Development of Low-Cost Wireless Sensing System for Smart Ultra-High Performance Concrete

Abstract

:1. Introduction

2. Proposed Wireless Sensing System for Multiple Electrical Resistance Measurements

2.1. Microcontroller Unit

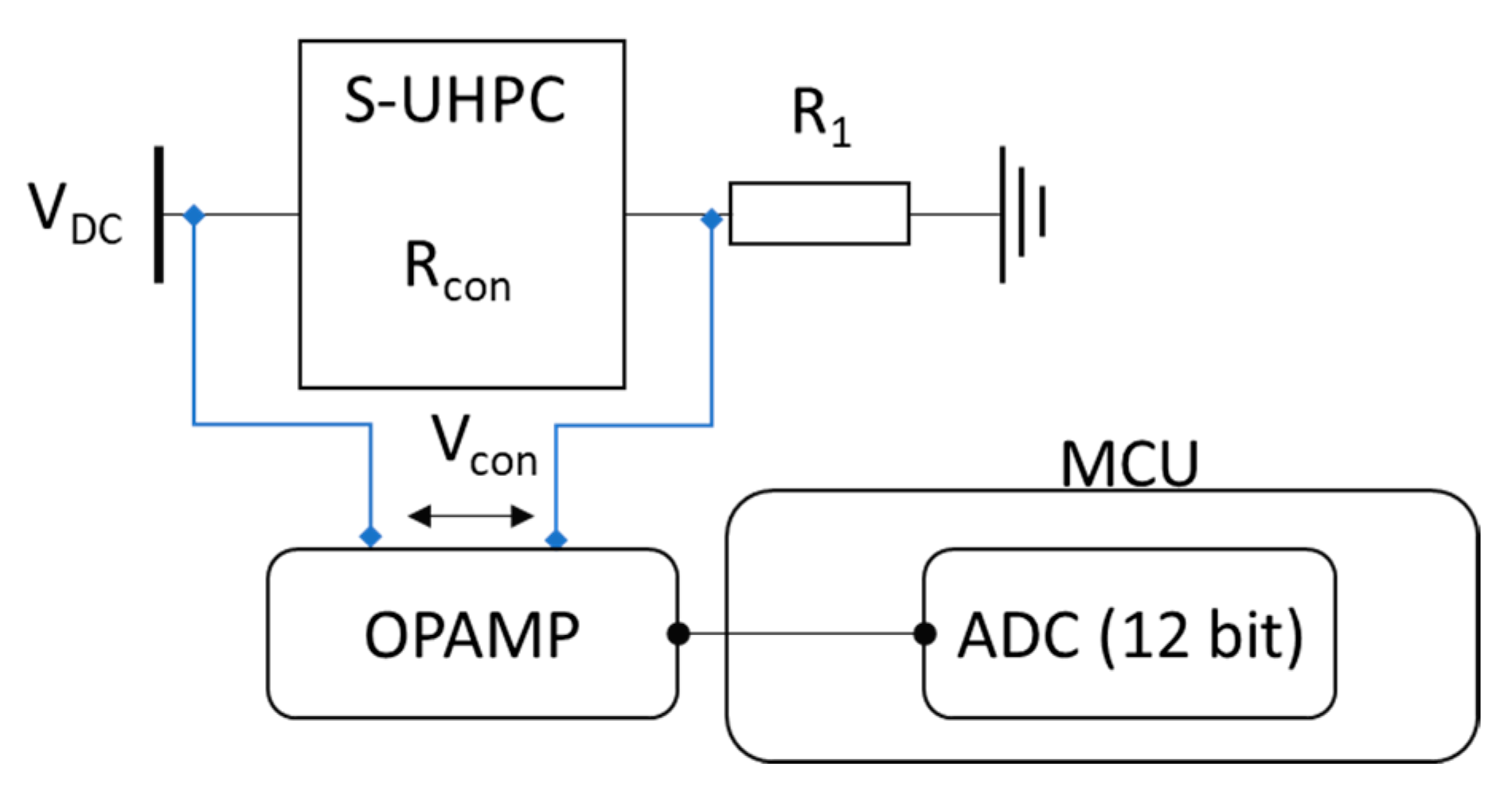

2.2. Electrical Resistance Sensing Circuit

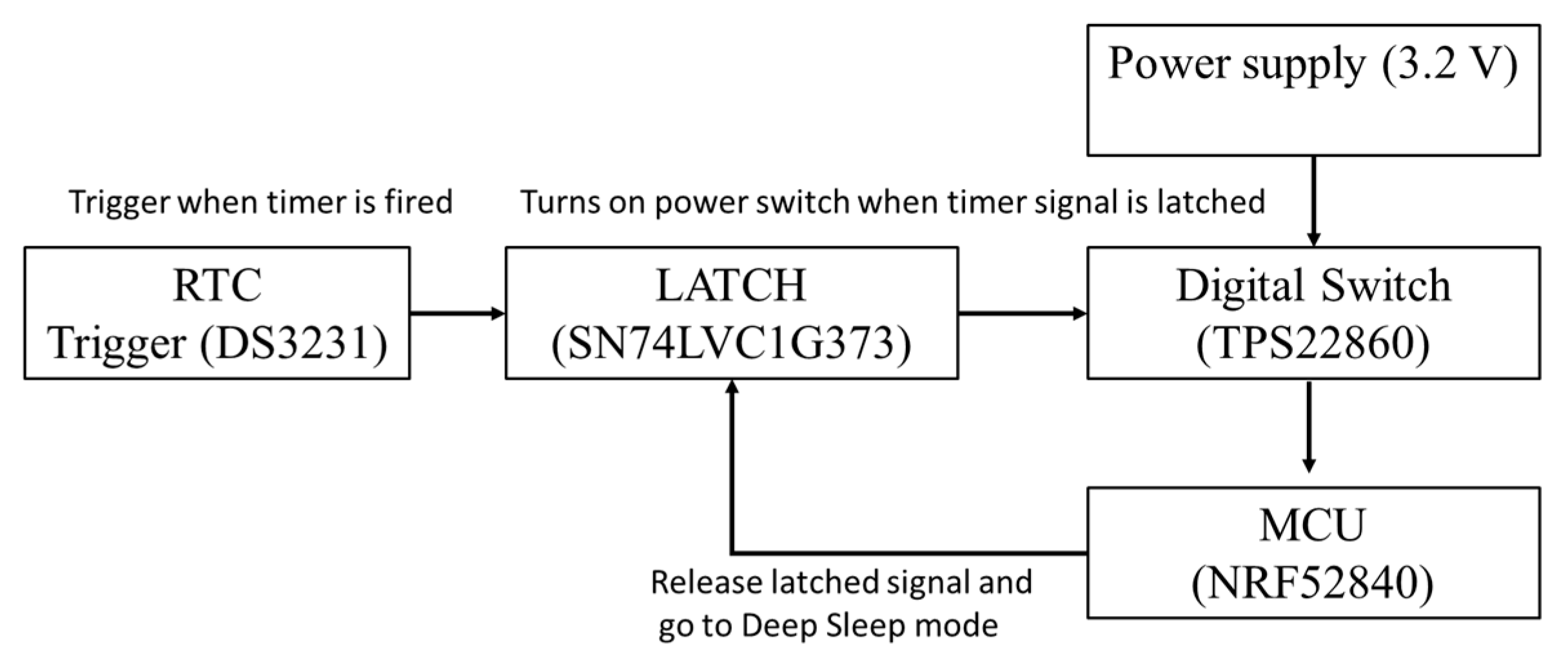

2.3. Power Management Circuit

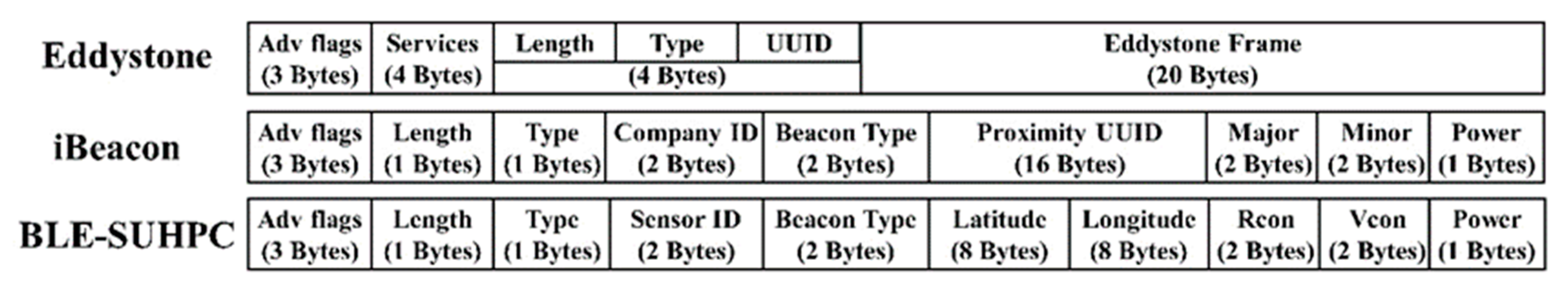

2.4. Bluetooth Communication

- Sensor ID (2-Bytes): Identification of the peripheral nodes S-UHPC (e.g., BLE-SUHPC).

- GPS coordinate: (16-Bytes): GPS (latitude (8-Byte) and longitude (8-Byte)) of the BLE-SUHPC.

- Rcon (2-Bytes): Resistance value of the S-UHPC.

- Vcon (2-Bytes): Voltage measured across the S-UHPC.

- Power (1-Byte): Transmission power, signal transmission strength of communication.

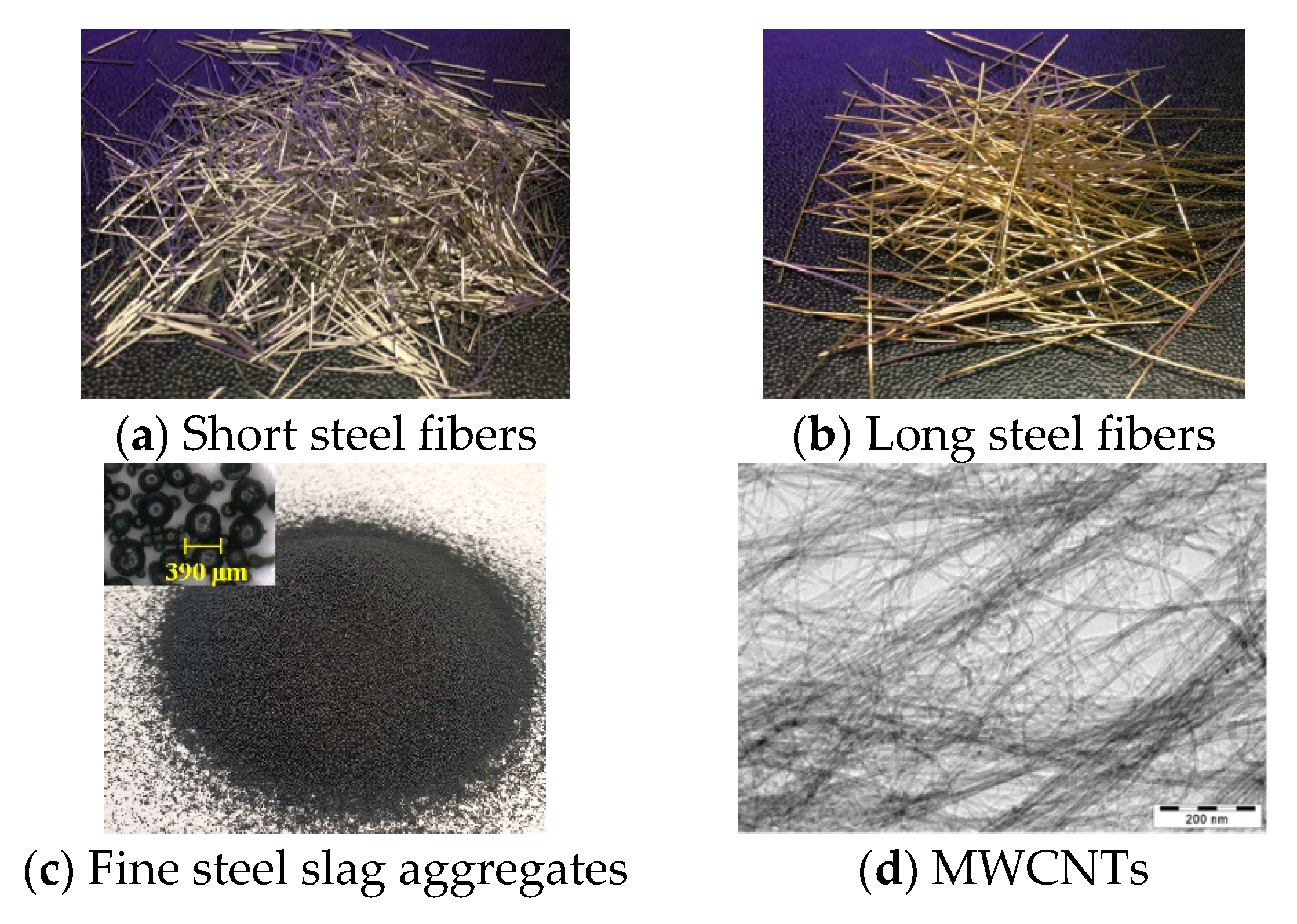

3. Smart Ultra-High-Performance Concrete Specimen

4. Experimental Validation

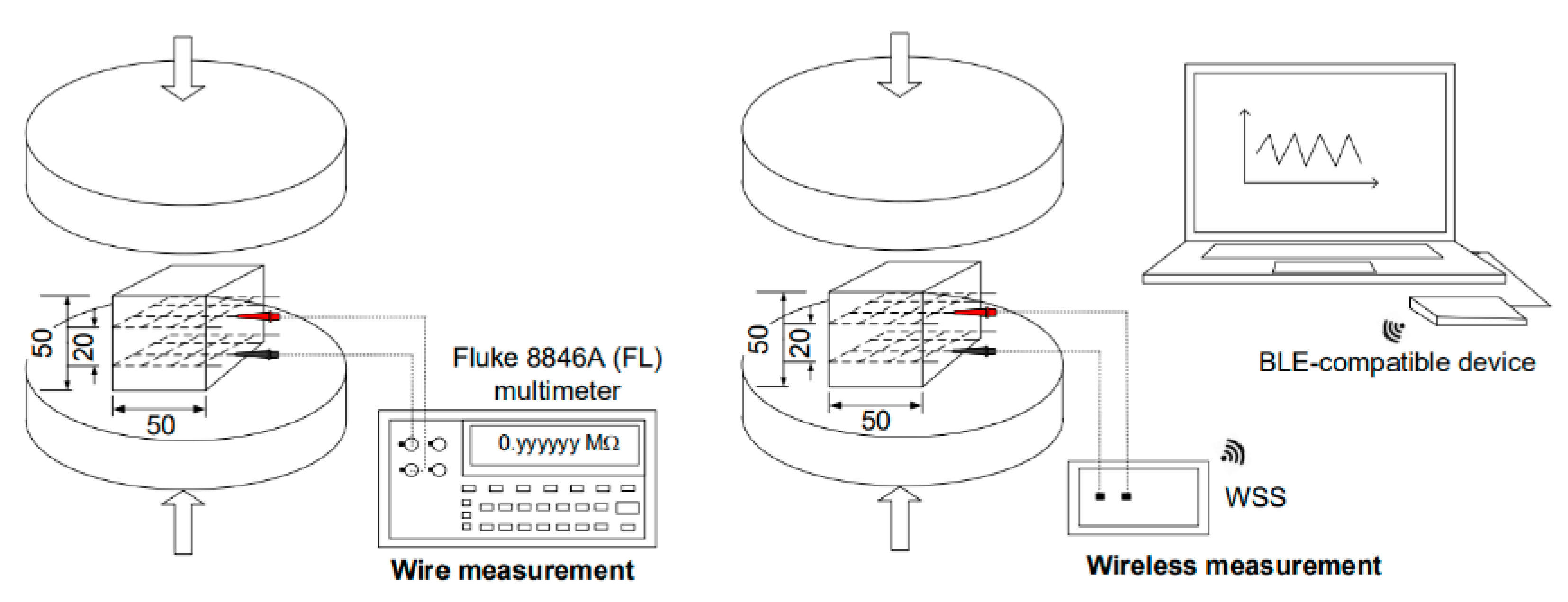

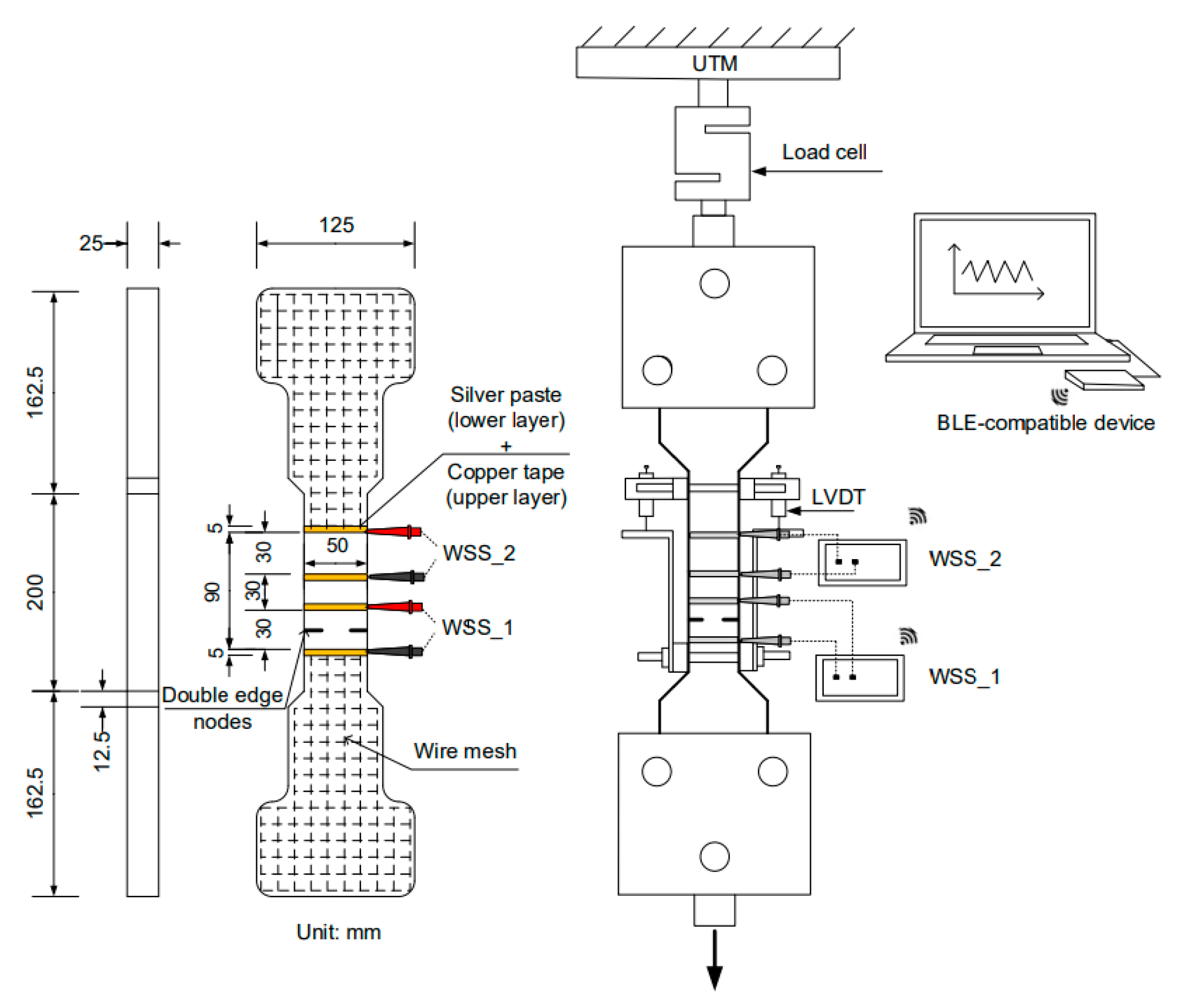

4.1. Test Setup

4.2. Results and Discussion

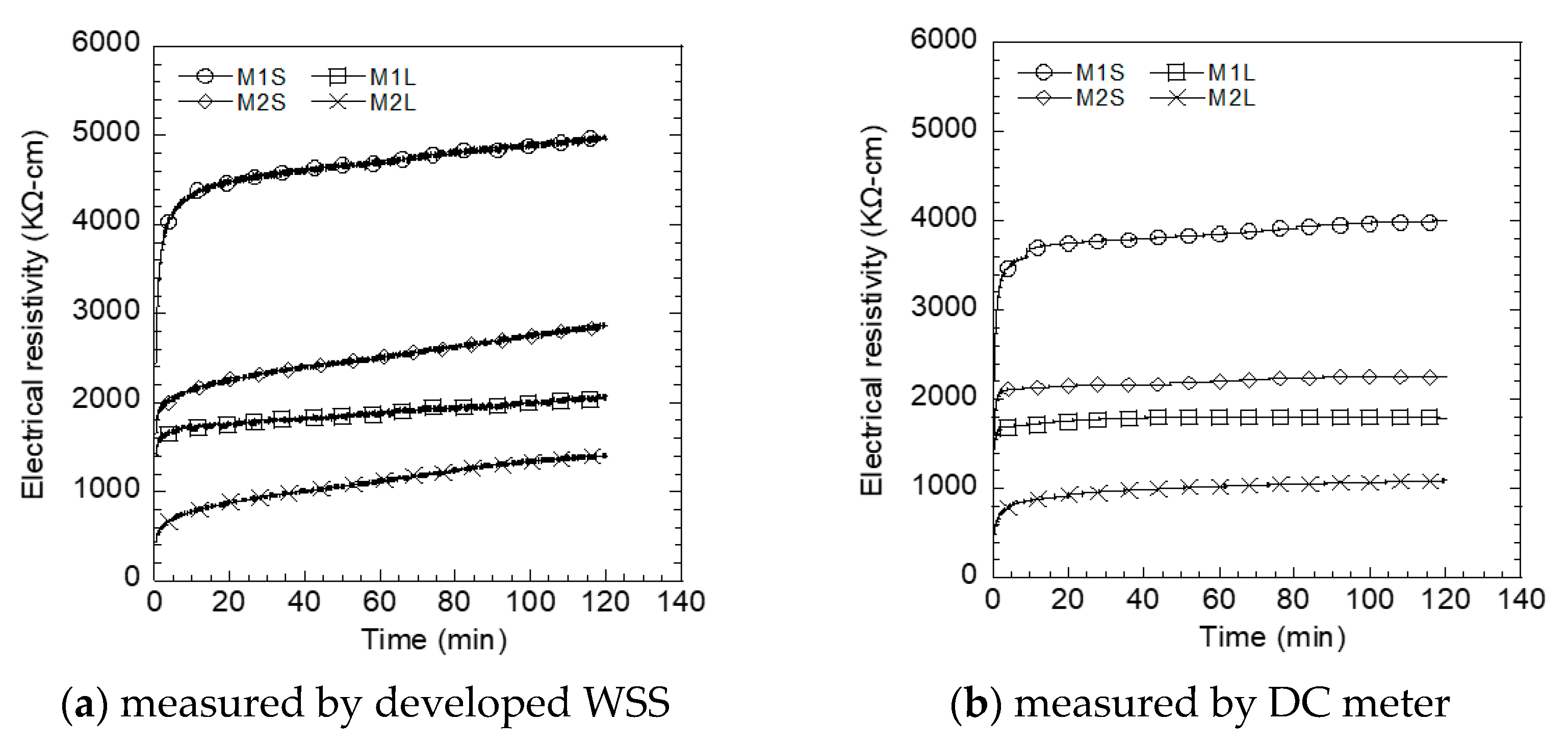

4.2.1. Polarization of S-UHPCs and Sensing Ability of WSS

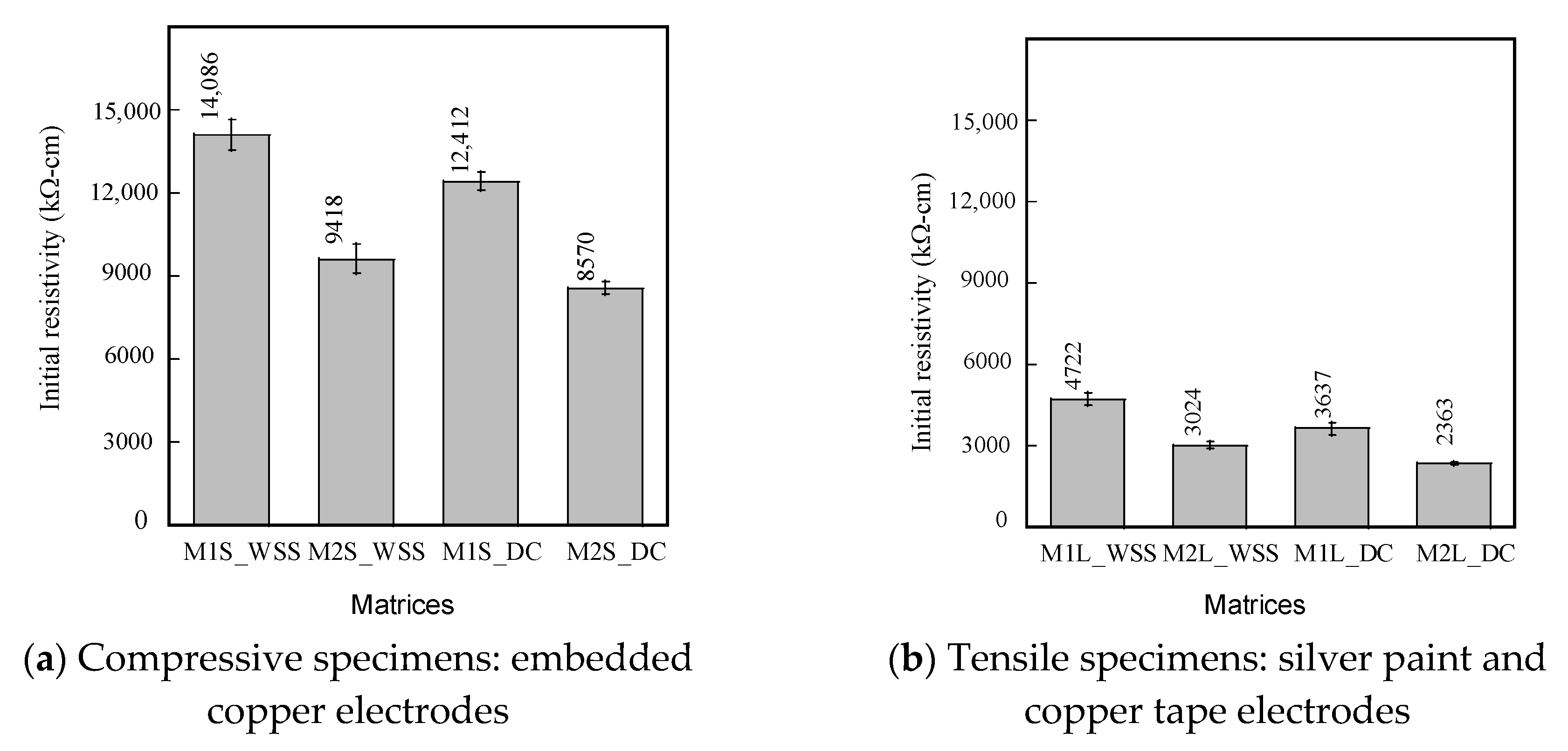

4.2.2. Self-Stress Sensing of S-UHPCs Using WSS and DC Measurements under Compression

4.2.3. Self-Damage Sensing of Smart UHPCs Using WSS under Tension

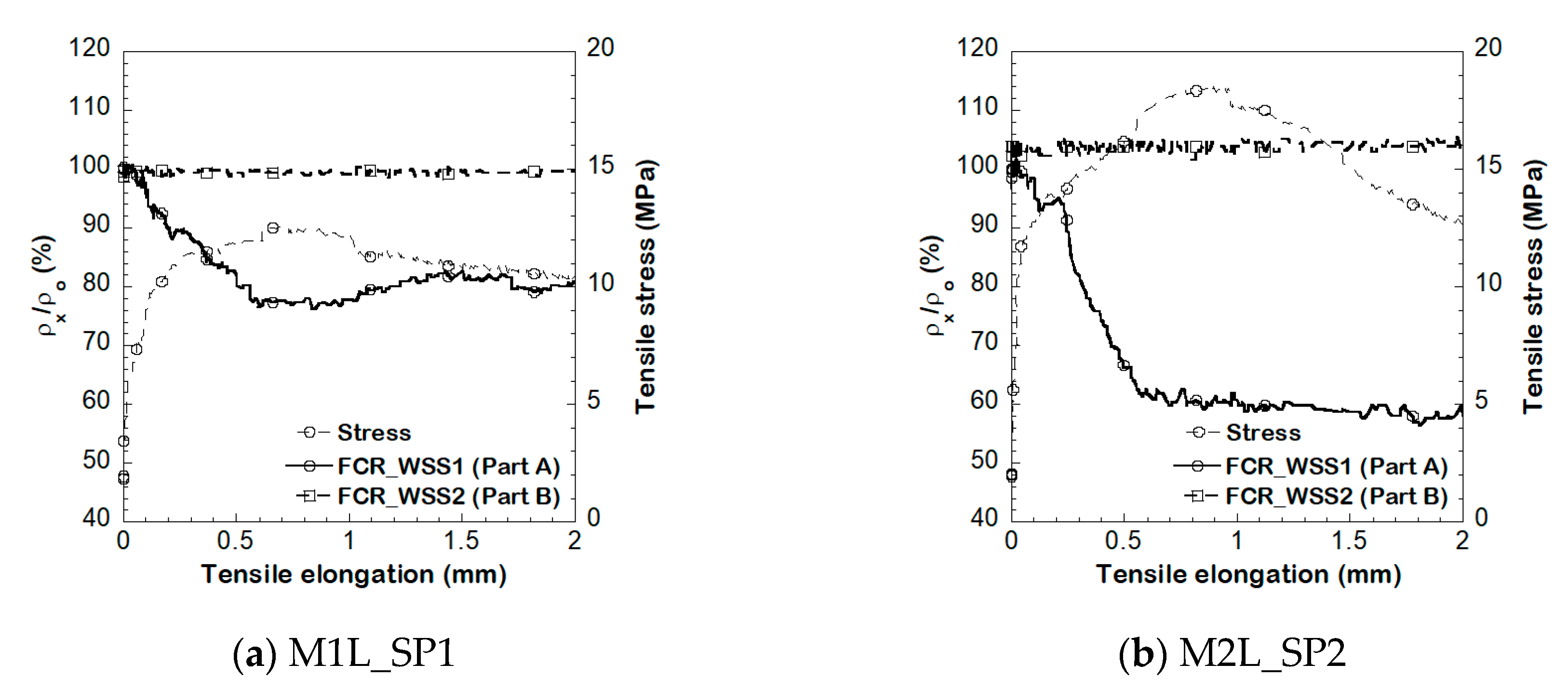

4.2.4. Detecting Crack Position of S-UHPCs Using WSS with Multiple Measurements under Tension

5. Conclusions

- A WSS was developed to measure electrical resistivity and broadcast measured response through a customized BLE beacon.

- The developed WSS has a power management circuit for long-term operation. With 10,000 mAh, the developed WSS can last 3.6 years without charging.

- The developed WSS is integrated with S-UHPCs to monitor the stress and damage of concrete composites under external loads to prove that it is a portable sensor with high accuracy, as a commercial DC wire measurement.

- Under compressive load, the WSS measurement measured higher electrical resistivity (14,086.18 and 12,411.52 kΩ-cm for M1 and M2, respectively) and FCRs (28.6% and 39.2% for M1 and M2, respectively) than those of DC meter measurement (9617.78 and 8570.34 kΩ-cm, 25.2% and 34.5% for the electrical resistivity and FCR of M1 and M2, respectively). The higher electrical resistivity of the S-UHPC using WSS rather than DC wire measurement is considered to be caused by a larger polarization effect due to a not fully optimized system code of WSS measurement.

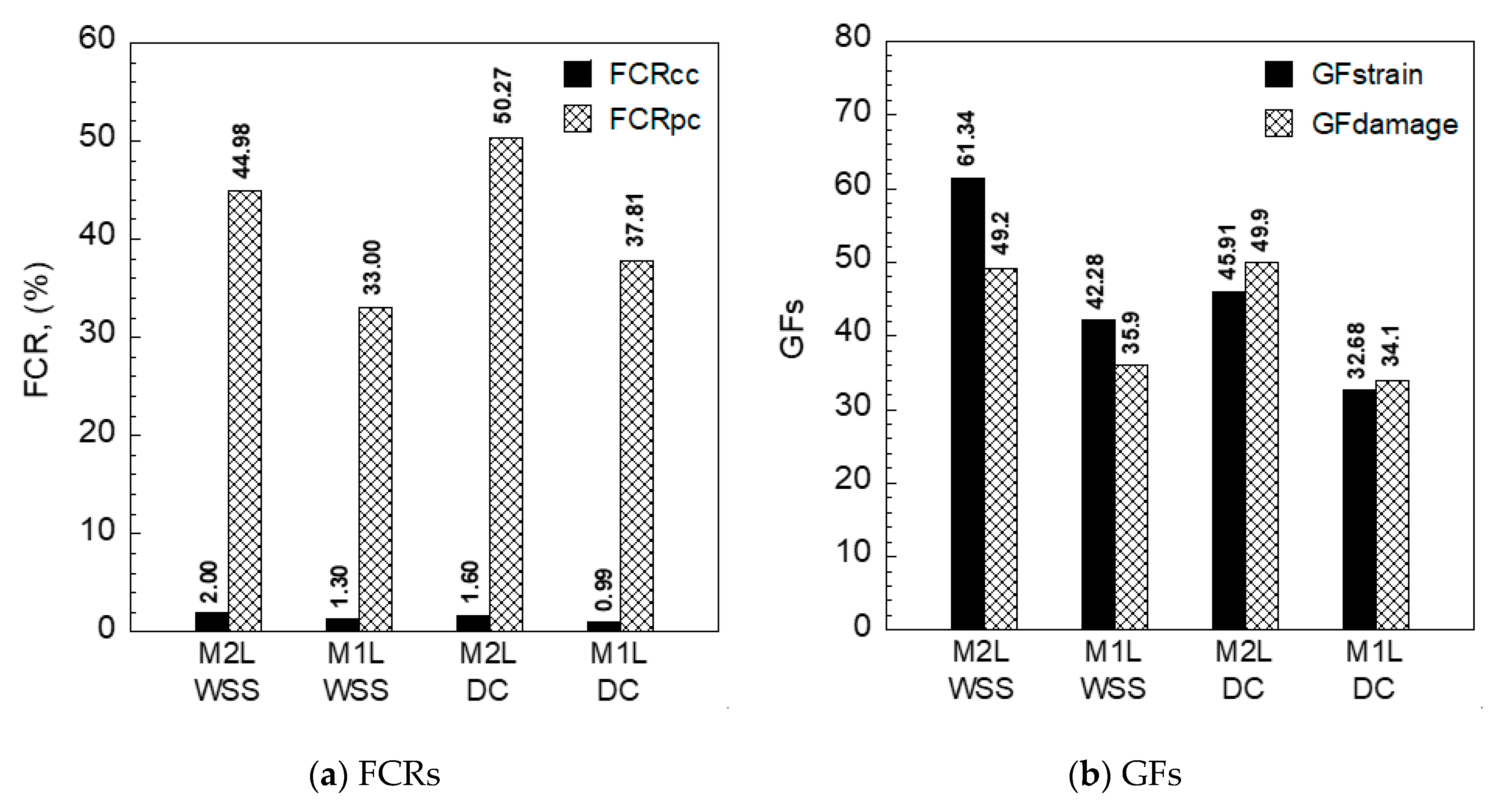

- Under tension, the FCRs (37.81% and 50.27% for M1 and M2, respectively) using DC wire measurement were higher than those (33.00% and 44.98% for M1 and M2, respectively) using WSS measurement. On the other hand, the values of GFstrain (42.28 and 61.34 for M1 and M2, respectively) using WSS measurement were larger than those (32.68 and 45.91 for M1 and M2, respectively) using DC wire measurement. The values of GFdamage (35.9 and 49.2 for M1 and M2, respectively) using WSS measurement and those (34.1 and 49.9 for M1 and M2, respectively) using DC meter measurement showed similar values.

- A WSS with multiple measurement channels tested using a BLE beacon by defining a unique sensor ID for each WSS. The electrical resistivity responses at different positions were simultaneously obtained during loading. The crack position was easily indicated based on the electrical resistivity response.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Han, B.; Yu, X.; Ou, J. Self-Sensing Concrete in Smart Structures; Butterworth-Heinemann: Oxford, UK, 2014. [Google Scholar]

- Chen, P.-W.; Chung, D. Concrete as a new strain/stress sensor. Compos. Part B Eng. 1996, 27, 11–23. [Google Scholar] [CrossRef]

- Lee, S.Y.; Le, H.V.; Kim, D.J. Self-stress sensing smart concrete containing fine steel slag aggregates and steel fibers under high compressive stress. Constr. Build. Mater. 2019, 220, 149–160. [Google Scholar] [CrossRef]

- Kim, D.; Noh, H.; Choi, S.; Hwang, R.; Lee, S. Smart concrete anchorage for monitoring pre-stressing loss. Korea Pat. 2019. Submitted. [Google Scholar]

- Le, H.V.; Kim, D.J. Detecting crack and damage location in self-sensing fiber reinforced cementitious composites. Constr. Build. Mater. 2020, 240, 117973. [Google Scholar] [CrossRef]

- Han, B.; Yu, Y.; Han, B.Z.; Ou, J. Development of a wireless stress/strain measurement system integrated with pressure-sensitive nickel powder-filled cement-based sensors. Sens. Actuators A Phys. 2008, 147, 536–543. [Google Scholar] [CrossRef]

- Downey, A.; D’Alessandro, A.; Ubertini, F.; Laflamme, S.; Geiger, R. Biphasic DC measurement approach for enhanced measurement stability and multi-channel sampling of self-sensing multi-functional structural materials doped with carbon-based additives. Smart Mater. Struct. 2017, 26, 065008. [Google Scholar] [CrossRef] [Green Version]

- Spencer, B., Jr.; Park, J.-W.; Mechitov, K.; Jo, H.; Agha, G. Next generation wireless smart sensors toward sustainable civil infrastructure. Procedia Eng. 2017, 171, 5–13. [Google Scholar] [CrossRef]

- Soyoz, S.; Feng, M.Q. Long-term monitoring and identification of bridge structural parameters. Comput. Aided Civ. Infrastruct. Eng. 2009, 24, 82–92. [Google Scholar] [CrossRef]

- Zhu, L.; Fu, Y.; Chow, R.; Spencer, B.F., Jr.; Park, J.W.; Mechitov, K. Development of a high-sensitivity wireless accelerometer for structural health monitoring. Sensors 2018, 18, 262. [Google Scholar] [CrossRef] [PubMed]

- Jang, S.; Jo, H.; Cho, S.; Mechitov, K.; Rice, J.A.; Sim, S.-H.; Jung, H.-J.; Yun, C.-B.; Spencer, B.F., Jr.; Agha, G. Structural health monitoring of a cable-stayed bridge using smart sensor technology: Deployment and evaluation. Smart Struct. Syst. 2010, 6, 439–459. [Google Scholar] [CrossRef] [Green Version]

- Spencer, B.F., Jr.; Jo, H.; Mechitov, K.A.; Li, J.; Sim, S.-H.; Kim, R.E.; Cho, S.; Linderman, L.; Moinzadeh, P.; Giles, R.K.; et al. Recent advances in wireless smart sensors for multi-scale monitoring and control of civil infrastructure. J. Civ. Struct. Health Monit. 2016, 6, 17–41. [Google Scholar] [CrossRef]

- Lynch, J.P. An overview of wireless structural health monitoring for civil structures. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2007, 365, 345–372. [Google Scholar] [CrossRef] [PubMed]

- Won, J.; Park, J.; Park, J.-W.; Kim, I. BLESeis: Low-cost IOT sensor for smart earthquake detection and notification. Sensors 2020, 20, 2963. [Google Scholar] [CrossRef]

- Lynch, J.P.; Sundararajan, A.; Law, K.H.; Sohn, H.; Farrar, C.R. Piezoelectric structural excitation using a wireless active sensing unit. In Proceedings of the 22nd International Modal Analysis Conference (IMAC XXII), Dearborn, MI, USA, 26–29 January 2004; Society for Experimental Mechanics (SEM): Bethel, CT, USA, 2004. [Google Scholar]

- Hou, T.-C.; Lynch, J.P. Conductivity-based strain monitoring and damage characterization of fiber reinforced cementitious structural components. In Smart Structures and Materials 2005: Sensors and Smart Structures Technologies for Civil, Mechanical, and Aerospace Systems; International Society for Optics and Photonics: Bellingham, WA, USA, 2005. [Google Scholar]

- Han, B.; Han, B.; Ou, J. Novel piezoresistive composite with high sensitivity to stress/strain. Mater. Sci. Technol. 2010, 26, 865–870. [Google Scholar] [CrossRef]

- Lee, S.-J.; Ahn, D.; You, I.; Yoo, D.-Y.; Kang, Y.-S. Wireless cement-based sensor for self-monitoring of railway concrete infrastructures. Autom. Constr. 2020, 119, 103323. [Google Scholar] [CrossRef]

- Han, B.; Zhang, K.; Yu, X.; Kwon, E.; Ou, J. Nickel particle-based self-sensing pavement for vehicle detection. Measurement 2011, 44, 1645–1650. [Google Scholar] [CrossRef]

- Kontakt.io. iBeacon and Eddystone. 2021. Available online: https://kontakt.io/ibeacon-and-eddystone/ (accessed on 20 January 2021).

- Le, H.V.; Lee, D.H.; Kim, D.J. Effects of steel slag aggregate size and content on piezoresistive responses of smart ultra-high-performance fiber-reinforced concretes. Sens. Actuators A Phys. 2020, 305, 111925. [Google Scholar] [CrossRef]

- Le, H.V.; Kim, M.K.; Kim, D.J.; Park, J. Electrical properties of smart ultra-high performance concrete under various temperatures, humidities, and age of concrete. Cem. Concr. Compos. 2021, 118, 103979. [Google Scholar] [CrossRef]

- Le, H.V.; Kim, M.K.; Kim, S.U.; Chung, S.-Y.; Kim, D.J. Enhancing self-stress sensing ability of smart ultra-high performance concretes under compression by using nano functional fillers. J. Build. Eng. 2021, 44, 102717. [Google Scholar] [CrossRef]

- Kim, M.K.; Le, H.V.; Kim, D.J. Electromechanical Response of Smart Ultra-High Performance Concrete under External Loads Corresponding to Different Electrical Measurements. Sensors 2021, 21, 1281. [Google Scholar] [CrossRef] [PubMed]

- Kim, M.K.; Kim, D.J.; An, Y.-K. Electro-mechanical self-sensing response of ultra-high-performance fiber-reinforced concrete in tension. Compos. Part B Eng. 2018, 134, 254–264. [Google Scholar] [CrossRef]

- Nguyen, D.L.; Song, J.; Manathamsombat, C.; Kim, D.J. Comparative electromechanical damage-sensing behaviors of six strain-hardening steel fiber-reinforced cementitious composites under direct tension. Compos. Part B Eng. 2015, 69, 159–168. [Google Scholar] [CrossRef]

- Le, H.V.; Kim, D.J. Effect of matrix cracking on electrical resistivity of high performance fiber reinforced cementitious composites in tension. Constr. Build. Mater. 2017, 156, 750–760. [Google Scholar] [CrossRef]

- Tran, N.T.; Tran, T.K.; Jeon, J.K.; Kil Park, J.; Kim, D.J. Fracture energy of ultra-high-performance fiber-reinforced concrete at high strain rates. Cem. Concr. Res. 2016, 79, 169–184. [Google Scholar] [CrossRef]

- Le, H.V.; Kim, D.J. Effects of matrix strength, fiber type, and fiber content on the electrical resistivity of steel-fiber-reinforced cement composites during fiber pullout. J. Korean Soc. Civ. Eng. 2019, 39, 675–689. [Google Scholar]

- Song, J.; Nguyen, D.L.; Manathamsombat, C.; Kim, D.J. Effect of fiber volume content on electromechanical behavior of strain-hardening steel-fiber-reinforced cementitious composites. J. Compos. Mater. 2015, 49, 3621–3634. [Google Scholar] [CrossRef]

- Nguyen, D.-L.; Kim, D.-J.; Thai, D.-K. Enhancing Damage-Sensing Capacity of Strain-Hardening Macro-Steel Fiber-Reinforced Concrete by Adding Low Amount of Discrete Carbons. Materials 2019, 12, 938. [Google Scholar] [CrossRef] [Green Version]

- Kim, M.K.; Kim, D.J. Electromechanical response of high-performance fiber-reinforced cementitious composites containing milled glass fibers under tension. Materials 2018, 11, 1115. [Google Scholar] [CrossRef] [Green Version]

| Device | Current Consumption (IIDLE) |

|---|---|

| DS3231 (RTC module) | 110 μA |

| SN74LVC1G373 (D-type latch) | 10 μA |

| 74AUP1G00 (NAND gate) | 0.9 μA |

| TPS22860 (Digital switch) | 0.1 μA |

| MCP1725 (Voltage regulators) | 120 μA |

| Electrical Resistance Sensing Circuit (S-UHPC: 1 MΩ + R1: 1 MΩ) | 1.6 μA |

| Total | 242.6 μA |

| No. | C | SF | SP | SS | FSSA | MWCNT | W | SPP | FS (vol%) | FL (vol%) | Flow (mm) | fc (MPa) | γ (kg/m3) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| M1S | 1 | 0.15 | 0.25 | 0.5 | 0.5 | - | 0.2 | 0.07 | 2 | - | 260 | 179 | 2423 |

| M1L | 1 | 0.15 | 0.25 | 0.5 | 0.5 | - | 0.2 | 0.07 | - | 2 | 260 | 179 | 2423 |

| M2S | 1 | 0.15 | 0.25 | 0.5 | 0.5 | 0.001 | 0.2 | 0.07 | 2 | - | 240 | 160 | 2573 |

| M2L | 1 | 0.15 | 0.25 | 0.5 | 0.5 | 0.001 | 0.2 | 0.07 | - | 2 | 240 | 160 | 2573 |

| Functional Filler | Size (mm) | Length (mm) | Density (g/cm3) | Elastic Modulus (GPa) |

|---|---|---|---|---|

| FSSA | <0.39 | - | 3.56 | - |

| FS | 0.2 | 6 | 7.85 | 200 |

| FL | 0.3 | 30 | 7.85 | 200 |

| MWCNT | 10−5 | 0.01 | 0.02–0.04 | - |

| Notation | σp (MPa) | ρo (kΩ-cm) | ρp (kΩ-cm) | Δρp = ρp − ρo (kΩ-cm) | FCR = Δρp/ρo (%) |

|---|---|---|---|---|---|

| M1S_WSS | |||||

| Sp1 | 170.51 | 13,370.37 | 9787.04 | 3379.63 | 26.80 |

| Sp2 | 170.86 | 14,157.41 | 9916.67 | 3898.14 | 29.95 |

| Sp3 | 170.69 | 14,730.77 | 10,365.38 | 4250.00 | 29.63 |

| Average | 170.69 | 14,086.18 | 10,023.03 | 3842.59 | 28.80 |

| STDV | 0.14 | 557.66 | 247.80 | 357.49 | 1.42 |

| M1S_DC | |||||

| Sp1 | 172.08 | 12,701.40 | 9337.33 | 3048.81 | 26.49 |

| Sp2 | 184.33 | 11,958.98 | 8927.14 | 2744.00 | 25.35 |

| Sp3 | 174.73 | 12,574.17 | 9582.15 | 2855.69 | 23.79 |

| Average | 177.05 | 12,411.52 | 9282.21 | 2882.83 | 25.21 |

| STDV | 5.26 | 324.18 | 270.23 | 125.91 | 1.11 |

| M2S_WSS | |||||

| Sp1 | 153.53 | 9591.67 | 6033.3 | 3558.34 | 37.10 |

| Sp2 | 149.03 | 8973.21 | 5250.0 | 3723.21 | 41.49 |

| Sp3 | 165.66 | 10,288.46 | 6269.23 | 4019.23 | 39.07 |

| Average | 156.07 | 9617.78 | 5850.85 | 3766.93 | 39.22 |

| STDV | 7.02 | 537.27 | 435.64 | 190.68 | 1.80 |

| M2S_DC | |||||

| Sp1 | 149.69 | 8340.47 | 5447.01 | 2620.71 | 34.69 |

| Sp2 | 164.31 | 8851.31 | 6001.94 | 2499.85 | 32.19 |

| Sp3 | 158.19 | 8519.25 | 5388.12 | 2960.74 | 36.75 |

| Average | 157.40 | 8570.34 | 5612.36 | 2693.77 | 34.55 |

| STDV | 5.99 | 211.66 | 276.52 | 195.12 | 1.86 |

| Notation | σpc (MPa) | ρo (kΩ-cm) | Δρpc (kΩ-cm) | Npc | FCRcc (%) | FCRpc (%) | FCR/Npc (%) | GFstrain | GFdamage |

|---|---|---|---|---|---|---|---|---|---|

| M1L_WSS | |||||||||

| SP1 | 17.45 | 5055 | 1380 | 3 | 1.48 | 27.30 | 9.10 | 54.95 | 37.4 |

| SP2 | 17.96 | 4520 | 1345 | 3.5 | 0.88 | 29.76 | 8.50 | 22.69 | 30.9 |

| SP3 | 19.45 | 4590 | 1925 | 4 | 1.53 | 41.94 | 10.49 | 49.20 | 38.16 |

| Average | 18.29 | 4721.67 | 1550 | 3.5 | 1.30 | 33.00 | 9.36 | 42.28 | 35.9 |

| STDV | 0.85 | 237.43 | 265.55 | 0.41 | 0.29 | 6.40 | 0.83 | 14.05 | 3.61 |

| M1L_DC | |||||||||

| SP1 | 17.99 | 3959.49 | 1295.43 | 3 | 0.99 | 32.72 | 10.91 | 42.85 | 29.3 |

| SP2 | 17.35 | 3505.23 | 1341.99 | 3 | 0.98 | 38.29 | 12.76 | 30.62 | 34.4 |

| SP3 | 16.88 | 3444.99 | 1461.15 | 4 | 1.01 | 42.41 | 10.60 | 24.56 | 38.6 |

| Average | 17.41 | 3636.57 | 1366.19 | 3.33 | 0.99 | 37.81 | 11.42 | 32.68 | 34.1 |

| STDV | 0.45 | 229.66 | 69.79 | 0.47 | 0.01 | 3.97 | 0.96 | 7.61 | 3.80 |

| M2L_WSS | |||||||||

| SP1 | 16.25 | 3081 | 1381 | 3.5 | 1.30 | 44.82 | 12.81 | 37.11 | 54.4 |

| SP2 | 20.18 | 2860 | 1380 | 3.5 | 2.80 | 48.25 | 13.79 | 96.46 | 38.1 |

| SP3 | 21.59 | 3130 | 1310 | 4 | 1.92 | 41.85 | 10.46 | 50.45 | 55.1 |

| Average | 19.34 | 3023.67 | 1357.0 | 3.67 | 2.00 | 44.98 | 12.35 | 61.34 | 49.2 |

| STDV | 2.26 | 117.45 | 33.24 | 0.24 | 0.61 | 2.62 | 1.39 | 25.42 | 7.85 |

| M2L_DC | |||||||||

| SP1 | 20.27 | 2390.58 | 1393.42 | 4 | 2.17 | 58.29 | 14.57 | 65.64 | 61.6 |

| SP2 | 17.66 | 2292.28 | 1090.78 | 3 | 1.74 | 47.58 | 15.86 | 40.36 | 46.1 |

| SP3 | 20.20 | 2405.80 | 1081.10 | 3 | 0.89 | 44.94 | 14.98 | 31.77 | 42.1 |

| Average | 19.38 | 2362.89 | 1181.43 | 3.33 | 1.60 | 50.27 | 15.14 | 45.91 | 49.9 |

| STDV | 1.21 | 50.31 | 145.00 | 0.47 | 0.53 | 5.77 | 0.54 | 14.36 | 8.41 |

| Notation | σpc (MPa) | ρo (kΩ-cm) | ρpc (kΩ-cm) | Δρ (kΩ-cm) | FCR (%) |

|---|---|---|---|---|---|

| M1L | |||||

| SP1 | 12.60 | 2995 | 2325 | 670 | 22.18 |

| SP2 | 15.12 | 3260 | 1953 | 1307 | 40.11 |

| SP3 | 16.53 | 2938 | 2068 | 870 | 29.62 |

| Average | 14.75 | 3064.33 | 2115.33 | 949 | 30.64 |

| STDV | 1.63 | 140.30 | 155.51 | 265.99 | 7.36 |

| M2L | |||||

| SP1 | 18.53 | 1541.7 | 883.3 | 658.3 | 42.70 |

| SP2 | 18.51 | 1550 | 925 | 625 | 40.32 |

| SP3 | 17.14 | 1716.7 | 1208.3 | 508.3 | 29.61 |

| Average | 18.06 | 1602.8 | 1005.6 | 597.2 | 37.55 |

| STDV | 0.65 | 80.61 | 144.38 | 64.32 | 5.69 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Le, H.-V.; Kim, T.-U.; Khan, S.; Park, J.-Y.; Park, J.-W.; Kim, S.-E.; Jang, Y.; Kim, D.-J. Development of Low-Cost Wireless Sensing System for Smart Ultra-High Performance Concrete. Sensors 2021, 21, 6386. https://doi.org/10.3390/s21196386

Le H-V, Kim T-U, Khan S, Park J-Y, Park J-W, Kim S-E, Jang Y, Kim D-J. Development of Low-Cost Wireless Sensing System for Smart Ultra-High Performance Concrete. Sensors. 2021; 21(19):6386. https://doi.org/10.3390/s21196386

Chicago/Turabian StyleLe, Huy-Viet, Tae-Uk Kim, Suleman Khan, Jun-Young Park, Jong-Woong Park, Seung-Eock Kim, Yun Jang, and Dong-Joo Kim. 2021. "Development of Low-Cost Wireless Sensing System for Smart Ultra-High Performance Concrete" Sensors 21, no. 19: 6386. https://doi.org/10.3390/s21196386

APA StyleLe, H.-V., Kim, T.-U., Khan, S., Park, J.-Y., Park, J.-W., Kim, S.-E., Jang, Y., & Kim, D.-J. (2021). Development of Low-Cost Wireless Sensing System for Smart Ultra-High Performance Concrete. Sensors, 21(19), 6386. https://doi.org/10.3390/s21196386