High Performance Predictable Quantum Efficient Detector Based on Induced-Junction Photodiodes Passivated with SiO2/SiNx

Abstract

1. Introduction

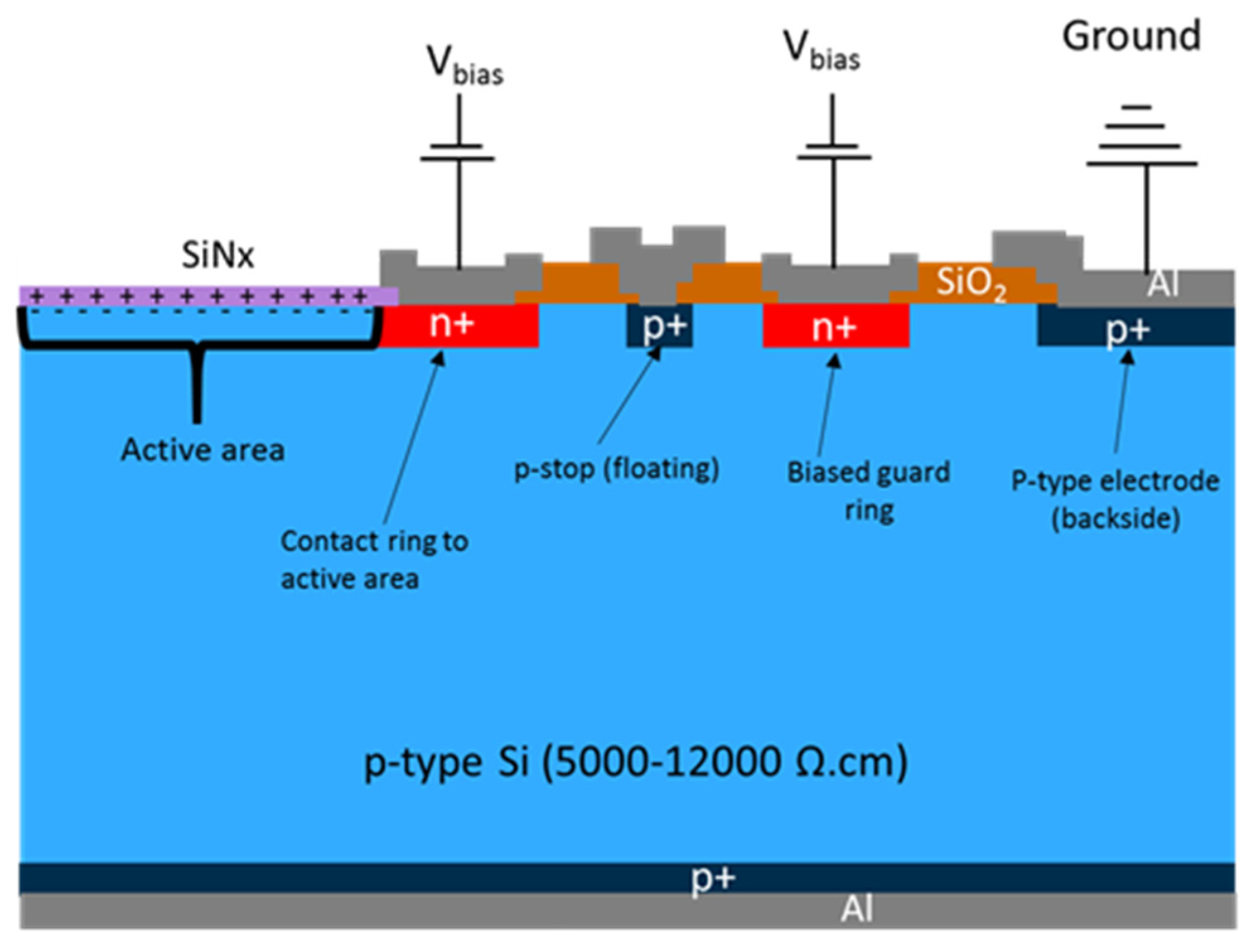

2. Inversion Layer Photodiode Structure and Operation

3. Development of Passivation Process

3.1. Methodology

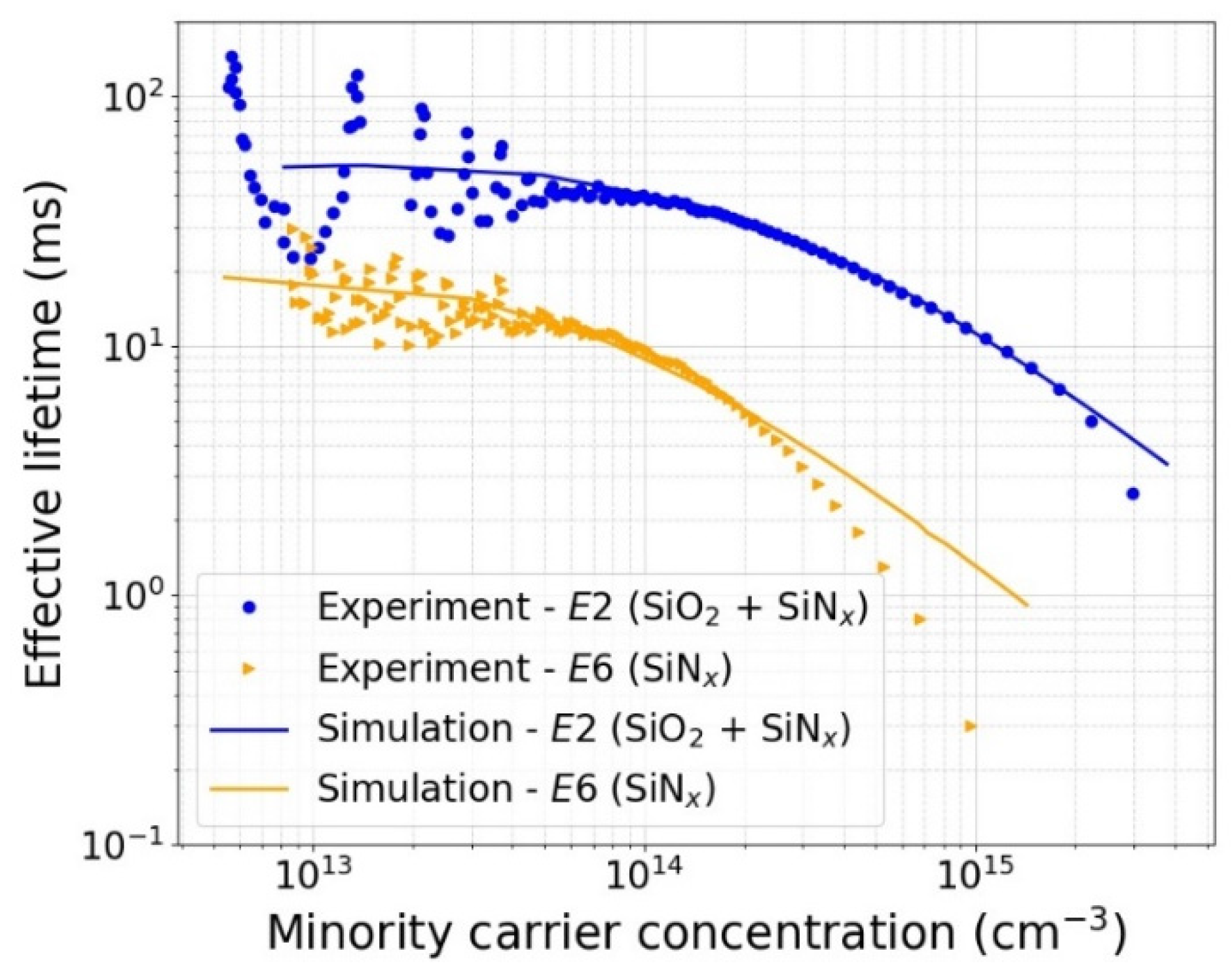

3.1.1. Lifetime Measurements

3.1.2. Fixed Charge Measurements

3.1.3. Ellipsometry Measurements and Reflectance Simulations

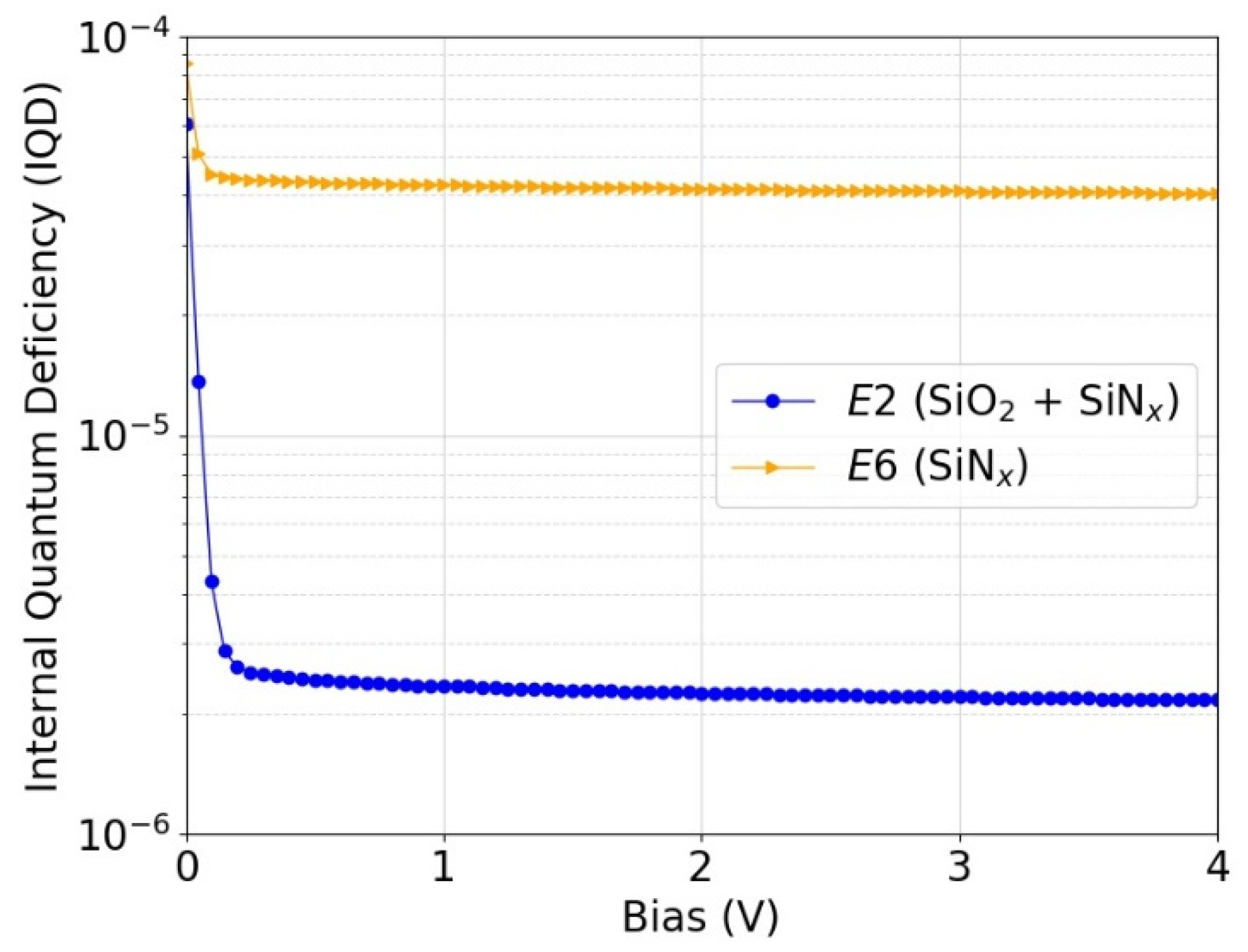

3.1.4. Modelling and Simulations of SRV and IQD

3.2. Passivation Process and Sample Preparation

3.3. Results

3.4. Predicted Photodiode Responsivity

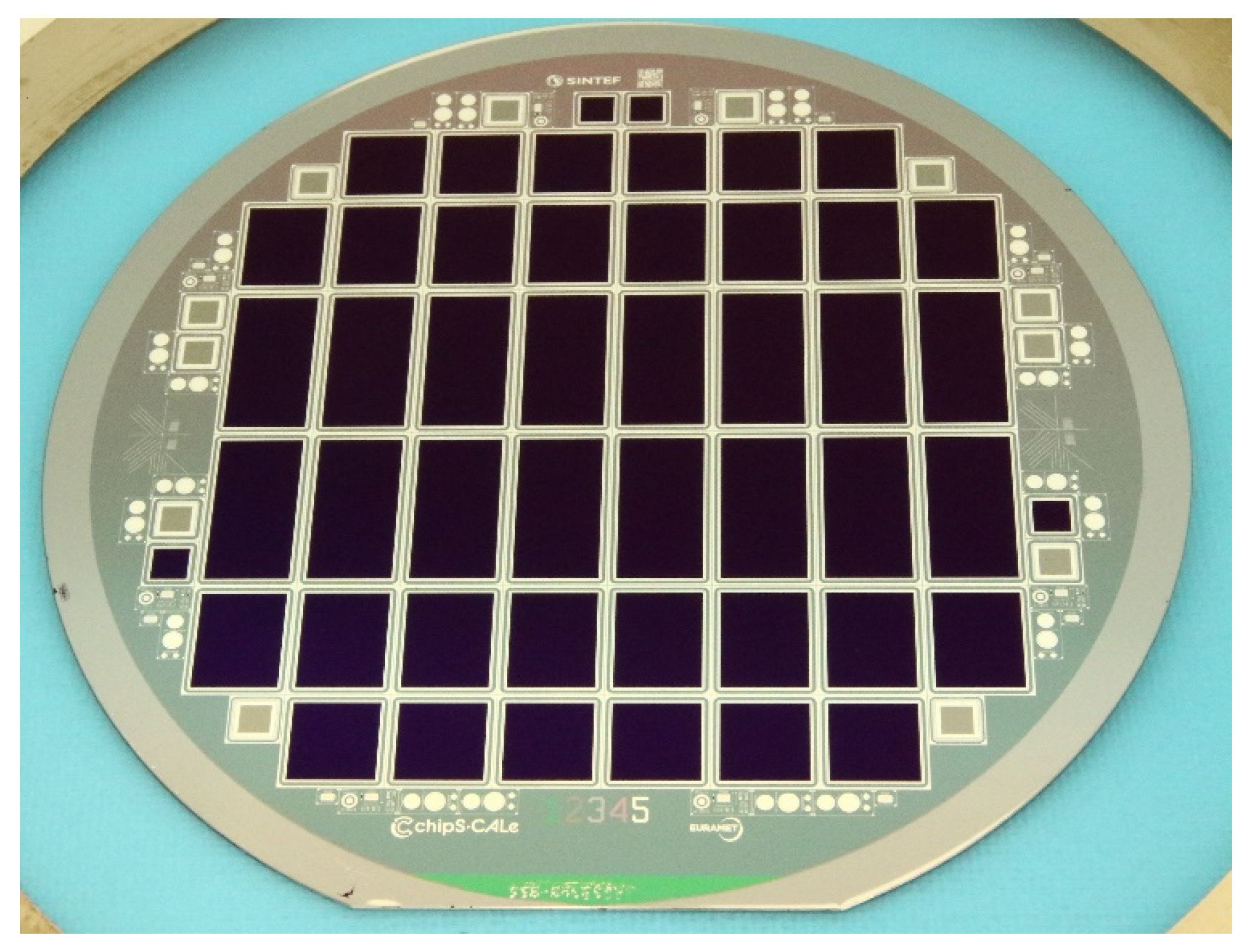

4. Photodiode Design and Fabrication

5. PQED Assembly and Test Results

5.1. PQED Assembly

5.2. IQD Measurements and Comparison with Simulated Response

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hansen, T.E. Silicon UV-photodiodes using natural inversion layers. Phys. Scr. 1978, 18, 471–475. [Google Scholar] [CrossRef]

- Geist, J.; Zalewski, E.F.; Schaefer, A.R. Spectral response self-calibration and interpolation of silicon photodiodes. Appl. Opt. 1980, 19, 3795–3799. [Google Scholar] [CrossRef]

- Geist, J.; Liang, E.; Schaefer, A.R. Complete collection of minority carriers from the inversion layer in induced junction diodes. J. Appl. Phys. 1981, 52, 4879–4881. [Google Scholar] [CrossRef]

- Zalewski, E.F.; Duda, C.R. Silicon photodiode device with 100% external quantum efficiency. Appl. Opt. 1983, 22, 2867–2873. [Google Scholar] [CrossRef] [PubMed]

- Sildoja, M.; Manoocheri, F.; Merimaa, M.; Ikonen, E.; Müller, I.; Werner, L.; Gran, J.; Kübarsepp, T.; Smîd, M.; Rastello, M.L. Predictable quantum efficient detector: I. Photodiodes and predicted responsivity. Metrologia 2013, 50, 385–394. [Google Scholar] [CrossRef]

- Müller, I.; Johannsen, U.; Linke, U.; Socaciu-Siebert, L.; Smîd, M.; Porrovecchio, G.; Sildoja, M.; Manoocheri, F.; Ikonen, E.; Gran, J.; et al. Predictable quantum efficient detector: II. Characterization and confirmed responsivity. Metrologia 2013, 50, 395–401. [Google Scholar] [CrossRef]

- Dönsberg, T.; Sildoja, M.; Manoocheri, F.; Merimaa, M.; Petroff, L.; Ikonen, E. A primary standard of optical power based on induced-junction silicon photodiodes operated at room temperature. Metrologia 2014, 51, 197–202. [Google Scholar] [CrossRef]

- Salffner, K.; Dönsberg, T.; Porrovecchio, G.; Smid Nield, K.; Nevas, S. Characterization of a room temperature predictable quantum efficient detector for applications in radiometry and photometry. Metrologia 2018, 55, 654. [Google Scholar] [CrossRef]

- Dönsberg, T.; Manoocheri, F.; Sildoja, M.; Juntunen, M.; Savin, H.; Tuovinen, E.; Ronkainen, H.; Prunnila, M.; Merimaa, M.; Tang, C.K.; et al. Predictable quantum efficient detector based on n-type silicon photodiodes. Metrologia 2017, 54, 821–836. [Google Scholar] [CrossRef]

- Juntunen, M.A.; Heinonen, J.; Vähänissi, V.; Repo, P.; Valluru, D.; Savin, H. Near-unity quantum efficiency of broadband black silicon photodiodes with an induced junction. Nat. Photon 2016, 10, 777–781. [Google Scholar] [CrossRef]

- Garin, M.; Heinonen, J.; Werner, L.; Pasanen, T.P.; Vähänissi, V.; Haarahiltunen, A.; Juntunen, M.A.; Savin, H. Black-Silicon Ultraviolet Photodiodes Achieve External Quantum Efficiency above 130%. Phys. Rev. Lett. 2020, 125, 117702. [Google Scholar] [CrossRef] [PubMed]

- Bonilla, R.S.; Hoex, B.; Hamer, P.; Wilshaw, P.R. Dielectric surface passivation for silicon solar cells: A review. Phys. Status Solidi A 2017, 214, 1700293. [Google Scholar] [CrossRef]

- Glunz, S.W.; Sproul, A.B.; Warta, W.; Wettling, W. Injection-leveldependent recombination velocities at the Si−SiO2 interface for various dopant concentrations. J. Appl. Phys. 1994, 75, 1611. [Google Scholar] [CrossRef]

- Vitkavage, S.C.; Irene, E.A.; Massoud, H. An investigation of Si-SiO2 interface charges in thermally oxidized (100), (110), (111), and (511) silicon. J. Appl. Phys. 1990, 68, 5262. [Google Scholar] [CrossRef]

- Lauinger, T.; Moschner, J.; Aberle, A.G.; Hezel, R. Optimization and characterization of remote plasma-enhanced chemical vapor deposition silicon nitride for the passivation of p-type crystalline silicon surfaces. J. Vac. Sci. Technol. A Vac. Surf. Film. 1998, 16, 530. [Google Scholar] [CrossRef]

- Aberle, A.G. Overview on SiN surface passivation of crystalline silicon solar cells. Sol. Energy Mater. Sol. Cells 2001, 65, 239. [Google Scholar] [CrossRef]

- Schmidt, J.; Kerr, M. Highest-quality surface passivation of low-resistivity p-type silicon using stoichiometric PECVD silicon nitride. Sol. Energy Mater. Sol. Cells 2001, 65, 585. [Google Scholar] [CrossRef]

- Mackel, H.; Ludemann, R. Detailed study of the composition of hydrogenated SiNx layers for high-quality silicon surface passivation. J. Appl. Phys. 2002, 92, 2602. [Google Scholar] [CrossRef]

- Moschner, J.D.; Henze, J.; Schmidt, J.; Hezel, R. High-quality surface passivation of silicon solar cells in an industrial-type inline plasma silicon nitride deposition system. Prog. Photovolt. Res. Appl. 2004, 12, 21. [Google Scholar] [CrossRef]

- Lelièvre, J.F.; Fourmond, E.; Kaminski, A.; Palais, O.; Ballutaud, D.; Lemiti, M. Study of the composition of hydrogenated silicon nitride SiNx:H for efficient surface and bulk passivation of silicon. Sol. Energy Mater. Sol. Cells 2009, 93, 1281. [Google Scholar] [CrossRef]

- Duttagupta, S.; Lin, F.; Wilson, M.; Boreland, M.B.; Hoex, B.; Aberle, A.G. Extremely low surface recombination velocities on low-resistivity n-type and p-type crystalline silicon using dynamically deposited remote plasma silicon nitride films. Prog. Photovolt. Res. Appl. 2012, 22, 641–647. [Google Scholar] [CrossRef]

- Wan, Y.; McIntosh, K.R.; Thomson, A.F. Characterisation and optimisation of PECVD SiNx as an antireflection coating and passivation layer for silicon solar cells. AIP Adv. 2013, 3, 032113. [Google Scholar] [CrossRef]

- Bazilchuk, M.; Haug, H.; Marstein, E.S. Modulating the fixed charge density in silicon nitride films while monitoring the surface recombination velocity by photoluminescence imaging. Appl. Phys. Lett. 2015, 106, 143505. [Google Scholar] [CrossRef]

- Gorowitz, B.; Gorczyca, T.B.; Saia, R.J. Applications of plasma enhanced chemical vapor deposition in VLSI. Solid State Technol. 1985, 28, 197. [Google Scholar]

- WCT-120TS. Available online: https://www.sintoninstruments.com/products/wct-120ts/ (accessed on 22 November 2021).

- Tompkins, H.G.; Hilfiker, J.N. Spectroscopic Ellipsometry: Practical Application to Thin Film Characterization. 2016. Available online: https://www.momentumpress.net/books/spectroscopic-ellipsometry-practical-application-thin-film-characterization (accessed on 10 October 2021).

- VASE-Ellipsometer. Available online: https://www.jawoollam.com/products/vase-ellipsometer (accessed on 22 November 2021).

- Sildoja, M.; Manoocheri, F.; Ikonen, E. Reflectance calculations for a predictable quantum efficient detector. Metrologia 2009, 46, S151. [Google Scholar] [CrossRef]

- Sildoja, M.; Dönsberg, T.; Mäntynen, H.; Merimaa, M.; Manoocheri, F.; Ikonen, E. Use of the predictable quantum efficient detector with light sources of uncontrolled state of polarization. Meas. Sci. Technol. 2013, 25, 015203. [Google Scholar] [CrossRef][Green Version]

- Cogenda. Available online: https://www.cogenda.com/ (accessed on 22 November 2021).

- Stokkan, T.S.; Haug, H.; Tang, C.K.; Marstein, E.S.; Gran, J. Enhanced surface passivation of predictable quantum efficient detectors by silicon nitride and silicon oxynitride/silicon nitride stack. J. Appl. Phys. 2018, 124, 214502. [Google Scholar] [CrossRef]

- Gran, J.; Kübarsepp, T.; Sildoja, M.; Manoocheri, F.; Ikonen, E.; Müller, I. Simulations of a predictable quantum efficient detector with PC1D. Metrologia 2012, 49, S130. [Google Scholar] [CrossRef]

- PECVD. Available online: https://www.spts.com/categories/pecvd (accessed on 22 November 2021).

- Runyan, W.R.; Bean, K.E. Semiconductor Integrated Circuit Processing Technology; Addison-Wesley: Hoboken, NJ, USA, 1990; pp. 74–75. [Google Scholar]

- Dingemans, G.; Terlinden, N.M.; Verheijen, M.A.; van de Sanden, M.C.M.; Kessels, W.M.M. Controlling the fixed charge and passivation properties of Si(100)/Al2O3 interfaces using ultrathin SiO2 interlayers synthesized by atomic layer deposition. J. Appl. Phys. 2011, 110, 093715. [Google Scholar] [CrossRef]

- The Qu-Candela Project Is an International Project Funded by the European Commission (FP7) under the iMERA Programme (Implementing Metrology in the European Research Area). Available online: http://www.quantumcandela.org/ (accessed on 22 November 2021).

- Porrovecchio, G.; Smid, M.; Werner, L.; Johannsen, U.; Linke, U. Long-term spectral responsivity stability of predictable quantum detectors. In Proceedings of the 29th CIE Session, Washington, DC, USA, 14–22 June 2019; p. 417. [Google Scholar]

| Sample ID | Thermally Grown SiO2 | Gettering After Oxidation | Annealing in Forming Gas after Oxidation | PECVD SiNx | Annealing in Forming Gas after PECVD SiNx Deposition |

|---|---|---|---|---|---|

| E1 | 6 nm | Yes | Yes | 150 nm | Yes |

| E2 | 6 nm | Yes | Yes | 65 nm | Yes |

| E3 | 6 nm | No | Yes | 150 nm | Yes |

| E4 | 6 nm | No | No | 65 nm | Yes |

| E5 | - | N/A | N/A | 150 nm | Yes |

| E6 | - | N/A | N/A | 65 nm | Yes |

| E7 | - | N/A | N/A | 150 nm | No |

| E8 | - | N/A | N/A | 65 nm | No |

| Sample ID | Δn (cm−3) | τeff (ms) |

|---|---|---|

| E1 | 1.8 × 1015 | 10.9 |

| E2 | 1.7× 1015 | 10.2 |

| E3 | 1.6 × 1015 | 9.4 |

| E4 | 1.5 × 1015 | 8.6 |

| E5 | 6.5 × 1014 | 3.9 |

| E6 | 5.9 × 1014 | 3.5 |

| E7 | 5.7 × 1014 | 3.4 |

| E8 | 5.3 × 1014 | 3.1 |

| Sample ID | E2 | E6 |

|---|---|---|

| Structure | SiNx/SiO2/Si | SiNx/Si |

| Fixed charge density Qf | 1.3 × 1012 cm−2 | 4 × 1012 cm−2 |

| Simulation bulk lifetime (τbulk) | 30 ms | 12 ms |

| Simulation SRV (S0n, S0p) | 1.5 × 103 cm/s | 6.0 × 104 cm/s |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Koybasi, O.; Nordseth, Ø.; Tran, T.; Povoli, M.; Rajteri, M.; Pepe, C.; Bardalen, E.; Manoocheri, F.; Summanwar, A.; Korpusenko, M.; et al. High Performance Predictable Quantum Efficient Detector Based on Induced-Junction Photodiodes Passivated with SiO2/SiNx. Sensors 2021, 21, 7807. https://doi.org/10.3390/s21237807

Koybasi O, Nordseth Ø, Tran T, Povoli M, Rajteri M, Pepe C, Bardalen E, Manoocheri F, Summanwar A, Korpusenko M, et al. High Performance Predictable Quantum Efficient Detector Based on Induced-Junction Photodiodes Passivated with SiO2/SiNx. Sensors. 2021; 21(23):7807. https://doi.org/10.3390/s21237807

Chicago/Turabian StyleKoybasi, Ozhan, Ørnulf Nordseth, Trinh Tran, Marco Povoli, Mauro Rajteri, Carlo Pepe, Eivind Bardalen, Farshid Manoocheri, Anand Summanwar, Mikhail Korpusenko, and et al. 2021. "High Performance Predictable Quantum Efficient Detector Based on Induced-Junction Photodiodes Passivated with SiO2/SiNx" Sensors 21, no. 23: 7807. https://doi.org/10.3390/s21237807

APA StyleKoybasi, O., Nordseth, Ø., Tran, T., Povoli, M., Rajteri, M., Pepe, C., Bardalen, E., Manoocheri, F., Summanwar, A., Korpusenko, M., Getz, M. N., Ohlckers, P., Ikonen, E., & Gran, J. (2021). High Performance Predictable Quantum Efficient Detector Based on Induced-Junction Photodiodes Passivated with SiO2/SiNx. Sensors, 21(23), 7807. https://doi.org/10.3390/s21237807