A Crack Size Quantification Method Using High-Resolution Lamb Waves

Abstract

:1. Introduction

2. Theory of High-Resolution Lamb Waveform Design

2.1. Theory of Lamb Wave Pulse Compression

2.2. Excitation Waveform Design

2.2.1. L-Chirp Signal

2.2.2. Golay Complementary Code

3. Excitation Waveform Design for Crack Detection

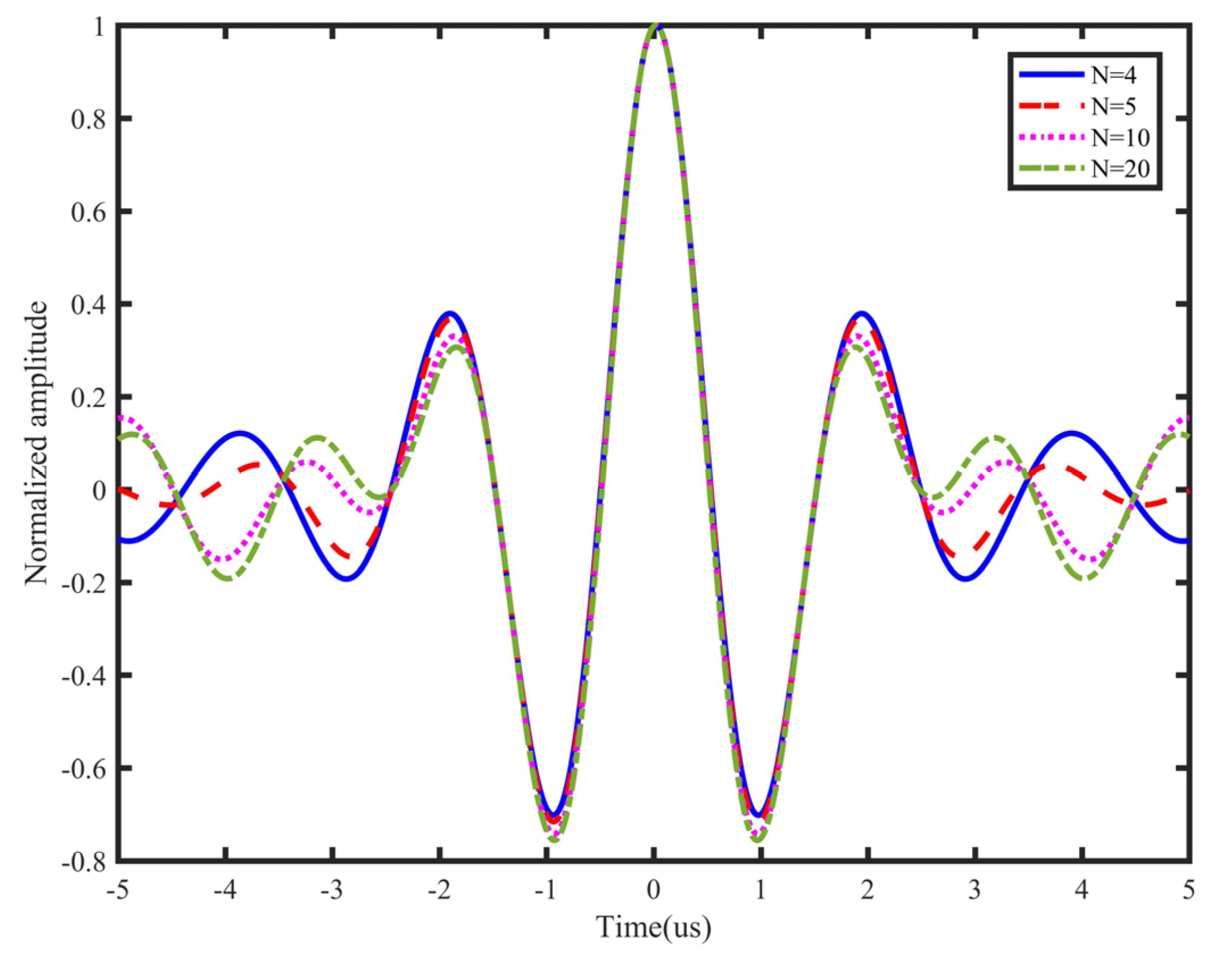

3.1. Number of Periods

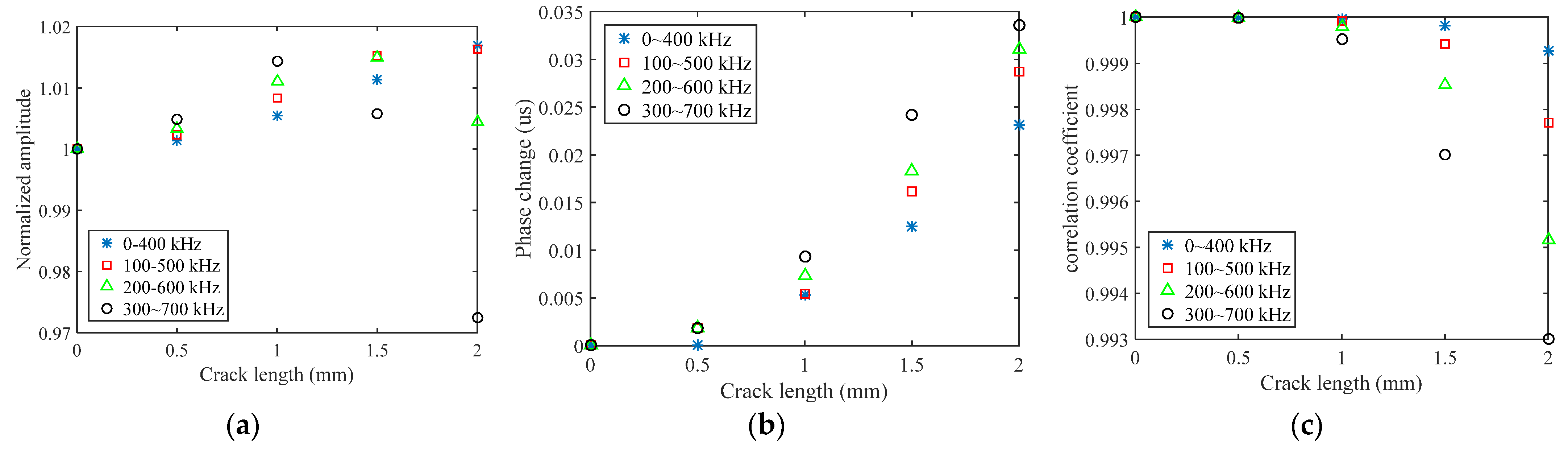

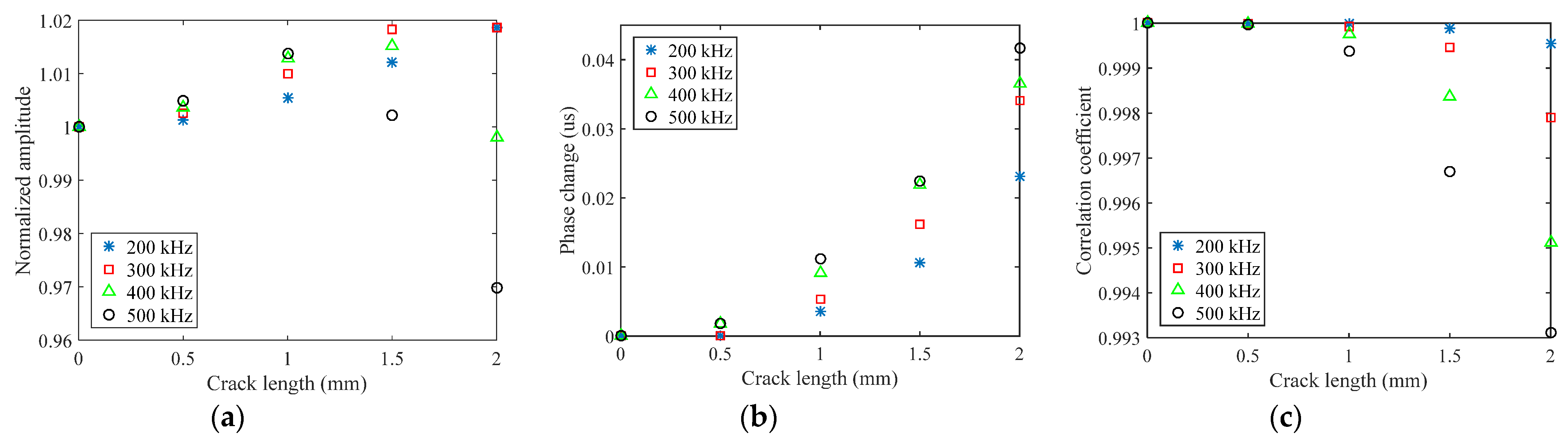

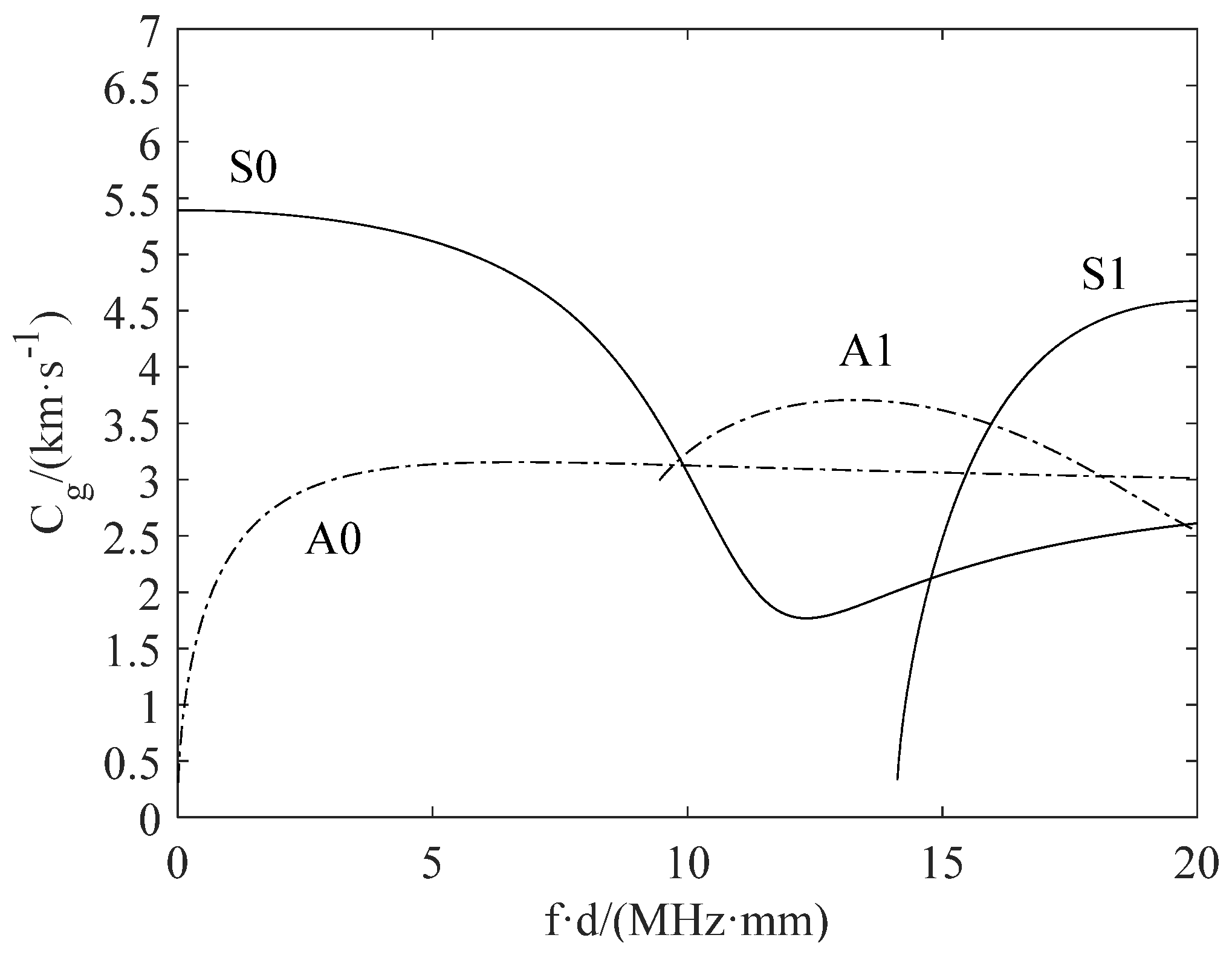

3.2. Frequency Range

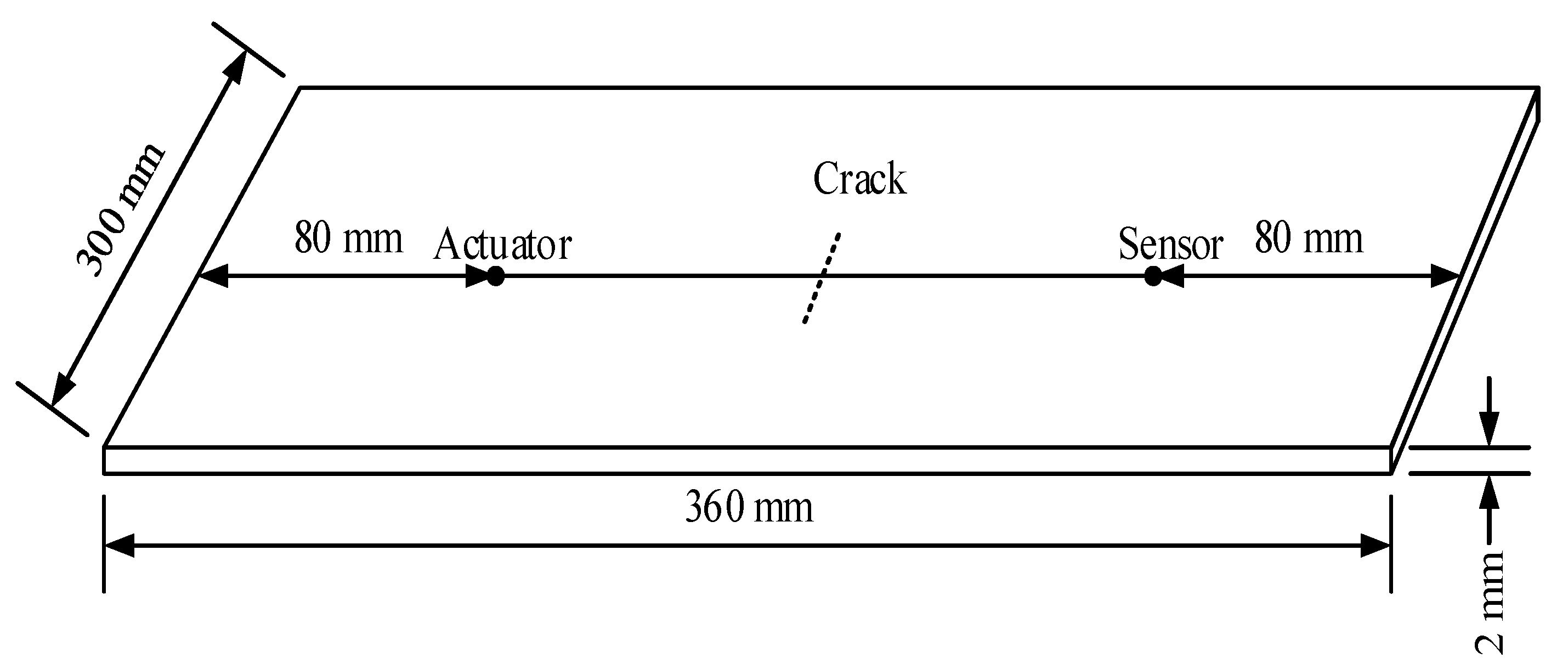

4. Detection Model Establishment

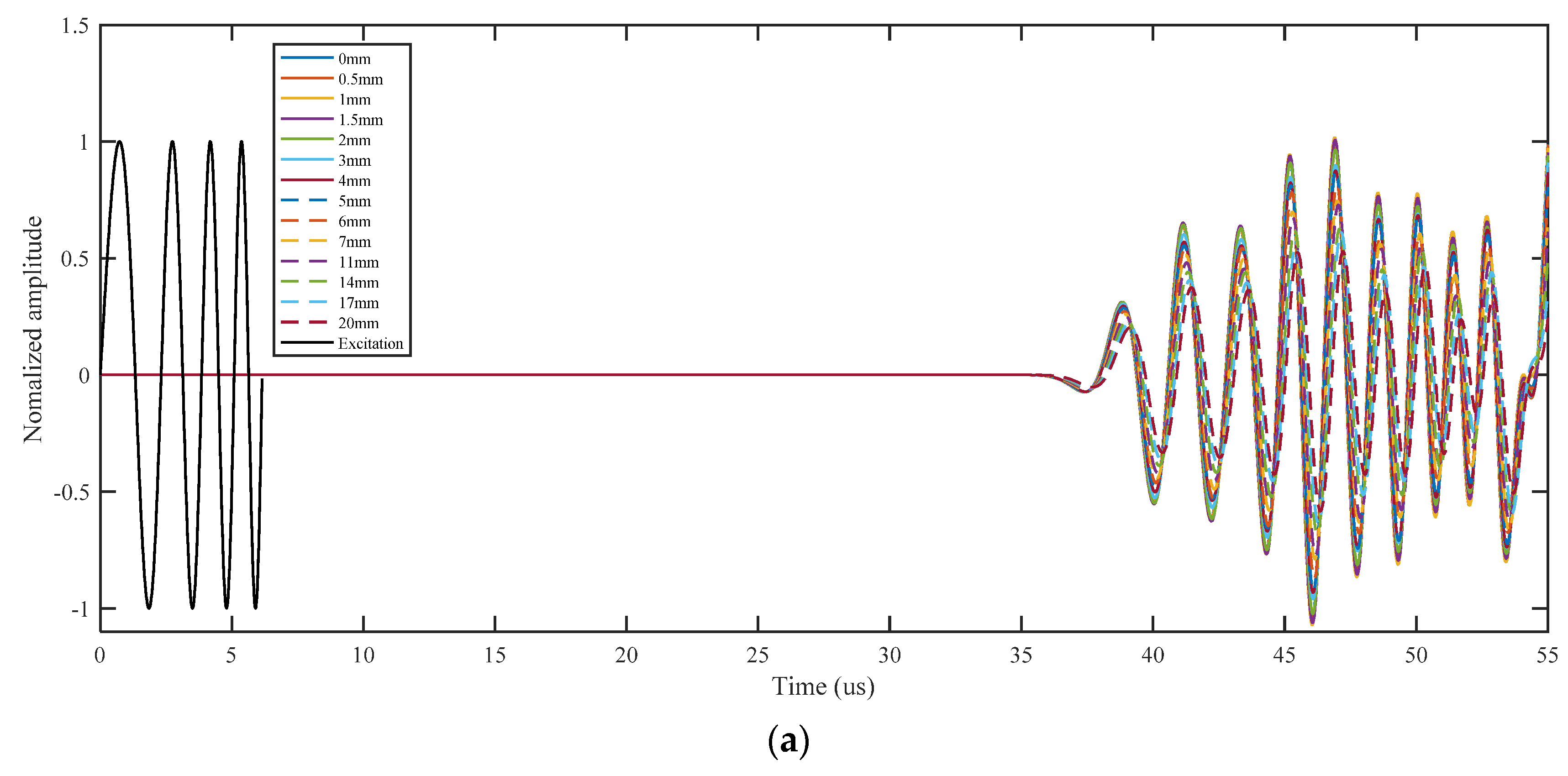

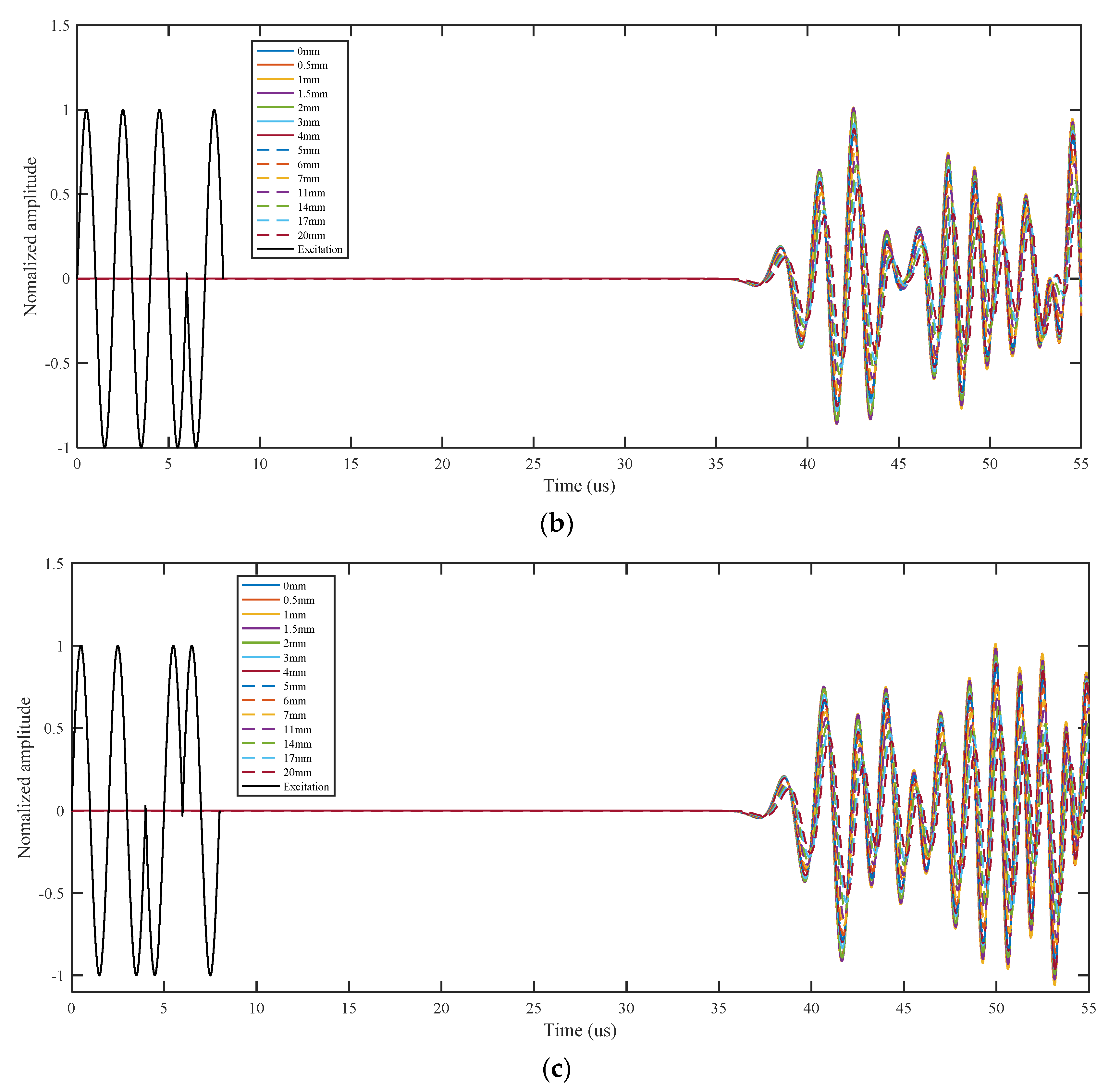

4.1. High-Resolution Lamb Wave Simulation

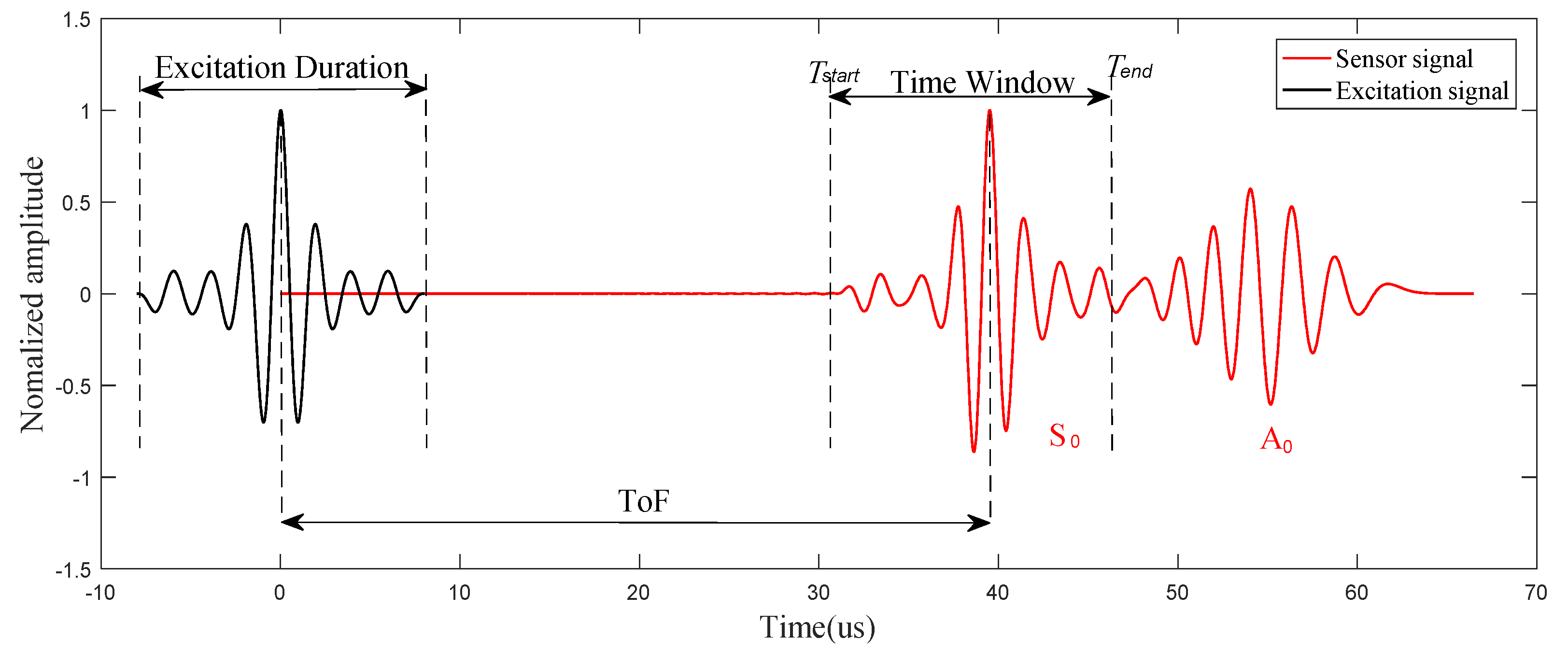

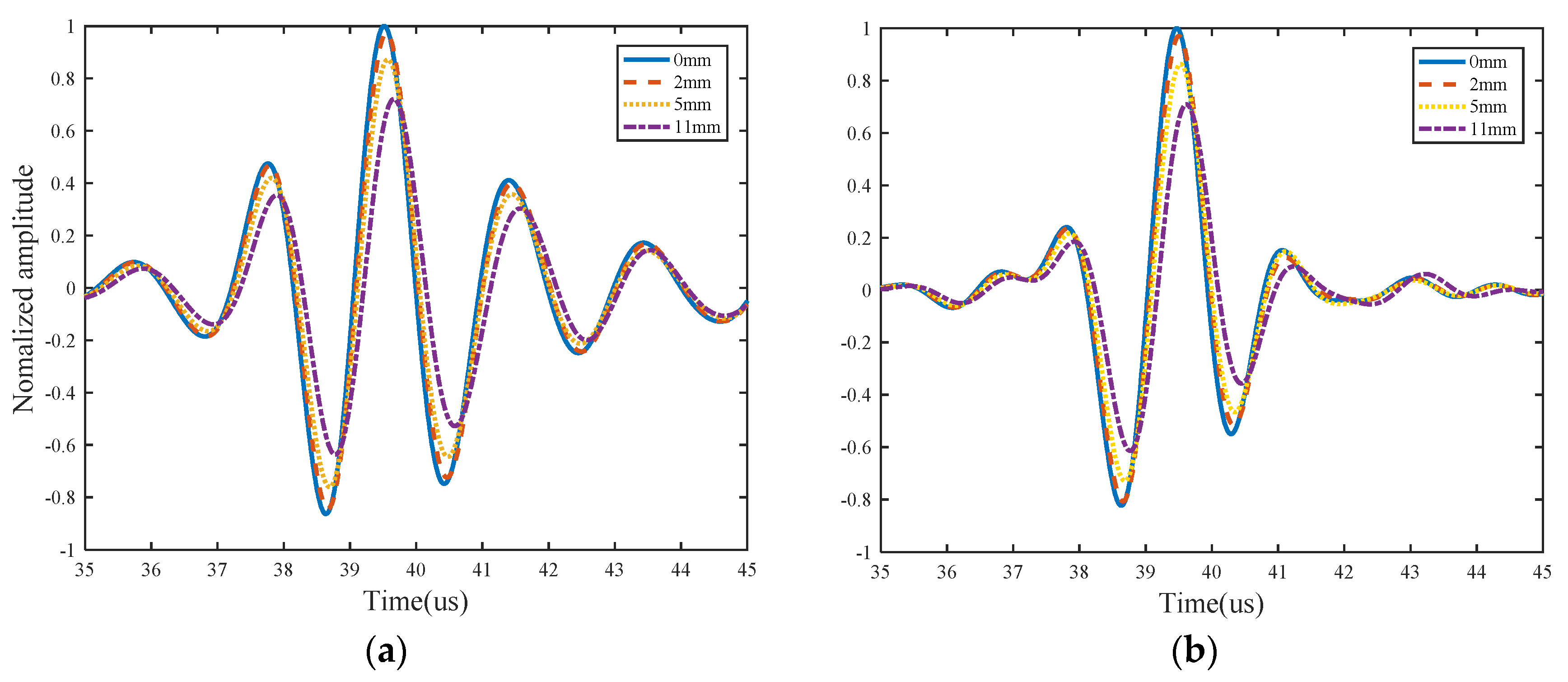

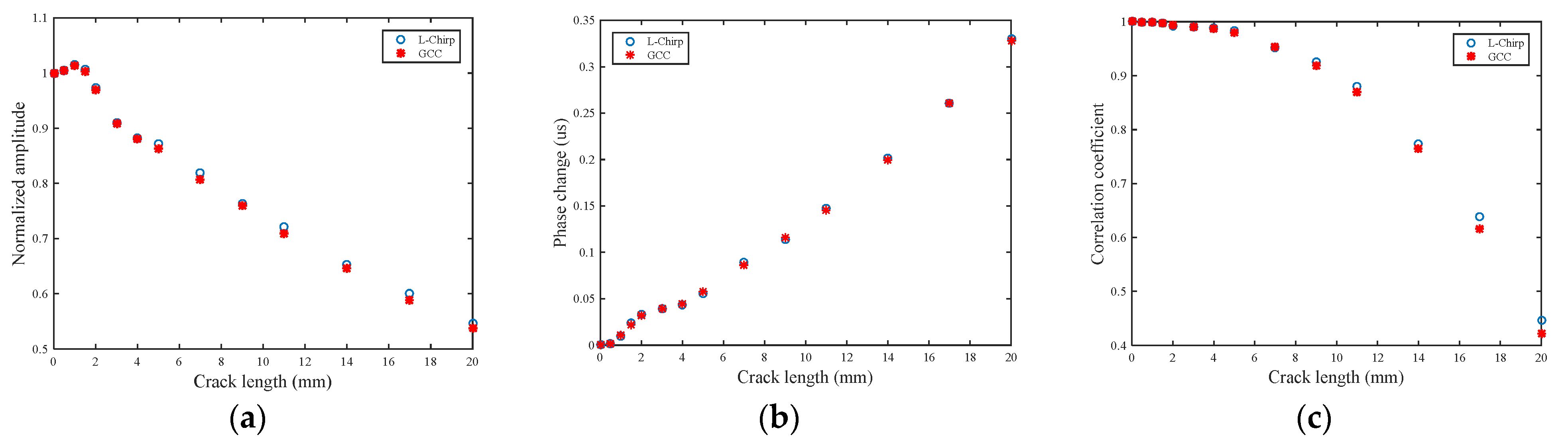

4.2. Signal Processing

4.3. Crack Quantification Model

4.4. Model Performance Verification

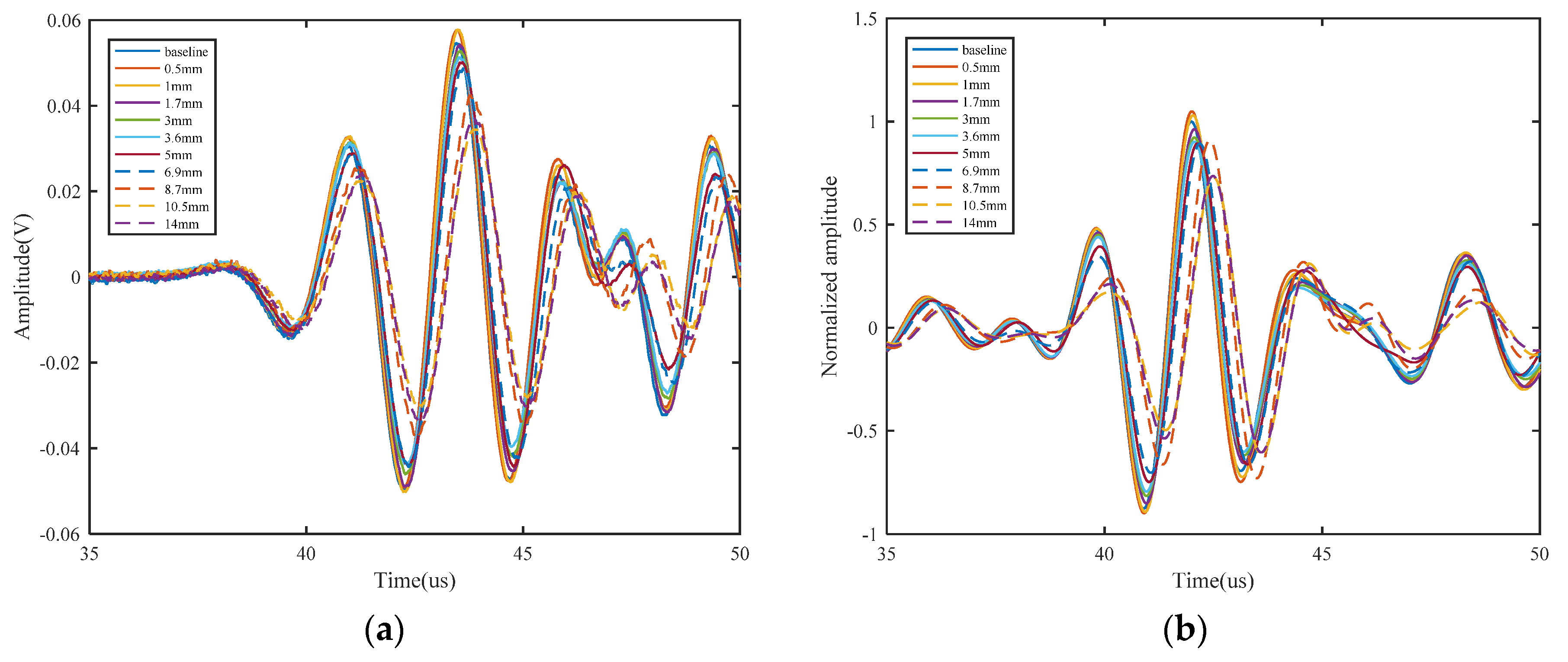

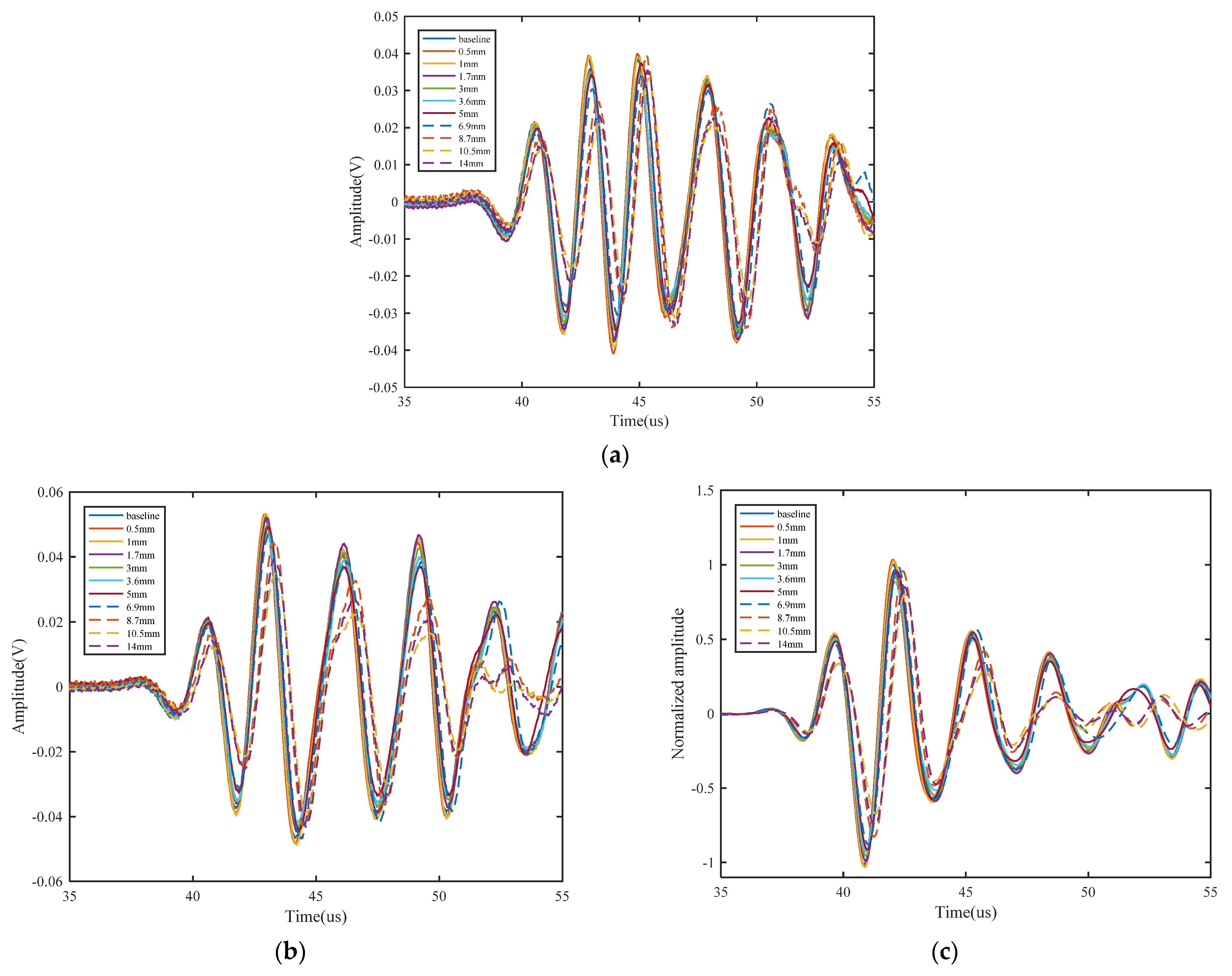

5. Experimental Validation

5.1. Experimental Designs

5.2. Crack Detection Results

6. Conclusions

- The parameter optimization of high-resolution waveforms for crack detection is studied, and a strategy for the number of periods and frequency range determination is established. The high-resolution Lamb wave can obtain a wider frequency range than a tone burst signal, which is beneficial for initial crack detection.

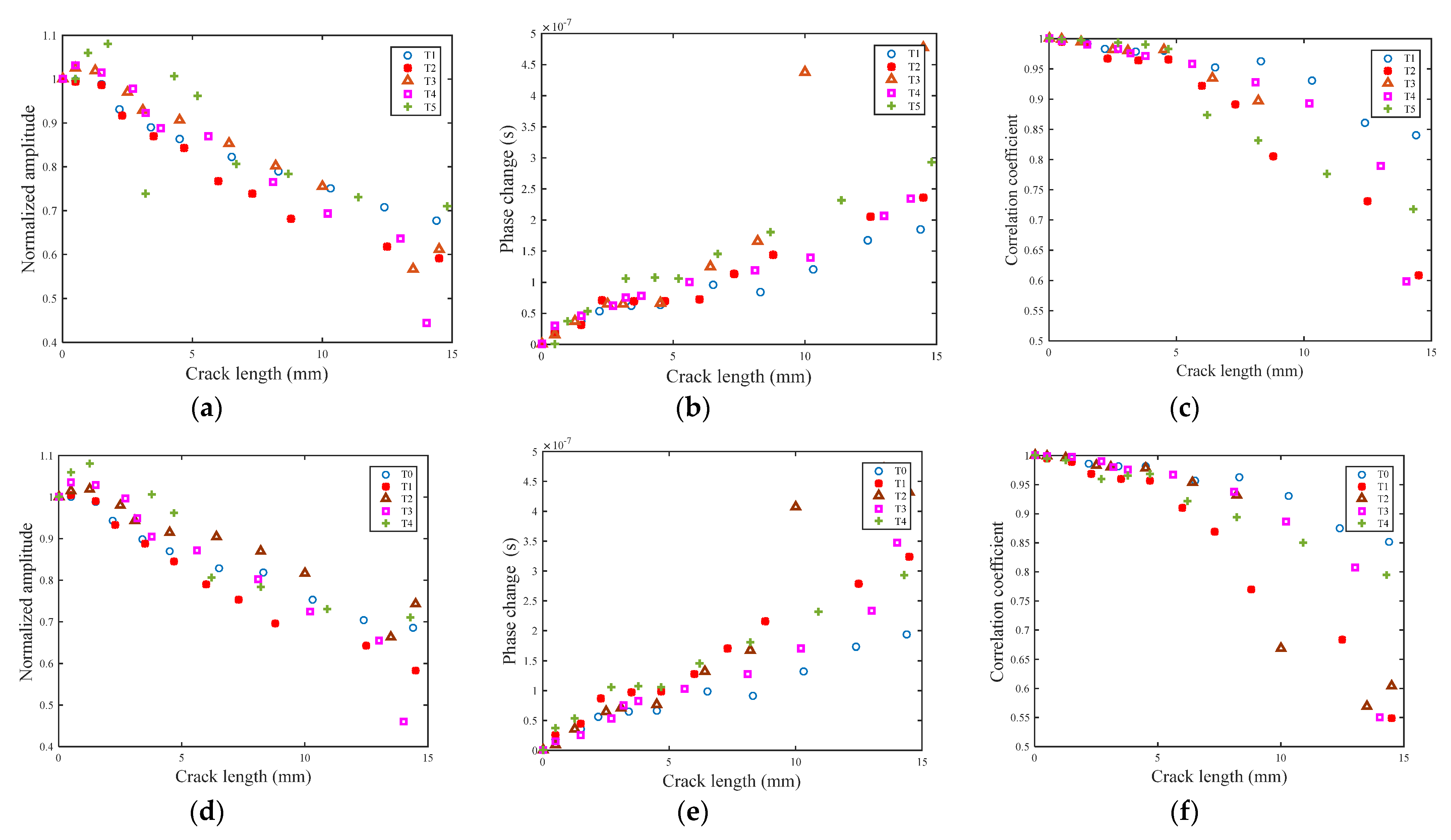

- The pulse compression technique is used to improve the resolution and make the processed waveform change more obvious in the damaged structure. Three damage features, namely normalized amplitude, phase change, and the correlation coefficient, are extracted from the S0 direct wave packets after pulse compression. The regression model using these three features yield satisfactory prediction results.

- The numerical studies and experimental validation are both conducted on the aluminum alloy plate for verification. The results illustrate that L-Chirp and GCC with higher frequency have a greater capacity for identifying both the initial crack and longer crack size than the traditional Hanning-widowed tone burst.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhao, X.L.; Qian, T.; Mei, G.; Kwan, C.; Zane, R.; Walsh, C.; Paing, T.; Popovic, Z. Active health monitoring of an aircraft wing with an embedded piezoelectric sensor/actuator network: II. Wireless approaches. Smart Mater. Struct. 2007, 16, 1218–1225. [Google Scholar] [CrossRef]

- Senyurek, V.Y. Detection of cuts and impact damage at the aircraft wing slat by using Lamb wave method. Measurement 2015, 67, 10–23. [Google Scholar] [CrossRef]

- Lu, Y.; Ye, L.; Su, Z.Q.; Huang, N. Quantitative evaluation of crack orientation in aluminium plates based on Lamb waves. Smart Mater. Struct. 2007, 16, 1907–1914. [Google Scholar] [CrossRef]

- Lin, J.; Hua, J.; Zeng, L.; Luo, Z. Excitation Waveform Design for Lamb Wave Pulse Compression. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2016, 63, 165–177. [Google Scholar] [CrossRef] [PubMed]

- Dubuc, B.; Ebrahimkhanlou, A.; Livadiotis, S.; Salamone, S. Inversion algorithm for Lamb-wave-based depth characterization of acoustic emission sources in plate-like structures. Ultrasonics 2019, 99, 105975. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Zhou, S.; Ning, H.; Yan, C.; Hu, N. An Inverse Approach of Damage Identification Using Lamb Wave Tomography. Sensors 2019, 19, 2180. [Google Scholar] [CrossRef] [Green Version]

- Su, C.H.; Jiang, M.S.; Lv, S.S.; Zhang, L.; Zhang, F.Y.; Lu, S.Z.; Sui, Q.M. Damage imaging for composite using Lamb wave based on minimum variance distortion-less response method. Trans. Inst. Meas. Control 2019, 41, 4179–4186. [Google Scholar] [CrossRef]

- He, J.; Yang, J.; Wang, Y.; Waisman, H.; Zhang, W. Probabilistic Model Updating for Sizing of Hole-Edge Crack Using Fiber Bragg Grating Sensors and the High-Order Extended Finite Element Method. Sensors 2016, 16, 1965. [Google Scholar] [CrossRef] [Green Version]

- Yang, J.; He, J.; Guan, X.; Wang, D.; Chen, H.; Zhang, W.; Liu, Y. A probabilistic crack size quantification method using in-situ Lamb wave test and Bayesian updating. Mech. Syst. Signal Process. 2016, 78, 118–133. [Google Scholar] [CrossRef]

- Ihn, J.-B.; Chang, F.-K. Detection and monitoring of hidden fatigue crack growth using a built-in piezoelectric sensor/actuator network: I. Diagnostics. Smart Mater. Struct. 2004, 13, 609–620. [Google Scholar] [CrossRef]

- Ihn, J.-B.; Chang, F.-K. Detection and monitoring of hidden fatigue crack growth using a built-in piezoelectric sensor/actuator network: II. Validation using riveted joints and repair patches. Smart Mater. Struct. 2004, 13, 621–630. [Google Scholar] [CrossRef]

- Liu, S.; Du, C.; Zhang, J. Intelligent diagnosis of structural cracks with optimized sensing network. Microsyst. Technol. 2013, 19, 1653–1660. [Google Scholar] [CrossRef]

- Dao, P.B.; Staszewski, W.J. Lamb wave based structural damage detection using cointegration and fractal signal processing. Mech. Syst. Signal Process. 2014, 49, 285–301. [Google Scholar] [CrossRef]

- Wang, C.H.; Rose, J.T.; Chang, F.-K. A synthetic time-reversal imaging method for structural health monitoring. Smart Mater. Struct. 2004, 13, 415–423. [Google Scholar] [CrossRef]

- He, J.J.; Guan, X.F.; Peng, T.S.; Liu, Y.M.; Saxena, A.; Celaya, J.; Goebel, K. A multi-feature integration method for fatigue crack detection and crack length estimation in riveted lap joints using Lamb waves. Smart Mater. Struct. 2013, 22, 12. [Google Scholar] [CrossRef]

- He, J.; Ran, Y.; Liu, B.; Yang, J.; Guan, X. A Fatigue Crack Size Evaluation Method Based on Lamb Wave Simulation and Limited Experimental Data. Sensors 2017, 17, 2097. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chen, J.; Yuan, S.; Qiu, L.; Cai, J.; Yang, W. Research on a Lamb Wave and Particle Filter-Based On-Line Crack Propagation Prognosis Method. Sensors 2016, 16, 320. [Google Scholar] [CrossRef] [Green Version]

- Wang, R.; Wu, Q.; Yu, F.; Okabe, Y.; Xiong, K. Nonlinear ultrasonic detection for evaluating fatigue crack in metal plate. Struct. Health Monit. 2018, 18, 869–881. [Google Scholar] [CrossRef]

- Malo, S.; Fateri, S.; Livadas, M.; Mares, C.; Gan, T.H. Wave Mode Discrimination of Coded Ultrasonic Guided Waves Using Two-Dimensional Compressed Pulse Analysis. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2017, 64, 1092–1101. [Google Scholar] [CrossRef]

- Lin, J.; Gao, F.; Luo, Z.; Zeng, L. High-Resolution Lamb Wave Inspection in Viscoelastic Composite Laminates. IEEE Trans. Ind. Electron. 2016, 63, 6989–6998. [Google Scholar] [CrossRef]

- Hutchins, D.; Burrascano, P.; Davis, L.; Laureti, S.; Ricci, M. Coded waveforms for optimised air-coupled ultrasonic nondestructive evaluation. Ultrasonics 2014, 54, 1745–1759. [Google Scholar] [CrossRef] [Green Version]

- Shen, C.C.; Shi, T.Y. Third harmonic transmit phasing for SNR improvement in tissue harmonic imaging with Golay-encoded excitation. Ultrasonics 2011, 51, 554–560. [Google Scholar] [CrossRef]

- Kazys, R.; Mazeika, L.; Barauskas, R.; Raisutis, R.; Cicenas, V.; Demcenko, A. 3D analysis of interaction of Lamb waves with defects in loaded steel plates. Ultrasonics 2006, 44 (Suppl. 1), e1127–e1130. [Google Scholar] [CrossRef]

- Wang, H.; Tang, Z.; Zhao, Y.; Chen, Y.; Zhu, Z.; Zhang, Y. Signal Processing and Target Fusion Detection via Dual Platform Radar Cooperative Illumination. Sensors 2019, 19, 5341. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yang, J.; Zhao, B.; Liu, B. Distance and Velocity Measurement of Coherent Lidar Based on Chirp Pulse Compression. Sensors 2019, 19, 2313. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- De Marchi, L.; Perelli, A.; Marzani, A. A signal processing approach to exploit chirp excitation in Lamb wave defect detection and localization procedures. Mech. Syst. Signal Process. 2013, 39, 20–31. [Google Scholar] [CrossRef]

- Liu, L.; Yuan, F.G. A Linear Mapping Technique for Dispersion Removal of Lamb Waves. Struct. Health Monit. Int. J. 2009, 9, 75–86. [Google Scholar] [CrossRef]

- Wilcox, P.D. A Rapid Signal Processing Technique to Remove the Effect of Dispersion from Guided Wave Signals. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2003, 50, 419–427. [Google Scholar] [CrossRef]

- Agrahari, J.K.; Kapuria, S. Effects of adhesive, host plate, transducer and excitation parameters on time reversibility of ultrasonic Lamb waves. Ultrasonics 2016, 70, 147–157. [Google Scholar] [CrossRef]

- Ihn, J.B.; Chang, F.K. Pitch-catch active sensing methods in structural health monitoring for aircraft structures. Struct. Health Monit. 2008, 7, 5–19. [Google Scholar] [CrossRef]

- Wang, D.; He, J.; Guan, X.; Yang, J.; Zhang, W. A model assessment method for predicting structural fatigue life using Lamb waves. Ultrasonics 2018, 84, 319–328. [Google Scholar] [CrossRef] [PubMed]

- Sbarufatti, C.; Manson, G.; Worden, K. A numerically-enhanced machine learning approach to damage diagnosis using a Lamb wave sensing network. J. Sound Vib. 2014, 333, 4499–4525. [Google Scholar] [CrossRef]

- Li, R.; Luo, J.; Hu, B. Lamb Wave-Based Damage Localization Feature Enhancement and Extraction Method for Stator Insulation of Large Generators Using VMD and Wavelet Transform. Sensors 2020, 20, 4205. [Google Scholar] [CrossRef] [PubMed]

- Tao, C.C.; Ji, H.L.; Qiu, J.H.; Zhang, C.; Wang, Z.; Yao, W.X. Characterization of fatigue damages in composite laminates using Lamb wave velocity and prediction of residual life. Compos. Struct. 2017, 166, 219–228. [Google Scholar] [CrossRef]

- Yu, X.D.; Ratassepp, M.; Fan, Z. Damage detection in quasi-isotropic composite bends using ultrasonic feature guided waves. Compos. Sci. Technol. 2017, 141, 120–129. [Google Scholar] [CrossRef]

- De Marchi, L.; Marzani, A.; Moll, J.; Kudela, P.; Radzieński, M.; Ostachowicz, W. A pulse coding and decoding strategy to perform Lamb wave inspections using simultaneously multiple actuators. Mech. Syst. Signal Process. 2017, 91, 111–121. [Google Scholar] [CrossRef]

- Yu, N.Y.; Gong, G. New Construction of M-Ary Sequence Families With Low Correlation From the Structure of Sidelnikov Sequences. IEEE Trans. Inf. Theory 2010, 57, 4061–4070. [Google Scholar] [CrossRef]

| Material | E (GPa) | v | ρ (kg/m3) |

|---|---|---|---|

| Al2024-T3 | 72 | 0.33 | 2780 |

| Parameters | Tone Burst Signal | 0~300 kHz L-Chirp | 150 kHz GCC | 300~700 kHz L-Chirp | 500 kHz GCC |

|---|---|---|---|---|---|

| a0 | −460.12 | −57.25 | −534.66 | −17.13 | −17.53 |

| a1 | −355.22 | −352.10 | −369.86 | −103.54 | −139.76 |

| a2 | 27.30 | 39.13 | 19.44 | 54.82 | 62.88 |

| a3 | 1624.77 | 451.29 | 1947.6 | 72.65 | 85.82 |

| a4 | 203.56 | 182.51 | 215.82 | 47.64 | 68.12 |

| a5 | −121.39 | −28.03 | −149.40 | 264.91 | 329.85 |

| a6 | −1233.09 | −223.91 | −1258.43 | 0.69 | 3.59 |

| Excitation Waveform | Tone Burst | 0~300 kHz L-Chirp | 150 kHz GCC | 300~700 kHz L-Chirp | 500 kHz GCC |

|---|---|---|---|---|---|

| average error (mm) | 0.3282 | 0.1941 | 0.1855 | 0.0886 | 0.0676 |

| Standard deviation (mm) | 0.5246 | 0.2443 | 0.2332 | 0.1187 | 0.0880 |

| R-square | 0.992852 | 0.998586 | 0.998711 | 0.999225 | 0.999621 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, X.; Yang, J.; Zhang, G. A Crack Size Quantification Method Using High-Resolution Lamb Waves. Sensors 2021, 21, 6941. https://doi.org/10.3390/s21206941

Li X, Yang J, Zhang G. A Crack Size Quantification Method Using High-Resolution Lamb Waves. Sensors. 2021; 21(20):6941. https://doi.org/10.3390/s21206941

Chicago/Turabian StyleLi, Xianjun, Jinsong Yang, and Guangdong Zhang. 2021. "A Crack Size Quantification Method Using High-Resolution Lamb Waves" Sensors 21, no. 20: 6941. https://doi.org/10.3390/s21206941

APA StyleLi, X., Yang, J., & Zhang, G. (2021). A Crack Size Quantification Method Using High-Resolution Lamb Waves. Sensors, 21(20), 6941. https://doi.org/10.3390/s21206941