An Identification Method for Rotor Direction Based on Charge Induction

Abstract

1. Introduction

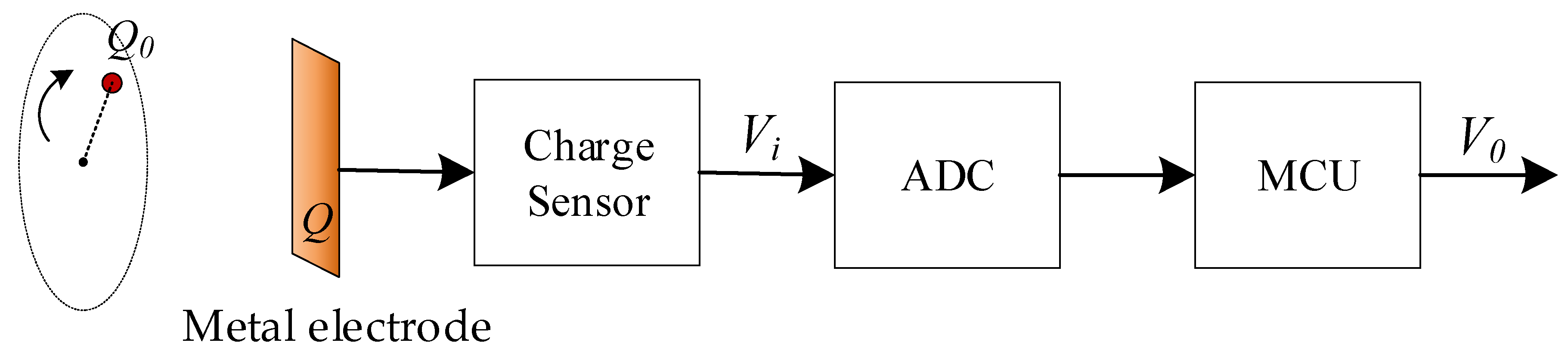

2. Detection Principle

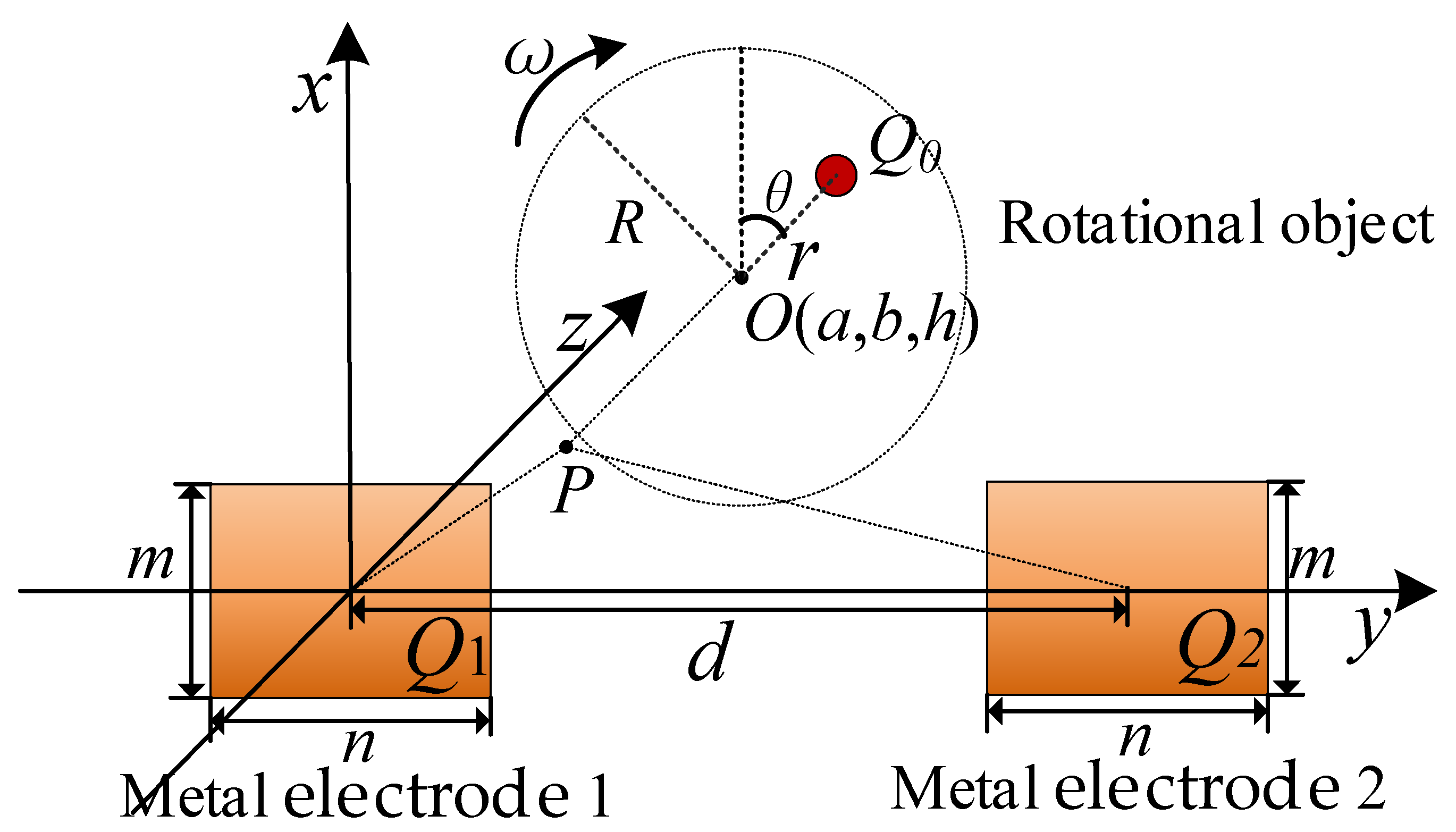

2.1. Charge Detection Model for Rotor

2.2. Rotor Direction Identification Model

3. Experimental Results and Discussion

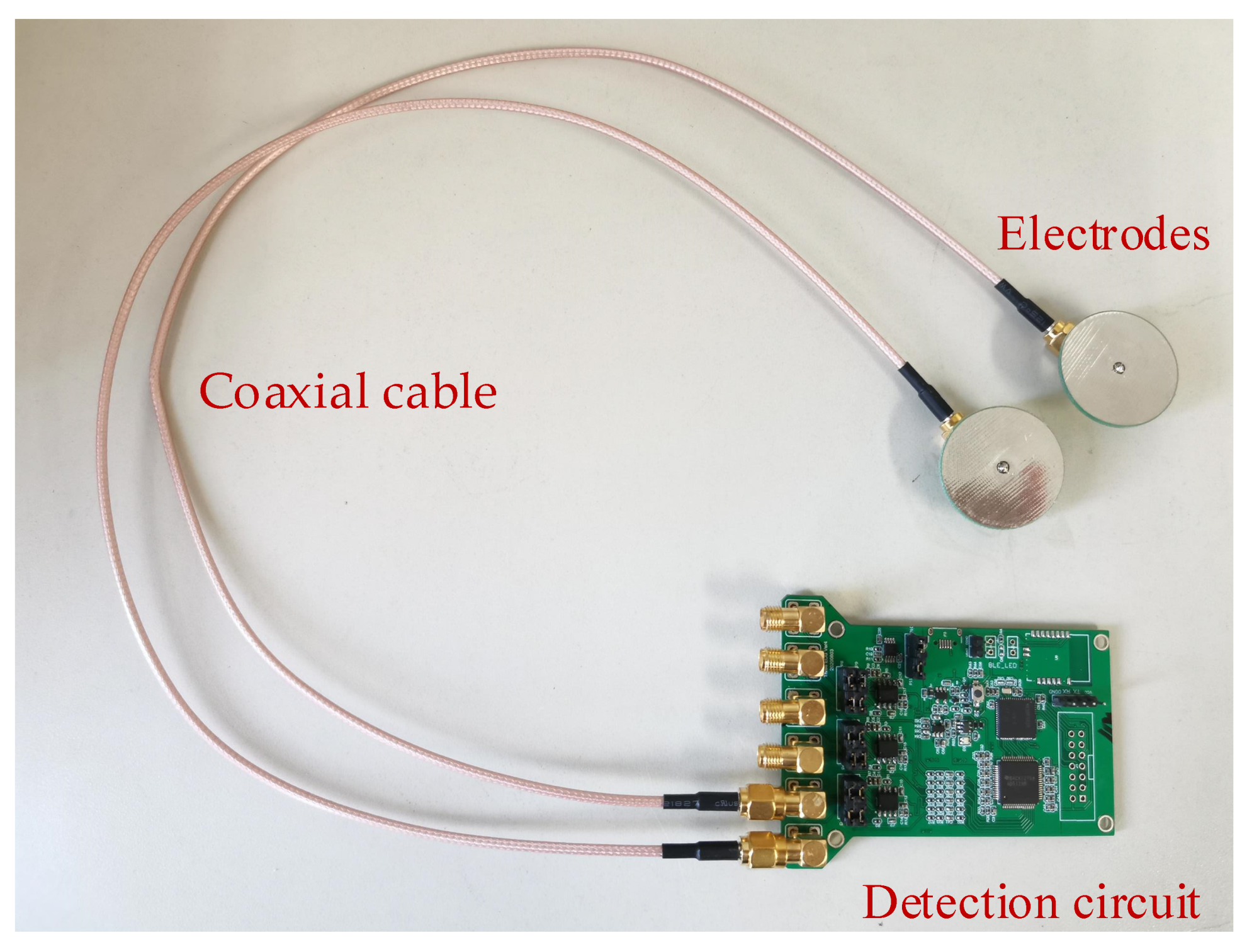

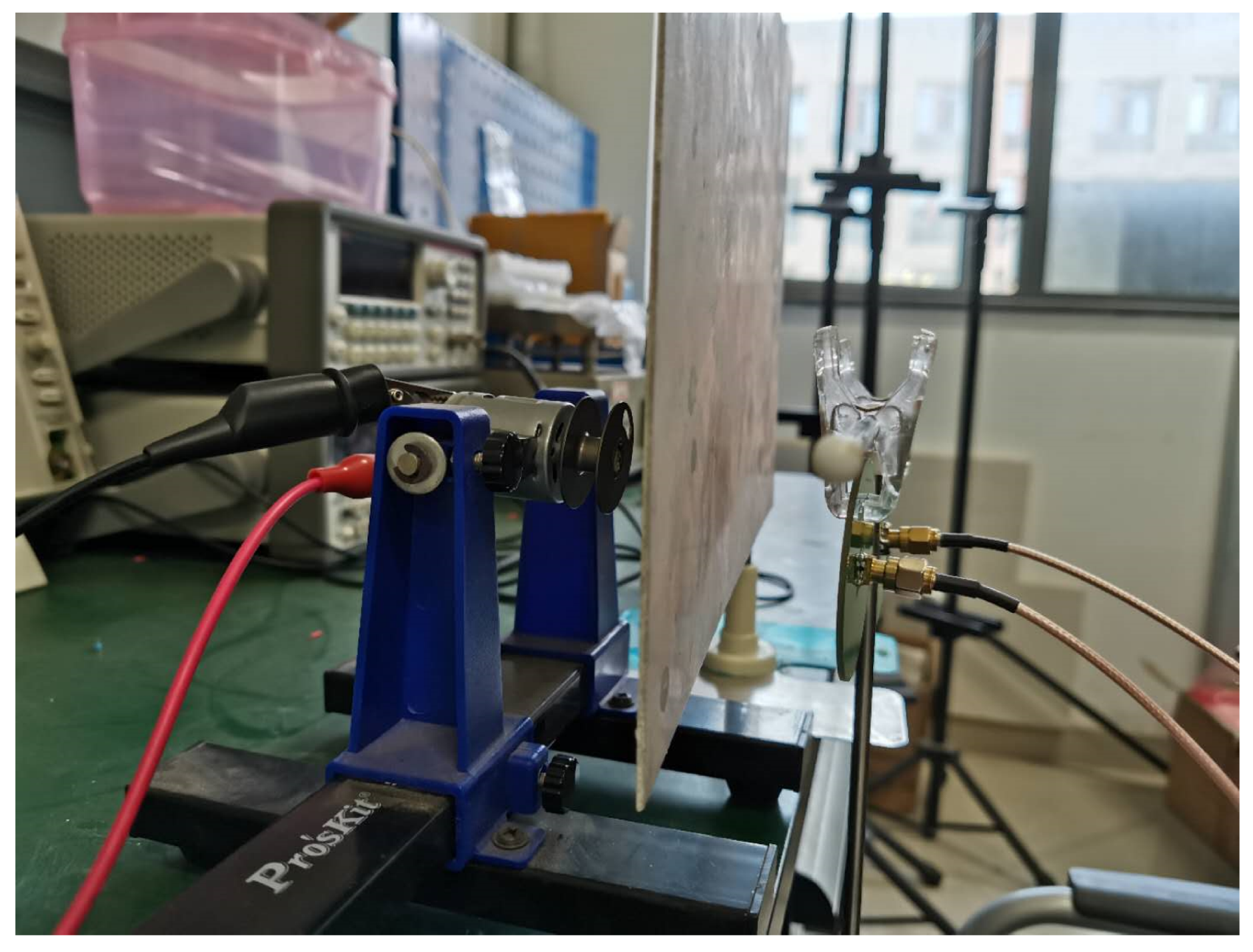

3.1. Experimental Condition

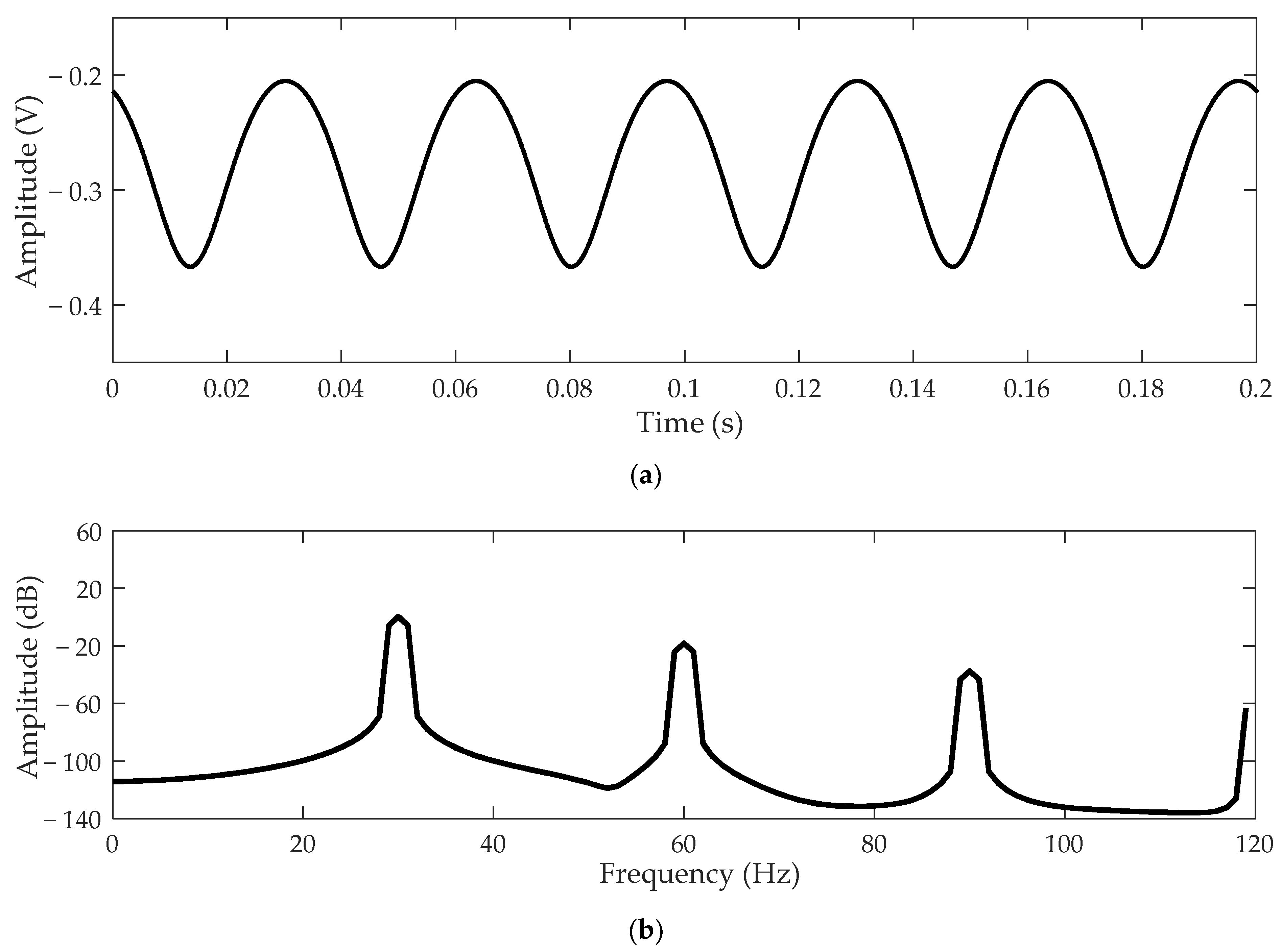

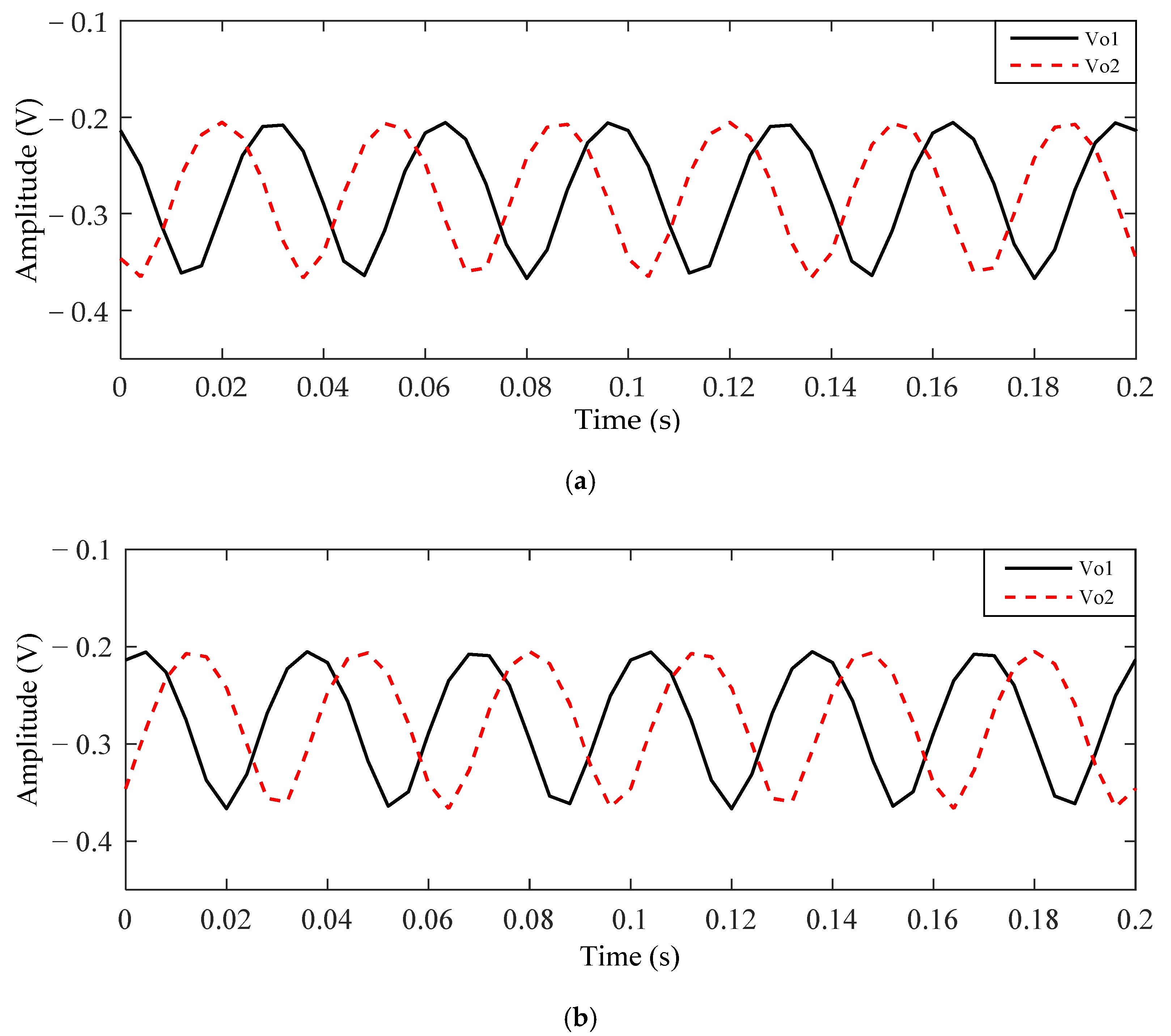

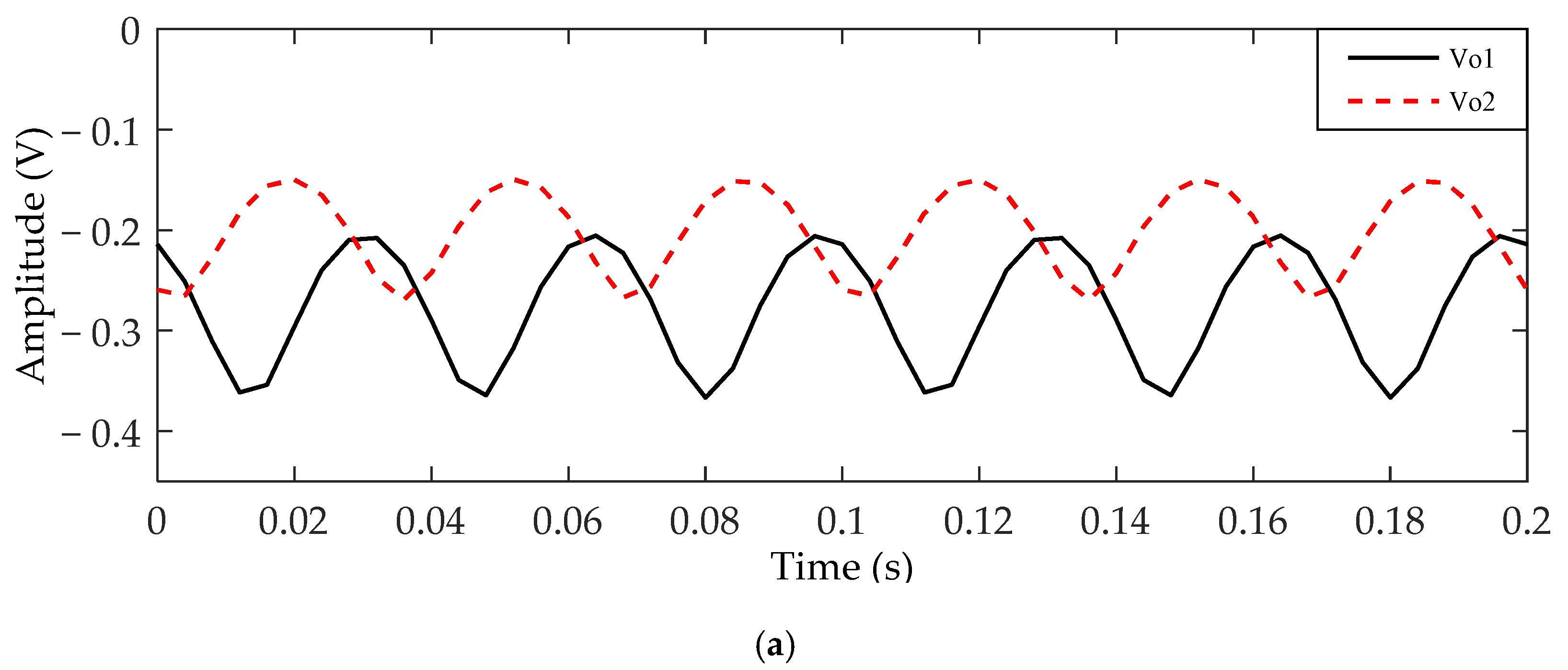

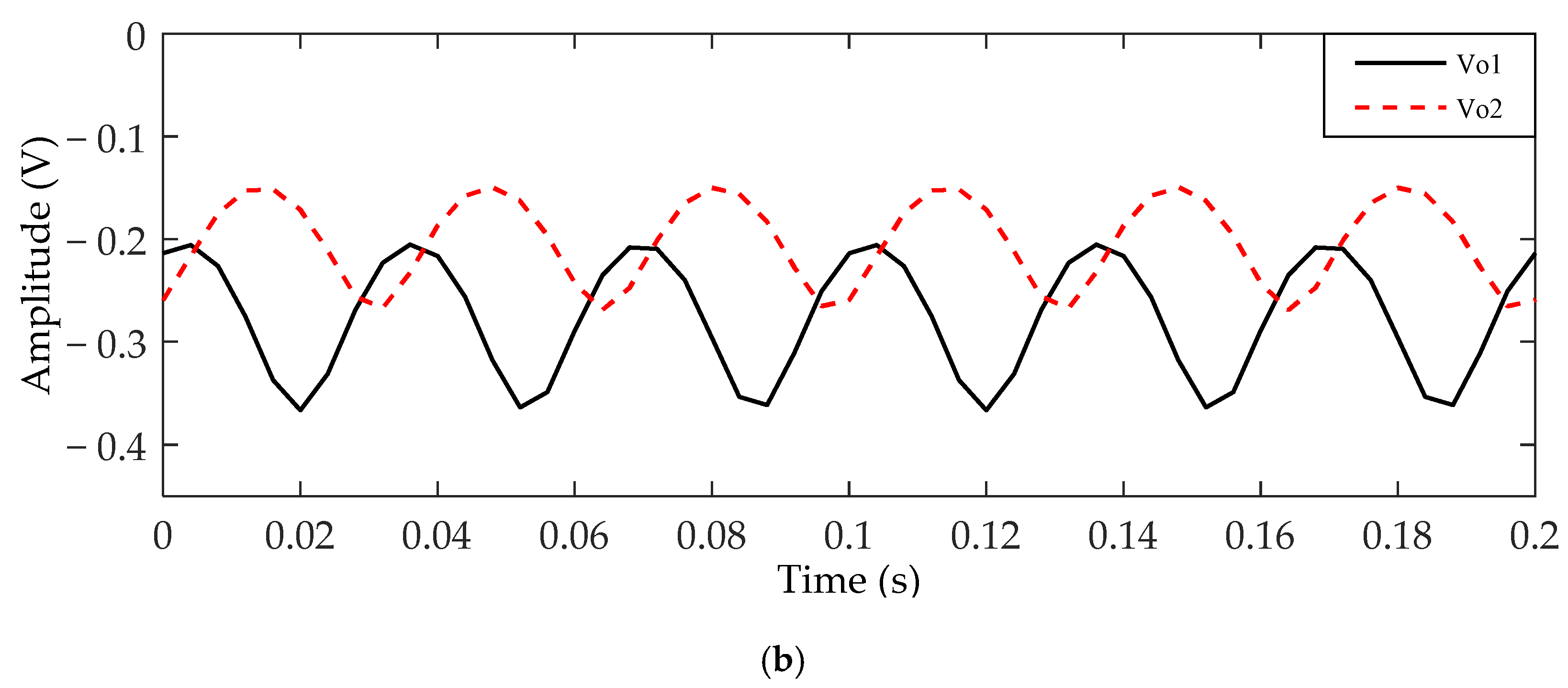

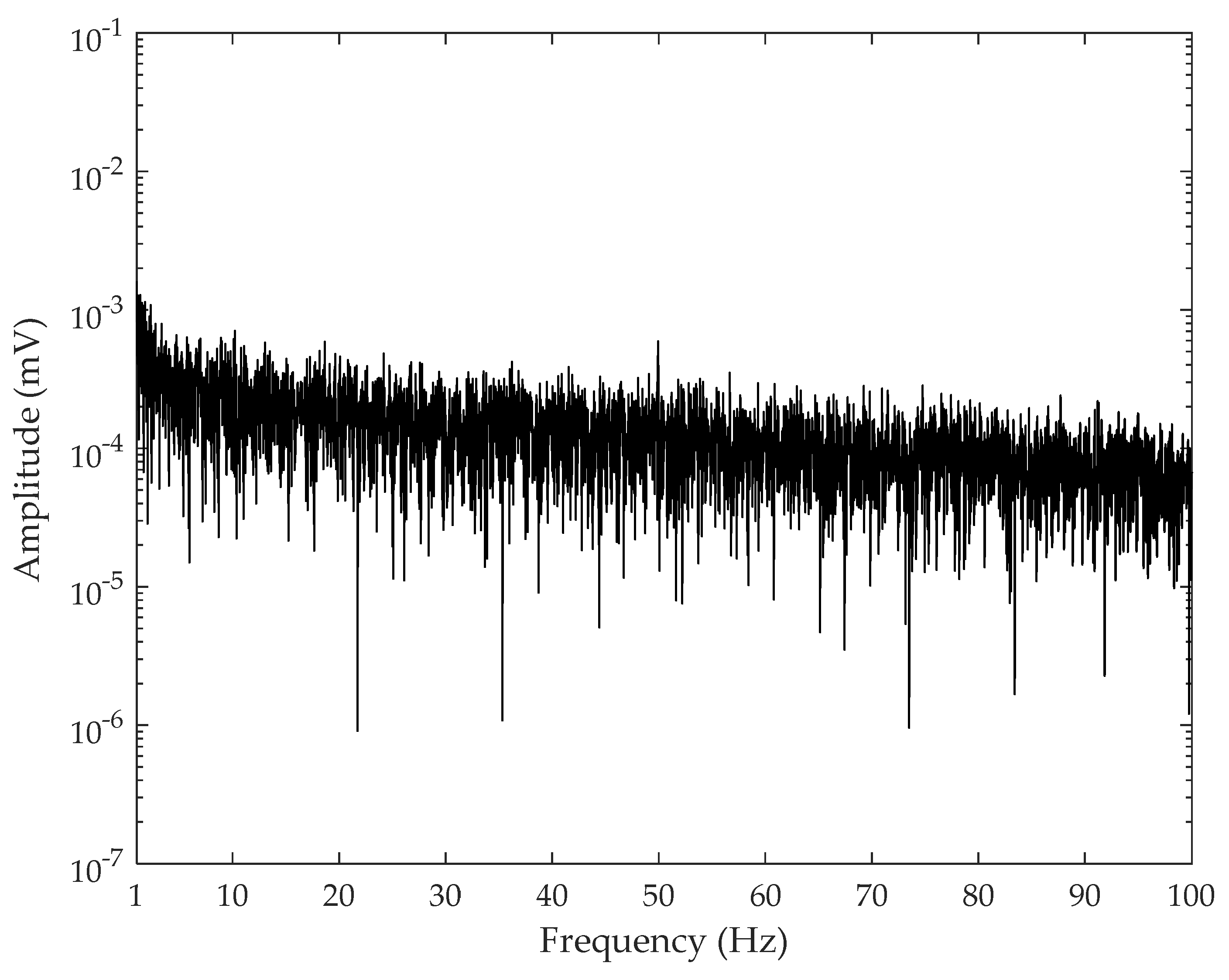

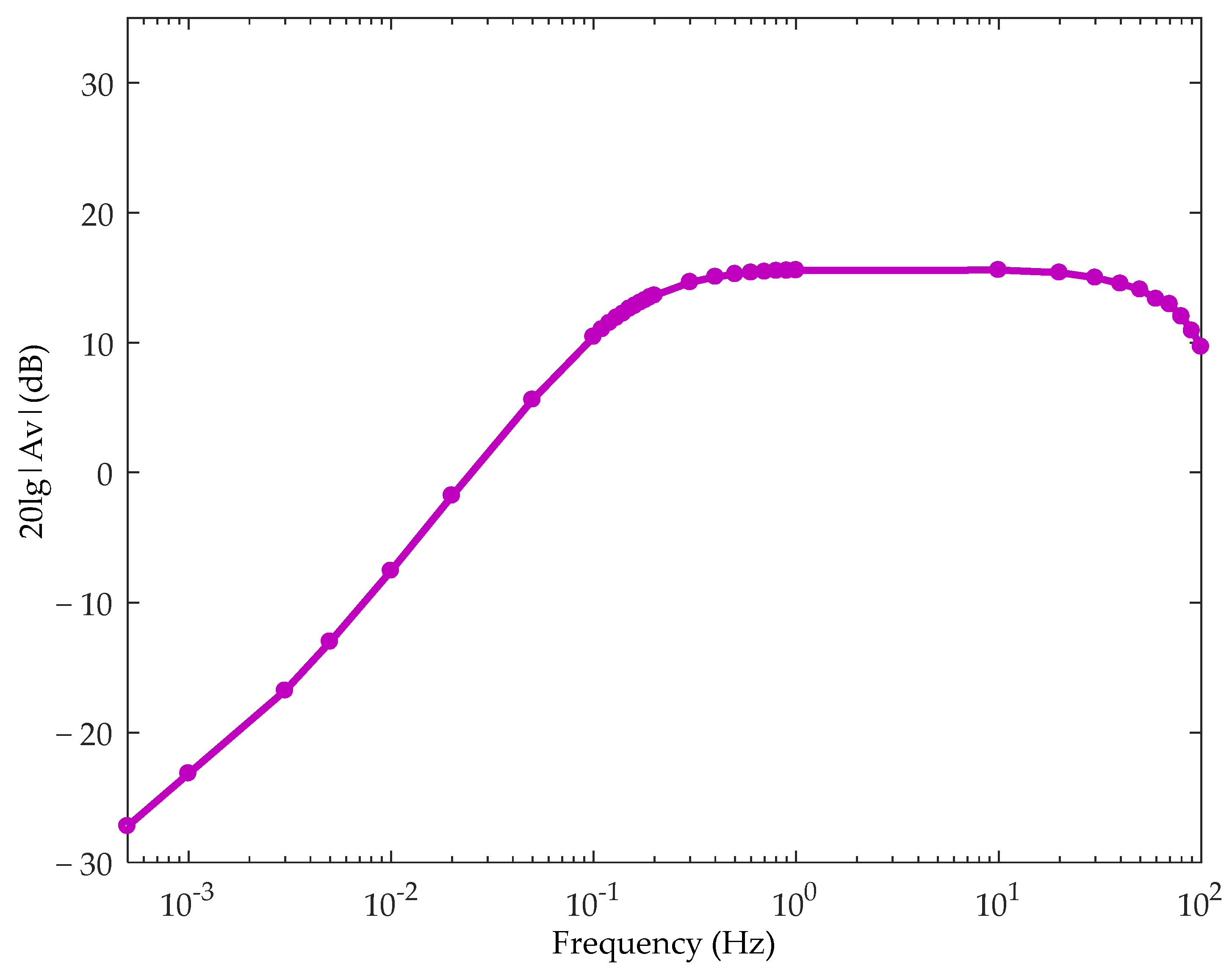

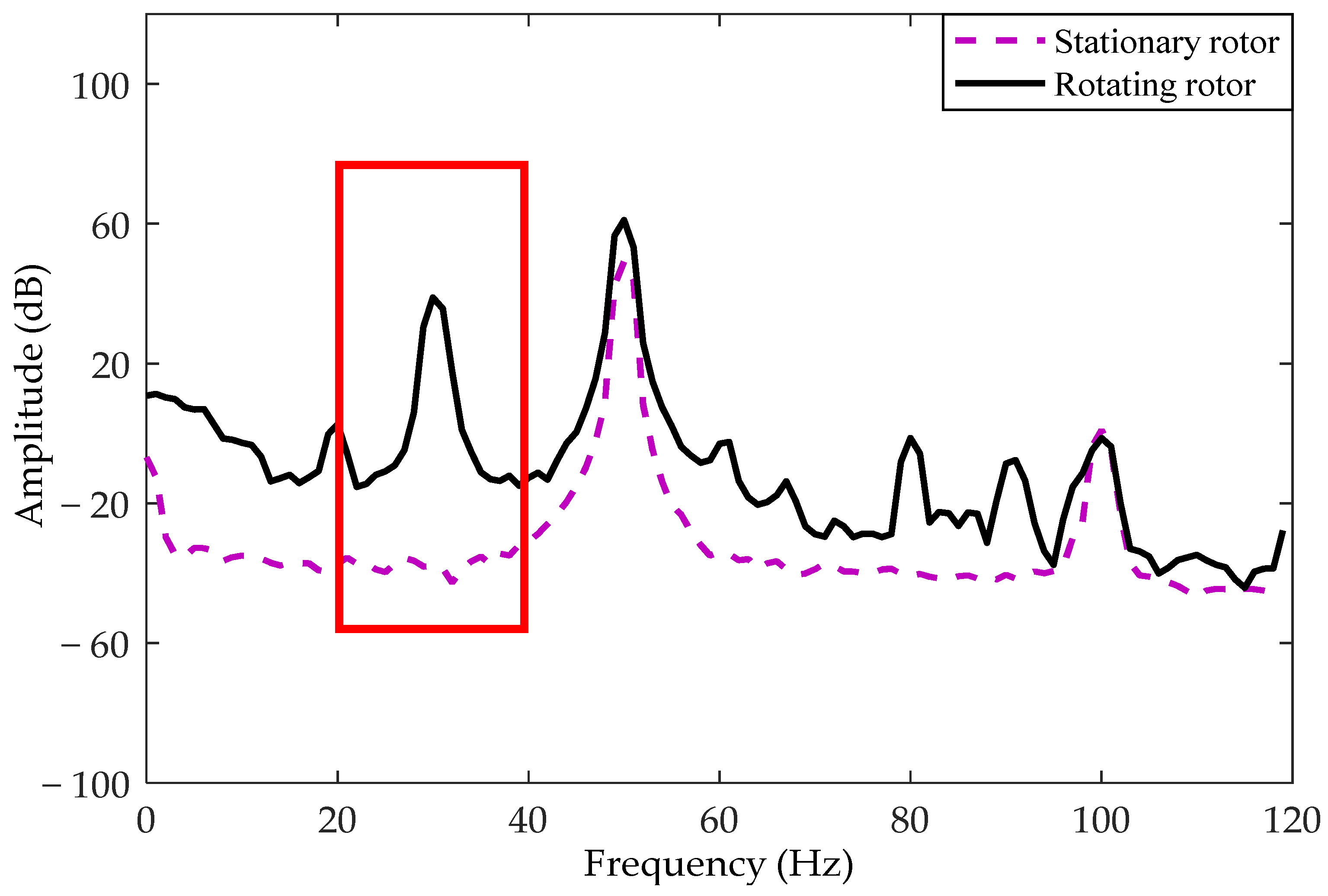

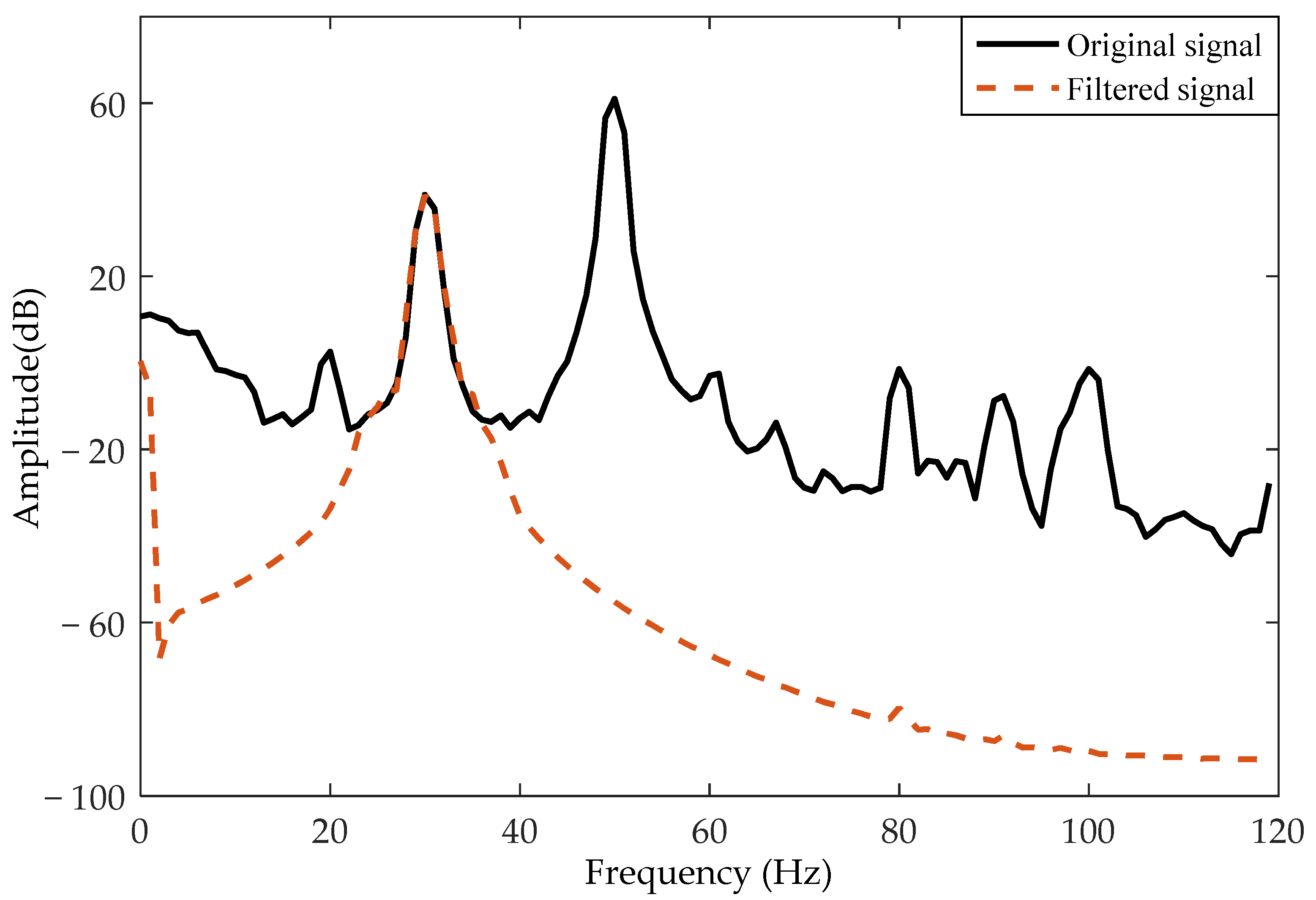

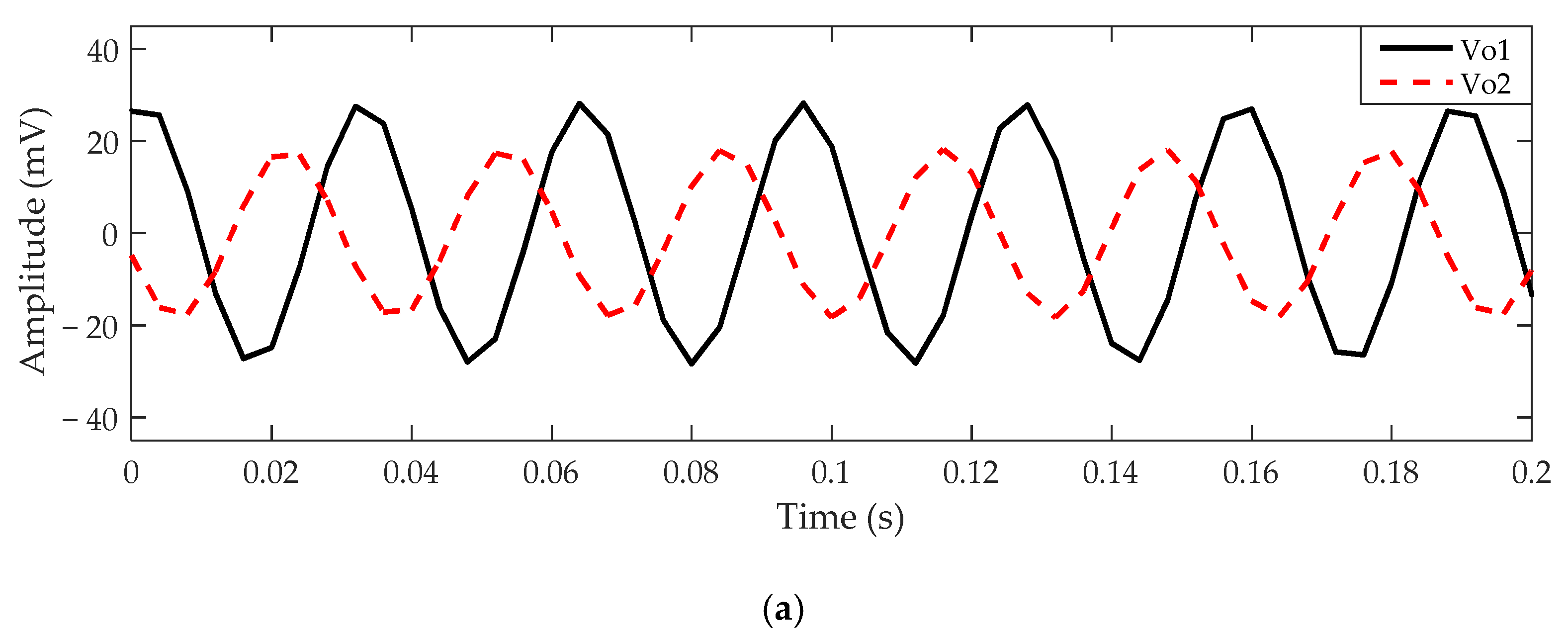

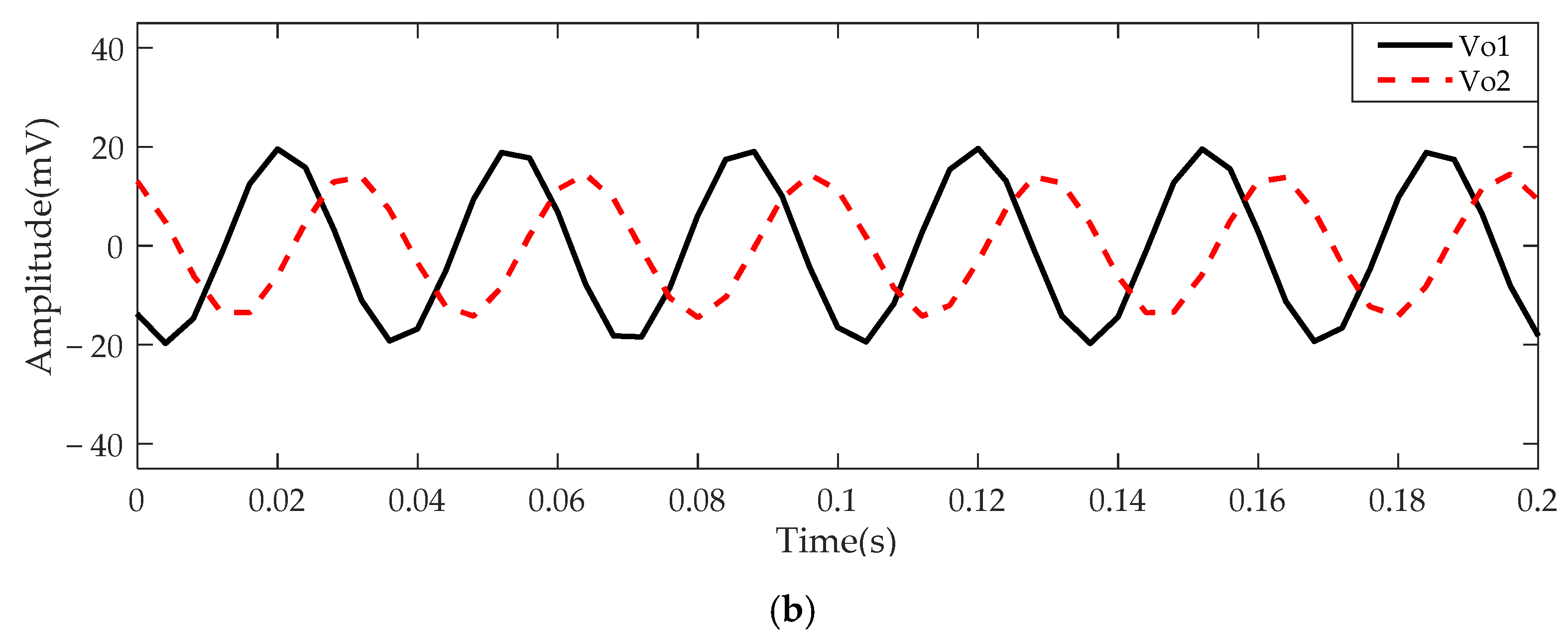

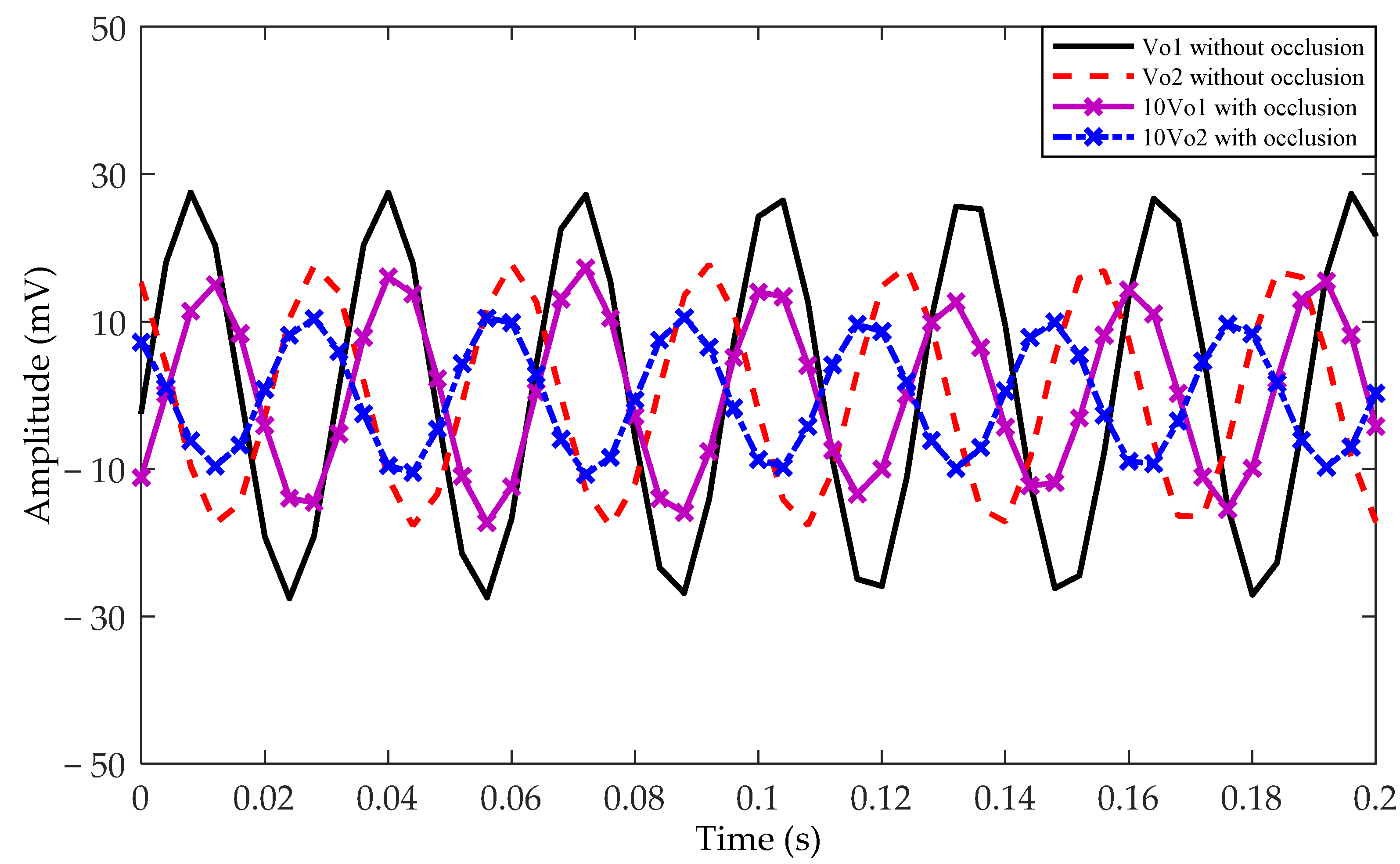

3.2. Signal Processing and Analysis

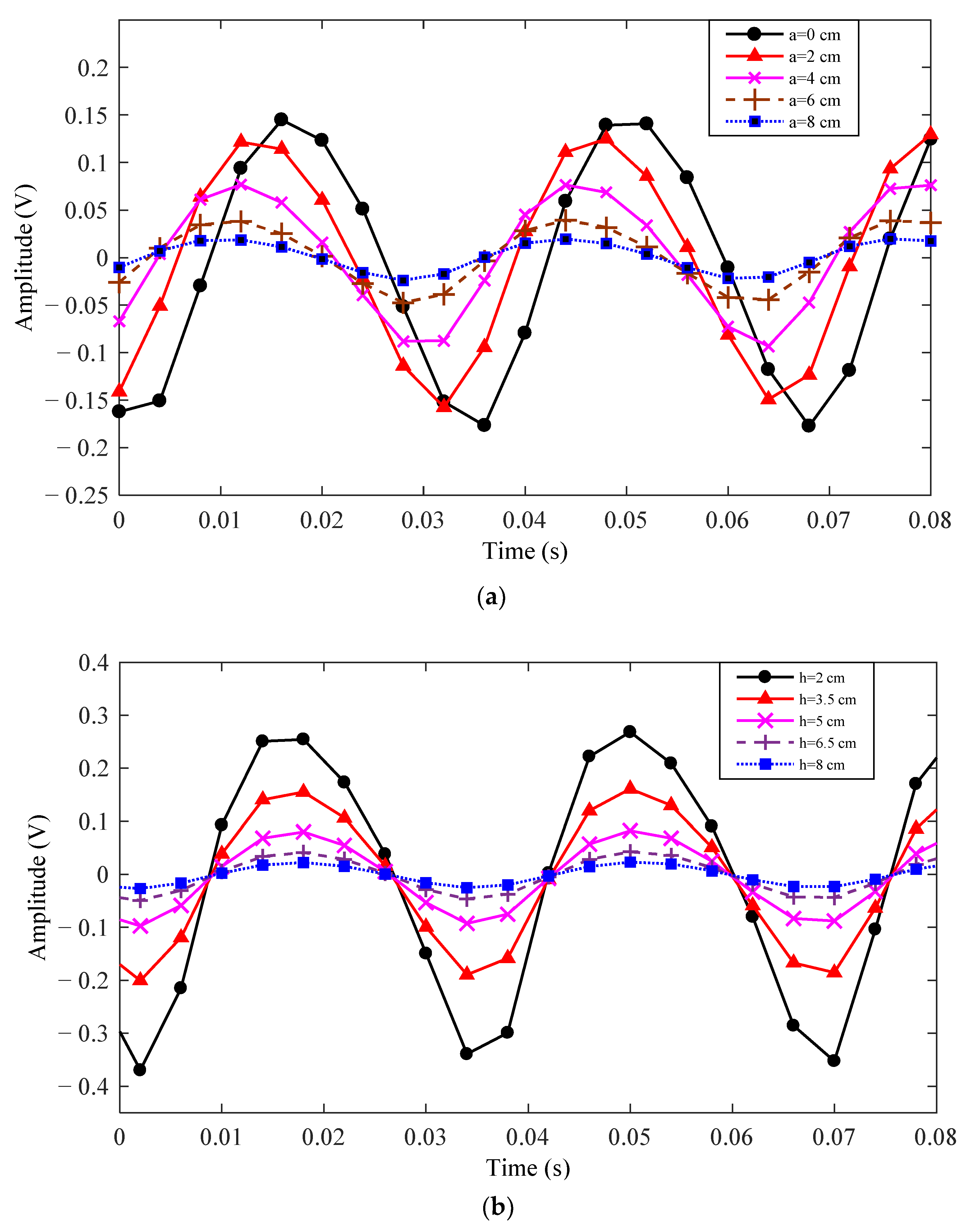

3.3. Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Carvalho, H.; Rocha, A.; Monteiro, J.L. An innovative device for bobbin thread consumption measurement on industrial lockstitch sewing machines. In Proceedings of the 2004 IEEE International Conference on Industrial Technology. IEEE ICIT ’04., Hammamet, Tunisia, 8–10 December 2004; Volume 1032, pp. 1034–1039. [Google Scholar]

- Liu, C.H.; Jywe, W.Y.; Tzeng, S.C. Simple three-dimensional laser angle sensor for three-dimensional small-angle measurement. Appl. Opt. 2004, 43, 2840–2845. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Liu, C.; Pong, P.W.T. Velocity Measurement Technique for Permanent Magnet Synchronous Motors Through External Stray Magnetic Field Sensing. IEEE Sens. J. 2018, 18, 4013–4021. [Google Scholar] [CrossRef]

- Chen, Q.; Xue, L.; Rao, H. Rotational speed measurement of ring spinning based on magnetic sensor. Meas. Sci. Technol. 2017, 28, 115106. [Google Scholar] [CrossRef]

- Todorovi, A.S.; Jevti, M.D. Rotational Speed Measurement Using Induction Coil Sensor Inserted in the Magnetic Field of the Rotational Permanent Magnet. Facta Univ. 2010, 23, 199–206. [Google Scholar] [CrossRef][Green Version]

- Liu, C.; Xu, Y.; Liu, J.; Sun, H.; Kennel, R. Rotational Speed Measurement Based on Avago ADNS-9800 Laser Mouse Sensor. In Proceedings of the PCIM Europe 2016; International Exhibition and Conference for Power Electronics, Intelligent Motion, Renewable Energy and Energy Management, Nuremberg, Germany, 10–12 May 2016; pp. 1–5. [Google Scholar]

- Didosyan, Y.S.; Hauser, H.; Wolfmayr, H.; Nicolics, J.; Fulmek, P. Magneto-optical rotational speed sensor. Sens. Actuator A Phys. 2003, 106, 168–171. [Google Scholar] [CrossRef]

- Qian, J.Q.; Cui, Y.; Xu, P. The study for measuring rotor speed and direction with quadrant photoelectric detector. Measurement 2008, 41, 626–630. [Google Scholar] [CrossRef]

- Fabian, M.; Hind, D.M.; Gerada, C.; Sun, T.; Grattan, K.T.V. Comprehensive Monitoring of Electrical Machine Parameters Using an Integrated Fiber Bragg Grating-Based Sensor System. J. Light. Technol. 2018, 36, 1046–1051. [Google Scholar] [CrossRef]

- Iura, H.; Ide, K.; Hanamoto, T.; Chen, Z. An Estimation Method of Rotational Direction and Speed for Free-Running AC Machines Without Speed and Voltage Sensor. IEEE Trans. Ind. Appl. 2011, 47, 153–160. [Google Scholar] [CrossRef]

- Zhang, X.; Chen, J.; Wang, Z.; Zhan, N.; Wang, R. Digital image correlation using ring template and quadrilateral element for large rotation measurement. Opt. Lasers Eng. 2012, 50, 922–928. [Google Scholar] [CrossRef]

- Wang, T.; Yan, Y.; Wang, L.; Hu, Y. Rotational Speed Measurement through Image Similarity Evaluation and Spectral Analysis. IEEE Access 2018, 6, 46718–46730. [Google Scholar] [CrossRef]

- Cheng, P.; Mustafa, M.S.M.; Oelmann, B. Contactless Rotor RPM Measurement Using Laser Mouse Sensors. IEEE Instrum. Meas. Mag. 2012, 61, 740–748. [Google Scholar] [CrossRef]

- Zhong, J.; Zhong, S.; Zhang, Q.; Peng, Z. Measurement of instantaneous rotational speed using double-sine-varying-density fringe pattern. Mech. Syst. Signal Process. 2018, 103, 117–130. [Google Scholar] [CrossRef]

- Zhong, J.; Zhong, S.; Zhang, Q.; Peng, Z.; Liu, S.; Yu, Y. Vision-Based Measurement System for Instantaneous Rotational Speed Monitoring Using Linearly Varying-Density Fringe Pattern. IEEE Trans. Instrum. Meas. 2018, 67, 1434–1445. [Google Scholar] [CrossRef]

- Guo, J.; Zhu, C.a.; Lu, S.; Zhang, D.; Zhang, C. Vision-based measurement for rotational speed by improving Lucas–Kanade template tracking algorithm. Appl. Opt. 2016, 55, 7186. [Google Scholar] [CrossRef] [PubMed]

- Fan, Y.; Ji, X. A Novel Rotation Speed Measurement Method Based on Surface Acoustic Wave. Acoust. Phys. 2018, 64, 122–128. [Google Scholar] [CrossRef]

- Mata-Contreras, J.; Herrojo, C.; Martín, F. Detecting the Rotation Direction in Contactless Angular Velocity Sensors Implemented With Rotors Loaded With Multiple Chains of Resonators. IEEE Sens. J. 2018, 18, 7055–7065. [Google Scholar] [CrossRef]

- Wang, L.; Yan, Y.; Hu, Y.; Qian, X. Rotational Speed Measurement through Electrostatic Sensing and Correlation Signal Processing. IEEE Trans. Instrum. Meas. 2014, 63, 1190–1199. [Google Scholar] [CrossRef]

- Wang, L.; Yan, Y.; Hu, Y.; Qian, X. Rotational Speed Measurement Using Single and Dual Electrostatic Sensors. IEEE Sens. J. 2015, 15, 1784–1793. [Google Scholar] [CrossRef]

- Li, L.; Hu, H.; Qin, Y.; Tang, K. Digital Approach to Rotational Speed Measurement Using an Electrostatic Sensor. Sensors 2019, 19, 2540. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.F.; Zhang, L.M.; Sun, F.; Dong, Z.N.; Yang, X.W. A Recognition Method for Hand Motion Direction Based on Charge Induction. IEEE Sens. J. 2019, 20, 415–424. [Google Scholar] [CrossRef]

- Wang, G.; Wang, S.F.; Zhang, L.M.; Sun, F.; Yang, X.W. A New Light Control Method with Charge Induction of Moving Target. IEEE Sens. J. 2019, 19, 6966–6974. [Google Scholar] [CrossRef]

- Trinks, H.; Haseborg, J.L.T. Electric Field Detection and Ranging of Aircraft. IEEE Trans. Aerosp. Electron. Syst. 2007, 3, 268–274. [Google Scholar] [CrossRef]

- Wu, R.; Tang, Y.; Li, Z.; Zhang, L.; Yan, F. A novel high input impedance front-end for capacitive biopotential measurement. Med. Biol. Eng. Comput. 2018, 56, 1–13. [Google Scholar] [CrossRef] [PubMed]

| Serial Number | Rotor Speed V(r/s) | Theoretical Phase Difference | Sampling Rate fs (Hz) | Number of Sampling Points N | Calculated Phase Difference | Error |

|---|---|---|---|---|---|---|

| 1 | 30 | 60° | 120 | 100 | 90° | +50% |

| 2 | 30 | 60° | 145 | 100 | 74.5° | +24.2% |

| 3 | 30 | 60° | 165 | 100 | 65.5 | +9.2% |

| 4 | 30 | 60° | 185 | 100 | 58.4° | −2.6% |

| 5 | 30 | 60° | 200 | 100 | 54° | −10% |

| 6 | 30 | 60° | 250 | 100 | 43.2° | −28% |

| 7 | 30 | 60° | 250 | 200 | 57.6° | −4% |

| 8 | 30 | 60° | 250 | 300 | 57.6° | −4% |

| 9 | 30 | 120° | 250 | 200 | 129.6° | +8% |

| 10 | 30 | −160° | 250 | 200 | −172.8° | −8% |

| 11 | 50 | −160° | 250 | 200 | −144° | +10% |

| 12 | 100 | −160° | 250 | 200 | −144° | +10% |

| 13 | >120 | −160° | 250 | 200 | Invalid | Invalid |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chang, R.; Zhang, L.; Lin, J.; Yan, F.; Chen, Y. An Identification Method for Rotor Direction Based on Charge Induction. Sensors 2021, 21, 1380. https://doi.org/10.3390/s21041380

Chang R, Zhang L, Lin J, Yan F, Chen Y. An Identification Method for Rotor Direction Based on Charge Induction. Sensors. 2021; 21(4):1380. https://doi.org/10.3390/s21041380

Chicago/Turabian StyleChang, Ronghui, Limin Zhang, Jiaqun Lin, Feng Yan, and Yong Chen. 2021. "An Identification Method for Rotor Direction Based on Charge Induction" Sensors 21, no. 4: 1380. https://doi.org/10.3390/s21041380

APA StyleChang, R., Zhang, L., Lin, J., Yan, F., & Chen, Y. (2021). An Identification Method for Rotor Direction Based on Charge Induction. Sensors, 21(4), 1380. https://doi.org/10.3390/s21041380