Ultra-Narrow SPP Generation from Ag Grating †

Abstract

:1. Introduction

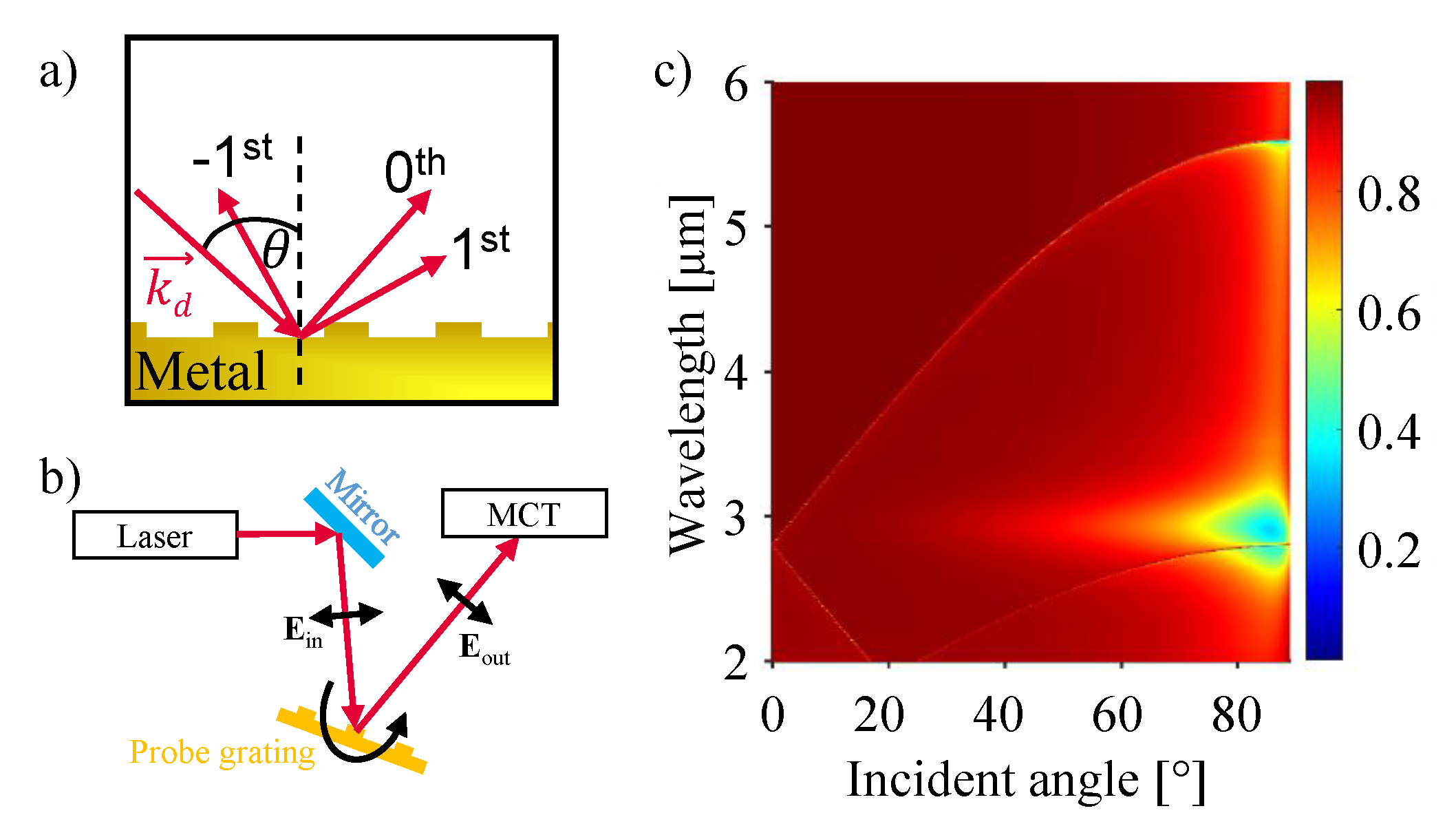

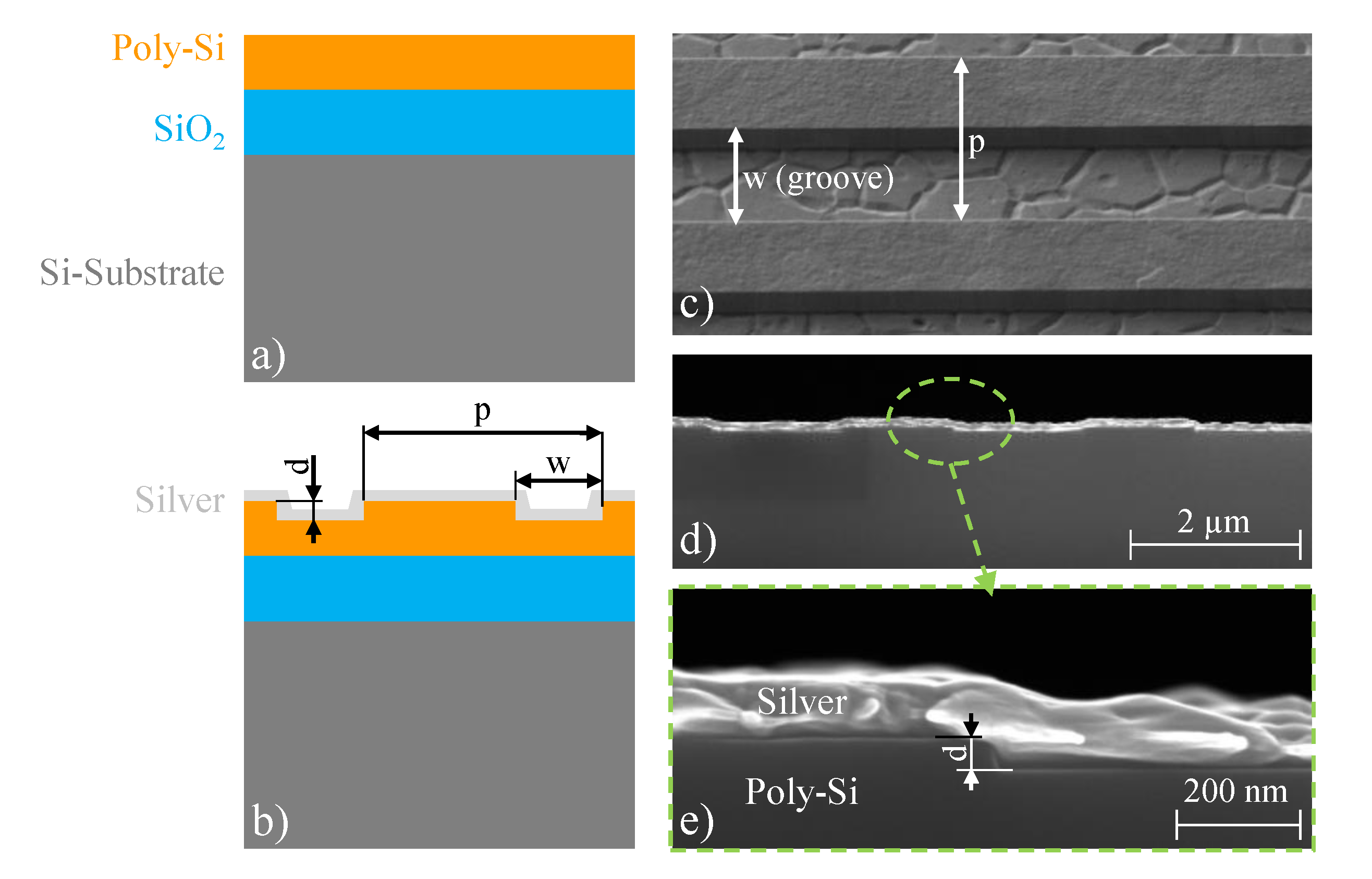

2. Materials and Methods

2.1. Surface Plasmon Polaritons

2.2. Optical Properties

2.3. Experimental Setup and Sample Fabrication

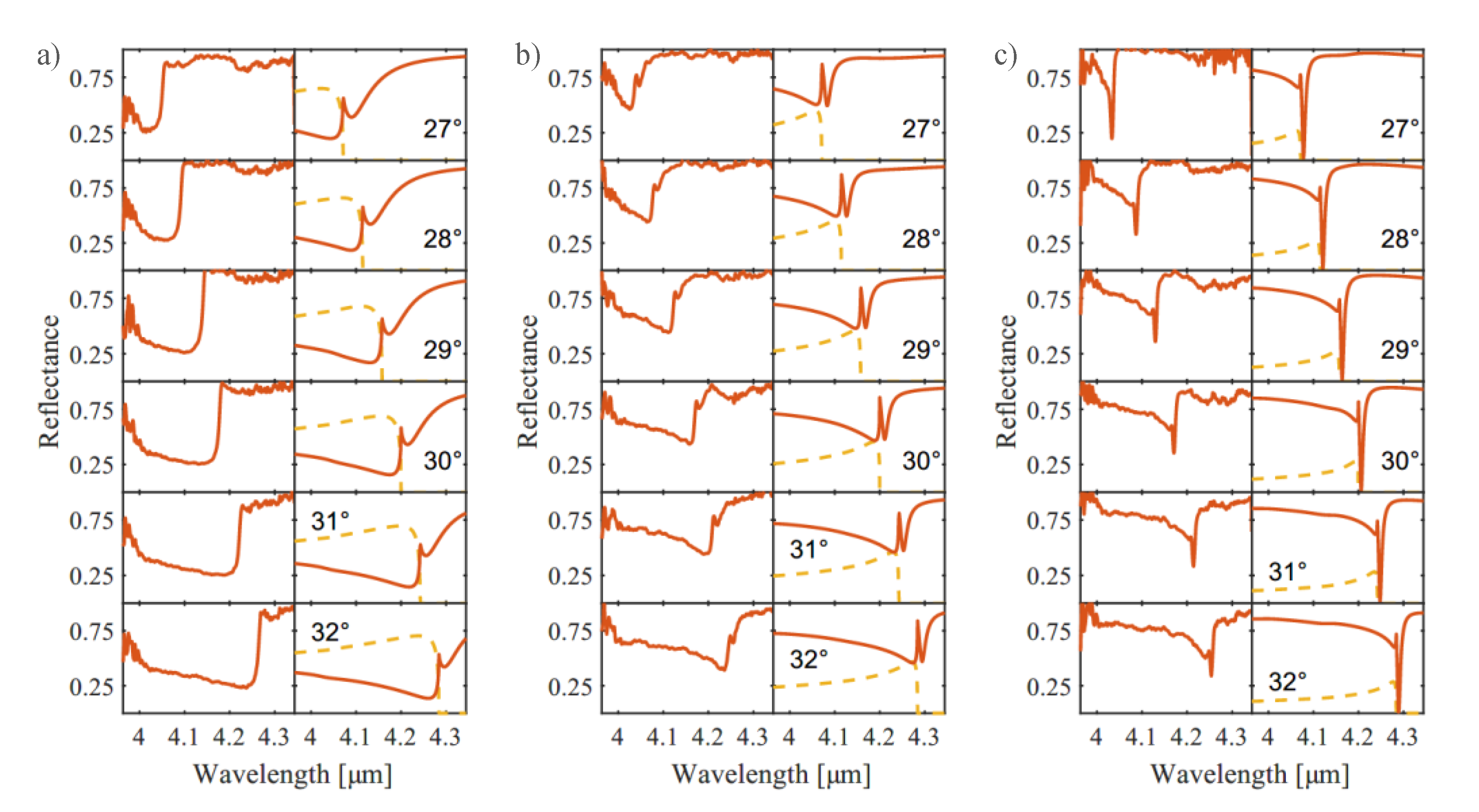

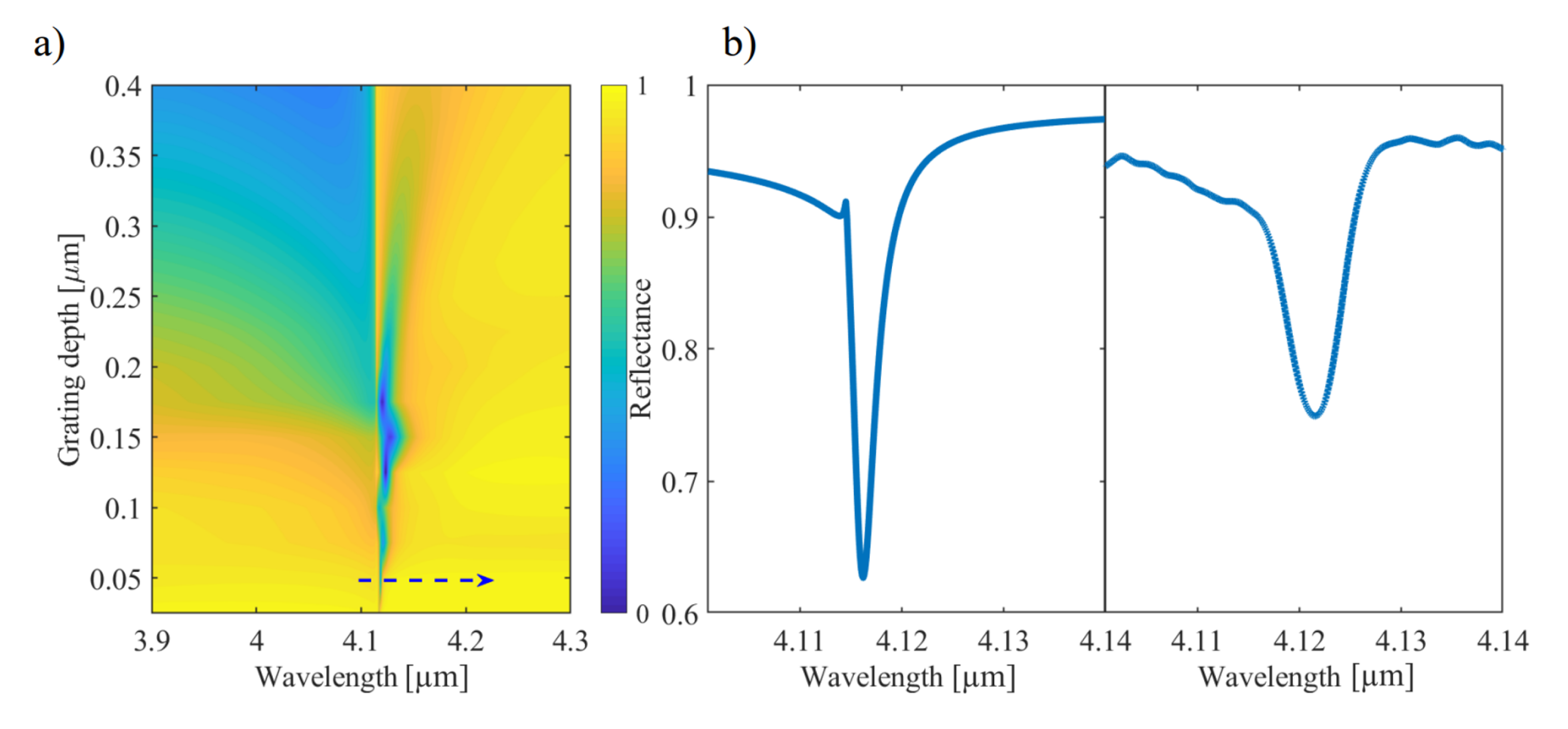

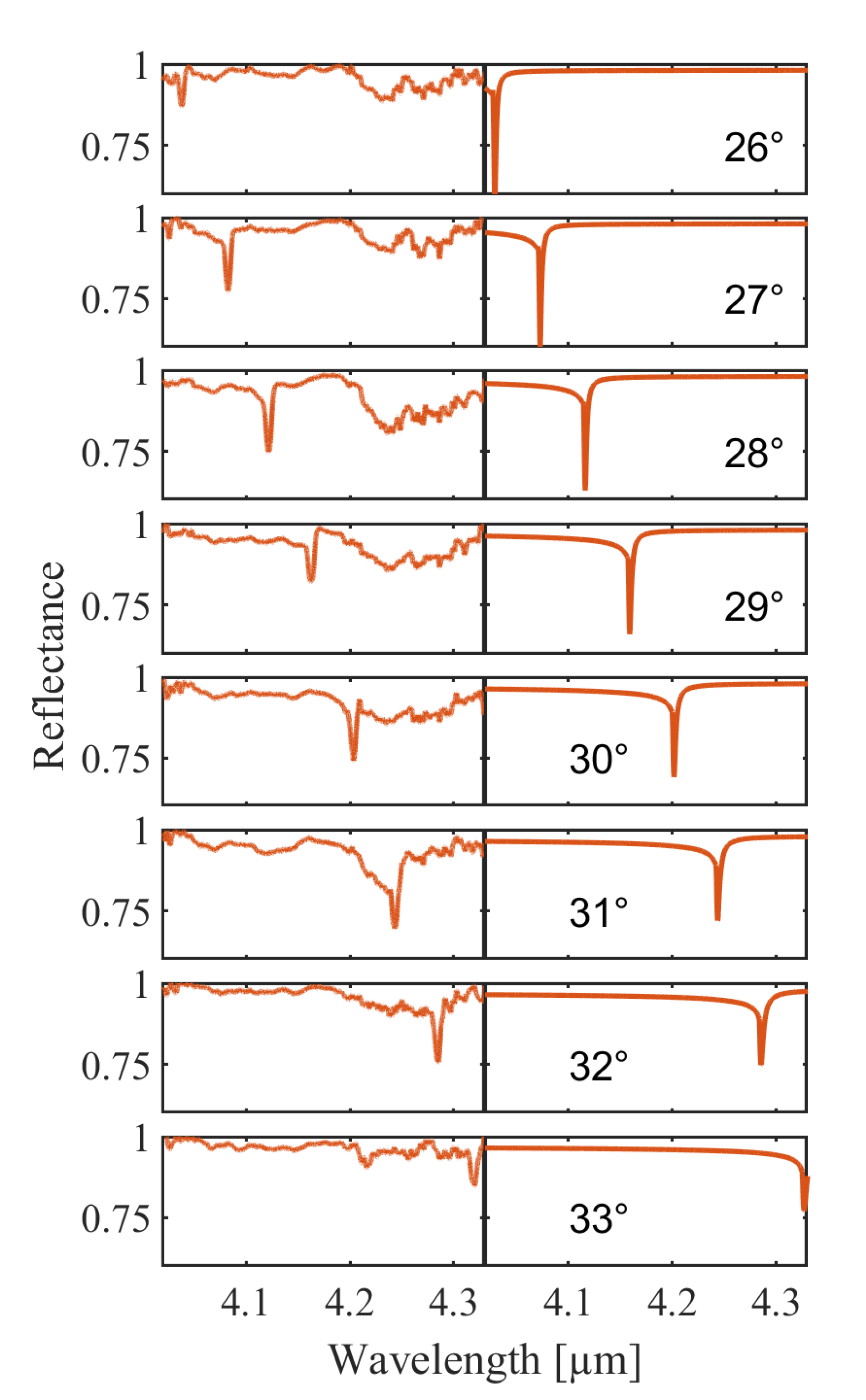

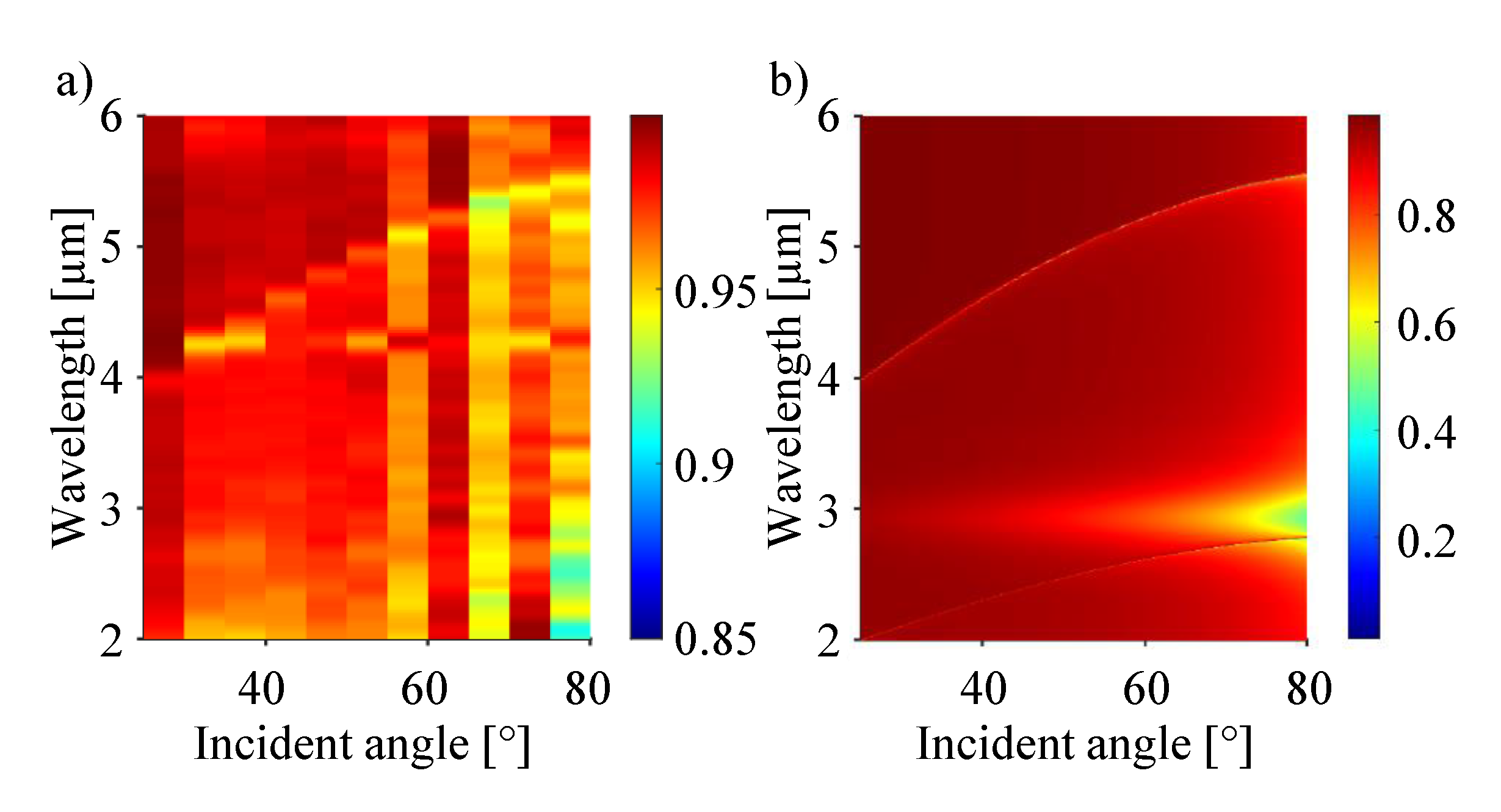

3. Results and Discussion

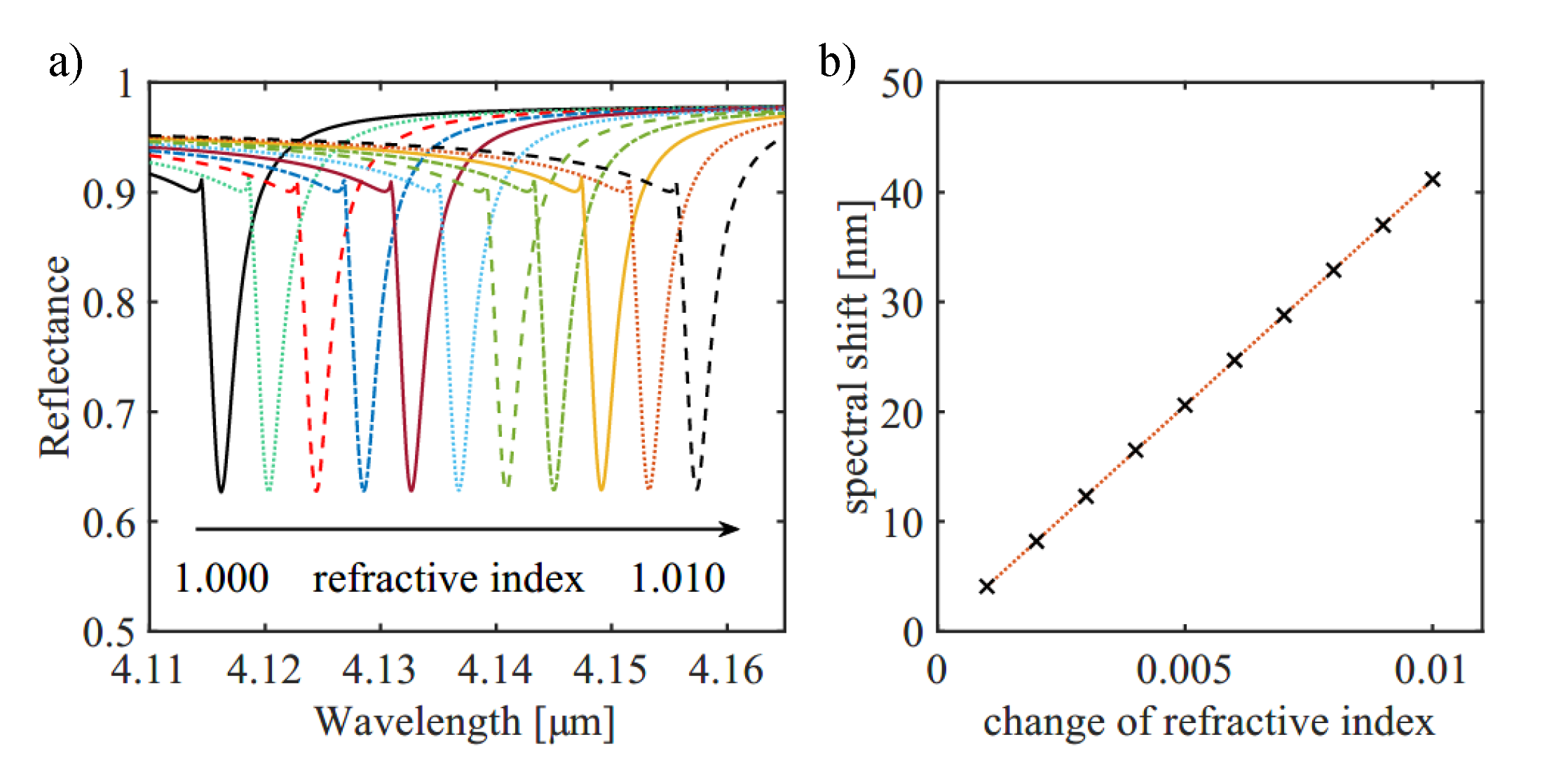

Potential Applications for Sensing

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Tong, L.; Wei, H.; Zhang, S.; Xu, H. Recent Advances in Plasmonic Sensors. Sensors 2014, 14, 7959–7973. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ibrahim, J.; Al Masri, M.; Verrier, I.; Kampfe, T.; Veillas, C.; Celle, F.; Cioulachtjian, S.; Lefèvre, F.; Jourlin, Y. Surface Plasmon Resonance Based Temperature Sensors in Liquid Environment. Sensors 2019, 19, 3354. [Google Scholar] [CrossRef] [Green Version]

- Liu, Y.; Ma, Y. One-Dimensional Plasmonic Sensors. Front. Phys. 2020, 8, 312. [Google Scholar] [CrossRef]

- Liu, N.; Mesch, M.; Weiss, T.; Hentschel, M.; Giessen, H. Infrared Perfect Absorber and Its Application As Plasmonic Sensor. Nano Lett. 2010, 10, 2342–2348. [Google Scholar] [CrossRef]

- Martínez, J.; Ródenas, A.; Aguiló, M.; Fernandez, T.; Solis, J.; Díaz, F. Mid-infrared surface plasmon polariton chemical sensing on fiber-coupled ITO coated glass. Opt. Lett. 2016, 41, 2493–2496. [Google Scholar] [CrossRef] [Green Version]

- Wan, B.F.; Zhou, Z.W.; Xu, Y.; Zhang, H.F. A Theoretical Proposal for a Refractive Index and Angle Sensor Based on One-Dimensional Photonic Crystals. IEEE Sens. J. 2021, 21, 331–338. [Google Scholar] [CrossRef]

- Wan, B.F.; Xu, Y.; Zhou, Z.W.; Zhang, D.; Zhang, H.F. Theoretical Investigation of a Sensor Based on One-Dimensional Photonic Crystals to Measure Four Physical Quantities. IEEE Sens. J. 2021, 21, 2846–2853. [Google Scholar] [CrossRef]

- Ranacher, C.; Consani, C.; Tortschanoff, A.; Jannesari, R.; Bergmeister, M.; Grille, T.; Jakoby, B. Mid-infrared absorption gas sensing using a silicon strip waveguide. Sens. Actuators Phys. 2018, 277, 117–123. [Google Scholar] [CrossRef]

- Miyazaki, H.T.; Ikeda, K.; Kasaya, T.; Yamamoto, K.; Inoue, Y.; Fujimura, K.; Kanakugi, T.; Okada, M.; Hatade, K.; Kitagawa, S. Thermal emission of two-color polarized infrared waves from integrated plasmon cavities. Appl. Phys. Lett. 2008, 92, 141114. [Google Scholar] [CrossRef]

- Liu, X.; Tyler, T.; Starr, T.; Starr, A.F.; Jokerst, N.M.; Padilla, W.J. Taming the Blackbody with Infrared Metamaterials as Selective Thermal Emitters. Phys. Rev. Lett. 2011, 107, 045901. [Google Scholar] [CrossRef] [Green Version]

- Ranacher, C.; Consani, C.; Tortschanoff, A.; Rauter, L.; Holzmann, D.; Fleury, C.; Stocker, G.; Fant, A.; Schaunig, H.; Irsigler, P.; et al. A CMOS Compatible Pyroelectric Mid-Infrared Detector Based on Aluminium Nitride. Sensors 2019, 19, 2513. [Google Scholar] [CrossRef] [Green Version]

- Cheng, F.; Yang, X.; Gao, J. Enhancing intensity and refractive index sensing capability with infrared plasmonic perfect absorbers. Opt. Lett. 2014, 39, 3185–3188. [Google Scholar] [CrossRef]

- Cerjan, B.; Yang, X.; Nordlander, P.; Halas, N.J. Asymmetric Aluminum Antennas for Self-Calibrating Surface-Enhanced Infrared Absorption Spectroscopy. ACS Photonics 2016, 3, 356–360. [Google Scholar] [CrossRef]

- Stocker, G.; Spettel, J.; Dao, T.D.; Tortschanoff, A.; Jannesari, R.; Pühringer, G.; Saeidi, P.; Dubois, F.; Fleury, C.; Consani, C.; et al. Plasmonic Silver Grating for Mid-Infrared Sensing. In Proceedings of the 21st International Conference on Solid-State Sensors, Actuators and Microsystems (Transducers), Orlando, FL, USA, 20–24 June 2021; pp. 1072–1075. [Google Scholar] [CrossRef]

- Maier, S.A. Plasmonics: Fundamentals And Applications; Springer: New York, NY, USA, 2007. [Google Scholar] [CrossRef]

- Barnes, W.L.; Dereux, A.; Ebbesen, T.W. Surface plasmon subwavelength optics. Nature 2003, 424, 824–830. [Google Scholar] [CrossRef] [PubMed]

- Kretschmann, E.; Raether, H. Radiative Decay of Non Radiative Surface Plasmons Excited by Light. Z. Naturfaroschung 1968, 23, 2135–2136. [Google Scholar] [CrossRef]

- Otto, A. Excitation of nonradiative surface plasma waves in silver by the method of frustrated total reflection. Z. Physik 1968, 216, 398–410. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, L.; Xu, W. Surface plasmon polaritons: Physics and applications. J. Phys. Appl. Phys. 2012, 45, 113001. [Google Scholar] [CrossRef]

- Sambles, J.R.; Bradbery, G.W.; Yang, F. Optical excitation of surface plasmons: An introduction. Contemp. Phys. 1991, 32, 173–183. [Google Scholar] [CrossRef]

- Meng, L.; Zhao, D.; Ruan, Z.; Li, Q.; Yang, Y.; Qiu, M. Optimized grating as an ultra-narrow band absorber or plasmonic sensor. Opt. Lett. 2014, 39, 1137–1140. [Google Scholar] [CrossRef] [PubMed]

- Fan, S.; Suh, W.; Joannopoulos, J.D. Temporal coupled-mode theory for the Fano resonance in optical resonators. J. Opt. Soc. Am. A 2003, 20, 569–572. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yoon, J.; Seol, K.H.; Song, S.H.; Magnusson, R. Critical coupling in dissipative surface-plasmon resonators with multiple ports. Opt. Express 2010, 18, 25702–25711. [Google Scholar] [CrossRef]

- Rakić, A.D.; Djurišić, A.B.; Elazar, J.M.; Majewski, M.L. Optical properties of metallic films for vertical-cavity optoelectronic devices. Appl. Opt. 1998, 37, 5271–5283. [Google Scholar] [CrossRef]

- West, P.; Ishii, S.; Naik, G.; Emani, N.; Shalaev, V.; Boltasseva, A. Searching for better plasmonic materials. Laser Photonics Rev. 2010, 4, 795–808. [Google Scholar] [CrossRef] [Green Version]

- Spettel, J.; Stocker, G.; Dao, T.D.; Jannesari, R.; Tortschanoff, A.; Saeidi, P.; Pühringer, G.; Dubois, F.; Fleury, C.; Consani, C.; et al. Aluminium, gold-tin and titanium-tungsten alloys for mid-infrared plasmonic gratings. Opt. Mater. Express 2021, 11, 1058–1069. [Google Scholar] [CrossRef]

- Pusep, Y.; Rodrigues, A.; Borrero-Gon, L.; Acquaroli, L.; Urteaga, R.; Arce, R.; Koropecki, R.; Tirado, M.; Comedi, D. Fano resonance in heavily doped porous silicon. J. Raman Spectrosc. 2011, 42, 1405. [Google Scholar] [CrossRef]

- Racu, A.M.; Menzel, D.; Schoenes, J.; Doll, K. Crystallographic disorder and electron-phonon coupling in Fe1-xCoxSi single crystals: Raman spectroscopy study. Phys. Rev. B 2007, 76, 115103. [Google Scholar] [CrossRef]

- Yue, W.; Wang, Z.; Yang, Y.; Han, J.; Li, J.; Guo, Z.; Tan, H.; Zhang, X.X. High Performance Infrared Plasmonic Metamaterial Absorbers and Their Applications to Thin-film Sensing. Plasmonics 2016, 11, 1557–1563. [Google Scholar] [CrossRef]

- Lodewijks, K.; Ryken, J.; Van Roy, W.; Borghs, G.; Lagae, L.; Van Dorpe, P. Tuning the Fano Resonance Between Localized and Propagating Surface Plasmon Resonances for Refractive Index Sensing Applications. Plasmonics 2013, 8, 1379–1385. [Google Scholar] [CrossRef] [Green Version]

- Wen, Y.; Sun, Y.; Deng, C.; Huang, L.; Hu, G.; Yun, B.; Zhang, R.; Cui, Y. High sensitivity and FOM refractive index sensing based on Fano resonance in all-grating racetrack resonators. Opt. Commun. 2019, 446, 141–146. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Stocker, G.; Spettel, J.; Dao, T.D.; Tortschanoff, A.; Jannesari, R.; Pühringer, G.; Saeidi, P.; Dubois, F.; Fleury, C.; Consani, C.; et al. Ultra-Narrow SPP Generation from Ag Grating. Sensors 2021, 21, 6993. https://doi.org/10.3390/s21216993

Stocker G, Spettel J, Dao TD, Tortschanoff A, Jannesari R, Pühringer G, Saeidi P, Dubois F, Fleury C, Consani C, et al. Ultra-Narrow SPP Generation from Ag Grating. Sensors. 2021; 21(21):6993. https://doi.org/10.3390/s21216993

Chicago/Turabian StyleStocker, Gerald, Jasmin Spettel, Thang Duy Dao, Andreas Tortschanoff, Reyhaneh Jannesari, Gerald Pühringer, Parviz Saeidi, Florian Dubois, Clement Fleury, Cristina Consani, and et al. 2021. "Ultra-Narrow SPP Generation from Ag Grating" Sensors 21, no. 21: 6993. https://doi.org/10.3390/s21216993

APA StyleStocker, G., Spettel, J., Dao, T. D., Tortschanoff, A., Jannesari, R., Pühringer, G., Saeidi, P., Dubois, F., Fleury, C., Consani, C., Grille, T., Aschauer, E., & Jakoby, B. (2021). Ultra-Narrow SPP Generation from Ag Grating. Sensors, 21(21), 6993. https://doi.org/10.3390/s21216993