Mobile Detection and Alarming Systems for Hazardous Gases and Volatile Chemicals in Laboratories and Industrial Locations

Abstract

1. Introduction

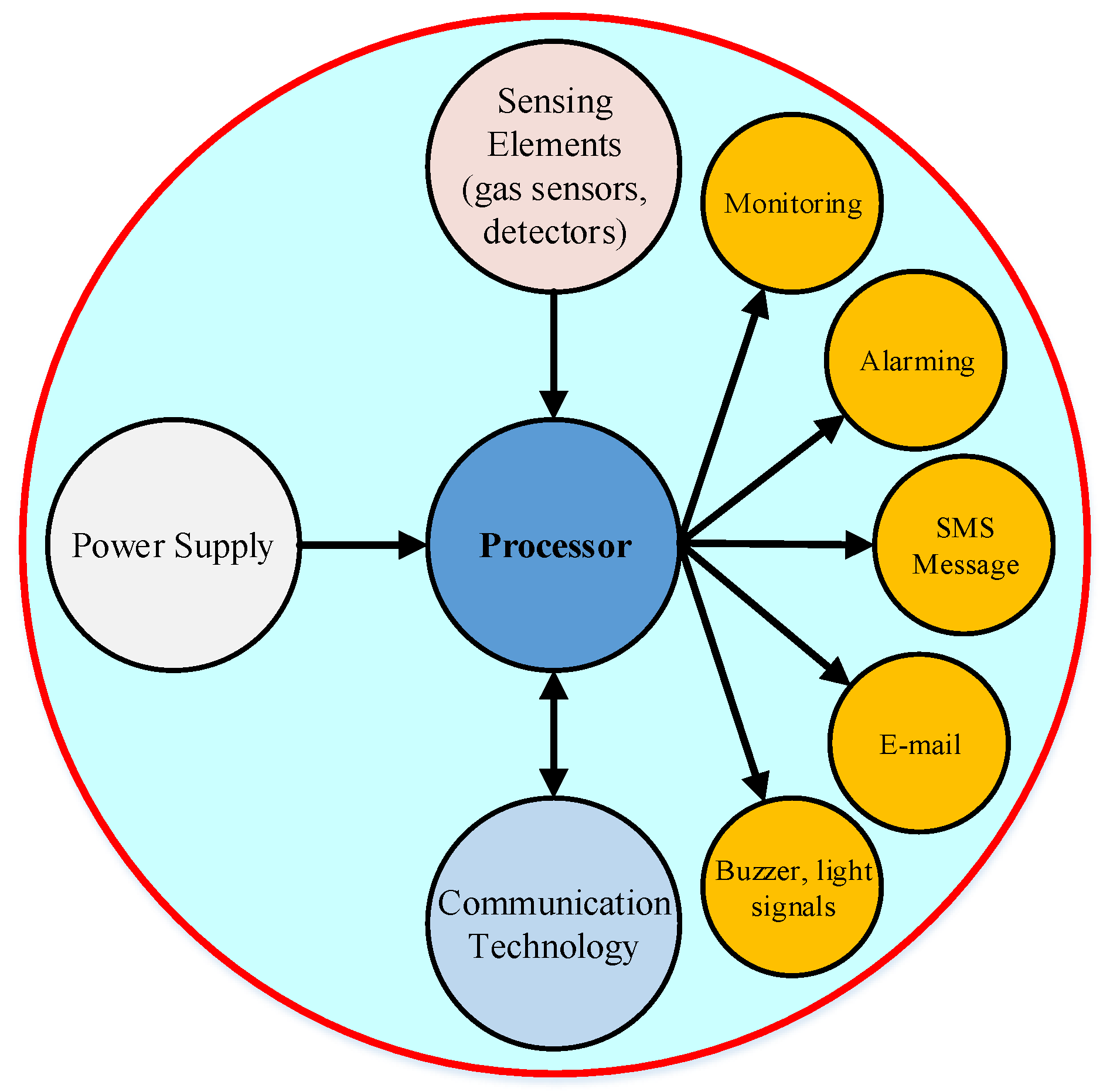

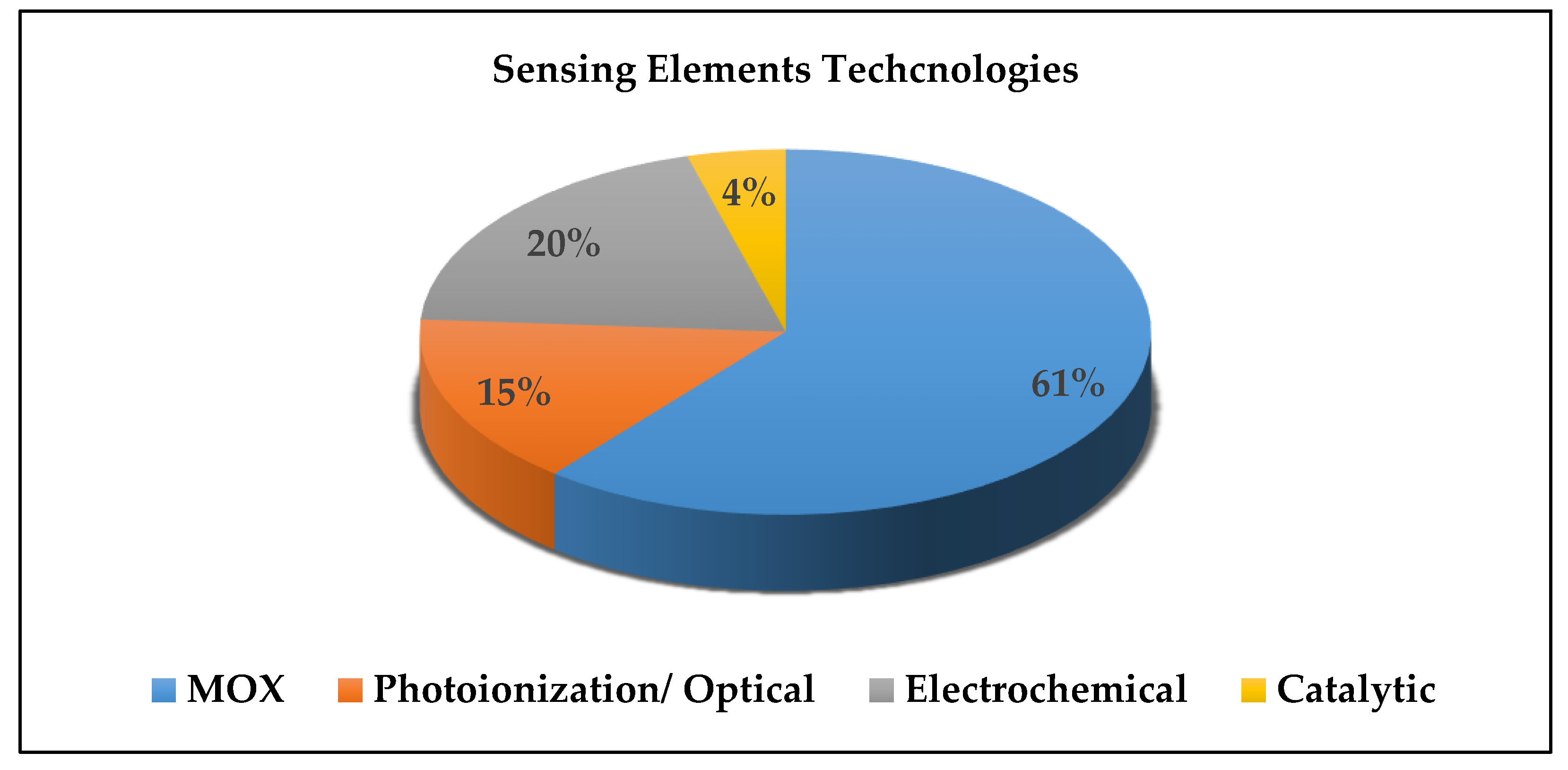

1.1. Sensing Element (Gas Sensor)

1.1.1. Catalytic Sensors

1.1.2. Electrochemical Sensors

1.1.3. Photoionization Sensors

1.1.4. Infrared Sensors/Optical Sensors

1.1.5. MOX Sensors/Chemical Sensors

1.2. Processor

1.3. Wireless Communication Technology

1.4. Power Supply

1.5. Monitoring and Alarm

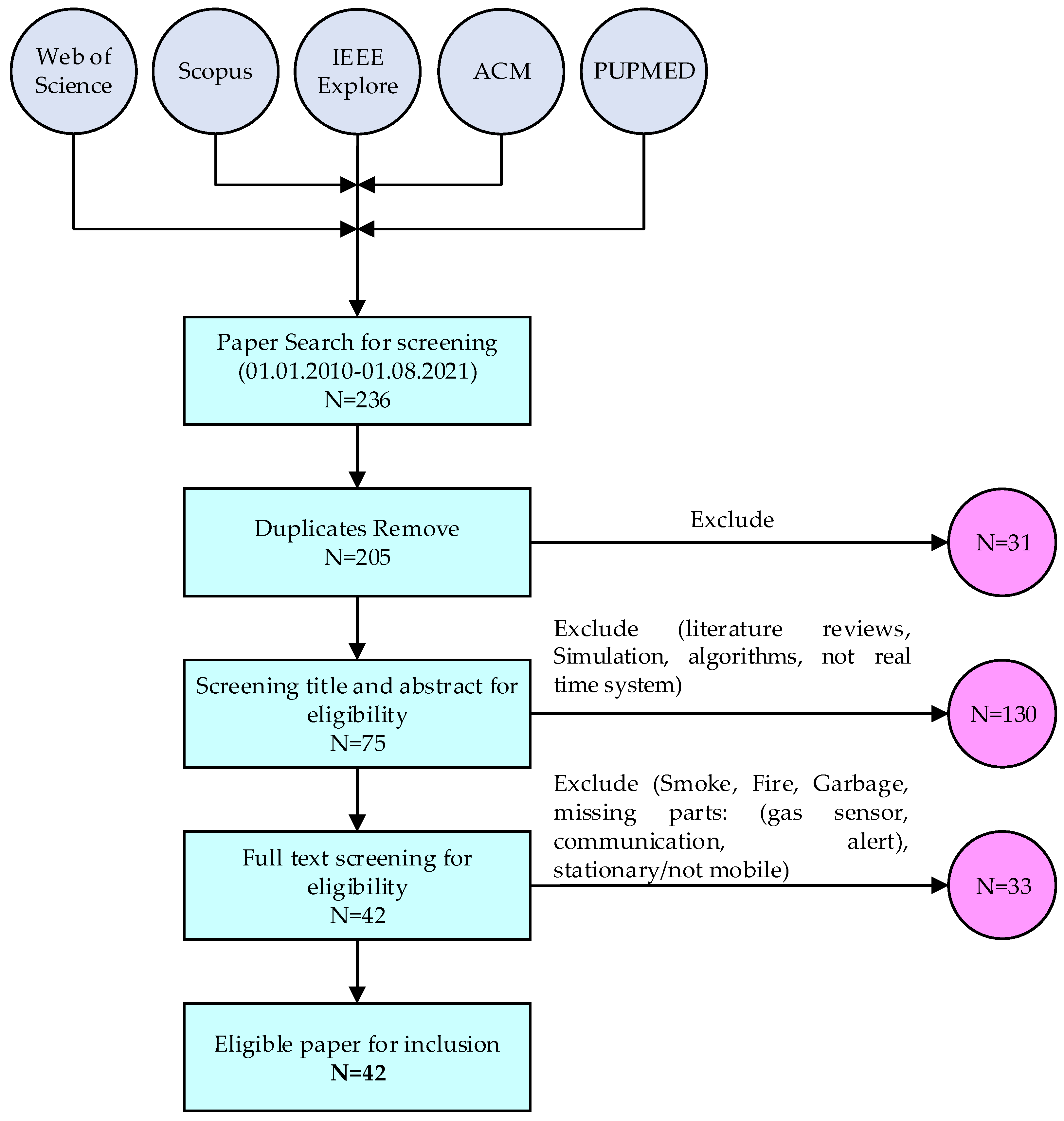

2. Materials and Methods

2.1. Search Strategy

2.2. Inclusion and Exclusion Criteria

- Inclusion Criteria

- -

- real-time system, small size

- -

- hazards or toxic gases sensors included

- -

- mobile system (movable, battery-powered, wireless technologies)

- -

- includes monitoring and alarming functions

- Exclusion Criteria

- -

- fixed/stationary system

- -

- simulation, algorithms, sensor testing, and manufacturing research’s

- -

- systems for general smoke, fire, and air quality without measuring specific hazardous and toxic gases levels

3. Mobile Detecting and Alarming System

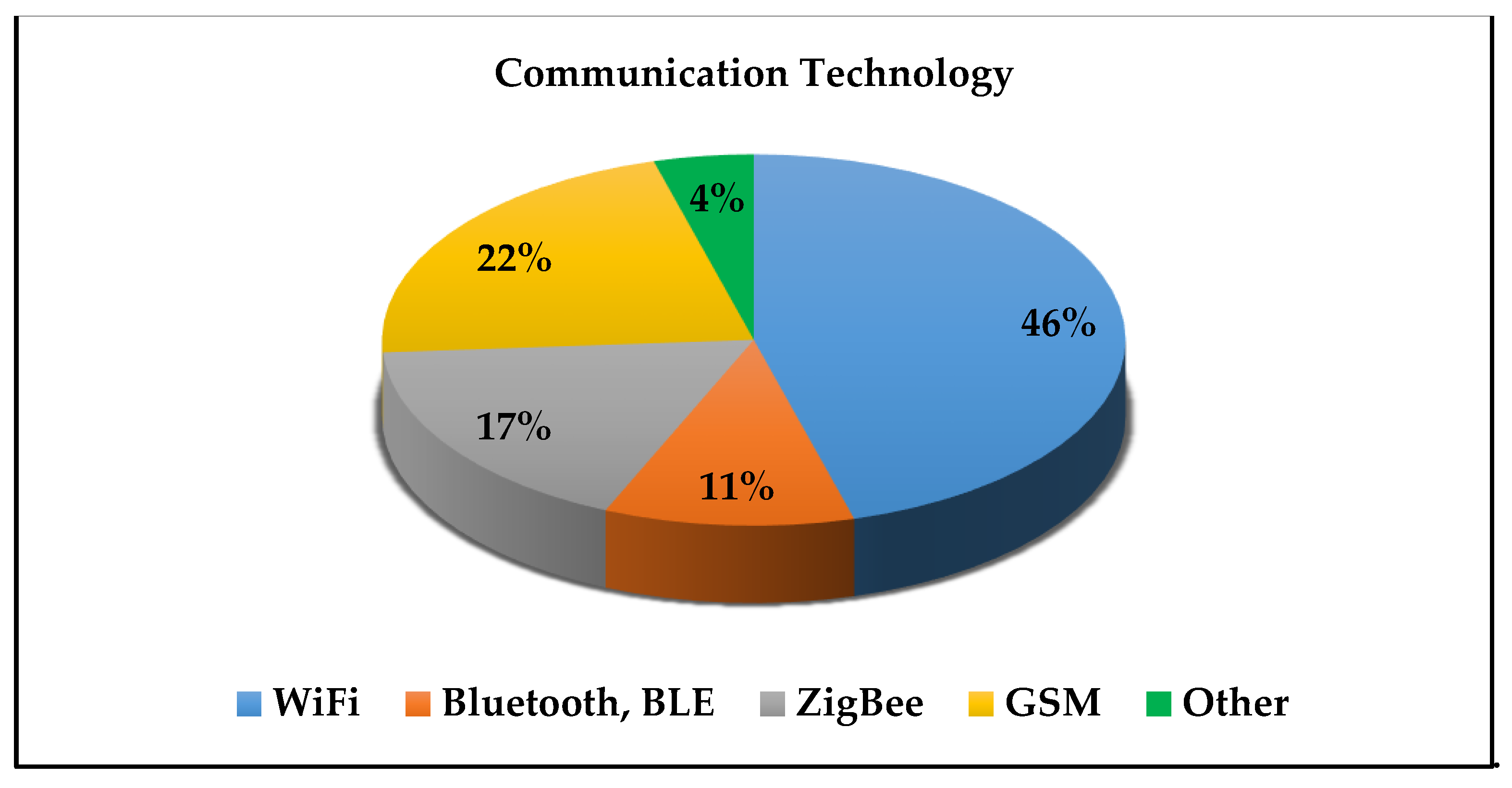

3.1. The Used Communication Technologies

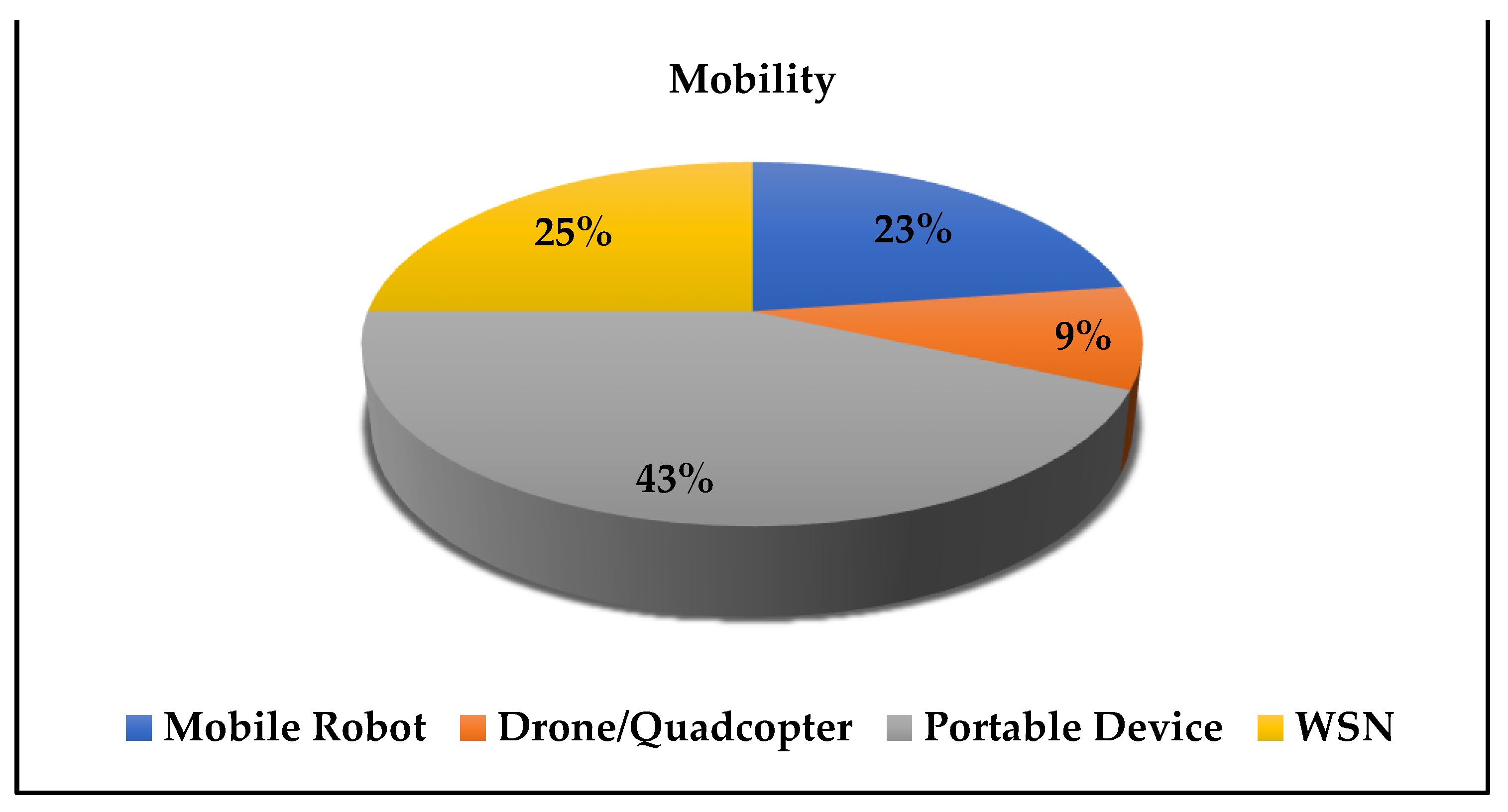

3.2. Systems with Robotics Integration

3.3. Systems Hosted by Drones/Quadcopters

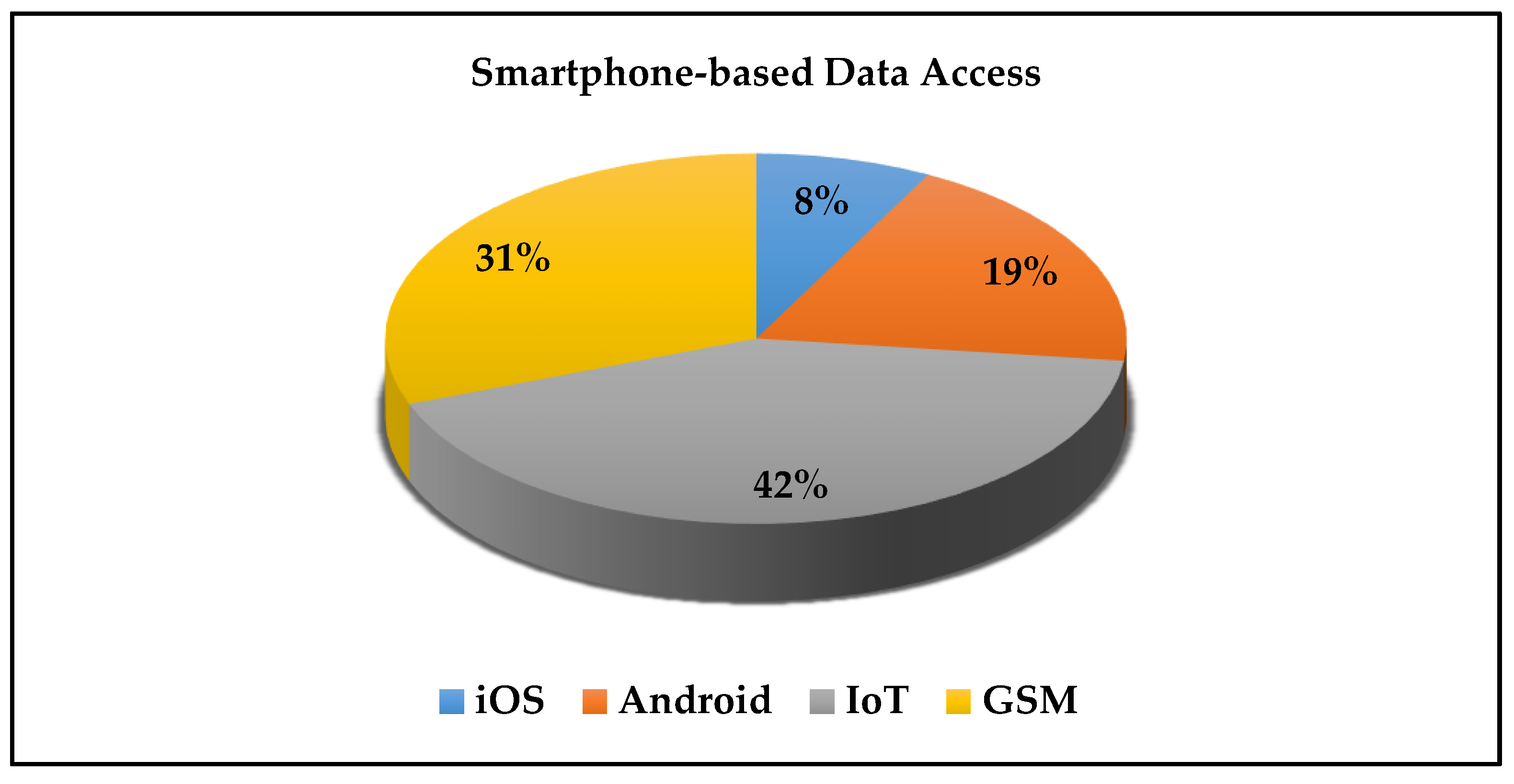

4. Results

5. Discussion

5.1. Hybrid/Multi-Sensor Systems

5.2. Communication Technology

- -

- More reliable multi-parameter monitoring and alarming

- -

- Better battery-based lifetime and power consumptions

- -

- Multi-Devices communication ability

- -

- More adapted to AI

- -

- Easy adapted with popular used personal smartphone/tablet devices

5.3. Robotic Based System

5.4. Data Accessing and Alarming

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- PennEHRS. SOP: Hazardous and Highly Toxic Gases. Available online: https://ehrs.upenn.edu/health-safety/lab-safety/chemical-hygiene-plan/standard-operating-procedures/sop-hazardous-and (accessed on 3 September 2021).

- Safeopedia. What Is Toxic Gas? Available online: http://www.safeopedia.com/definition/2337/toxic-gas (accessed on 3 September 2021).

- Matthews, G. Toxic gases. Postgrad. Med. J. 1989, 65, 224–232. [Google Scholar] [CrossRef] [PubMed]

- Canary in a Coal Mine. Available online: https://en.wiktionary.org/w/index.php?title=canary_in_a_coal_mine&oldid=62946727 (accessed on 17 October 2021).

- Lin, T.; Lv, X.; Hu, Z.; Xu, A.; Feng, C. Semiconductor Metal Oxides as Chemoresistive Sensors for Detecting Volatile Organic Compounds. Sensors 2019, 19, 233. [Google Scholar] [CrossRef] [PubMed]

- Saini, J.; Dutta, M.; Marques, G. A comprehensive review on indoor air quality monitoring systems for enhanced public health. Sustain. Environ. Res. 2020, 30, 6. [Google Scholar] [CrossRef]

- Haghi, M.; Danyali, S.; Ayasseh, S.; Wang, J.; Aazami, R.; Deserno, T.M. Wearable Devices in Health Monitoring from the Environmental towards Multiple Domains: A Survey. Sensors 2021, 21, 2130. [Google Scholar] [CrossRef] [PubMed]

- School of Chemical Sciences at Illinois. Toxic Gas List. Available online: https://scs.illinois.edu/resources/safety-and-facilities-management/toxic-gas-list (accessed on 27 August 2021).

- Guo, M.; Luo, N.; Chen, Y.; Fan, Y.; Wang, X.; Xu, J. Fast-response MEMS xylene gas sensor based on CuO/WO3 hierarchical structure. J. Hazard. Mater. 2021, 127471. [Google Scholar] [CrossRef]

- Operating Principle-Electrochemical-Type Gas Sensor. Available online: https://www.figaro.co.jp/en/technicalinfo/principle/electrochemical-type.html (accessed on 23 November 2021).

- Matthey, J. Sensors for Toxic Gas Detection. Available online: https://www.technology.matthey.com/article/37/3/146-150/ (accessed on 23 November 2021).

- Liang, Y.; Wu, C.; Jiang, S.; Li, Y.J.; Wu, D.; Li, M.; Cheng, P.; Yang, W.; Cheng, C.; Li, L.; et al. Field comparison of electrochemical gas sensor data correction algorithms for ambient air measurements. Sens. Actuators B Chem. 2021, 327, 128897. [Google Scholar] [CrossRef]

- Kang, X.; Wang, J.; Wu, H.; Liu, J.; Aksay, I.A.; Lin, Y. A graphene-based electrochemical sensor for sensitive detection of paracetamol. Talanta 2010, 81, 754–759. [Google Scholar] [CrossRef] [PubMed]

- Marrazza, G.; Chianella, I.; Mascini, M. Disposable DNA electrochemical sensor for hybridization detection. Biosens. Bioelectron. 1999, 14, 43–51. [Google Scholar] [CrossRef]

- Guth, U.; Vonau, W.; Zosel, J. Recent developments in electrochemical sensor application and technology—A review. Meas. Sci. Technol. 2009, 20, 042002. [Google Scholar] [CrossRef]

- Wan, H.; Yin, H.; Lin, L.; Zeng, X.; Mason, A.J. Miniaturized Planar Room Temperature Ionic Liquid Electrochemical Gas Sensor for Rapid Multiple Gas Pollutants Monitoring. Sens. Actuators B Chem. 2018, 255, 638–646. [Google Scholar] [CrossRef] [PubMed]

- Baron, R.; Saffell, J. Amperometric Gas Sensors as a Low Cost Emerging Technology Platform for Air Quality Monitoring Applications: A Review. ACS Sens. 2017, 2, 1553–1566. [Google Scholar] [CrossRef]

- Ali, F.I.; Awwad, F.; Greish, Y.E.; Mahmoud, S.T. Hydrogen Sulfide (H2S) Gas Sensor: A Review. IEEE Sens. J. 2019, 19, 2394–2407. [Google Scholar] [CrossRef]

- Liam. How Many Types of Gas Detectors Are There? Newctle. Saf. Serv. Available online: https://newcastlesafetyservicing.com/types-of-gas-detectors/ (accessed on 27 August 2021).

- Vigdor, B. 7 Types Of Industrial Gas Detectors: #7 Is The Best. Available online: https://nevadanano.com/industrial-gas-detectors/ (accessed on 27 August 2021).

- Hu, K.; Wang, F.; Shen, Z.; Liu, H.; Xiong, J. Ternary heterojunctions synthesis and sensing mechanism of Pd/ZnO–SnO2 hollow nanofibers with enhanced H2 gas sensing properties. J. Alloys Compd. 2021, 850, 156663. [Google Scholar] [CrossRef]

- Barsan, N.; Weimar, U. 7.3.3 Fundamentals of Metal Oxide Gas Sensors. In Proceedings of the 14th International Meeting on Chemical Sensors—IMCS 2012, Nuremberg, Germany, 20–23 May 2012; pp. 618–621. [Google Scholar] [CrossRef]

- Velladurai, V.S.; Saravanan, M.; Vigneshbabu, R.; Karthikeyan, P.; Dhlipkumar, A. Human Safety System in Drainage, Unused Well and Garbage Alerting System for Smart City. In Proceedings of the 2017 International Conference on I-SMAC (IoT in Social, Mobile, Analytics and Cloud) (I-SMAC), Palladam, India, 10–11 February 2017; pp. 6–9. [Google Scholar]

- Sanger, J.B.; Sitanayah, L.; Ahmad, I. A Sensor-based Garbage Gas Detection System. In Proceedings of the 2021 IEEE 11th Annual Computing and Communication Workshop and Conference (CCWC), Las Vegas, NV, USA, 27–30 January 2021; pp. 1347–1353. [Google Scholar] [CrossRef]

- Nath, S.; Dey, A.; Pachal, P.; Chowdhury, S.R.; Sing, J.K.; Sarkar, S.K. Nano Structured Gas Sensing Device and Its Application in Underground Mines. In Proceedings of the 2018 IEEE Electron Devices Kolkata Conference (EDKCON), Kolkata, India, 24–25 November 2018; pp. 445–449. [Google Scholar] [CrossRef]

- Zinnuraain, S.M.; Hasan, M.; Hakque, M.A.; Arefin, M.M.N. Smart Gas Leakage Detection with Monitoring and Automatic Safety System. In Proceedings of the 2019 International Conference on Wireless Communications Signal Processing and Networking (WiSPNET), Chennai, India, 21–23 March 2019; pp. 406–409. [Google Scholar] [CrossRef]

- Parmar, G.; Lakhani, S.; Chattopadhyay, M.K. An IoT Based Low Cost Air Pollution Monitoring System. In Proceedings of the 2017 International Conference on Recent Innovations in Signal processing and Embedded Systems (RISE), Bhopal, India, 27–29 October 2017; pp. 524–528. [Google Scholar] [CrossRef]

- Thomas, G.W.; Sousan, S.; Tatum, M.; Liu, X.; Zuidema, C.; Fitzpatrick, M.; Koehler, K.A.; Peters, T.M. Low-Cost, Distributed Environmental Monitors for Factory Worker Health. Sensors 2018, 18, 1411. [Google Scholar] [CrossRef] [PubMed]

- Suh, J.H.; Cho, I.; Kang, K.; Kweon, S.J.; Lee, M.; Yoo, H.J.; Park, I. Fully integrated and portable semiconductor-type multi-gas sensing module for IoT applications. Sens. Actuators B Chem. 2018, 265, 660–667. [Google Scholar] [CrossRef]

- Singh, R.; Gaur, N.; Bathla, S. IoT based Air Pollution Monitoring device Using Raspberry Pi and Cloud Computing. In Proceedings of the 2020 4th International Conference on Electronics, Communication and Aerospace Technology (ICECA), Coimbatore, India, 5–7 November 2020; pp. 702–707. [Google Scholar] [CrossRef]

- Wu, Y.; Liu, T.; Ling, S.H.; Szymanski, J.; Zhang, W.; Su, S.W. Air Quality Monitoring for Vulnerable Groups in Residential Environments Using a Multiple Hazard Gas Detector. Sensors 2019, 19, 362. [Google Scholar] [CrossRef] [PubMed]

- Chang, B.R.; Tsai, H.F.; Lin, Y.C.; Yin, T.K. Unmanned Mobile Multipurpose Monitoring System—iMonitor. Sens. Mater. 2021, 33, 1457. [Google Scholar] [CrossRef]

- Mabrouki, J.; Azrour, M.; Fattah, G.; Dhiba, D.; El Hajjaji, S. Intelligent monitoring system for biogas detection based on the Internet of Things: Mohammedia, Morocco city landfill case. Big Data Min. Anal. 2021, 4, 10–17. [Google Scholar] [CrossRef]

- Juel, M.T.I.; Ahmed, M.S.; Islam, T. Design of IoT Based Multiple Hazards Detection and Alarming System. In Proceedings of the 2019 4th International Conference on Electrical Information and Communication Technology (EICT), Khulna, Bangladesh, 20–22 December 2019; pp. 1–5. [Google Scholar] [CrossRef]

- Joseph, T.; Naik, S.; Shaikh, A.; Phadnis, R.; Karmarkar, A.; Tyagi, K.; Khole, S.; Chaudhari, S. Portable Gas Detection and Warning System for Olfactory Disabled People. In Proceedings of the 2020 International Conference for Emerging Technology (INCET), Belgaum, India, 5–7 June 2020; pp. 1–5. [Google Scholar] [CrossRef]

- Chávez, E.; Vidal, R.; Tejada, A.; Grados, J. Image Processing for the Detection and Monitoring of Toxic Gases in Confined Environments: An Approach for Application in Shipping Containers in Callao-Peru. In Proceedings of the 2020 6th International Conference on Mechatronics and Robotics Engineering (ICMRE), Barcelona, Spain, 12–15 February 2020; pp. 160–164. [Google Scholar] [CrossRef]

- Jo, J.; Jo, B.; Kim, J.; Kim, S.; Han, W. Development of an IoT-Based Indoor Air Quality Monitoring Platform. J. Sens. 2020, 2020, e8749764. [Google Scholar] [CrossRef]

- Cheung, W.F.; Lin, T.H.; Lin, Y.C. A Real-Time Construction Safety Monitoring System for Hazardous Gas Integrating Wireless Sensor Network and Building Information Modeling Technologies. Sensors 2018, 18, 436. [Google Scholar] [CrossRef]

- Eamsa-ard, T.; Seesaard, T.; Kerdcharoen, T. Wearable Sensor of Humanoid Robot-Based Textile Chemical Sensors for Odor Detection and Tracking. In Proceedings of the 2018 International Conference on Engineering, Applied Sciences, and Technology (ICEAST), Phuket, Thailand, 4–7 July 2018; pp. 1–4. [Google Scholar] [CrossRef]

- Benammar, M.; Abdaoui, A.; Ahmad, S.H.; Touati, F.; Kadri, A. A Modular IoT Platform for Real-Time Indoor Air Quality Monitoring. Sensors 2018, 18, 581. [Google Scholar] [CrossRef]

- Pavani, M.; Rao, P.T. Real time pollution monitoring using Wireless Sensor Networks. In Proceedings of the 2016 IEEE 7th Annual Information Technology, Electronics and Mobile Communication Conference (IEMCON), Vancouver, BC, Canada, 13–15 October 2016; pp. 1–6. [Google Scholar] [CrossRef]

- Pérez-Garrido, C.; González-Castano, F.J.; Chaves-Diéguez, D.; Rodríguez-Hernández, P.S. Wireless remote monitoring of toxic gases in shipbuilding. Sensors 2014, 14, 2981–3000. [Google Scholar] [CrossRef] [PubMed]

- Jero, S.E.; Ganesh, A.B. PIC18LF4620 Based Customizable Wireless Sensor Node to Detect Hazardous Gas Pipeline Leakage. In Proceedings of the 2011 International Conference on Emerging Trends in Electrical and Computer Technology, Nagercoil, India, 23–24 March 2011; pp. 563–566. [Google Scholar] [CrossRef]

- Deshmukh, L.P.; Mujawar, T.H.; Kasbe, M.S.; Mule, S.S.; Akhtar, J.; Maldar, N.N. A LabVIEW Based Remote Monitoring and Controlling of Wireless Sensor Node for LPG Gas Leakage Detection. In Proceedings of the 2016 International Symposium on Electronics and Smart Devices (ISESD), Bandung, Indonesia, 29–30 November 2016; pp. 115–120. [Google Scholar] [CrossRef]

- Choi, S.; Park, K.; Lee, S.; Lim, Y.; Oh, B.; Chae, H.Y.; Park, C.S.; Shin, H.; Kim, J.J. A Three-Step Resolution-Reconfigurable Hazardous Multi-Gas Sensor Interface for Wireless Air-Quality Monitoring Applications. Sensors 2018, 18, 761. [Google Scholar] [CrossRef]

- Heng, I.; Zhang, A.; Heimbinder, M.; Yap, R. A Unique Environmental Mobile Device for Detecting Hazardous Chemicals. In Proceedings of the 2012 IEEE Global Humanitarian Technology Conference, Seattle, WA, USA, 21–24 October 2012; pp. 59–65. [Google Scholar] [CrossRef]

- Shi, L.; Wang, X.; Zhang, T.; Hu, C.; Luo, K.; Bai, B. Hazardous Gas Detection Four-Rotor UAV System Development. In Proceedings of the 2016 IEEE International Conference on Mechatronics and Automation, Harbin, China, 7–10 August 2016; pp. 2461–2465. [Google Scholar] [CrossRef]

- Jualayba, M.; Regio, K.; Quiozon, H.; Destreza, A. Hazardous Gas Detection and Notification System. In Proceedings of the 2018 IEEE 10th International Conference on Humanoid, Nanotechnology, Information Technology, Communication and Control, Environment and Management (HNICEM), Baguio City, Philippines, 29 November–2 December 2018; pp. 1–4. [Google Scholar] [CrossRef]

- Varma, A.; Prabhakar, S.; Jayavel, K. Gas Leakage Detection and Smart Alerting and Prediction Using IoT. In Proceedings of the 2017 2nd International Conference on Computing and Communications Technologies (ICCCT), Chennai, India, 23–24 February 2017; pp. 327–333. [Google Scholar] [CrossRef]

- Asthana, N.; Bahl, R. IoT Device For Sewage Gas Monitoring And Alert System. In Proceedings of the 2019 1st International Conference on Innovations in Information and Communication Technology (ICIICT), Chennai, India, 26–26 April 2019; pp. 1–7. [Google Scholar] [CrossRef]

- Karthika, S.; Vanitha, U.; Rejina, P.J.; Supraja, A.T.; Sampritha, R.V.; Srinithi, K. Toxic Gas Detection using Low Power Controller with Alert System. Int. J. Innov. Technol. Explor. Eng. 2019, 8, 1074–1079. [Google Scholar] [CrossRef]

- Manes, G.; Collodi, G.; Gelpi, L.; Fusco, R.; Ricci, G.; Manes, A.; Passafiume, M. Realtime Gas Emission Monitoring at Hazardous Sites Using a Distributed Point-Source Sensing Infrastructure. Sensors 2016, 16, 121. [Google Scholar] [CrossRef]

- Kumar, A.; Kumar, M.; Singh, B. Designing and Implementaion of Smart LPG Trolley with Home Safety. In Proceedings of the 2016 2nd International Conference on Next Generation Computing Technologies (NGCT), Dehradun, India, 14–16 October 2016; pp. 185–190. [Google Scholar] [CrossRef]

- Palacín, J.; Martínez, D.; Clotet, E.; Pallejà, T.; Burgués, J.; Fonollosa, J.; Pardo, A.; Marco, S. Application of an Array of Metal-Oxide Semiconductor Gas Sensors in an Assistant Personal Robot for Early Gas Leak Detection. Sensors 2019, 19, 1957. [Google Scholar] [CrossRef] [PubMed]

- Fan, H.; Hernandez Bennetts, V.; Schaffernicht, E.; Lilienthal, A.J. Towards Gas Discrimination and Mapping in Emergency Response Scenarios Using a Mobile Robot with an Electronic Nose. Sensors 2019, 19, 685. [Google Scholar] [CrossRef]

- Barber, R.; Rodriguez-Conejo, M.A.; Melendez, J.; Garrido, S. Design of an Infrared Imaging System for Robotic Inspection of Gas Leaks in Industrial Environments. Int. J. Adv. Robot. Syst. 2015, 12, 23. [Google Scholar] [CrossRef]

- Faisal, M.; Alsulaiman, M.; Al-Muteb, K.; Hedjar, R.; Mathkour, H.; Emaduddin, M. Gas Detection and Mapping Using an Autonomous Mobile Robot. 2015. Available online: https://www.semanticscholar.org/paper/Gas-Detection-and-Mapping-Using-an-Autonomous-Robot-Faisal-Alsulaiman/7f0eea2bf2164511ecf993dfb738c1b1bed1350f (accessed on 2 September 2021).

- Das, T.; Sut, D.J.; Gupta, V.; Gohain, L.; Kakoty, P.; Kakoty, N.M. A Mobile Robot for Hazardous Gas Sensing. In Proceedings of the 2020 International Conference on Computational Performance Evaluation (ComPE), Shillong, India, 2–4 July 2020; pp. 62–66. [Google Scholar] [CrossRef]

- Zhigang, N.; Lu, W. Hazardous Gas Detecting Method Applied in Coal Mine Detection Robot. In Proceedings of the 2011 Third International Conference on Measuring Technology and Mechatronics Automation, Shanghai, China, 6–7 January 2011; Volume 2, pp. 308–311. [Google Scholar] [CrossRef]

- Joshna, V.; Kashyap, M.; Ananya, V.; Manitha, P.V. Fully Autonomous Robot to Detect and Degasify Hazardous Gas after Flood Disaster. In Proceedings of the 2019 2nd International Conference on Power and Embedded Drive Control (ICPEDC), Chennai, India, 21–23 August 2019; pp. 134–139. [Google Scholar] [CrossRef]

- Xing, Y.; Vincent, T.A.; Fan, H.; Schaffernicht, E.; Bennetts, V.H.; Lilienthal, A.J.; Cole, M.; Gardner, J.W. FireNose on Mobile Robot in Harsh Environments. IEEE Sens. J. 2019, 19, 12418–12431. [Google Scholar] [CrossRef]

- Gallego, V.; Rossi, M.; Brunelli, D. Unmanned Aerial Gas Leakage Localization and Mapping Using Microdrones. In Proceedings of the 2015 IEEE Sensors Applications Symposium (SAS), Zadar, Croatia, 13–15 April 2015; pp. 1–6. [Google Scholar] [CrossRef]

- Burgués, J.; Hernández, V.; Lilienthal, A.J.; Marco, S. Smelling Nano Aerial Vehicle for Gas Source Localization and Mapping. Sensors 2019, 19, 478. [Google Scholar] [CrossRef] [PubMed]

- Xiaoyuan, Y.; Jiwei, D.; Tianjie, Y.; Qingfu, Q. A Method for Improving Detection of Gas Concentrations Using Quadrotor. In Proceedings of the 2016 IEEE Information Technology, Networking, Electronic and Automation Control Conference, Chongqing, China, 20–22 May 2016; pp. 971–975. [Google Scholar] [CrossRef]

- Al-Okby, M.F.R.; Neubert, S.; Stoll, N.; Thurow, K. Low-Cost, Flexible, and Reliable Hybrid Wheelchair Controller for Patients with Tetraplegia. In Proceedings of the 2019 IEEE International Conference on Cyborg and Bionic Systems (CBS), Munich, Germany, 18–20 September 2019; pp. 177–183. [Google Scholar] [CrossRef]

- Al-Okby, M.F.R.; Neubert, S.; Stoll, N.; Thurow, K. Complementary Functions for Intelligent Wheelchair Head Tilts Controller. In Proceedings of the 2017 IEEE 15th International Symposium on Intelligent Systems and Informatics (SISY), Subotica, Serbia, 14–16 September 2017; pp. 000117–000122. [Google Scholar] [CrossRef]

- Ruzaij, M.F.; Neubert, S.; Stoll, N.; Thurow, K. A Speed Compensation Algorithm for a Head Tilts Controller Used for Wheelchairs and Rehabilitation Applications. In Proceedings of the 2017 IEEE 15th International Symposium on Applied Machine Intelligence and Informatics (SAMI), Herl’any, Slovakia, 26–28 January 2017; pp. 497–502. [Google Scholar] [CrossRef]

- Al-Okby, M.F.R.; Neubert, S.; Stoll, N.; Thurow, K. Development and Testing of Intelligent Low-Cost Wheelchair Controller for Quadriplegics and Paralysis Patients. In Proceedings of the 2017 2nd International Conference on Bio-engineering for Smart Technologies (BioSMART), Paris, France, 30 August–1 September 2017; pp. 1–4. [Google Scholar] [CrossRef]

- Sui, T.; Marelli, D.; Sun, X.; Fu, M. Multi-sensor state estimation over lossy channels using coded measurements. Automatica 2020, 111, 108561. [Google Scholar] [CrossRef]

- Liu, F.; Zhang, G.; Lu, J. Multisource Heterogeneous Unsupervised Domain Adaptation via Fuzzy Relation Neural Networks. IEEE Trans. Fuzzy Syst. 2021, 29, 3308–3322. [Google Scholar] [CrossRef]

- Al-Okby, M.F.R.; Al-Barrak, S.S. New Approach for Fall Detection System Using Embedded Technology. In Proceedings of the 2020 IEEE 24th International Conference on Intelligent Engineering Systems (INES), Reykjavík, Iceland, 8–10 July 2020; pp. 209–214. [Google Scholar] [CrossRef]

- Al-Okby, M.F.R.; Thurow, K. WeMos IoT Controller-Based Low-Cost Fall Detection System for Elderly Users. J. Biomim. Biomater. Biomed. Eng. 2021, 50, 59–72. [Google Scholar] [CrossRef]

- Lv, Z.; Chen, D.; Lou, R.; Song, H. Industrial Security Solution for Virtual Reality. IEEE Internet Things J. 2021, 8, 6273–6281. [Google Scholar] [CrossRef]

- Liu, F.; Zhang, G.; Lu, J. Heterogeneous Domain Adaptation: An Unsupervised Approach. IEEE Trans. Neural Netw. Learn. Syst. 2020, 31, 5588–5602. [Google Scholar] [CrossRef]

- Lv, Z.; Qiao, L.; Song, H. Analysis of the Security of Internet of Multimedia Things. ACM Trans. Multimed. Comput. Commun. Appl. 2020, 16, 97:1–97:16. [Google Scholar] [CrossRef]

- Neubert, S.; Roddelkopf, T.; Al-Okby, M.F.R.; Junginger, S.; Thurow, K. Flexible IoT Gas Sensor Node for Automated Life Science Environments Using Stationary and Mobile Robots. Sensors 2021, 21, 7347. [Google Scholar] [CrossRef]

| Wireless Technology | Protocol | Coverage Range | Frequency | Data Rate | Power Consumption | Net. Topology |

|---|---|---|---|---|---|---|

| Wi-Fi | IEEE 802.11 | ∼30–250 m | 2.4, 3.7, 5 GHz | >45 Mb/s | High | P2P, Star, Tree |

| Bluetooth, BLE | IEEE 802.15.1 | ∼100 m | 2.4 GHz | 1–3, 1 Mb/s, | Low, Very Low | P2P, Star |

| LoRa | LPWAN | ∼10 Km | 868,915 MHz | 50 Kb/s | Very Low | Star, Mesh |

| ZigBee/XBee | IEEE 802.15.4 | ∼10–100 m | 868,915 (MHz), 2.4 (GHz) | 250 Kb/s | Medium | P2P, Star, Tree, Mesh |

| GSM 2G, 4G | GSM | GSM network coverage (>10 km) | 933–960 MHz | 270 Kb/s, 3.6 Mbit/s | High | TDMA/FDMA |

| Parameter | ENS160 | MiCS-VZ-89TE | SGP40 | ZMOD4410 | TED110 | BME688 |

|---|---|---|---|---|---|---|

| Target gases | TVOC, eCO2, AQI | TVOC, eCO2, AQI | AQI | TVOC, eCO2, AQI | TVOC, eCO2, AQI | TVOC, eCO2, AQI |

| TVOC range | 0–65,000 ppm | 0–1000 ppb | 0–1000 ppm | 0–1000 ppm | 0–1000 ppm | - |

| eCO2 range | 400–65,000 ppm | 400–2000 ppm | - | 400–5000 ppm | - | - |

| “Warm-Up” period | 1 min | 15 min | <60 s | 2 min | - | 2 ms |

| Response time | - | <5 s | <10 s | 5 s | 10 s | 8 s |

| Refresh Output Frequency | 1 MHz | 1 Hz | 1 Hz | 100 kHz | - | 182 Hz |

| IoT devices | Yes | No | Yes | Yes | Yes | Yes |

| communication | I2C, SPI | I2C | I2C | I2C | I2C | I2C, SPI |

| AI | No | No | No | Yes | No | Yes |

| Technology | MOX | MOX | MOX | MOX | MOX, MEMS | MOX, MEMS |

| Power consumption | - | - | 2.6 mA at 3.3 V | 1.5 mW | 3.9 mW | <0.1 mA |

| Lifetime | - | - | >10 years | 10 years | >5 years | - |

| Operation voltage | 1.7–3.6 V | 3.3 V | 1.7 to 3.6 V | 1.7 to 3.6 V | 3.3 V | 1.7 to 3.6 V |

| Reference No., Year | Used Sensors | Sensor Type | Parameter | Communication Interface | MCU | Data Access | Mobility/Host |

|---|---|---|---|---|---|---|---|

| [23], 2017 | MQ-4, 7, 135, 136 | MOX | H2S, CO, CH4 | Wi-Fi, GSM | PIC16F887 | Smartphone | Portable Device |

| [24], 2021 | MQ-136, MQ-137, TGS-2611 | MOX | CH4, H2S, NH3 | Wi-Fi | Arduino Uno | Web/Cloud, PC/Laptop, Smartphone | Portable Device |

| [25], 2018 | Au-TiO2, Au-SnO2, Au-WO3, Au-ZnO | MOX, Catalytic | CH4, H2, N2 | Wi-Fi | Node-MCU-ESP8266 | Web/Cloud, PC/Laptop | Portable Device |

| [26], 2019 | MQ-2 | MOX | LPG | Wi-Fi | Node-MCU ESP8266, Arduino Mega 2560 | Smartphone | WSN |

| [27], 2017 | MQ-7, 135 | MOX | CO, CO2, SO2, NO2 | Wi-Fi | Raspberry pi 3, Nucleo F401RE | Web/Cloud, Smartphone | Portable Device |

| [28], 2018 | Sharp-DN7C3CA006, Alphasense-CO-B4, OX-B431 | Optical, MOX | CO2, O3, NO2 | Wi-Fi | Teensy 3.2, Arduino-ATmega32u4, | Web/Cloud | WSN |

| [29], 2018 | SnO2, ZnO | Electrochemical, Catalytic | H2S, CO | Wi-Fi/RF, BLE | ESP-WROOM-32 | Web/Cloud, PC/Laptop, Smartphone | WSN |

| [30], 2020 | MQ-135 | MOX | CO2 | Wi-Fi | Arduino Uno, Raspberry Pi 3 | PC/Laptop | Portable Device |

| [31], 2019 | TGS2620, TGS2603, TGS2600 | MOX | C2H5OH | Wi-Fi | Arduino Uno | Web/Cloud, PC/Laptop, Smartphone | Robot |

| [32], 2021 | MQ-2, Grove-MICS6814, CO2 gas sensor | MOX | CO2, LPG, CO, NH3, NO2, C3H8, C4H10, CH4, H2, C2H5OH | Wi-Fi | Raspberry Pi 3 | Web/Cloud, Internal-Memory, Smartphone | Robot |

| [33], 2021 | ME2-O2, MQ-4,7,136, MICS-6814 | MOX, Electrochemical | CH4, CO2, N2, O2, H2S | Wi-Fi, BLE, GSM | Arduino UNO | Web/Cloud, PC/Laptop, Smartphone | Portable Device |

| [34], 2019 | MQ-2 | MOX | LPG | Wi-Fi | Node-MCU ESP8266 | Web/Cloud | Portable Device |

| [35], 2020 | MQ-7,9,136 | MOX | LPG, CH4, CO, H2S, C4H10 | Wi-Fi | Atmega 328P | Web/Cloud, Smartphone | Portable Device |

| [36], 2020 | Reagents | Optical | NH3, CO | Wi-Fi | Raspberry Pi 3 | PC/Laptop, Smartphone | Portable Device |

| [37], 2020 | PID | Photoionization/Optical | CO, CO2, VOC | Wi-Fi | STM32F407IG | Web/Cloud, PC/Laptop, Smartphone | WSN, Portable Device |

| [38], 2018 | MQ-2 | MOX | CH4 | ZigBee | Gadgeteer | Web/Cloud, PC/Laptop | WSN |

| [39], 2018 | NA | Electrochemical | NH3 | ZigBee/XBee | LilyPad Arduino328 | PC/Laptop | Portable Device |

| [40], 2018 | 4-SO2-20, 4-NO2-20, OX-A431, INE20-CO2P-NCVSP, 4-CO-500, 4-Cl2-50 | Electrochemical | CO2, CO, SO2, NO2, O3, Cl2 | ZigBee/XBee | ATmega1281 | Web/Cloud, Internal-Memory, Smartphone, PC/Laptop | WSN |

| [41], 2016 | Figaro’s TGS4161, KE-25 | Electrochemical | CO2, CO, O2, NO2 | ZigBee | ATmega1281 | Web/Cloud, PC/Laptop | WSN |

| [42], 2014 | Dr¨ager X-am 5000 | Electrochemical | NA | ZigBee | Texas Instruments CC2530-CC2591EM | PC/Laptop | WSN |

| [43], 2011 | Figaro’s TGS4161, KE-50 | Electrochemical | CO2, O2 | ZigBee | PIC18LF4620 | Web/Cloud, PC/Laptop | WSN |

| [44], 2016 | MQ-2 | MOX | LPG/CNG | ZigBee | Atmega 328 | Web/Cloud, PC/Laptop, Smartphone | WSN |

| [45], 2018 | MQ-7, GSNT11, MQ-5, MQ-8, | Semiconductor, MOX | CO, H2, NO, CH4, C6H6, SO2 | Bluetooth | NA | Smartphone | Portable Device |

| [46], 2012 | NA | MOX | CO, NO2 | Bluetooth | Arduino UNO | Web/Cloud, PC/Laptop, Smartphone | Portable Device |

| [47], 2016 | MQ-2 | MOX | C2H5OH, CO, CH4, H2 | Bluetooth | STM32F1 | PC/Laptop, Smartphone | Drone/Quad-copter |

| [48], 2018 | MQ-2,5,8 | MOX | LPG | GSM | Arduino UNO | Smartphone | Portable Device |

| [49], 2017 | MQ-2 | MOX | LPG, C2H5OH, CO, CH4, H2 | GSM | Arduino UNO | PC/Laptop, Smartphone | Portable Device |

| [50], 2019 | MQ-4,7 | MOX | CO, CH4 | GSM | Arduino UNO | PC/Laptop, Smartphone | Portable Device |

| [51], 2019 | MQ-5 | MOX | LPG | GSM | Arduino UNO | Smartphone | Portable Device |

| [52], 2016 | PID-AH | Photoionization/Optical | H2S, VOC | GSM | ARM-9 | Web/Cloud | WSN |

| [53], 2016 | MQ-5 | MOX | LPG | GSM | PIC18F | Smartphone | Portable Device |

| [54], 2019 | FIGARO TGS 2600, 2602, 2611, 2620 | MOX | C2H5OH, C3H6O | Wi-Fi/RF | STM32F407VGT6 | PC/Laptop | Robot |

| [55], 2018 | UWAR nose | MEMS, MOX, Optical, Electrochemical | C2H5OH, C3H6O | Wi-Fi/RF | STM32 | PC/Laptop | Robot |

| [56], 2015 | Infrared | Optical | CH4, CO2 | NA | TurtleBot | PC/Laptop, | Robot |

| [57], 2015 | MultiRAE Lite | Electrochemical, Optical, MOX | CH4, CO | Wi-Fi/RF | PowerBot | PC/Laptop | Robot |

| [58], 2020 | MQ-5, MQ-135 | MOX | LPG, CO2, C2H5OH | ZigBee | NA | Other | Robot |

| [59], 2011 | Infrared | Optical | CH4, CO | NA | NA | PC/Laptop, Internal-Memory | Robot |

| [60], 2019 | MQ-2, MQ-3 | MOX | C2H5OH, CO | GSM | Arduino UNO | PC/Laptop | Robot |

| [61], 2019 | MICS2614, MICS5524, MICS5914, MICS2714, MICS4514 | MOX, Optical | C2H5OH, C3H8O, C3H6O | Wi-Fi | Teensy 3.6 | Internal-Memory, PC/Laptop | Portable Device, Robot |

| [62], 2015 | MiCS-5121, MiCS-5525 | MOX | CO, HC, VOC | GSM, RF | Jennic JN5148 | Internal-Memory, Smartphone | Drone/Quadcopter |

| [63], 2019 | TGS 8100 | MOX | C2H5OH | Wi-Fi/RF | STM32F405 | PC/Laptop, Smartphone | Drone/Quadcopter |

| [64], 2016 | MP-3 Planar | MOX | C2H5OH | Wi-Fi | NA | Other | Drone/Quadcopter |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Al-Okby, M.F.R.; Neubert, S.; Roddelkopf, T.; Thurow, K. Mobile Detection and Alarming Systems for Hazardous Gases and Volatile Chemicals in Laboratories and Industrial Locations. Sensors 2021, 21, 8128. https://doi.org/10.3390/s21238128

Al-Okby MFR, Neubert S, Roddelkopf T, Thurow K. Mobile Detection and Alarming Systems for Hazardous Gases and Volatile Chemicals in Laboratories and Industrial Locations. Sensors. 2021; 21(23):8128. https://doi.org/10.3390/s21238128

Chicago/Turabian StyleAl-Okby, Mohammed Faeik Ruzaij, Sebastian Neubert, Thomas Roddelkopf, and Kerstin Thurow. 2021. "Mobile Detection and Alarming Systems for Hazardous Gases and Volatile Chemicals in Laboratories and Industrial Locations" Sensors 21, no. 23: 8128. https://doi.org/10.3390/s21238128

APA StyleAl-Okby, M. F. R., Neubert, S., Roddelkopf, T., & Thurow, K. (2021). Mobile Detection and Alarming Systems for Hazardous Gases and Volatile Chemicals in Laboratories and Industrial Locations. Sensors, 21(23), 8128. https://doi.org/10.3390/s21238128