Development of an Algorithm for an Automatic Determination of the Soil Field Capacity Using of a Portable Weighing Lysimeter

Abstract

:1. Introduction

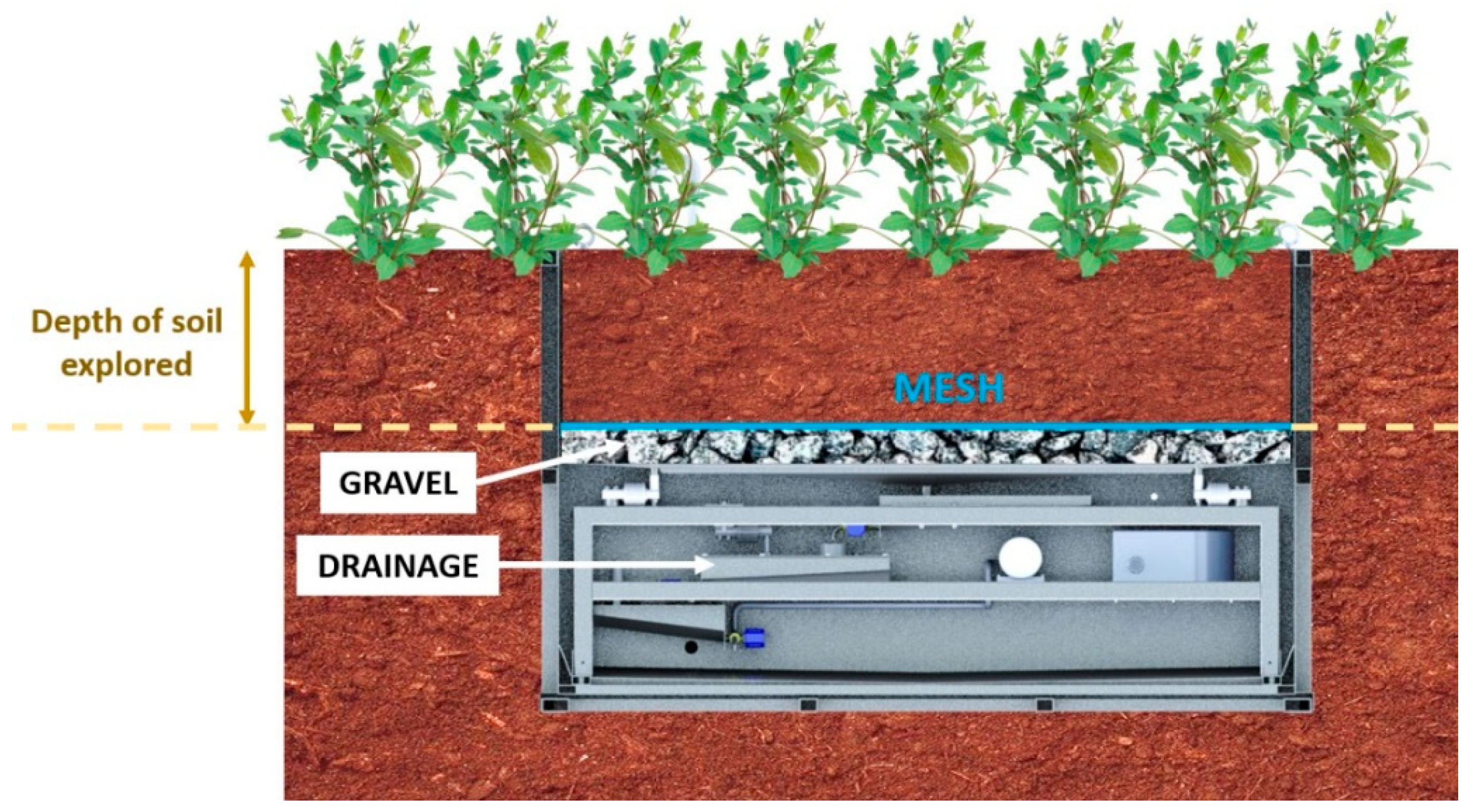

2. Materials and Methods

2.1. Test Preparation

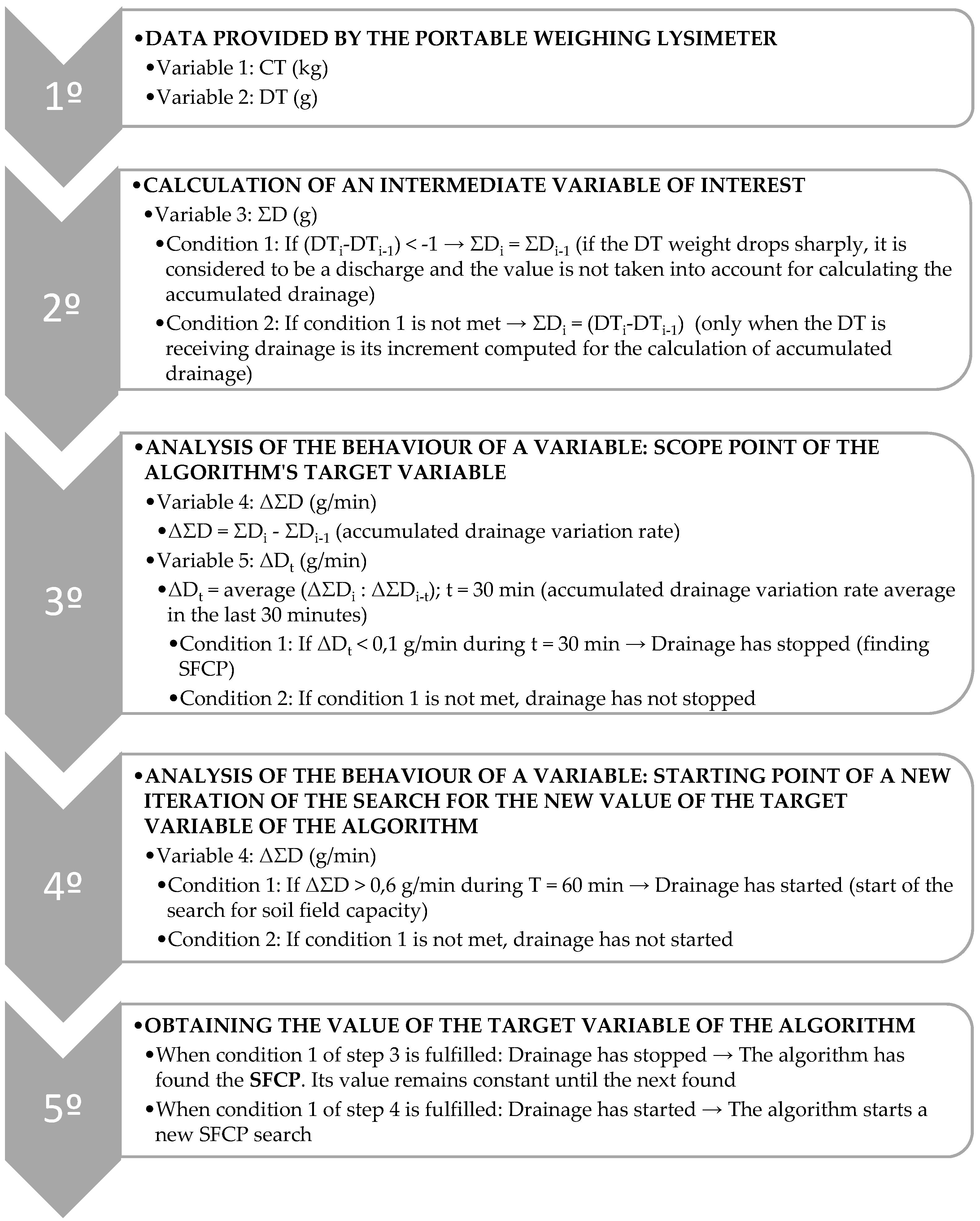

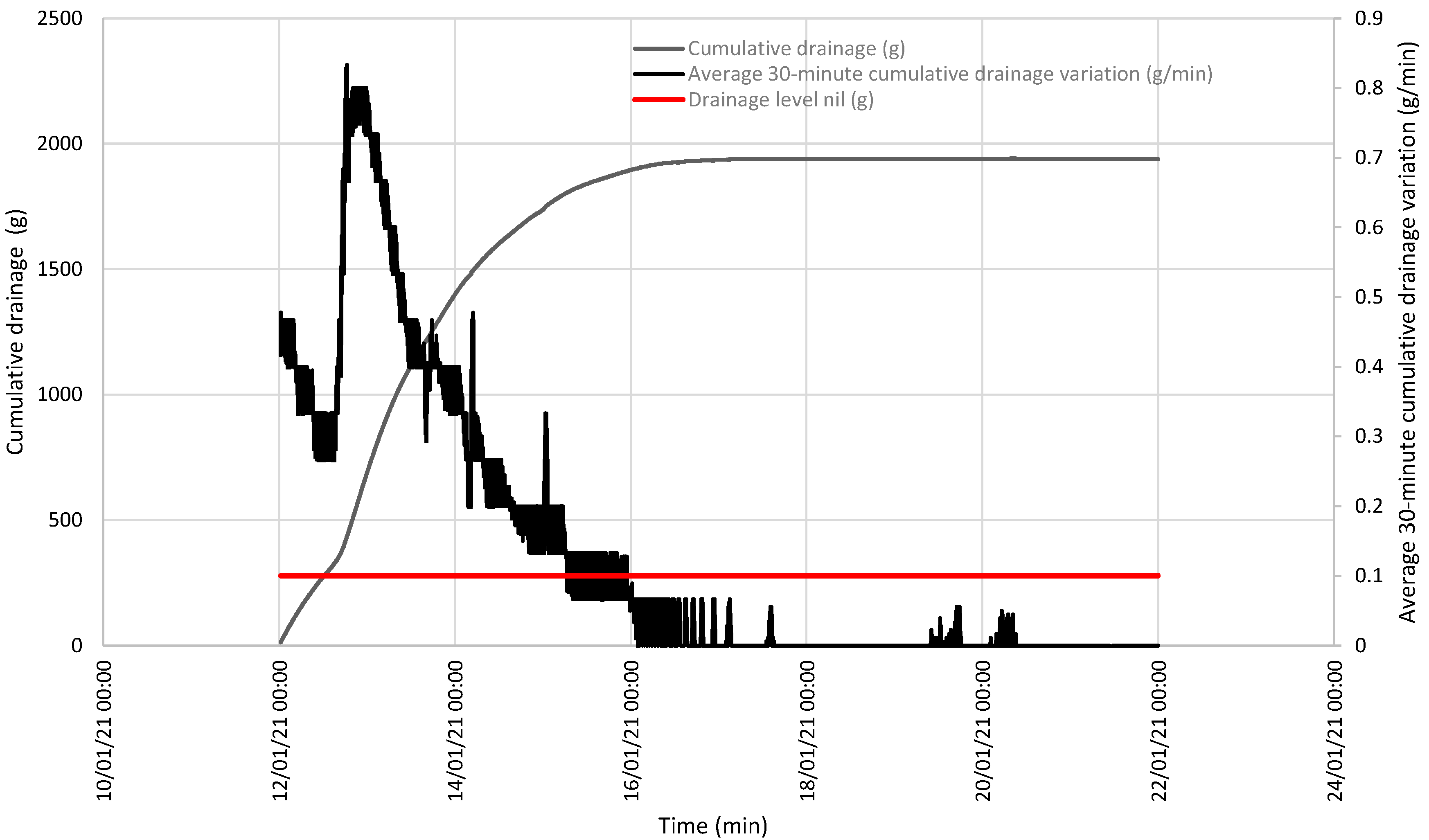

2.2. Establishing an Algorithm to Detect SFCP by Weighing Lysimetry

- Variable 1: the CT weight, expressed as kg and determined by the following sensor structure: four load cells (500 kg) connected in parallel by a junction box linked with a six-thread cable, plus a mesh, to a 24-bit weight indicator. This indicator records the obtained data in real time with filters configured for signal peaks that do not correspond to correct readings. By means of an RS485A serial connection and the MODBUS RTU protocol, every 3 s a CAMPBELL CR300® datalogger reads the record obtained by the weight indicator for the connected junction box and offers a table with the minute average of the obtained readings.

- Variable 2: the DT weight, expressed as g and determined by the following sensor structure: one load cell (15 kg) connected with a six-thread cable, plus a mesh, to a 24-bit weight indicator. This indicator records the obtained data in real time with filters configured for signal peaks that do not correspond to correct readings. By means of an RS485 serial connection and the MODBUS RTU protocol, every 3 s a CAMPBELL CR300® datalogger reads the record obtained by the weight indicator for the connected load cell and offers a table with the minute average of the obtained readings.

- Variable 3: accumulated drainage (ΣD), expressed as g, determined by the equation below:

If not, then ΣDi = (DTi−DTi−1) + ΣDi−1

- Variable 4: variation in accumulated drainage (ΔΣD), expressed as g/min, determined by the algorithm below:

- ○

- Constant 1: minimum time to obtain a variation in drainage below the threshold limit (t), expressed as minutes, to set a time range to check that the variation in the DT does not exceed the set value and to consider the DT weight to be constant.

- ○

- Constant 2: threshold limit of variation in weight over a given time period t (d), expressed as g, by establishing a maximum value for variation in the DT within a time interval t below which drainage is taken to be null and DT = ct and, therefore, SFCP has been found. This value is established to be equal to the DT’s balance resolution.

- Variable 5: accumulated drainage variation average within time interval t (ΔDt), expressed as g/min, calculated with the following equation:

- ○

- Constant 3: condition for setting the SFCP (Cd), expressed as grams per minute, determined by the following equation:

- ○

- Constant 4: time during which an increase in weight in the DT (T), expressed in minutes, must be detected, which will allow to detect that a drainage event has occurred in the soil contained in the CT:

- ○

- Constant 5: start condition for the iteration of new SFCP calculations as:

- Variable 6: soil field capacity point (SFCP), expressed as kg, which shall be a fixed quantity at the moment when the above conditions are met. Its value shall be the weight of the TC at that instant; thereafter it shall remain constant until a new SFCP is obtained again.

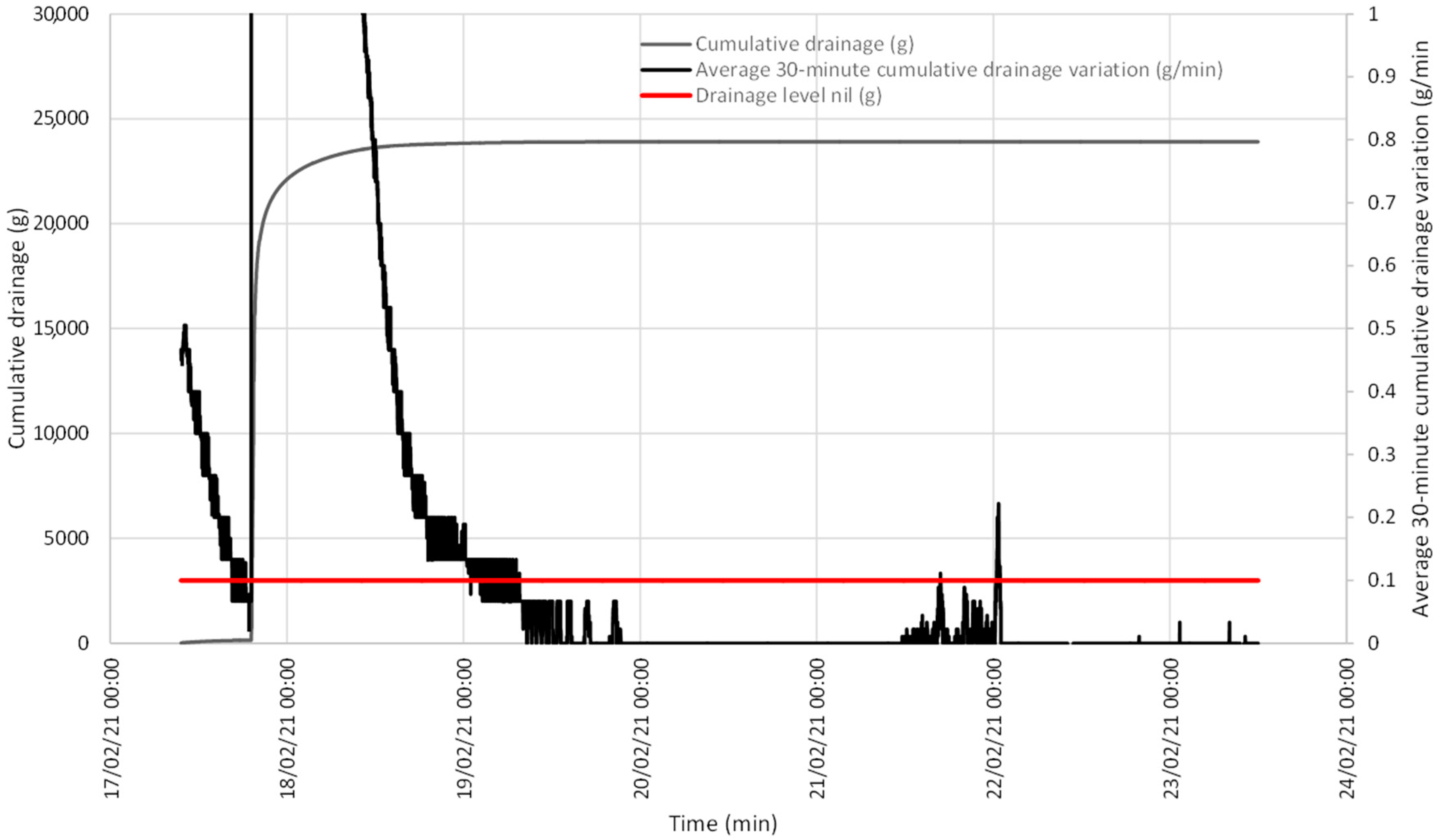

If (ΣDi – ΣDi−T) > 0.6 × T, or, in other words,

If (ΣDi – ΣDi-60) > 0.6 × 60 = 36 g

Then, the iteration of the drain stop search is started.

If ΔDi < Cd ≥ ΔDi < 0.1 g/min during t = 30 min, this is

If ΣΔDi (1 a t) < 0.1 × t, or, in other words,

If ΣΔDi (1 a t) < 0.1 × 30 = 3 g

Then, CCi = RCi

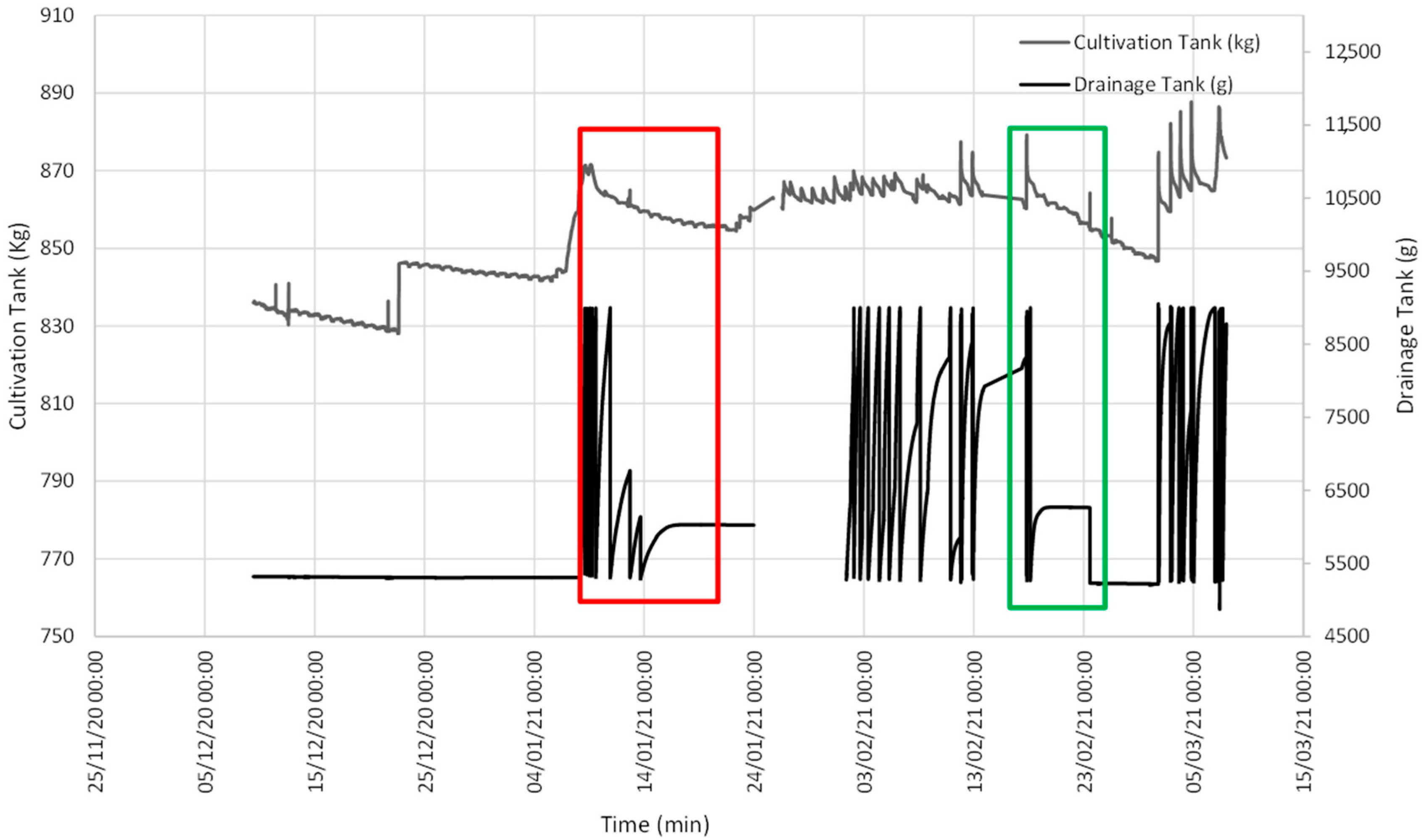

2.3. Validating Excess Irrigation Events, Drying and Soil Moisture Normalization

- (a)

- Excess irrigation periods:

- a

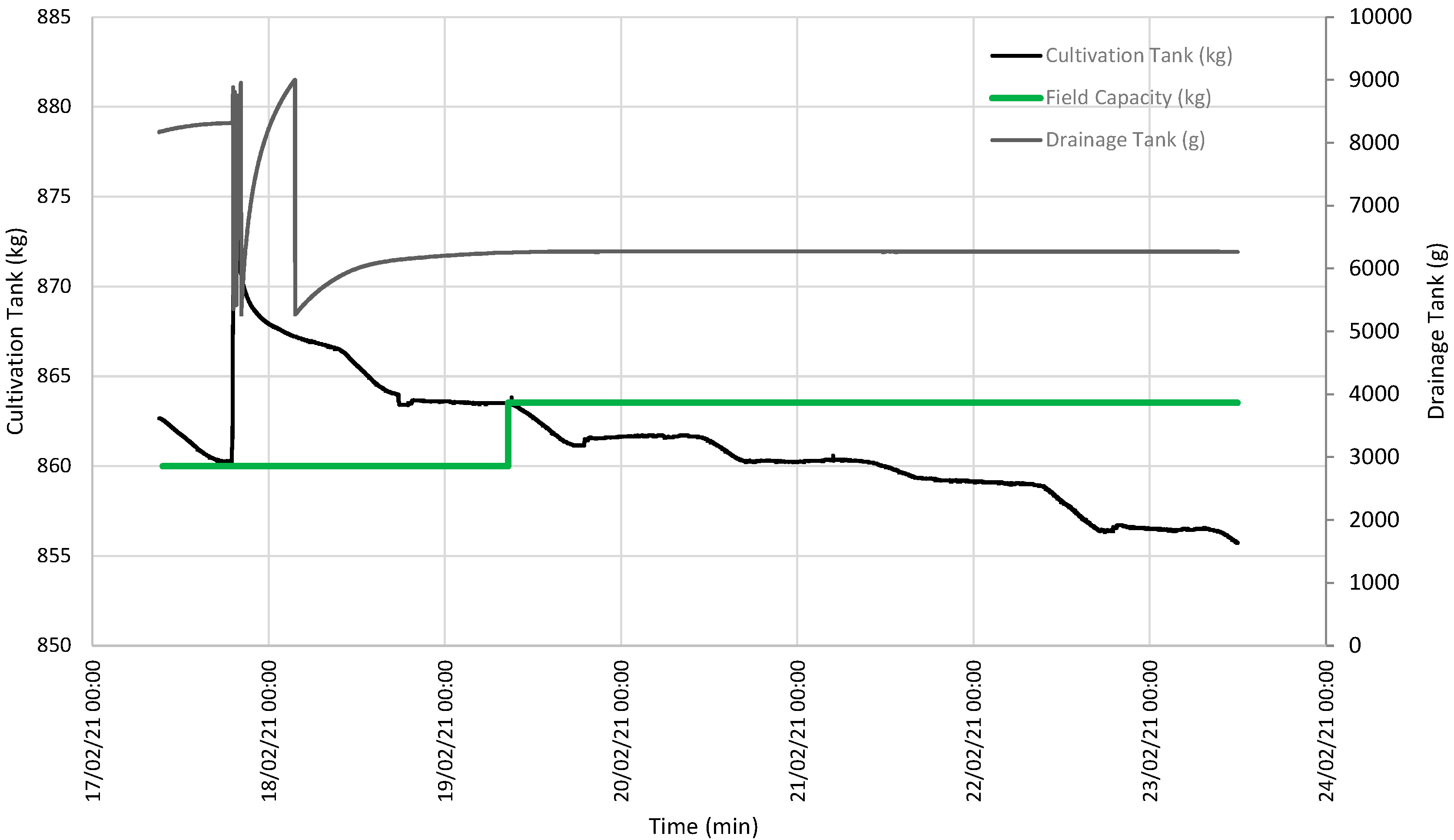

- Variable 1: the CT weight must be maintained at high levels, and shows not only incremented points that correspond to irrigation events, but also lowering points corresponding to loss of drainage water that occurs after an irrigation event until immediately before the next irrigation event starts.

- b

- Variable 2: the DT weight must continue to increase its maximum capacity. Then it is immediately emptied until it reaches the weight value that it has when it is empty, and the cycle starts again.

- (b)

- Drying periods:

- a

- Variable 1: the CT weight must display a lowering tendency, and this variable is in accordance with: (i) If drainage still continues, it will lower more quickly than if drainage stops; (ii) If it occurs in the daytime or nighttime as it lowers more quickly in the daytime due to evapotranspiration demand.

- b

- Variable 2: the DT weight continues to increase, but less intensely so, and releases occur increasingly less with time until they become constant.

2.4. Validating Irrigation Events in the Lysimeter by Comparing Irrigation Counter Data

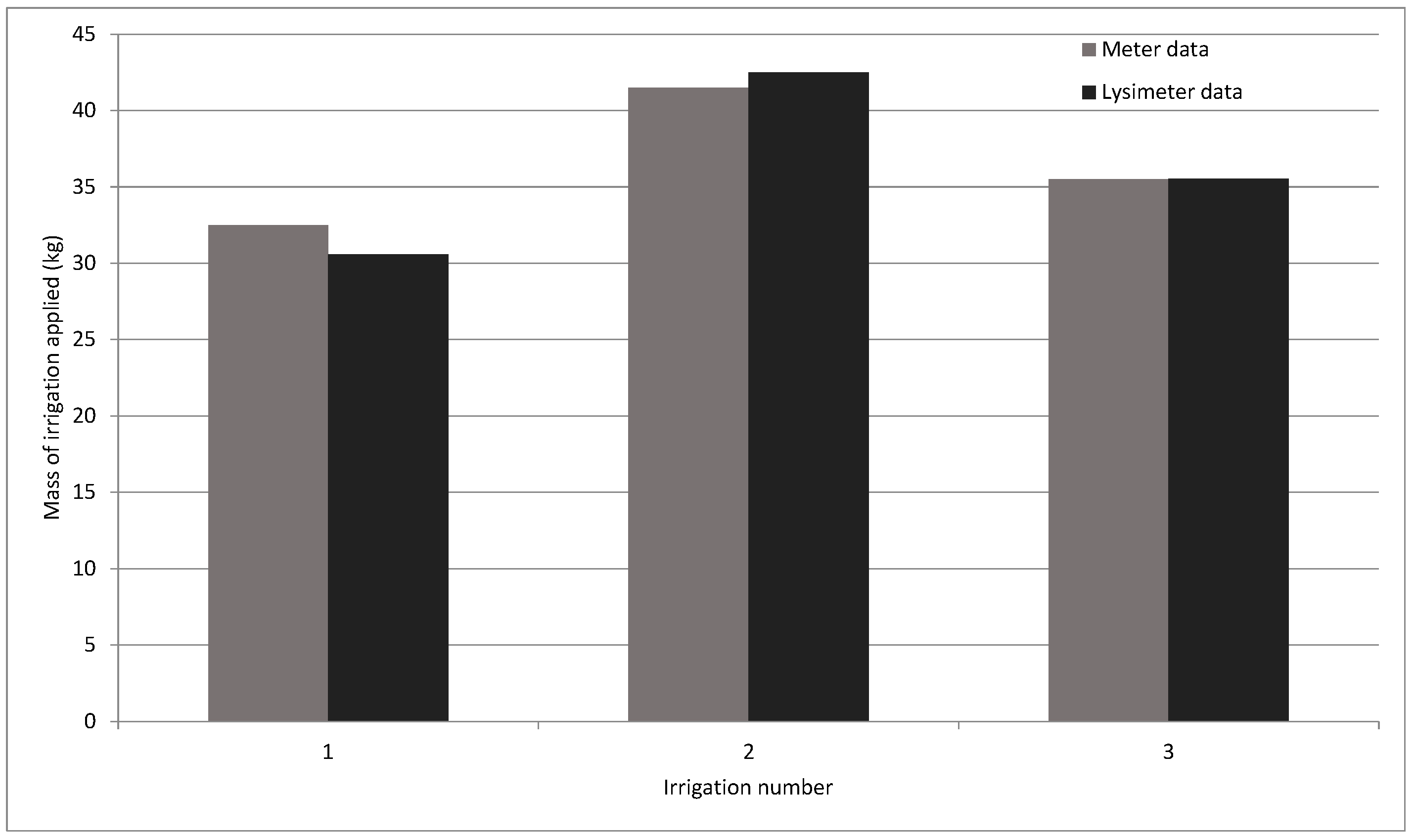

- Variable 7: irrigation volume at initial meter (Vi), expressed as liters, obtained from the data provided by the data acquisition equipment used.

- Variable 8: irrigation volume at final meter (Vf), expressed as liters, obtained from the data provided by the data acquisition equipment used.

- Variable 9: irrigation volume emitted to the portable weighing lysimeter in an irrigation event (Vlis), expressed as liters, obtained by the following equation:

- Variable 10: mass of irrigation emitted in an irrigation event to the portable weighing lysimeter (Ric), expressed as kilograms, obtained by the multiplication of the irrigation volume of variable 9 per the density of water (δ), taken as 1 kg·L−1.

- Variable 11: mass of irrigation emitted in an irrigation event to the portable weighing lysimeter (Rilis), expressed as kilograms, obtained by the difference between the mass at the end of irrigation (RCfRi) and the mass at the start of irrigation (RCiRi) in the CT, plus the difference between the accumulated drainage at the end of irrigation (ΣDfRi) and the accumulated drainage at the start of irrigation (ΣDiRi) in the DT, both quantities expressed as kilograms, calculated by the following equation:

2.5. Validating the Algorithm with Data from Other Experiments

3. Results

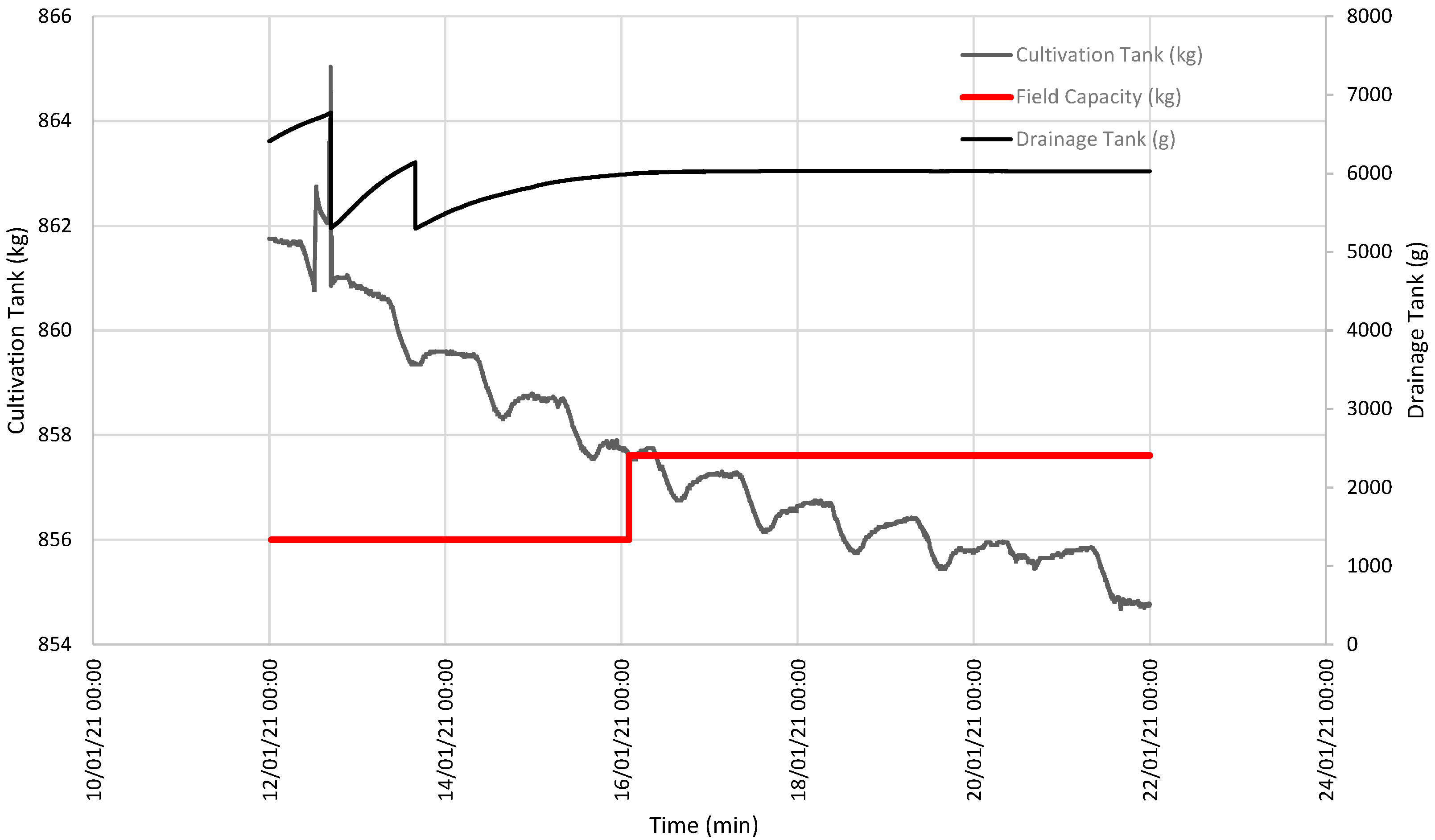

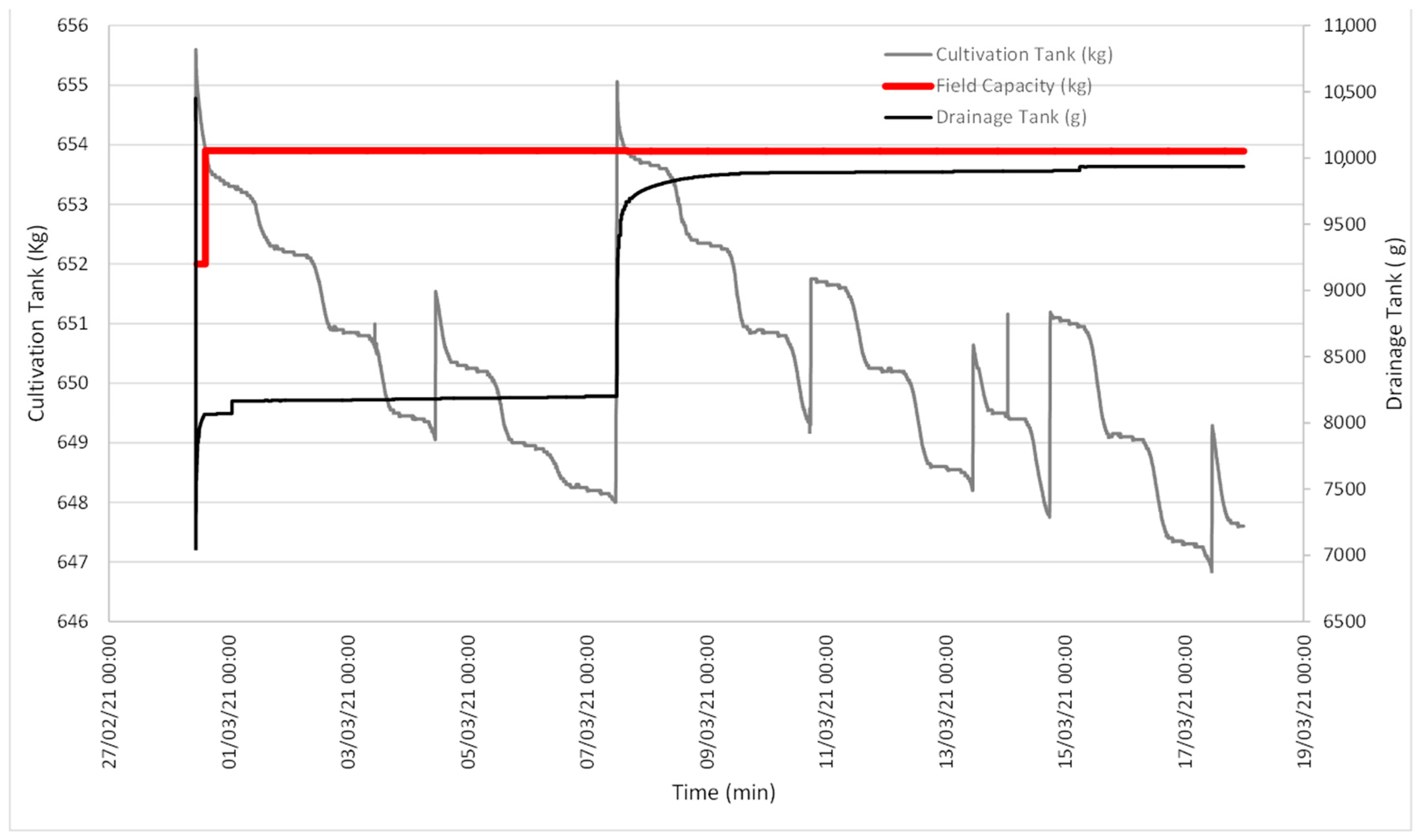

3.1. Results of the Initially Developed Algorithm to Detect SFCP with a Weighing Lysimeter

3.2. Data about Excessive Irrigation Events, Drying and Soil Moisture Normalization

3.3. Results of Recording Irrigation Events in the Lysimeter by Comparing Irrigation Counters Data

3.4. Results of Applying the Algorithm Using Data from Other Experiments

4. Discussion

- The DT management algorithm suitably works;

- When soil reaches SFCP, draining stops and, thus, the DT weight becomes constant.

- -

- How frequently must evapo-transpired water be reported? This depends on many factors like: water and/or energy availability; quantity, quality, and cost; crop management strategies; irrigation system characteristics, etc.

- -

- What amount of draining should be sought? It is necessary to bear in mind irrigation water quality, supplied nutrients, absorbed nutrients, quality of the obtained drainage water, etc., to know the best wash fraction that balances crop yield loss due to environmental pollution.

- Knowing the TC weight at a given moment (which will depend on the combination of parameterized dose and frequency), and knowing what the TC weight is when it is considered to be SFCP, the amount of irrigation to be applied at that moment is determined.

- The drainage percentage that will increase the irrigation contribution will be considered.

- From the rainfall of the irrigation system, it can be related to the amount of irrigation indicated by the portable weighing lysimeter, and the duration of irrigation to be applied is calculated.

- The irrigation controller can be commanded to execute this instruction.

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Juan, J.A.d.; Tarjuelo, J.M.; Valiente, M.; García, P. Model for optimal cropping patterns within the farm based on crop water production functions and irrigation uniformity I: Development of a decision model. Agric. Water Manag. 1996, 31, 115–143. [Google Scholar] [CrossRef]

- Merino Labrador, F.A. Un recurso finito. Forum Calid. 2018, 296, 54–57. [Google Scholar]

- Zinkernagel, J.; Maestre-Valero, J.F.; Seresti, S.Y.; Intrigliolo, D.S. New technologies and practical approaches to improve irrigation management of open field vegetable crops. Agric. Water Manag. 2020, 242, 106404. [Google Scholar] [CrossRef]

- Soler-Méndez, M.; Parras-Burgos, D.; Mas-Espinosa, E.; Ruíz-Canales, A.; Intrigliolo, D.S.; Molina-Martínez, J.M. Standardization of the Dimensions of a Portable Weighing Lysimeter Designed to Be Applied to Vegetable Crops in Mediterranean Climates. Sustainability 2021, 13, 2210. [Google Scholar] [CrossRef]

- Vázquez, N.; Pardo, A.; Suso, M.L.; Quemada, M. Drainage and nitrate leaching under processing tomato growth with drip irrigation and plastic mulching. Agric. Ecosyst. Environ. 2006, 112, 313–323. [Google Scholar] [CrossRef]

- Visconti, F.; Salvador, A.; Navarro, P.; de Paz, J.M. Effects of three irrigation systems on ‘Piel de sapo’ melon yield and quality under salinity conditions. Agric. Water Manag. 2019, 226, 105829. [Google Scholar] [CrossRef]

- Vera-Repullo, J.; Ruiz-Peñalver, L.; Jiménez-Buendía, M.; Rosillo, J.; Molina-Martínez, J. Software for the automatic control of irrigation using weighing-drainage lysimeters. Agric. Water Manag. 2015, 151, 4–12. [Google Scholar] [CrossRef]

- Placidi, P.; Morbidelli, R.; Fortunati, D.; Papini, N.; Gobbi, F.; Scorzoni, A. Monitoring Soil and Ambient Parameters in the IoT Precision Agriculture Scenario: An Original Modeling Approach Dedicated to Low-Cost Soil Water Content Sensors. Sensors 2021, 21, 5110. [Google Scholar] [CrossRef] [PubMed]

- Ferrández-Villena, M.; Ruiz-Canales, A. Advances on ICTs for water management in agriculture. Agric. Water Manag. 2017, 100, 1–3. [Google Scholar] [CrossRef]

- Mohammed, M.; Riad, K.; Alqahtani, N. Efficient IoT-Based Control for a Smart Subsurface Irrigation System to Enhance Irrigation Management of Date Palm. Sensors 2021, 21, 3942. [Google Scholar] [CrossRef] [PubMed]

- Sahu, B.; Chatterjee, S.; Mukherjee, S.; Sharma, C. Tools of precision agriculture: A review. Int. J. Chem. Stud. 2019, 7, 2692–2696. [Google Scholar]

- Soler-Méndez, M.; Molina-Martínez, J.M.; Ávila Dávila, L.; Ruíz-Peñalver, L. Sistema de inteligencia artificial para la gestión de la fertirrigación mediante redes de lisimetría de pesada y sensores agronómicos. In Proceedings of the II Congreso de Jóvenes investigadores en Ciencias Agroalimentarias, Almería, Spain, 17 October 2019. [Google Scholar]

- Nicolás-Cuevas, J.A.; Parras-Burgos, D.; Soler-Méndez, M.; Ruiz-Canales, A.; Molina-Martínez, J.M. Removable Weighing Lysimeter for Use in Horticultural Crops. Appl. Sci. 2020, 10, 4865. [Google Scholar] [CrossRef]

- Ruiz-Peñalver, L.; Vera-Repullo, J.; Jiménez-Buendía, M.; Guzmán, I.; Molina-Martínez, J. Development of an innovative low cost weighing lysimeter for potted plants: Application in lysimetric stations. Agric. Water Manag. 2015, 151, 103–113. [Google Scholar] [CrossRef]

- FAO. Definición Capacidad de Campo. Available online: http://www.fao.org/3/y4690s/y4690s02.htm#:~:text=Capacidad%20de%20campo%20%2D%20se%20refiere,de%2048%20horas%20de%20drenaje.&text=La%20Capacidad%20de%20Campo%20se,de%2048%20horas%20de%20drenaje (accessed on 7 October 2021).

- Pachés Giner, M.A. El Agua en el Suelo. Fuerzas de Retención. Available online: https://riunet.upv.es/bitstream/handle/10251/121154/Pach%c3%a9s%20-%20El%20agua%20en%20el%20suelo.%20Fuerzas%20de%20retenci%c3%b3n.pdf?sequence=1&isAllowed=y (accessed on 7 December 2020).

- Cong, Z.-T.; Lü, H.-F.; Ni, G.-H. A simplified dynamic method for field capacity estimation and its parameter analysis. Water Sci. Eng. 2014, 7, 351–362. [Google Scholar]

- Zotarelli, L.; Dukes, M.D.; Morgan, K.T. Interpretación del Contenido de la Humedad del Suelo Para Determinar Capacidad de Campo y Evitar Riego Excesivo en Suelos Arenosos Utilizando Sensores de Humedad; IFAS Extension. University of Florida: Gainesville, FL, USA, 2013; Volume 2013. [Google Scholar]

- Ahuja, L.R.; Nielsen, D.R. Field Soil-Water Relations. Irrigation of Agricultural Crops; ASA-CSSA-SSSA: Madison, WI, USA, 1990. [Google Scholar]

| Description | Value | Unit |

|---|---|---|

| ANALYSIS OF DATA PROVIDED BY METERS | ||

| Initial meter reading at start of irrigation | 9962 | m3 |

| Initial meter reading at the end of irrigation | 10.007 | m3 |

| Volume detected by the initial counter (Vi) | 0.046 | m3 |

| Volume detected by the initial counter (Vi) | 46 | L |

| Final meter reading at start of irrigation | 8911 | m3 |

| Final meter reading at the end of irrigation | 8924 | m3 |

| Volume detected by the final counter (Vf) | 0.013 | m3 |

| Volume detected by the final counter (Vf) | 13 | L |

| Irrigation volume emitted to the lysimeter (meter) (Vlis) | 33 | L |

| Mass of irrigation emitted to the lysimeter (meter) (Ric) | 33 | kg |

| ANALYSIS OF LYSIMETER DATA | ||

| Mass of the CT at the start of irrigation (RCiRi) | 860.775 | kg |

| Mass of the CT at the end of irrigation (RCfRi) | 879.017 | kg |

| Mass increase in the CT during irrigation (RCfRi − RCiRi) | 18.242 | kg |

| Increase of accumulated drainage in the DT (ΣDfRi − ΣDiRi) | 12.346 | kg |

| Irrigation mass quantified by the lysimeter (Rilis) | 30.588 | kg |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Soler-Méndez, M.; Parras-Burgos, D.; Cisterne-López, A.; Mas-Espinosa, E.; Intrigliolo, D.S.; Molina-Martínez, J.M. Development of an Algorithm for an Automatic Determination of the Soil Field Capacity Using of a Portable Weighing Lysimeter. Sensors 2021, 21, 7203. https://doi.org/10.3390/s21217203

Soler-Méndez M, Parras-Burgos D, Cisterne-López A, Mas-Espinosa E, Intrigliolo DS, Molina-Martínez JM. Development of an Algorithm for an Automatic Determination of the Soil Field Capacity Using of a Portable Weighing Lysimeter. Sensors. 2021; 21(21):7203. https://doi.org/10.3390/s21217203

Chicago/Turabian StyleSoler-Méndez, Manuel, Dolores Parras-Burgos, Adrián Cisterne-López, Estefanía Mas-Espinosa, Diego S. Intrigliolo, and José Miguel Molina-Martínez. 2021. "Development of an Algorithm for an Automatic Determination of the Soil Field Capacity Using of a Portable Weighing Lysimeter" Sensors 21, no. 21: 7203. https://doi.org/10.3390/s21217203

APA StyleSoler-Méndez, M., Parras-Burgos, D., Cisterne-López, A., Mas-Espinosa, E., Intrigliolo, D. S., & Molina-Martínez, J. M. (2021). Development of an Algorithm for an Automatic Determination of the Soil Field Capacity Using of a Portable Weighing Lysimeter. Sensors, 21(21), 7203. https://doi.org/10.3390/s21217203