Digital Twins Supporting Efficient Digital Industrial Transformation

Abstract

:1. Introduction

- The CTs, and in particular, the ability of each CT to digitally represent a specific complex industrial machine via a semantic description of the machine, to communicate with the corresponding machines to obtain its data and send machine settings and other actuation to the machine, and to simulate the machine operation to facilitate Industry 4.0 application testing;

- CT-based Industry 4.0 application development that utilizes CTs instead of individual sensors and actuators to make Industry 4.0 application development more cost-efficient. Unlike IoT platform-based Industry 4.0 application development that can integrate the individual sensors and actuators of the machine, CT-based application development can integrate entire-complex machines reducing the cost of application development, especially when CTs are used by multiple Industry 4.0 applications;

- A novel cost model for estimating the cost of developing an Industry 4.0 application. To the best of our knowledge, no other model currently exists for that.

- An evaluation of CT-based applications using a sample application from the dairy industry that shows the benefits of CT-based Industry 4.0 application development.

2. Related Work

2.1. DTs and DT-Based Industry 4.0 Application Development

2.2. Traditional Industry 4.0 Application Development

2.3. Industry 4.0 Application Development Cost Modelling

2.4. Summary

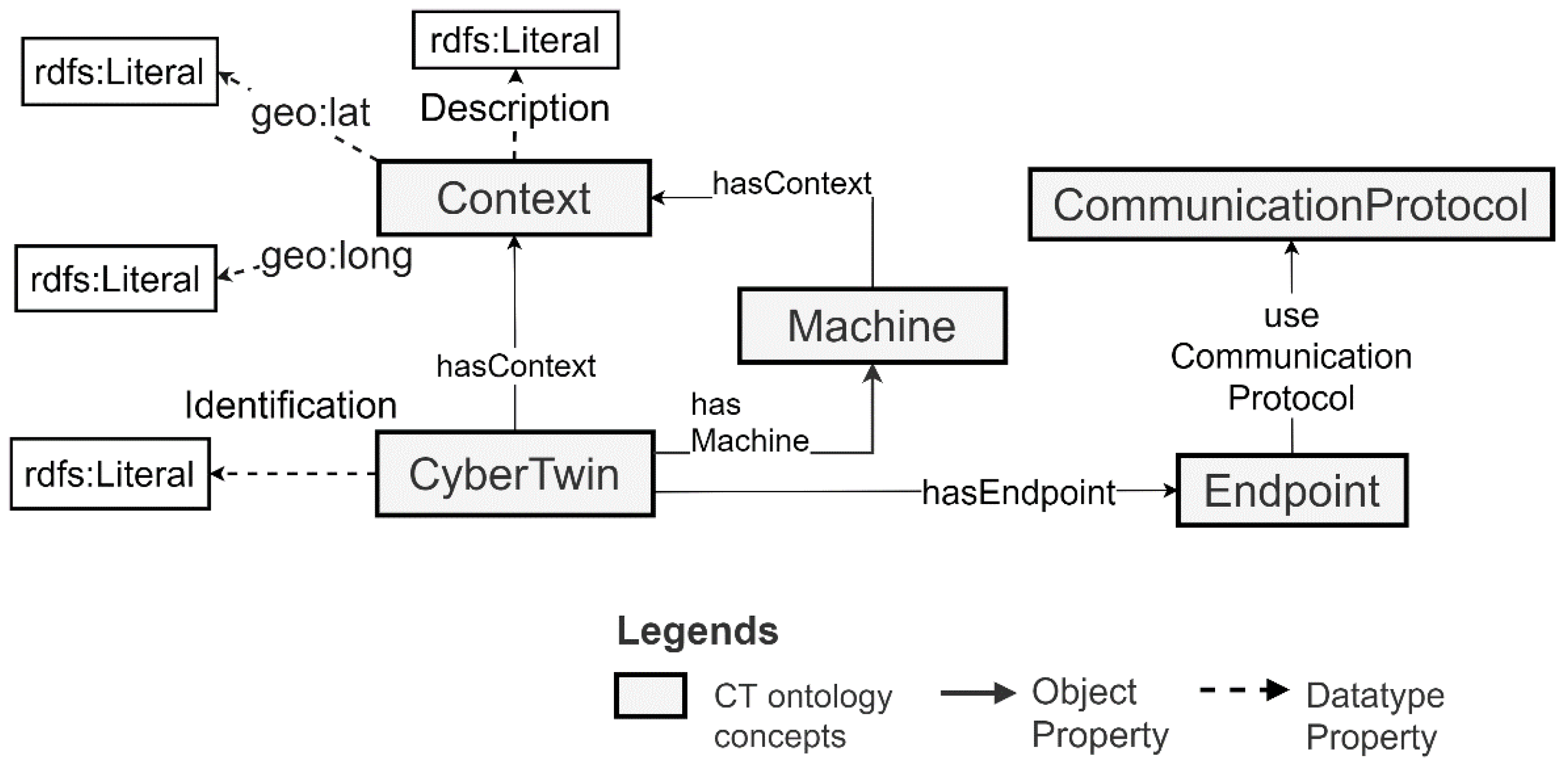

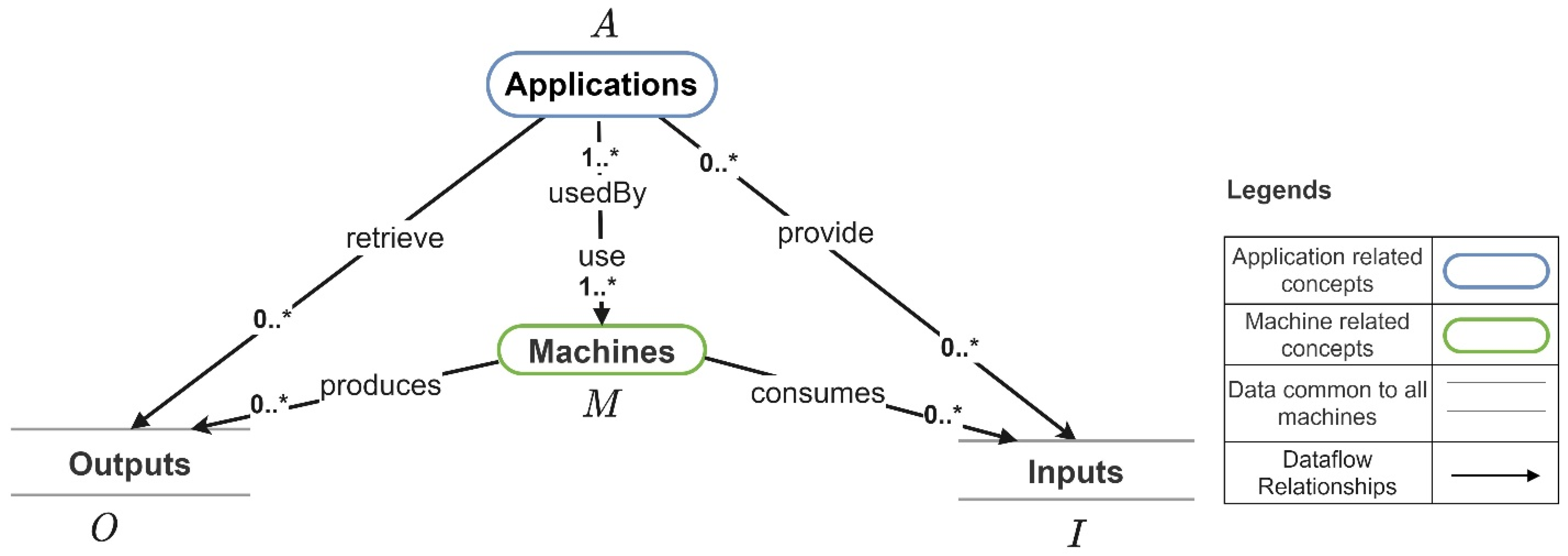

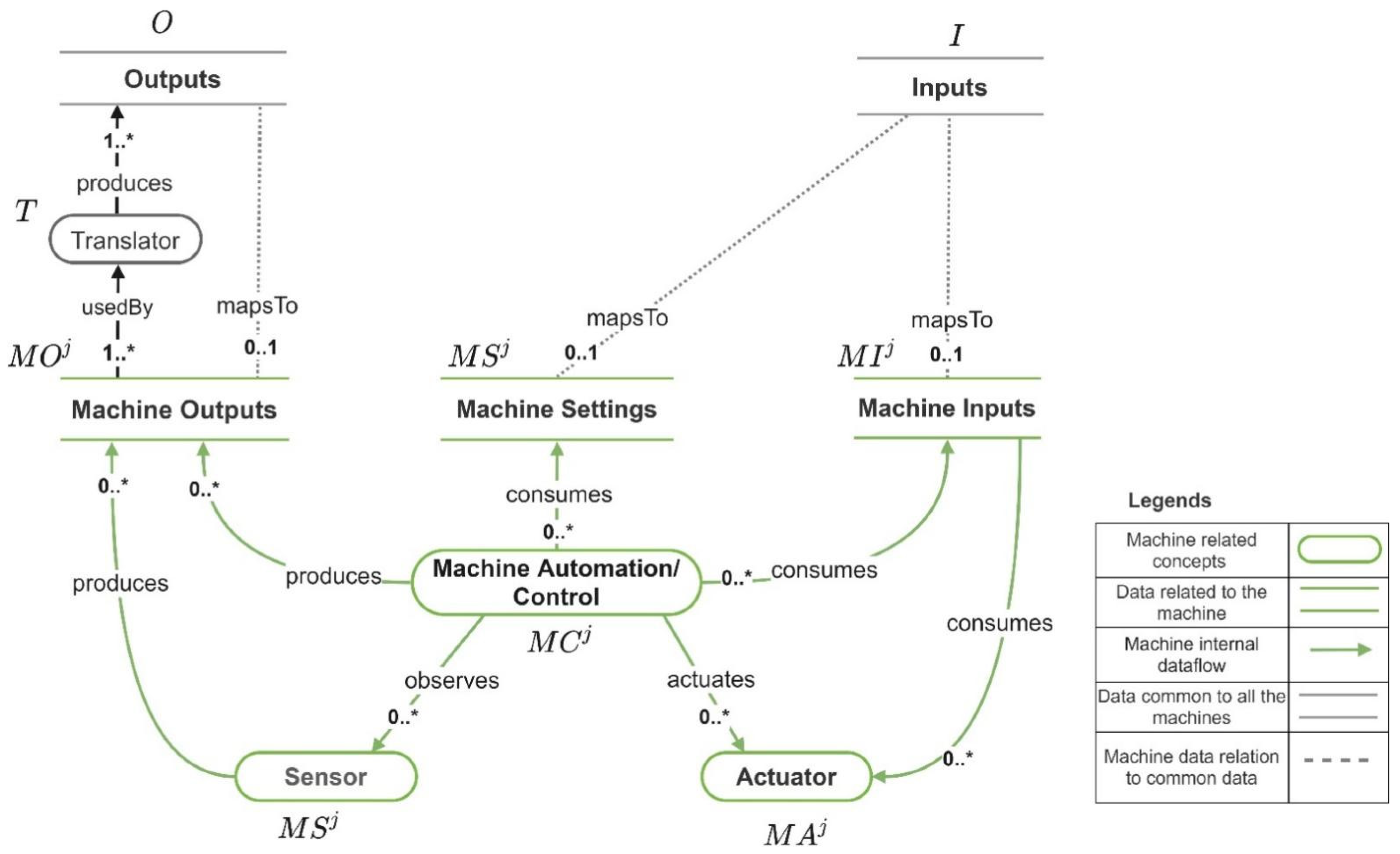

3. Cyber Twins (CTs)

- Query the semantic description of the machine that is represented by the CT;

- Communicate with the machine including obtaining the data produced by the machine, applying the machine settings, and sending other inputs to the machine;

- Interact with the machine emulator or simulator that is incorporated in the CT to support application testing.

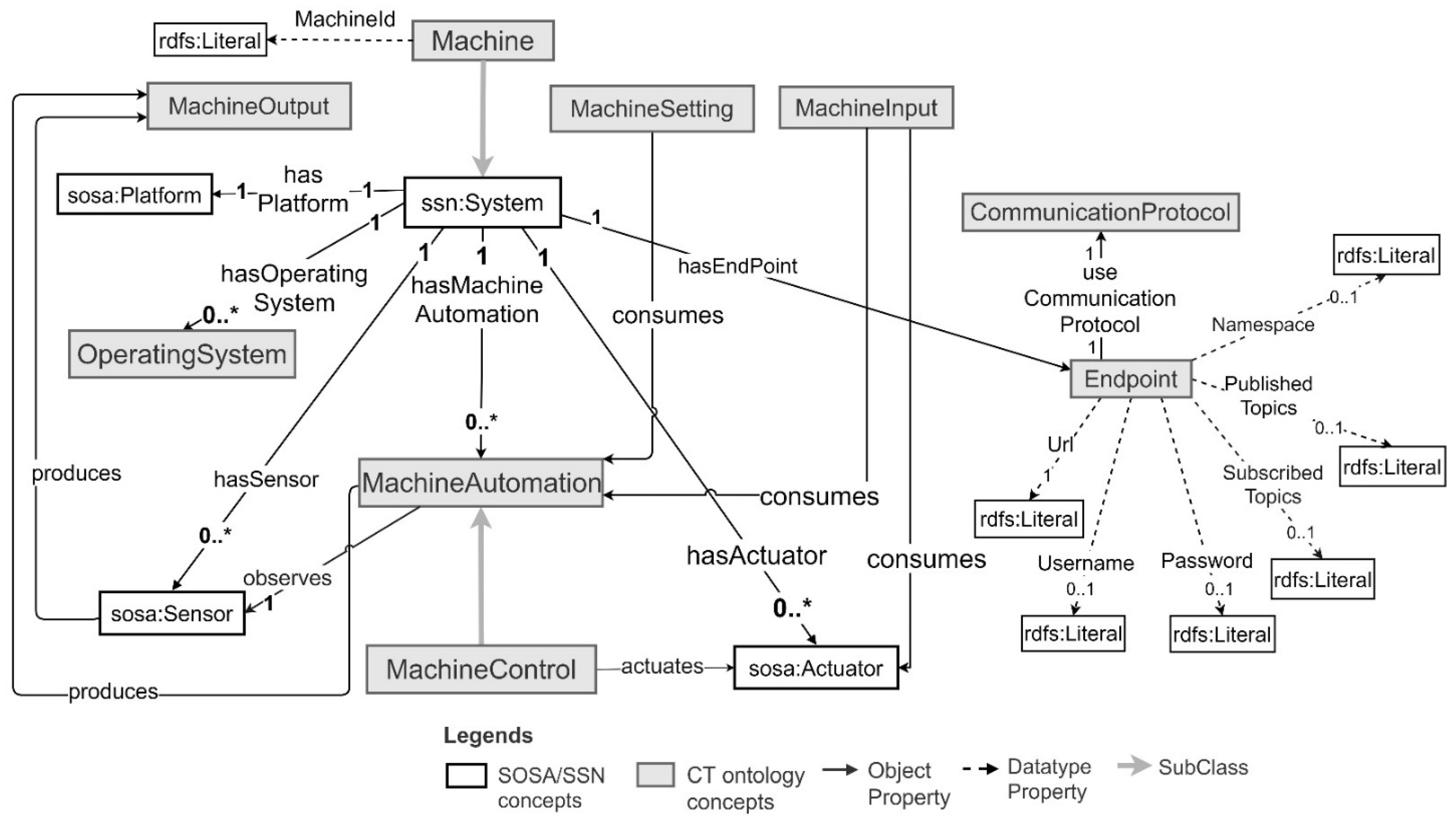

3.1. CT Ontology for Describing Complex Industrial Machines

3.2. CT Management Framework

3.3. Simulators in CTs and Their Support for Testing

4. CT-Based Industry 4.0 Application Development and Costing

4.1. CT-Based Industry 4.0 Application Development: Activities and Roles

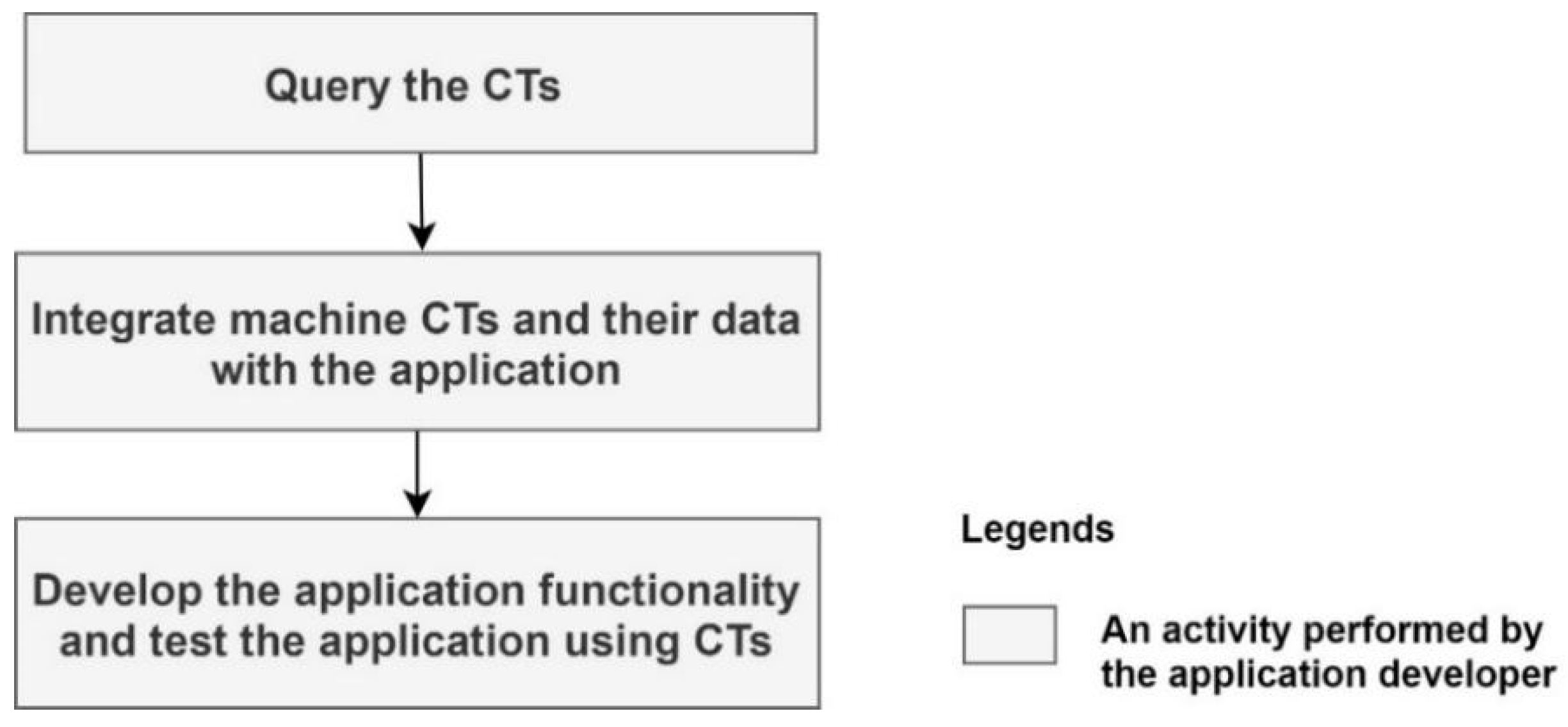

4.1.1. Developing a New CT-Based Industry 4.0 Application

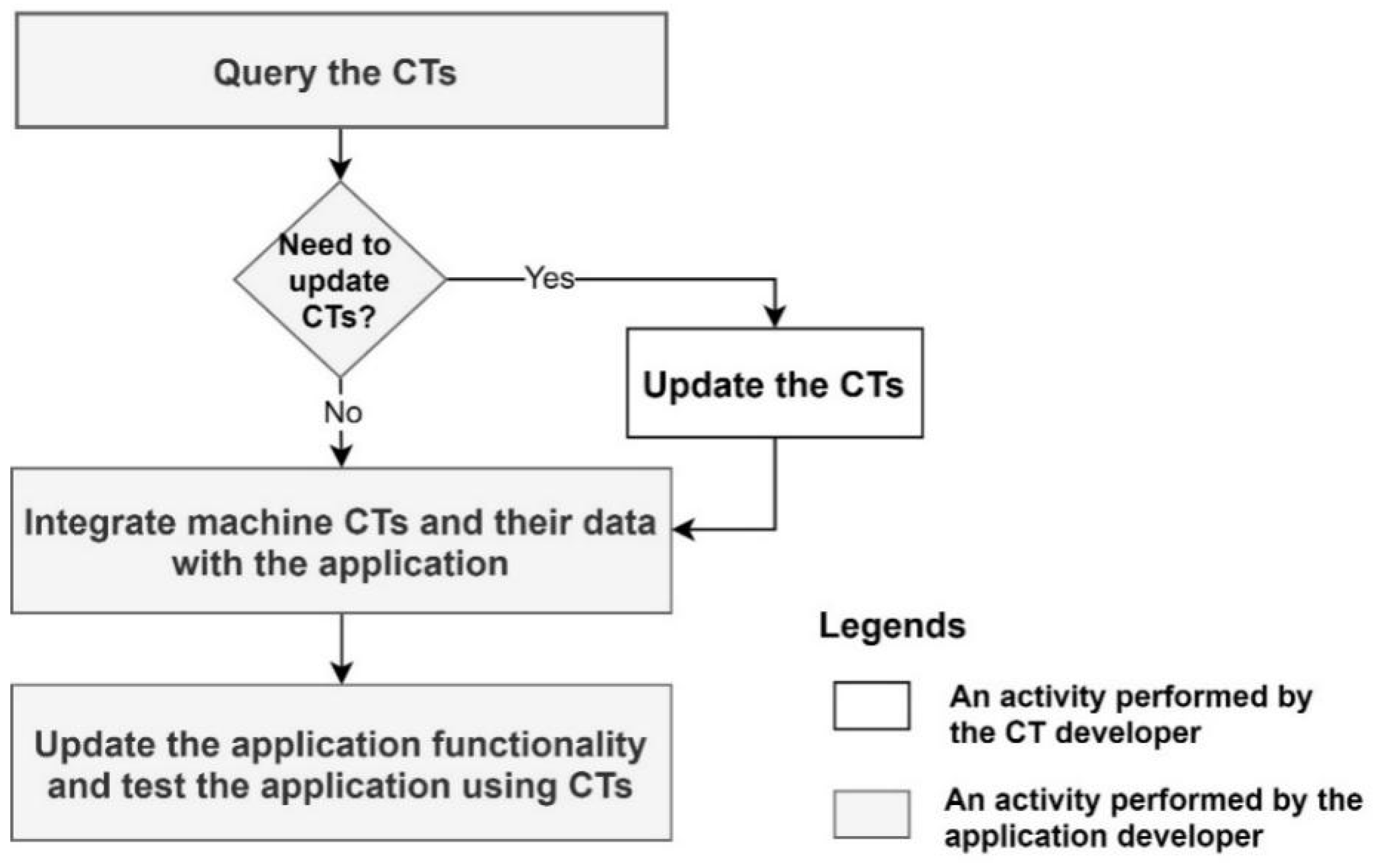

4.1.2. Updating an Existing CT-Based Industry 4.0 Application

4.1.3. Porting an Existing CT-Based Industry 4.0 Application

4.2. A Cost Model for Industry 4.0 Application Development

4.2.1. Cost of Identifying the Machine Data Required by the Application

4.2.2. Cost of Integrating Machines and Machine Data with the Application

4.2.3. Cost of Developing the Application Functionality and Testing the Application

4.2.4. Degree of Adaptability of an Industry 4.0 Application

4.2.5. Degree of Portability of an Industry 4.0 Application

5. Experimental Evaluation of a CT-Based Industry 4.0 Application

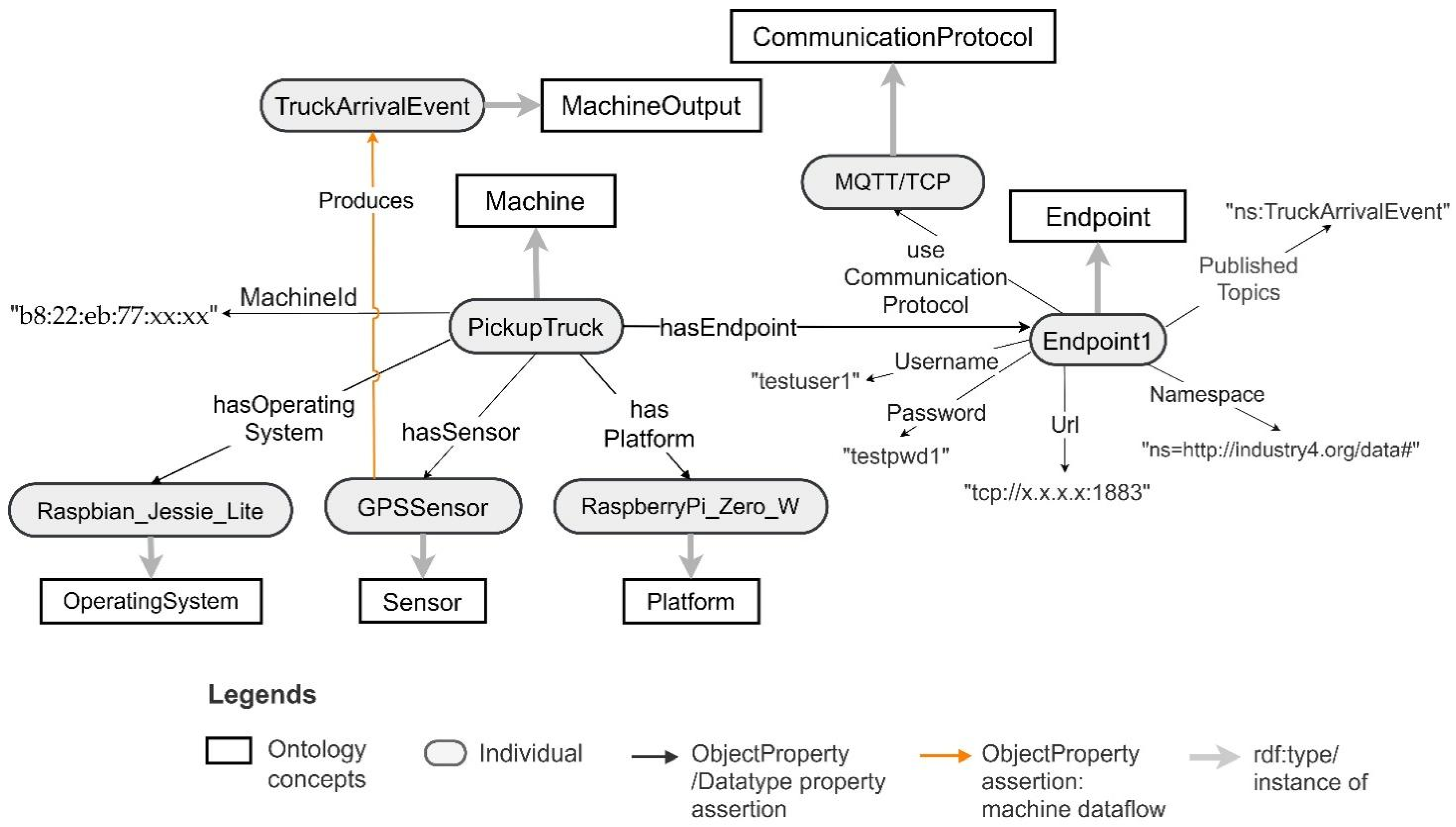

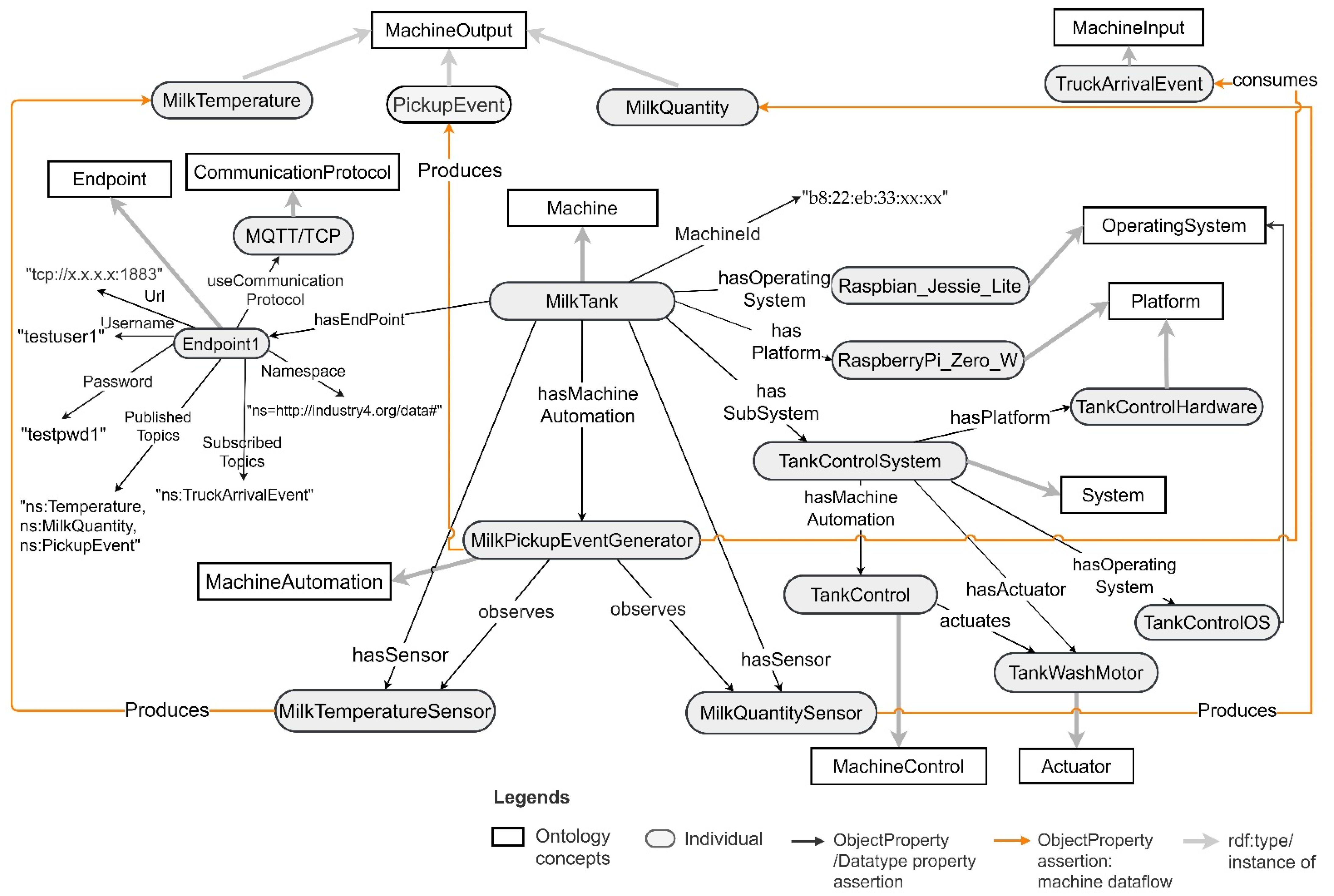

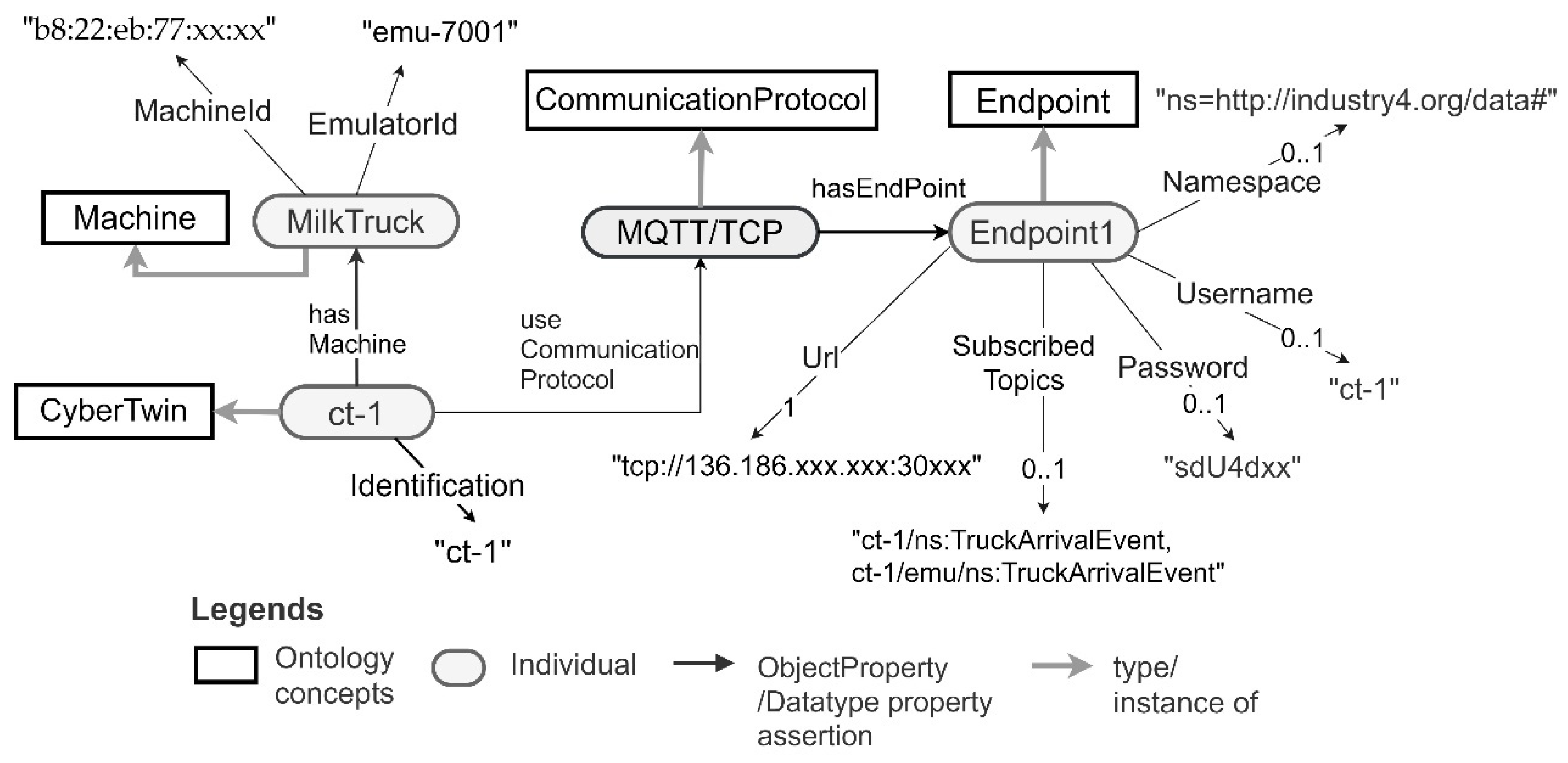

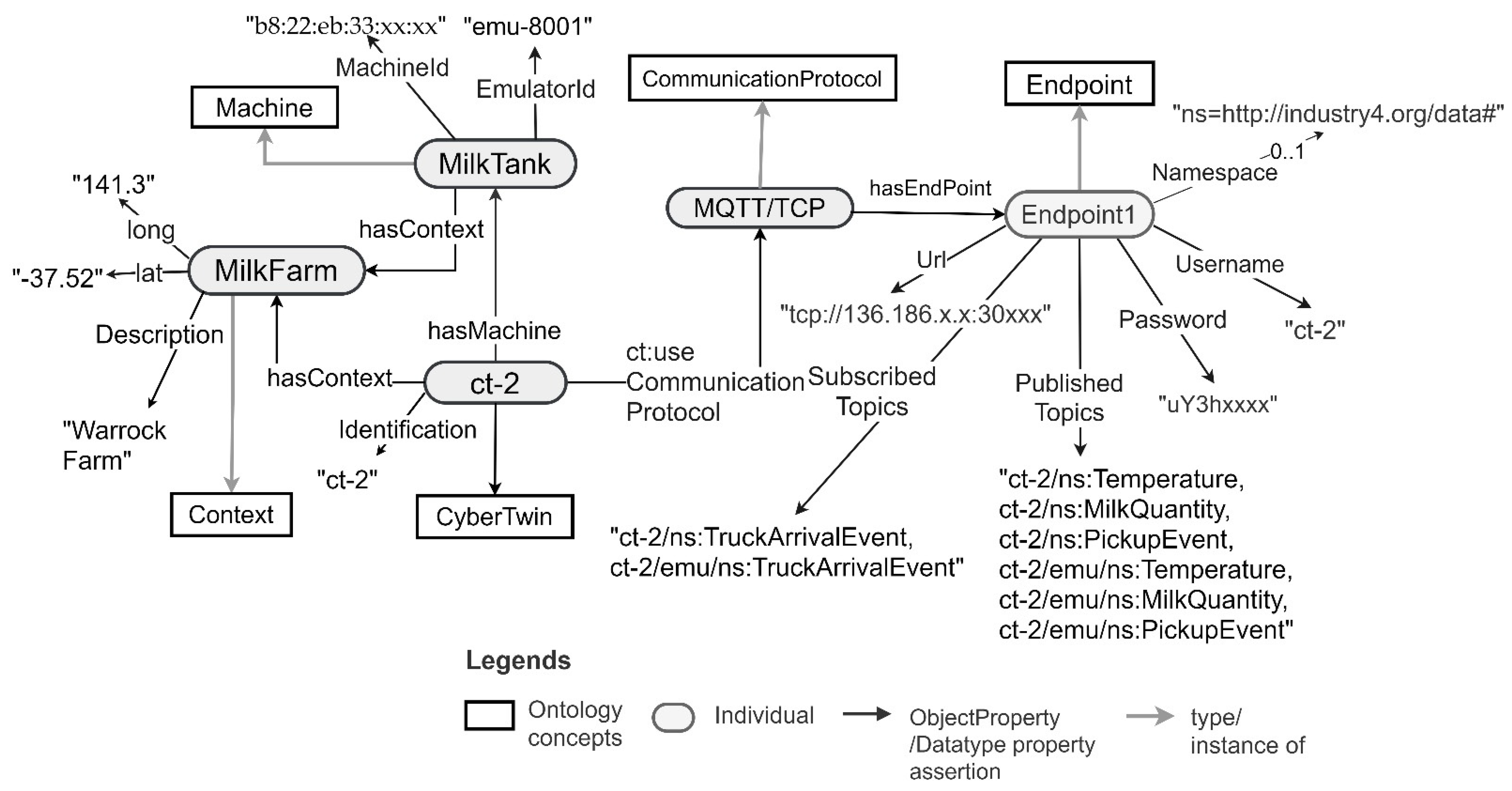

5.1. CT Ontology-Based Models of the Pickup Truck and the Milk Tank Machines

5.2. CTs of the Pickup Truck and the Milk Tank

5.2.1. CT Descriptions of the Milk Tank and Pickup Truck Machines

5.2.2. Machine Simulators of the Milk Tank and Pickup Truck

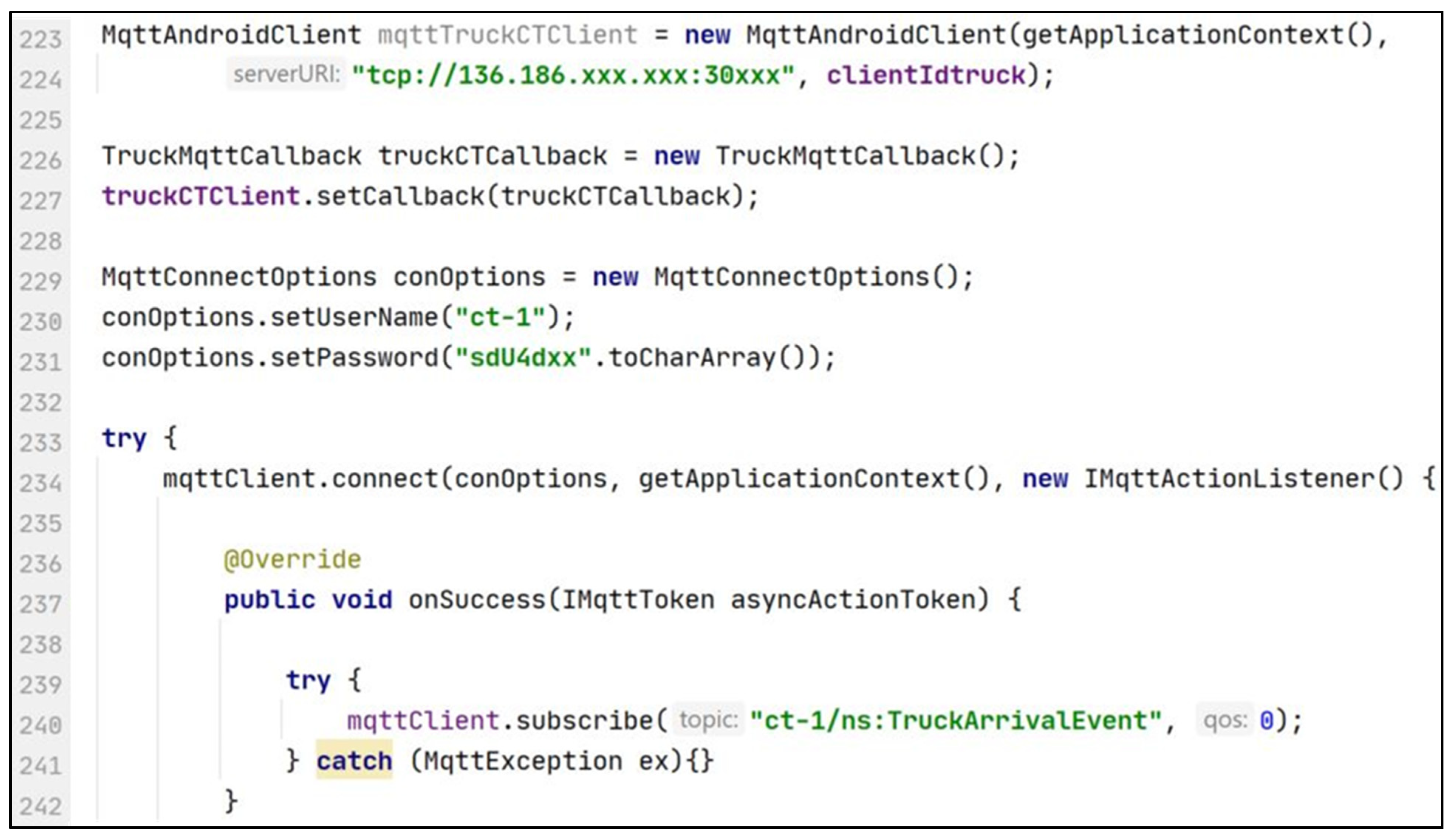

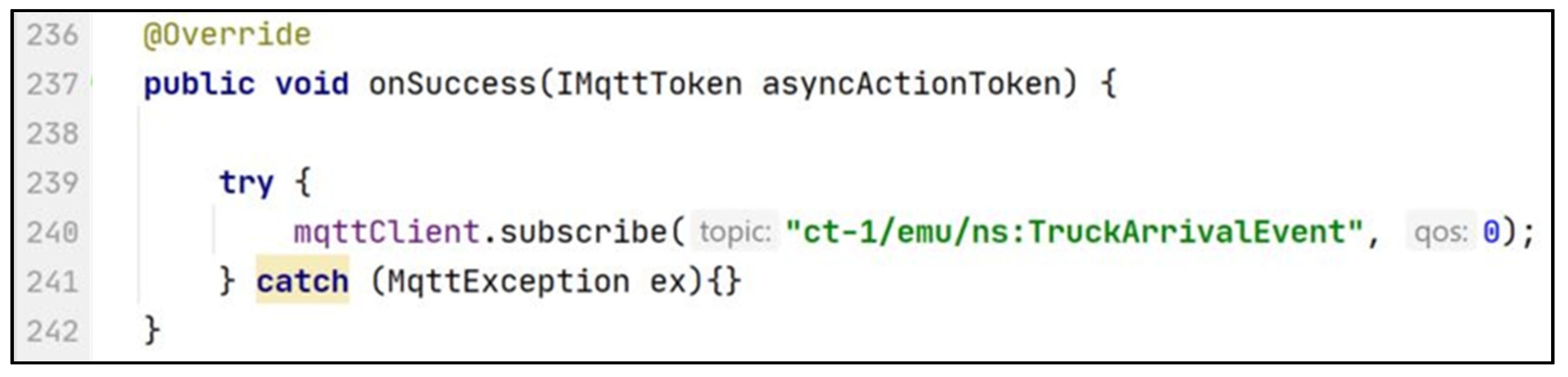

5.3. CT-Based Milk Pickup Monitoring Application Development

5.3.1. Developing a New CT-Based Milk Pickup Monitoring Application

5.3.2. Updating an Existing CT-Based Milk Pickup Monitoring Application

5.3.3. Porting the CT-Based Milk Pickup Monitoring Application to a Different Milk Farm

5.4. Experimentally Evaluating CT-Based Industry 4.0 Application Development

5.4.1. Experimental Setup and Methodology for Experiments

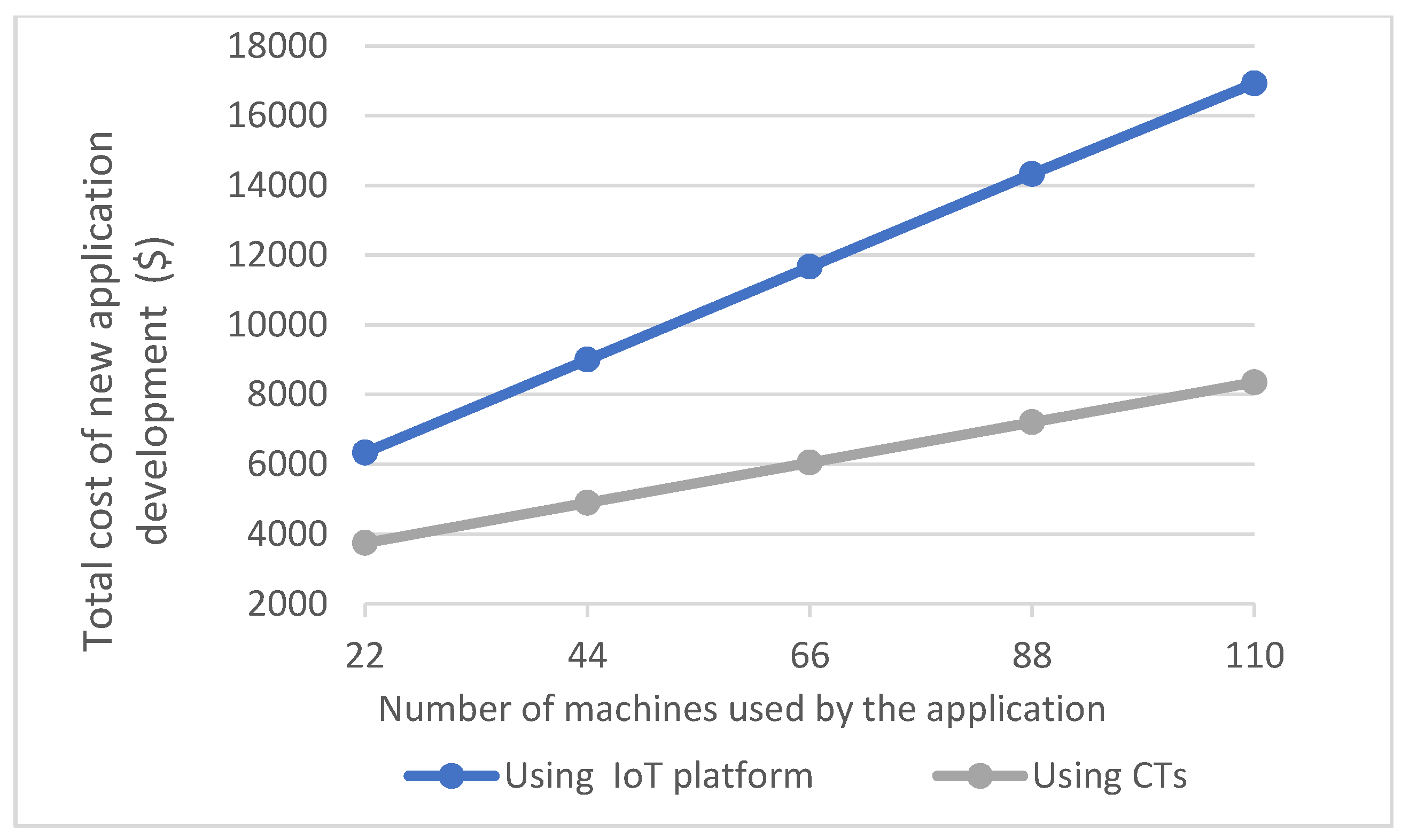

5.4.2. Estimating the Costs of New Industry 4.0 Application Development

- When developing the CT-based application we assumed that and were already integrated with their CTs. Therefore, the CT generation cost was not considered in the calculation of application development cost;

- In Azure IoT we assumed and were already integrated with the Azure IoT platform via the Azure IoT Hub [60]. Therefore, the cost of integration with the IoT platform was not considered in the calculation of the application development cost. Moreover, we assumed that and had sufficient and accurate machine descriptions associated with them that could be directly used by the application developer.

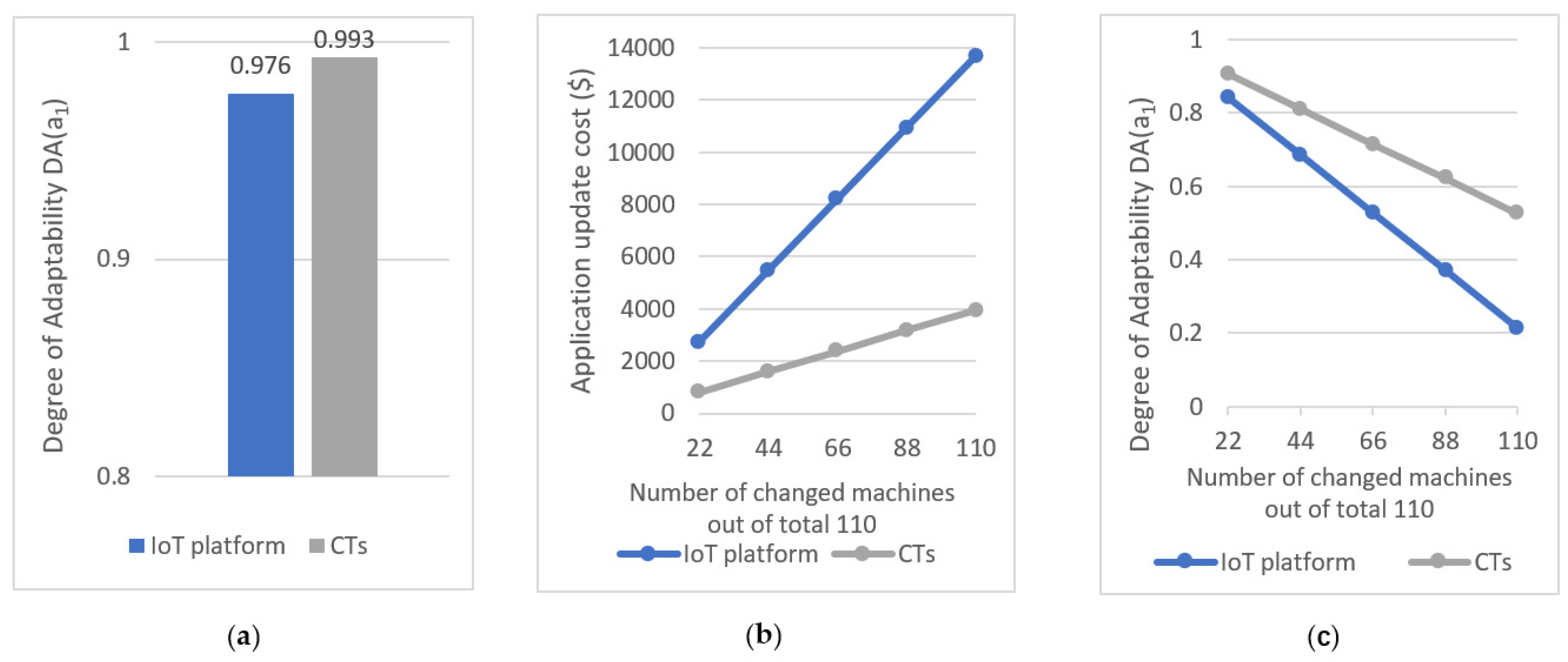

5.4.3. Estimating the Costs of Industry 4.0 Application Update

- When updating to use , we assumed that the CT of was updated to connect with without generating a new CT for ;

- When updating the application using Azure, we assumed that was already integrated with the same IoT Hub instance as and had a different device id.

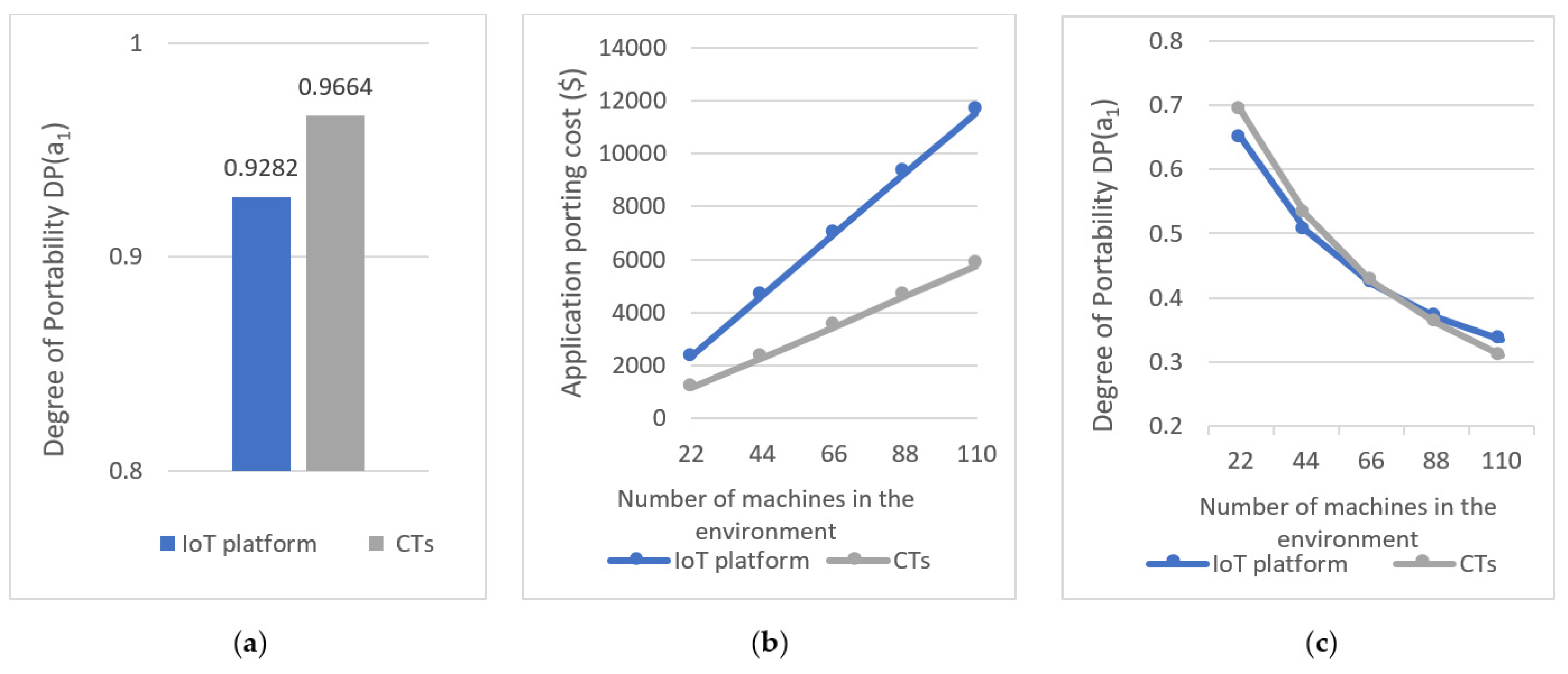

5.4.4. Estimating the Costs of Industry 4.0 Application Porting

- When porting that uses CTs to we assumed that CTs were available for and ;

- When porting using Azure IoT, we assumed and connected to a different IoT Hub and had different device ids, and they were already connected with the IoT Hub.

5.5. Discussion

6. Conclusions and Future Research

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Georgakopoulos, D.; Fazia, M.; Villari, M.; Rajiv, R. Internet of Things and Edge Cloud Computing Roadmap for Manufacturing. IEEE Cloud Comput. 2016, 3, 66–73. [Google Scholar] [CrossRef]

- Ranjan, R.; Hsu, C.H.; Chen, L.Y.; Georgakopoulos, D. Holistic Technologies for Managing Internet of Things Services. IEEE Trans. Serv. Comput. 2020, 13, 597–601. [Google Scholar] [CrossRef]

- Milojevic, M. Digital Industrial Transformation with the Internet of Things; CXP Group: Glasgow, UK, 2017. [Google Scholar]

- Zhang, L.; Schultz, M.A.; Cash, R.; Barrett, D.M.; McCarthy, M.J. Determination of quality parameters of tomato paste using guided microwave spectroscopy. Food Control 2014, 40, 214–223. [Google Scholar] [CrossRef]

- Montori, F.; Liao, K.; Jayaraman, P.P.; Bononi, L.; Sellis, T.; Georgakopoulos, D. Classification and Annotation of Open Internet of Things Datastreams. In Proceedings of the International Conference on Web Information Systems Engineering, Dubai, United Arab Emirates, 12–15 November 2018; pp. 209–224. [Google Scholar]

- Madithiyagasthenna, D.; Jayaraman, P.P.; Morshed, A.; Forkan, A.R.M.; Georgakopoulos, D.; Kang, Y.B.; Piechowski, M. A solution for annotating sensor data streams-An industrial use case in building management system. In Proceedings of the 2020 21st IEEE International Conference on Mobile Data Management (MDM), Versailles, France, 30 June–3 July 2020; pp. 194–201. [Google Scholar]

- Bamunuarachchi, D.; Banerjee, A.; Jayaraman, P.P.; Georgakopoulos, D. Cyber Twins Supporting Industry 4.0 Application Development. In Proceedings of the 18th International Conference on Advances in Mobile Computing and Multimedia (MoMM ’20), Chiang Mai, Thailand, 30 November–2 December 2020; pp. 64–73. [Google Scholar]

- Microsoft. Tutorial: Build out an End-to-End Solution. Available online: https://docs.microsoft.com/en-us/azure/digital-twins/tutorial-end-to-end (accessed on 19 April 2021).

- Microsoft. Azure IoT Device Simulation. Available online: https://azure.microsoft.com/en-au/resources/videos/azure-iot-device-simulation/ (accessed on 8 July 2021).

- Fuller, A.; Fan, Z.; Day, C.; Barlow, C. Digital Twin: Enabling Technologies, Challenges and Open Research. IEEE Access 2020, 8, 108952–108971. [Google Scholar] [CrossRef]

- Sepasgozar, S.M.E. Differentiating Digital Twin from Digital Shadow: Elucidating a Paradigm Shift to Expedite a Smart, Sustainable Built Environment. Buildings 2021, 11, 151. [Google Scholar] [CrossRef]

- Schleich, B.; Anwer, N.; Mathieu, L.; Wartzack, S. Shaping the digital twin for design and production engineering. CIRP Annals 2017, 66, 141–144. [Google Scholar] [CrossRef] [Green Version]

- Tao, F.; Zhang, H.; Liu, A.; Nee, A.Y.C. Digital Twin in Industry: State-of-the-Art. IEEE Trans. Ind. Inform. 2019, 15, 2405–2415. [Google Scholar] [CrossRef]

- Negri, E.; Berardi, S.; Fumagalli, L.; Macchi, M. MES-integrated digital twin frameworks. J. Manuf. Syst. 2020, 56, 58–71. [Google Scholar] [CrossRef]

- Chhetri, S.R.; Faezi, S.; Canedo, A.; Faruque, M.A.A. QUILT: Quality Inference from Living Digital Twins in IoT–Enabled Manufacturing Systems. IoTDI’19 2019, 237–248. [Google Scholar] [CrossRef]

- Qiao, Q.; Wang, J.; Ye, L.; Gao, R.X. Digital Twin for Machining Tool Condition Prediction. Procedia CIRP 2019, 81, 1388–1393. [Google Scholar] [CrossRef]

- Liu, C.; Vengayil, H.; Zhong, R.Y.; Xu, X. A systematic development method for cyber-physical machine tools. J. Manuf. Syst. 2018, 48, 13–24. [Google Scholar] [CrossRef]

- Mourtzis, D.; Vlachou, E. A cloud-based cyber-physical system for adaptive shop-floor scheduling and condition-based maintenance. J. Manuf. Syst. 2018, 47, 179–198. [Google Scholar] [CrossRef]

- Wang, J.; Ye, L.; Gao, R.X.; Li, C.; Zhang, L. Digital Twin for rotating machinery fault diagnosis in smart manufacturing. Int. J. Prod. Res. 2019, 57, 3920–3934. [Google Scholar] [CrossRef]

- Vachalek, J.; Bartalsky, L.; Rovny, O.; Sismisova, D.; Morhac, M.; Loksik, M. The digital twin of an industrial production line within the industry 4.0 concept. In Proceedings of the 2017 21st International Conference on Process Control, Strbske Pleso, Slovakia, 6–9 June 2017; pp. 258–262. [Google Scholar]

- Bamunuarachchi, D.; Georgakopoulos, D.; Jayaraman, P.P.; Banerjee, A. A Framework for Enabling Cyber-Twins based Industry 4.0 Application Development. (In press). In Proceedings of the 2021 IEEE International Conference on Services Computing (SCC), Online, 5–11 September 2021; pp. 64–73. [Google Scholar]

- Juarez, M.G.; Botti, V.J.; Giret, A.S. Digital Twins: Review and Challenges. J. Comput. Inf. Sci. Eng. 2021, 21, 030802. [Google Scholar] [CrossRef]

- Ladj, A.; Wang, Z.; Meski, O.; Belkadi, F.; Ritou, M.; Da Cunha, C. A knowledge-based Digital Shadow for machining industry in a Digital Twin perspective. J. Manuf. Syst. 2021, 58, 168–179. [Google Scholar] [CrossRef]

- Schuh, G.; Jussen, P.; Harland, T. The Digital Shadow of Services: A Reference Model for Comprehensive Data Collection in MRO Services of Machine Manufacturers. Procedia CIRP 2018, 73, 271–277. [Google Scholar] [CrossRef]

- Schuh, G.; Kelzenberg, C.; Wiese, J.; Ochel, T. Data Structure of the Digital Shadow for Systematic Knowledge Management Systems in Single and Small Batch Production. Procedia CIRP 2019, 84, 1094–1100. [Google Scholar] [CrossRef]

- Riesener, M.; Schuh, G.; Dölle, C.; Tönnes, C. The Digital Shadow as Enabler for Data Analytics in Product Life Cycle Management. Procedia CIRP 2019, 80, 729–734. [Google Scholar] [CrossRef]

- Barthelmey, A.; Lee, E.; Hana, R.; Deuse, J. Dynamic digital twin for predictive maintenance in flexible production systems. In Proceedings of the IECON 2019-45th Annual Conference of the IEEE Industrial Electronics Society, Lisbon, Portugal, 14–17 October 2019; pp. 4209–4214. [Google Scholar]

- Liu, J.; Yu, D.; Bi, X.; Hu, Y.; Yu, H.; Li, B. The Research of Ontology-based Digital Twin Machine Tool Modeling. In Proceedings of the 2020 IEEE 6th International Conference on Computer and Communications (ICCC), Chengdu, China, 11–14 December 2020; pp. 2130–2134. [Google Scholar]

- Schroeder, G.N.; Steinmetz, C.; Pereira, C.E.; Espindola, D.B. Digital Twin Data Modeling with AutomationML and a Communication Methodology for Data Exchange. IFAC-PapersOnLine 2016, 49, 12–17. [Google Scholar] [CrossRef]

- Hoebert, T.; Lepuschitz, W.; List, E.; Merdan, M. Cloud-Based Digital Twin for Industrial Robotics. In Proceedings of the International Conference on Industrial Applications of Holonic and Multi-Agent Systems, Linz, Austria, 26–29 August 2019; pp. 105–116. [Google Scholar]

- Lu, Y.; Xu, X. Resource virtualization: A core technology for developing cyber-physical production systems. J. Manuf. Syst. 2018, 47, 128–140. [Google Scholar] [CrossRef]

- Cai, Y.; Starly, B.; Cohen, P.; Lee, Y.-S. Sensor Data and Information Fusion to Construct Digital-twins Virtual Machine Tools for Cyber-physical Manufacturing. Procedia Manuf. 2017, 10, 1031–1042. [Google Scholar] [CrossRef]

- GE. Predix Platform. Available online: https://www.ge.com/digital/iiot-platform (accessed on 4 April 2021).

- MindSphere: Siemens. MindSphere. Available online: https://siemens.mindsphere.io/en (accessed on 15 June 2021).

- Eclipse Ditto™. Eclipse Ditto. Available online: https://www.eclipse.org/ditto/ (accessed on 4 April 2021).

- SiteWhere LLC. The Open Platform for the Internet of Things™. Available online: https://sitewhere.io/en/ (accessed on 15 June 2021).

- Microsoft. Azure IoT. Available online: https://azure.microsoft.com/en-us/overview/iot/ (accessed on 22 August 2020).

- Cumulocity GmbH. Sensor Library–Cumulocity IoT Guides. Available online: https://cumulocity.com/guides/reference/sensor-library/ (accessed on 10 August 2020).

- Hussain, I.; Park, S.J. HealthSOS: Real-Time Health Monitoring System for Stroke Prognostics. IEEE Access 2020, 8, 213574–213586. [Google Scholar] [CrossRef]

- Hussain, I.; Park, S.J. Big-ECG: Cardiographic Predictive Cyber-Physical System for Stroke Management. IEEE Access 2021, 9, 123146–123164. [Google Scholar] [CrossRef]

- Dawod, A.; Georgakopoulos, D.; Jayaraman, P.P.; Nirmalathas, A. An IoT-owned Service for Global IoT Device Discovery, Integration and (Re)use. In Proceedings of the 2020 IEEE International Conference on Services Computing (SCC), Beijing, China, 7–11 November 2020; pp. 312–320. [Google Scholar]

- Soldatos, J.; Kefalakis, N.; Hauswirth, M.; Serrano, M.; Calbimonte, J.-P.; Riahi, M.; Aberer, K.; Jayaraman, P.P.; Zaslavsky, A.; Žarko, I.P.; et al. OpenIoT: Open Source Internet–of–Things in the Cloud. In Proceedings of the Interoperability and Open-Source Solutions for the Internet of Things, Split, Croatia, 18 September 2014; pp. 13–25. [Google Scholar]

- Compton, M.; Barnaghi, P.; Bermudez, L.; García-Castro, R.; Corcho, O.; Cox, S.; Graybeal, J.; Hauswirth, M.; Henson, C.; Herzog, A.; et al. The SSN ontology of the W3C semantic sensor network incubator group. J. Web Semant. 2012, 17, 25–32. [Google Scholar] [CrossRef]

- Datta, S.K.; Bonnet, C. Easing IoT application development through DataTweet framework. In Proceedings of the 2016 IEEE 3rd World Forum on Internet of Things (WF-IoT), Reston, VA, USA, 12–14 December 2016; pp. 430–435. [Google Scholar]

- Cirillo, F.; Solmaz, G.; Berz, E.L.; Bauer, M.; Cheng, B.; Kovacs, E. A Standard-based Open Source IoT Platform: FIWARE. IEEE Internet Things Mag. 2020, 3, 12–18. [Google Scholar] [CrossRef]

- FIWARE Foundation. SMART DATA MODELS. Available online: https://www.fiware.org/developers/smart-data-models/ (accessed on 15 June 2021).

- Kim, M.; Lee, J.; Jeong, J. Open Source Based Industrial IoT Platforms for Smart Factory: Concept, Comparison and Challenges. In Proceedings of the Computational Science and Its Applications-ICCSA 2019, Saint Petersburg, Russia, 1–4 July 2019; pp. 105–120. [Google Scholar]

- Microsoft. Azure IoT Device Telemetry Simulator. Available online: https://docs.microsoft.com/en-us/samples/azure-samples/iot-telemetry-simulator/azure-iot-device-telemetry-simulator/ (accessed on 14 June 2021).

- Boehm, B.; Clark, B.; Horowitz, E.; Westland, C.; Madachy, R.; Selby, R. Cost models for future software life cycle processes: COCOMO 2.0. J. Softw. Eng. 1995, 1, 57–94. [Google Scholar] [CrossRef]

- Mooney, J.D. Issues in the specification and measurement of software portability. In Proceedings of the 15th International Conference on Software Engineering, Baltimore, MD, USA, 17–21 May 1993. [Google Scholar]

- Devanbu, P.; Karstu, S.; Melo, W.; Thomas, W. Analytical and empirical evaluation of software reuse metrics. In Proceedings of the 18th international conference on Software Engineering, Berlin, Germany, 25–29 March 1996; pp. 189–199. [Google Scholar]

- Janowicz, K.; Haller, A.; Cox, S.J.D.; Phuoc, D.L.; Lefrançois, M. SOSA: A lightweight ontology for sensors, observations, samples, and actuators. J. Web Semant. 2019, 56, 1–10. [Google Scholar] [CrossRef] [Green Version]

- Musen, M.A. The protégé project: A look back and a look forward. AI Matters 2015, 1, 4–12. [Google Scholar] [CrossRef]

- All3DP. Available online: https://all3dp.com/2/cnc-simulator-online-software/ (accessed on 18 September 2021).

- FANUC America Corporation. FANUC. Available online: https://www.fanucamerica.com/products/cnc/fanuc-simulators/cnc-machine-simulation-software (accessed on 18 September 2021).

- Platt, E.R. Virtual Peripheral interfaces in emulated embedded computer systems. Ph.D. Thesis, The University of Texas at Austin, Austin, TX, USA, December 2016. [Google Scholar]

- Index of/pub/raspberrypi/raspbian_lite/images/raspbian_lite-2017-07-05. Available online: http://ftp.jaist.ac.jp/pub/raspberrypi/raspbian_lite/images/raspbian_lite-2017-07-05/ (accessed on 12 September 2021).

- Gartner, Inc. Magic Quadrant for Industrial IoT Platforms. Available online: https://www.gartner.com/doc/reprints?id=1-2434LPHV&ct=200903&st=sb (accessed on 18 August 2021).

- Microsoft. Azure Industrial IoT. Available online: https://azure.microsoft.com/en-us/solutions/industry/manufacturing/iot/ (accessed on 18 August 2021).

- Microsoft. Read Device-to-Cloud Messages from the Built-in Endpoint. Available online: https://docs.microsoft.com/en-us/azure/iot-hub/iot-hub-devguide-messages-read-builtin (accessed on 15 June 2021).

- Palle Pedersen. The Open Source Community as a Top 100 Country. Available online: http://www.inside-open-source.com/2007/11/open-source-community-as-top-100.html (accessed on 20 April 2021).

| Notation | Description |

|---|---|

| Set of applications () | |

| Set of machines in a plant () | |

| Set of inputs | |

| Set of outputs | |

| Set of machines that are utilized by () | |

| Set of inputs provided by , to | |

| Set of outputs retrieved by , from | |

| Set of sensors in | |

| Set of actuators in | |

| Set of machine automation/machine controls in | |

| Set of machine inputs consumed by () | |

| Set of machine outputs produced by () | |

| Set of machine settings consumed by () | |

| Set of data translators | |

| Set of data translators used by for translating machine outputs produced by | |

| The total cost of developing by using | |

| Cost of identifying the data needed by from | |

| Cost of integrating and their data with | |

| Cost of developing and testing using |

| Notation | Description |

|---|---|

| Environment being monitored | |

| Pickup monitoring application | |

| Pickup truck | |

| Machine outputs of | |

| Milk tank | |

| Machine outputs of | |

| Machine input of | |

| Pickup event generator machine automation of |

| Industry 4.0 Application | Identify (NoQ) | Identify (NoC) | Integrate (NoC) | Integrate (SloC) | Dev and Test (NoC) | Dev and Test (SloC) | Total Cost ($) |

|---|---|---|---|---|---|---|---|

| IoT platform | 0 | 2 | 4 | 42 | 2 | 159 | 3762.00 |

| CTs | 0 | 2 | 3 | 32 | 0 | 112 | 2682.00 |

| Number of Milk Tanks | Number of Milk Trucks | Cost of Identifying | Cost of Integration | Cost of Dev and Test | Total Cost ($) |

|---|---|---|---|---|---|

| 20 | 2 | 396.00 | 2286.00 | 4050.00 | 6732.00 |

| 40 | 4 | 792.00 | 3402.00 | 5202.00 | 9396.00 |

| 60 | 6 | 1188.00 | 4518.00 | 6354.00 | 12,060.00 |

| 80 | 8 | 1584.00 | 5634.00 | 7506.00 | 14,724.00 |

| 100 | 10 | 1980.00 | 6750.00 | 8658.00 | 17,388.00 |

| Number of Milk Tanks | Number of Milk Trucks | Cost of Identifying | Cost of Integration | Cost of Dev and Test | Total Cost ($) |

|---|---|---|---|---|---|

| 20 | 2 | 396.00 | 1332.00 | 2016.00 | 3744.00 |

| 40 | 4 | 792.00 | 2088.00 | 2016.00 | 4896.00 |

| 60 | 6 | 1188.00 | 2844.00 | 2016.00 | 6048.00 |

| 80 | 8 | 1584.00 | 3600.00 | 2016.00 | 7206.00 |

| 100 | 10 | 1980.00 | 4356.00 | 2016.00 | 8352.00 |

| Industry 4.0 Application | Identify (NoQ) | Identify (NoC) | Integration (NoC) | Integration (SloC) | Dev and Test (NoC) | Dev and Test (SloC) | Total Cost ($) |

|---|---|---|---|---|---|---|---|

| IoT platform | 0 | 1 | 0 | 2 | 3 | 0 | 90.00 |

| CTs | 0 | 1 | 1 | 0 | 0 | 0 | 36.00 |

| Changed Machines/Total No. of Machines | Cost of Updating | Cost of Redev. | Degree of Adaptability |

|---|---|---|---|

| 22/110 | 2736.00 | 17,388.00 | 0.8426 |

| 44/110 | 5472.00 | 17,388.00 | 0.6853 |

| 66/110 | 8208.00 | 17,388.00 | 0.5279 |

| 88/110 | 10,944.00 | 17,388.00 | 0.3706 |

| 110/110 | 13,680.00 | 17,388.00 | 0.2133 |

| Changed Machines/Total No. of Machines | Cost of Updating | Cost of Redev. | Degree of Adaptability |

|---|---|---|---|

| 22/110 | 792.00 | 8352.00 | 0.9052 |

| 44/110 | 1584.00 | 8352.00 | 0.8103 |

| 66/110 | 2376.00 | 8352.00 | 0.7156 |

| 88/110 | 3168.00 | 8352.00 | 0.6207 |

| 110/110 | 3960.00 | 8352.00 | 0.5259 |

| Industry 4.0 Application | Identify (NoQ) | Identify (NoC) | Integration (NoC) | Integration (SLoC) | Dev and Test (NoC) | Dev and Test (SLoC) | Total Cost ($) |

|---|---|---|---|---|---|---|---|

| Azure IoT | 0 | 2 | 4 | 3 | 2 | 4 | 270.00 |

| CTs | 0 | 2 | 3 | 0 | 0 | 0 | 90.00 |

| No. of Machines | Cost of Porting | Cost of Redev. | Degree of Portability |

|---|---|---|---|

| 22 | 2358.00 | 6732.00 | 0.6497 |

| 44 | 4662.00 | 9396.00 | 0.5039 |

| 66 | 6966.00 | 12,060.00 | 0.4224 |

| 88 | 9270.00 | 14,724.00 | 0.3704 |

| 110 | 11,574.00 | 17,388.00 | 0.3344 |

| No. of Machines | Cost of Porting | Cost of Redev. | Degree of Portability |

|---|---|---|---|

| 22 | 1152.00 | 3744.00 | 0.6923 |

| 44 | 2304.00 | 4896.00 | 0.5294 |

| 66 | 3456.00 | 6048.00 | 0.4256 |

| 88 | 4608.00 | 7200.00 | 0.3600 |

| 110 | 5760.00 | 8352.00 | 0.3103 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bamunuarachchi, D.; Georgakopoulos, D.; Banerjee, A.; Jayaraman, P.P. Digital Twins Supporting Efficient Digital Industrial Transformation. Sensors 2021, 21, 6829. https://doi.org/10.3390/s21206829

Bamunuarachchi D, Georgakopoulos D, Banerjee A, Jayaraman PP. Digital Twins Supporting Efficient Digital Industrial Transformation. Sensors. 2021; 21(20):6829. https://doi.org/10.3390/s21206829

Chicago/Turabian StyleBamunuarachchi, Dinithi, Dimitrios Georgakopoulos, Abhik Banerjee, and Prem Prakash Jayaraman. 2021. "Digital Twins Supporting Efficient Digital Industrial Transformation" Sensors 21, no. 20: 6829. https://doi.org/10.3390/s21206829

APA StyleBamunuarachchi, D., Georgakopoulos, D., Banerjee, A., & Jayaraman, P. P. (2021). Digital Twins Supporting Efficient Digital Industrial Transformation. Sensors, 21(20), 6829. https://doi.org/10.3390/s21206829