Facile and Electrically Reliable Electroplated Gold Contacts to p-Type InAsSb Bulk-Like Epilayers

Abstract

:1. Introduction

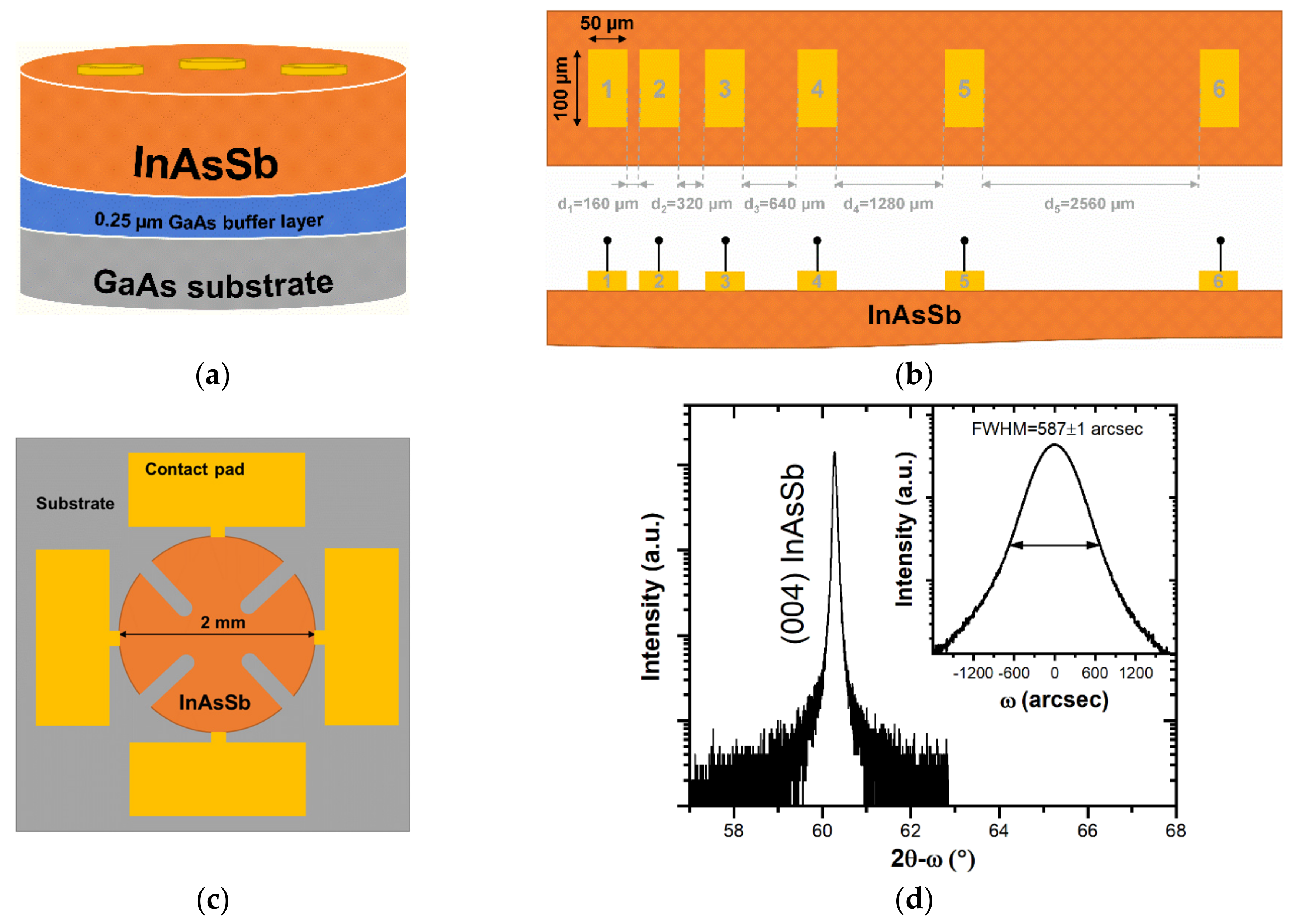

2. Materials and Methods

2.1. p-InAsSb Epilayer Growth and Processing

2.2. Characterization Methods

3. Results and Discussion

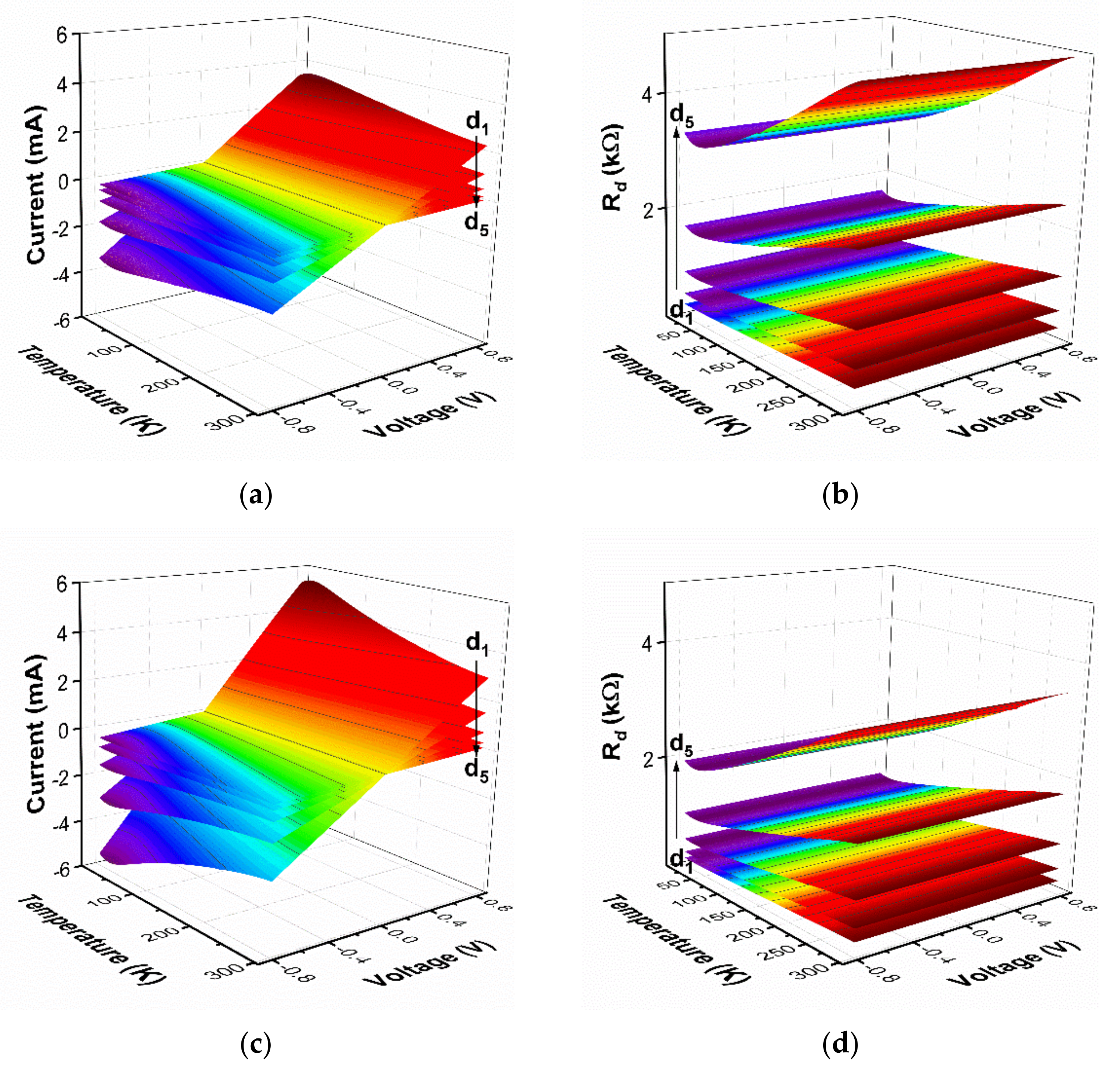

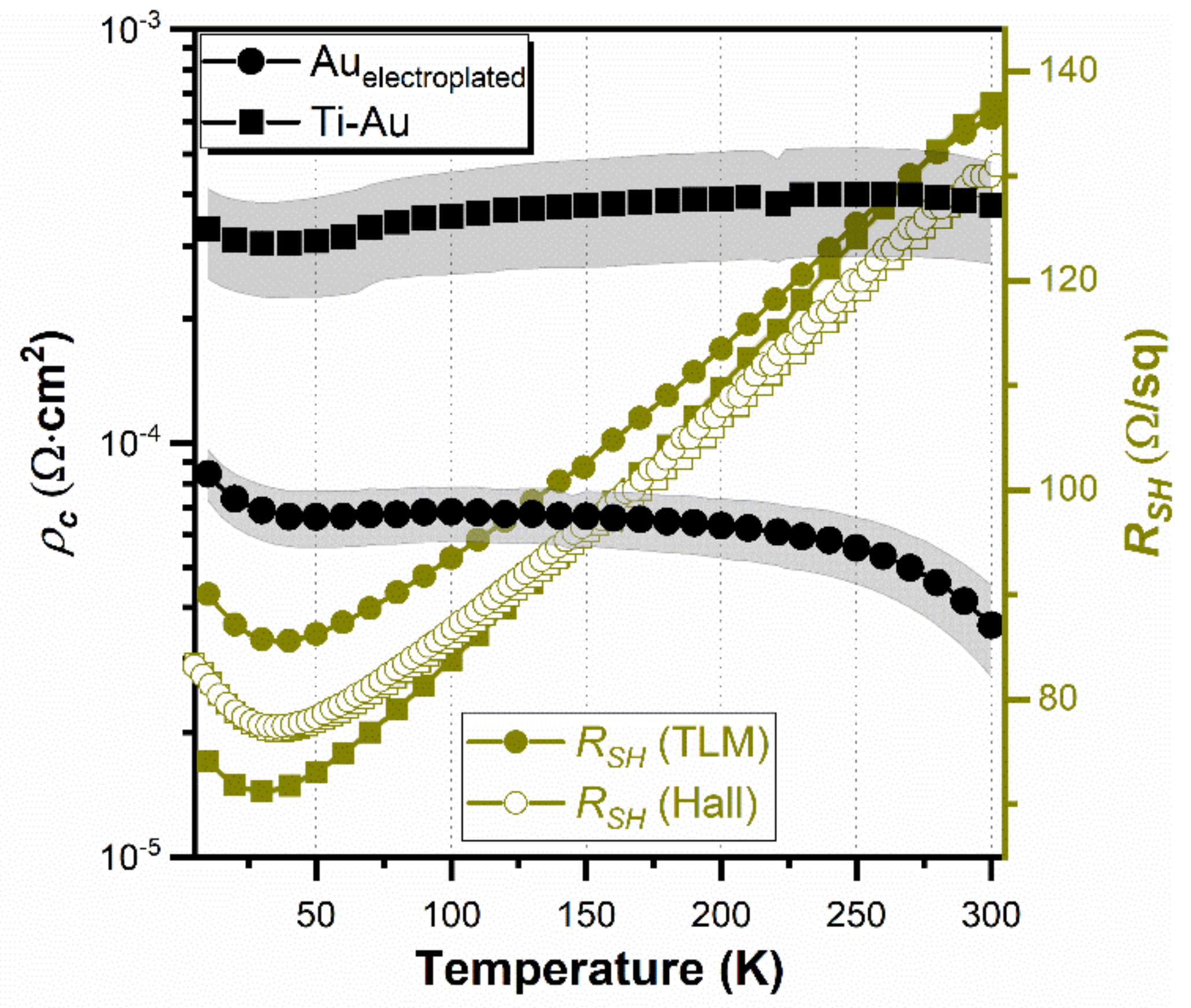

3.1. Metallization Approaches

3.2. Contact Resistance

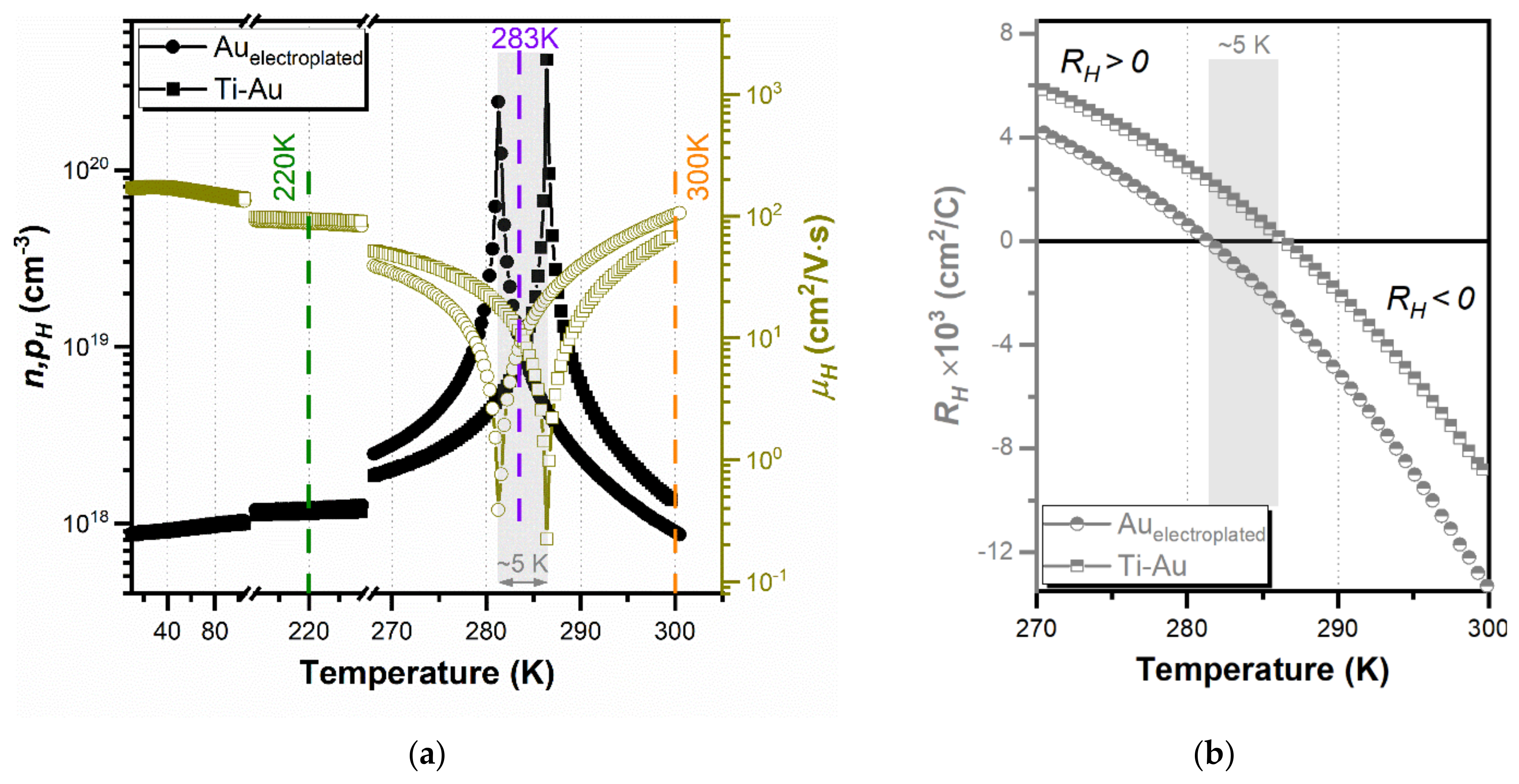

3.3. Magnetotransport Measurements

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Rogalski, A. III–V Detectors. In Infrared and Terahertz Detectors, 3rd ed.; Rogalski, A., Ed.; CRC Press: Boca Raton, FL, USA, 2018; pp. 361–416. [Google Scholar]

- Rogalski, A.; Martyniuk, P.; Kopytko, M.; Madejczyk, P.; Krishna, S. InAsSb-Based Infrared Photodetectors: Thirty Years Later On. Sensors 2020, 20, 7047. [Google Scholar] [CrossRef] [PubMed]

- Tetyorkin, V.; Sukach, A.; Tkachuk, A. Infrared Photodiodes on II–VI and III–V Narrow-Gap Semiconductors. In Photodiodes: From Fundamentals to Applications; Yun, I., Ed.; IntechOpen: London, UK, 2012; pp. 215–260. [Google Scholar]

- Suo, F.; Tong, J.; Qian, L.; Zhang, D.H. Study of dark current in mid-infrared InAsSb-based heteron-i-pphotodiode. J. Phys. D Appl. Phys. 2018, 51, 275102. [Google Scholar] [CrossRef]

- Delli, E.; Letka, V.; Hodgson, P.D.; Repiso, E.; Hayton, J.P.; Craig, A.P.; Lu, Q.; Beanland, R.; Krier, A.; Marshall, A.R.J.; et al. Mid-Infrared InAs/InAsSb Superlattice nBn Photodetector Monolithically Integrated onto Silicon. ACS Photonics 2019, 6, 538–544. [Google Scholar] [CrossRef]

- Steenbergen, E.H.; Morath, C.P.; Maestas, D.; Jenkins, G.D.; Logan, J.V. Comparing II–VI and III–V infrared detectors for space applications. In Proceedings of the SPIE Defense + Commercial Sensing, Baltimore, MD, USA, 14–18 April 2019; p. 110021B. [Google Scholar]

- Bouschet, M.; Zavala-Moran, U.; Arounassalame, V.; Alchaar, R.; Bataillon, C.; Ribet-Mohamed, I.; de Anda-Salazar, F.; Perez, J.-P.; Péré-Laperne, N.; Christol, P. Influence of Pixel Etching on Electrical and Electro-Optical Performances of a Ga-Free InAs/InAsSb T2SL Barrier Photodetector for Mid-Wave Infrared Imaging. Photonics 2021, 8, 194. [Google Scholar] [CrossRef]

- Wróbel, J.; Ciupa, R.; Rogalski, A. Performance limits of room-temperature InAsSb photodiodes. In Proceedings of the SPIE—The International Society for Optical Engineering, Orlando, FL, USA, 5–9 April 2010; p. 766033. [Google Scholar]

- Schroder, D.K. Contact Resistance and Schottky Barriers. In Semiconductor Material and Device Characterization; Schroder, D.K., Ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2005; pp. 127–184. [Google Scholar]

- Mönch, W. Electronic Properties of Semiconductor Interfaces. In Springer Handbook of Electronic and Photonic Materials; Kasap, S., Capper, P., Eds.; Springer International Publishing: Berlin/Heidelberg, Germany, 2017; pp. 175–192. [Google Scholar]

- Schuler-Sandy, T.; Myers, S.; Klein, B.; Gautam, N.; Ahirwar, P.; Tian, Z.B.; Rotter, T.; Balakrishnan, G.; Plis, E.; Krishna, S. Gallium free type II InAs/InAsxSb1−x superlattice photodetectors. Appl. Phys. Lett. 2012, 101, 071111. [Google Scholar] [CrossRef]

- Schuler-Sandy, T.; Klein, B.; Casias, L.; Mathews, S.; Kadlec, C.; Tian, Z.; Plis, E.; Myers, S.; Krishna, S. Growth of InAs–InAsSb SLS through the use of digital alloys. J. Cryst. Growth 2015, 425, 29–32. [Google Scholar] [CrossRef]

- Ariyawansa, G.; Reyner, C.J.; Duran, J.M.; Reding, J.D.; Scheihing, J.E.; Steenbergen, E.H. Unipolar infrared detectors based on InGaAs/InAsSb ternary superlattices. Appl. Phys. Lett. 2016, 109, 021112. [Google Scholar] [CrossRef]

- Jia, B.W.; Tan, K.H.; Loke, W.K.; Wicaksono, S.; Lee, K.H.; Yoon, S.F. Monolithic Integration of InSb Photodetector on Silicon for Mid-Infrared Silicon Photonics. ACS Photonics 2018, 5, 1512–1520. [Google Scholar] [CrossRef]

- Stareev, G.; Künzel, H.; Dortmann, G. A controllable mechanism of forming extremely low-resistance nonalloyed ohmic contacts to group III–V compound semiconductors. J. Appl. Phys. 1993, 74, 7344–7356. [Google Scholar] [CrossRef]

- Lee, C.-T.; Jaw, K.-L.; Tsai, C.-D. Thermal stability of Ti/Pt/Au ohmic contacts on InAs/graded InGaAs layers. Solid-State Electron. 1998, 42, 871–875. [Google Scholar] [CrossRef]

- Lysczek, E.M.; Robinson, J.A.; Mohney, S.E. Ohmic contacts to p-type InAs. Mater. Sci. Eng. B 2006, 134, 44–48. [Google Scholar] [CrossRef]

- Mohney, S.E.; Lysczek, E.; Wang, S.; Robinson, J. Ohmic Contacts to p-Type III–V Semiconductors for the Base of Heterojunction Bipolar Transistors. ECS Trans. 2006, 3, 47–56. [Google Scholar] [CrossRef]

- Guo, L.W.; Lu, W.; Bennett, B.R.; Boos, J.B.; del Alamo, J.A. Ultralow Resistance Ohmic Contacts for p-Channel InGaSb Field-Effect Transistors. IEEE Electron Device Lett. 2015, 36, 546–548. [Google Scholar] [CrossRef]

- Goodman, P. Current and future uses of gold in electronics. Gold Bull. 2002, 35, 21–26. [Google Scholar] [CrossRef] [Green Version]

- Carraro, C.; Maboudian, R.; Magagnin, L. Metallization and nanostructuring of semiconductor surfaces by galvanic displacement processes. Surf. Sci. Rep. 2007, 62, 499–525. [Google Scholar] [CrossRef]

- Depestel, L.M.; Strubbe, K. Electrodeposition of gold from cyanide solutions on different n-GaAs crystal faces. J. Electroanal. Chem. 2004, 572, 195–201. [Google Scholar] [CrossRef]

- Topçu, E.; Dağcı Kıranşan, K. Flexible gold nanoparticles/rGO and thin film/rGO papers: Novel electrocatalysts for hydrogen evolution reaction. J. Chem. Technol. Biotechnol. 2019, 94, 3895–3904. [Google Scholar] [CrossRef]

- Ma, Y.; Di, J.; Yan, X.; Zhao, M.; Lu, Z.; Tu, Y. Direct electrodeposition of gold nanoparticles on indium tin oxide surface and its application. Biosens. Bioelectron. 2009, 24, 1480–1483. [Google Scholar] [CrossRef] [PubMed]

- Ye, W.; Kou, H.; Liu, Q.; Yan, J.; Zhou, F.; Wang, C. Electrochemical deposition of Au–Pt alloy particles with cauliflower-like microstructures for electrocatalytic methanol oxidation. Int. J. Hydrogen Energy 2012, 37, 4088–4097. [Google Scholar] [CrossRef]

- Fratini, E.; Girella, A.; Saldan, I.; Milanese, C.; Dobrovetska, O.; Sus, L.; Okhremchuk, Y.; Kuntyi, O.; Reshetnyak, O. Nucleation and growth of Au and Au–Pd nanoparticles at the beginning of electrochemical deposition. Mater. Lett. 2015, 161, 263–266. [Google Scholar] [CrossRef]

- Sus, L.; Okhremchuk, Y.; Saldan, I.; Kuntyi, O.; Reshetnyak, O.; Korniy, S. Controlled gold deposition by pulse electrolysis. Mater. Lett. 2015, 139, 296–299. [Google Scholar] [CrossRef]

- González-Buch, C.; Herraiz-Cardona, I.; Ortega, E.M.; Mestre, S.; Pérez-Herranz, V. Synthesis and characterization of Au-modified macroporous Ni electrocatalysts for alkaline water electrolysis. Int. J. Hydrogen Energy 2016, 41, 764–772. [Google Scholar] [CrossRef] [Green Version]

- Monaico, E.V.; Monaico, E.I.; Ursaki, V.V.; Tiginyanu, I.M. Free-Standing Large-Area Nanoperforated Gold Membranes Fabricated by Hopping Electrodeposition. ECS J. Solid State Sci. Technol. 2020, 9, 064010. [Google Scholar] [CrossRef]

- Vicenzo, A.; Cavallotti, P.L. Gold electroplating. In Gold: Science and Applications; CRC Press: Boca Raton, FL, USA, 2009; pp. 231–278. [Google Scholar]

- Grover, S.; Sahu, S.; Zhang, P.; Davis, K.O.; Kurinec, S.K. Standardization of Specific Contact Resistivity Measurements using Transmission Line Model (TLM). In Proceedings of the 2020 IEEE 33rd International Conference on Microelectronic Test Structures (ICMTS), Edinburgh, UK, 4–18 May 2020; pp. 1–6. [Google Scholar]

- Benyahia, D.; Kubiszyn, Ł.; Michalczewski, K.; Kębłowski, A.; Martyniuk, P.; Piotrowski, J.; Rogalski, A. Molecular beam epitaxial growth and characterization of InAs layers on GaAs (001) substrate. Opt. Quantum Electron. 2016, 48, 1–7. [Google Scholar] [CrossRef] [Green Version]

- Wróbel, J.; Grodecki, K.; Benyahia, D.; Murawski, K.; Michalczewski, K.; Grzonka, J.; Boguski, J.; Gorczyca, K.; Umana-Membreno, G.A.; Kubiszyn, Ł.; et al. Structural and optical characterization of the high quality Be-doped InAs epitaxial layer grown on GaAs substrate. In Proceedings of the Thirteenth Integrated Optics: Sensors, Sensing Structures and Methods Conference, Szczyrk, Poland, 26 February–2 March 2018; p. 108300S. [Google Scholar]

- Boguski, J.; Kolwas, K.; Kubiszyn, Ł.; Michalczewski, K.; Piotrowski, J.; Wróbel, J.; Gorczyca, K.; Kębłowski, A.; Martyniuk, P. Study on the specific contact resistance of evaporated or electroplated golden contacts to n- and p- type InAs epitaxial layers grown by MBE. Mater. Sci. Semicond. Process. 2018, 81, 60–63. [Google Scholar] [CrossRef]

- Kowalewski, A.; Martyniuk, P.; Markowska, O.; Benyahia, D.; Gawron, W. New wet etching solution molar ratio for processing T2SLs InAs/GaSb nBn MWIR infrared detectors grown on GaSb substrates. Mater. Sci. Semicond. Process. 2016, 41, 261–264. [Google Scholar] [CrossRef]

- Kowalewski, A.; Wróbel, J.; Boguski, J.; Gorczyca, K.; Martyniuk, P. Semiconductor Contact Layer Characterization in a Context of Hall Effect Measurements. Metrol. Meas. Syst. 2019, 26, 109–114. [Google Scholar] [CrossRef]

- Beck, W.A.; Anderson, J.R. Determination of electrical transport properties using a novel magnetic field-dependent Hall technique. J. Appl. Phys. 1987, 62, 541–554. [Google Scholar] [CrossRef]

- Antoszewski, J.; Seymour, D.J.; Faraone, L.; Meyer, J.R.; Hoffman, C.A. Magneto-transport characterization using quantitative mobility-spectrum analysis. J. Electron. Mater. 1995, 24, 1255–1262. [Google Scholar] [CrossRef]

- Dobbelaere, W.; de Boeck, J.; van Hove, M.; Deneffe, K.; de Raedt, W.; Mertens, R.; Borghs, G. Long wavelength InAs02Sb0.8 detectors grown on patterned Si substrates by molecular beam epitaxy. In Proceedings of the International Technical Digest on Electron Devices Meeting, Washington, DC, USA, 3–6 December 1989; pp. 717–720. [Google Scholar]

- Wu, D.; Durlin, Q.; Dehzangi, A.; Zhang, Y.; Razeghi, M. High quantum efficiency mid-wavelength infrared type-II InAs/InAs1−xSbx superlattice photodiodes grown by metal-organic chemical vapor deposition. Appl. Phys. Lett. 2019, 114, 011104. [Google Scholar] [CrossRef]

- Stremsdoerfer, G.; Perrot, H.; Martin, J.R.; Cléchet, P. Autocatalytic Deposition of Gold and Palladium onto n-GaAs in Acidic Media. J. Electrochem. Soc. 1988, 135, 2881–2886. [Google Scholar] [CrossRef]

- Jacobs, J.W.M.; Rikken, J.M.G. Photoelectrochemically-Induced Gold Deposition on p - GaAs Electrodes: Part I. Nucleation and Growth. J. Electrochem. Soc. 1989, 136, 3633–3640. [Google Scholar] [CrossRef]

- Oskam, G.; Vanmaekelbergh, D.; Kelly, J.J. The influence of electrodeposited gold on the properties of III–V semiconductor electrodes—Part 1. Results of current—potential measurements on p-GaAs. Electrochim. Acta 1993, 38, 291–300. [Google Scholar] [CrossRef]

- Depestel, L.M.; Strubbe, K. Influence of the crystal orientation on the electrochemical behaviour of n-GaAs in Au(i)-containing solutions. Phys. Chem. Chem. Phys. 2003, 5, 2881–2885. [Google Scholar] [CrossRef]

- Todeschini, M.; Bastos da Silva Fanta, A.; Jensen, F.; Wagner, J.B.; Han, A. Influence of Ti and Cr Adhesion Layers on Ultrathin Au Films. ACS Appl. Mater. Interfaces 2017, 9, 37374–37385. [Google Scholar] [CrossRef] [Green Version]

- Dick, K.A.; Deppert, K.; Karlsson, L.S.; Wallenberg, L.R.; Samuelson, L.; Seifert, W. A New Understanding of Au-Assisted Growth of III–V Semiconductor Nanowires. Adv. Funct. Mater. 2005, 15, 1603–1610. [Google Scholar] [CrossRef]

- Jany, B.R.; Janas, A.; Piskorz, W.; Szajna, K.; Kryshtal, A.; Cempura, G.; Indyka, P.; Kruk, A.; Czyrska-Filemonowicz, A.; Krok, F. Towards the understanding of the gold interaction with AIII-BV semiconductors at the atomic level. Nanoscale 2020, 12, 9067–9081. [Google Scholar] [CrossRef] [Green Version]

- Besikci, C.; Choi, Y.H.; Labeyrie, G.; Bigan, E.; Razeghi, M.; Cohen, J.B.; Carsello, J.; Dravid, V.P. Detailed analysis of carrier transport in InAs0.3Sb0.7 layers grown on GaAs substrates by metalorganic chemical-vapor deposition. J. Appl. Phys. 1994, 76, 5820–5828. [Google Scholar] [CrossRef]

- Kim, J.D.; Wu, D.; Wojkowski, J.; Piotrowski, J.; Xu, J.; Razeghi, M. Long-wavelength InAsSb photoconductors operated at near room temperatures (200–300 K). Appl. Phys. Lett. 1996, 68, 99–101. [Google Scholar] [CrossRef]

- Venter, A.; Shamba, P.; Botha, L.; Botha, J.R. Growth and electrical characterization of Zn-doped InAs and InAs1−xSbx. Thin Solid Film. 2009, 517, 4468–4473. [Google Scholar] [CrossRef]

- Kopytko, M.; Gomolka, E.; Martyniuk, P.; Madejczyk, P.; Rutkowski, J.; Rogalski, A. High-operating temperature InAsSb/AlSb heterostructure infrared detectors grown on GaAs substrates by molecular beam epitaxy. Opt. Eng. 2018, 57, 1–6. [Google Scholar] [CrossRef]

- Chrastina, D.; Hague, J.P.; Leadley, D.R. Application of Bryan’s algorithm to the mobility spectrum analysis of semiconductor devices. J. Appl. Phys. 2003, 94, 6583–6590. [Google Scholar] [CrossRef] [Green Version]

- Virtanen, P.; Gommers, R.; Oliphant, T.E.; Haberland, M.; Reddy, T.; Cournapeau, D.; Burovski, E.; Peterson, P.; Weckesser, W.; Bright, J.; et al. SciPy 1.0: Fundamental algorithms for scientific computing in Python. Nat. Methods 2020, 17, 261–272. [Google Scholar] [CrossRef] [PubMed] [Green Version]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Złotnik, S.; Wróbel, J.; Boguski, J.; Nyga, M.; Kojdecki, M.A.; Wróbel, J. Facile and Electrically Reliable Electroplated Gold Contacts to p-Type InAsSb Bulk-Like Epilayers. Sensors 2021, 21, 5272. https://doi.org/10.3390/s21165272

Złotnik S, Wróbel J, Boguski J, Nyga M, Kojdecki MA, Wróbel J. Facile and Electrically Reliable Electroplated Gold Contacts to p-Type InAsSb Bulk-Like Epilayers. Sensors. 2021; 21(16):5272. https://doi.org/10.3390/s21165272

Chicago/Turabian StyleZłotnik, Sebastian, Jarosław Wróbel, Jacek Boguski, Małgorzata Nyga, Marek Andrzej Kojdecki, and Jerzy Wróbel. 2021. "Facile and Electrically Reliable Electroplated Gold Contacts to p-Type InAsSb Bulk-Like Epilayers" Sensors 21, no. 16: 5272. https://doi.org/10.3390/s21165272

APA StyleZłotnik, S., Wróbel, J., Boguski, J., Nyga, M., Kojdecki, M. A., & Wróbel, J. (2021). Facile and Electrically Reliable Electroplated Gold Contacts to p-Type InAsSb Bulk-Like Epilayers. Sensors, 21(16), 5272. https://doi.org/10.3390/s21165272