1. Introduction

The use of micro-electromechanical system (MEMS) technology satisfies various demands in the field of microsensors for small size, low power consumption, low cost, mass production, high accuracy, high sensitivity, etc. These advantages have led to multiple advances in the field of micro flow sensors [

1]. Currently, MEMS-based micro flow sensors are found in various applications in industrial settings. The combination of MEMS technology and automatic control/AI technology is suitable for use in smart homes/green buildings, safety/environmental sensing, and healthcare fields [

2], with the objective of realizing Internet of Things’ technology in relation to the construction of smart homes/green buildings. In addition, since it is also important to present a mathematical model in the design process prior to developing these MEMS devices, there was an effort to build a physical-mathematical model that is a basis for both presenting the operating conditions of the device and an objective explanation of the results. [

3]. However, in the field of micro flow sensors, the most notable recent developments have been related to the healthcare sector and the measurement of biosignals, and many studies and advancements are currently underway in this area [

4,

5,

6].

There are three main types of MEMS-based flow sensors: thermal flow sensors, piezoresistive flow sensors, and piezoelectric flow sensors. Of these, the simple structure and principle of the thermal flow sensor and its ability to measure a wide range of flow rates in both liquids and gases makes it popular in many different fields [

7]. Three different thermal flow sensor methods can be used according to the means of measurement, and an appropriate technique can be selected according to the type of fluid and flow rate. The hot-wire method measures heat loss, the calorimetric method measures the thermal equilibrium between two thermistors, and the time-of-flight method measures the arrival time of heat pulses. In some studies, advanced sensor performance has been realized using a combination of these principles to maximize the advantages of each method [

8,

9,

10,

11].

To date, many different types of thermal flow sensors have been studied and developed, although few have progressed into commercial products. The majority of thermal flow sensors are used to measure the low flow rates of gases or liquids up to several milliliters/minute, and most reported data refer only to continuous flow rates. Preventing heat loss from a sensor by blocking the conduction of heat to a substrate is challenging for the thermal flow sensor.

Ashauer et al. realized a response time of under 2 ms and a resolution of 0.1 mm/s in a thermal flow sensor across a wide range of flow rates by creating a thermally isolated structure using thermopiles on a silicon nitride membrane [

12]. Dijkstra et al. implemented a calorimetric-based flow sensor with low hydraulic resistance that included a microchannel that was thermally isolated from the substrate with a channel height of several tens of micrometers to prevent any step coverage problems from occurring. The developed sensor detected a signal fluid flow as low as 300 nL/min [

13]. Ahmed et al. developed a wireless, dual-mode, low-powered, calorimetric-based complementary metal–oxide semiconductor MEMS flow sensor to measure bidirectional gas [

14,

15].

The studies of micro thermal flow sensors for biomedical application are remarkable. Mistry and Mahapatra modeled a thermal flow sensor to develop a MEMS-based implantable sensor to monitor arterial blood flow and simulated the thermal distribution of the fluid flow [

16]. Li et al. developed a smart catheter flow sensor to monitor cerebral blood flow; they used the constant temperature mode in the thermal diffusion flow measurement principle to establish a method for providing reliable data without drift [

17]. Additionally, they used a compensation circuit system to solve the problem of continually increasing temperature in a medium. Jiang et al. developed a non-invasive respiratory monitoring system using a flexible hot-film smart sensing strip that was attached to a person’s upper lip to measure real-time respiration [

18]. They used a Bluetooth module for wireless data acquisition and a smart device as a display module, which could be configured as a wearable device to monitor conditions such as sleep apnea. Okihara et al. fabricated a detachable flexible flow sensor to evaluate the partial respiration characteristics of the airway and measured the local flow [

19]. The flexible sensors can be applied to the medical and industrial fields that require micro-flow measurement and analysis since they have a deformable property, which can access narrow and winding areas that are difficult to access with conventional sensors, and thus more accurate results can be expected. Finally, Hedrich et al. developed a MEMS-based thermal membrane anemometric flow sensor for connection to a breathing mask for long-term respiratory monitoring related to cardiovascular disease [

20].

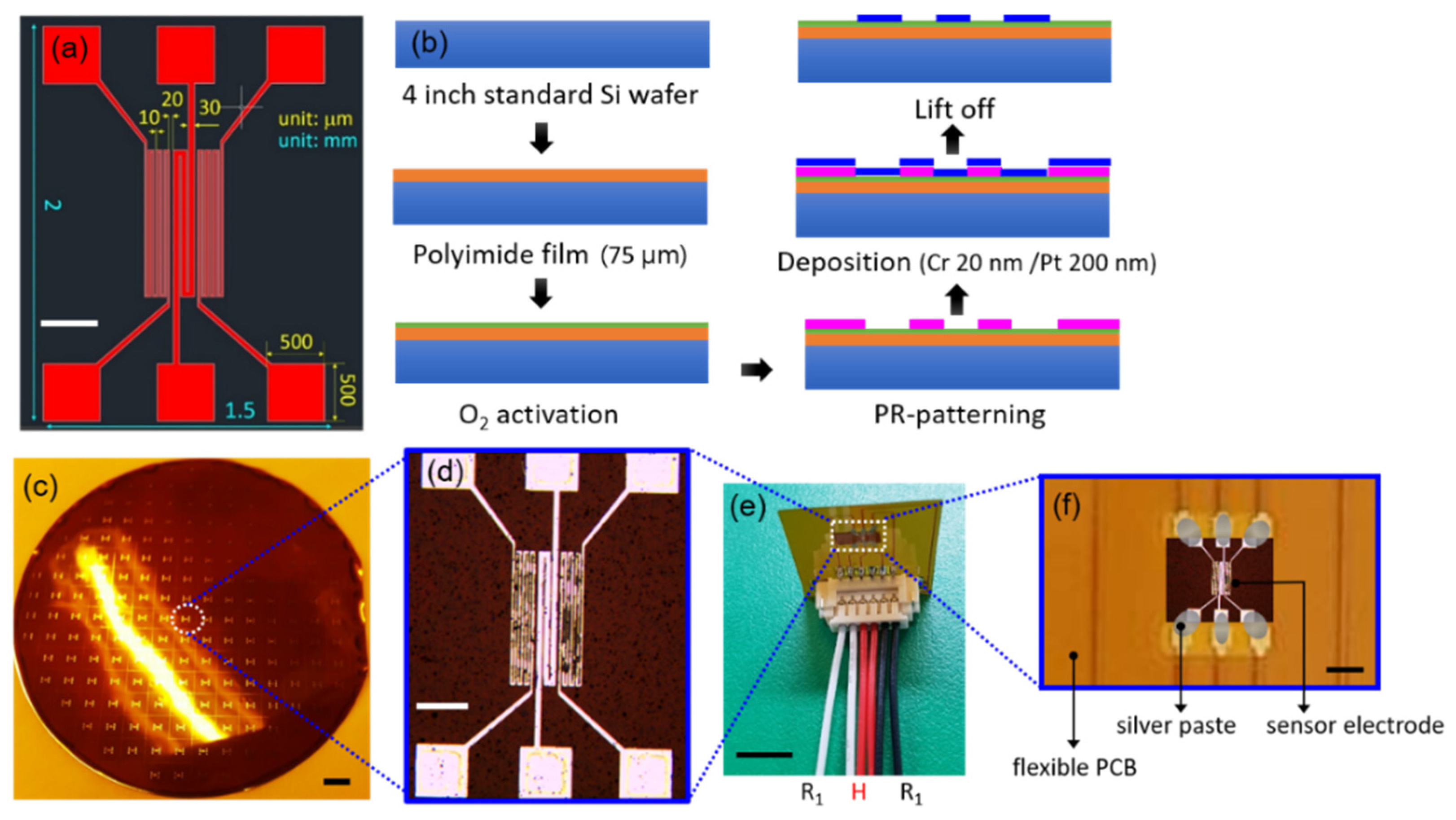

In this study, we developed a flexible microthermal flow sensor for simultaneously measuring high flow rates in gases and liquids from tens to hundreds of milliliters/minute using the MEMS process on a flexible substrate. It is anticipated that the sensor could be used in many fields for different purposes, including healthcare. Generally, the differential pressure meter, which is known to be suitable for high flow, has a limited dynamic range, and is also difficult to apply to a pulsating flow [

12]. However, the present study’s flexible thermal flow sensor can measure high-flow fluids and has obtained meaningful results with pulsating liquid flows. In addition, the developed sensor can effectively reduce heat loss compared to metal or silicon-based sensors by using a polyimide film with a low thermal conductivity. This suggests that the developed sensor has the potential for future use in medical applications.

This study’s sensor electrode was designed with one central microheater and two thermistors—one on either side. It was developed by applying a calorimetric principle that measures the flow rate by detecting the change in the equilibrium state of both thermistors under a flow. A computational fluid dynamics (CFD) analysis determined the structure and size of the sensor, and the output voltage from the electrical circuit was designed and monitored in real time using LabVIEW software. The sensor signal was measured within a flow range of 25–200 sccm using N2 gas at 25–150 mL/min for a continuous liquid flow with a syringe pump. The signal was also verified in a pulsating liquid flow using an artificial heartbeat model within a flow range of 25–200 mL/min. A highly accurate result was obtained using the simplest type of bridge circuit based on the calorimetric principle; many studies use a complicated circuit to compensate for the signal drift phenomenon.

This study fabricated a MEMS-based flexible micro flow sensor and conducted flow velocity measurement tests on gases and liquids using a basic technique. Important experimental results were obtained within a range of sizes applicable to the human body. The future development of electrical packaging for the developed sensor can extend its application to the measurement of biosignals in the healthcare field, including for the measurement of respiration and body fluids.

3. Results and Discussion

3.1. Visualization of the Temperature Changes by Simulation

This section uses computational simulations to predict the general performance and results of the detection of fluid flow using the fabricated sensor. Several factors to be considered when fabricating the sensor were checked in advance and were reflected in the design of the device. The simulation visualized the temperature difference between the two thermistors, and the variations provided the magnitude of the output voltage, which is directly or inversely proportional to the flow velocity depending on the properties of the fluid. According to the CFD analysis for the temperature difference between the thermistors of the sensor electrodes with respect to the flow rate of the fluid, in the case of gas, ΔT (ThermistorDownstream − ThermistorUpstream) showed a tendency to increase as the velocity also increased. However, when the physical properties of the fluid were changed to those of blood (which is a liquid), there was a tendency for ΔT to decrease at speeds exceeding 1 cm/s.

Generally, in a calorimetric thermal flow sensor, the temperature of a downstream sensor is higher than that of an upstream one according to the heat provided by a heater. Accordingly, the temperature difference, ΔT, is defined as the value obtained by subtracting the upstream temperature from the downstream temperature. For gas, the temperature decrease of the upstream sensor according to the flow rate is greater than that of the downstream sensor; therefore, the ΔT increases according to the increase in flow rate. However, for liquid, there is a rapid temperature decrease for the upstream sensor under a flow; consequently, the additional temperature reduction according to the flow rate is much lower than the size of the temperature decrease in the downstream sensor. Therefore, the temperature difference between the two sensors is inversely proportional to the increase in flow rate. It is believed that this phenomenon is attributed to the difference in thermal conductivity between gas (air) and liquid (blood) of 0.025–0.03 and 0.52–0.6 W/m·k, respectively, representing a difference of approximately 17–20 times.

Additionally, when the width of both thermistors and the microheater was 0.1 mm and the distance between the heater and thermistors was symmetrically 0.01–0.02 mm, the temperature difference between the two thermistors increased or decreased almost linearly with the change in the flow rate of the fluid.

Figure 5 and

Figure 6 present the simulation results in graph form for gas and liquid, respectively. When the velocity of the fluid increased by 10 cm/s, the temperature difference between the two thermistors increased by approximately 0.1 °C for gas, whereas it decreased by 0.2 °C for liquid.

3.2. Experimental Results for Gas Flow

To evaluate the performance of the developed flexible thermal flow sensor, this study configured an experimental setup to detect the change in voltage according to the change in flow rate. The MEMS flow sensor module was inserted into 3 mm diameter tubing to locate the sensor electrode in the center of the tube, and the cables from the sensor were connected to the electrical circuit system outside the tubing. The two thermistors on either side of the sensor electrode were connected to the Wheatstone bridge circuit, respectively, and 1.2 V of voltage was applied to the microheater. This experiment used nitrogen gas and a gas generator to control the flow rate, and the gas pipe was connected to the tubing containing the micro flow sensor. The flow rates of the N2 gas (in sccm (cm/s)) in the tube were controlled to 25.65 (5), 51.3 (10), 77 (15), 102.6 (20), 128 (25), 154 (30), 179.5 (35), and 205.2 sccm (40 cm/s) (the numerical value in parentheses indicates the velocity of the fluid inside the tubing). A signal monitoring system performed real-time checks on the output voltage, whereas nitrogen (N2) gas flowed at a specific flow rate from the gas generator to the micro flow sensor.

As the flow rate varied between 5 and 40 cm/s, the change in resistance resulting from the temperature difference between the two thermistors (located on either side of the microheater) was converted into a voltage change. The results are presented in

Figure 7.

Figure 7a contains a stair-like graph of increasing flow rate over time. A graph showing the voltage value against the flow rate was derived using the average voltage value from each flow rate range, and a simulation result for the gas flow was plotted in

Figure 7b for reference. The result of the gas flow measurements for the coefficient of determination of the graph for the change in the voltage against a flow rate between 5 and 40 cm/s was 0.99, which demonstrates an excellent linearity. For each flow rate range, the average standard deviation of the values was 0.38 mV; as the flow rate increased by 1 cm/s, the voltage increased by 1.2 mV. The maximum noise signal was 0.77 mV, and a resolution of 0.64 cm/s was achieved in the flow rate.

3.3. MEMS Flow Sensor Test in Continuous Liquid Flow

The sensor’s performance was analyzed in a continuous liquid flow system using a syringe pump (KDS 200; KD Scientific, Holliston, MA, USA). A 40 mm diameter syringe with a capacity of 200 mL was mounted on the syringe pump, and a 3 mm diameter tube was connected to the syringe. The micro flow sensor was inserted in the middle of the tube in the perpendicular direction of the flow—the sensor electrodes meet the fluid in the order of an upstream sensor, the heater, and a downstream sensor—and was sealed tightly to prevent leakage. A water temperature of 30–40 °C was maintained throughout the experiment.

Figure 8a,b illustrates the experimental setups for analyzing the flow of a liquid using a syringe pump and an artificial heartbeat model, respectively. The correlation between the output voltage generated from the sensor within the specific flow rate range and the fluid flow rate generated by the system was determined by adjusting the flow rate to achieve the desired speed within the tube containing the sensor. Within the tube, the flow rate was controlled to between 5 and 30 cm/s, and the sensor’s output voltage was measured within the controlled flow. The two thermistors and the microheater were connected to the PCB, which included the Wheatstone bridge circuit, and the output value was adjusted to zero by controlling the variable resistance inserted in the PCB under the initial flow. Then, the output voltage generated according to the fluid flow rate was monitored. It was revealed that as the flow rate increased, the output voltage decreased accordingly.

Figure 9a shows the change in the output voltage of the sensor with varying flow rates over time.

Figure 9b presents a graph showing the output voltage value of the sensor according to the flow rate of the fluid with the liquid flow simulation rate for comparison. At over 0.98, the coefficient of determination for the voltage value against the flow rate revealed a good linearity. Despite maintaining the same flow rate for over 10 s, the voltage value remained constant. The results of this experiment reveal that an increase in flow rate of 1 cm/s caused an average decrease of 3.6 mV in the output voltage; furthermore, the average standard deviation of each flow rate section was ±2 mV, which indicates a sufficient resolution of 2 cm/s or less.

3.4. Results of the Liquid Flow Experiment Using an Artificial Heartbeat Model

To evaluate the performance of the flow sensor in a liquid flow under constant pulsation (rather than under only a constant flow), this experiment used a cardiovascular model to simulate the heartbeat movement of a living body. The cardiovascular model comprised two water reservoirs, a pump, 3 mm diameter tubing (to replicate blood vessels), and a signal control system. A commercial flow sensor (FD-XS1; Keyence, USA) was inserted in the center of the tube to measure the real-time flow rate, and the MEMS flow sensor was equipped with the same line as the commercial sensor. The control system of the cardiovascular model allowed the beat rate, relative pressure, and stroke to be adjusted to provide a linear increase in flow rate with increases in relative pressure and stroke. The parameters for this experiment included a beat rate of 40 bpm and an internal flow rate velocity range of 5–40 cm/s; the data from the MEMS flow sensor were obtained within this range.

Figure 9c shows the output voltage value of the MEMS flow sensor according to the flow rate produced by the artificial heartbeat. This experiment found that when the fluid velocity increased by 1 cm/s, the voltage decreased by an average of 0.36 mV. The average standard deviation in each flow rate range was 0.09 mV. The flexible MEMS flow sensor fabricated in this study was confirmed to realize a resolution of 0.5 cm/s for a pulsating liquid flow. The resolution was different between continuous flows and pulsatile flows in this study, and it is thought that the high level of noise signal in the continuous flow reduced the resolution.

Table 2 summarizes the performance of the flexible MEMS flow sensors in the gas and liquid flow tests.