Analysis of Factors Influencing Vibration Suppression of Spray Boom-Air Suspension for Medium and Small-Scale High-Clearance Sprayers

Abstract

:1. Introduction

2. Materials and Methods

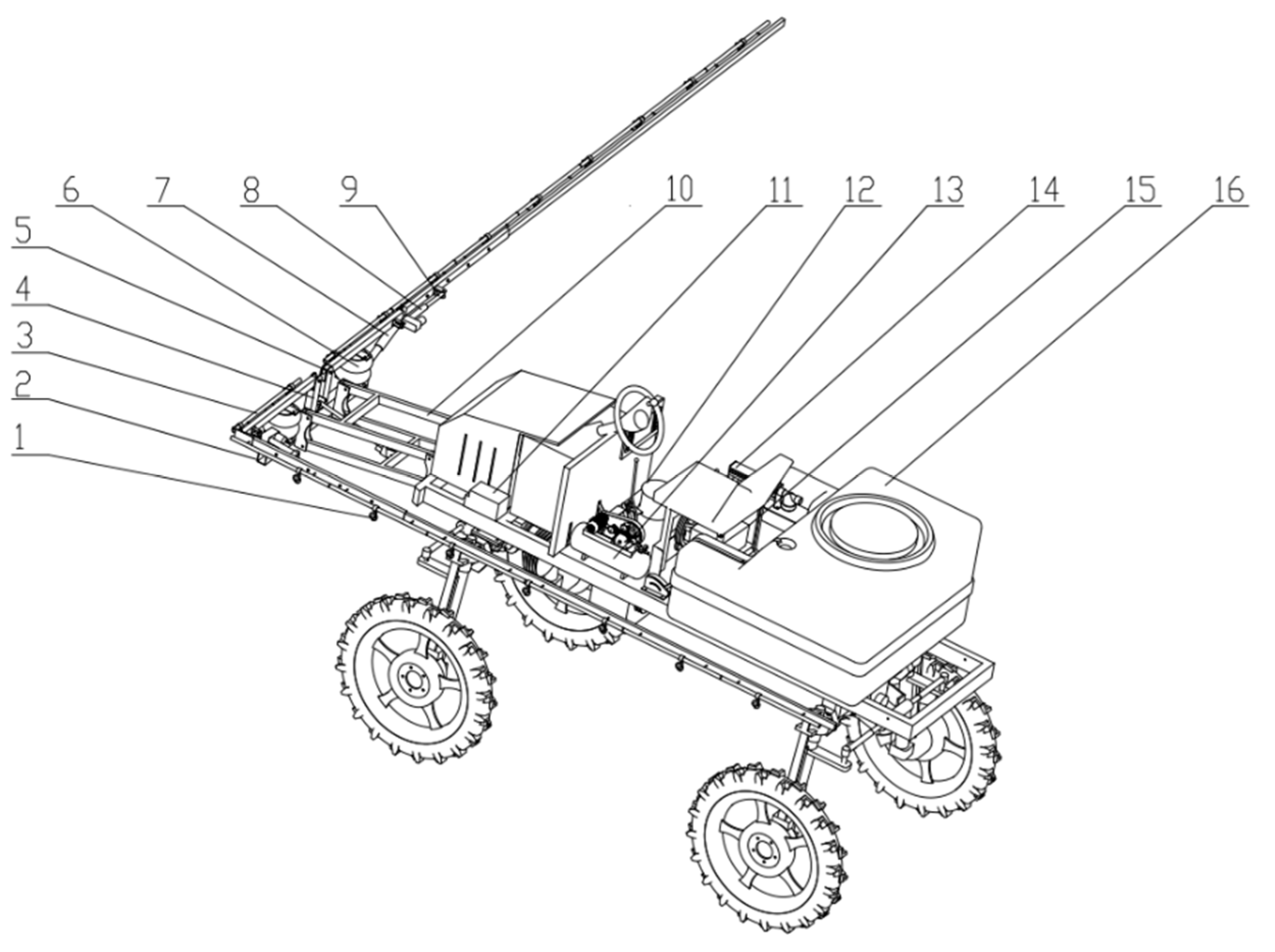

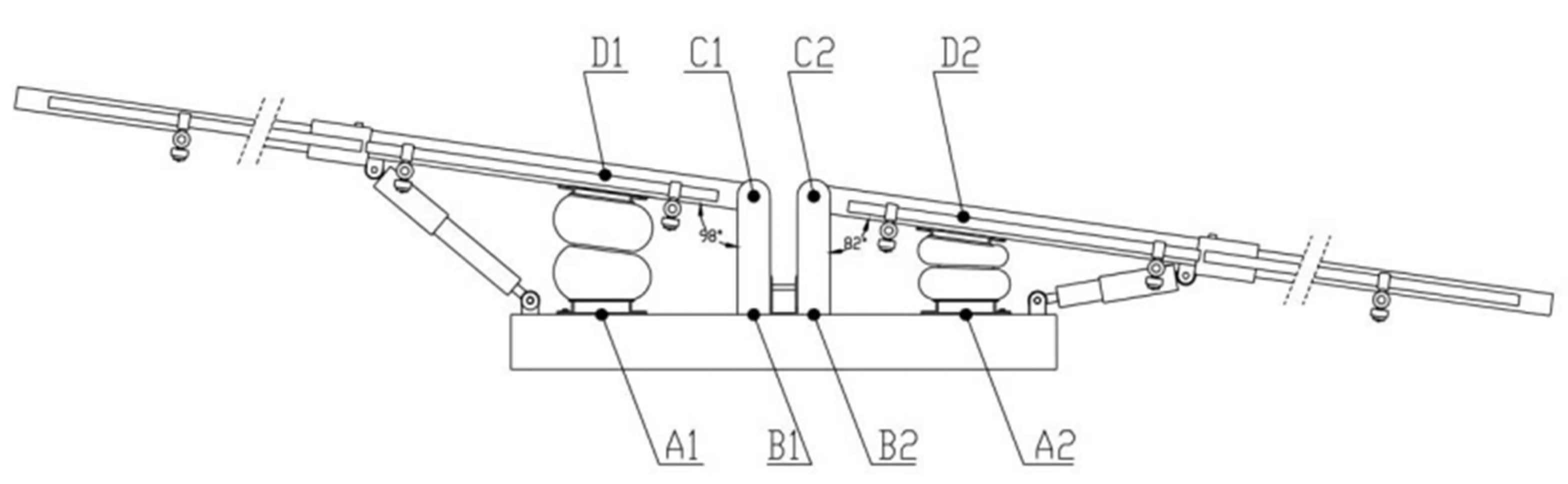

2.1. Spray Boom-Air Suspension System

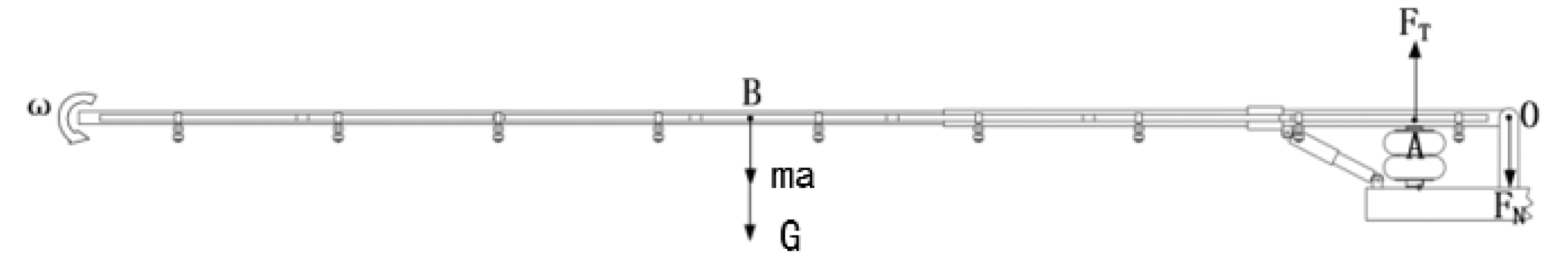

2.2. Parameter Design of Air Suspension for Spray Boom

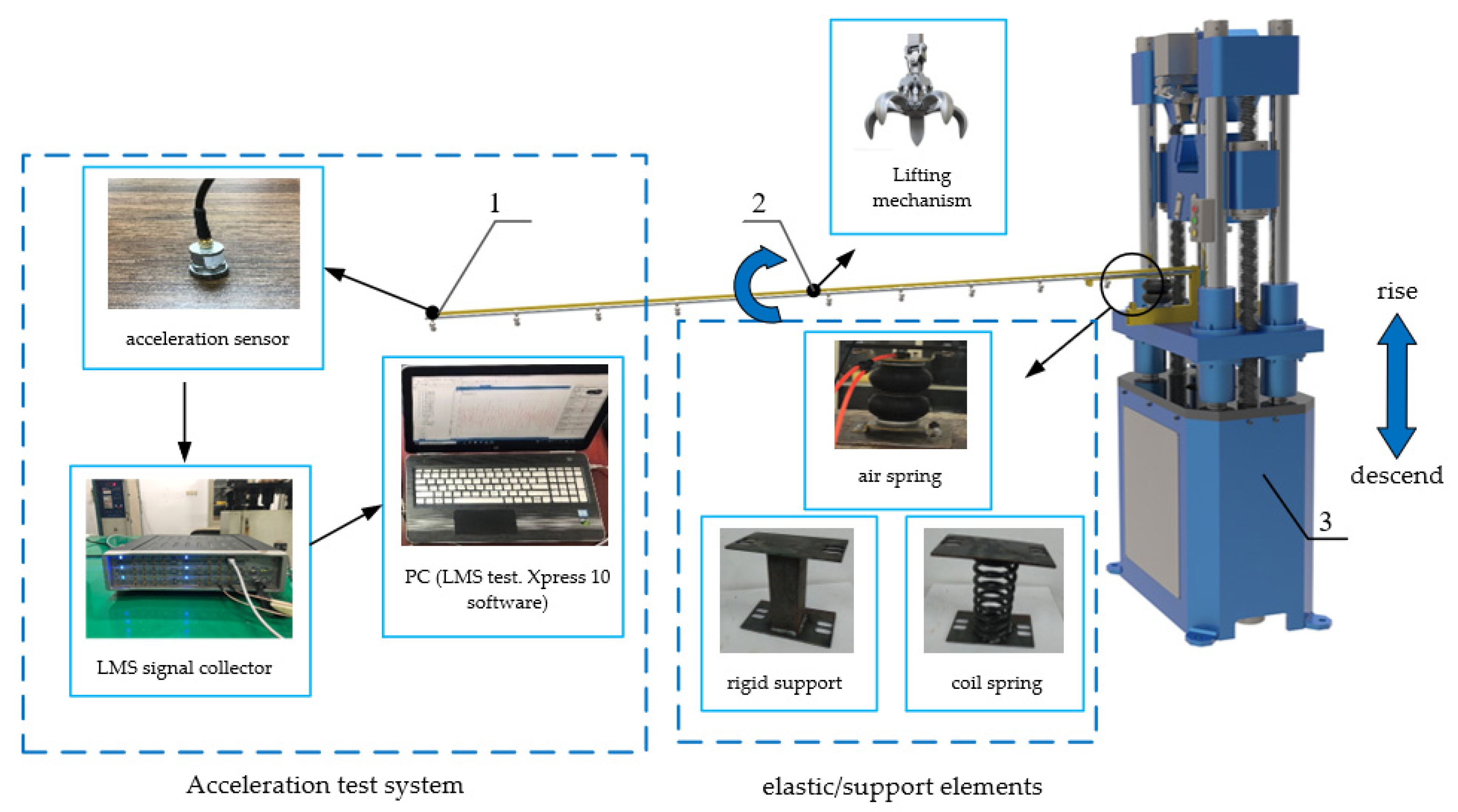

2.3. Comparative Analysis and Test on the Influence of Elastic Elements on the Dynamic Characteristics of Spray Boom Suspension

2.4. Comparative Analysis and Test on the Influence of Different Soil Conditions

3. Results and Analysis

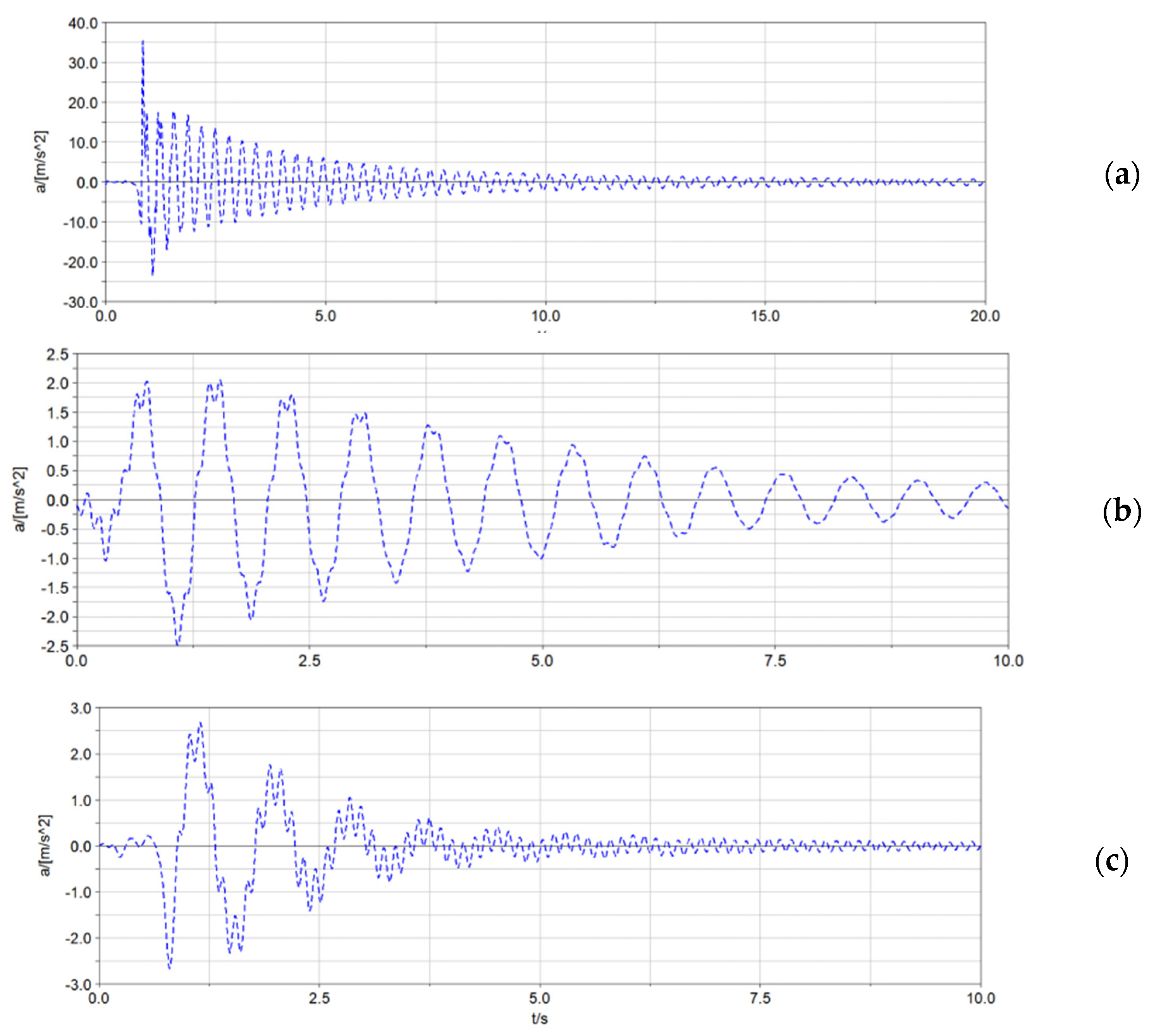

3.1. Comparison of Vibration Suppression Effects of Elastic Elements on the Spray Boom under the Transient Excitation

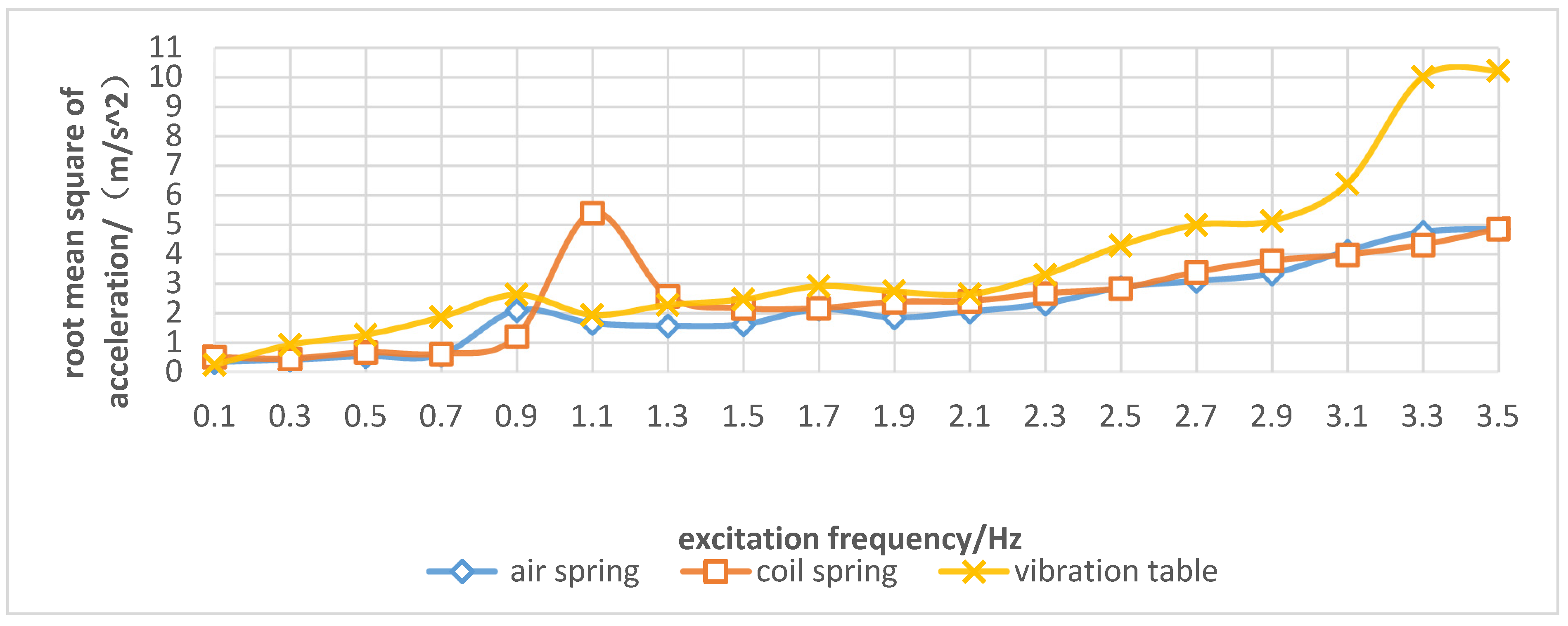

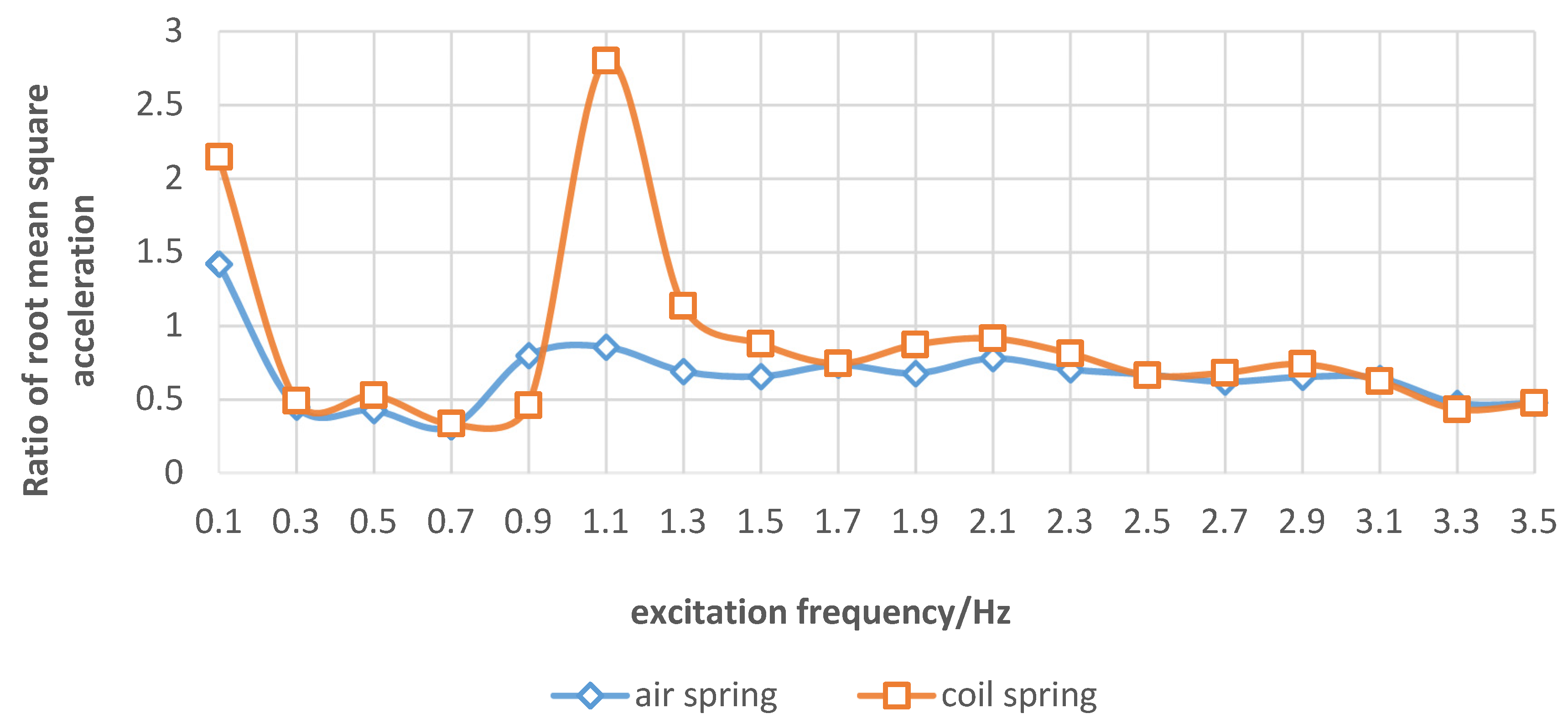

3.2. Comparison of Vibration Suppression Effects of Elastic Elements on the Spray Boom under the Sinusoidal Excitation

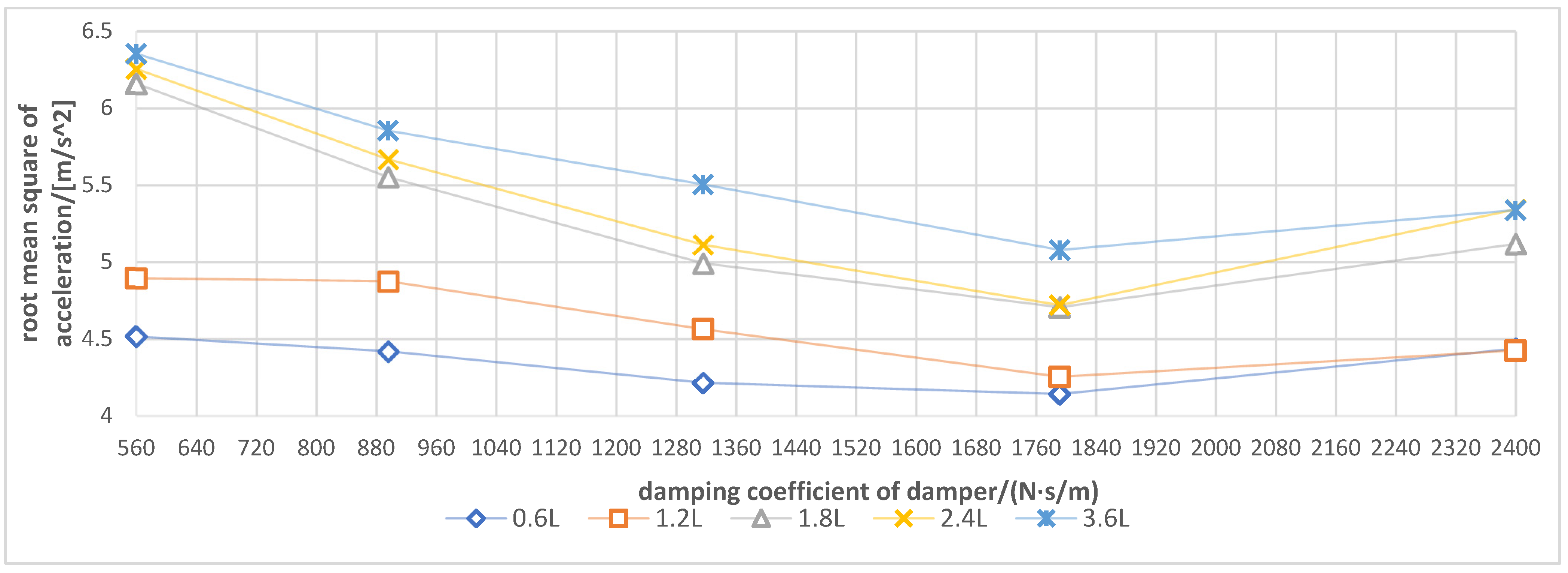

3.3. Influence of Spray Boom-Air Suspension System on Damping Performance under Different Soil Conditions

4. Discussion

5. Conclusions

- (1)

- A spray boom-air suspension system was designed. This paper described the composition and layout of the system. After theoretical calculations, the air spring and damper were selected to reduce the vibration intensity of the boom. This paper serves as a foundation for improving the spray uniformity of high-clearance sprayers.

- (2)

- Via a bench test, the dynamic characteristics of the spray boom suspension were analyzed. The obtained results indicate that under transient excitation, the spray boom equipped with the air spring can trigger the fastest vibration attenuation, the smallest peak value, and root mean square of the vibration acceleration. Under sinusoidal excitation, the air spring exhibited a better vibration suppression effect than the coil spring. The air spring expanded the vibration isolation frequency domain of the spray boom air suspension and weakened the resonance effect.

- (3)

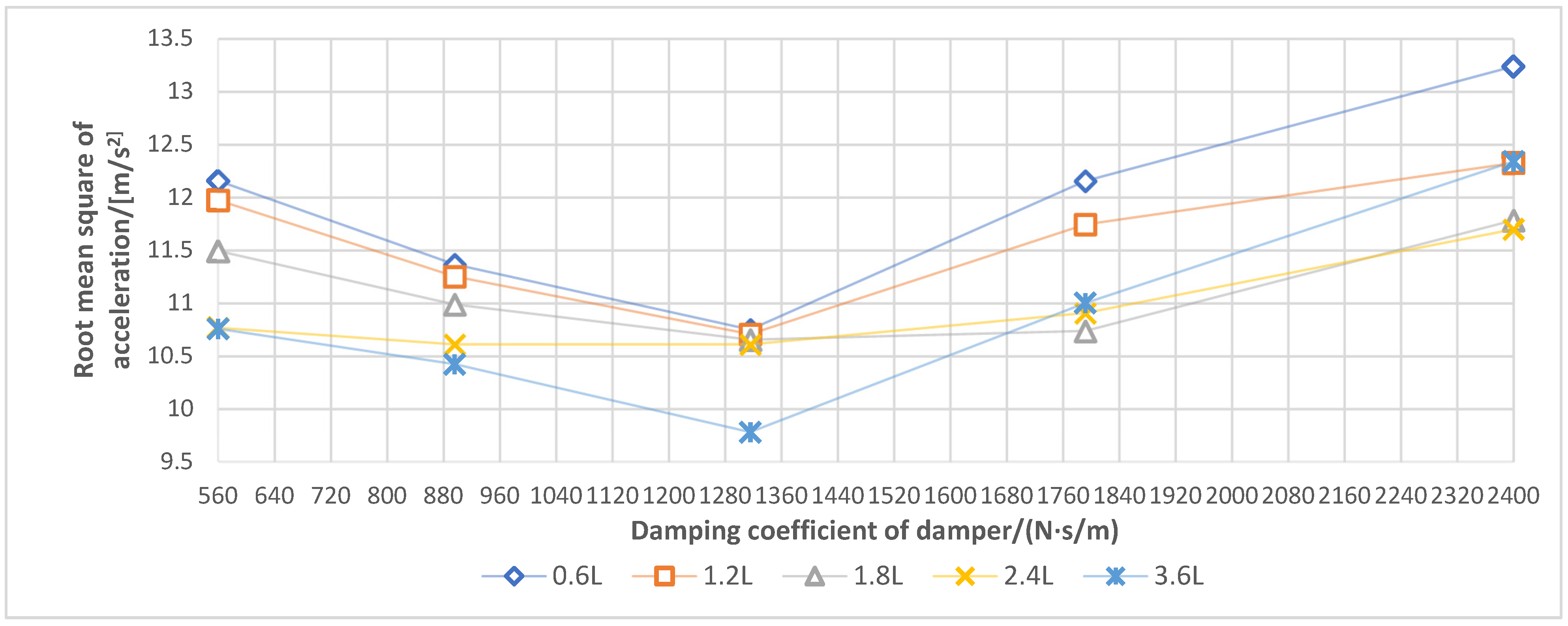

- Field experiments were carried out to analyze the effects of soil conditions, additional air chamber volume of air spring, and damping coefficient of the damper on the vibration suppression of the spray boom-air suspension system. The obtained findings indicate that the soil with a low moisture content and high firmness was unfavorable to the vibration of the spray boom. When the soil firmness was low, the spray boom exhibited a low vibration frequency and intensity. The suspension system should include an additional air chamber with a volume of approximately 0.6 L, and the damping coefficient of the damper should be approximately 1792 N·s/m. Accordingly, sufficient damping can be generated. An excessively big additional air chamber with an over-large system stiffness was not suitable for reducing vibration. In addition, the excessive damping coefficient of the damper can potentially lead to an incomplete action of the air spring. Regarding the solid soil, the spray boom exhibited high vibration frequency and high strength. The suspension system should match a large additional air chamber of approximately 3.6 L, and the damping coefficient should be set to approximately 1316 N·s/m to avoid excessive stiffness, which was unsuitable for vibration damping. If the volume of the additional air chamber was too small and the damping coefficient of the shock absorber was too low, the suspension would not adapt to the system vibration. Furthermore, the large damper gear also triggered an incomplete action of the air spring.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhou, Z.Y.; Yuan, W.; Chen, S.D. Current status and future directions of rice plant protection machinery in China. Guangdong Agric. 2014, 41, 178–183. [Google Scholar]

- Qiao, B.Y.; Ding, S.M.; Xue, X.Y.; Cui, L.F.; Zhou, Q.Q.; Zhang, Y.P. The Research Status and Prospects of Spray Boom. J. Agric. Mech. Res. 2017, 39, 246–250, 256. [Google Scholar]

- Zhuang, T.F. Theoretical Analysis and Experimental Research on Boom Vibration of Large-Scale High Clearance Sprayer; Chinese Academy of Agricultural Mechanization Sciences: Beijing, China, 2020. [Google Scholar]

- Cui, L.F.; Xue, X.Y.; Le, F.X.; Ding, S.M. Design and evaluation method of testing bench for spray boom suspension systems. Trans. Chin. Soc. Agric. Eng. 2019, 35, 23–31. [Google Scholar]

- Ramon, H.; De Baerdemaeker, J. Spray Boom Motions and Spray Distribution: Part 1, Derivation of a Mathematical Relation. J. Agric. Eng. Res. 1996, 66, 23–29. [Google Scholar] [CrossRef]

- Clijmans, L.; Ramon, H.; Swevers, J. Sprayer boom motion: Part 1 derivation of the mathematical model using experimental system identification theory. J. Agric. Eng. Res. 2000, 76, 61–69. [Google Scholar] [CrossRef]

- Chen, D.; Chen, Z.; Zhou, L.P.; Yan, H.R.; Yang, X.J. Improvement and Verification of Isosceles Trapezoid Boom Sprayer suspension. J. Agric. Mech. Res. 2014, 36, 171–174, 178. [Google Scholar]

- Chen, C.; Xue, X.Y.; Gu, W.; Ma, L.X. Current situation and development trend of spray boom suspension system for sprayer. J. Chin. Agric. Mech. 2015, 36, 98–101. [Google Scholar]

- Zhang, J.Y. Finite Element Modeling and Robust Control of Spray Rod Rigid Frame of Plant Protection Machine; Shenyang University of Technology: Shenyang, China, 2019. [Google Scholar]

- Jeon, H.Y.; Womac, A.R.; Gunn, J. Sprayer boom dynamic effects on application uniformity. Trans. ASABE 2004, 47, 647–658. [Google Scholar] [CrossRef]

- Cui, L.F.; Xue, X.Y.; Ding, S.M.; Yue, L.X.; Gu, W. Design of large boom dynamic simulator and field condition reappearance experiment. J. Jiangsu Univ. (Nat. Sci. Ed.) 2020, 41, 51–59. [Google Scholar]

- Nation, H.J. The design and performance of a gimbal-type mounting for sprayer booms 1. Development procedure. J. Agric. Eng. Res. 1987, 36, 233–246. [Google Scholar] [CrossRef]

- Nation, H.J. The design and performance of a gimbal-type mounting for sprayer booms 2. Optimization model and validation. J. Agric. Eng. Res. 1987, 36, 247–260. [Google Scholar] [CrossRef]

- Anthonis, J.; Ramon, H. Design of an active suspension to suppress the horizontal vibrations of a spray boom. J. Sound Vib. 2003, 266, 573–583. [Google Scholar] [CrossRef]

- Wu, J.B. Lightweight Design and Dynamic Characteristics Analysis of Sprayer Boom; Wuhan University of Technology: Wuhan, China, 2016. [Google Scholar]

- Cai, W. Study on Active Vibration Suppression Control of Wide Spray Arm; Yanshan University: Qinhuangdao, China, 2018. [Google Scholar]

- Anthonis, J.; Kennes, P.; Ramon, H. Design and evaluation of a low-power mobile shaker for vibration tests on heavy wheeled vehicles. J. Terra Mech. 2000, 37, 191–205. [Google Scholar] [CrossRef]

- Anthonis, J.; Audenaert, J.; Ramon, H. Design optimization for the vertical suspension of a crop sprayer boom. Biosyst. Eng. 2005, 90, 153–160. [Google Scholar] [CrossRef]

- Wu, J.L.; Miao, Y.B. Dynamic Characteristics analysis of boom for wide sprayer with different exciting sources. Trans. Chin. Soc. Agric. Eng. 2012, 28, 39–44. [Google Scholar]

- Cui, L.F.; Xue, X.Y.; Ding, S.M.; Gu, W.; Chen, C.; Yue, F.X. Modeling and Simulation of Dynamic Behavior of Large Spray Boom with Active and Passive Pendulum Suspension. Trans. Chin. Soc. Agric. Mach. 2017, 48, 82–90. [Google Scholar]

- Cui, L.F.; Xue, X.Y.; Ding, S.M.; Qiao, B.Y.; Yue, F.X. Analysis and test of dynamic characteristics of large spraying boom and pendulum suspension damping system. Trans. Chin. Soc. Agric. Eng. 2017, 33, 61–68. [Google Scholar]

- Zhuang, T.F.; Yang, X.J.; Dong, X.; Zhang, T.; Yan, H.R.; Wang, Z.D. Modal Analysis and test of Large High Ground Clearance Sprayer Boom. Agric. Eng. 2020, 10, 85–92. [Google Scholar]

- Zhuang, T.F.; Yang, X.J.; Dong, X.; Zhang, T.; Yan, H.R.; Sun, X. Research status and development trend of large self-propelled sprayer booms. Trans. Chin. Soc. Agric. Mach. 2018, 49, 189–198. [Google Scholar]

- Xue, T.; Li, W.; Du, Y.F.; Mao, E.R.; Wen, H.J. Adaptive fuzzy sliding mode control of spray boom active suspension for large high clearance sprayer. Trans. Chin. Soc. Agric. Eng. 2018, 34, 47–56. [Google Scholar]

- Qiao, C.; Wen, H.; Liu, X.; Wang, G. Damping Control and Experiment on Active Hydro-Pneumatic Suspension of Sprayer Based on Genetic Algorithm Optimization. Front. Neurorobot. 2021, 15. [Google Scholar] [CrossRef]

- Kennes, P.; Ramom, H. Modelling the Effect of Passive Vertical Suspensions on the Dynamic Behaviour of Sprayer Booms. J. Agric. Eng. Res. 1999, 72, 217–229. [Google Scholar] [CrossRef]

- He, Y.J.; Qiu, B.J.; Yang, Y.F.; Ma, J. Deformation analysis and control of elastic deformation for sprayer boom based on finite element model. Trans. Chin. Soc. Agric. Eng. 2014, 30, 28–36. [Google Scholar]

- Zhen, M.J.; Chen, X.K.; Lin, Y. Dynamical Model and Characteristics Analysis of Air Spring. Trans. Chin. Soc. Agric. Mach. 2008, 5, 10–14. [Google Scholar]

- Wang, J.S. Research on Dynamic Characteristics of Air Spring with Auxiliary Chamber; Nanjing Agricultural University: Nanjing, China, 2009. [Google Scholar]

- Zhang, J.L. Parameters matching and performance analysis of heavy vehicles with air suspension. Manuf. Autom. 2015, 37, 96–99. [Google Scholar]

- Li, Y. The Research on Stiff Match and Damping Control of Air Suspension; Hunan University: Hunan, China, 2013. [Google Scholar]

- Zhang, X.L.; Hu, Z.Q.; Chu, S.L. Methods for Measuring Soil Water Content: A Review. Chin. J. Soil Sci. 2005, 1, 118–123. [Google Scholar]

- Ma, Y.Y.; Lei, Y.W.; Zhang, X.P.; Chen, Y.X. Volume replacement method for direct measurement of soil moisture and bulk density. Trans. Chin. Soc. Agric. Eng. 2013, 29, 86–93. [Google Scholar]

- Clijmans, L.; Ramon, H.; Sas, P.; Swevers, J. Sprayer boom motion: Part 2 validation of the model and effect of boom vibration on spray liquid deposition. J. Agric. Eng. Res. 2000, 76, 121–128. [Google Scholar] [CrossRef]

- Clijmans, L.; Ramon, H.; De Baerdemaeker, J. Structural modification effects on the dynamic behaviour of an agricultural tractor. Trans. ASAE 1998, 41, 5–10. [Google Scholar] [CrossRef]

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| Boundary dimension (length × width × height)/m × m × m | 4.25 × 1.8 × 2.06 | Maximum folding angle of spray boom/⁰ | 90° |

| Structural mass/kg | 1150 | Length of electric linear actuator/m | 0.4 |

| Power/kW | 13.9 | Length of suspension base/m | 1 |

| Operating speed/m·s−1 | 1–4 | Length of single side spray boom/m | 4.8 |

| Wheel track (Between the left and right wheels)/m | 1.5 | Mass of single side spray boom and connector/kg | 13 |

| Spray height/m | 0.48–1.48 | Air compressor type | Positive displacement |

| Parameters | Value |

|---|---|

| Maximum bearing capacity of spring (N) | 7000 |

| Natural diameter of spring (mm) | 146 |

| Natural height of spring (mm) | 160 |

| Maximum elongation of spring (mm) | 200 |

| Minimum compression of spring (mm) | 75 |

| Spring stroke (mm) | 125 |

| Maximum spring stiffness (N/mm) | 176 |

| Gear | 1 | 2 | 3 | 4 | 5 |

|---|---|---|---|---|---|

| Damping coefficient/(N·s/m) | 560 | 896 | 1316 | 1792 | 2400 |

| Soil Condition | Soil Depth/cm | Moisture Content/% | Firmness/kPa |

|---|---|---|---|

| Dry field | 5 | 2.47 ± 0.09 | 902 ± 5.00 |

| 10 | 1.96 ± 0.08 | 1103 ± 6.56 | |

| 15 | 1.64 ± 0.04 | 1373 ± 6.08 | |

| Water field | 5 | 22.07 ± 1.19 | 46 ± 3.61 |

| 10 | 19.01 ± 0.47 | 158 ± 11.53 | |

| 15 | 14.87 ± 0.02 | 947 ± 5.57 |

| Type | Peak Value/m/s2 | Peak Time/s | Root Mean Square/m/s2 | Stabilization Time/s | First-Order Natural Frequency/Hz | Second-Order Natural Frequency/Hz |

|---|---|---|---|---|---|---|

| Spray boom-rigid support system | 35.47 | 0.85 | 4.29 | 16.42 | 3.13 | 11.72 |

| Spray boom-coil spring system | 2.49 | 1.10 | 0.83 | 7.24 | 1.37 | 7.62 |

| Spray boom-air spring system | 2.68 | 1.15 | 0.62 | 4.07 | 1.17 | 7.62 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qiu, W.; Yao, X.; Zhu, Y.; Sun, H.; Zhou, L.; Xiao, M. Analysis of Factors Influencing Vibration Suppression of Spray Boom-Air Suspension for Medium and Small-Scale High-Clearance Sprayers. Sensors 2021, 21, 6753. https://doi.org/10.3390/s21206753

Qiu W, Yao X, Zhu Y, Sun H, Zhou L, Xiao M. Analysis of Factors Influencing Vibration Suppression of Spray Boom-Air Suspension for Medium and Small-Scale High-Clearance Sprayers. Sensors. 2021; 21(20):6753. https://doi.org/10.3390/s21206753

Chicago/Turabian StyleQiu, Wei, Xinyue Yao, Yue Zhu, Hao Sun, Liangfu Zhou, and Maohua Xiao. 2021. "Analysis of Factors Influencing Vibration Suppression of Spray Boom-Air Suspension for Medium and Small-Scale High-Clearance Sprayers" Sensors 21, no. 20: 6753. https://doi.org/10.3390/s21206753

APA StyleQiu, W., Yao, X., Zhu, Y., Sun, H., Zhou, L., & Xiao, M. (2021). Analysis of Factors Influencing Vibration Suppression of Spray Boom-Air Suspension for Medium and Small-Scale High-Clearance Sprayers. Sensors, 21(20), 6753. https://doi.org/10.3390/s21206753