Vision-Based Approach in Contact Modelling between the Footpad of the Lander and the Analogue Representing Surface of Phobos

Abstract

:1. Introduction

2. Materials and Methods

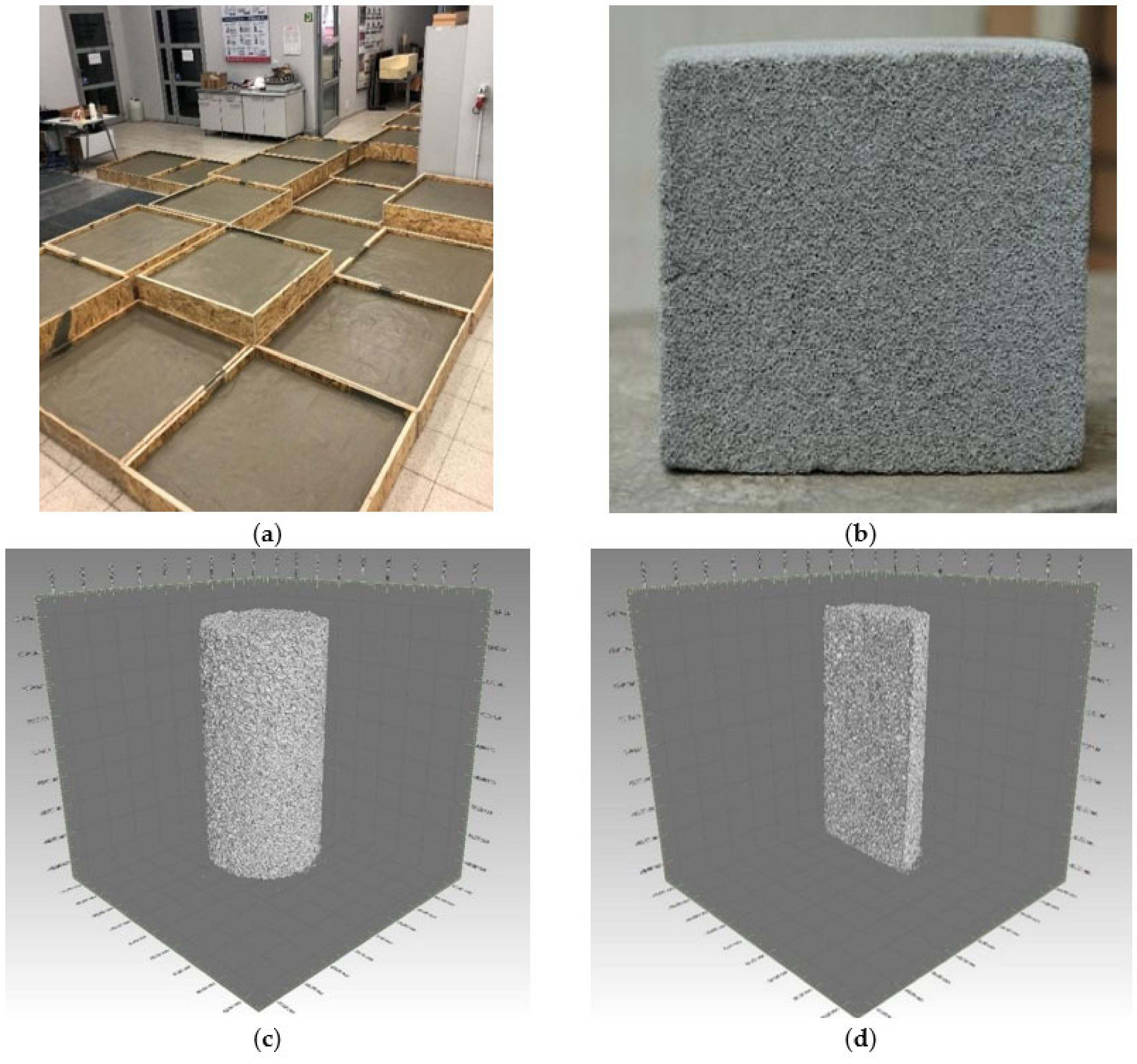

2.1. Tested Analogue

- volume density based on EN ISO 17892−2 [55],

- uniaxial compressive strength according to EN 12390−3:2009 [56],

- tensile strength using the Brazilian method based on EN 12390-6:2009 [57],

- Young’s modulus based on EN 12390−13:2014 [58]—method A,

- structural analysis using the computed tomography (CT) technique (Figure 1c,d).

2.2. Testbed

- Drive system (pneumatic system of elements that trigger the movement of the runner element with the model of the footpad at the predefined velocity. This system consists of an air compressor and a pneumatic drive element);

- Runner element (the device that represents the weight of the lander, to which the footpad is attached);

- Electromagnet (the device that releases the runner element);

- Track structure (steel construction for linear movement of the runner element with the footpad model with minor sliding friction);

- Test analogue mounting system (a system of steel members enabling stable attachment of test analogues with different test surface inclination angles to the lander footpad);

- Measuring system;

- Safety system (the safety system is composed of a bi-directional pneumatic actuator powered by compressed air and a steel structure designed to block the pneumatic drive element from uncontrolled release);

- Main control panel (a panel that controls operation of the safety system, pneumatic drive element, and measuring system. The device is situated above the testbed localization).

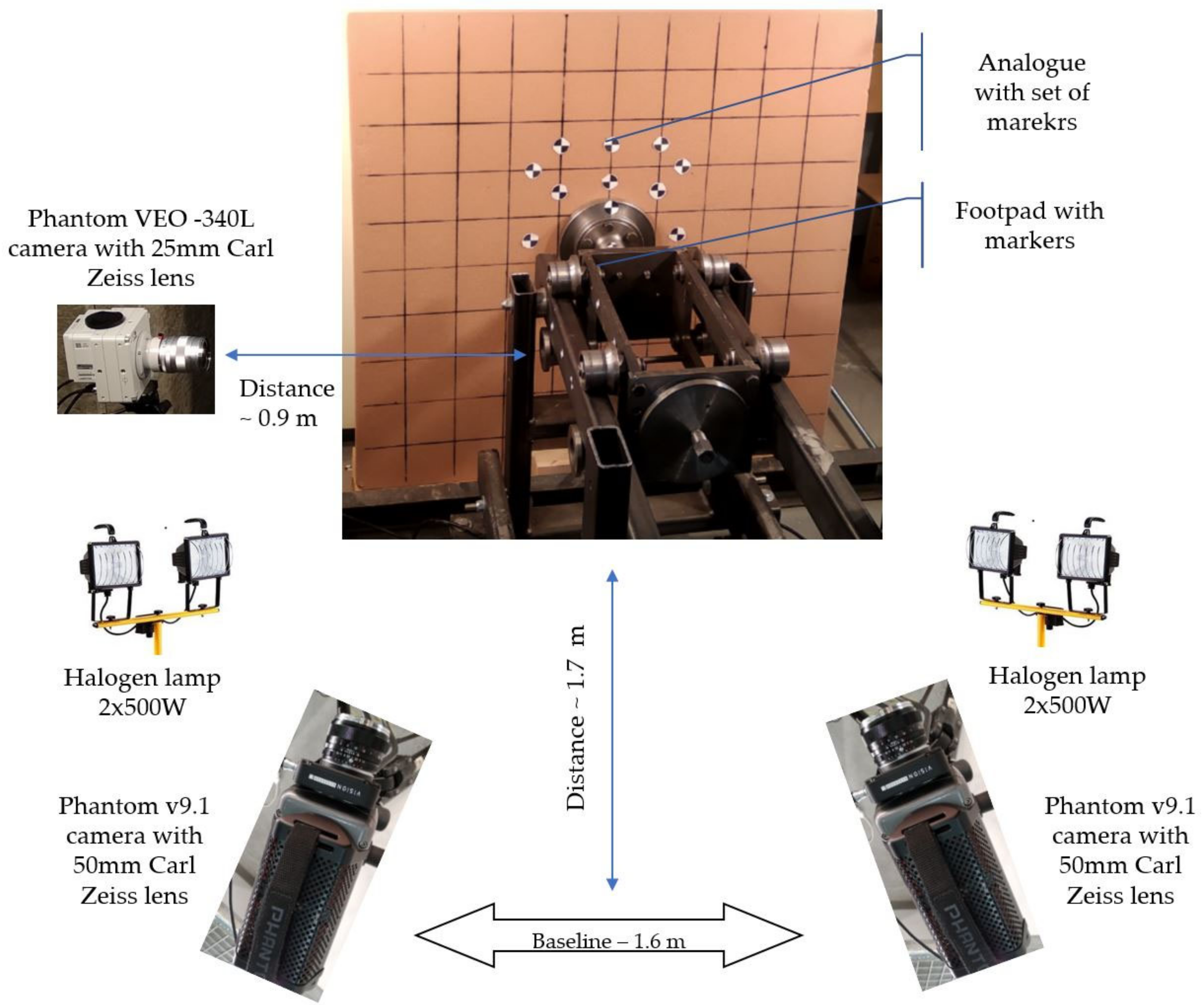

2.3. Measuring System

2.3.1. Three-Dimensional Vision System-Level of Measurement Noise

2.3.2. Two-Dimensional Vision System-Level of Measurement Noise

2.4. Mapping the Analogue Deformation

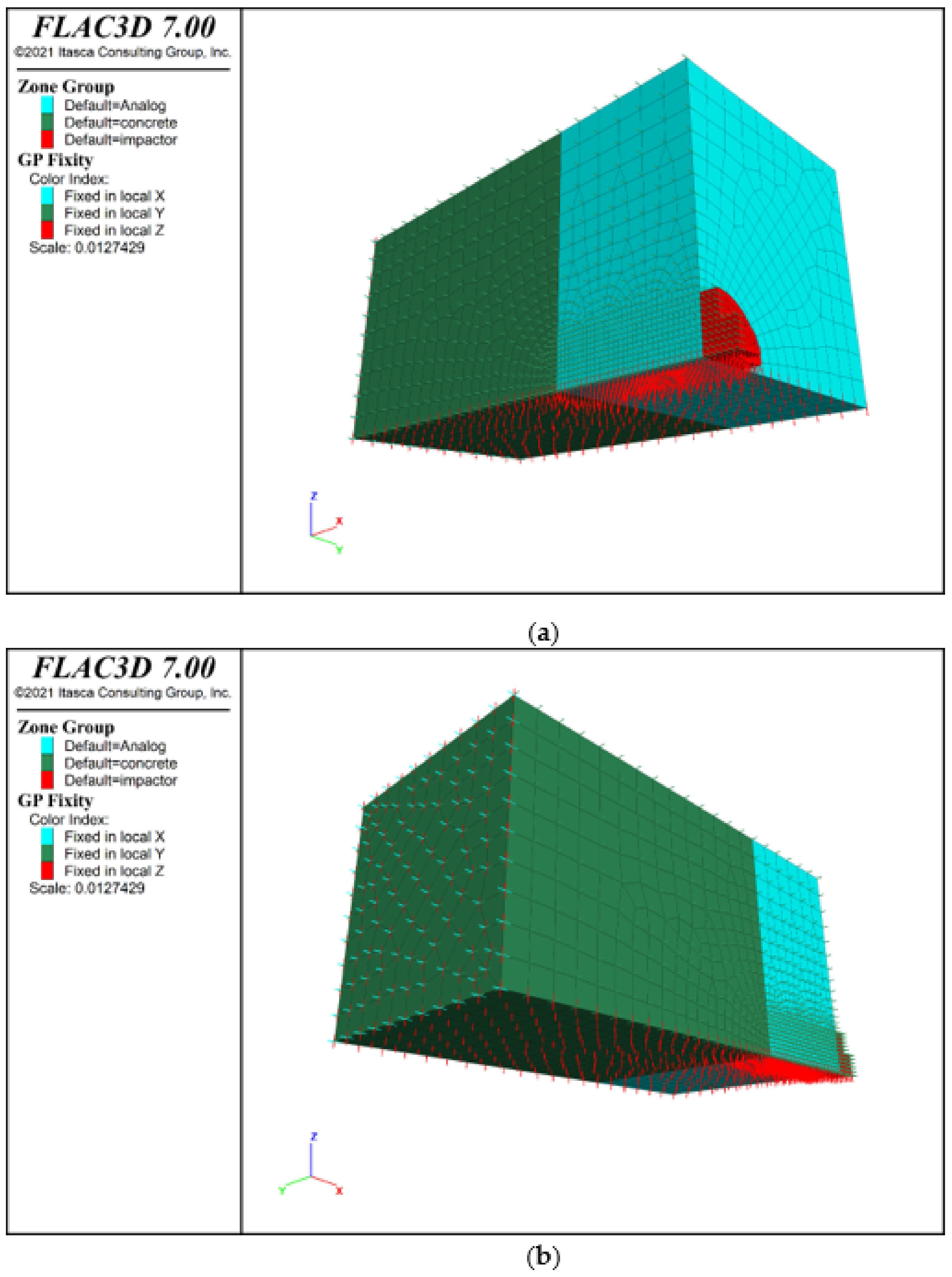

2.5. Numerical Simulations

3. Results and Discussion

3.1. Laboratory Test Results of Foam Concrete

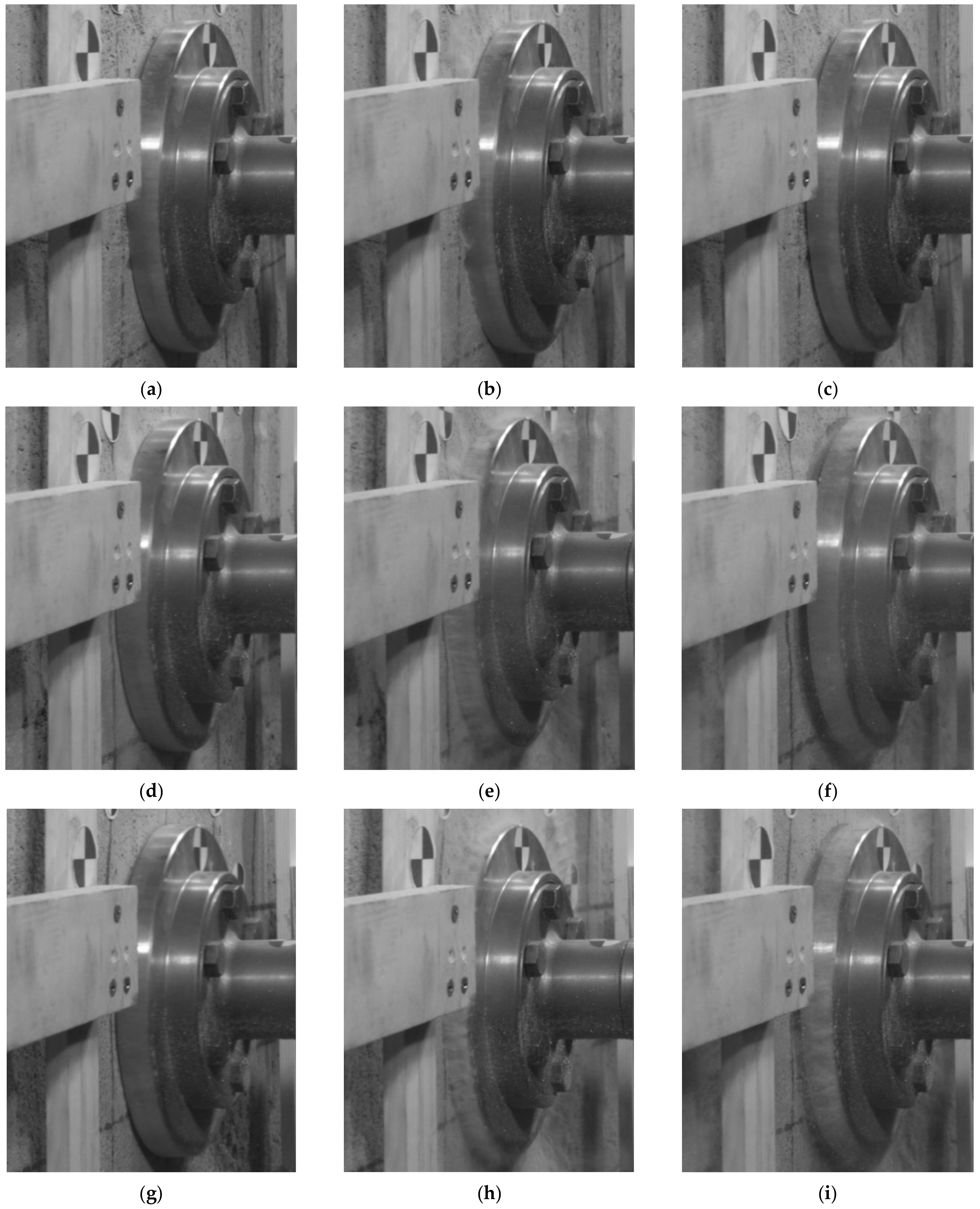

3.2. Results of Two-Dimensional Vision System Measurements

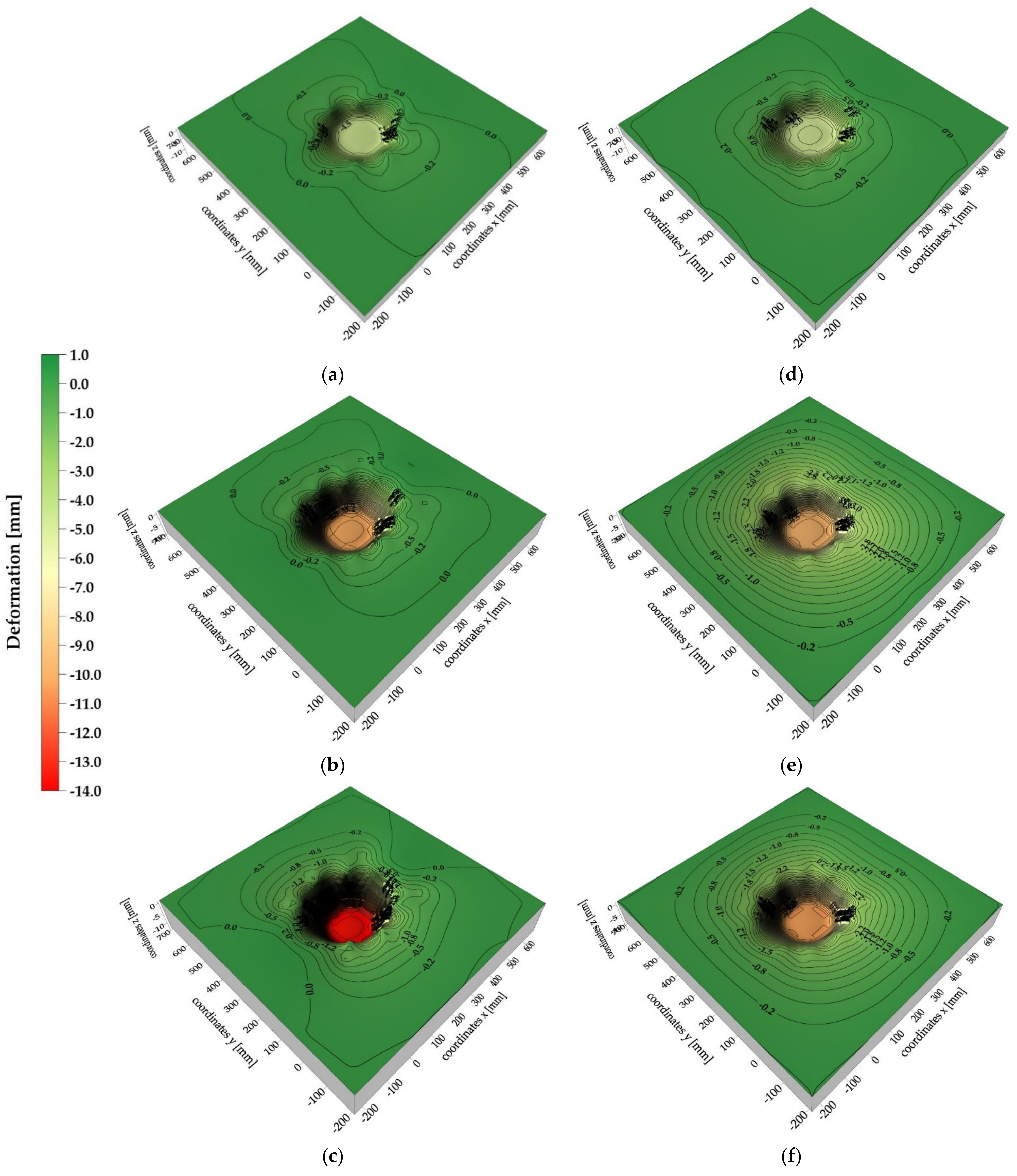

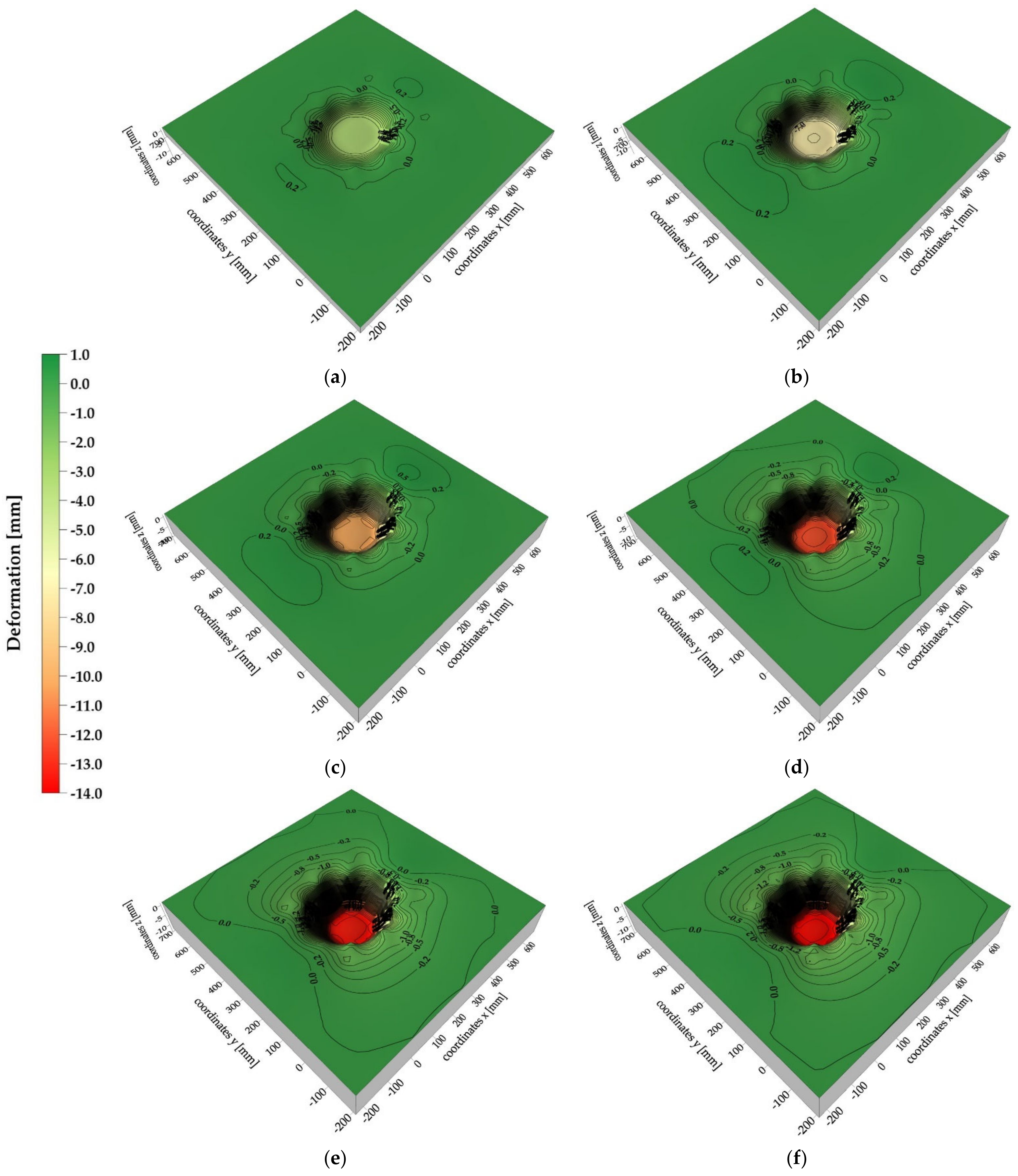

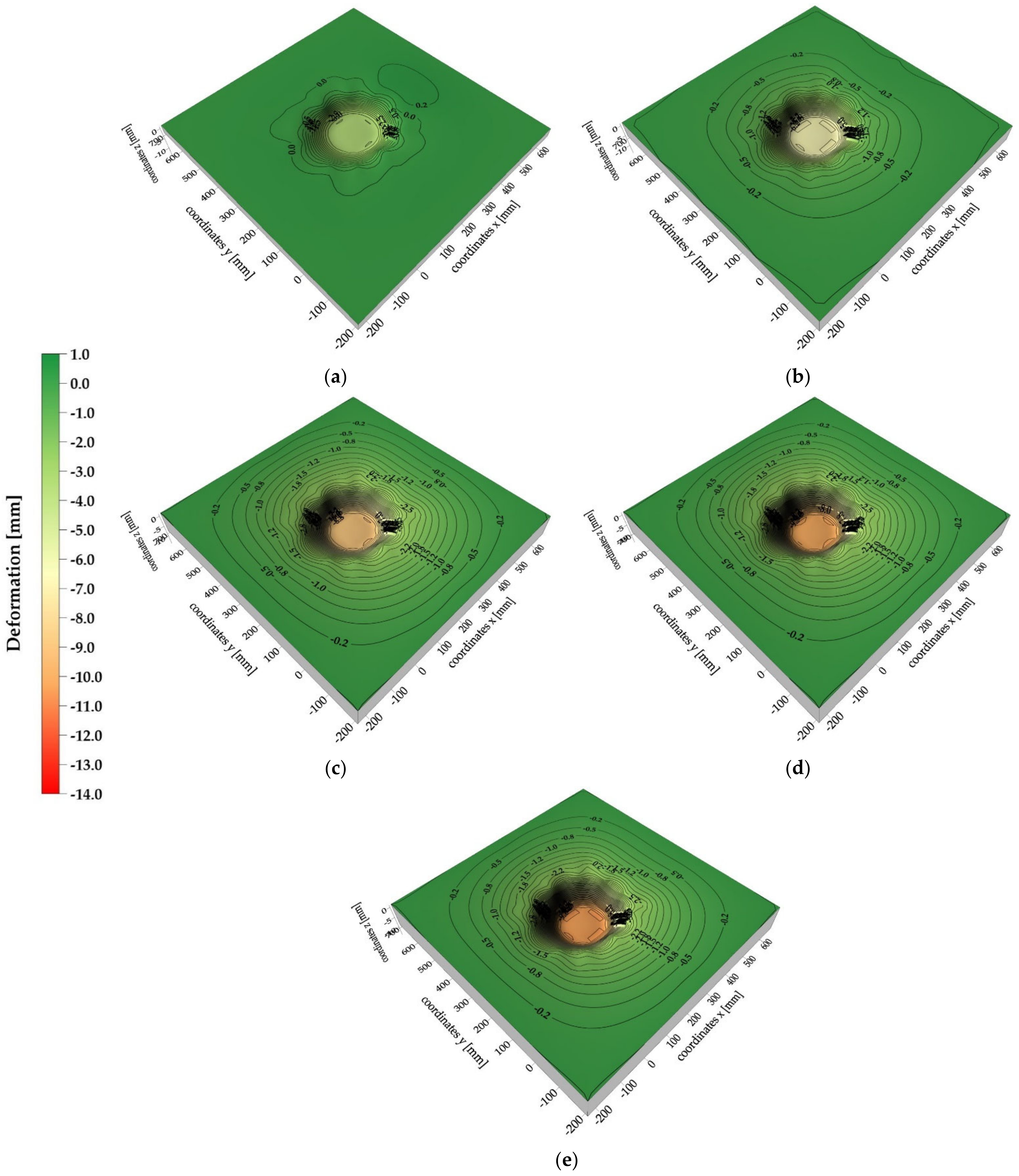

3.3. Results of 3D Vision System Measurements

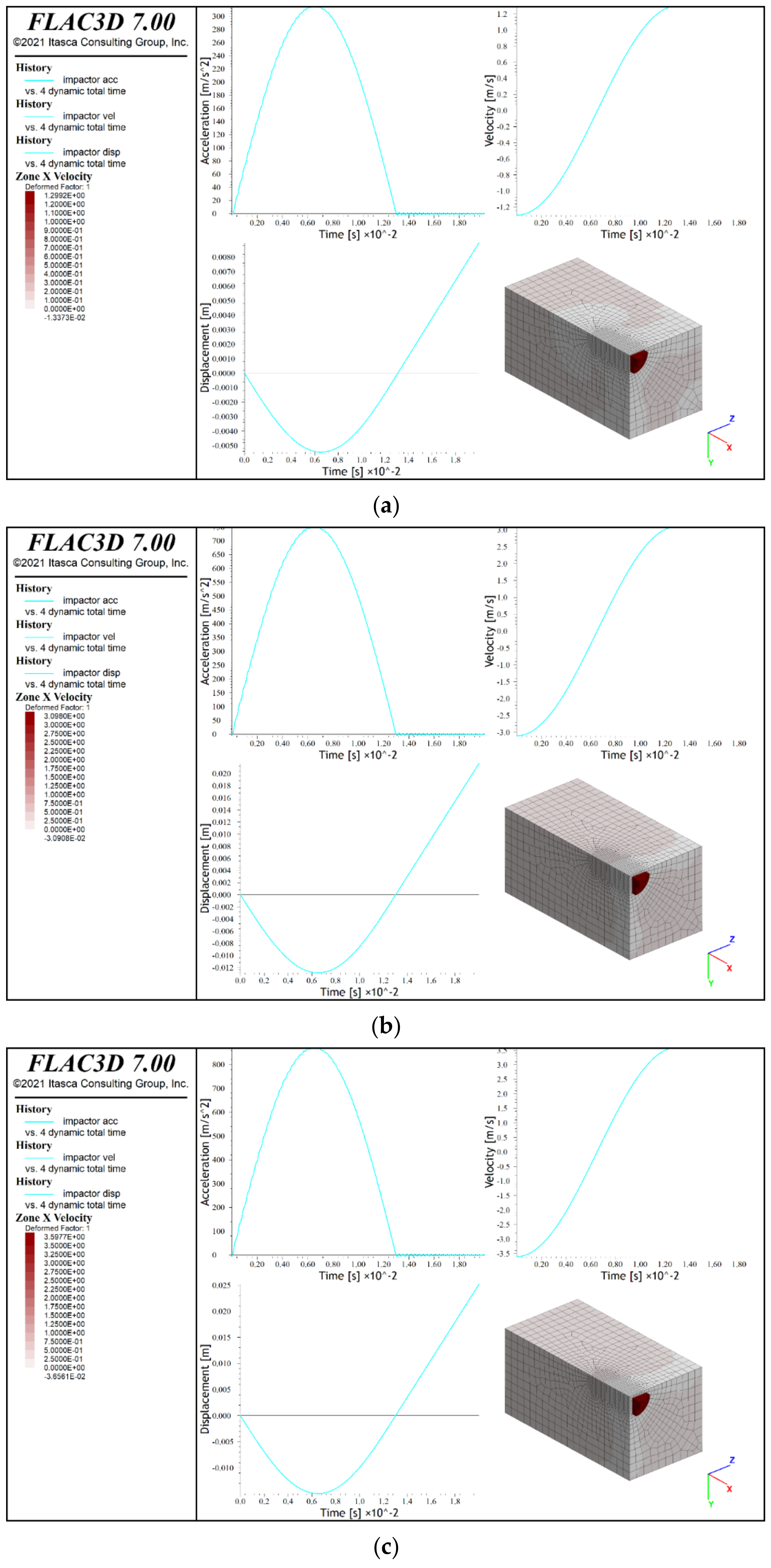

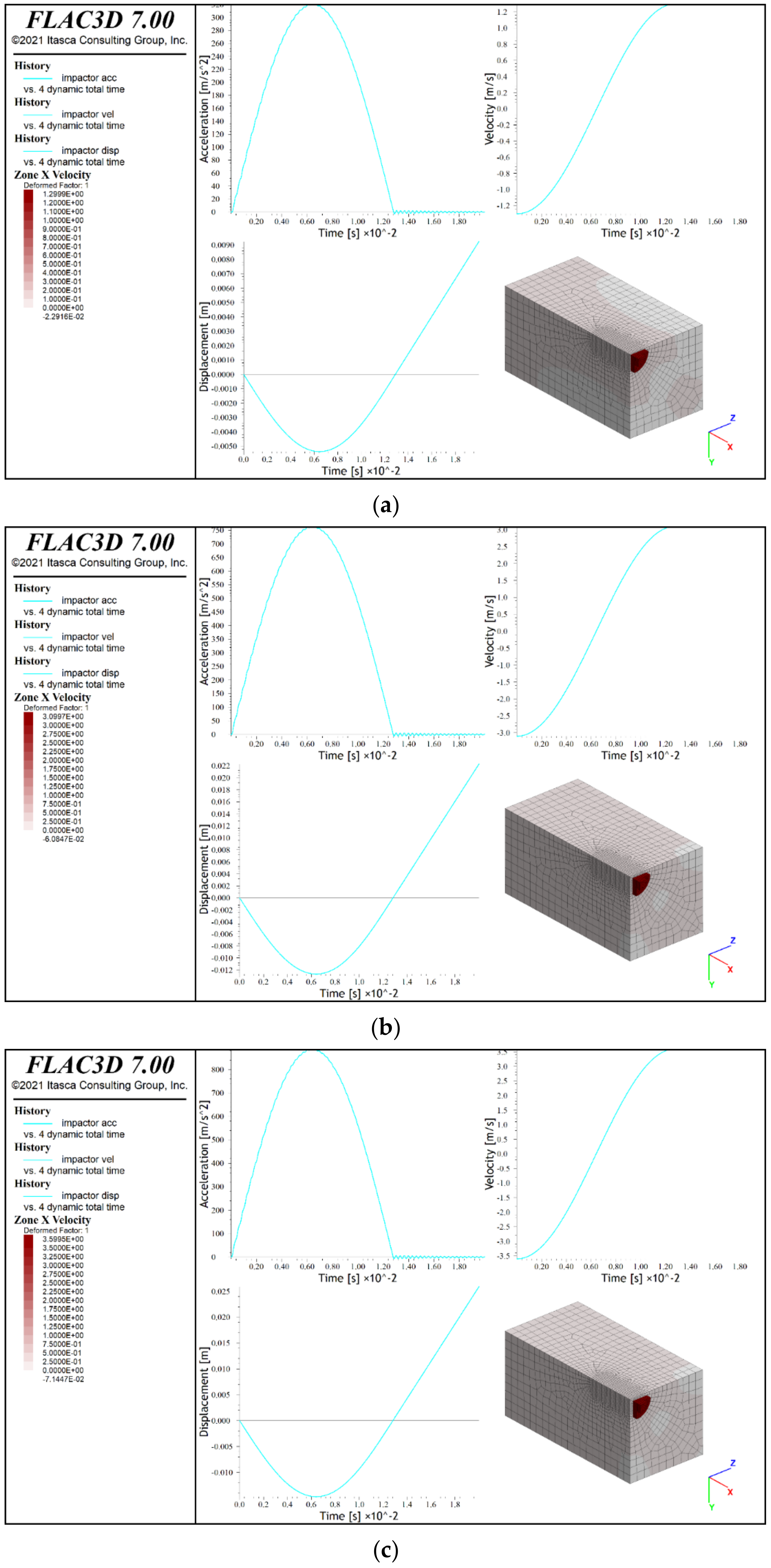

3.4. Numerical Simulation Results

- the layered arrangement of the concrete slabs that underlie the analogues and the contact conditions between the slabs;

- friction and other movement resistances of the lander foot;

- the additional fixing of 30 cm thick analogues;

- shearing of the analogue material when in direct contact with the lander foot;

- the lack of actual parallelism of the surface of the analogue with the surface of the lander foot;

- misalignment of the actual perpendicularity of the camera’s optical axis to the plane of the runner element in the vision-based calculation of the marker displacement on the runner element.

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Koch, C.; Georgieva, K.; Kasireddy, V.; Akinci, B.; Fieguth, P. A review on computer vision based defect detection and condition assessment of concrete and asphalt civil infrastructure. Adv. Eng. Inform. 2015, 29, 196–210. [Google Scholar] [CrossRef] [Green Version]

- Kim, H.; Ahn, E.; Cho, S.; Shin, M.; Sim, S.-H. Comparative analysis of image binarization methods for crack identification in concrete structures. Cem. Concr. Res. 2017, 99, 53–61. [Google Scholar] [CrossRef]

- Cha, Y.-J.; Choi, W.; Suh, G.; Mahmoudkhani, S.; Büyüköztürk, O. Autonomous Structural Visual Inspection Using Region-Based Deep Learning for Detecting Multiple Damage Types. Comput. Civ. Infrastruct. Eng. 2017, 33, 731–747. [Google Scholar] [CrossRef]

- Chen, F.-C.; Jahanshahi, M.R. NB-CNN: Deep Learning-Based Crack Detection Using Convolutional Neural Network and Naïve Bayes Data Fusion. IEEE Trans. Ind. Electron. 2018, 65, 4392–4400. [Google Scholar] [CrossRef]

- Kim, B.; Cho, S. Automated Vision-Based Detection of Cracks on Concrete Surfaces Using a Deep Learning Technique. Sensors 2018, 18, 3452. [Google Scholar] [CrossRef] [Green Version]

- Ai, D.; Jiang, G.; Lam, S.-K.; He, P.; Li, C. Automatic pixel-wise detection of evolving cracks on rock surface in video data. Autom. Constr. 2020, 119, 103378. [Google Scholar] [CrossRef]

- Attard, L.; Debono, C.J.; Valentino, G.; Di Castro, M. Vision-based change detection for inspection of tunnel liners. Autom. Constr. 2018, 91, 142–154. [Google Scholar] [CrossRef]

- Yeum, C.M.; Choi, J.; Dyke, S.J. Automated region-of-interest localization and classification for vision-based visual assessment of civil infrastructure. Struct. Health Monit. 2019, 18, 675–689. [Google Scholar] [CrossRef]

- Gao, Y.; Mosalam, K.M. Deep Transfer Learning for Image-Based Structural Damage Recognition. Comput. Civ. Infrastruct. Eng. 2018, 33, 748–768. [Google Scholar] [CrossRef]

- Narazaki, Y.; Hoskere, V.; Hoang, T.A.; Fujino, Y.; Sakurai, A.; Spencer, B.F. Vision-based automated bridge component recognition with high-level scene consistency. Comput. Civ. Infrastruct. Eng. 2020, 35, 465–482. [Google Scholar] [CrossRef]

- Feng, D.; Feng, M.Q. Computer vision for SHM of civil infrastructure: From dynamic response measurement to damage detection–A review. Eng. Struct. 2018, 156, 105–117. [Google Scholar] [CrossRef]

- Kohut, P.; Holak, K.; Uhl, T.; Ortyl, Ł.; Owerko, T.; Kuras, P.; Kocierz, R. Monitoring of a civil structure’s state based on noncontact measurements. Struct. Health Monit. 2013, 12, 411–429. [Google Scholar] [CrossRef]

- Tang, Y.-C.; Li, L.-J.; Feng, W.-X.; Liu, F.; Zou, X.-J.; Chen, M.-Y. Binocular vision measurement and its application in full-field convex deformation of concrete-filled steel tubular columns. Measurement 2018, 130, 372–383. [Google Scholar] [CrossRef]

- Sun, L.; Abolhasannejad, V.; Gao, L.; Li, Y. Non-contact optical sensing of asphalt mixture deformation using 3D stereo vision. Measurement 2016, 85, 100–117. [Google Scholar] [CrossRef]

- Yang, Y.-S.; Huang, C.-W.; Wu, C.-L. A simple image-based strain measurement method for measuring the strain fields in an RC-wall experiment. Earthq. Eng. Struct. Dyn. 2012, 41, 1–17. [Google Scholar] [CrossRef]

- Hu, H.; Liang, J.; Xiao, Z.-Z.; Tang, Z.-Z.; Asundi, A.; Wang, Y.-X. A four-camera videogrammetric system for 3-D motion measurement of deformable object. Opt. Lasers Eng. 2012, 50, 800–811. [Google Scholar] [CrossRef]

- Tang, Y.; Li, L.; Wang, C.; Chen, M.; Feng, W.; Zou, X.; Huang, K. Real-time detection of surface deformation and strain in recycled aggregate concrete-filled steel tubular columns via four-ocular vision. Robot. Comput. Manuf. 2019, 59, 36–46. [Google Scholar] [CrossRef]

- Chen, M.; Tang, Y.; Zou, X.; Huang, K.; Li, L.; He, Y. High-accuracy multi-camera reconstruction enhanced by adaptive point cloud correction algorithm. Opt. Lasers Eng. 2019, 122, 170–183. [Google Scholar] [CrossRef]

- Yang, Y.; Dorn, C.; Mancini, T.; Talken, Z.; Kenyon, G.; Farrar, C.; Mascareñas, D. Blind identification of full-field vibration modes from video measurements with phase-based video motion magnification. Mech. Syst. Signal. Process. 2017, 85, 567–590. [Google Scholar] [CrossRef]

- Wang, W.; Mottershead, J.E.; Siebert, T.; Pipino, A. Frequency response functions of shape features from full-field vibration measurements using digital image correlation. Mech. Syst. Signal. Process. 2012, 28, 333–347. [Google Scholar] [CrossRef]

- Kohut, P.; Kurowski, P. Application of modal analysis supported by 3d vision-based measurements. J. Theor. Appl. Mech. 2009, 47, 855–870. [Google Scholar]

- Yoneyama, S.; Ueda, H. Bridge Deflection Measurement Using Digital Image Correlation with Camera Movement Correction. Mater. Trans. 2012, 53, 285–290. [Google Scholar] [CrossRef] [Green Version]

- Kohut, P.; Gąska, A.; Holak, K.; Ostrowska, K.; Sładek, J.; Uhl, T.; Dworakowski, Z. A structure’s deflection measurement and monitoring system supported by a vision system. TM Tech. Mess. 2014, 81, 635–643. [Google Scholar] [CrossRef]

- Lee, J.; Lee, K.-C.; Cho, S.; Sim, S.-H. Computer Vision-Based Structural Displacement Measurement Robust to Light-Induced Image Degradation for In-Service Bridges. Sensors 2017, 17, 2317. [Google Scholar] [CrossRef] [Green Version]

- Jeon, H.; Bang, Y.; Myung, H. A paired visual servoing system for 6-DOF displacement measurement of structures. Smart Mater. Struct. 2011, 20, 045019. [Google Scholar] [CrossRef]

- Poozesh, P.; Baqersad, J.; Niezrecki, C.; Avitabile, P.; Harvey, E.; Yarala, R. Large-area photogrammetry based testing of wind turbine blades. Mech. Syst. Signal. Process. 2017, 86, 98–115. [Google Scholar] [CrossRef] [Green Version]

- Kohut, P.; Holak, K.; Martowicz, A.; Uhl, T. Experimental assessment of rectification algorithm in vision-based deflection measurement system. Nondestruct. Test. Eval. 2017, 32, 200–226. [Google Scholar] [CrossRef]

- Feng, D.; Feng, M.Q.; Ozer, E.; Fukuda, Y. A Vision-Based Sensor for Noncontact Structural Displacement Measurement. Sensors 2015, 15, 16557–16575. [Google Scholar] [CrossRef] [PubMed]

- Feng, D.; Feng, M.Q. Experimental validation of cost-effective vision-based structural health monitoring. Mech. Syst. Signal. Process. 2017, 88, 199–211. [Google Scholar] [CrossRef]

- Spencer, B.F.; Hoskere, V.; Narazaki, Y. Advances in Computer Vision-Based Civil Infrastructure Inspection and Monitoring. Engineering 2019, 5, 199–222. [Google Scholar] [CrossRef]

- Greenbaum, R.J.Y.; Smyth, A.W.; Chatzis, M. Monocular Computer Vision Method for the Experimental Study of Three-Dimensional Rocking Motion. J. Eng. Mech. 2016, 142, 04015062. [Google Scholar] [CrossRef]

- Chang, C.-C.; Xiao, X.H. Three-Dimensional Structural Translation and Rotation Measurement Using Monocular Videogrammetry. J. Eng. Mech. 2010, 136, 840–848. [Google Scholar] [CrossRef]

- Xu, J.; Wang, E.; Zhou, R. Real-time measuring and warning of surrounding rock dynamic deformation and failure in deep roadway based on machine vision method. Measurement 2020, 149, 107028. [Google Scholar] [CrossRef]

- Chen, Y.L.; Abdelbarr, M.; Jahanshahi, M.R.; Masri, S.F. Color and depth data fusion using an RGB-D sensor for inexpensive and contactless dynamic displacement-field measurement. Struct. Control. Health Monit. 2017, 24, e2000. [Google Scholar] [CrossRef]

- Carroll, J.; Abuzaid, W.; Lambros, J.; Sehitoglu, H. High resolution digital image correlation measurements of strain accumulation in fatigue crack growth. Int. J. Fatigue 2013, 57, 140–150. [Google Scholar] [CrossRef]

- Mahal, M.; Blanksvärd, T.; Täljsten, B.; Sas, G. Using digital image correlation to evaluate fatigue behavior of strengthened reinforced concrete beams. Eng. Struct. 2015, 105, 277–288. [Google Scholar] [CrossRef]

- Pieczonka, Ł.; Kohut, P.; Dziedziech, K.; Uhl, T.; Staszewski, W.J. Experimental Investigation of Crack-Wave Interactions for Structural Damage Detection. In Advances in Technical Diagnostics; Timofiejczuk, A., Łazarz, B.E., Chaari, F., Burdzik, R., Eds.; Springer International Publishing: New York, NY, USA, 2018. [Google Scholar]

- Kohut, P.; Holak, K.; Obuchowicz, R.; Ekiert, M.; Mlyniec, A.; Ambrozinski, L.; Tomaszewski, K.; Uhl, T. Modeling and Identification of the Mechanical Properties of Achilles Tendon With Application in Health Monitoring. J. Nondestruct. Eval. Diagn. Progn. Eng. Syst. 2019, 2, 011007. [Google Scholar] [CrossRef]

- Ballouz, R.-L.; Baresi, N.; Crites, S.; Kawakatsu, Y.; Fujimoto, M. Surface refreshing of Martian moon Phobos by orbital eccentricity-driven grain motion. Nat. Geosci. 2019, 12, 229–234. [Google Scholar] [CrossRef]

- Popel, S.I.; Zakharov, A.V.; Zelenyi, L.M. Dusty plasmas at Martian satellites. J. Physics: Conf. Ser. 2019, 1147, 012110. [Google Scholar] [CrossRef] [Green Version]

- Hemmi, R.; Miyamoto, H. Morphology and Morphometry of Sub-kilometer Craters on the Nearside of Phobos and Implications for Regolith Properties. Trans. Jpn. Soc. Aeronaut. Space Sci. 2020, 63, 124–131. [Google Scholar] [CrossRef]

- Glotch, T.D.; Edwards, C.S.; Yesiltas, M.; Shirley, K.A.; McDougall, D.S.; Kling, A.M.; Bandfield, J.L.; Herd, C.D.K. MGS-TES Spectra Suggest a Basaltic Component in the Regolith of Phobos. J. Geophys. Res. Planets 2018, 123, 2467–2484. [Google Scholar] [CrossRef]

- Miyamoto, H.; Niihara, T.; Grott, M.; Knollenberg, J.; Helbert, J.; Sakatani, N.; Ogawa, K. Phobos regolith simulant for MMX mission: Spectral measurement for remote target identification and deconvolution system training. In Proceedings of the 50th Lunar and Planetary Science Conference, Woodlands, TX, USA, 18–22 March 2019; pp. 1–179. [Google Scholar]

- Basilevsky, A.; Lorenz, C.; Shingareva, T.; Head, J.; Ramsley, K.; Zubarev, A. The surface geology and geomorphology of Phobos. Planet. Space Sci. 2014, 102, 95–118. [Google Scholar] [CrossRef]

- Zharkova, A.Y.; Kolenkina, M.M.; Kokhanov, A.A.; Karachevtseva, I.P. Relief of mercury and the moon: From morphometry to morphological mapping. Int. Arch. Photogramm. Remote. Sens. Spat. Inf. Sci. 2019, XLII-2/W13, 1487–1492. [Google Scholar] [CrossRef] [Green Version]

- Pieters, C.M.; Murchie, S.; Thomas, N.; Britt, D. Composition of Surface Materials on the Moons of Mars. Planet. Space Sci. 2014, 102, 144–151. [Google Scholar] [CrossRef]

- Murchie, S.; Thomas, N.; Britt, D.; Herkenhoff, K.; Bell, J.F. Mars Pathfinder spectral measurements of Phobos and Deimos: Comparison with previous data. J. Geophys. Res. Space Phys. 1999, 104, 9069–9079. [Google Scholar] [CrossRef]

- Thomas, N.; Stelter, D.; Ivanov, A.; Bridges, N.; Herkenhoff, K.; McEwen, A. Spectral heterogeneity on Phobos and Deimos: HiRISE observations and comparisons to Mars Pathfinder results. Planet. Space Sci. 2011, 59, 1281–1292. [Google Scholar] [CrossRef]

- Pajola, M.; Lazzarin, M.; Ore, C.M.D.; Cruikshank, D.P.; Roush, T.L.; Magrin, S.; Bertini, I.; La Forgia, F.; Barbieri, C. Phobos as a D-type captured asteroid, spectral modeling from 0.25 to 4.0 μm. Astrophys. J. 2013, 777, 127. [Google Scholar] [CrossRef] [Green Version]

- Black, B.A.; Mittal, T. The demise of Phobos and development of a Martian ring system. Nat. Geosci. 2015, 8, 913–917. [Google Scholar] [CrossRef]

- Rosenblatt, P. The origin of the Martian moons revisited. Astron. Astrophys. Rev. 2011, 19, 1–26. [Google Scholar] [CrossRef]

- Hofmeister, P.G.; Blum, J.; Heiβelmann, D. The Flow Of Granular Matter Under Reduced-Gravity Conditions. In AIP Conference Proceedings; American Institute of Physics: College Park, MD, USA, 2009; Volume 1145, pp. 71–74. [Google Scholar] [CrossRef] [Green Version]

- Scheeres, D.; Hartzell, C.; Sánchez, P.; Swift, M. Scaling forces to asteroid surfaces: The role of cohesion. Icarus 2010, 210, 968–984. [Google Scholar] [CrossRef] [Green Version]

- PN-B 06565:1959. Foam Concrete; Polish Committee of Standardization: Warsaw, Poland, 1959. (In Polish) [Google Scholar]

- EN ISO 17892-2:2014. Geotechnical Investigation and Testing–Laboratory Testing of Soil–Part 2: Determination of Bulk Density; International Standards Organization: Geneva, Switzerland, 2014. [Google Scholar]

- EN 12390-3:2009. Testing Hardened Concrete–Part 3: Compressive Strength of Test Specimens; International Standards Organization: Geneva, Switzerland, 2009. [Google Scholar]

- EN 12390-6:2009. Testing Hardened Concrete–Part 6: Tensile Splitting Strength of Test Specimens; International Standards Organization: Geneva, Switzerland, 2009. [Google Scholar]

- EN 12390-13:2014. Testing Hardened Concrete–Part 13: Determination of Secant Modulus of Elasticity in Compression; International Standards Organization: Geneva, Switzerland, 2014. [Google Scholar]

- Cała, M.; Wałach, D.; Dybeł, P.; Kucharska, M.; Jaskowska-Lemańska, J.; Guzy, Z.; Barciński, T.; Baran, J.; Musiał, J.; Sikorski, A.; et al. Landing Once on Phobos LOOP: D5.1.1: LBT and GTT Design Description. Project funded by European Space Agency. Unpublished work. 2021. [Google Scholar]

- TEMA User’s Guide; Image Systems AB: Linköping, Switzerland, 2011.

- Goldsztejn, P.; Skrzypek, G. Application of interpolation methods for numerical plotting of geologic surface maps from irregularly distributed data. Prz. Geol. 2004, 52, 233–236. (In Polish) [Google Scholar]

- Cała, M.; Kowalski, M. Landing Once on Phobos LOOP: D6.3: GTT & LBT Numerical Validation Report. Project funded by European Space Agency. Unpublished work. 2021. [Google Scholar]

- Cała, M.; Kolano, M.; Kucharska, M.; Cyran, K. Landing Once on Phobos LOOP: D3.1: Test Report Selected Materials Properties. Project funded by European Space Agency. Unpublished work. 2021. [Google Scholar]

- Cała, M.; Wałach, D.; Kohut, P.; Holak, K.; Kucharska, M.; Kaczmarczyk, G. Landing Once on Phobos LOOP: D6.1: LBT Test Report. Project funded by European Space Agency. Unpublished work. 2021. [Google Scholar]

| 2D Vision System | 3D Vision System |

|---|---|

One high-speed camera (Phantom VEO 340L) equipped with:

| Two high-speed cameras (Phantom v9.1) equipped with:

|

Settings:

and an analogue: 898 mm | Settings:

and an analogue: ~1.5 m |

| A lighting system: Two halogen lamps (2 × 500 W) | |

| Image-based processing software: Tema-Automotive [60] | |

| Properties of Materials | Foam Concrete | Concrete |

|---|---|---|

| Bulk density (g/cm3) | 0.80 | 2.24 |

| Uniaxial compressive strength (MPa) | 6.30 | 49.53 |

| Splitting tensile strength (MPa) | 1.25 | 3.23 |

| Modulus of elasticity (GPa) | 6.21 | 34.12 |

| Test No. | I | II | III | IV | V | VI |

|---|---|---|---|---|---|---|

| Thickness of analogue/concrete (cm) | 30/70 | 30/70 | 30/70 | 10/90 | 10/90 | 10/90 |

| Contact duration (ms) | 5 | 5 | 6 | 6 | 5 | 5 |

| Velocity at the time of contact (m/s) | −1.216 | −2.924 | −3.466 | −1.196 | −2.910 | −3.326 |

| Velocity relative to the 1 ms before beginning of contact (m/s) | −1.239 | −3.028 | −3.537 | −1.211 | −3.050 | −3.520 |

| Velocity relative to the 2 ms before beginning of contact (m/s) | −1.244 | −3.044 | −3.556 | −1.213 | −3.071 | −3.541 |

| Maximum displacement of the lander foot from the moment of contact with analogue (mm) | 4.485 | 10.035 | 13.439 | 4.918 | 9.547 | 10.259 |

| Test No. | I | II | III | IV | V | VI |

|---|---|---|---|---|---|---|

| Thickness of analogue/concrete (cm) | 30/70 | 30/70 | 30/70 | 10/90 | 10/90 | 10/90 |

| Velocity during contact (experiments) (m/s) | −1.216 | −2.924 | −3.466 | −1.196 | −2.911 | −3.326 |

| Velocity during contact (numerical simulations) (m/s) | −1.2 | −3.0 | −3.5 | −1.2 | −3.0 | −3.5 |

| Contact duration (experiments) (ms) | 5 | 5 | 6 | 6 | 5 | 5 |

| Contact duration (numerical simulations) (ms) | 6.4 | 6.4 | 6.5 | 6.4 | 6.4 | 6.4 |

| Maximum lander foot displacement since contact with analogue (experiments) (mm) | 4.485 | 10.035 | 13.439 | 4.918 | 9.547 | 10.259 |

| Maximum lander foot displacement since contact with analogue (numerical simulations) (mm) | 5.4 | 12.5 | 14.9 | 5.3 | 12.5 | 14.8 |

| Maximum lander foot acceleration since contact with analogue (experiments) (m/s2) | 308.341 | 643.614 | 733.067 | 269.583 | 646.673 | 780.951 |

| Maximum lander foot acceleration since contact with analogue (numerical simulations) (m/s2) | 320 | 750 | 880 | 320 | 750 | 880 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cała, M.; Kohut, P.; Holak, K.; Wałach, D. Vision-Based Approach in Contact Modelling between the Footpad of the Lander and the Analogue Representing Surface of Phobos. Sensors 2021, 21, 7009. https://doi.org/10.3390/s21217009

Cała M, Kohut P, Holak K, Wałach D. Vision-Based Approach in Contact Modelling between the Footpad of the Lander and the Analogue Representing Surface of Phobos. Sensors. 2021; 21(21):7009. https://doi.org/10.3390/s21217009

Chicago/Turabian StyleCała, Marek, Piotr Kohut, Krzysztof Holak, and Daniel Wałach. 2021. "Vision-Based Approach in Contact Modelling between the Footpad of the Lander and the Analogue Representing Surface of Phobos" Sensors 21, no. 21: 7009. https://doi.org/10.3390/s21217009

APA StyleCała, M., Kohut, P., Holak, K., & Wałach, D. (2021). Vision-Based Approach in Contact Modelling between the Footpad of the Lander and the Analogue Representing Surface of Phobos. Sensors, 21(21), 7009. https://doi.org/10.3390/s21217009