5.1. Baseline Case at Two Different Power Nozzle Velocities

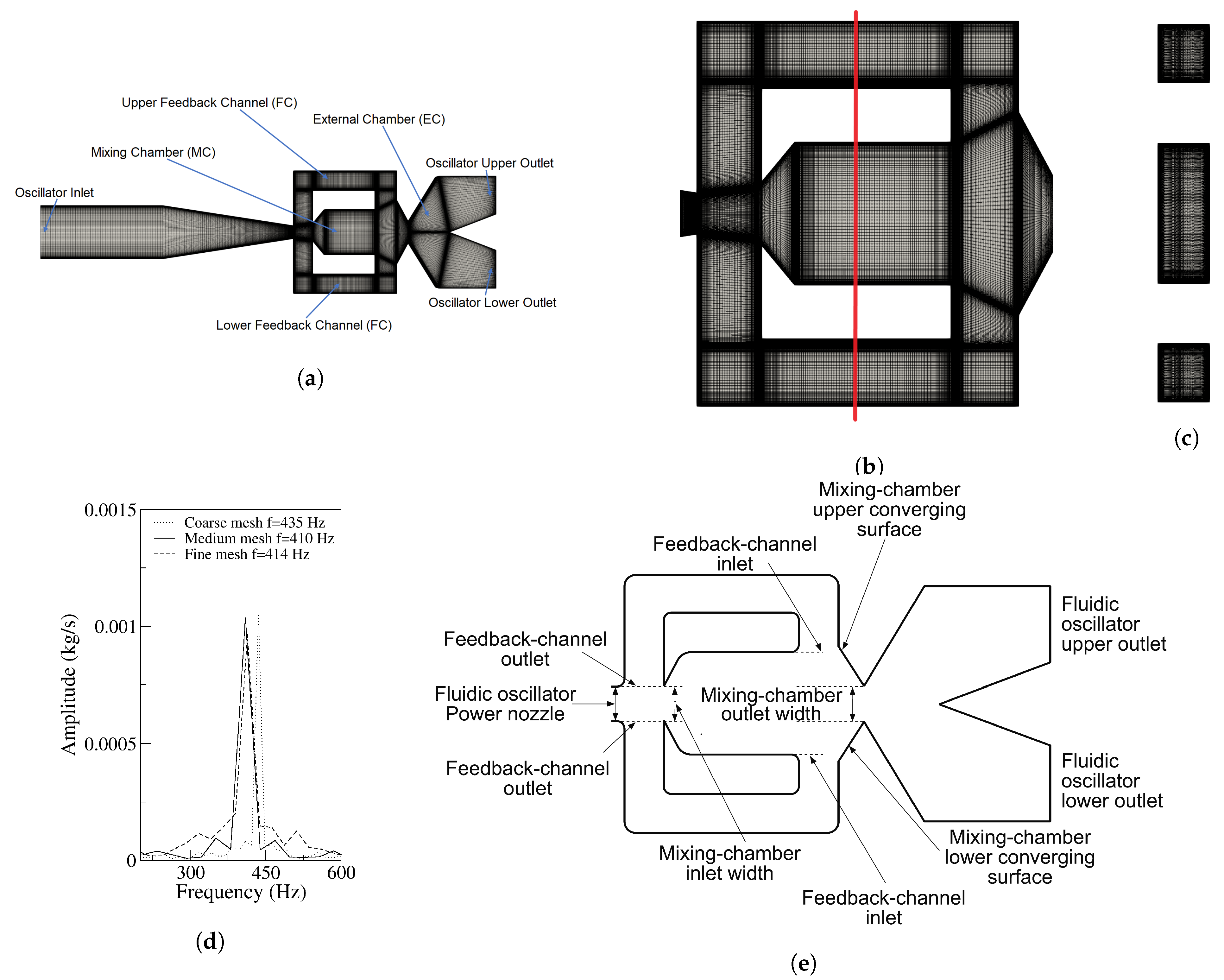

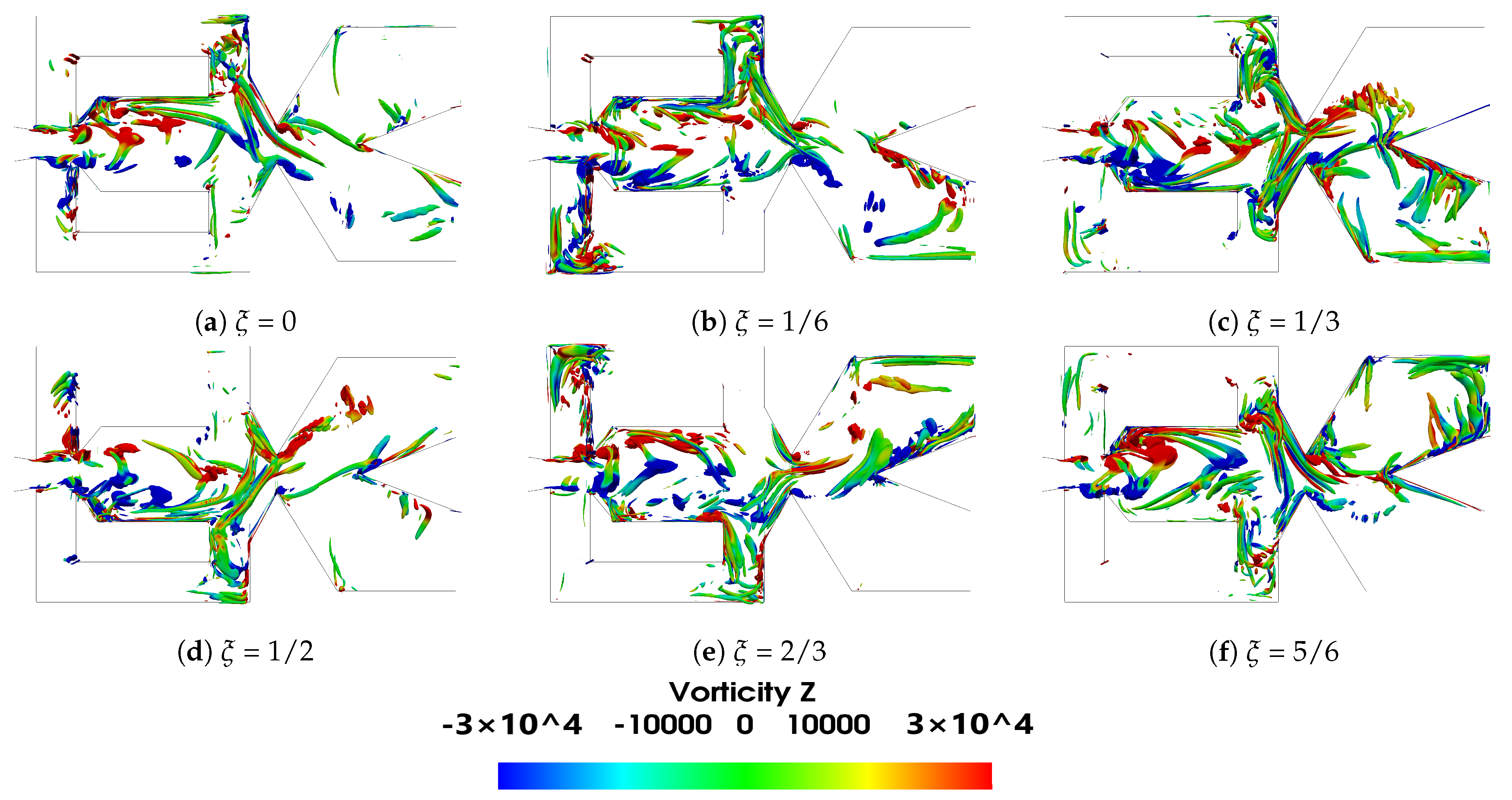

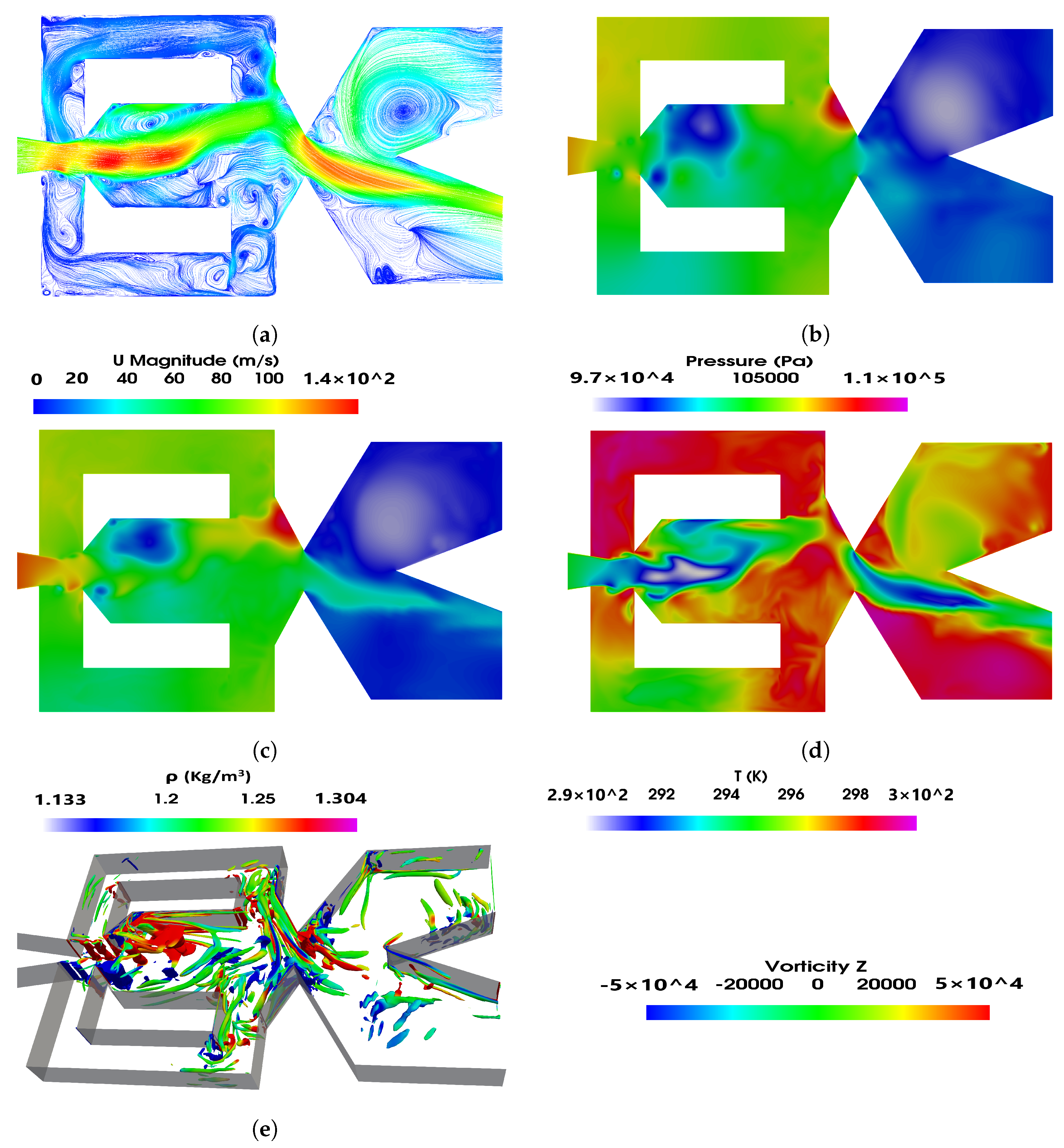

In the present subsection, the main flow parameters associated to the FO working under compressible flow conditions and at the two Mach numbers evaluated are introduced. The initial analysis is focused on the baseline case. The main vortical structures inside the FO mixing and external chambers, given for a period of oscillation

divided in six equally spaced time steps, are presented based on the Q criterion in

Figure 4 and

Figure 5 for the two power nozzle velocities evaluated, 65 m/s and 97 m/s, respectively. Both figures show how the positive and negative vortical structures are alternatively appearing inside the mixing chamber and being shed downstream. The Q criterion evaluates the relative dominance of the rotational over the stretching component in the deformation of a fluid element, mathematically defined as

. Notice that the vorticity is defined as angular momentum in radians per second. Particularly large positive three-dimensional vortical structures inside the MC are clearly seen at time periods

,

and

, large negative vortical structures are observed at time periods

and

. Similar structures on the same FO configuration but under incompressible flow conditions were recently presented in [

24,

39]. The dimension of the vortical structures is very much the same for the two velocities studied, but the maximum vorticity associated to the main vortical structures increases about

when the power nozzle velocity is increased from 65 m/s to 97 m/s. Notice that the vortical structures having associated the maximum and minimum vorticity values, appear alternatively inside the mixing chamber, just after the MC inlet width, in the locations where the minimum pressure is observed, see

Figure 6 and

Figure 7. The main vortical structures break and become more random as they are being shed downstream. Inside the feedback channels, weak vortical structures appear alternatively at the FC’s inlet and also at the opposite FC left hand side corner, see

Figure 4b,e and

Figure 5b,e, indicating the locations where the flow is generating eddies. As already observed by [

20], the FC’s eddies could be minimized by rounding the FC’s corners. Rather weak vortical structures appear at the external chamber (EC), indicating that although large vortices are generated in this chamber, see

Figure 6a and

Figure 7a, their intensity is much weaker than the vortical structures generated inside the MC.

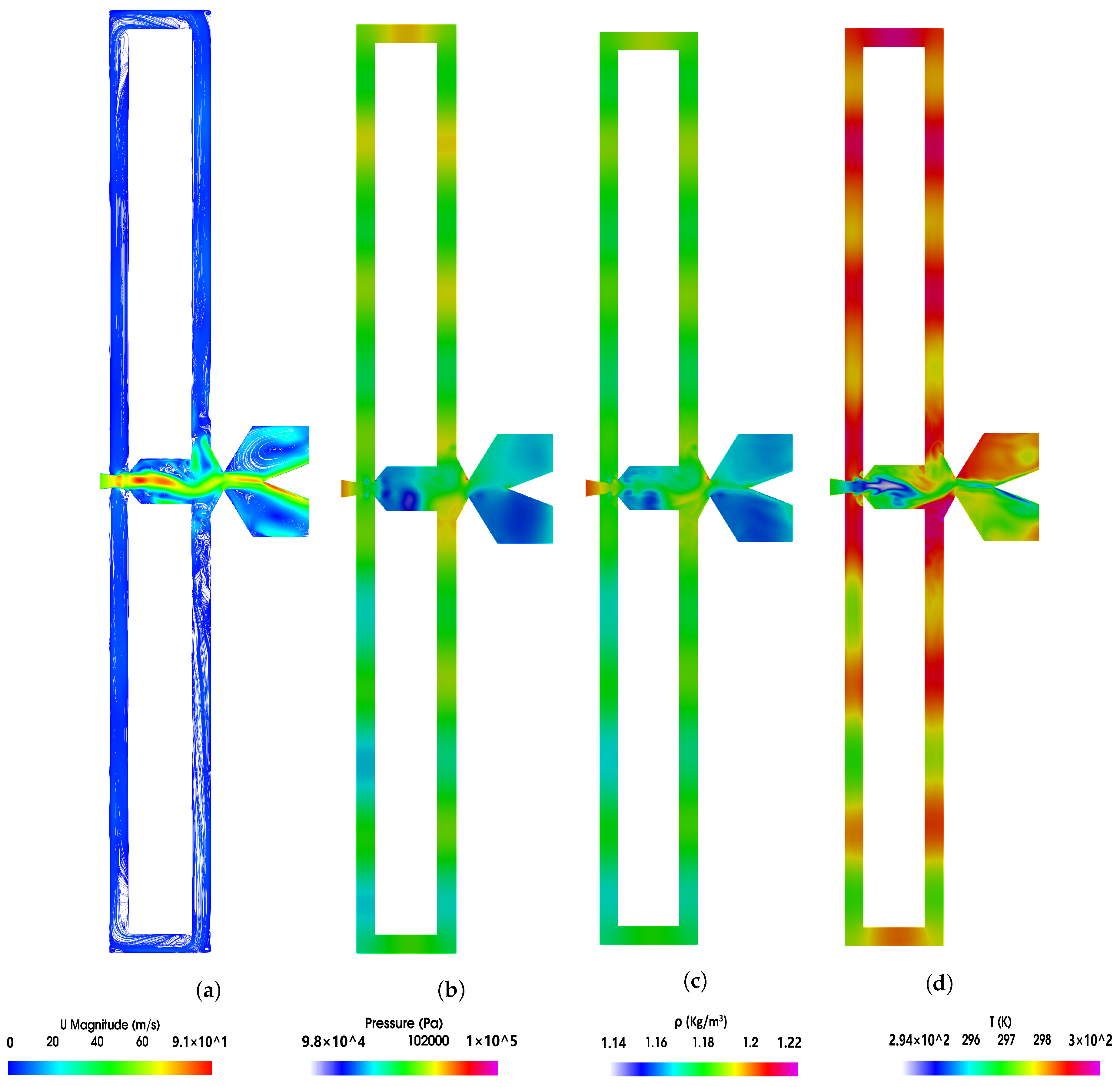

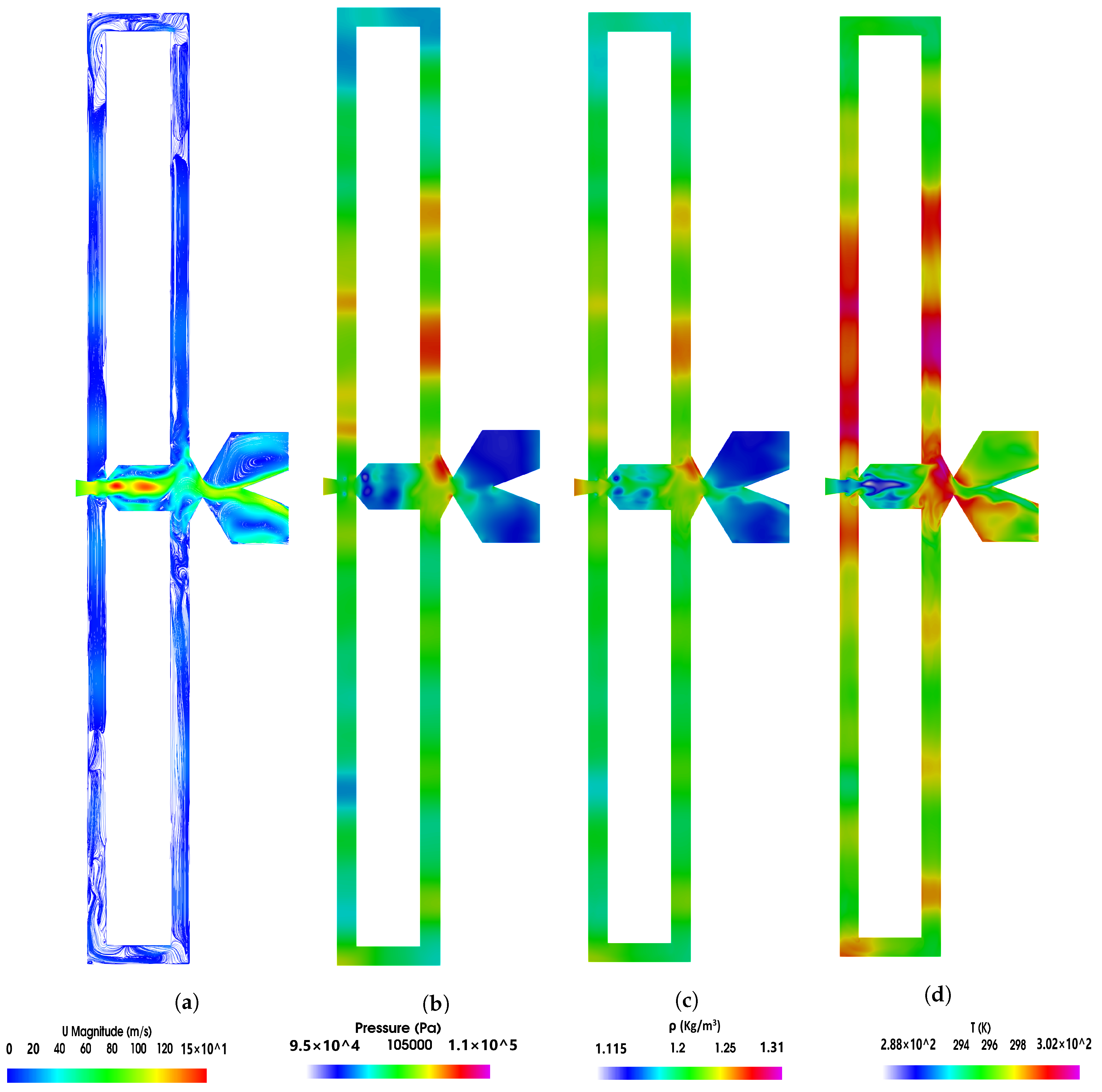

Figure 6 and

Figure 7 show the instantaneous velocity, pressure, density and temperature fields; in the FO mixing and external chambers, the power nozzle velocities are 65 m/s and 97 m/s, respectively. A three-dimensional Q criterion plot generated at the same instant is as well presented in each figure. The time instant shown in

Figure 6 and

Figure 7 corresponds to the time period

presented in

Figure 4 and

Figure 5, respectively. It is interesting to realize that the fluid expands inside the mixing chamber, the pressure decreases about 10,000 Pa in

Figure 5 and about 13,000 Pa in

Figure 6, versus the respective one at the power nozzle. The maximum velocity and Mach number at the MC outlet reach values 35% and 44% higher than the ones at the power nozzle, respectively. The fluid suffers a second expansion when it reaches the external chamber, the pressure being rather homogeneous across it. In both

Figure 6a and

Figure 7a, a large vortical structure of nearly the same size is observed at the external chamber upper side. When comparing these two figures it can be clearly stated that the vortical structure shown in

Figure 7 has a higher turning speed associated than the one appearing in

Figure 6. In fact, in

Figure 7, the pressure at the vortex central core is about 3000 Pa lower than the one observed at the surrounding area, this pressure drop is about 1000 Pa in

Figure 6.

The feedback channels are alternatively pressurized, but due to the fluid compressibility, it can be seen that just parts of the feedback channels are pressurized; in other words, pressure waves can be seen moving along the FCs. The videos presented in

Supplementary Materials are designed to help in clarifying this point. Pressure waves traveling along FCs were very recently reported by [

40]. At the instant presented in

Figure 6, the lower FC outlet is slightly pressurized while the upper one is not, therefore suggesting that the jet inside the mixing chamber is being pushed upwards.

Figure 7 shows the opposite, the upper FC outlet is slightly pressurized while the lower one is not, indicating the main jet entering the MC is at this instant being pushed downwards. At this point it needs to be clarified that although

Figure 6 and

Figure 7 are defined at time

, this instantaneous initial time represents different physical conditions for each figure.

Pressure waves originate at the MC converging walls and are due to the stagnation pressure points appearing alternatively at these surfaces. When carefully looking at

Figure 6b–d and

Figure 7b–d, it is seen that pressure waves also originate at the FC’s outlets, see the small red point at the lower FC outlet internal vertical wall,

Figure 6b. Notice that from this point pressure waves are being generated and move from the FC outlet towards the FC inlet.

Figure 6b clearly shows the existence of two pressure waves, one is moving along the upper FC, from FC inlet to the outlet and the other is moving along the lower FC from the FC outlet to the FC inlet. The pressure wave generated at the FC outlet has associated a smaller intensity than the other one. Although the maximum value of the stagnation pressure was found to be at the FC outlet, the time during which the stagnation pressure point is observed is much smaller than the time stagnation pressure is seen to last at the MC converging walls. This explains the different intensities of the pressure waves generated on each FC end. As will be clarified in the remaining part of the paper, whenever pressure waves originate at each side of the FCs, the resulting net momentum acting over the main jet as well as the stagnation pressure dynamics at the MC converging walls have associated particularly high fluctuations.

Pressure waves generated at the MC converging walls do not appear to be moving downstream towards the external chamber; it seems that the main jet flowing across the mixing chamber outlet width blocks them from displacing downstream. The same happens to the pressure waves generated at the FC outlets’ internal vertical walls. The waves propagate along the FC but not towards the MC, the main jet entering the MC appears to be acting as a barrier to the pressure wave propagation. On the other hand, some high-frequency waves are likely to dissipate into heat. The fluid expansion suffered at the EC tends to help in dissipating the pressure waves effect in this chamber. The Q criterion plots presented in

Figure 6e and

Figure 7e show the three-dimensional structures already presented in two dimensions in

Figure 4a and

Figure 5a, respectively. Notice that the main three-dimensional structures, alternatively appearing at the MC inlet, maintain their form along the spanwise direction. Four videos introducing the velocity field and the pressure contours characterizing the two power nozzle velocities studied and for the baseline case are presented in the

Supplementary Materials.

When studding the same FO configuration under incompressible flow conditions and at Reynolds numbers up to 32,000, refs. [

39,

41] established that flow oscillations were driven by the alternating pressure variation at the FC’s outlets. Based on the results presented in this sub section, the required force responsible for driving the jet oscillations inside the MC appears to be generated by the pressure difference at the FC’s outlets. This hypothesis shall be proved in the remaining part of the present manuscript.

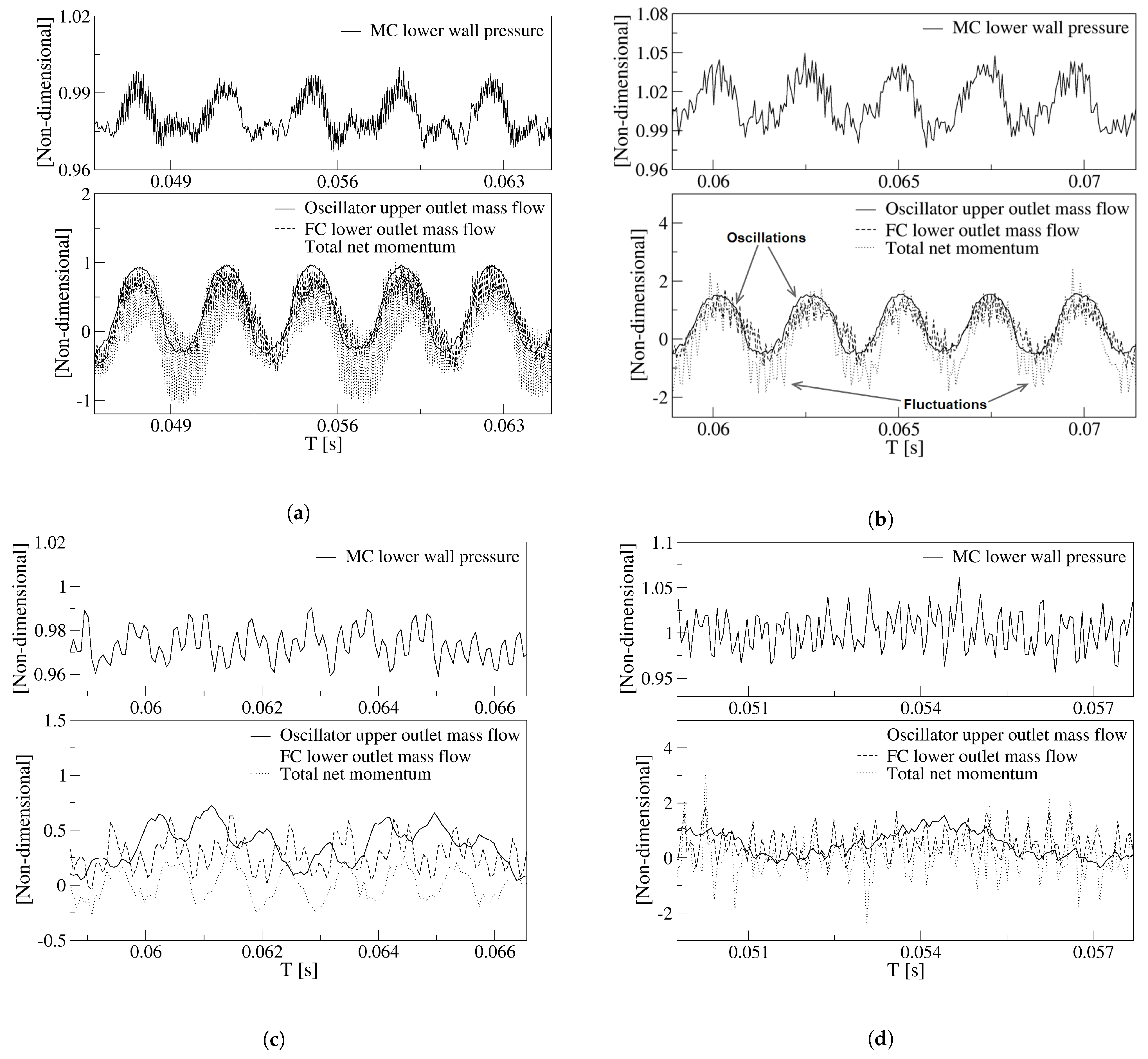

In order to determine the origin of the forces responsible of the jet oscillations inside the MC,

Figure 8 was created. It presents for the two velocities studied and in non-dimensional form, the dynamics of the maximum stagnation pressure measured at the MC lower converging wall, the FO upper outlet mass flow, the lower FC mass flow and the net momentum applied to the jet entering the MC.

Figure 8a,b characterize the baseline case, and

Figure 8c,d introduce the same information for the maximum feedback channel length studied, 9L. The first thing to realize is that, for the baseline case and for both power nozzle velocities, all these parameters follow the same trend. On the other hand, for the longest FC length studied, the main jet oscillations are deeply affected by random fluctuations, and under these conditions the main jet inside the MC is mostly fluctuating although performing as well a low amplitude oscillation. In

Figure 8a,b, the stagnation pressure oscillations measured at the MC lower converging wall appear at the same frequency as the rest of the parameters, indicating that there must be a correlation between them. The amplitude of these parameters also appears to be correlated. The oscillating frequencies of all these parameters when the power nozzle velocities are 65 m/s and 97 m/s are respectively of 275.4 Hz and 410 Hz.

When the power nozzle inlet velocity is of 65 m/s,

Figure 8a, the stagnation pressure oscillations are particularly scattered, the FC mass flow and in particular the net momentum acting on the jet entering the MC show as well as very scattered curves, which appear to be affected by very high frequency fluctuations. For this particular inlet velocity, as shown in

Figure 6b, a stagnation pressure point is observed at the FC lower outlet internal vertical wall. From this point, pressure waves are being generated and move from the FC outlet towards the FC inlet. These pressure waves interact with the ones generated at the MC converging walls and create the high-frequency fluctuations observed in the pressure, net momentum and FC mass flow curves shown in

Figure 8a. All these pressure waves bounce on the different FC walls which help in generating high-frequency fluctuations.

As the power nozzle velocity increases to 97 m/s, the stagnation pressure point appearing at the FC outlet internal vertical wall reaches a smaller value than in the previous case, compare

Figure 7b,c with

Figure 6b,c. Fewer fluid particles from the incoming jet are impinging in this vertical wall, and as a result the pressure waves generated at this particular point are weaker than in the previous velocity studied. The result is that a much smoother stagnation pressure oscillation is observed at the MC converging walls and at the FC mass flow, the net-momentum measured at the FC outlet surfaces is also affected by less fluctuating perturbations, see

Figure 8b. The fluctuations associated to all these curves show a much smaller frequency than in the previous case. Yet, the net momentum acting on the MC incoming jet is still showing large amplitude fluctuations, which is due to the pressure waves periodically generated at the MC converging walls and bouncing on the FC’s walls, alternatively pressurizing and depressurizing the FC’s outlets. For a power nozzle velocity of 65 m/s, the stagnation pressure peak-to-peak oscillations amplitude are about 3.5% of the maximum stagnation pressure at this power nozzle velocity. The non-dimensional peak-to-peak stagnation pressure oscillations amplitude increases to about 5% when the power nozzle velocity reaches 97 m/s. In reality, both pressure waves show a main oscillating peak and a smaller one, this second one coincides with the instant the main jet impinges on the opposite MC converging wall, therefore pressurizing the opposite FC. The increase of the peak-to-peak stagnation pressure amplitude at the MC converging walls is triggering the amplitude increase of the FO outlet mass flow, the FC mass flow and the net momentum evaluated at the FC outlets. Notice that all these parameters show a much larger peak-to-peak amplitude in

Figure 8b when compared to the ones in

Figure 8a. The net-momentum peak-to-peak amplitude at 97 m/s almost doubles the value observed at 65 m/s. From these two figures it can also be observed that for any of the two velocities studied, the FO outlet mass flow, the FC mass flow and the net momentum have, during approximately 1/4 of the oscillating cycle, negative values. This clearly indicates there is reverse flow at the FO outlet and inside the FCs. Reverse flow at the lower FC outlet can be clearly seen in

Figure 6a. The increase of power nozzle velocity does not seem to affect much the minimum negative values of the FC mass flow and the FO mass flow. Even the time oscillating parameters remain negative, 1/4 of the oscillating cycle appears to be unaffected by the power nozzle inlet velocity.

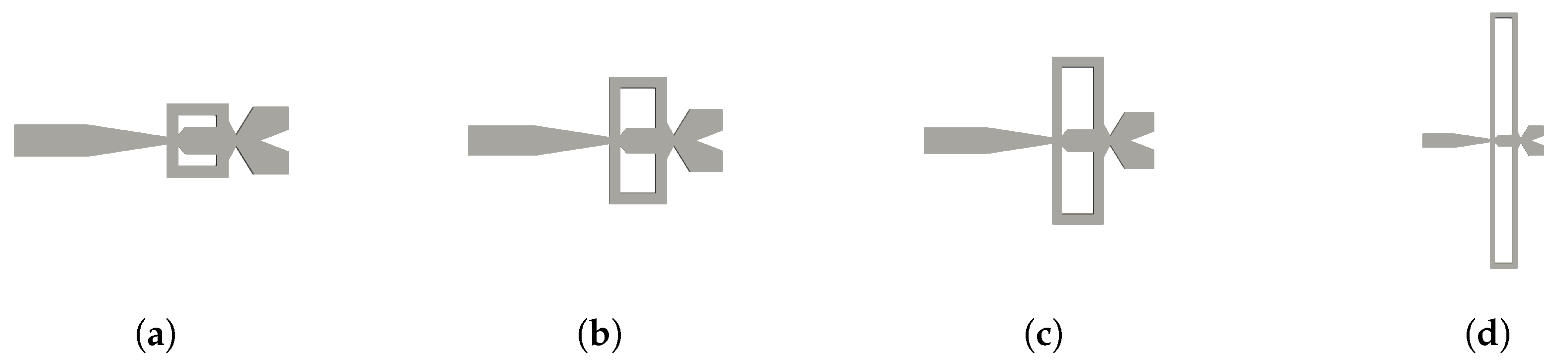

5.2. The Effect of the Feedback Channel Length

From the comparison of

Figure 8a,b, baseline case, with

Figure 8c,d, feedback channel length 9L, it is observed that regardless of the inlet velocity employed, the FO outlet flow drastically reduces its peak-to-peak amplitude when the longest feedback channel length is used. Although the different graphs are not presented in this paper, it was observed that the stagnation pressure oscillation amplitude at the MC converging walls decreased as the feedback channel length increased. The second major observation from

Figure 8 is that unlike in the baseline case, for the FC length 9L, there is not an apparent link between the stagnation pressure at the MC convergent walls and the rest of the parameters. However, when closely looking at the different curves presented in

Figure 8c, it can be observed the different curves tend to follow, although with a phase lag, the stagnation pressure oscillations appearing at the MC converging wall. Again this appears to indicate that the origin of the jet oscillations and even the fluctuations is the stagnation pressure variations at the MC converging walls. For a FC length of 9L and for both velocities studied, the jet inside the MC is mostly fluctuating at high frequencies, the fluctuation amplitude is of the same order of the oscillation amplitude. The fluctuation frequency increases with an increase of the inlet velocity; in fact, for the highest velocity and FC length studied,

Figure 8d, random fluctuations dominate the flow, high Reynolds numbers and long FC lengths seem to enhance flow randomness.

To be able to further understand the effect of the FC length on the FO outlet mass flow frequency and amplitude,

Figure 9 was generated. Regardless of the inlet velocity employed, as the FC length increases, the FO outlet mass flow oscillating frequency and its peak-to-peak amplitude tend to decrease. At 65 m/s, the equations characterizing the FO outlet mass flow amplitude and frequency decrease, normalized by its maximum respective value, and as a function of the FC length increase are respectively:

;

, where

take the values of the different FC lengths, 1, 2, 3 and 9. The evolution of the rest of the parameters, net-momentum and stagnation pressure at the MC converging walls, follow exactly the same trend. Although they used a different FO configuration, the oscillating frequency variation is in full agreement with the observations made by [

37].

In fact, and regardless of the velocity studied, the curves showing the FO outlet mass flow become scattered as FC length increases. It appears as if instead of clean oscillations, the main jet undergoes some vibrational movement, although still maintaining a low amplitude oscillatory displacement, see

Figure 8c,d and

Figure 9b. For a power nozzle velocity of 65 m/s,

Figure 9a, the jet fluctuations (vibrational movement) can be clearly seen when the FC length is 3L; they are almost as large as the peak-to-peak oscillation amplitude when the FC length is 9L. Under these conditions, the main jet at the FO outlet undergoes a high-frequency fluctuating movement while performing a small oscillation cycle. For a FC length of 9L, the frequencies associated to the respective fluctuating and oscillating jet movements measured at the FO outlet mass flow are 1037.4 Hz and 251.6 Hz. When the power nozzle velocity is of 97 m/s, the fluctuating wave can be clearly seen for a FC length of 2L, see

Figure 9b. Whenever the FC length is 3L, the jet fluctuations have a peak-to-peak amplitude of about 25% of the oscillation one. For this particular case, the frequencies associated to the fluctuating and oscillating movements are 2401.8 Hz and 179.3 Hz, respectively. For the longest FC length L9, the peak-to-peak amplitude associated to the jet fluctuations are smaller than for the FC length L3; in reality the fluctuations as well as the oscillations have become quite random, a set of different frequencies appear, the frequencies associated to the major flow fluctuations and to the jet main oscillating displacement are respectively of 2708.8 Hz and 132.1 Hz. In any case, it can be concluded that the randomness associated to the oscillations increases with the FC length increase, and/or with the FO inlet velocity increase. Based on these results, it can be estimated that a further increase of the FC length would make the oscillations stop, as it is about to happen in

Figure 9b for the maximum FC length L9. The simulations demonstrate that reverse flow has to be expected at the FO outlet, the reverse flow at the FO outlet tends to disappear as the FC length increases.

Figure 9a,b demonstrate there is no reverse flow at the FO outlet for a FC length of 9L.

Figure 10 presents for the two power nozzle velocities and the four FC lengths the evolution of the oscillating and fluctuating frequencies, as well as their respective amplitudes. The information is obtained based on the FO outlet mass flow. At 65 m/s, the oscillation amplitude decreases by about

when comparing the results for the longest FC length 9L with the baseline case. For the same conditions, the oscillation frequency decreases by

. For a FC length of 9L, a clear fluctuating frequency of 1037.4 Hz, which is superposed to the oscillating wave, can be observed. Whenever the power nozzle velocity is of 97 m/s,

Figure 10b, and when comparing the results of the baseline case with the ones for the longest FC length, the oscillation amplitude decreases by about 72% and the frequency by 67%. At high speeds, the compressibility effect along with the chaotic stage make the oscillating frequency highly dependent on the FC length, generating a drastic decrease of the oscillating frequency and the appearance of several fluctuating frequencies. Especially at 97 m/s, the outlet mass flow fluid oscillations become chaotic as the FC length increases, oscillations are rather chaotic for a FC length of 9L. As observed in

Figure 10, fluctuating frequencies are one or several orders of magnitude higher than the oscillation ones.

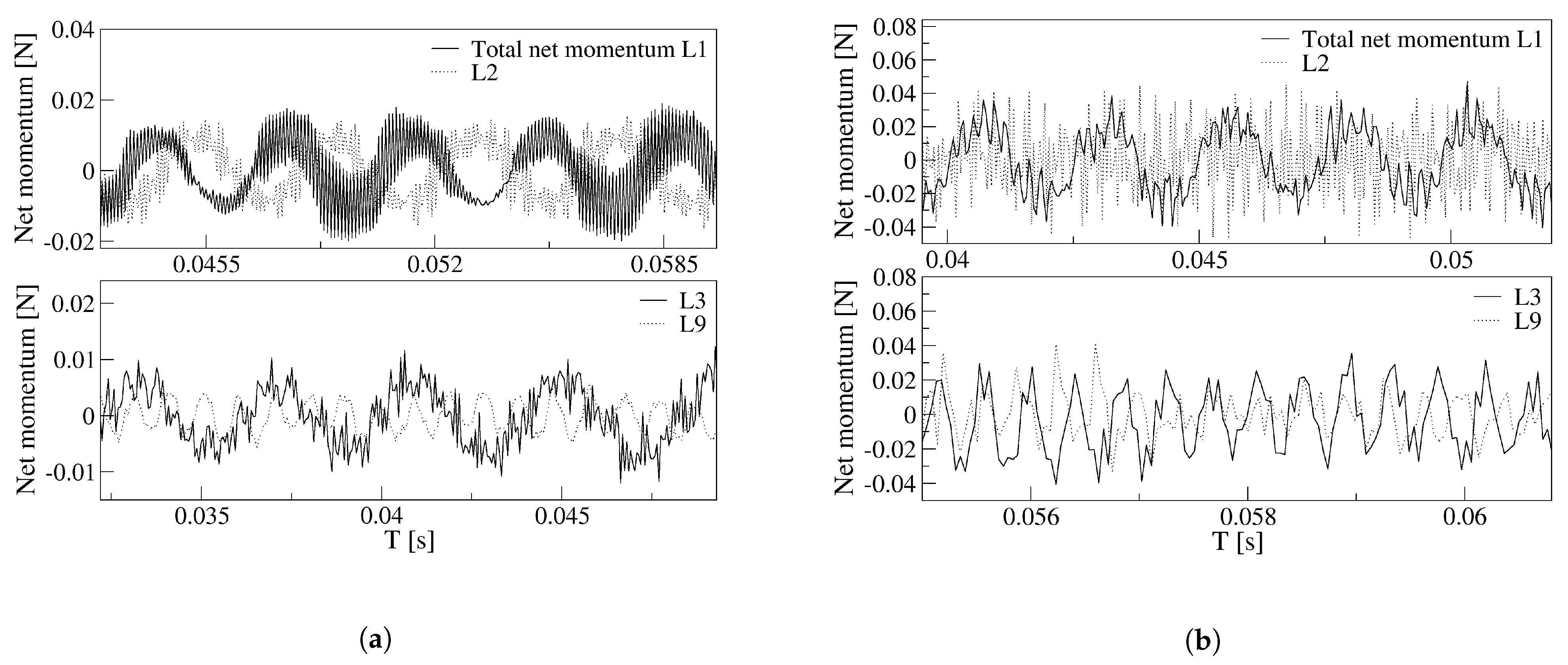

Once the main FO outlet flow characteristics are evaluated, it is interesting to analyze the fluid evolution inside the MC and the feedback channels. For the two power nozzle velocities and the four FC lengths, the overall forces acting on the main jet at the MC inlet, expressed as the net-momentum acting onto the FC’s outlets are presented in

Figure 11. For the two power nozzle velocities studied, the net momentum oscillation amplitude and frequency associated decreases with the FC length increase. The net-momentum oscillation becomes highly random as the FC length increases, the inlet velocity increase enhances this effect. At high FC lengths, large amplitude pressure fluctuations are mostly observed on the MC converging walls, see

Figure 8c,d, and these fluctuations take control of the main flow and of the net momentum acting on the jet, as observed in

Figure 11b. For the baseline case and for the smaller velocity studied, 65 m/s,

Figure 11a, the net-momentum oscillating displacement appears to be particularly noisy, the frequency associated to the fluctuations (noise) is of 9988.6 Hz, about 35 times the oscillating frequency, which is of 275.4 Hz. This very high frequency appears to be associated to the pressure waves generated at the MC inclined walls and to the bouncing of the pressure waves on the FC walls. In the previous section it was already explained that under these conditions, a particularly high stagnation pressure point appears at the FC’s outlet internal vertical wall, see

Figure 6. Pressure waves are simultaneously generated at this point and at the MC converging walls, the interaction between these pressure waves, which displaces in opposite directions, is the origin of these particular high-frequency fluctuations observed in

Figure 11a for a FC length L1.

Figure 11b for FC lengths L3 and L9, show that the main net-momentum oscillation is almost gone and the main jet is affected by very high frequency fluctuations, of which the peak-to-peak amplitude is larger than the oscillating one. Notice that for these particular cases, the FO outlet mass flow,

Figure 9b, presents high-frequency fluctuations superposed on a highly random oscillation. Notice as well that the net-momentum pattern has close similarities with the outlet mass flow pattern and the mixing chamber pressure one on the converging walls. To highlight these similarities,

Figure 12 and

Figure 13 were generated.

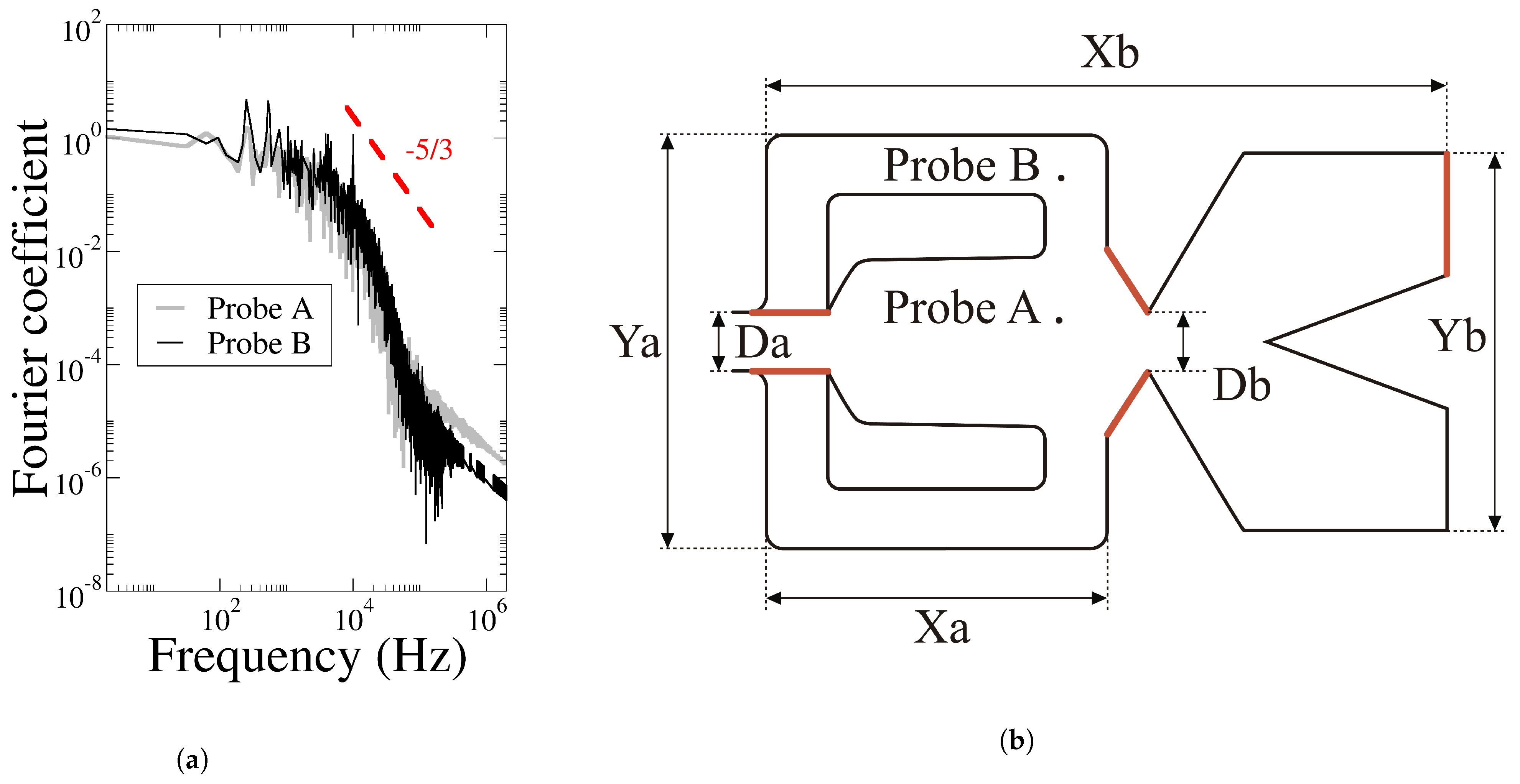

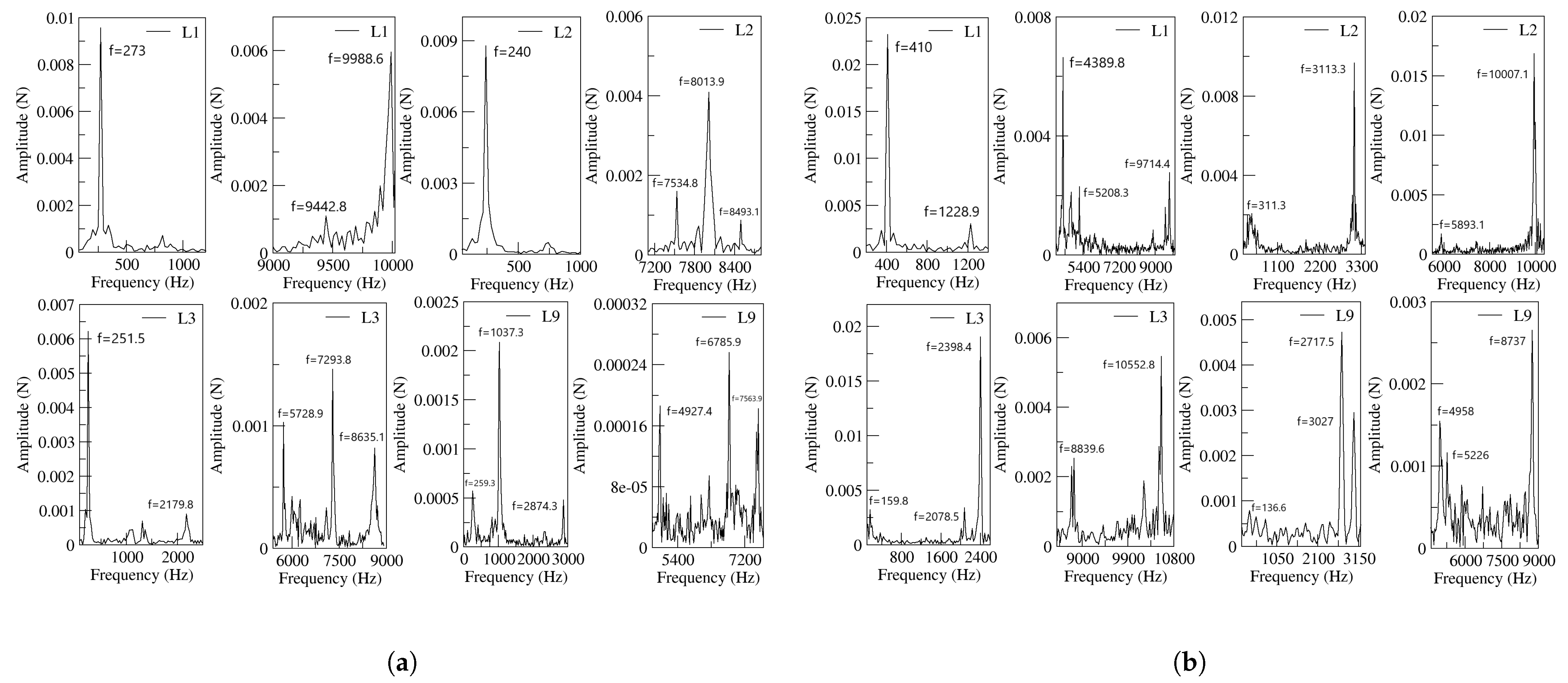

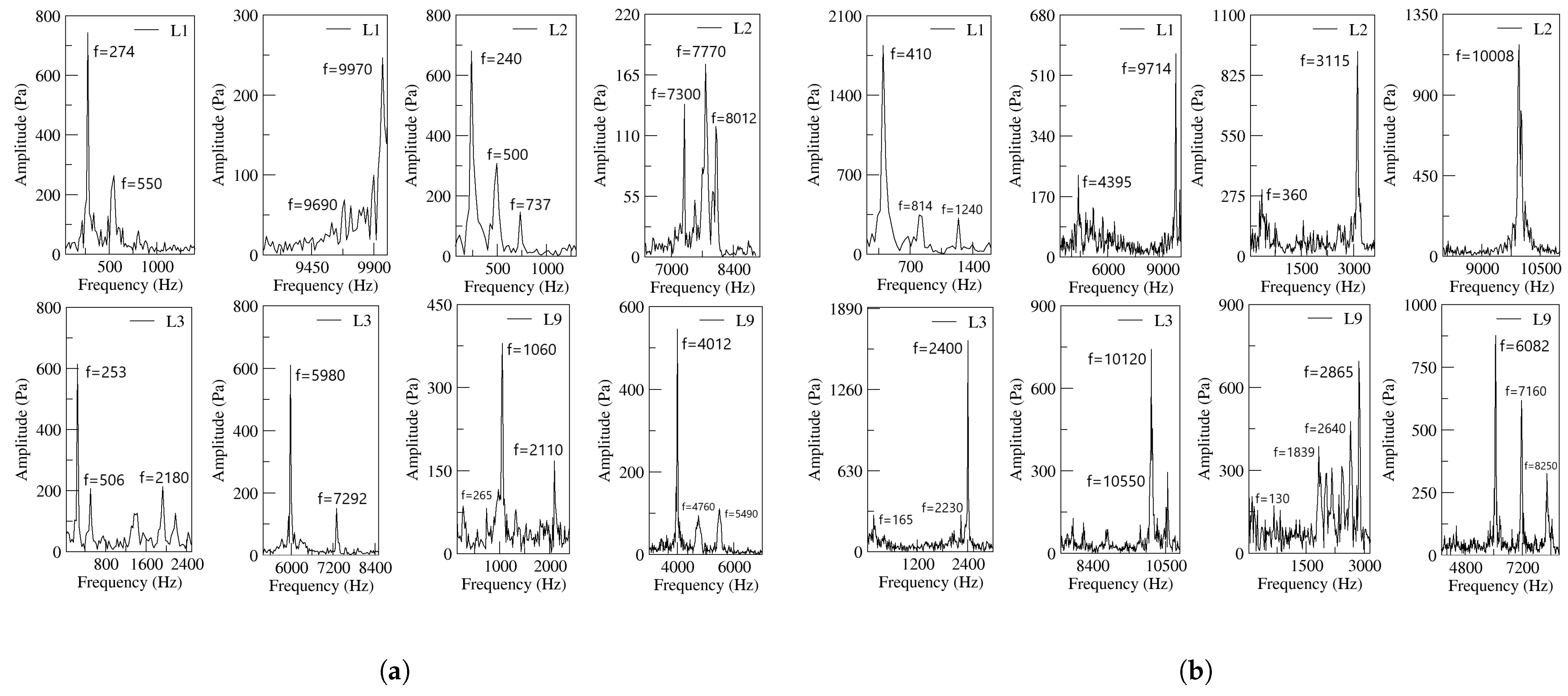

Figure 12 introduces the Fast Fourier Transformation (FFT) of the net-momentum signals determined at the FC’s outlets. The results for both power nozzle velocities and the four FC’s lengths are presented. From the comparison of

Figure 10 and

Figure 12, it is seen that the main oscillating frequencies presented in

Figure 10 are also observed in

Figure 12. This means there must be a correlation between the output mass flow and the net momentum acting on the jet entering the MC (FC’s outlet). At the FC’s outlets, several high-frequency peaks not appearing at the FO outlet are observed. These very high fluctuation frequencies are likely to be associated to the pressure waves traveling along the FC’s, but they do not seam to be transferred to the FO outlet. It looks as though the main jet flowing thought the MC outlet width acts as a barrier for most of the fluctuating waves existing inside the MC. In fact, part of the energy associated to these very high frequency fluctuations may dissipate into heat inside the MC and FCs.

In order to prove that the origin of FO oscillations is the stagnation pressure temporal evolution at the MC converging walls, the FFT of the stagnation pressure signal measured at the MC lower converging wall is presented in

Figure 13. The four FC lengths and the two inlet velocities are considered in this figure. From the comparison of

Figure 10,

Figure 12 and

Figure 13, it can be concluded that the main oscillating frequencies appear in the three figures, proving that there must be a correlation between the stagnation pressure, net momentum acting onto the jet entering the MC and the FO outlet mass flow. High fluctuating frequencies are observed in

Figure 12 and

Figure 13 but hardly in

Figure 10, suggesting that the jet fluctuations travel along the FCs but barely downstream.

Another important point to clarify is which of the two terms characterizing the net momentum acting onto the jet is the dominant one. In a previous numerical work done by Baghaei and Bergada [

39,

41], using the same oscillator configuration but under incompressible flow conditions, water was used as working fluid, it was stated that the net-momentum pressure term, see Equations (1) and (2), was the dominating one and therefore was responsible for the main jet oscillations. Under compressible flow conditions,

Figure 14 compares for the baseline case and the maximum FC length L9, the net-momentum mass flow term

with the net-momentum pressure term

measured at the FC outlets. This figure clearly shows that regardless of the feedback channel length and the power nozzle velocity, the net momentum due to the pressure term is over an order of magnitude higher than the one generated by the mass flow term. The conclusion is that the forces driving the oscillations in this particular FO configuration are due to the pressure difference acting at the FC’s outlets. Modifying the FC length, the inlet velocity or evaluating the fluid under compressible or incompressible conditions does not change this statement.

In order to visualize the flow topology for a FC length of 9L, instantaneous velocity, pressure, density and temperature fields and for the two power nozzle velocities of 65 m/s and 97 m/s are presented in

Figure 15 and

Figure 16, respectively. Four videos showing the velocity and pressure fields for each power nozzle velocity and for a feedback channel length of 9L are also provided in the

Supplementary Materials. From

Figure 15 it is observed that there are several pressure waves traveling along the feedback channels. At this instant, particularly high intensity pressure waves are seen at the upper feedback channel, lower-intensity waves are observed in the lower FC. It is important to realize that pressure waves traveling along a given FC have different strengths, see the different color intensities. Notice as well that the waves are observed at regular distances, the distance between two consecutive waves (d) should coincide with the sound speed divided by a particularly high amplitude oscillating or fluctuating frequency,

.

Table 1 introduces, for the two power nozzle velocities and the four FC lengths studied, the maximum fluctuating frequency previously presented in

Figure 13, for the case of 65 m/s and L9 the first harmonic of the frequency having the maximum amplitude is employed. Considering each particular frequency and the corresponding fluid temperature at the MC converging walls, the distance between two consecutive pressure waves is analytically determined. The distance separating two consecutive pressure waves is also measured and implemented in the same table. The agreement between the two distances is very good for all cases studied. At this point it can be stated that pressure waves traveling along the FCs are generated at the MC converging walls at a frequency coinciding with the jet fluctuating frequency for each case. As jet fluctuations sit on the top of the jet oscillations, pressure waves have a particular high intensity whenever both waves coincide (impinge) on the MC converging walls. Whenever the jet impinges perpendicular to the MC inclined wall, it helps in generating a higher-intensity pressure wave. For a power nozzle velocity of 97 m/s and a FC length 9L,

Figure 16, it can be seen that the pressure waves appearing along the feedback channels are not generated regularly and their intensity differs temporally. As previously observed, fluid randomness is particularly high at long FCs and high speeds. These results fully coincide with the MC converging wall stagnation pressure presented in

Figure 8d, where it is clearly seen that the degree of randomness is particularly high at 97 m/s. The randomness associated to the jet fluctuation can also be seen in

Figure 11b for FC lengths of 3L and 9L.

The relation between the maximum and minimum pressure observed in

Figure 15 shows a variation of about

, the fluid density changes about

while the maximum to minimum temperature variation is of about

. The maximum fluid velocity has increased by

versus the power nozzle one. For a power nozzle velocity of 97 m/s, the pressure variation observed in

Figure 16 is of

, the density variation is about

and the temperature variation is about

. The percentage of velocity increase inside the MC is around

versus the power nozzle one. As expected, the percentage variation of the different parameters is higher for higher power nozzle velocities.

Another question which may arise is whether the maximum and minimum values of the velocity, pressure, density and temperature are affected by the feedback channel length. Despite the full information generated not being presented in this manuscript, it can be concluded that the maximum and minimum values of all these parameters remain very stable for all different feedback channel lengths studied, their variation was just found to depend on the power nozzle velocity.