PubMed]

- Ali, A.; Baheti, V.; Militky, J.; Khan, Z. Utility of Silver-Coated Fabrics as Electrodes in Electrotherapy Applications. J. Appl. Polym. Sci. 2018, 135, 46357. [Google Scholar] [CrossRef]

- Yang, K.; Freeman, C.; Torah, R.; Beeby, S.; Tudor, J. Screen Printed Fabric Electrode Array for Wearable Functional Electrical Stimulation. Sens. Actuators A Phys. 2014, 213, 108–115. [Google Scholar] [CrossRef]

- Gniotek, K.; Frydrysiak, M.; Zięba, J.; Tokarska, M.; Stempien, Z. Innovative Textile Electrodes for Muscles Electrostimulation. In Proceedings of the IEEE International Workshop on Medical Measurements and Applications Proceedings, Bari, Italy, 30–31 May 2011; Savino, M., Ed.; IEEE: Piscataway, NJ, USA, 2011; pp. 305–310. [Google Scholar]

- Zięba, J.; Frydrysiak, M.; Tesiorowski, L.; Tokarska, M. Textronic Matrix of Electrode System to Electrostimulation. In Proceedings of the IEEE International Symposium on Medical Measurements and Applications proceedings (MeMeA), Budapest, Hungary, 18–19 May 2012; IEEE: Piscataway, NJ, USA, 2012; pp. 1–5. [Google Scholar]

- Cho, H.-S.; Koo, S.-M.; Lee, J.; Cho, H.; Kang, D.-H.; Song, H.-Y.; Lee, J.-W.; Lee, K.-H.; Lee, Y.-J. Heart Monitoring Garments Using Textile Electrodes for Healthcare Applications. J. Med. Syst. 2011, 35, 189–201. [Google Scholar] [CrossRef] [PubMed]

- Vojtech, L.; Bortel, R.; Neruda, M.; Kozak, M. Wearable Textile Electrodes for ECG Measurement. Adv. Electr. Electron. 2013, 11, 410–414. [Google Scholar] [CrossRef]

- Arquilla, K.; Webb, A.K.; Anderson, A.P. Textile Electrocardiogram (ECG) Electrodes for Wearable Health Monitoring. Sensors 2020, 20, 1013. [Google Scholar] [CrossRef] [PubMed]

- Ozturk, O.; Yapici, M.K. Muscular Activity Monitoring and Surface Electromyography (sEMG) with Graphene Textiles. In Proceedings of the IEEE Sensors, Montreal, QC, Canada, 27–30 October 2019; Volume 19, pp. 1–4. [Google Scholar]

- Awan, F.; He, Y.; Le, L.; Tran, L.L.; Han, H.D.; Nguyen, L.P. ElectroMyography Acquisition System Using Graphene-based e-Textiles. In Proceedings of the 2019 International Symposium on Electrical and Electronics Engineering, Ho Chi Minh, Vietnam, 10–12 October 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 59–62. [Google Scholar]

- Servati, A.; Zou, L.; Wang, Z.J.; Ko, F.; Servati, P. Novel Flexible Wearable Sensor Materials and Signal Processing for Vital Sign and Human Activity Monitoring. Sensors 2017, 17, 1622. [Google Scholar] [CrossRef]

- Posada-Quintero, H.F.; Reljin, N.; Eaton-Robb, C.; Noh, Y.; Riistama, J.; Chon, K.H. Analysis of Consistency of Transthoracic Bioimpedance Measurements Acquired with Dry Carbon Black PDMS Electrodes, Adhesive Electrodes, and Wet Textile Electrodes. Sensors 2018, 18, 1719. [Google Scholar] [CrossRef] [PubMed]

- Xu, P.J.; Zhang, H.; Tao, X.M. Textile-Structured Electrodes for Electrocardiogram. Text. Prog. 2008, 40, 183–213. [Google Scholar] [CrossRef]

- Dodla, M.C.; Alvarado-Velez, M.; Mukhatyar, V.J.; Bellamkonda, R.V. Peripheral Nerve Regeneration. In Principles of Regenerative Medicine, 3rd ed.; Atala, A., Lanza, R., Mikos, T., Nerem, R., Eds.; Elsevier: Amsterdam, The Netherlands, 2019; Volume 1223–1236. [Google Scholar]

- Majkowski, M.G.R.J.; Gill, N.W. Physical Therapy Modalities. In The Sports Medicine Resource Manual; Seidenberg, P.H., Beutler, A.I., Eds.; Elsevier: Amsterdam, The Netherlands, 2008; pp. 453–464. [Google Scholar]

- Neuman, M.R. Therapeutic and Prosthetic Devices. In Medical Instrumentation, 4th ed.; Webster, J.G., Clark, J.W., Eds.; Wiley: Hoboken, NJ, USA, 2010; pp. 590–635. [Google Scholar]

- Ardiç, F.; Sarhus, M.; Topuz, O. Comparison of Two Different Techniques of Electrotherapy on Myofascial Pain. J. Back Musculoskelet. Rehabil. 2002, 16, 11–16. [Google Scholar] [CrossRef] [PubMed]

- Rattfalt, L.; Chedid, M.; Hult, P.; Linden, M.; Ask, P. Electrical Properties of Textile Electrodes. In Proceedings of the 29th Annual International Conference of the IEEE Engineering in Medicine and Biology Society, Lyon, France, 22–26 August 2007; IEEE: Piscataway, NJ, USA, 2007; pp. 5735–5738. [Google Scholar]

- Moineau, B.; Marquez-Chin, C.; Alizadeh-Meghrazi, M.; Popovic, M.R. Garments for functional electrical stimulation: Design and proofs of concept. J. Rehabil. Assist. Technol. Eng. 2019, 6, 1–15. [Google Scholar] [CrossRef]

- Curteza, A.; Cretu, V.; Macovei, L.; Poboroniuc, M. The Manufacturing of Textile Products with Incorporated Electrodes. Autex Res. J. 2016, 16, 13–18. [Google Scholar] [CrossRef]

- Li, L.; Au, W.M.; Li, Y.; Wan, K.M.; Wan, S.H.; Wong, K.S. Design of Intelligent Garment with Transcutaneous Electrical Nerve Stimulation Function Based on the Intarsia Knitting Technique. Text. Res. J. 2010, 80, 279–286. [Google Scholar] [CrossRef]

- Nawaz, N.; Nayak, R. Seamless Garments. In Garment Manufacturing Technology; Nayak, R., Padhye, R., Eds.; Woodhead Publishing: Cambridge, UK, 2015; Volume 168, pp. 373–383. [Google Scholar]

- Yapici, M.K.; Alkhidir, T.; Samad, Y.A.; Liao, K. Graphene-Clad Textile Electrodes for Electrocardiogram Monitoring. Sens. Actuators B Chem. 2015, 221, 1469–1474. [Google Scholar] [CrossRef]

- Kye, M.J.; Cho, J.; Yu, J.C.; Chang, Y.-W.; Han, J.; Lee, E.; Lim, H.S.; Lim, J.A. “Drop-On-Textile” Patternable Aqueous PEDOT Composite Ink Providing Highly Stretchable and Wash-Resistant Electrodes for Electronic Textiles. Dyes Pigm. 2018, 155, 150–158. [Google Scholar] [CrossRef]

- Castrillón, R.; Pérez, J.J.; Andrade-Caicedo, H. Electrical Performance of PEDOT:PSS-Based Textile Electrodes for Wearable ECG Monitoring: A Comparative Study. Biomed. Eng. Online 2018, 17, 1–23. [Google Scholar] [CrossRef] [PubMed]

- Zhou, H.; Lu, Y.; Chen, W.; Wu, Z.; Zou, H.; Krundel, L.; Li, G. Stimulating the Comfort of Textile Electrodes in Wearable Neuromuscular Electrical Stimulation. Sensors 2015, 15, 17241–17257. [Google Scholar] [CrossRef]

- Papaiordanidou, M.; Takamatsu, S.; Rezaei-Mazinani, S.; Lonjaret, T.; Martin, A.; Ismailova, E. Cutaneous Recording and Stimulation of Muscles Using Organic Electronic Textiles. Adv. Healthc. Mater. 2016, 5, 2001–2006. [Google Scholar] [CrossRef] [PubMed]

- Stewart, A.M.; Pretty, C.G.; Chen, X. An Evaluation of the Effect of Stimulation Parameters and Electrode Type on Bicep Muscle Response for a Voltage-controlled Functional Electrical Stimulator. IFAC-PapersOnLine 2017, 50, 15109–15114. [Google Scholar] [CrossRef]

- Poboroniuc, M.-S.; Irimia, D.-C.; Curteza, A.; Cretu, V.; Macovei, L. Improved Neuroprostheses by Means of Knitted Textiles Electrodes used for Functional Electrical Stimulation. In Proceedings of the EPE 2016, Iasi, Romania, 20–22 October 2016; IEEE: Piscataway, NJ, USA; pp. 320–325. [Google Scholar]

- An, X.; Tangsirinaruenart, O.; Stylios, G.K. Investigating the Performance of Dry Textile Electrodes for Wearable End-Uses. J. Text. Inst. 2019, 110, 151–158. [Google Scholar] [CrossRef]

- Puurtinen, M.M.; Komulainen, S.M.; Kauppinen, P.K.; Malmivuo, J.A.V.; Hyttinen, J.A.K. Measurement of Noise and Impedance of Dry and Wet Textile Electrodes, and Textile Electrodes with Hydrogel. In Proceedings of the International Conference of the IEEE Engineering in Medicine and Biology Society, New York, NY, USA, 30 August–3 September 2006; IEEE: Piscataway, NJ, USA, 2006; pp. 6012–6015. [Google Scholar]

- Liu, M.; Ward, T.; Young, D.; Matos, H.; Wei, Y.; Adams, J.; Yang, K. Electronic Textiles Based Wearable Electrotherapy for Pain Relief. Sensor Actuat. A Phys. 2020, 303, 111701. [Google Scholar] [CrossRef]

- Paiva, A.; Carvalho, H.; Catarino, A.; Postolache, O.; Postolache, G. Development of Dry Textile Electrodes for Electromiography—A Comparison between Knitted Structures and Conductive Yarns. In Proceedings of the 9th International Conference on Sensing Technology, Auckland, New Zealand, 8–10 December 2015; IEEE: Piscataway, NJ, USA, 2015; pp. 447–451. [Google Scholar]

- Beckmann, L.; Neuhaus, C.; Medrano, G.; Jungbecker, N.; Walter, M.; Gries, T.; Leonhardt, S. Characterization of Textile Electrodes and Conductors using Standardized Measurement Setups. Physiol. Meas. 2010, 31, 233–247. [Google Scholar] [CrossRef]

- Yun-Hsuan, C.; Op de Beeck, M.; Vanderheyden, L.; Carrette, E.; Mihajlović, V.; Vanstreels, K.; Grundlehner, B.; Gadeyne, S.; Boon, P.; Van Hoof, C. Soft, Comfortable Polymer Dry Electrodes for High Quality ECG and EEG Recording. Sensors 2014, 14, 23758–23780. [Google Scholar]

- Doucet, B.M.; Lam, A.; Griffin, L. Neuromuscular Electrical Stimulation for Skeletal Muscle Function. Yale J. Biol. Med. 2012, 85, 201–215. [Google Scholar]

- Gibson, W.; Wand, B.M.; Meads, C.; Catley, M.J.; O’Connell, N.E. Transcutaneous Electrical Nerve Stimulation (TENS) for Chronic Pain—An Overview of Cochrane Reviews. Cochrane Database Syst. Rev. 2019, 4, CD011890. [Google Scholar]

- Sluka, K.A.; Walsh, D. Transcutaneous Electrical Nerve Stimulation: Basic Science Mechanisms and Clinical Effectiveness. J. Pain 2003, 4, 109–121. [Google Scholar] [CrossRef]

- Márquez Ruiz, J.C. Sensor-Based Garments that Enable the Use of Bioimpedance Technology: Towards Personalized Healthcare Monitoring. Ph.D. Thesis, University of Borås, Stockholm, Sweden, January 2013. [Google Scholar]

- Weder, M.; Hegemann, D.; Amberg, M.; Hess, M.; Boesel, L.F.; Abächerli, R.; Meyer, V.R.; Rossi, R.M. Embroidered Electrode with Silver/Titanium Coating for Long-Term ECG Monitoring. Sensors 2015, 15, 1750–1759. [Google Scholar] [CrossRef] [PubMed]

- Keller, T.; Kuhn, A. Electrodes for Transcutaneous (Surface) Electrical Stimulation. J. Autom. Contr. 2008, 18, 35–45. [Google Scholar] [CrossRef]

- Tjelta, M.; Sunde, S. Current-Distribution Effects on the Impedance of Porous Electrodes and Electrodes Covered with Films. J. Electroanal. Chem. 2015, 737, 65–77. [Google Scholar] [CrossRef]

- Soroudi, A.; Hernández, N.; Wipenmyr, J.; Nierstrasz, V. Surface Modification of Textile Electrodes to improve Electrocardiography Signals in Wearable Smart Garment. J. Mater. Sci. Mater. Electr. 2019, 30, 16666–16675. [Google Scholar] [CrossRef]

- Tallgren, P.; Vanhatalo, S.; Kaila, K.; Voipio, J. Evaluation of Commercially Available Electrodes and Gels for Recording of Slow EEG Potentials. Clin. Neurophysiol. 2005, 116, 799–806. [Google Scholar] [CrossRef] [PubMed]

- An, X.; Stylios, G.K. A Hybrid Textile Electrode for Electrocardiogram (ECG) Measurement and Motion Tracking. Materials 2018, 11, 1887. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Euler, L.; Guo, L.; Persson, N.-K. Textile Electrodes: Influence of Knitting Construction and Pressure on the Contact Impedance. Sensors 2021, 21, 1578. https://doi.org/10.3390/s21051578

Euler L, Guo L, Persson N-K. Textile Electrodes: Influence of Knitting Construction and Pressure on the Contact Impedance. Sensors. 2021; 21(5):1578. https://doi.org/10.3390/s21051578

Chicago/Turabian StyleEuler, Luisa, Li Guo, and Nils-Krister Persson. 2021. "Textile Electrodes: Influence of Knitting Construction and Pressure on the Contact Impedance" Sensors 21, no. 5: 1578. https://doi.org/10.3390/s21051578

APA StyleEuler, L., Guo, L., & Persson, N.-K. (2021). Textile Electrodes: Influence of Knitting Construction and Pressure on the Contact Impedance. Sensors, 21(5), 1578. https://doi.org/10.3390/s21051578