Maintenance Strategies for Industrial Multi-Stage Machines: The Study of a Thermoforming Machine

Abstract

:1. Introduction

1.1. Preventive Programming Maintenance (PPM)

1.2. Improvement Preventive Programming Maintenance (IPPM)

1.3. Algorithm Life Optimisation Programming (ALOP)

1.4. Digital Behaviour Twin (DBT)

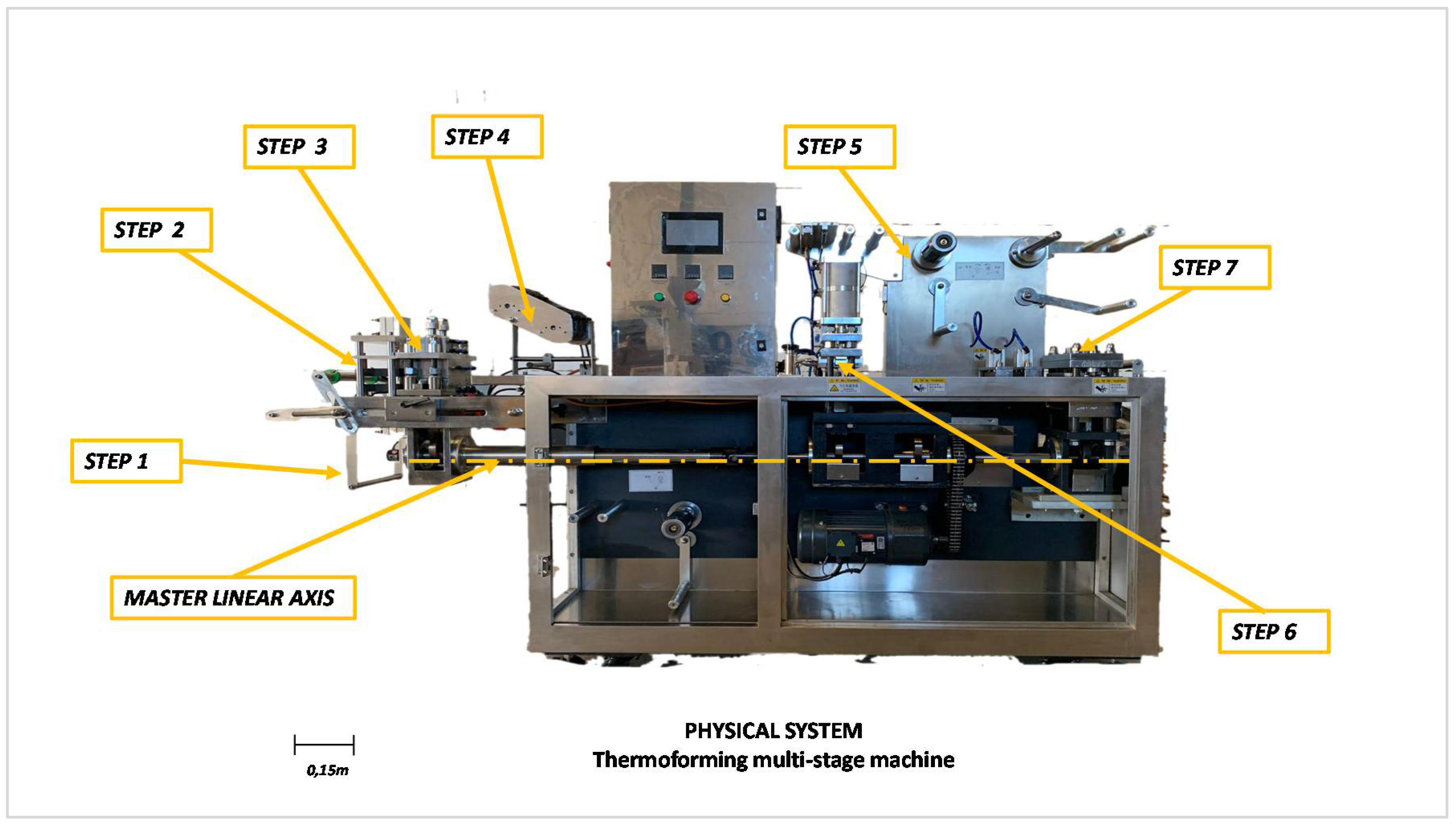

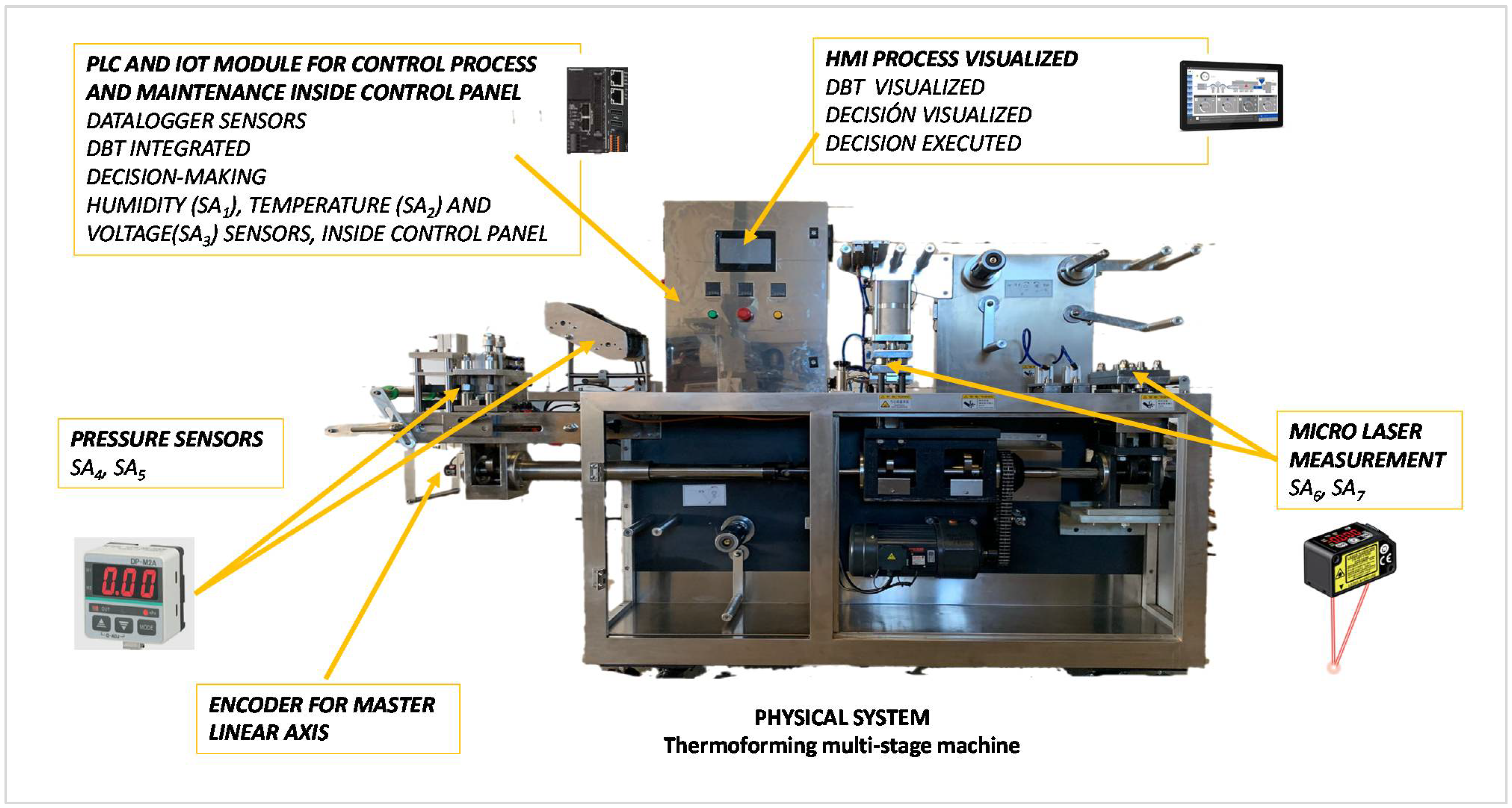

1.5. Methodology of the Case Studied

- Conceptualisation of the machine. In this section, the most important components, whose reliability, efficiency and availability were to be studied, were selected;

- Analysis of the causes and consequences of a failure in the selected components. (See Table 1);

- Proposition of individual maintenance times per component, as well as equations for calculating reliability, efficiency and availability;

- Proposition and location of appropriate sensors whose values are associated with the proper functioning of the components;

- Proposition and development of algorithms for ALOP and DBT strategies;

- Location of a master linear axis for the case of DBT, by means of which the study is related to the position of the encoder and subsequently converted to units of time;

- Configuration of the Programmable Logic Controller (PLC) datalogger function and record all the relevant values in each strategy;

- Recording of the failures and errors detected in ALOP and DBT;

- Evaluation of the results obtained.

- Obtain a systematic approach to managing the maintenance of multi-stage machines, so that it can allow their use not only in the case studied;

- Evaluate and compare the results that are obtained with the different of maintenance strategies;

- Propose a maintenance strategy for the detection of unexpected failures that cause manufacturing without expected quality or production stoppage.

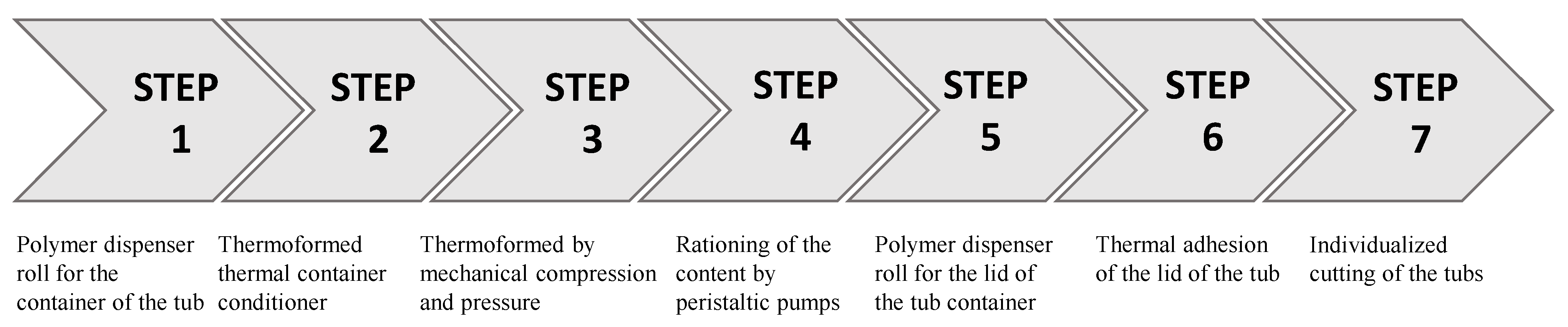

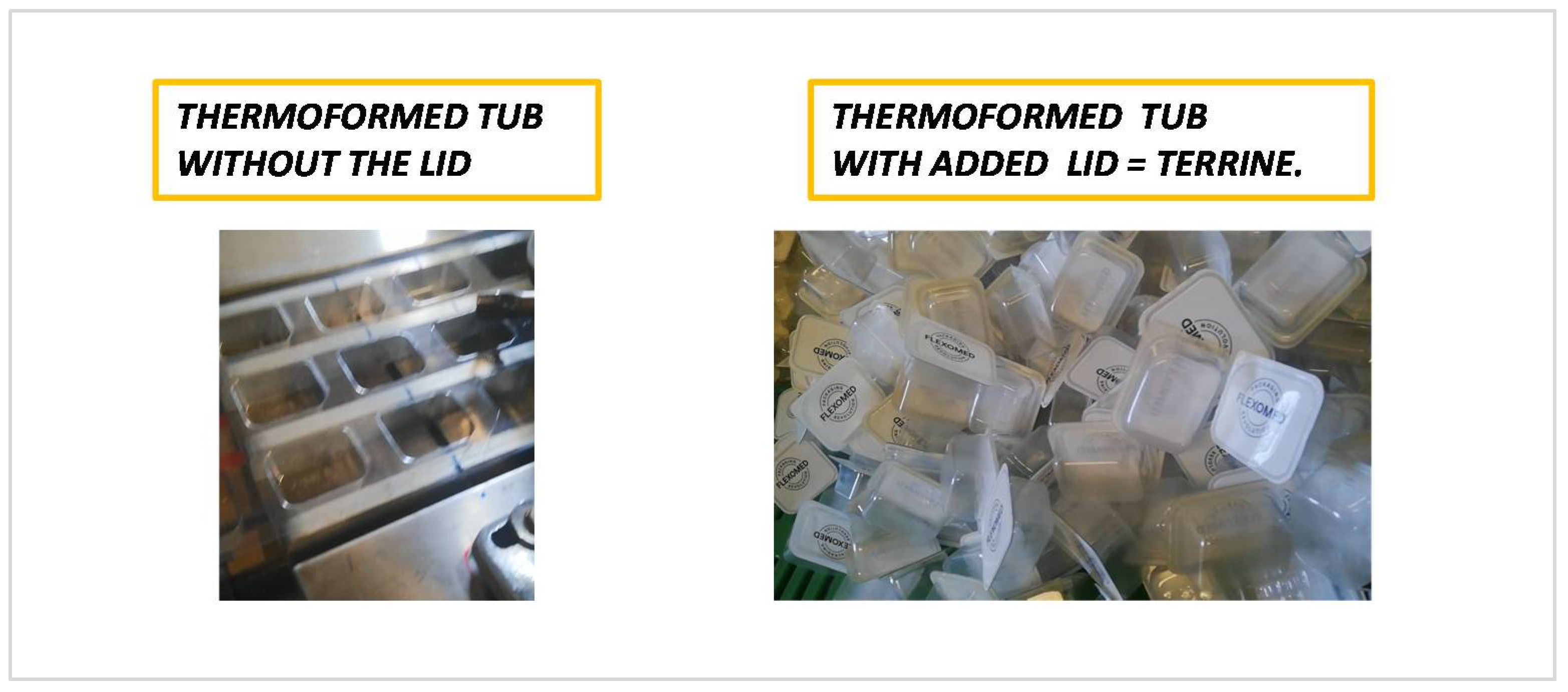

2. Case Studied

- A structural, fixed part, usually not subject to wear and tear but must be adequately protected against corrosion and meet health and food standards;

- Electronic components, power actuators, servo drives, motors, gearboxes, variable speed drives, electrical and electronic devices, including the HMI operator terminal, which are usually 4.3, 7 and 10 inch touch screens;

- Mechanical components subject to movement, such as bearings, shafts, belts and cams. They are generally designed with fatigue-resistant materials but may be damaged by wear and tear and environmental conditions;

- The peristaltic and pneumatic drive system, with which the filling of the terrines and the upward and downward movements of sets of cylinders for adhesion, sealing, glueing and cutting of the terrines are produced, respectively. These systems have bronze bushings, which often suffer from wear and tear;

- A polymer roll dosing system for the top and bottom of the tray. The movement of these rollers is carried out as required at any given moment.

- TTRP: Time to replace a component;

- TTC: Time to configure;

- TTMA: Time to mechanical adjustment;

- TTPR: Time to provisioning;

- MTTR: Mean time to repair;

- MTTF: Mean time to failure;

- MTBF: Mean time between failure;

- TTLR: Line restart time, defined by expert knowledge;

- TLP: Time lost production.

3. Maintenance Strategies for the Multi-Stage Thermoforming Machine

3.1. PPM: Preventive Programming Maintenance

3.2. IPPM: Improvement Preventive Programming Maintenance

3.3. ALOP: Algorithm Life Optimisation Programming

Mathematical Model of the Algorithm

- STEP 1.

- The time for evaluation and recalculation of values is set as t = 1000 s.

- STEP 2.

- From t = 0, values are taken from the “j” sensors measurements, SAj. every 10 s.

- STEP 3.

- And σj is calculated every 100 s.

- STEP 4.

- At t = 1000 s, is calculated for each component “i”.

- STEP 5.

- The values and are calculated.

- STEP 6.

- The value of is compared with and subsequently with .

- STEP 7.

- The risk factor of component “i” is calculated. It is compared to the cost of component “i”:

- STEP 8.

- If the notification for acquiring component “i” is initiated.

- STEP 9.

- If there are no warnings in Steps 7 and 8, compliance with the following is verified:

- STEP 10.

- At t = 1000 s, MTBF0 values are updated to MTBF1000 since the 1000 s that has elapsed is to be deducted from the mean time to failure of component “j”.

- STEP 11.

- Start the algorithm again at Step 2.

3.4. DBT: Digital Behaviour Twin

DBT Mathematical Model

- STEP 1.

- The assessment procedure starts every 10 encoder positions (EP10 to EP1000).

- STEP 2.

- An assessment is carried out every 10 positions:

- Actuator values ACz (binary value zero or one);

- Values of SAi sensors (analogue signals)

- STEP 3.

- Pattern checks:

- The ACz activations reading for the Encoder Position (EP) 10 value should coincide with the valid pattern (see Table 5)If not → PLC or encoder fault.

- The SAi sensor reading for the EP10 value should coincide with the valid standard (see Table 5)If not → Step 4.

- The ACz activations reading for the SAi value should coincide with the valid pattern (see Table 6)If not → Step 4.

- STEP 4.

- Checking deviations of SAi sensors:where dmax and dmin are the maximum and minimum deviations allowed in the measurements of the “i” sensors.

- STEP 5.

- The trend is assessed by analysing the mean and standard deviation of the last 1000 cumulative measurements of the SAi value of sensor “i”, whose value is other than zero.

- STEP 6.

- Decision taking.

- Deviations in the measurements of the “j” sensors, whose relationship is established with the “i” items by Table 4;

- Whether the evolution of any of the “z” actuator activation/deactivation commands is correctly coordinated and is proceeding according to the normal pattern;

- If any of the measurements of the “j” sensors conform to the encoder position;

- If any of the measurements of the “j” sensors conform to the activation pattern of the “z” actuators at each encoder position;

- Whether the absolute encoder is providing the shaft position information correctly;

- Whether the process control, PLC, is executing the commands correctly according to the encoder position.

- Take early decisions on machine components and prevent unwanted faults by assessing the measurements of each sensor and observing the measurement trend;

- Know the planned production that can be performed without a failure;

- Adjust the dmax and dmin values for each SAi sensor, allowing the establishment of a confidence margin where the output meets industry quality standards;

- Very precise control of deviations from nominal measurements of the “j” sensors by being assessed only when indicated by the position of the encoder and the “z” actuators and the sensor shows a value other than zero (see Step 5 of the DBT algorithm).

4. Results and Conclusions

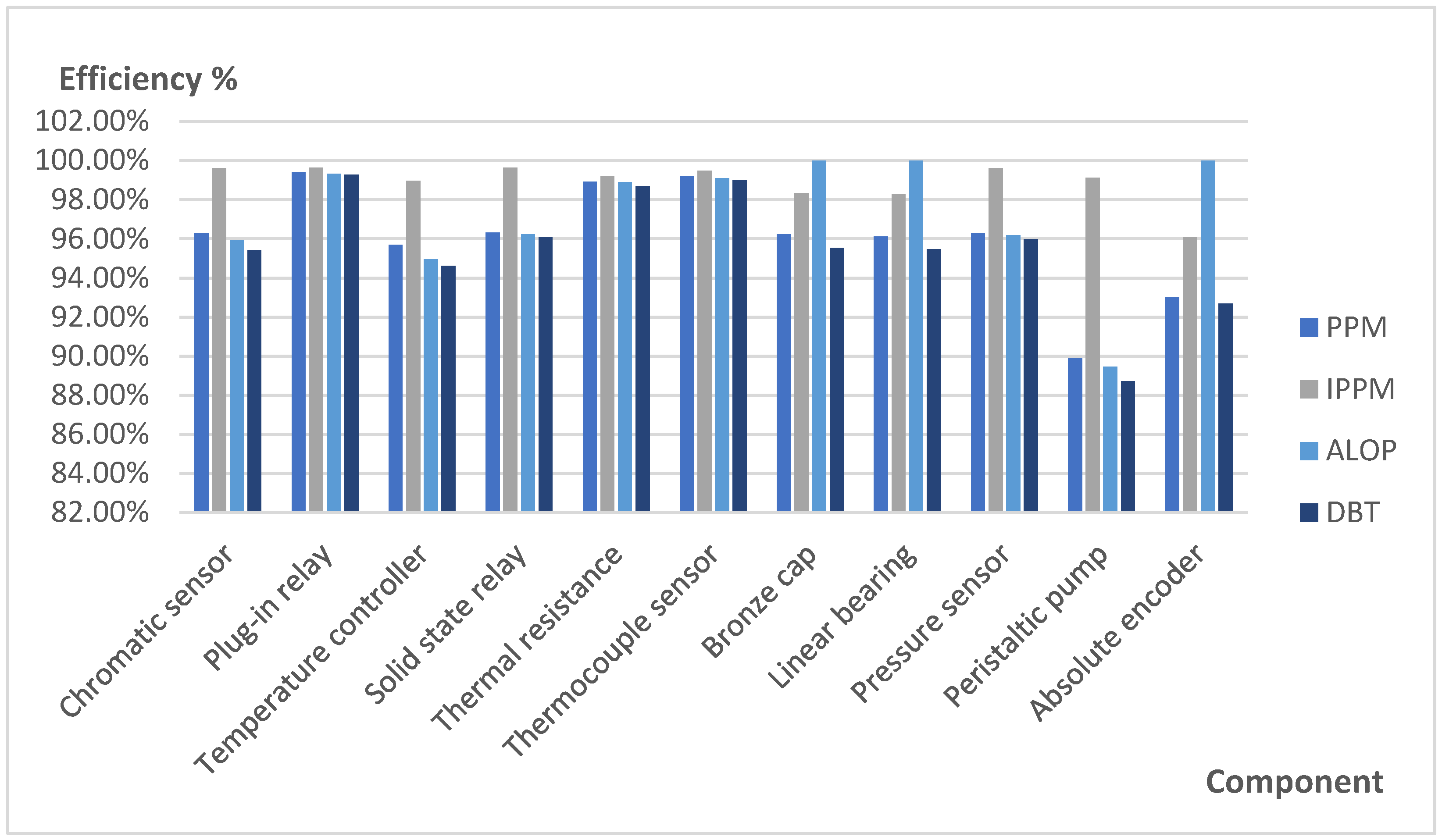

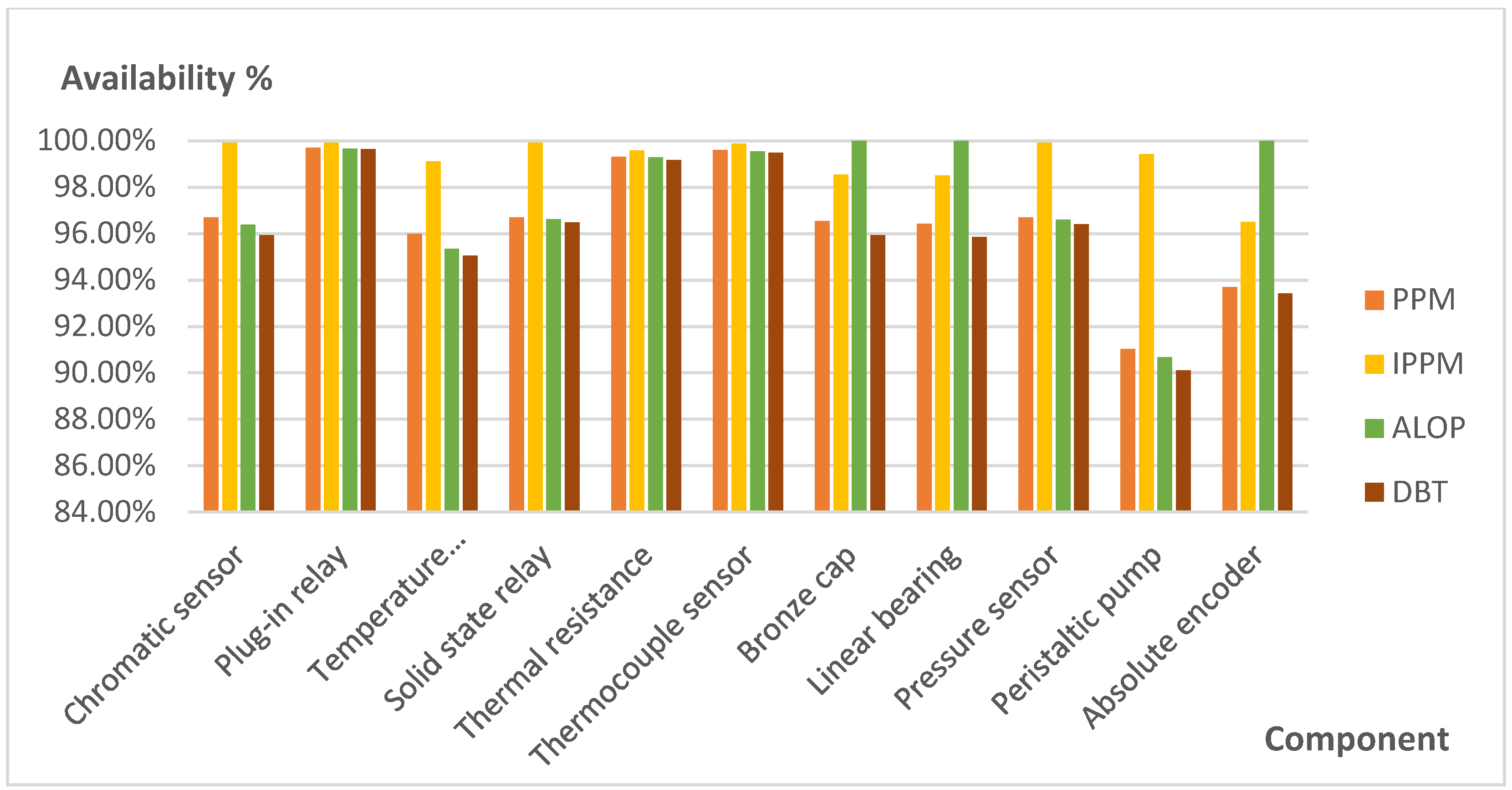

- The algorithms proposed for the ALOP and DBT strategies show favorable results, and their use can be proposed for managing the maintenance of other multi-stage machines;

- Because multi-stage machines require better maintenance control to detect unexpected failures, ALOP and DBT can be proposed as suitable strategies for this type of machine;

- Unexpected failures can be detected with ALOP and DBT strategies. The authors consider that both strategies complement PPM or IPPM, and their combined study could be an avenue for future research;

- The accuracy of the measurement evaluation procedure of the DBT strategy allows the detection of faults in moving mechanical components with very low deviations from nominal values;

- Knowledge of a normal operating pattern of machines is a very reliable source of knowledge for maintenance management. It allows the best assessment of component lifetime by setting limit deviations (dmax and dmin) (See Step 4 in the DBT algorithm) on sensor-measured values, based on the quality standards of each industry;

- The detection of unexpected mechanical or electronic components failures may be due to alterations of environmental operating conditions and non-recommended voltage values;

- The knowledge of the production that can be performed without failures is only achieved with the DBT model;

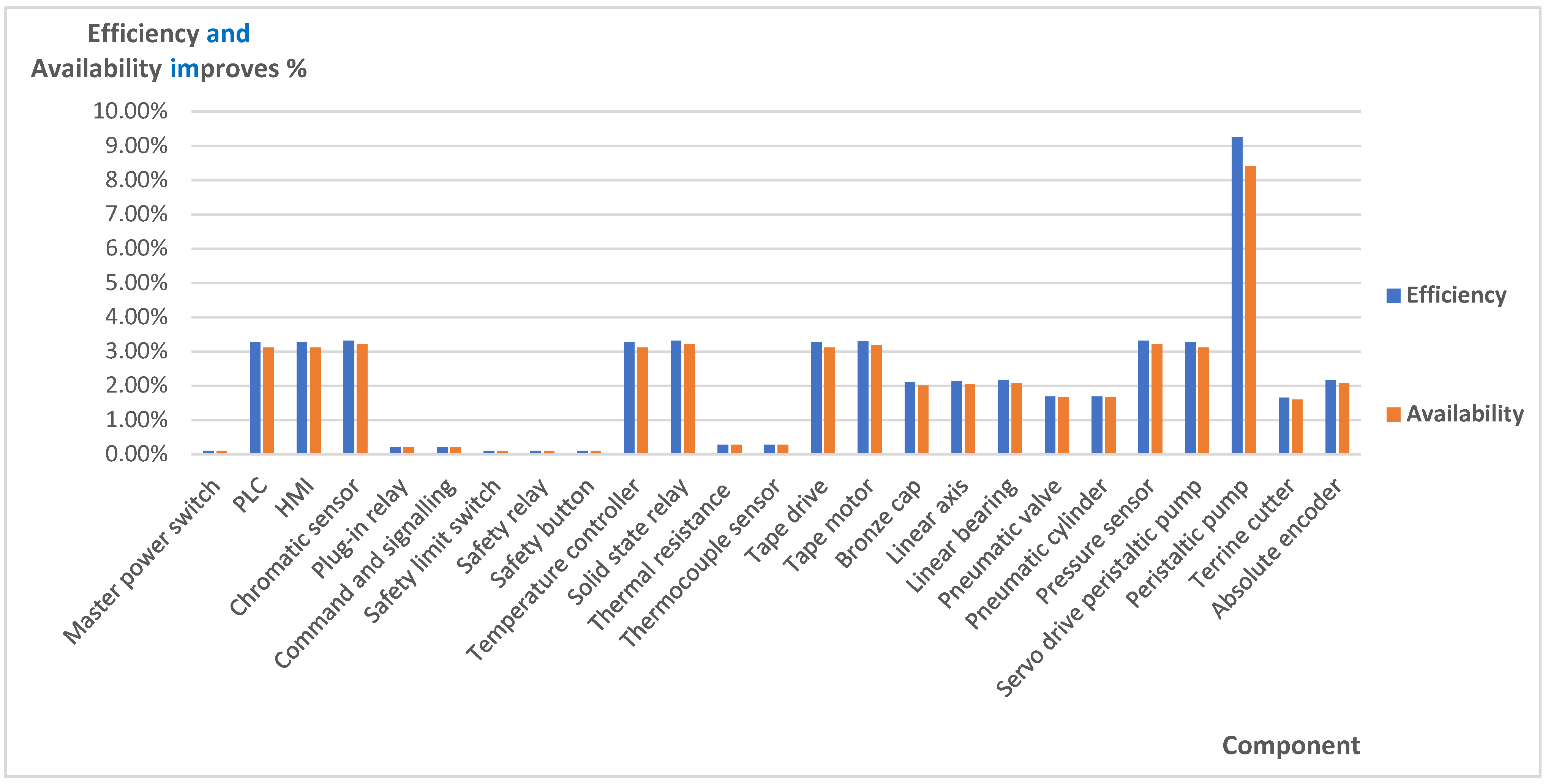

- The IPPM application offers improvements of efficiency and availability and minimises MTTR, but stock costs can grow;

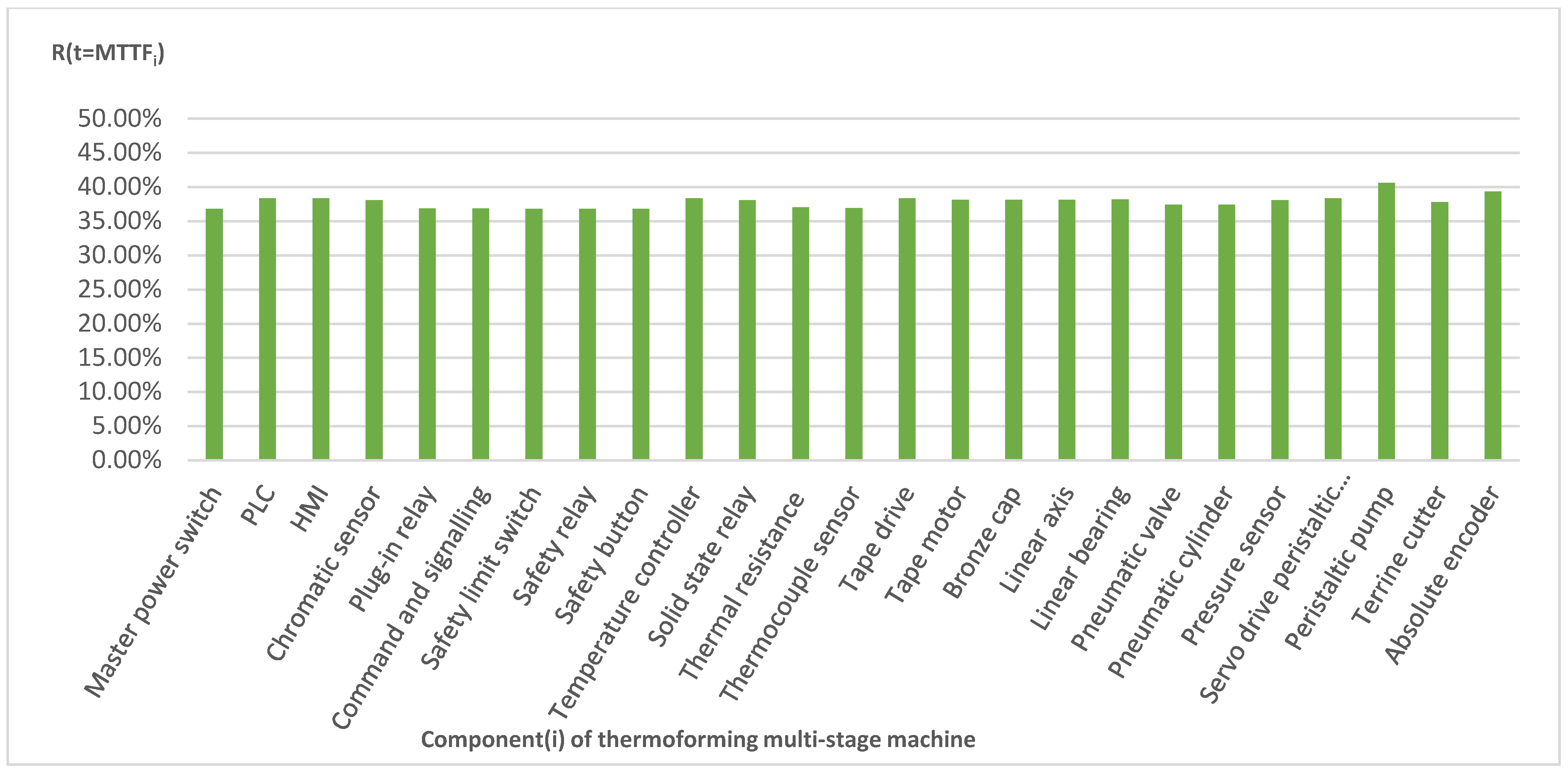

- Improvements in the efficiency and availability of the electronic components (see components 2, 3, 4, 10, 11, 14, 15, 21 and 22 in Figure 5) and partially the mechanical components (see components 10, 16, 17, 18, 19 and 23 in Figure 5) are noticeable. As with PPM, this strategy also fails to detect unexpected failures;

- Applying PM techniques based on the time scale is interesting if the SAi sensor values provide constant and similar measurements throughout the process. Otherwise, the dispersion in values may not correctly reflect reality. On multi-stage thermoforming machines, it is very beneficial to evaluate the measurements on the scale of the encoder positions and then decide on the time scale.

- Comparative study between the decrease in efficiency and availability by applying ALOP and DBT strategies, and the benefits of detecting unexpected failures compared with static value of MMTF provided by the PPM and IPPM strategies;

- Study of the application of different maintenance strategies for each kind of component in the same multi-stage machine;

- Study of the cost of the different maintenance strategies in a multi-stage machine.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Hoffmann Souza, M.L.; Da Costa, C.A.; Oliveira Ramos, G.D.; Da Rosa Righi, R. A survey on decision-making based on system reliability in the context of Industry 4.0. J. Manuf. Syst. 2020, 56, 133–156. [Google Scholar] [CrossRef]

- Cavalieri, S.; Salafia, M.G. A Model for Predictive Maintenance Based on Asset Administration Shell. Sensors 2020, 20, 6028. [Google Scholar] [CrossRef] [PubMed]

- Baum, J.; Laroque, C.; Oeser, B.; Skoogh, A.; Subramaniyan, M. Applications of Big Data analytics and Related Technologies in Maintenance—Literature-Based Research. Machines 2018, 6, 54. [Google Scholar] [CrossRef] [Green Version]

- Bouabdallaoui, Y.; Lafhaj, Z.; Yim, P.; Ducoulombier, L.; Bennadji, B. Predictive Maintenance in Building Facilities: A Machine Learning-Based Approach. Sensors 2021, 21, 1044. [Google Scholar] [CrossRef]

- Tan, Y.; Yang, W.; Yoshida, K.; Takakuwa, S. Application of IoT-Aided Simulation to Manufacturing Systems in Cyber-Physical System. Machines 2019, 7, 2. [Google Scholar] [CrossRef] [Green Version]

- Ghaleb, M.; Taghipour, S.; Sharifi, M.; Zolfagharinia, H. Integrated production and maintenance scheduling for a single degrading machine with deterioration-based failures. Comput. Ind. Eng. 2020, 143, 106432. [Google Scholar] [CrossRef]

- Duffuaa, S.; Kolus, A.; Al-Turki, U.; El-Khalifa, A. An integrated model of production scheduling, maintenance and quality for a single machine. Comput. Ind. Eng. 2020, 142, 106239. [Google Scholar] [CrossRef]

- Panagiotis, H.T.; Arvanitoyannis, J.S.; Varzakas, T.H. Reliability and maintainability analysis of cheese (feta) production line in a Greek medium-size company: A case study. J. Food Eng. 2009, 94, 233–240. [Google Scholar] [CrossRef]

- Rahmati, S.H.A.; Ahmadi, A.; Karimi, B. Developing simulation-based optimization mechanism for a novel stochastic reliability centered maintenance problem. Sci. Iran. E 2018, 25, 2788–2806. [Google Scholar] [CrossRef] [Green Version]

- Niu, G.C.; Wang, Y.; Hu, Z.; Zhao, Q.; Hu, D.M. Application of AHP and EIE in Reliability Analysis of Complex Production Lines Systems. Math. Probl. Eng. 2019, 2019, 7238785. [Google Scholar] [CrossRef] [Green Version]

- Jiři, D.; Tuhý, T.; Jančíková, Z.K. Method for optimizing maintenance location within the industrial plant. Int. Sci. J. Logist. 2019, 6, 55–62. [Google Scholar] [CrossRef]

- Liberopoulos, G.; Tsarouhas, P. Reliability analysis of an automated pizza production line. J. Food Eng. 2005, 69, 79–96. [Google Scholar] [CrossRef]

- Gharbi, A.; Kenne, J.-P.; Beit, M. Optimal safety stocks and preventive maintenance periods in unreliable manufacturing systems. Int. J. Prod. Econ. 2007, 107, 422–434. [Google Scholar] [CrossRef] [Green Version]

- Mauricio-Moreno, H.; Miranda, J.; Chavarría, D.; Ramírez-Cadena, M.; Molina, A. Design S3-RF (Sustainable x Smart x Sensing—Reference Framework) for the Future Manufacturing Enterprise. Science Direct. IFAC Pap. Line 2015, 48, 58–63. [Google Scholar] [CrossRef]

- Weichhart, G.; Molina, A.; Chen, D.; Whitman, L.E.; Vernadat, F. Challenges and current developments for Sensing, Smart and Sustainable Enterprise Systems. Comput. Ind. 2016, 79, 34–46. [Google Scholar] [CrossRef]

- Miranda, J.; Pérez-Rodríguez, R.; Borja, V.; Wright, P.K.; Molina, A. Integrated Product, Process and Manufacturing System Development Reference Model to develop Cyber-Physical Production Systems–The Sensing, Smart and Sustainable Microfactory Case Study. Science Direct. FAC Pap. Line 2017, 50, 13065–13071. [Google Scholar] [CrossRef]

- Botch, B.; Rajagopal, V.; Bukkapatnam, S.T. Process-machine interactions and a multi-sensor fusion approach to predict surface roughness in cylindrical plunge grinding process. Procedia Manuf. 2018, 26, 700–711. [Google Scholar] [CrossRef]

- Miranda, J.; Ponce, P.; Molina, A.; Wright, P. Sensing, smart and sustainable technologies for Agri-Food 4.0. Comput. Ind. 2019, 108, 21–36. [Google Scholar] [CrossRef]

- Ponce, P.; Meier, A.; Miranda, J.; Molina, A.; Peffer, T. The Next Generation of Social Products Based on Sensing, Smart and Sustainable (S3) Features: A Smart Thermostat as Case Study. Science Direct. IFAC Pap. Line 2019, 52, 2390–2395. [Google Scholar] [CrossRef]

- Alcácer, V.; Cruz-Machado, V. Scanning the Industry 4.0: A Literature Review on Technologies for Manufacturing Systems. Eng. Sci. Technol. Int. J. 2019, 22, 899–919. [Google Scholar] [CrossRef]

- Phuyal, S.; Bista, D.; Bista, R. Challenges, Opportunities and Future Directions of Smart Manufacturing: A State of Art Review. Sustain. Futures 2020, 2, 100023. [Google Scholar] [CrossRef]

- Longfei, H.; Mei, X.; Bin, G. Internet-of-things enabled supply chain planning and coordination with big data services: Certain theoretic implications. J. Manag. Sci. Eng. 2020, 5, 1–22. [Google Scholar] [CrossRef]

- Singh, A.; Payal, A.; Bharti, S. A walkthrough of the emerging IoT paradigm: Visualizing inside functionalities, key features, and open issues. J. Netw. Comput. Appl. 2019, 143, 111–151. [Google Scholar] [CrossRef]

- Kim, S.; Pérez Del Castillo, R.; Caballero, I.; Lee, J.; Lee, C.; Lee, D.; Lee, S.; Mate, A. Extending Data Quality Management for Smart Connected Product Operations. IEEE Access 2019, 7, 144663–144678. [Google Scholar] [CrossRef]

- Perez-Castillo, R.; Carretero, A.G.; Rodriguez, M.; Caballero, I.; Piattini, M. Data Quality Best Practices in IoT Environments. In Proceedings of the International Conference on the Quality of Information and Communications Technology, Coimbra, Portugal, 4–7 September 2018. [Google Scholar] [CrossRef]

- Alsharif, M.; Rawat, D.B. Study of Machine Learning for Cloud Assisted IoT Security as a Service. Sensors 2021, 21, 1034. [Google Scholar] [CrossRef] [PubMed]

- Luque, A.; Estela Peralta, M.; De las Heras, A.; Córdoba, A. State of the Industry 4.0 in the Andalusian food sector. Proc. Manuf. 2017, 13, 1199–1205. [Google Scholar] [CrossRef]

- Corallo, A.; Latino, M.E.; Menegoli, M. From Industry 4.0 to Agriculture 4.0: A Framework to Manage Product Data in Agri-Food Supply Chain for Voluntary Traceability. Int. J. Nutr. Food Eng. 2018, 12, 5. [Google Scholar]

- Short, A.R.; Leligou, H.C.; Theocharis, E. Execution of a Federated Learning process within a smart contract. In Proceedings of the 2021 IEEE International Conference on Consumer Electronics (ICCE), Las Vegas, NV, USA, 10–12 January 2021. [Google Scholar] [CrossRef]

- Escobar, L.; Carvajal, L.; Naranjo, J.; Ibarra, A.; Villacís, C.; Zambrano, M.; Galárraga, F. Design and implementation of complex systems using Mechatronics and Cyber-Physical Systems approaches. In Proceedings of the International Conference on Mechatronics an Automation, Takamatsu, Japan, 6–9 August 2017. [Google Scholar]

- Jamaludin, J.; Mohd Rohani, J. Cyber-Physical System (CPS): State of the Art. In Proceedings of the 2018 International Conference on Computing, Electronic and Electrical Engineering (ICE Cube), Quetta, Pakistan, 12–13 November 2018. [Google Scholar] [CrossRef]

- Villarreal Lozanoa, C.; Kathiresh Vijayan, K. Literature review on Cyber Physical Systems Design. Procedia Manuf. 2020, 45, 295–300. [Google Scholar] [CrossRef]

- Capota, E.A.; Sorina Stangaciu, C.; Victor Micea, M.; Curiac, D.-I. Towards mixed criticality task scheduling in cyber physical systems: Challenges and perspectives. J. Syst. Softw. 2019, 156, 204–216. [Google Scholar] [CrossRef]

- Colombo, A.W.; Karnouskos, S.; Kaynak, O.; Shi, Y.; Yin, S. Industrial Cyberphysical Systems: A Backbone of the Fourth Industrial Revolution. IEEE Ind. Electron. Mag. 2017, 11, 6–16. [Google Scholar] [CrossRef]

- Iqbal, R.; Doctor, F.; More, B.; Mahmud, S.; Yousuf, U. Big Data analytics and Computational Intelligence for Cyber–Physical Systems: Recent trends and state of the art applications. Future Gener. Comput. Syst. 2020, 105, 766–778. [Google Scholar] [CrossRef] [Green Version]

- Meng, K.; Cao, Y.; Peng, X.; Prybutok, V.; Youcef-Toumi, K. Smart recovery decision-making for end-of-life products in the context of ubiquitous information and computational intelligence. J. Clean. Prod. 2020, 272, 122804. [Google Scholar] [CrossRef]

- Stary, C. Digital Twin Generation: Re-Conceptualizing Agent Systems for Behavior-Centered Cyber-Physical System Development. Sensors 2021, 21, 1096. [Google Scholar] [CrossRef]

- Schützer, K.; De Andrade Bertazzia, J.; Sallati, C.; Anderl, R.; Zancul, E. Contribution to the development of a Digital Twin based on product lifecycle to support the manufacturing process. Procedia CIRP 2019, 84, 82–87. [Google Scholar] [CrossRef]

- Ganguli, R.; Adhikari, S. The digital twin of discrete dynamic systems: Initial approaches and future challenges. Appl. Math. Model. 2020, 77, 1110–1128. [Google Scholar] [CrossRef]

- Xia, K.; Sacco, C.; Kirkpatrick, M.; Saidy, C.; Nguyen, L.; Kircaliali, A.; Harik, R. A digital twin to train deep reinforcement learning agent for smart manufacturing plants: Environment, interfaces and intelligence. J. Manuf. Syst. 2021, 58, 210–230. [Google Scholar] [CrossRef]

- Liu, M.; Fang, S.; Dong, H.; Xu, C. Review of digital twin about concepts, technologies, and industrial applications. J. Manuf. Syst. 2021, 58, 346–361. [Google Scholar] [CrossRef]

- Ritto, T.G.; Rochinha, F.A. Digital twin, physics-based model, and machine learning applied to damage detection in structures. Mech. Syst. Signal Process. 2021, 155, 107614. [Google Scholar] [CrossRef]

- Lin, T.Y.; Jia, Z.; Yang, C.; Xiao, Y.; Lan, S.; Shi, G.; Zeng, B.; Li, H. Evolutionary digital twin: A new approach for intelligent industrial product development. Adv. Eng. Inform. 2021, 47, 101209. [Google Scholar] [CrossRef]

- Wright, L.; Davidson, S. How to tell the difference between a model and a digital twin. Adv. Modeling Simul. Eng. Sci. 2020, 7, 13. [Google Scholar] [CrossRef]

- Chakraborty, S.; Adhikari, S. Machine learning based digital twin for dynamical systems with multiple time-scales. Comput. Struct. 2021, 243, 106410. [Google Scholar] [CrossRef]

- Latifa, H.; Starly, B. A Simulation Algorithm of a Digital Twin for Manual Assembly Process. Procedia Manuf. 2020, 48, 932–939. [Google Scholar] [CrossRef]

- Ladj, A.; Wang, Z.; Meski, O.; Belkadi, F.; Ritou, M.; Da Cunha, C. A knowledge-based Digital Shadow for machining industry in a Digital Twin perspective. J. Manuf. Syst. 2021, 58, 168–179. [Google Scholar] [CrossRef]

- Lemonte, A.J. A new exponential-type distribution with constant, decreasing, increasing, upside-down bathtub and bathtub-shaped failure rate function. Comput. Stat. Data Anal. 2013, 62, 149–170. [Google Scholar] [CrossRef]

- Yang, D.Y.; Frangopol, D.M.; Han, X. Error analysis for approximate structural life-cycle reliability and risk using machine learning methods. Struct. Saf. 2021, 89, 102033. [Google Scholar] [CrossRef]

- Masachusetts Institute of Technology. Available online: https://news.mit.edu/2012/explained-sigma-0209 (accessed on 30 September 2021).

| Item | Component | Type | Fault Source | Consequence of Failure |

|---|---|---|---|---|

| 1 | Master power switch | Power Machine/Static | Ambient condition, Power supplier event | Stop |

| 2 | PLC | Control/Static | Ambient condition, Power supplier event | Stop |

| 3 | HMI | Control/Static | Ambient condition, Power supplier event, Crash | Stop |

| 4 | Chromatic sensor | Sensor/Static | Ambient condition, Power supplier event, Crash | Malfunction |

| 5 | Plug-in relay | Control device/Static | Ambient condition, Power supplier event | Stop |

| 6 | Command and signalling | Control | Ambient condition, Power supplier event, Crash | Stop |

| 7 | Safety limit switch | Security/Static | Ambient condition, Power supplier event | Stop |

| 8 | Safety relay | Security/Static | Ambient condition, Power supplier event | Stop |

| 9 | Safety button | Security/Static | Ambient condition, Power supplier event, Crash | Stop |

| 10 | Temperature controller | Control/Static | Ambient condition, Power supplier event | Stop |

| 11 | Solid state relay | Actuator/Static | Ambient condition, Power supplier event | Malfunction |

| 12 | Thermal resistance | Actuator/Dynamic | Global fatigue | Malfunction |

| 13 | Thermocouple sensor | Control/Dynamic | Global fatigue | Malfunction |

| 14 | Tape drive | Actuator/Static | Ambient condition, Power supplier event | Stop |

| 15 | Tape Motor | Motor/Dynamic | Global fatigue | Malfunction |

| 16 | Bronze cap | Mechanism/Dynamic | Global fatigue | Malfunction |

| 17 | Linear axis | Mechanism/Dynamic | Global fatigue | Malfunction |

| 18 | Lineal bearing | Mechanism/Dynamic | Global fatigue | Malfunction |

| 19 | Pneumatic valve | Actuator/Dynamic | Pressure failure, Failure valve | Malfunction |

| 20 | Pneumatic cylinder | Actuator/Dynamic | Pressure failure, Cylinder failure | Malfunction |

| 21 | Pressure sensor | Control/Static | Ambient condition, Power supplier event | Stop |

| 22 | Servo drive peristaltic pump | Actuator/Dynamic | Ambient condition, Power supplier event | Stop |

| 23 | Peristaltic pump | Actuator/Dynamic | Global fatigue | Malfunction |

| 24 | Terrine cutter | Mechanism/Dynamic | Global fatigue, Mechanical hit | Malfunction |

| 25 | Absolute encoder | Control/Dynamic | Ambient condition, Power supplier event. Mechanical hit | Stop |

| Component | MTTR | TTRP | TTC | TTMA | TTPR | MTTF | TLP | Efficiency | MTBF | Availability |

|---|---|---|---|---|---|---|---|---|---|---|

| Master power switch | 14,400 | 3600 | 0 | 0 | 10,800 | 9,999,999 | 28,800 | 99.71% | 10,014,399 | 99.86% |

| PLC | 435,600 | 3600 | 86,400 | 0 | 345,600 | 9,999,999 | 450,000 | 95.69% | 10,4435,599 | 95.99% |

| HMI | 435,600 | 3600 | 86,400 | 0 | 345,600 | 9,999,999 | 450,000 | 95.69% | 10,435,599 | 95.99% |

| Chromatic sensor | 176,520 | 3600 | 120 | 0 | 172,800 | 5,000,000 | 190,920 | 96.31% | 5,176,520 | 96.70% |

| Plug-in relay | 14,400 | 3600 | 0 | 0 | 10,800 | 5,000,000 | 28,800 | 99.43% | 5,014,400 | 99.71% |

| Command and signalling | 14,400 | 3600 | 0 | 0 | 10,800 | 5,000,000 | 28,800 | 99.43% | 5,014,400 | 99.71% |

| Safety limit switch | 14,400 | 3600 | 0 | 0 | 10,800 | 9,999,999 | 28,800 | 99.71% | 10,014,399 | 99.86% |

| Safety relay | 14,400 | 3600 | 0 | 0 | 10,800 | 9,999,999 | 28,800 | 99.71% | 10,014,399 | 99.86% |

| Safety button | 14,400 | 3600 | 0 | 0 | 10,800 | 9,999,999 | 28,800 | 99.71% | 10,014,399 | 99.86% |

| Temperature controller | 435,600 | 3600 | 86,400 | 0 | 345,600 | 9,999,999 | 450,000 | 95.69% | 10,435,599 | 95.99% |

| Solid state relay | 176,400 | 3600 | 0 | 0 | 172,800 | 5,000,000 | 190,800 | 96.31% | 5,176,400 | 96.70% |

| Thermal resistance | 25,500 | 14,400 | 0 | 300 | 10,800 | 3,700,800 | 39,900 | 98.93% | 3,726,300 | 99.32% |

| Thermocouple sensor | 14,700 | 3600 | 0 | 300 | 10,800 | 3,700,800 | 29,100 | 99.22% | 3,715,500 | 99.61% |

| Tape drive | 435,600 | 3600 | 86,400 | 0 | 345,600 | 9,999,999 | 450,000 | 95.69% | 10,435,599 | 95.99% |

| Tape motor | 187,200 | 14,400 | 0 | 0 | 172,800 | 5,000,000 | 201,600 | 96.11% | 5,187,200 | 96.52% |

| Bronze cap | 288,000 | 28,800 | 0 | 86,400 | 172,800 | 7,750,000 | 302,400 | 96.24% | 8,038,000 | 96.54% |

| Linear axis | 288,000 | 28,800 | 0 | 86,400 | 172,800 | 7,625,000 | 302,400 | 96.18% | 7,913,000 | 96.49% |

| Lineal bearing | 288,000 | 28,800 | 0 | 86,400 | 172,800 | 7,500,000 | 302,400 | 96.12% | 7,788,000 | 96.43% |

| Pneumatic valve | 176,400 | 3600 | 0 | 0 | 172,800 | 9,999,999 | 190,800 | 98.13% | 10,176,399 | 98.30% |

| Pneumatic cylinder | 176,400 | 3600 | 0 | 0 | 172,800 | 9,999,999 | 190,800 | 98.13% | 10,176,399 | 98.30% |

| Pressure sensor | 176,700 | 3600 | 300 | 0 | 172,800 | 5,000,000 | 191,100 | 96.31% | 5,176,700 | 96.70% |

| Servo drive peristaltic pump | 435,600 | 3600 | 86,400 | 0 | 345,600 | 9,999,999 | 450,000 | 95.69% | 10,435,599 | 95.99% |

| Peristaltic pump | 547,200 | 14,400 | 0 | 14,400 | 518,400 | 5,000,000 | 561,600 | 89.88% | 5,547,200 | 91.02% |

| Terrine cutter | 288,000 | 28,800 | 0 | 86,400 | 172,800 | 9,999,999 | 302,400 | 97.06% | 10,287,999 | 97.28% |

| Absolute encoder | 360,000 | 14,400 | 86,400 | 86,400 | 172,800 | 5,000,000 | 374,400 | 93.01% | 5,360,000 | 93.71% |

| Item | Component | PPM | IPPM | Difference IPPM-PPM | |||

|---|---|---|---|---|---|---|---|

| Efficiency | Availability | Efficiency | Availability | Efficiency | Availability | ||

| 1 | Master power switch | 99.71% | 99.86% | 99.82% | 99.96% | 0.10% | 0.10% |

| 2 | PLC | 95.69% | 95.99% | 98.96% | 99.11% | 3.27% | 3.12% |

| 3 | HMI | 95.69% | 95.99% | 98.96% | 99.11% | 3.27% | 3.12% |

| 4 | Chromatic sensor | 96.31% | 96.70% | 99.63% | 99.92% | 3.32% | 3.22% |

| 5 | Plug-in relay | 99.43% | 99.71% | 99.63% | 99.92% | 0.21% | 0.21% |

| 6 | Command and signalling | 99.43% | 99.71% | 99.63% | 99.92% | 0.21% | 0.21% |

| 7 | Safety limit switch | 99.71% | 99.86% | 99.82% | 99.96% | 0.10% | 0.10% |

| 8 | Safety relay | 99.71% | 99.86% | 99.82% | 99.96% | 0.10% | 0.10% |

| 9 | Safety button | 99.71% | 99.86% | 99.82% | 99.96% | 0.10% | 0.10% |

| 10 | Temperature controller | 95.69% | 95.99% | 98.96% | 99.11% | 3.27% | 3.12% |

| 11 | Solid state relay | 96.31% | 96.70% | 99.63% | 99.92% | 3.32% | 3.22% |

| 12 | Thermal resistance | 98.93% | 99.32% | 99.21% | 99.60% | 0.28% | 0.28% |

| 13 | Thermocouple sensor | 99.22% | 99.61% | 99.50% | 99.89% | 0.28% | 0.28% |

| 14 | Tape drive | 95.69% | 95.99% | 98.96% | 99.11% | 3.27% | 3.12% |

| 15 | Tape Motor | 96.11% | 96.52% | 99.42% | 99.71% | 3.31% | 3.19% |

| 16 | Bronze cap | 96.24% | 96.54% | 98.35% | 98.55% | 2.11% | 2.01% |

| 17 | Linear axis | 96.18% | 96.49% | 98.32% | 98.53% | 2.14% | 2.04% |

| 18 | Linear bearing | 96.12% | 96.43% | 98.29% | 98.51% | 2.18% | 2.07% |

| 19 | Pneumatic valve | 98.13% | 98.30% | 99.82% | 99.96% | 1.69% | 1.66% |

| 20 | Pneumatic cylinder | 98.13% | 98.30% | 99.82% | 99.96% | 1.69% | 1.66% |

| 21 | Pressure sensor | 96.31% | 96.70% | 99.63% | 99.92% | 3.32% | 3.22% |

| 22 | Servo drive peristaltic pump | 95.69% | 95.99% | 98.96% | 99.11% | 3.27% | 3.12% |

| 23 | Peristaltic pump | 89.88% | 91.02% | 99.14% | 99.42% | 9.26% | 8.40% |

| 24 | Terrine cutter | 97.06% | 97.28% | 98.72% | 98.87% | 1.66% | 1.59% |

| 25 | Absolute encoder | 96.12% | 96.43% | 98.29% | 98.51% | 2.18% | 2.07% |

| Sensor | Description | Items Affected |

|---|---|---|

| SA1 | % humidity inside the control panel | 1, 2, 3, 4, 5, 8, 10, 11, 14, 22, 24, 25 |

| SA2 | Cª temperature inside control panel | 1, 2, 3, 4, 5, 8, 10, 11, 14, 22, 24, 25 |

| SA3 | Voltage RMS in IGBT | 1, 2, 3, 4, 5, 8, 10, 12, 14, 15, 19, 20, 21, 22, 23, 25 |

| SA4 | Pressure sensor for thermoformer tub MODEL DPM2A of PANASONIC | 10, 12, 13, 16, 18, 19, 20, 21 |

| SA5 | Pressure sensor for peristaltic pumps MODEL DPM2A of PANASONIC | 22, 23 |

| SA6 | Micro laser measurement, side front MODEL HGC of PANASONIC | 14, 15, 16, 17, 18 |

| SA7 | Micro laser measurement, side rear MODEL HGC of PANASONIC | 14, 15, 16, 17, 18 |

| EP (Encoder Position) | 0 | 10 | 100 | 200 | 300 | 400 | 450 | 500 | 600 | 700 | 800 | 900 | 970 | 980 | 990 | 999 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| AC1: Cam bottom dead centre | 1 | 1 | 1 | 1 | 1 | 0 | 0 | 0 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| AC2: Drag start point | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| AC3: Blown Time | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| AC4: Start of heater operation | 0 | 0 | 0 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 0 |

| AC5: Dosing point | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| AC6: Top point cams | 0 | 0 | 0 | 0 | 1 | 1 | 1 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| AC7: Home pushers | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 0 | 0 | 0 |

| AC8: Start blowing | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| SA1: Humidity % inside Control Panel | 60 | 60 | 60 | 60 | 60 | 60 | 60 | 60 | 60 | 60 | 60 | 60 | 60 | 60 | 60 | 60 |

| SA2: Temperature inside Control Panel | 40 | 40 | 40 | 40 | 40 | 40 | 40 | 40 | 40 | 40 | 40 | 40 | 40 | 40 | 40 | 40 |

| SA3: Voltage supplier inside Control Panel | 230 | 230 | 230 | 230 | 230 | 230 | 230 | 230 | 230 | 230 | 230 | 230 | 230 | 230 | 230 | 230 |

| SA4: Pressure sensor Thermoforming step (bar) | 0 | 0 | 4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| SA5: Pressure sensor after Peristaltic Pump (bar) | 0 | 0 | 0 | 0 | 0.2 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| SA6: Laser measure hp heat seal front (Data in mm) | 0 | 0 | 0 | 0 | 5.0 | 5.0 | 5.0 | 5.0 | 0.0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| SA7: Laser measure hp heat seal rear (Data in mm) | 0 | 0 | 0 | 0 | 5.0 | 5.0 | 5.0 | 5.0 | 0.0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| Item | Component | ALOP True | ALOP False | DBT True |

|---|---|---|---|---|

| 1 | Master power switch | |||

| 2 | PLC | |||

| 3 | HMI | |||

| 4 | Chromatic sensor | 1 | 1 | |

| 5 | Plug-in relay | 1 | 1 | 1 |

| 6 | Command and signalling | |||

| 7 | Safety limit switch | |||

| 8 | Safety relay | |||

| 9 | Safety button | |||

| 10 | Temperature controller | 1 | 1 | 1 |

| 11 | Solid state relay | 1 | 1 | |

| 12 | Thermal resistance | 1 | 1 | 1 |

| 13 | Thermocouple sensor | 1 | 1 | 1 |

| 14 | Tape drive | |||

| 15 | Tape Motor | |||

| 16 | Bronze cap | 1 | ||

| 17 | Linear axis | |||

| 18 | Linear bearing | 1 | ||

| 19 | Pneumatic valve | |||

| 20 | Pneumatic cylinder | |||

| 21 | Pressure sensor | 1 | 1 | |

| 22 | Servo drive peristaltic pump | |||

| 23 | Peristaltic pump | 1 | 1 | |

| 25 | Absolute encoder | 1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

García, F.J.Á.; Salgado, D.R. Maintenance Strategies for Industrial Multi-Stage Machines: The Study of a Thermoforming Machine. Sensors 2021, 21, 6809. https://doi.org/10.3390/s21206809

García FJÁ, Salgado DR. Maintenance Strategies for Industrial Multi-Stage Machines: The Study of a Thermoforming Machine. Sensors. 2021; 21(20):6809. https://doi.org/10.3390/s21206809

Chicago/Turabian StyleGarcía, Francisco Javier Álvarez, and David Rodríguez Salgado. 2021. "Maintenance Strategies for Industrial Multi-Stage Machines: The Study of a Thermoforming Machine" Sensors 21, no. 20: 6809. https://doi.org/10.3390/s21206809

APA StyleGarcía, F. J. Á., & Salgado, D. R. (2021). Maintenance Strategies for Industrial Multi-Stage Machines: The Study of a Thermoforming Machine. Sensors, 21(20), 6809. https://doi.org/10.3390/s21206809