Prediction of Tool Forces in Manual Grinding Using Consumer-Grade Sensors and Machine Learning

Abstract

:1. Introduction

2. Materials and Methods

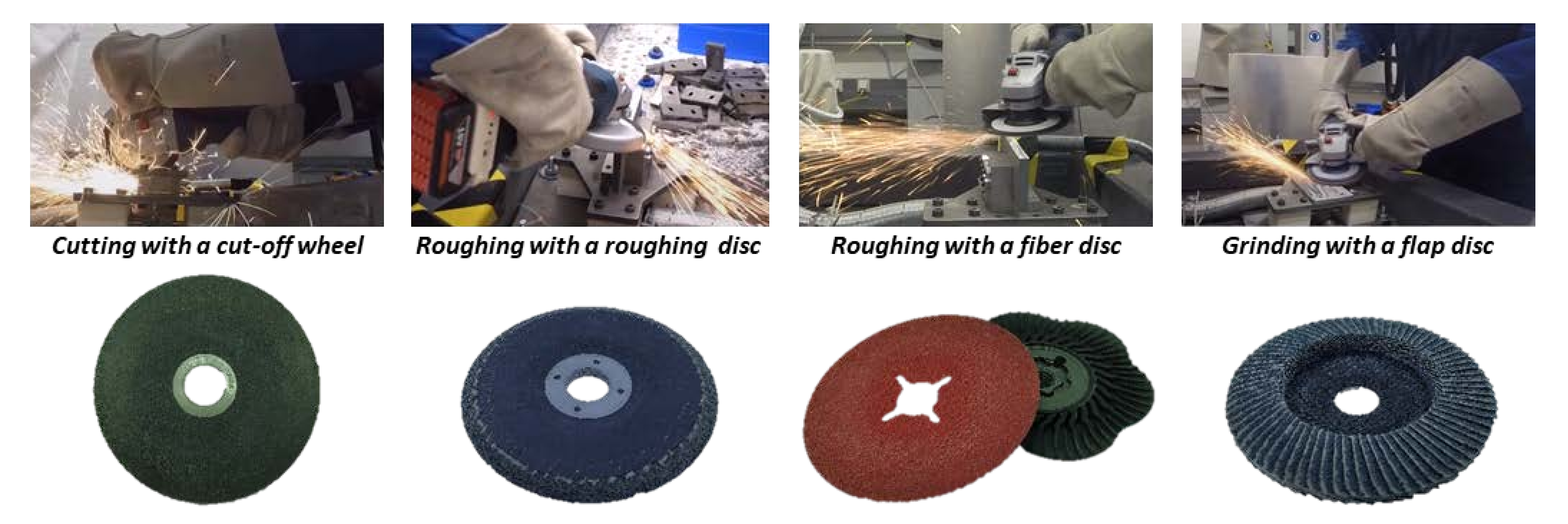

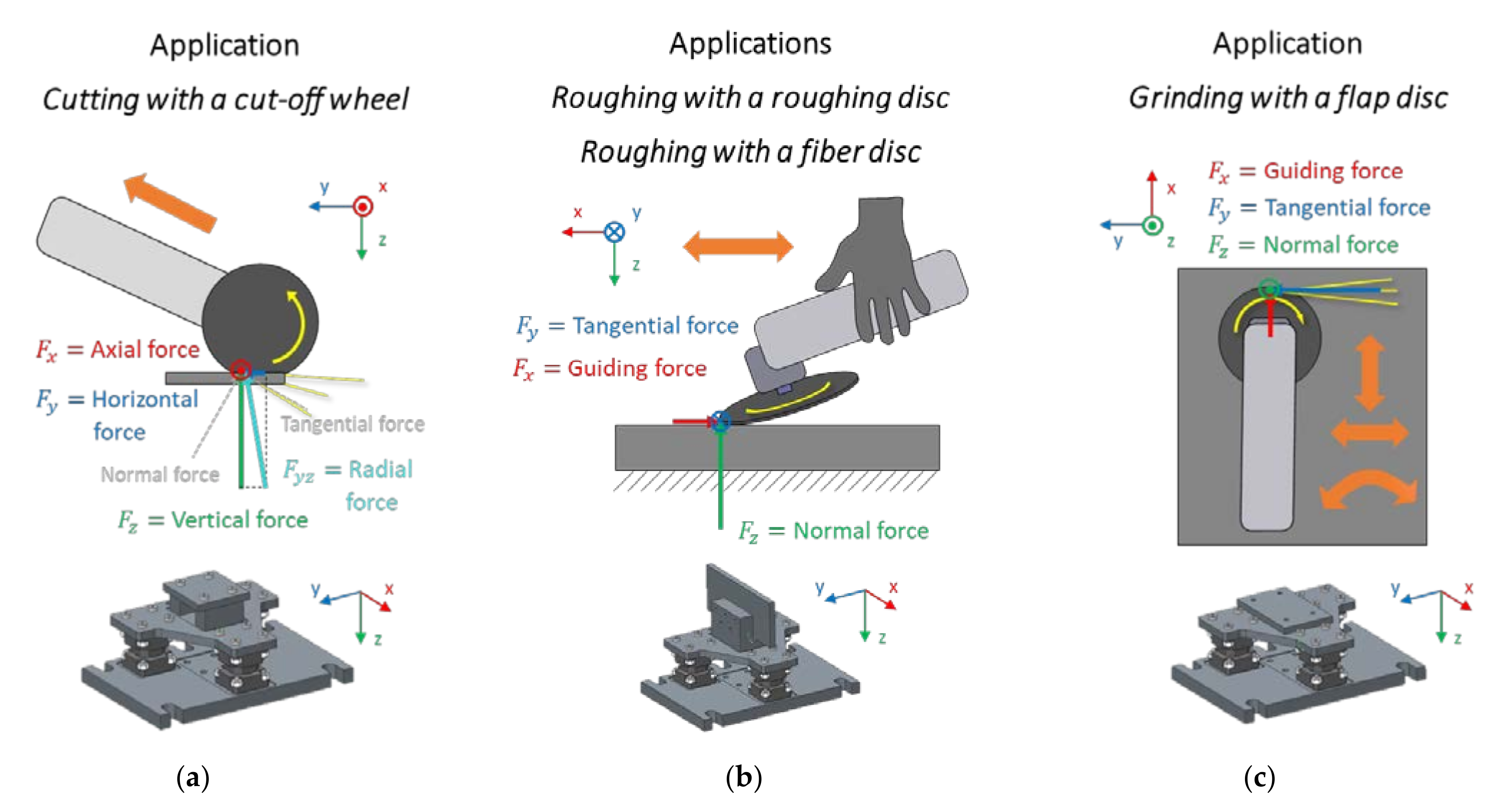

2.1. Experimental Study

2.2. Test Setup for Force Measurement and Data Loggers

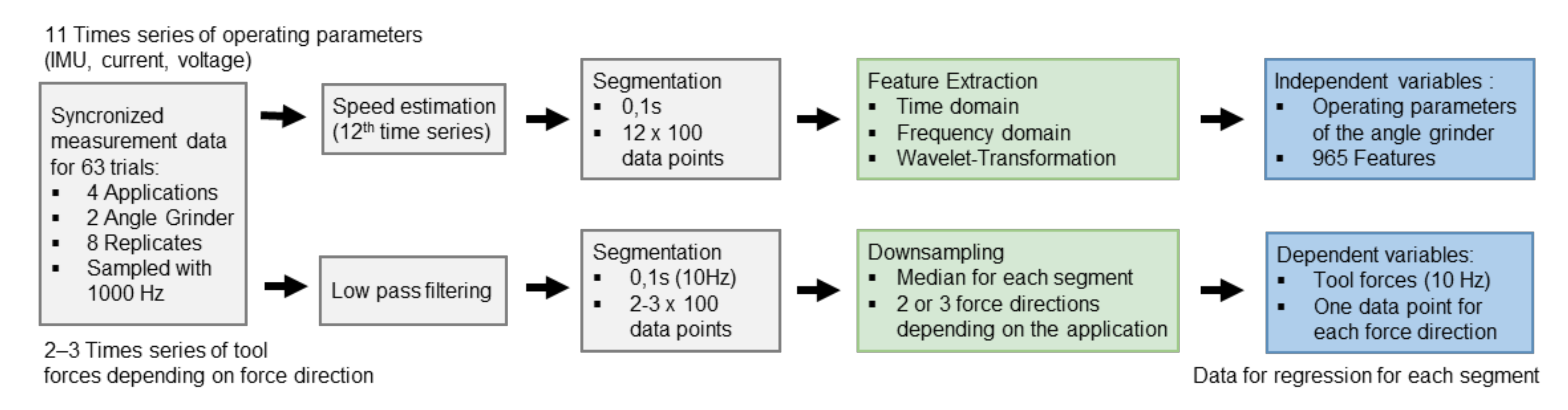

2.3. Data Processing

- (a)

- Minimum, maximum, sum, abs sum, mean, median,

- (b)

- standard deviation, root mean square, interquartile range, skewness, several percentiles (5%, 20%, 80%, 95%),

- (c)

- peak2peak, peak2rms, margin factor, root sum of squares, absolute root mean,

- (d)

- zero-crossing rate, mean crossing rate,

- (e)

- mean frequency, median frequency,

- (f)

- value and frequency of the three highest peaks in amplitude spectrum,

- (g)

- spectral energy in 20 defined sections of the amplitude spectrum (e.g., 80–150 Hz, 350–500 Hz) and

- (h)

- several Daubechies wavelets (e.g., db2_Wavelets_approx, db2_Wavelets_shannon_Entropy3).

2.4. Regression

2.5. Gaussian Process Regression (GPR)

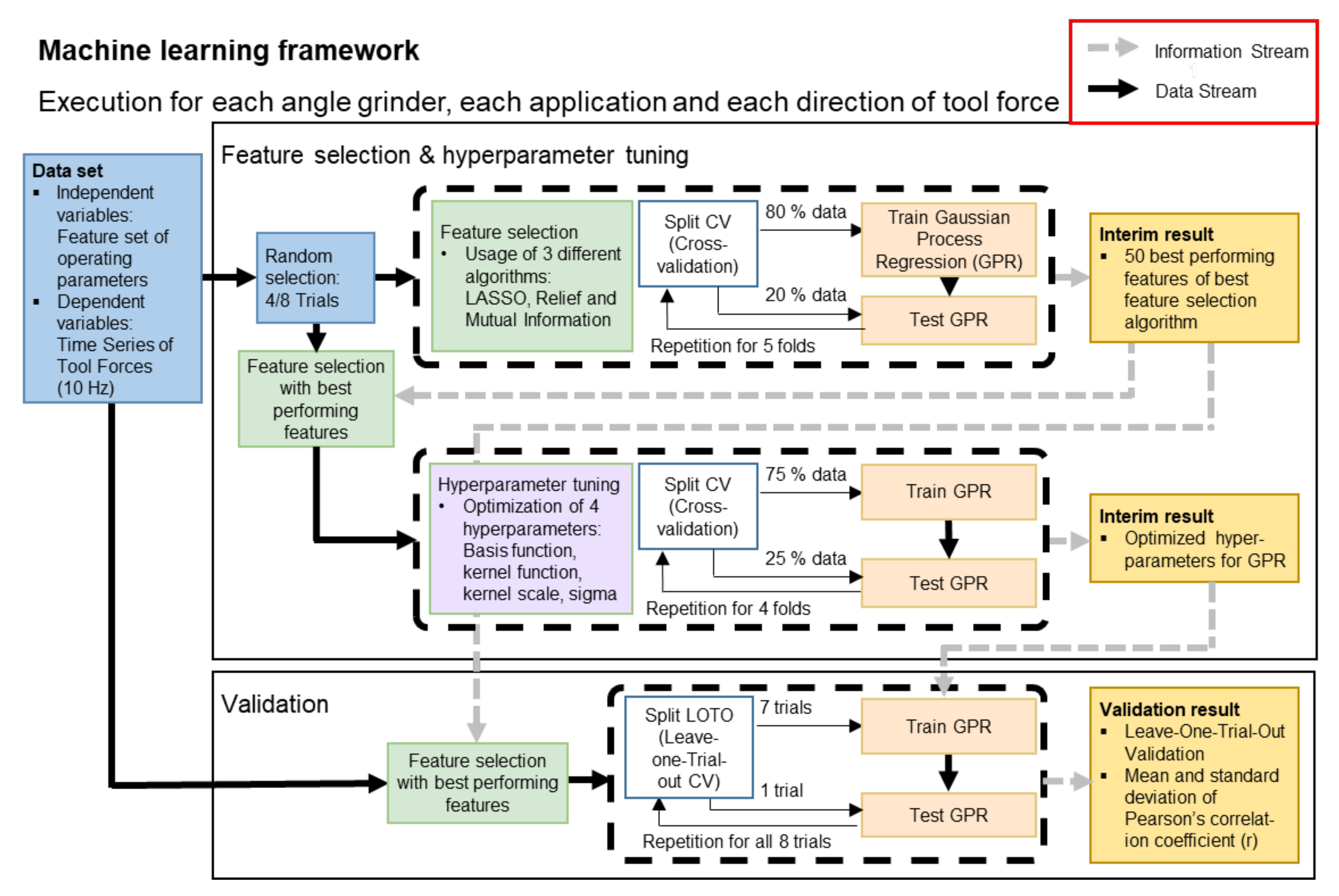

2.6. Machine Learning Framework

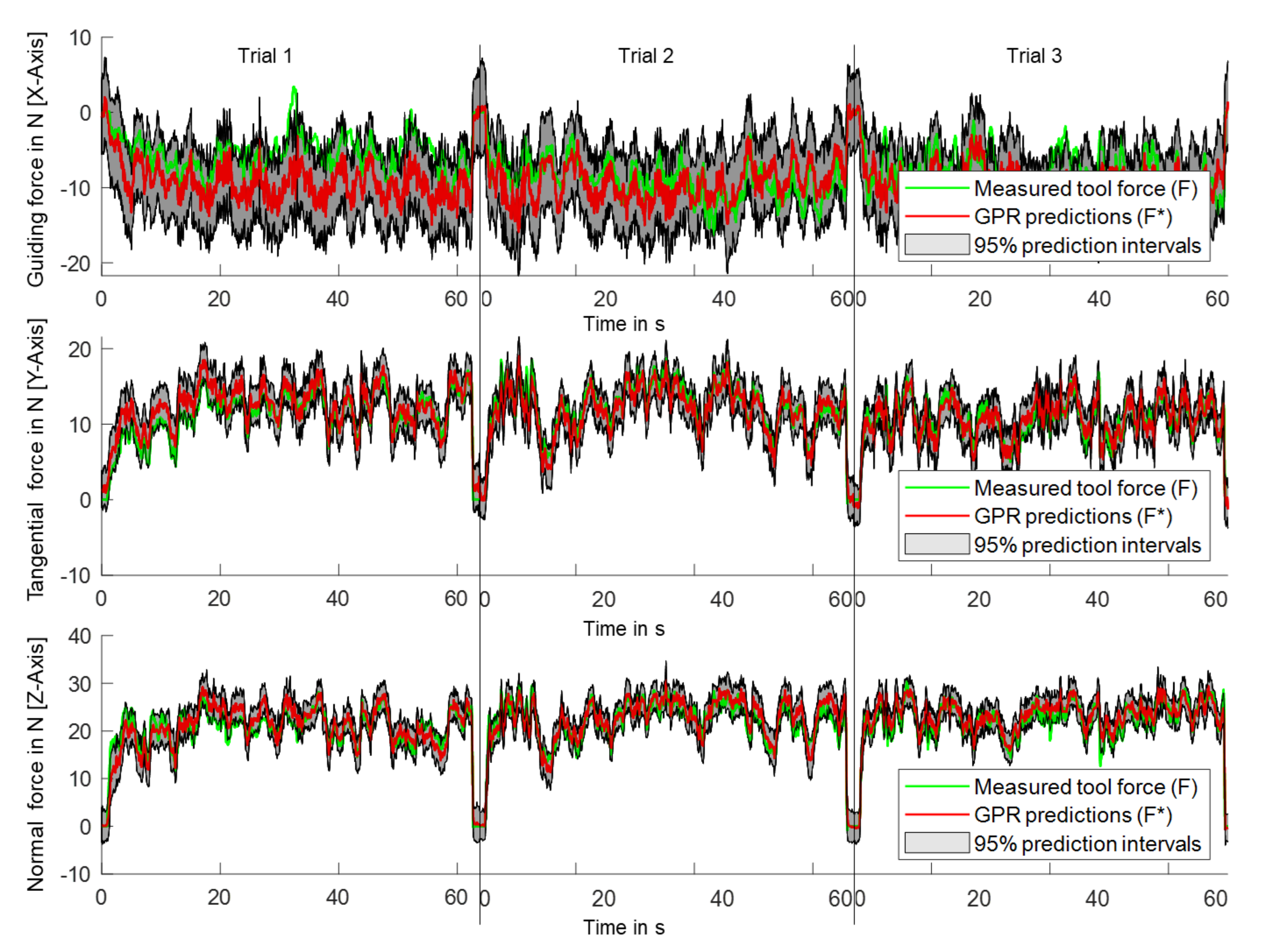

3. Results

4. Discussion

4.1. Discussion of the Results and Comparison of the Applications and Hand-Held Grinding Machines

4.2. Comparison of the Result with the State of the Research

4.3. Limitations and Further Research Directions

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| CV | cross validation |

| GP | Gaussian process |

| GPR | Gaussian process regression |

| KJF | knee joint forces |

| IMU | inertial measurement unit |

| LOTO | leave-one-trial-out |

| MAE | mean absolute error |

| r | Pearson correlation coefficient |

| R2 | coefficient of determination |

| rMAE | relative mean absolute error |

| SVM | support vector machine |

References

- Das, J.; Bales, G.L.; Kong, Z.; Linke, B. Integrating Operator Information for Manual Grinding and Characterization of Process Performance Based on Operator Profile. J. Manuf. Sci. Eng. 2018, 140, 081011. [Google Scholar] [CrossRef] [Green Version]

- Malkin, S.; Guo, C. Grinding technology: Theory & Application of Machining with Abrasives, 2nd ed.; Industrial Press: New York, NY, USA, 2008; ISBN 0831132477. [Google Scholar]

- Bracke, S.; Hinz, M.; Inoue, M.; Patelli, E.; Kutz, S.; Gottschalk, H.; Ulutas, B.; Hartl, C.; Mörs, P.; Bonnaud, P. Reliability engineering in face of shorten product life cycles: Challenges, technique trends and method approaches to ensure product reliability. In Risk, Reliability and Safety: Innovating Theory and Practice, Proceedings of the ESREL 2016, Glasgow, Scotland, 25–29 September 2016; Walls, L., Revie, M., Bedford, T., Eds.; CRC Press: London, UK, 2016; pp. 2884–2891. ISBN 9781138029972. [Google Scholar]

- Lim, A.; Kim, J.; Zechmann, E. Development of an Experimental Method to Estimate the Operating Force of a Hand-Held Power Tool Utilizing Measured Transfer Functions. In Proceedings of the ASME 2013 International Mechanical Engineering Congress and Exposition. Volume 4A: Dynamics, Vibration and Control, San Diego, CA, USA, 15–21 November 2013. [Google Scholar]

- Phan, G.; Kana, S.; Campolo, D. Instrumentation of a grinding tool for capturing dynamic interactions with the workpiece. In Proceedings of the 2017 IEEE International Conference on Cybernetics and Intelligent Systems (CIS) and IEEE Conference on Robotics, Automation and Mechatronics (RAM), IEEE International Conferences on CIS & RAM, Ningbo, China, 19–21 November 2017; pp. 551–555, ISBN 9781538631355. [Google Scholar]

- Arrazola, P.J.; Özel, T.; Umbrello, D.; Davies, M.; Jawahir, I.S. Recent advances in modelling of metal machining processes. CIRP Ann. 2013, 62, 695–718. [Google Scholar] [CrossRef]

- Kuntoğlu, M.; Aslan, A.; Pimenov, D.Y.; Usca, Ü.A.; Salur, E.; Gupta, M.K.; Mikolajczyk, T.; Giasin, K.; Kapłonek, W.; Sharma, S. A Review of Indirect Tool Condition Monitoring Systems and Decision-Making Methods in Turning: Critical Analysis and Trends. Sensors 2021, 21, 108. [Google Scholar]

- Sousa, V.F.C.; Silva, F.J.G.; Fecheira, J.S.; Lopes, H.M.; Martinho, R.P.; Casais, R.B.; Ferreira, L.P. Cutting Forces Assessment in CNC Machining Processes: A Critical Review. Sensors 2020, 20, 4536. [Google Scholar] [CrossRef] [PubMed]

- Sarhan, A.A.D.; Matsubara, A.; Sugihara, M.; Saraie, H.; Ibaraki, S.; Kakino, Y. Monitoring Method of Cutting Force by Using Additional Spindle Sensors. JSME Int. J. Ser. C 2006, 49, 307–315. [Google Scholar] [CrossRef] [Green Version]

- Liu, C.-S.; Ou, Y.-J. Grinding Wheel Loading Evaluation by Using Acoustic Emission Signals and Digital Image Processing. Sensors 2020, 20, 4092. [Google Scholar] [CrossRef] [PubMed]

- Kaufmann, T.; Sahay, S.; Niemietz, P.; Trauth, D.; Maas, W.; Bergs, T. AI-based Framework for Deep Learning Applications in Grinding. In IEEE 18th World Symposium on Applied Machine Intelligence and Informatics, Proceedings of the SAMI, Herlany, Slovakia, 23–25 January 2020; IEEE: Piscataway, NJ, USA, 2020; pp. 195–200. ISBN 9781728131498. [Google Scholar]

- Odum, K.; Castillo, M.C.; Das, J.; Linke, B. Sustainability Analysis of Grinding with Power Tools. In Proceedings of the 6th CIRP International Conference on High Performance Cutting: Procedia CIRP Volume 14. HPC2014, Berkeley, CA, USA, 23–25 June 2014; Dornfeld, D., Ed.; Curran: New York, NY, USA, 2014; pp. 570–574. [Google Scholar]

- Das, J.; Linke, B. Effect of Manual Grinding Operations on Surface Integrity. In Proceedings of the 3rd CIRP Conference on Surface Integrity (CSI 2016): Procedia CIRP Volume 45. CSI 2016, Charlotte, NC, USA, 10 June 2016; Davies, M.A., M’Saoubi, R., Eds.; Curran: New York, NY, USA, 2016; pp. 95–98. [Google Scholar]

- Bales, G.L.; Das, J.; Tsugawa, J.; Linke, B.; Kong, Z. Digitalization of Human Operations in the Age of Cyber Manufacturing: Sensorimotor Analysis of Manual Grinding Performance. J. Manuf. Sci. Eng. 2017, 139, 101011. [Google Scholar] [CrossRef] [Green Version]

- Kamath, A.K.; Linke, B.S.; Chu, C.-H. Enabling Advanced Process Control for Manual Grinding Operations. Smart Sustain. Manuf. Syst. 2020, 4, 210–230. [Google Scholar] [CrossRef]

- Matthiesen, S.; Gwosch, T.; Bruchmueller, T. Experimentelle Identifikation von Schwingungsursachen in Antriebssträngen von Power-Tools: VDI Fachtagung Schwingungen 2017: Berechnung, Überwachung, Anwendung. In Proceedings of the VDI Fachtagung Schwingungen 2017: Berechnung, Überwachung, Anwendung. VDI-Fachtagung Schwingungen 2017, Nürtingen, Germany, 10–11 October 2017; VDI Verlag: Dusseldorf, Germany, 2017. [Google Scholar]

- Bales, G.; Das, J.; Linke, B.; Kong, Z. Recognizing Gaze-Motor Behavioral Patterns in Manual Grinding Tasks. In Proceedings of the 44th North American Manufacturing Research Conference. NAMRC, Blacksburg, VA, USA, 27 June–1 July 2016; Shih, A., Wang, L., Eds.; Elsevier: Amsterdam, The Netherlands, 2016; pp. 106–121. [Google Scholar]

- Matthiesen, S.; Dörr, M.; Zimprich, S. Testfallgenerierung—Vorgehen zur Lastkollektivermittlung durch Data Mining am Winkelschleifer. In Design for X: Proceedings of the 29th Symposium 2018. DfX; Krause, D., Paetzold, K., Wartzack, S., Eds.; TuTech Verlag: Hamburg, Germany, 2018; pp. 295–306. [Google Scholar]

- Matthiesen, S.; Gwosch, T.; Schäfer, T.; Dültgen, P.; Pelshenke, C.; Gittel, H.-J. Experimental identification of component loads in a power tool power-train through indirect measurement in realistically applications as an element of subsystem validation. Forsch. im Ing.-Eng. Res. 2016, 80, 17–27. [Google Scholar] [CrossRef]

- Matthiesen, S.; Gwosch, T.; Mangold, S.; Dültgen, P.; Pelshenke, C.; Gittel, H.-J. Realitätsnahe Komponententests zur Unterstützung der Produktentwicklung bei der Validierung von Power-Tools. Konstruktion 2017, 69, 76–81. [Google Scholar] [CrossRef]

- Dong, R.G.; Welcome, D.E.; Xu, X.S.; McDowell, T.W. Identification of effective engineering methods for controlling handheld workpiece vibration in grinding processes. Int. J. Ind. Ergon. 2020, 77, 102946. [Google Scholar] [CrossRef]

- Phan, G.-H.; Hansen, C.; Tommasino, P.; Hussain, A.; Campolo, D. Design and characterization of an instrumented hand-held power tool to capture dynamic interaction with the workpiece during manual operations. Int. J. Adv. Manuf. Technol. 2020, 111, 199–212. [Google Scholar] [CrossRef]

- Giarmatzis, G.; Zacharaki, E.I.; Moustakas, K. Real-Time Prediction of Joint Forces by Motion Capture and Machine Learning. Sensors 2020, 20, 6933. [Google Scholar] [CrossRef]

- Stetter, B.J.; Ringhof, S.; Krafft, F.C.; Sell, S.; Stein, T. Estimation of Knee Joint Forces in Sport Movements Using Wearable Sensors and Machine Learning. Sensors 2019, 19, 3690. [Google Scholar] [CrossRef] [Green Version]

- Lim, H.; Kim, B.; Park, S. Prediction of Lower Limb Kinetics and Kinematics during Walking by a Single IMU on the Lower Back Using Machine Learning. Sensors 2019, 20, 130. [Google Scholar] [CrossRef] [Green Version]

- Lu, H.; Schomaker, L.R.; Carloni, R. IMU-based Deep Neural Networks for Locomotor Intention Prediction. In Proceedings of the 2020 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS). 2020 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Las Vegas, NV, USA, 24 October 2020–24 January 2021; pp. 4134–4139, ISBN 9781728162126. [Google Scholar]

- Choi, A.; Jung, H.; Mun, J.H. Single Inertial Sensor-Based Neural Networks to Estimate COM-COP Inclination Angle during Walking. Sensors 2019, 19, 2974. [Google Scholar] [CrossRef] [Green Version]

- Wu, C.-C.; Wen, Y.-T.; Lee, Y.-J. IMU sensors beneath walking surface for ground reaction force prediction in gait. IEEE Sens. J. 2020, 20, 9372–9376. [Google Scholar] [CrossRef]

- Voet, H.; Altenhof, M.; Ellerich, M.; Schmitt, R.H.; Linke, B. A Framework for the Capture and Analysis of Product Usage Data for Continuous Product Improvement. J. Manuf. Sci. Eng. 2019, 141, 021010. [Google Scholar] [CrossRef]

- Dörr, M.; Peters, J.; Matthiesen, S. Data-Driven Analysis of Human-Machine Systems—A Data Logger and Possible Use Cases for Field Studies with Cordless Power Tools. In Human Interaction, Emerging Technologies and Future Applications III; Ahram, T., Taiar, R., Langlois, K., Choplin, A., Eds.; Springer International Publishing: Cham, Switzerland, 2021; pp. 56–62. ISBN 9783030553067. [Google Scholar]

- ISO—International Organization for Standardization. Mechanical Vibration and Shock—Coupling Forces at the Man—Machine Interface for Hand-Transmitted Vibration; Beuth Verlag: Berlin, Germany, 2007; ISO 15230:2007. [Google Scholar]

- Angelini, C. Regression Analysis. In Encyclopedia of Bioinformatics and Computational Biology; Ranganathan, S., Gribskov, M., Nakai, K., Schönbach, C., Eds.; Academic Press: Oxford, UK, 2019; pp. 722–730. ISBN 9780128114322. [Google Scholar]

- Rasmussen, C.E.; Williams, C.K.I. Gaussian Processes for Machine Learning; The MIT Press: London, UK, 2006; ISBN 026218253X. [Google Scholar]

- Kern, T.A.; Matysek, M.; Meckel, O.; Rausch, J.; Rettig, A.; Roese, A.; Sindlinger, S. Entwicklung Haptischer Geräte: Ein Einstieg für Ingenieure; Springer International Publishing: Cham, Switzerland, 2009; ISBN 9783540876434. [Google Scholar]

- Meddour, I.; Yallese, M.A.; Bensouilah, H.; Khellaf, A.; Elbah, M. Prediction of surface roughness and cutting forces using RSM, ANN, and NSGA-II in finish turning of AISI 4140 hardened steel with mixed ceramic tool. Int. J. Adv. Manuf. Technol. 2018, 97, 1931–1949. [Google Scholar] [CrossRef]

- Sharma, V.S.; Dhiman, S.; Sehgal, R.; Sharma, S.K. Estimation of cutting forces and surface roughness for hard turning using neural networks. J. Intell. Manuf. 2008, 19, 473–483. [Google Scholar] [CrossRef]

- Aykut, Ş.; Gölcü, M.; Semiz, S.; Ergür, H.S. Modeling of cutting forces as function of cutting parameters for face milling of satellite 6 using an artificial neural network. J. Mater. Process. Technol. 2007, 190, 199–203. [Google Scholar] [CrossRef]

- Dörr, M.; Zimprich, S.; Dürkopp, A.; Bruchmüller, T.; Gittel, H.-J.; Matthiesen, S.; Pelshenke, C.; Dültgen, P. Experimental Abrasive Contact Analysis—Dynamic Forces between Grinding Discs and Steel for common Angle Grinder Applications. In Proceedings of the 11th TOOLING 2019 conference & exhibition, TOOLING, Aachen, Germany, 12–16 May 2019; TEMA Technologie Marketing AG: Aachen, Germany, 2019. [Google Scholar]

- Sanhudo, L.; Calvetti, D.; Martins, J.P.; Ramos, N.M.; Mêda, P.; Gonçalves, M.C.; Sousa, H. Activity classification using accelerometers and machine learning for complex construction worker activities. J. Build. Eng. 2021, 35, 102001. [Google Scholar]

- Heinis, T.B.; Loy, C.L.; Meboldt, M. Improving Usage Metrics for Pay-per-Use Pricing with IoT Technology and Machine Learning. Res. Technol. Manag. 2018, 61, 32–40. [Google Scholar] [CrossRef]

- Dörr, M.; Ries, M.; Gwosch, T.; Matthiesen, S. Recognizing Product Application based on Integrated Consumer Grade Sensors: A Case Study with Handheld Power Tools: Procedia 29th CIRP Design Conference. In Proceedings of the 29th CIRP Design Conference: Procedia CIRP Volume 84, CIRP Design, Póvoa de Varzim, Portgal, 8–10 May 2019; Putnik, G.D., Ed.; Curran: New York, NY, USA, 2019; pp. 798–803. [Google Scholar]

| Application | MAE [N] | rMAE [%] | r | MAE [N] | rMAE [%] | r | MAE [N] | rMAE [%] | r |

|---|---|---|---|---|---|---|---|---|---|

| Roughing with a roughing disc | |||||||||

| 2.83 (0.64) | 137.25 (67.77) | 0.47 (0.12) | 1.66 (0.43) | 20.91 (4.09) | 0.85 (0.04) | 2.15 (0.56) | 9.42 (2.31) | 0.91 (0.04) | |

| Roughing with a fiber disc | |||||||||

| 2.64 (0.52) | 64.38 (42.52) | 0.48 (0.11) | 1.03 (0.21) | 11.11 (2.43) | 0.89 (0.05) | 1.80 (0.36) | 10.06 (1.57) | 0.80 (0.19) | |

| Grinding with a flap disc | |||||||||

| 6.84 (1.77) | 108.93 (67.21) | 0.10 (0.19) | 2.28 (0.73) | 27.71 (16.37) | 0.59 (0.14) | 3.79 (1.67) | 25.34 (16.83) | 0.58 (0.16) | |

| Cutting with a cutoff-wheel | |||||||||

| 3.14 (1.08) | 630.23 (888.75) | 0.09 (0.14) | 4.66 (2.99) | 24.03 (9.88) | 0.70 (0.05) | ||||

| Application | MAE [N] | rMAE [%] | r | MAE [N] | rMAE [%] | r | MAE [N] | rMAE [%] | r |

|---|---|---|---|---|---|---|---|---|---|

| Roughing with a roughing disc | |||||||||

| 2.63 (0.78) | 84.47 (16.62) | 0.17 (0.17) | 1.69 (0.40) | 23.27 (5.47) | 0.81 (0.06) | 2.01 (0.38) | 8.68 (1.67) | 0.85 (0.21) | |

| Roughing with a fiber disc | |||||||||

| 2.94 (0.90) | 39.04 (7.08) | 0.58 (0.07) | 1.14 (0.25) | 12.32 (4.67) | 0.91 (0.07) | 1.66 (0.27) | 7.62 (1.01) | 0.94 (0.02) | |

| Grinding with a flap disc | |||||||||

| 7.87 (0.99) | 88.06 (54.40) | 0.41 (0.11) | 1.67 (0.37) | 13.97 (4.40) | 0.83 (0.08) | 1.81 (0.40) | 7.52 (1.71) | 0.94 (0.02) | |

| Cutting with a cutoff-wheel | |||||||||

| 4.62 (2.04) | 503.67 (532.58) | 0.16 (0.16) | 2.61 (0.42) | 15.31 (3.63) | 0.90 (0.04) | ||||

| Application | rMAE [%] | R2 | rMAE [%] | R2 | rMAE [%] | R2 | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 Hz | 10 Hz | 20 Hz | CV | CV | 1 Hz | 10 Hz | 20 Hz | CV | CV | 1 Hz | 10 Hz | 20 Hz | CV | CV | |

| Roughing with a roughing disc | |||||||||||||||

| 131.60 (75.57) | 137.25 (67.77) | 136.87 (69.77) | 62.90 | 0.58 | 23.73 (3.10) | 20.91 (4.09) | 20.82 (3.58) | 15.38 | 0.81 | 12.79 (4.95) | 9.42 (2.31) | 9.41 (2.73) | 7.63 | 0.87 | |

| Roughing with a fiber disc | |||||||||||||||

| 71.57 (51.55) | 64.38 (42.52) | 62.99 (40.15) | 50.66 | 0.26 | 14.27 (3.54) | 11.11 (2.43) | 12.62 (2.88) | 9.14 | 0.86 | 11.42 (1.03) | 10.06 (1.57) | 10.90 (2.41) | 11.85 | 0.69 | |

| Grinding with a flap disc | |||||||||||||||

| 100.82 (69.40) | 108.93 (67.21) | 102.40 (64.12) | 75.31 | 0.24 | 80.61 (109.90) | 27.71 (16.37) | 71.59 (106.04) | 13.92 | 0.68 | 30.49 (24.28) | 25.34 (16.83) | 31.96 (12.95) | 10.91 | 0.71 | |

| Cutting with a cutoff-wheel | |||||||||||||||

| 490.22 (517.88) | 630.23 (888.75) | 644.98 (886.18) | 624.30 | 0.24 | 19.94 (11.69) | 24.03 (9.88) | 23.34 (9.00) | 14.87 | 0.76 | ||||||

| Application | rMAE [%] | R2 | rMAE [%] | R2 | rMAE [%] | R2 | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 Hz | 10 Hz | 20 Hz | CV | CV | 1 Hz | 10 Hz | 20 Hz | CV | CV | 1 Hz | 10 Hz | 20 Hz | CV | CV | |

| Roughing with a roughing disc | |||||||||||||||

| 78.12 (32.19) | 84.47 (16.62) | 82.18 (20.77) | 52.03 | 0.71 | 24.73 (2.95) | 23.27 (5.47) | 23.09 (6.48) | 15.33 | 0.81 | 12.02 (1.49) | 8.68 (1.67) | 8.59 (1.11) | 7.67 | 0.87 | |

| Roughing with a fiber disc | |||||||||||||||

| 38.99 (6.89) | 39.04 (7.08) | 40.05 (11.08) | 37.53 | 0.58 | 23.92 (11.36) | 12.32 (4.67) | 14.30 (5.94) | 7.97 | 0.89 | 12.03 (3.28) | 7.62 (1.01) | 8.37 (1.14) | 7.07 | 0.87 | |

| Grinding with a flap disc | |||||||||||||||

| 83.18 (52.71) | 88.06 (54.40) | 95.59 (58.97) | 65.92 | 0.41 | 16.65 (4.80) | 13.97 (4.40) | 13.95 (4.12) | 13.49 | 0.71 | 9.23 (2.32) | 7.52 (1.71) | 8.10 (1.62) | 10.83 | 0.71 | |

| Cutting with a cutoff-wheel | |||||||||||||||

| 715.05 (1161.6) | 503.67 (532.58) | 529.96 (557.62) | 553.79 | 0.36 | 19.83 (5.49) | 15.31 (3.63) | 19.26 (5.64) | 14.86 | 0.76 | ||||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dörr, M.; Ott, L.; Matthiesen, S.; Gwosch, T. Prediction of Tool Forces in Manual Grinding Using Consumer-Grade Sensors and Machine Learning. Sensors 2021, 21, 7147. https://doi.org/10.3390/s21217147

Dörr M, Ott L, Matthiesen S, Gwosch T. Prediction of Tool Forces in Manual Grinding Using Consumer-Grade Sensors and Machine Learning. Sensors. 2021; 21(21):7147. https://doi.org/10.3390/s21217147

Chicago/Turabian StyleDörr, Matthias, Lorenz Ott, Sven Matthiesen, and Thomas Gwosch. 2021. "Prediction of Tool Forces in Manual Grinding Using Consumer-Grade Sensors and Machine Learning" Sensors 21, no. 21: 7147. https://doi.org/10.3390/s21217147

APA StyleDörr, M., Ott, L., Matthiesen, S., & Gwosch, T. (2021). Prediction of Tool Forces in Manual Grinding Using Consumer-Grade Sensors and Machine Learning. Sensors, 21(21), 7147. https://doi.org/10.3390/s21217147