Deep Learning Based Monitoring of Spatter Behavior by the Acoustic Signal in Selective Laser Melting

Abstract

:1. Introduction

2. Experimental Setup and Datasets

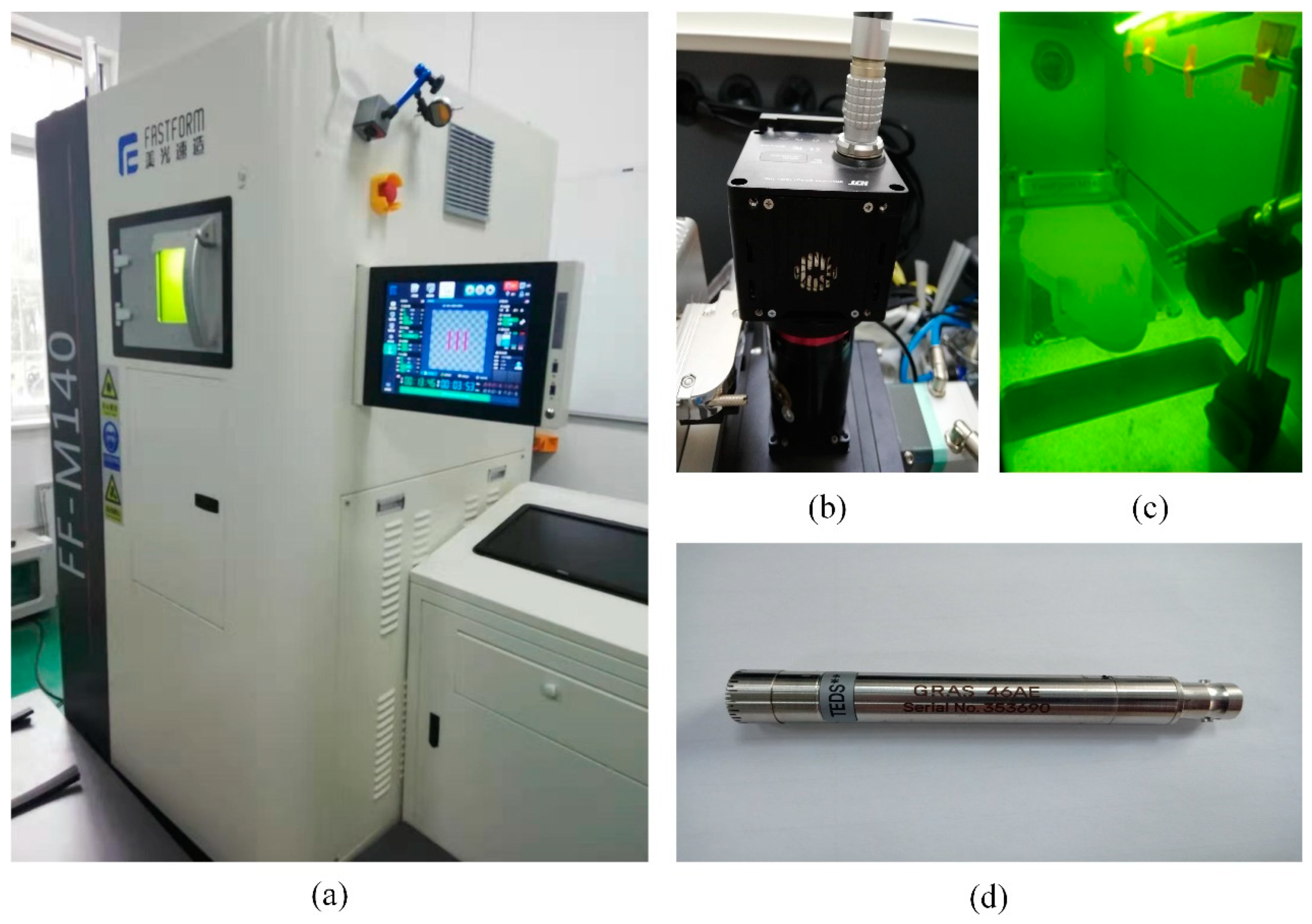

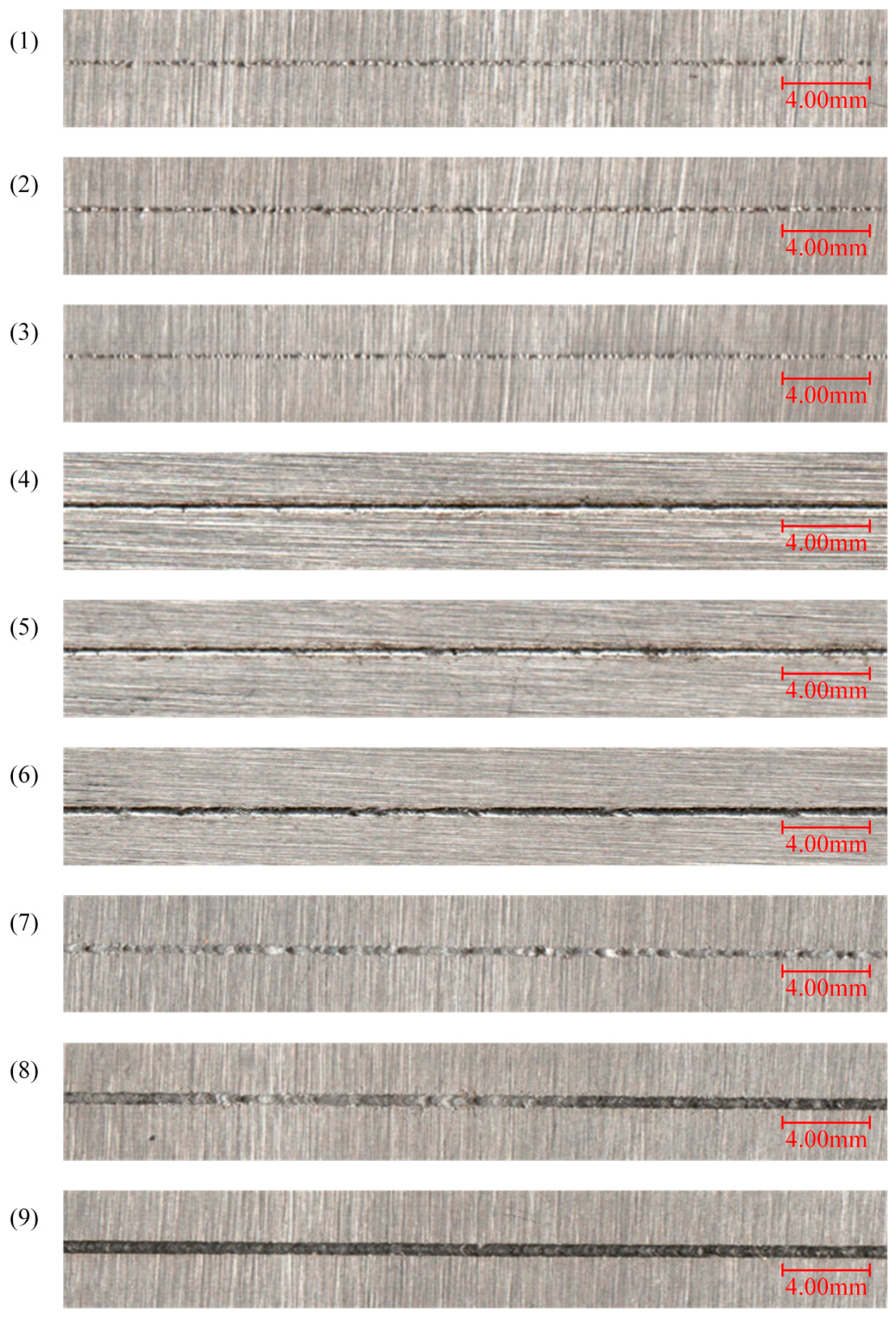

2.1. Experimental Setup and Material

2.2. Data Acquisition

3. Methodology

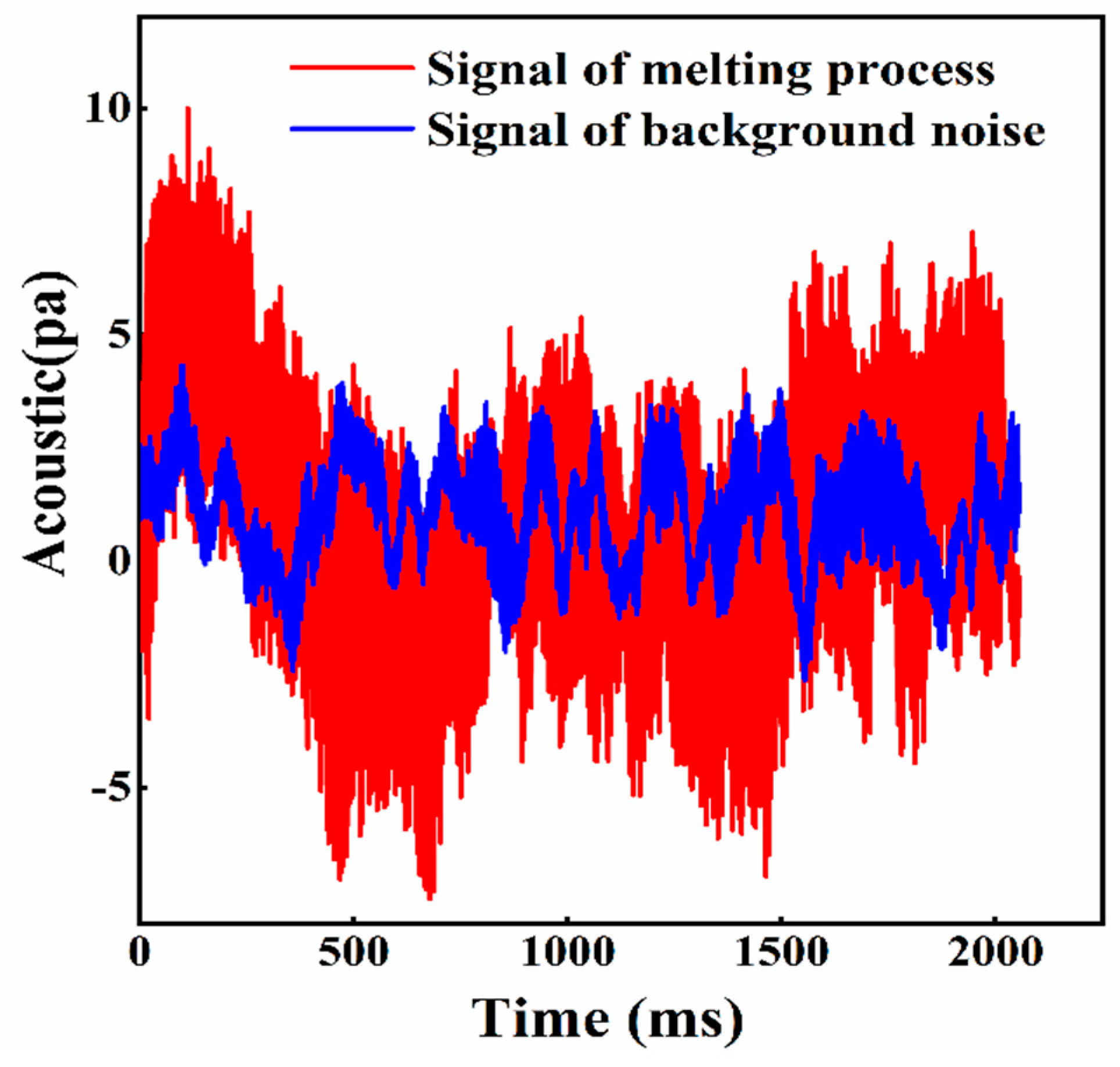

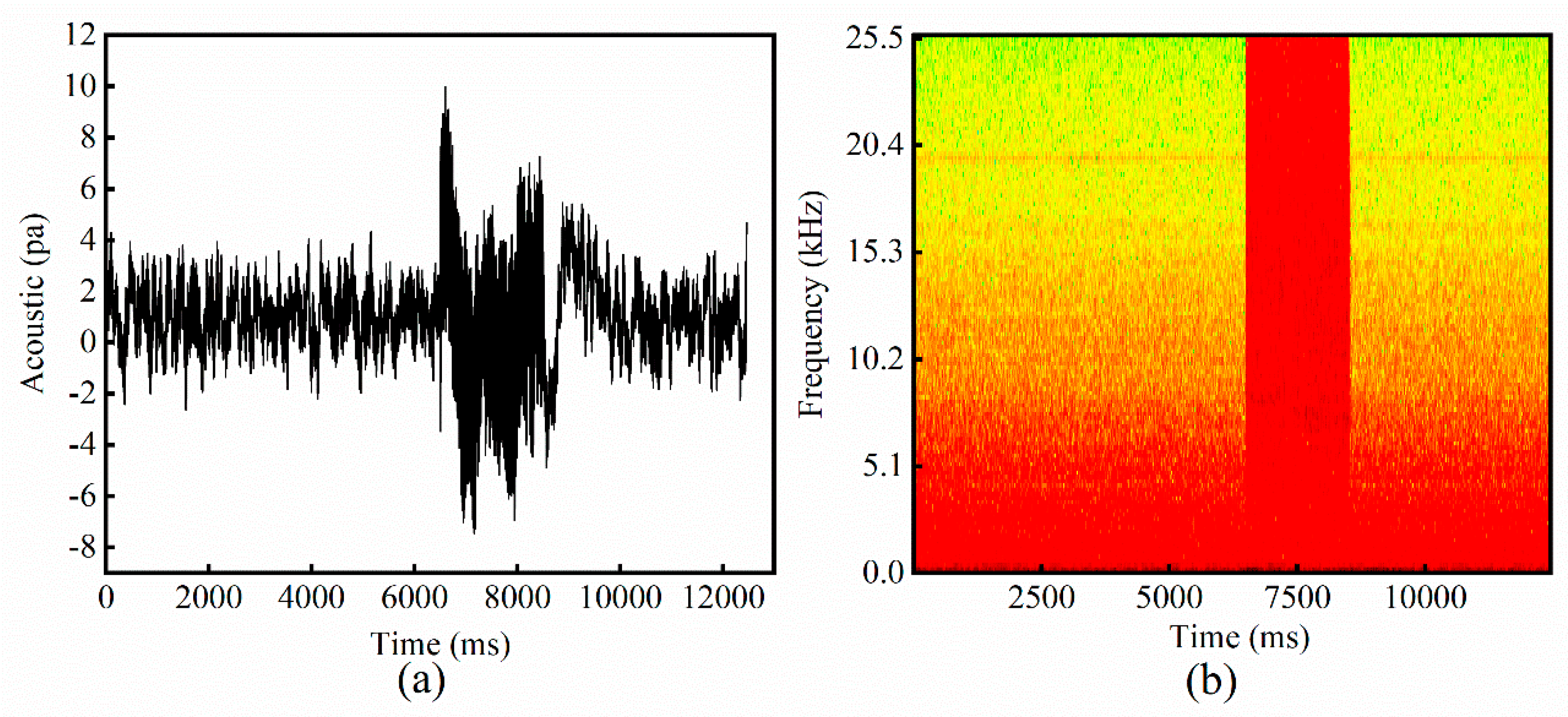

3.1. The Acoustic Signals during SLM Process

3.2. In-Situ Data Processing

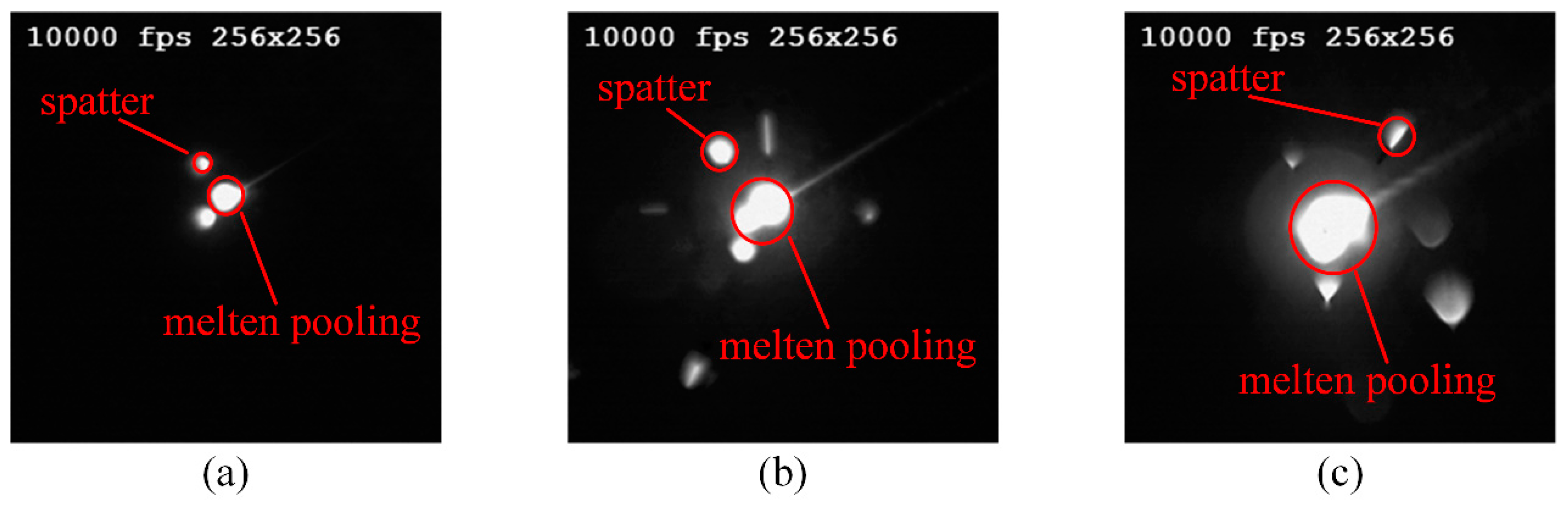

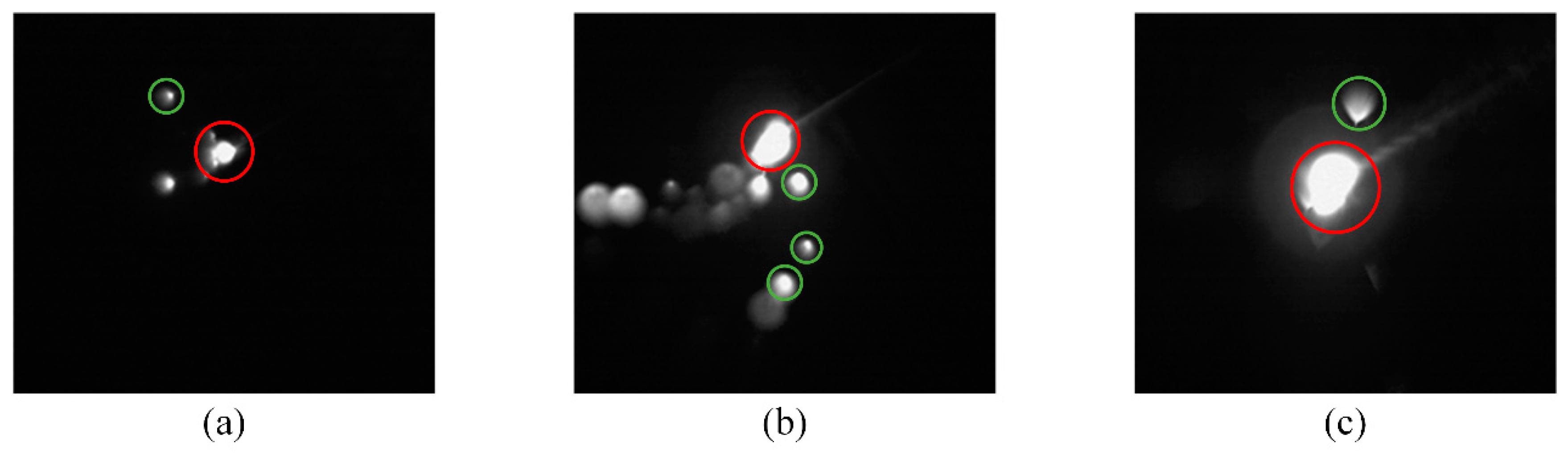

3.2.1. Preprocessing of Spatter Image

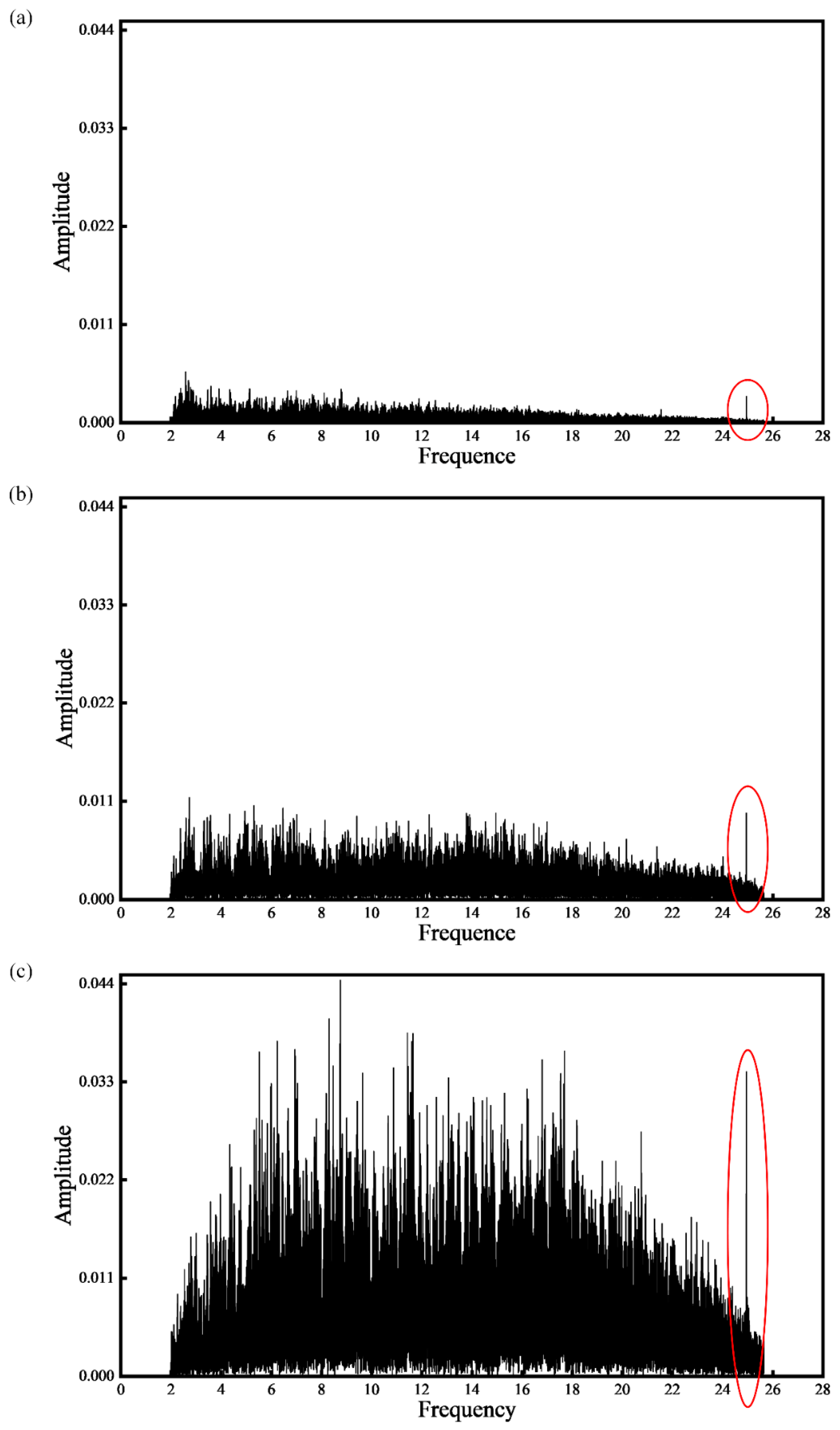

3.2.2. Preprocessing of Acoustic Signals

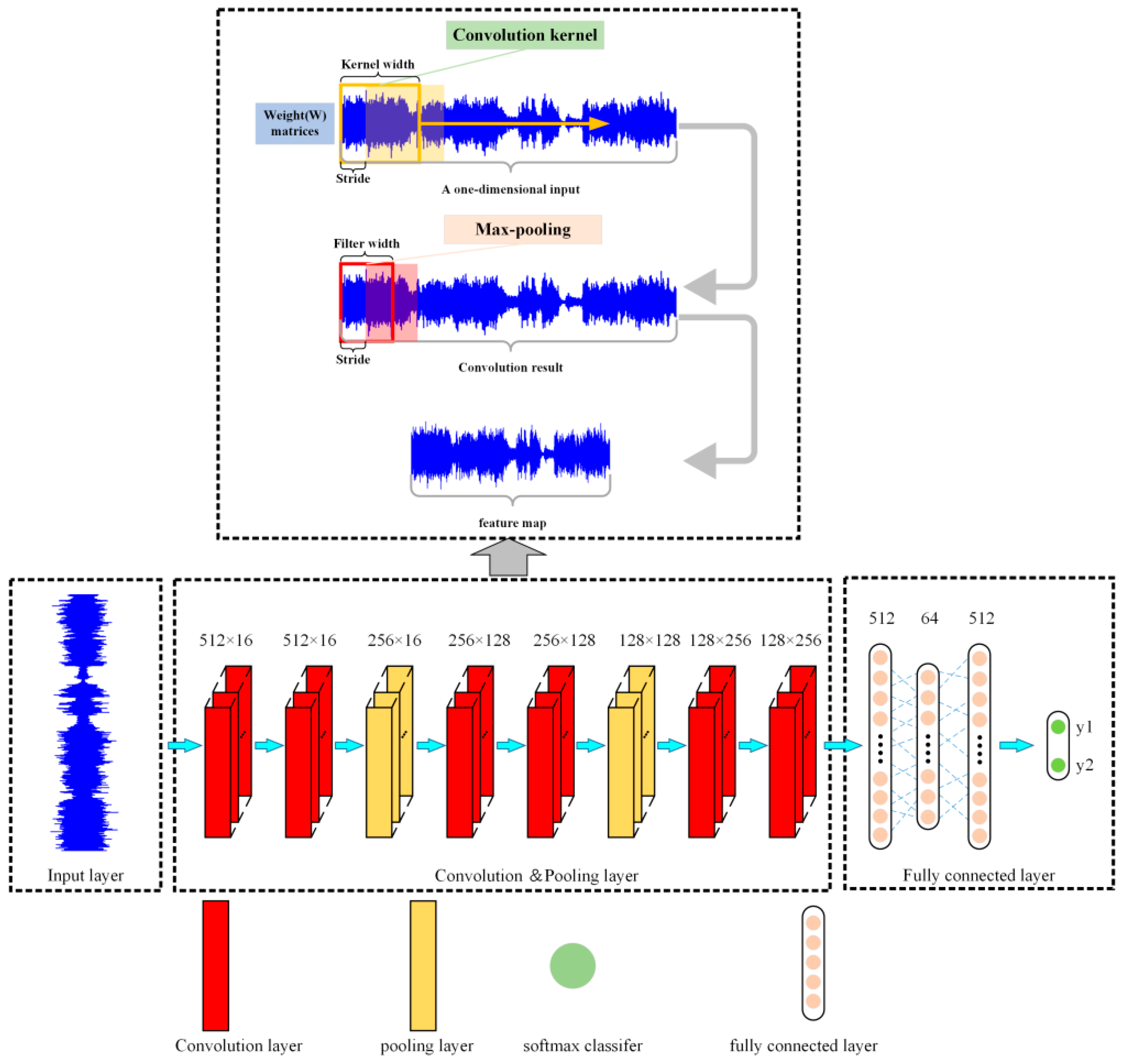

3.2.3. Convolutional Neural Network

4. Results and Discussion

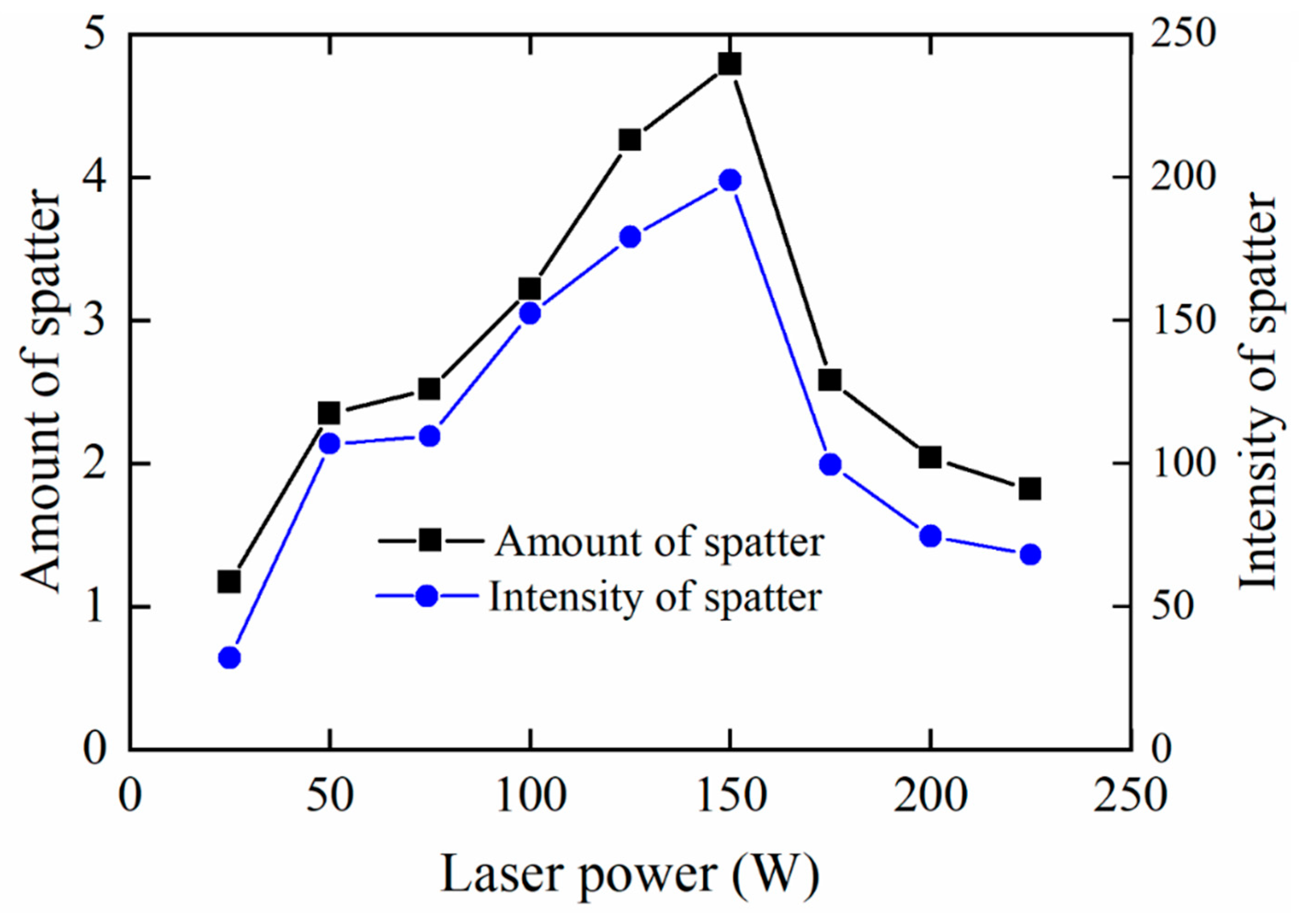

4.1. Analysis of Spatter Image

4.2. Analysis of Acoustic Signal

4.3. Classification of the Spatters

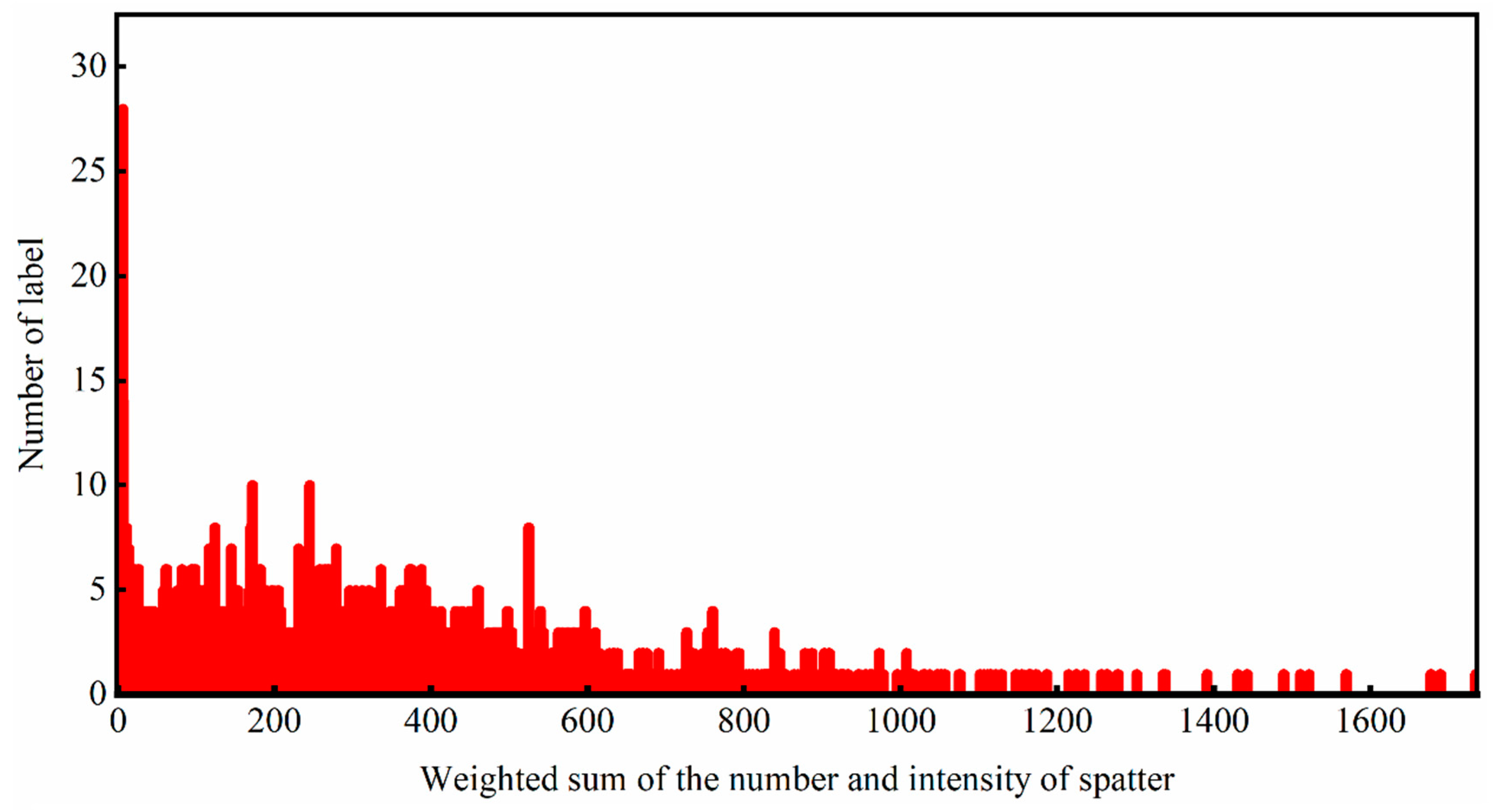

4.3.1. Data Partitioning

4.3.2. Construction of the Proposed CNN

4.3.3. Results of Classification

5. Conclusions and Future Work

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| SLM | Selective Laser Melting |

| AM | Additive manufacturing |

| CNN | Convolutional Neural Network |

| RNN | Recurrent Neural Network |

| LSTM | Long Short Term Memory |

| GRU | Gated Recurrent Unit |

| SVM | Support Vector Machine |

| DBN | Deep Belief Network |

| STFT | Short-Time Fourier Transform |

| FFT | Fast Fourier Transform |

| ROI | Region of Interest |

| 1D CNN | One-dimensional Convolutional Neural Network |

| 2D CNN | Two-dimensional Convolutional Neural Network |

| TSNE | T-Distributed Stochastic Neighbor Embedding |

References

- Attar, H.; Calin, M.; Zhang, L.C.; Scudino, C.; Eckert, J. Manufacture by selective laser melting and mechanical behavior of commercially pure titanium. Mater. Sci. Eng. 2014, 593, 170–177. [Google Scholar] [CrossRef]

- Everton, S.K.; Hirsch, M.; Stravroulakis, P.; Leach, R.K.; Clare, A.T. Review of in-situ process monitoring and in-situ metrology for metal additive manufacturing. Mater. Des. 2016, 95, 431–445. [Google Scholar] [CrossRef]

- Hu, Z.H.; Zhu, H.H.; Zhang, H.; Zeng, X.Y. Experimental investigation on selective laser melting of 17-4PH stainless steel. Opt. Laser Technol. 2017, 87, 17–25. [Google Scholar] [CrossRef]

- Wang, D.; Wu, S.B.; Fu, F.; Mai, S.Z.; Yang, Y.Q.; Liu, Y.; Song, C.H. Mechanisms and characteristics of spatter generation in SLM processing and its effect on the properties. Mater. Des. 2017, 117, 121–130. [Google Scholar] [CrossRef]

- Ye, D.; Hong, G.S.; Zhang, Y.J.; Zhu, K.P.; Fuh, J.Y.H. Defect detection in selective laser melting technology by acoustic signals with deep belief networks. Int. J. Adv. Manuf. Technol. 2018, 96, 2791–2801. [Google Scholar] [CrossRef]

- Gunenthiram, V.; Peyre, P.; Schneider, M.; Dal, M.; Coste, F.; Koutiri, I.; Fabbro, R. Experimental analysis of spatter generation and melt-pool behavior during the powder bed laser beam melting process. J. Mater. Process. Technol. 2018, 251, 376–386. [Google Scholar] [CrossRef]

- Khairallah, S.A.; Martin, A.A.; Lee, J.R.I.; Guss, G.; Calta, N.P.; Hammons, J.A.; Nielsen, M.H.; Chaput, K.; Schwalbach, E.; Shah, M.N.; et al. Controlling interdependent meso-nanosecond dynamics and defect generation in metal 3D printing. Science 2020, 368, 660–665. [Google Scholar] [CrossRef]

- Tan, Z.B.; Fang, Q.H.; Li, H.; Liu, S.; Zhu, W.K.; Yang, D.K. Neural network based image segmentation for spatter extraction during laser-based powder bed fusion processing. Opt. Laser Technol. 2020, 130, 106347. [Google Scholar] [CrossRef]

- Zhang, Y.; Fuh, J.Y.H.; Ye, D.S.; Hong, G.S. In-situ monitoring of laser-based PBF via off-axis vision and image processing approaches. Addit. Manuf. 2019, 25, 263–274. [Google Scholar] [CrossRef]

- Zhang, B.; Zoegert, J.; Farahi, F.; Davies, A. In situ surface topography of laser powder bed fusion using fringe projection. Addit. Manuf. 2016, 12, 100–107. [Google Scholar] [CrossRef] [Green Version]

- Saad, E.; Wang, H.J.; Kovacevic, R. Classification of molten pool modes in variable polarity plasma arc welding based on acoustic signature. J. Mater. Process. Technol. 2006, 174, 127–136. [Google Scholar] [CrossRef]

- Yang, Z.; Jin, L.; Yan, Y.; Mei, Y. Filament breakage monitoring in fused deposition modeling using acoustic emission technique. Sensors 2018, 18, 749. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Stanger, L.; Rockett, T.; Lyle, A.; Davies, M.; Anderson, M.; Todd, I.; Willmott, J.R. Reconstruction of Microscopic Thermal Fields from Oversampled Infrared Images in Laser-Based Powder Bed Fusion. Sensors 2021, 21, 4859. [Google Scholar] [CrossRef] [PubMed]

- Eschner, N.; Weiser, L.; Hafner, B.; Lanza, G. Development of an acoustic process monitoring system for selective laser melting (SLM). In Proceedings of the 29th Annual International Solid Freeform Fabrication Symposium–An Additive Manufacturing Conference Reviewed Paper, Austin, TX, USA, 13–15 August 2018; pp. 2097–2117. [Google Scholar]

- Song, S.; Chen, H.B.; Lin, T.; Wu, D.; Chen, S.B. Penetration state recognition based on the double-sound-sources characteristic of VPPAW and hidden Markov Model. J. Mater. Process. Technol. 2016, 234, 33–44. [Google Scholar] [CrossRef]

- Shevchik, S.A.; Kenel, C.; Leinenbach, C.; Wasmer, K. Acoustic emission for in situ quality monitoring in additive manufacturing using spectral convolutional neural networks. Addit. Manuf. 2018, 21, 598–604. [Google Scholar] [CrossRef]

- Ye, D.S.; Fuh, Y.H.J.; Zhang, Y.J.; Hong, G.S.; Zhu, K.P. Defects Recognition in Selective Laser Melting with Acoustic Signals by SVM Based on Feature Reduction. In Proceedings of the 2018 3rd International Conference on Advanced Materials Research and Manufacturing Technologies, Shanghai, China, 16–18 October 2018. [Google Scholar]

- Cheng, B.K.; Lei, J.C.; Xiao, H. A photoacoustic imaging method for in-situ monitoring of laser assisted ceramic additive manufacturing. Opt. Laser Technol. 2019, 115, 459–464. [Google Scholar] [CrossRef]

- Li, X.; Jia, X.D.; Yang, Q.B.; Lee, J. Quality analysis in metal additive manufacturing with deep learning. J. Intell. Manuf. 2020, 31, 2003–2017. [Google Scholar] [CrossRef]

- Zhang, B.; Liu, S.Y.; Shin, Y.C. In-Process monitoring of porosity during laser additive manufacturing process. Addit. Manuf. 2019, 28, 497–505. [Google Scholar] [CrossRef]

- Scime, L.; Beuth, J. Using machine learning to identify in-situ melt pool signatures indicative of flaw formation in a laser powder bed fusion additive manufacturing process. Addit. Manuf. 2019, 25, 151–165. [Google Scholar] [CrossRef]

- Okaro, I.A.; Jayasinghe, S.; Sutcliffe, C.; Black, K.; Paoletti, P.; Green, P.L. Automatic fault detection for laser powder-bed fusion using semi-supervised machine learning. Addit. Manuf. 2019, 27, 42–53. [Google Scholar] [CrossRef]

- Shevchik, S.A.; Masinelli, G.; Kenel, C.; Leinenbach, C.; Wasmer, K. Deep learning for in situ and real-time quality monitoring in additive manufacturing using acoustic emission. IEEE Trans. Ind. Inform. 2019, 15, 5194–5203. [Google Scholar] [CrossRef]

- Wasmer, K.; Le, Q.T.; Meylan, B.; Shevchik, S.A. In Situ Quality Monitoring in AM Using Acoustic Emission: A Reinforcement Learning Approach. J. Mater. Eng. Perform. 2019, 28, 666–672. [Google Scholar] [CrossRef]

- Gobert, C.; Reutzel, E.W.; Petrich, J.; Nassar, A.R.; Phoha, S. Application of supervised machine learning for defect detection during metallic powder bed fusion additive manufacturing using high resolution imaging. Addit. Manuf. 2018, 21, 517–528. [Google Scholar] [CrossRef]

- Coeck, S.; Bisht, M.; Plas, J.; Verbist, F. Prediction of lack of fusion porosity in selective laser melting based on melt pool monitoring data. Addit. Manuf. 2019, 25, 347–356. [Google Scholar] [CrossRef]

- Bartolomeu, F.; Buciumeanu, M.; Pinto, E.; Alves, N.; Carvalho, O.; Silva, F.S.; Miranda, G. 316L stainless steel mechanical and tribological behavior-A comparison between selective laser melting, hot pressing and conventional casting. Addit. Manuf. 2017, 16, 81–89. [Google Scholar] [CrossRef]

- Bidare, P.; Bitharas, I.; Ward, R.M.; Attallah, M.M.; Moore, A.J. Fluid and particle dynamics in laser powder bed fusion. Acta Mater. 2018, 142, 107–120. [Google Scholar] [CrossRef]

- Becker, P.; Roth, C.; Roennau, A.; Dillmann, R. Acoustic Anomaly Detection in Additive Manufacturing with Long Short-Term Memory Neural Networks. In Proceedings of the 2020 IEEE 7th International Conference on Industrial Engineering and Applications (ICIEA), Bangkok, Thailand, 16–18 April 2020. [Google Scholar]

- Yuan, B.; Guss, G.M.; Wilson, A.C.; Hau-Riege, S.P.; DePond, P.J.; McMains, S.; Matthews, M.J.; Giera, B. Machine-Learning-Based Monitoring of Laser Powder Bed Fusion. Adv. Mater. Technol. 2018, 3, 1800136. [Google Scholar] [CrossRef]

- Zhao, B.; Zhang, X.M.; Li, H.; Yang, Z.B. Intelligent fault diagnosis of rolling bearings based on normalized CNN considering data imbalance ands variable working conditions. Knowl.-Based Syst. 2020, 199, 105971. [Google Scholar] [CrossRef]

- Cui, W.Y.; Zhang, Y.L.; Zhang, X.C.; Li, L.; Liou, F. Metal Additive Manufacturing Parts Inspection Using Convolutional Neural Network. Appl. Sci. 2020, 10, 545. [Google Scholar] [CrossRef] [Green Version]

- Dey, R.; Salem, F.M. Gate-variants of gated recurrent unit (GRU) neural networks. In Proceedings of the 2017 IEEE 60th International Midwest Symposium on Circuits and Systems (MWSCAS), Boston, MA, USA, 6–9 August 2017; IEEE: Medford, OR, USA, 2017; pp. 1597–1600. [Google Scholar]

| C | Si | Mn | S | P | Cr | Ni | Mo | Fe |

|---|---|---|---|---|---|---|---|---|

| 0.03 | 1.00 | 2.00 | 0.01 | 0.02 | 17.5~18 | 12.5~13 | 2.25~2.5 | Bal. |

| Parameters | Value |

|---|---|

| Maximum print size | 120 mm × 120 mm × 120 mm |

| Power range | 25 W~250 W |

| Diameter of laser spot | 50~80 μm |

| Protective gas | Argon |

| Maximum scanning speed | 7000 mm/s |

| No. | Laser Power (W) | Scanning Speed (mm/s) |

|---|---|---|

| 1 | 25 | 30 |

| 2 | 50 | 30 |

| 3 | 75 | 30 |

| 4 | 100 | 30 |

| 5 | 125 | 30 |

| 6 | 150 | 30 |

| 7 | 175 | 30 |

| 8 | 200 | 30 |

| 9 | 225 | 30 |

| Network Structure | Data Processing | Classification Rate (%) |

|---|---|---|

| 1D CNN | Raw data | 85.08 |

| Data after FTT | 81.78 | |

| RNN | Raw data | 75.69 |

| Data after FTT | 81.22 | |

| LSTM | Raw data | 77.90 |

| Data after FTT | 83.98 | |

| GRU | Raw data | 81.22 |

| Data after FTT | 80.11 | |

| 2D CNN | Data after transform | 80.56 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Luo, S.; Ma, X.; Xu, J.; Li, M.; Cao, L. Deep Learning Based Monitoring of Spatter Behavior by the Acoustic Signal in Selective Laser Melting. Sensors 2021, 21, 7179. https://doi.org/10.3390/s21217179

Luo S, Ma X, Xu J, Li M, Cao L. Deep Learning Based Monitoring of Spatter Behavior by the Acoustic Signal in Selective Laser Melting. Sensors. 2021; 21(21):7179. https://doi.org/10.3390/s21217179

Chicago/Turabian StyleLuo, Shuyang, Xiuquan Ma, Jie Xu, Menglei Li, and Longchao Cao. 2021. "Deep Learning Based Monitoring of Spatter Behavior by the Acoustic Signal in Selective Laser Melting" Sensors 21, no. 21: 7179. https://doi.org/10.3390/s21217179

APA StyleLuo, S., Ma, X., Xu, J., Li, M., & Cao, L. (2021). Deep Learning Based Monitoring of Spatter Behavior by the Acoustic Signal in Selective Laser Melting. Sensors, 21(21), 7179. https://doi.org/10.3390/s21217179