Fabrication of Microchannels in a Nodeless Antiresonant Hollow-Core Fiber Using Femtosecond Laser Pulses

Abstract

:1. Introduction

2. Materials and Methods

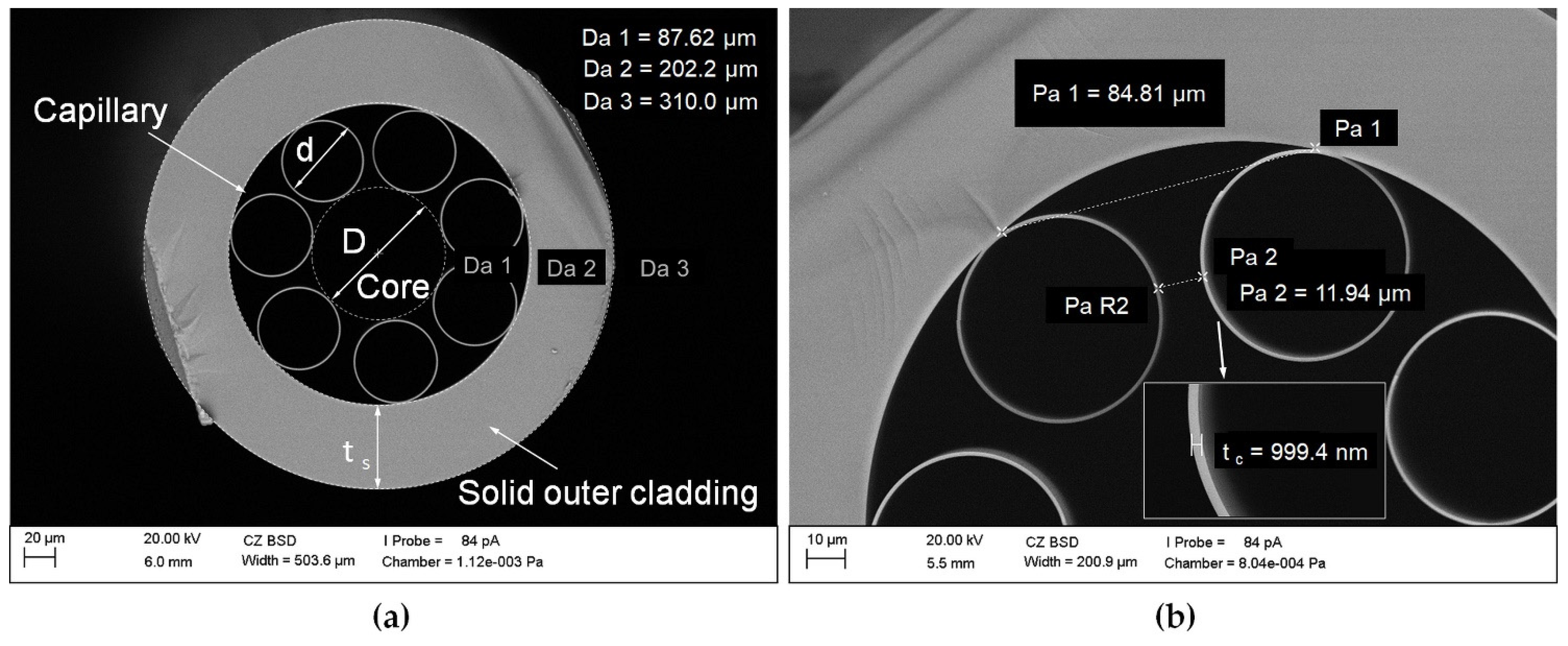

2.1. Antiresonant Hollow-Core Fiber

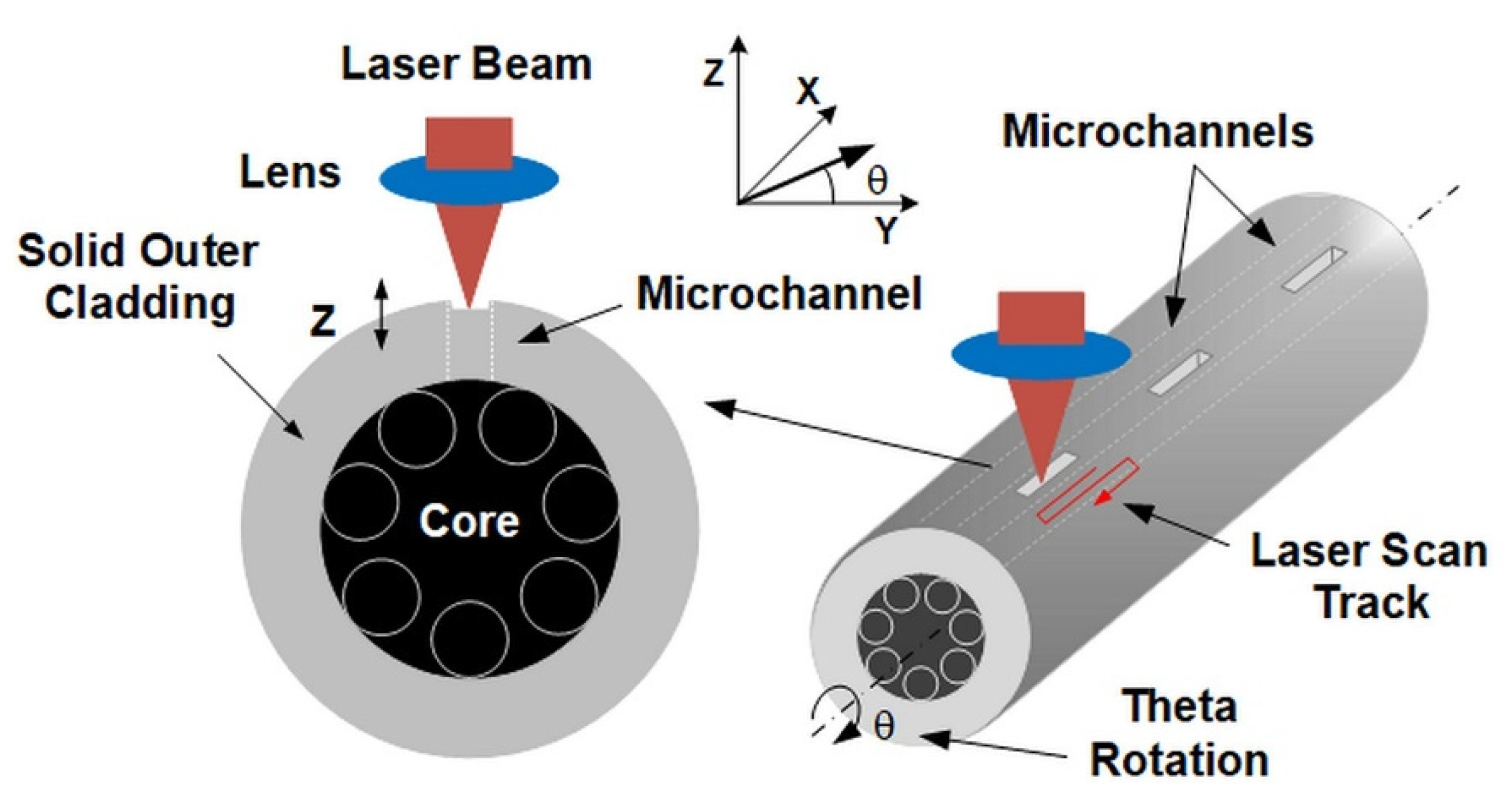

2.2. Methodology

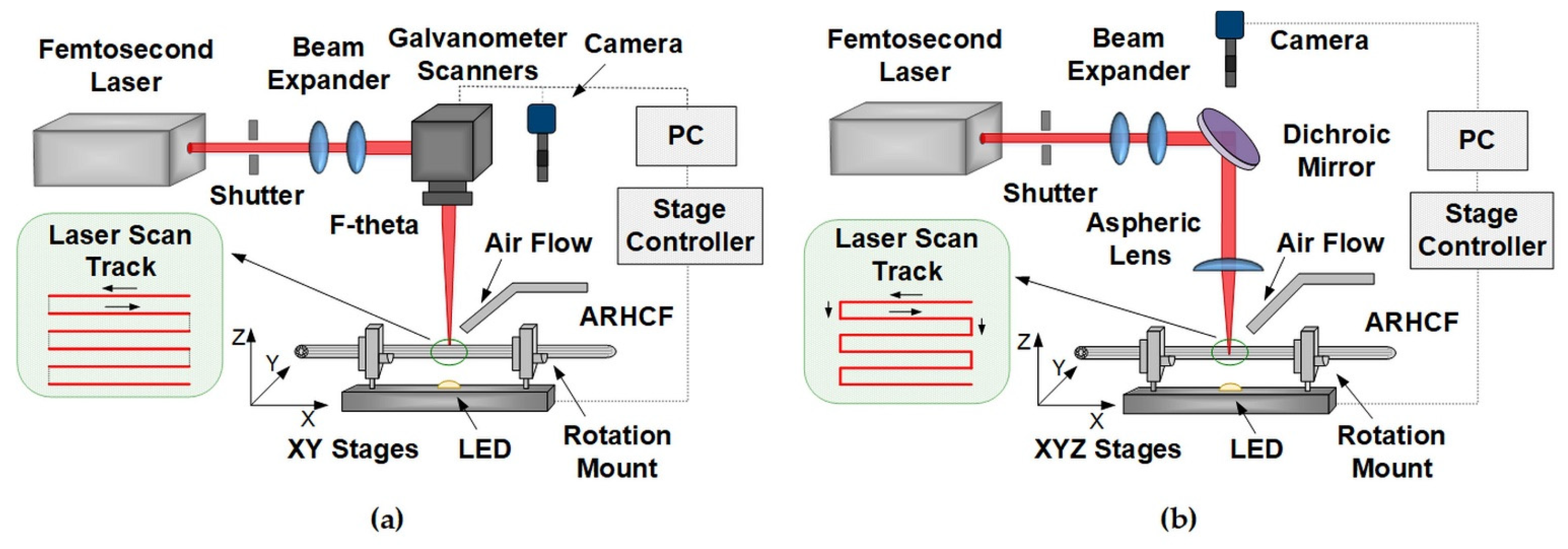

2.3. Experimental Setup and Procedure

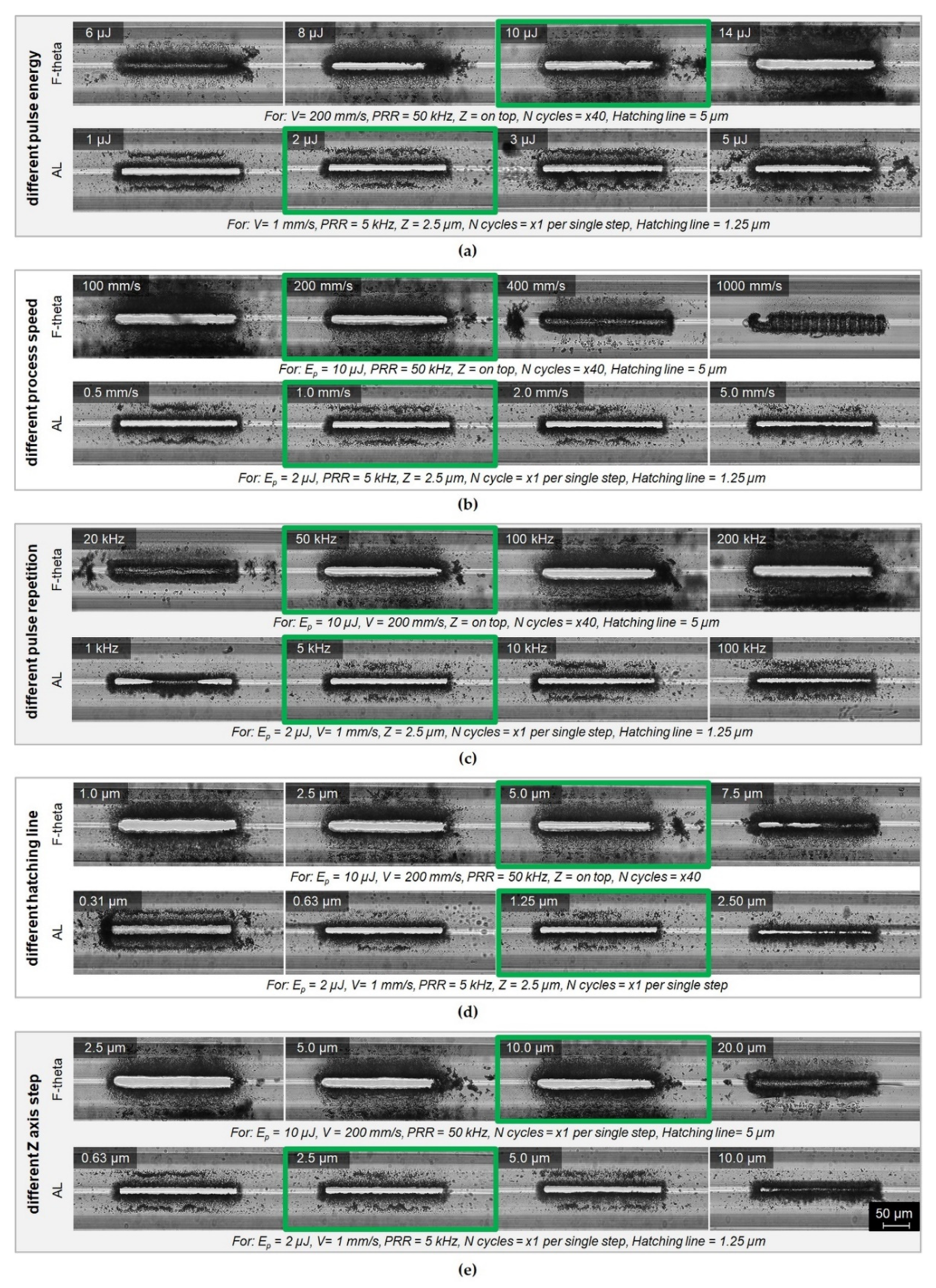

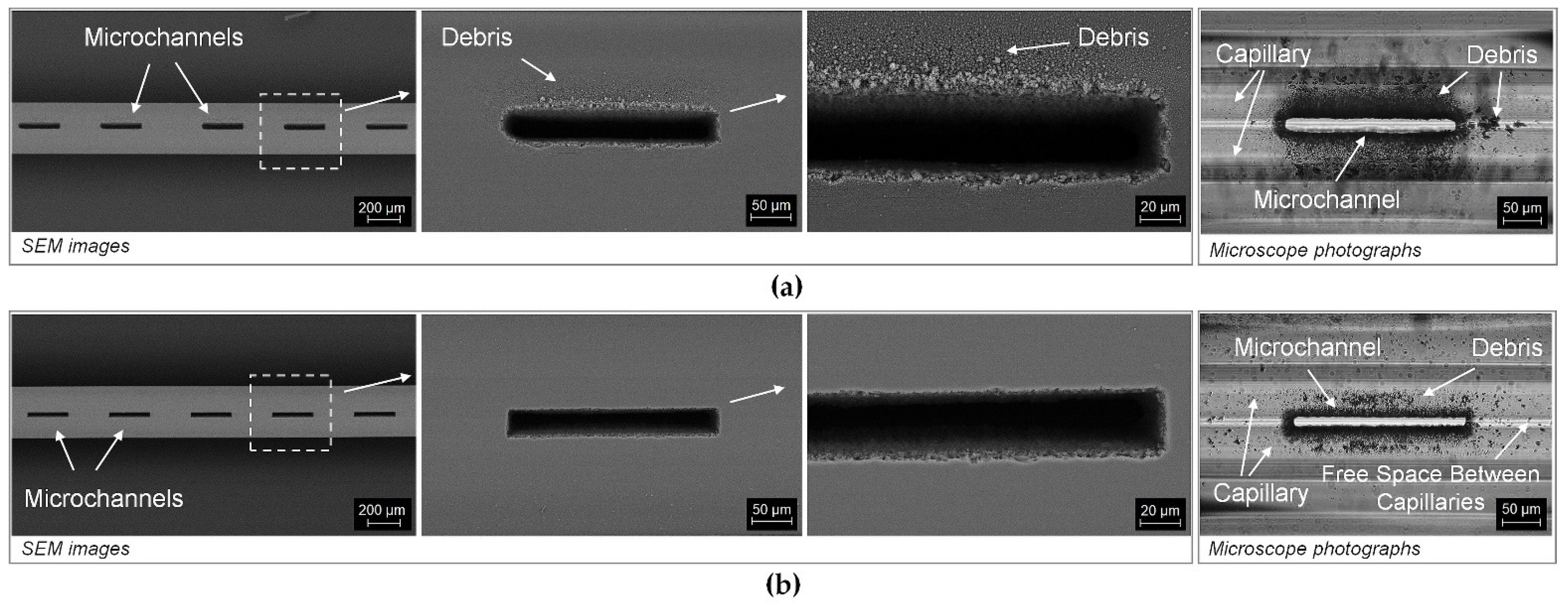

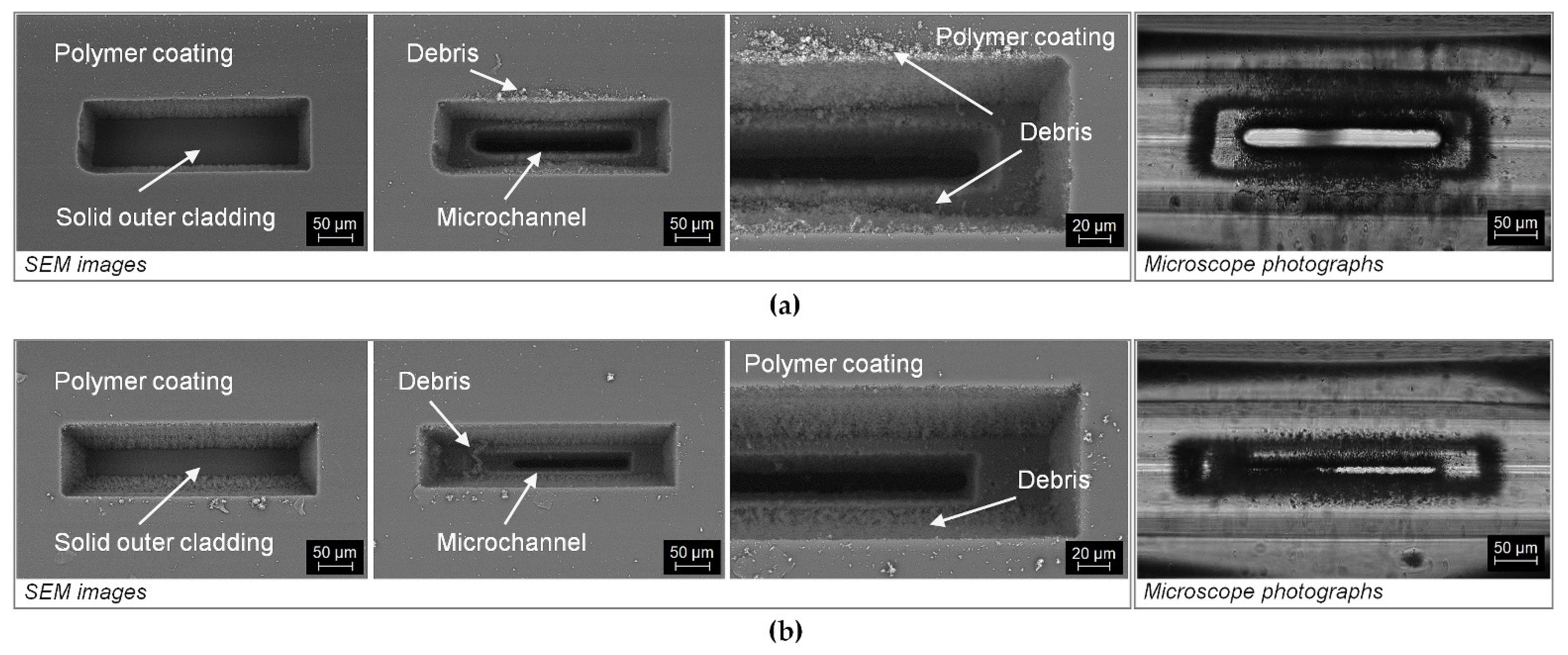

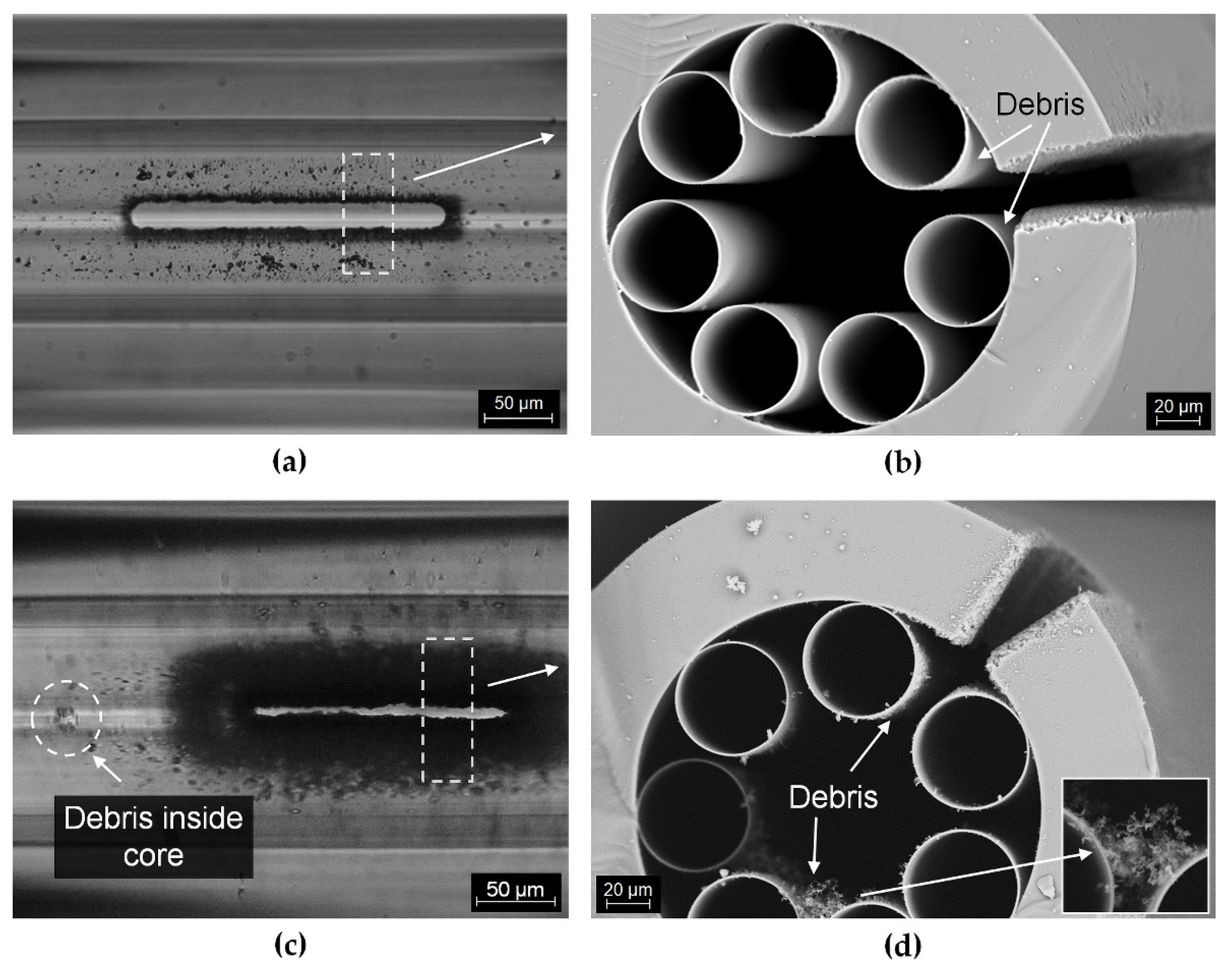

3. Results

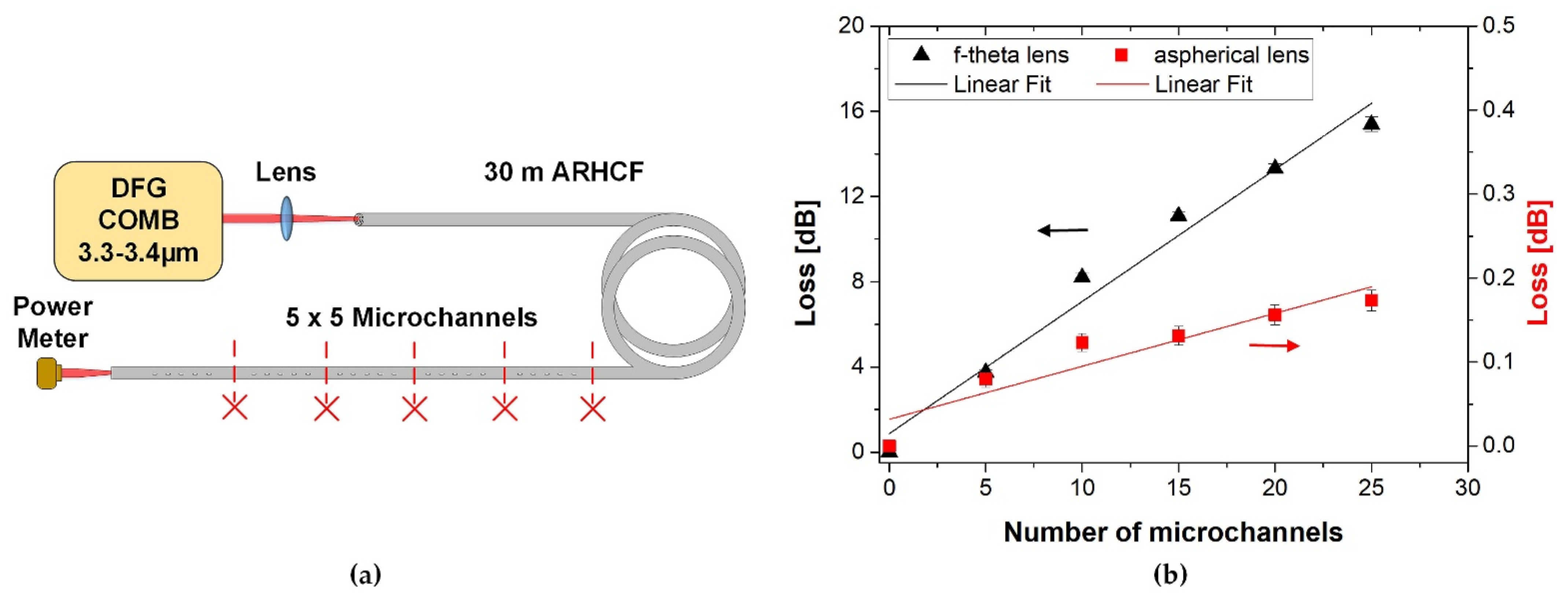

3.1. Influence of Laser Microchannel Processing on the ARHCF Transmission Characteristic

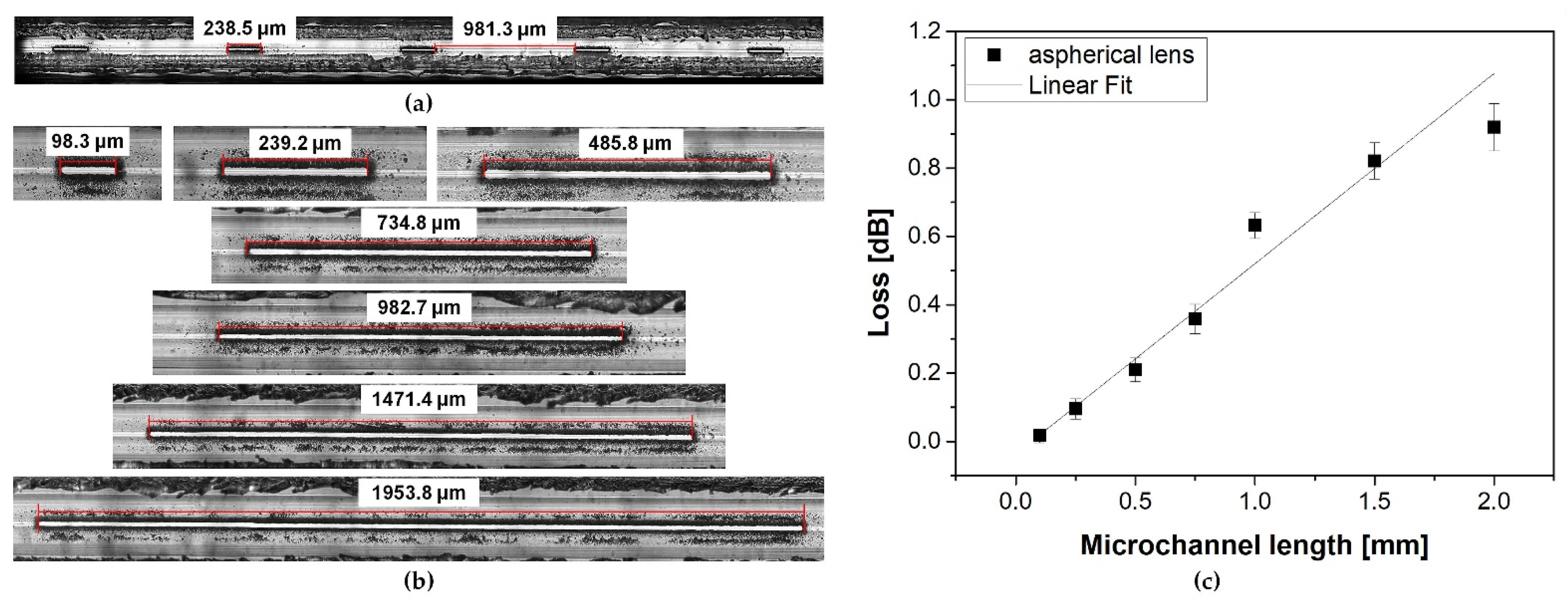

3.2. Influence of Microchannel Length on the ARHCF Transmission

3.3. Bending Performance of the ARHCF with Manufactured Microchannels

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Cui, R.; Dong, L.; Wu, H.; Li, S.; Zhang, L.; Ma, W.; Yin, W.; Xiao, L.; Jia, S.; Tittel, F.K. Highly Sensitive and Selective CO Sensor Using a 2.33 µm Diode Laser and Wavelength Modulation Spectroscopy. Opt. Express 2018, 26, 24318. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wan, F.; Zhou, F.; Hu, J.; Wang, P.; Wang, J.; Chen, W.; Zhu, C.; Liu, Y. Highly Sensitive and Precise Analysis of SF6 Decomposition Component CO by Multi-Comb Optical-Feedback Cavity Enhanced Absorption Spectroscopy with a 2.3 µm Diode Laser. Sci. Rep. 2019, 9, 9690. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Dong, L.; Yao, Y.; Zhao, Y.; Cui, N.; Liu, S.; Zhang, H.; Zhang, Y.; Xu, Y. A High-Sensitive Methane Measuring Telemetry System Based on a Direct Optical Absorption Technique. Laser Phys. 2020, 30, 126201. [Google Scholar] [CrossRef]

- Swinehart, D.F. The Beer-Lambert Law. J. Chem. Educ. 1962, 39, 333–335. [Google Scholar] [CrossRef]

- Yu, R.; Chen, Y.; Shui, L.; Xiao, L. Hollow-Core Photonic Crystal Fiber Gas Sensing. Sensors 2020, 20, 2996. [Google Scholar] [CrossRef]

- Krzempek, K.; Abramski, K.; Nikodem, M. Kagome Hollow Core Fiber-Based Mid-Infrared Dispersion Spectroscopy of Methane at Sub-Ppm Levels. Sensors 2019, 19, 3352. [Google Scholar] [CrossRef] [Green Version]

- Jaworski, P.; Krzempek, K.; Dudzik, G.; Sazio, P.J.; Belardi, W. Nitrous Oxide Detection at 5.26 Μm with a Compound Glass Antiresonant Hollow-Core Optical Fiber. Opt. Lett. OL 2020, 45, 1326–1329. [Google Scholar] [CrossRef]

- Li, J.; Yan, H.; Dang, H.; Meng, F. Structure Design and Application of Hollow Core Microstructured Optical Fiber Gas Sensor: A Review. Opt. Laser Technol. 2021, 135, 106658. [Google Scholar] [CrossRef]

- Hoo, Y.L.; Jin, W.; Ho, H.L.; Ju, J.; Wang, D.N. Gas Diffusion Measurement Using Hollow-Core Photonic Bandgap Fiber. Sens. Actuators B Chem. 2005, 105, 183–186. [Google Scholar] [CrossRef]

- Hoo, Y.L.; Jin, W.; Shi, C.; Ho, H.L.; Wang, D.N.; Ruan, S.C. Design and Modeling of a Photonic Crystal Fiber Gas Sensor. Appl. Opt. 2003, 42, 3509–3515. [Google Scholar] [CrossRef] [Green Version]

- Ritari, T.; Tuominen, J.; Ludvigsen, H.; Petersen, J.C.; Sørensen, T.; Hansen, T.P.; Simonsen, H.R. Gas Sensing Using Air-Guiding Photonic Bandgap Fibers. Opt. Express OE 2004, 12, 4080–4087. [Google Scholar] [CrossRef]

- Jaworski, P.; Kozioł, P.; Krzempek, K.; Wu, D.; Yu, F.; Bojęś, P.; Dudzik, G.; Liao, M.; Abramski, K.; Knight, J. Antiresonant Hollow-Core Fiber-Based Dual Gas Sensor for Detection of Methane and Carbon Dioxide in the Near- and Mid-Infrared Regions. Sensors 2020, 20, 3813. [Google Scholar] [CrossRef]

- Challener, W.A.; Kasten, A.M.; Yu, F.; Puc, G.; Mangan, B.J. Dynamics of Trace Methane Diffusion/Flow Into Hollow Core Fiber Using Laser Absorption Spectroscopy. IEEE Sens. J. 2021, 21, 6287–6292. [Google Scholar] [CrossRef]

- Wynne, R.M.; Barabadi, B.; Creedon, K.J.; Ortega, A. Sub-Minute Response Time of a Hollow-Core Photonic Bandgap Fiber Gas Sensor. J. Lightwave Technol. 2009, 27, 1590–1596. [Google Scholar] [CrossRef]

- Karp, J.; Challener, W.; Kasten, M.; Choudhury, N.; Palit, S.; Pickrell, G.; Homa, D.; Floyd, A.; Cheng, Y.; Yu, F.; et al. Fugitive Methane Leak Detection Using Mid-Infrared Hollow-Core Photonic Crystal Fiber Containing Ultrafast Laser Drilled Side-Holes. In Proceedings of the Fiber Optic Sensors and Applications XIII; International Society for Optics and Photonics: Baltimore, MD, USA, 2016; Volume 9852, p. 985210. [Google Scholar]

- van Brakel, A.; Grivas, C.; Petrovich, M.N.; Richardson, D.J. Micro-Channels Machined in Microstructured Optical Fibers by Femtosecond Laser. Opt. Express OE 2007, 15, 8731–8736. [Google Scholar] [CrossRef] [PubMed]

- Hensley, C.J.; Broaddus, D.H.; Schaffer, C.B.; Gaeta, A.L. Photonic Band-Gap Fiber Gas Cell Fabricated Using Femtosecond Micromachining. Opt. Express OE 2007, 15, 6690–6695. [Google Scholar] [CrossRef] [PubMed]

- Martelli, C.; Olivero, P.; Canning, J.; Groothoff, N.; Gibson, B.; Huntington, S. Micromachining Structured Optical Fibers Using Focused Ion Beam Milling. Opt. Lett. OL 2007, 32, 1575–1577. [Google Scholar] [CrossRef] [Green Version]

- Amanzadeh, M.; Aminossadati, S.M. A New Approach for Drilling Lateral Microchannels in Photonic Crystal Fibres. In Proceedings of the 2016 IEEE Photonics Conference (IPC), Waikoloa, HI, USA, 2–6 October 2016; pp. 779–780. [Google Scholar]

- Novo, C.C.; Choudhury, D.; Siwicki, B.; Thomson, R.R.; Shephard, J.D. Femtosecond Laser Machining of Hollow-Core Negative Curvature Fibres. Opt. Express OE 2020, 28, 25491–25501. [Google Scholar] [CrossRef] [PubMed]

- Belardi, W. Design and Properties of Hollow Antiresonant Fibers for the Visible and Near Infrared Spectral Range. J. Lightwave Technol. 2015, 33, 4497–4503. [Google Scholar] [CrossRef]

- Adamu, A.I.; Wang, Y.; Correa, R.A.; Bang, O.; Bang, O.; Bang, O.; Markos, C.; Markos, C.; Markos, C. Low-Loss Micro-Machining of Anti-Resonant Hollow-Core Fiber with Focused Ion Beam for Optofluidic Application. Opt. Mater. Express OME 2021, 11, 338–344. [Google Scholar] [CrossRef]

- Hao, Y.; Xiao, L.; Benabid, F. Optimized Design of Unsymmetrical Gap Nodeless Hollow Core Fibers for Optofluidic Applications. J. Lightwave Technol. 2018, 36, 3162–3168. [Google Scholar] [CrossRef]

- Yu, F.; Song, P.; Wu, D.; Birks, T.; Bird, D.; Knight, J. Attenuation Limit of Silica-Based Hollow-Core Fiber at Mid-IR Wavelengths. APL Photonics 2019, 4, 080803. [Google Scholar] [CrossRef] [Green Version]

- Litchinitser, N.M.; Abeeluck, A.K.; Headley, C.; Eggleton, B.J. Antiresonant Reflecting Photonic Crystal Optical Waveguides. Opt. Lett. OL 2002, 27, 1592–1594. [Google Scholar] [CrossRef]

- Matsumura, T.; Kazama, A.; Yagi, T. Generation of Debris in the Femtosecond Laser Machining of a Silicon Substrate. Appl. Phys. A 2005, 81, 1393–1398. [Google Scholar] [CrossRef]

- Odachi, G.; Sakamoto, R.; Hara, K.; Yagi, T. Effect of Air on Debris Formation in Femtosecond Laser Ablation of Crystalline Si. Appl. Surf. Sci. 2013, 282, 525–530. [Google Scholar] [CrossRef]

- Bulgakova, N.M.; Zhukov, V.P.; Collins, A.R.; Rostohar, D.; Derrien, T.J.-Y.; Mocek, T. How to Optimize Ultrashort Pulse Laser Interaction with Glass Surfaces in Cutting Regimes? Appl. Surf. Sci. 2015, 336, 364–374. [Google Scholar] [CrossRef]

- Hou, M.; Zhu, F.; Wang, Y.; Wang, Y.; Liao, C.; Liu, S.; Lu, P. Antiresonant Reflecting Guidance Mechanism in Hollow-Core Fiber for Gas Pressure Sensing. Opt. Express 2016, 24, 27890. [Google Scholar] [CrossRef] [Green Version]

- Song, P.; Phoong, K.Y.; Bird, D. Quantitative Analysis of Anti-Resonance in Single-Ring, Hollow-Core Fibres. Opt. Express 2019, 27, 27745. [Google Scholar] [CrossRef]

| Parameter | F-theta Lens | Aspheric Lens |

|---|---|---|

| Wavelength (nm) | 1030 | |

| Pulse duration (fs) | 270 | |

| Spot size (1/e2) (µm) | ~12 | ~2 |

| Pulse Energy (µJ) | 6–14 | 1–6 |

| Repetition ratio (kHz) | 20–1000 | 1–200 |

| Speed (mm/s) | 50–1000 | 0.5–5 |

| Z move step (µm) | 2.5–20 | 0.5–10 |

| Number of cycles N | 1 per step × 10–× 50 | 1 per step |

| - | ||

| Hatching line (µm) | 1–10 | 0.5–2.5 |

| Type of Fiber | Microchannel Type | Loss (Per Single Channel) | Ref. |

|---|---|---|---|

| HC-PBGF | V-shaped microchannel 20 µm diameter (on top cladding) | 1 dB | [29] |

| SC-HF | V-shaped microchannel 20 µm diameter (on top cladding) | 0.5 dB | [16] |

| HC-PBGF | Hole diameter 1.5 µm (on top cladding) | 0.35 dB | [17] |

| HC-NCF | Slot x-axis—150 µm, y-axis across the fiber | 0.45 dB | [20] |

| ARHCF | Microchannel size x-axis—250 µm, y-axis—30 µm | 0.007 dB | [this work] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kozioł, P.; Jaworski, P.; Krzempek, K.; Hoppe, V.; Dudzik, G.; Yu, F.; Wu, D.; Liao, M.; Knight, J.; Abramski, K. Fabrication of Microchannels in a Nodeless Antiresonant Hollow-Core Fiber Using Femtosecond Laser Pulses. Sensors 2021, 21, 7591. https://doi.org/10.3390/s21227591

Kozioł P, Jaworski P, Krzempek K, Hoppe V, Dudzik G, Yu F, Wu D, Liao M, Knight J, Abramski K. Fabrication of Microchannels in a Nodeless Antiresonant Hollow-Core Fiber Using Femtosecond Laser Pulses. Sensors. 2021; 21(22):7591. https://doi.org/10.3390/s21227591

Chicago/Turabian StyleKozioł, Paweł, Piotr Jaworski, Karol Krzempek, Viktoria Hoppe, Grzegorz Dudzik, Fei Yu, Dakun Wu, Meisong Liao, Jonathan Knight, and Krzysztof Abramski. 2021. "Fabrication of Microchannels in a Nodeless Antiresonant Hollow-Core Fiber Using Femtosecond Laser Pulses" Sensors 21, no. 22: 7591. https://doi.org/10.3390/s21227591

APA StyleKozioł, P., Jaworski, P., Krzempek, K., Hoppe, V., Dudzik, G., Yu, F., Wu, D., Liao, M., Knight, J., & Abramski, K. (2021). Fabrication of Microchannels in a Nodeless Antiresonant Hollow-Core Fiber Using Femtosecond Laser Pulses. Sensors, 21(22), 7591. https://doi.org/10.3390/s21227591