Concept of an In-Plane Displacement Sensor Based on Grating Interferometry with a Stepwise Change of Sensitivity

Abstract

:1. Introduction

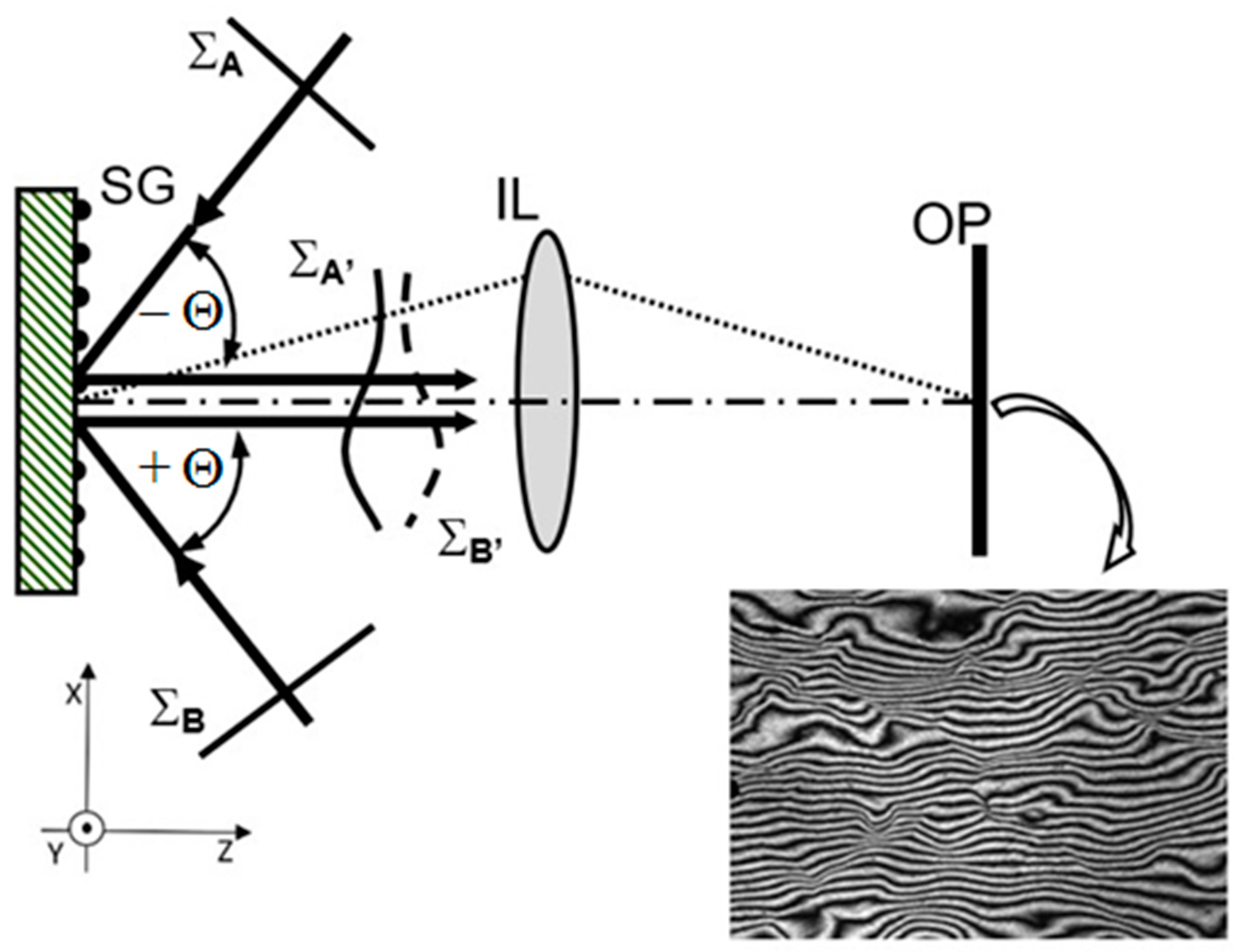

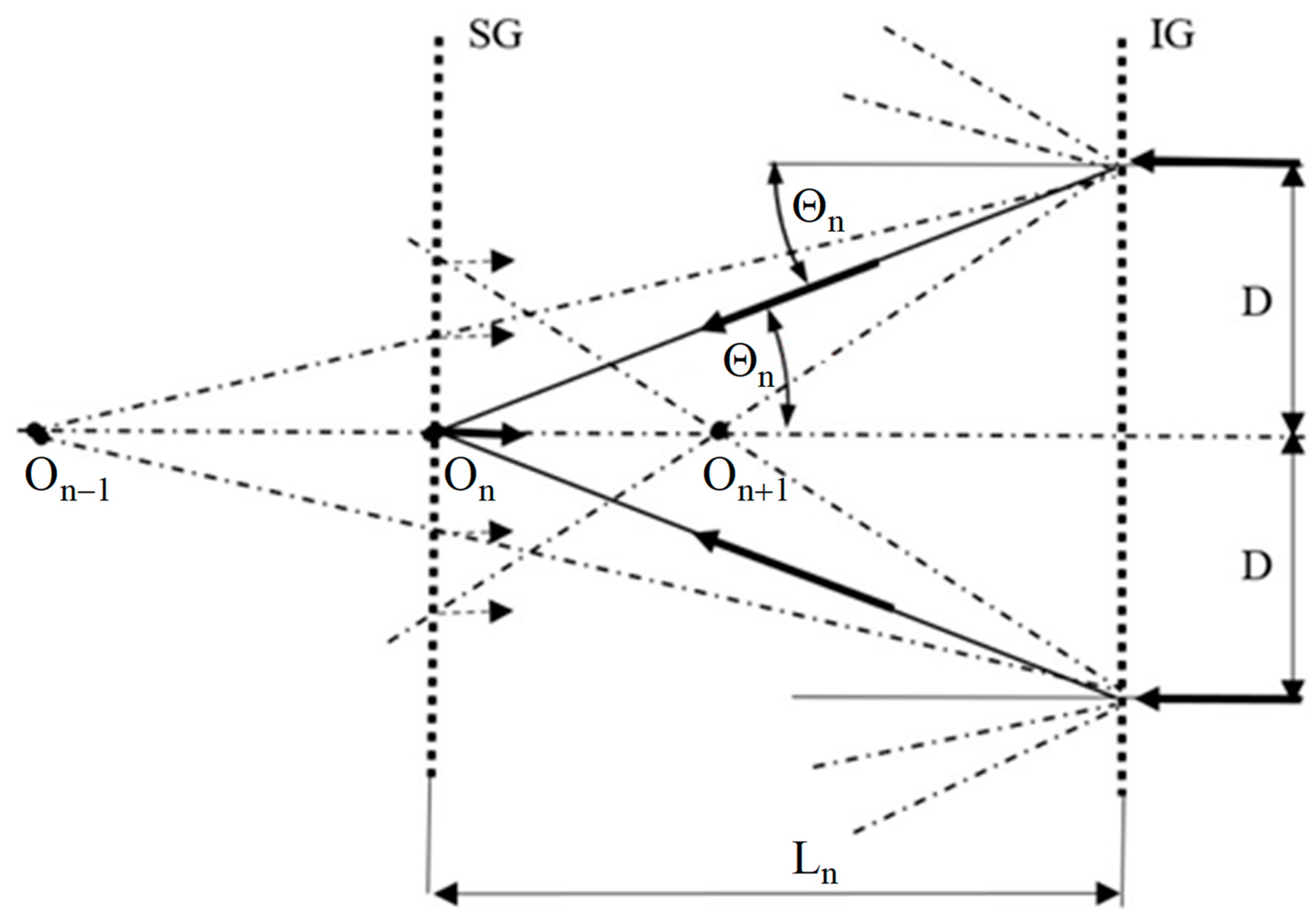

2. Theoretical Description

3. Method of Filtration of the Selected Diffraction Beams

- For diffraction orders n and n − 1:

- For diffraction orders n and n + 1:

- HL—the distance between the centers of the areas illuminated by the beams of the n and n − 1 diffractive order,

- HH—the distance between the centers of the areas illuminated by the beams of the n + 1 and n diffractive order,

- Ln—distance between gratings IG and SG for selected diffraction order determined according to Equation (6).

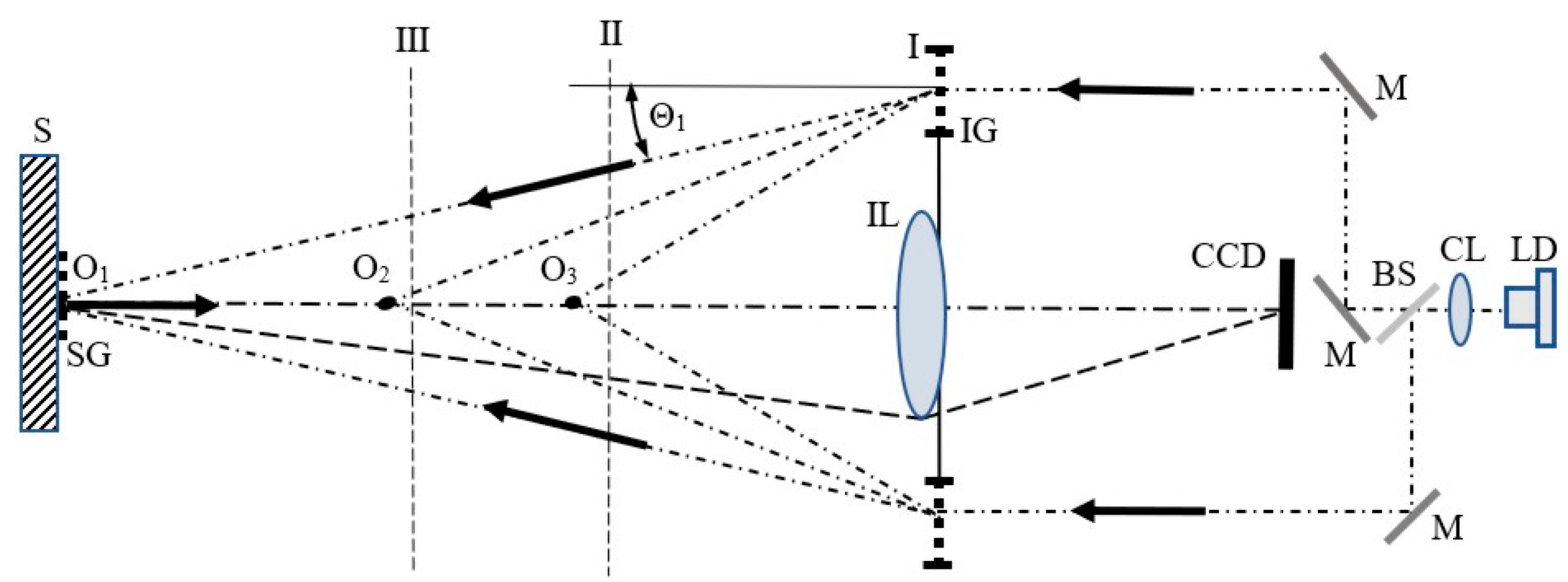

4. Concept of the Technical Implementation

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Vahdati, N.; Wang, X.; Shiryayev, O.; Rostron, P.; Yap, F.F. External Corrosion Detection of Oil Pipelines Using Fiber Optics. Sensors 2020, 20, 684. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Korganbayev, S.; Orrico, A.; Bianchi, L.; De Landro, M.; Wolf, A.; Dostovalov, A.; Saccomandi, P. Closed-Loop Temperature Control Based on Fiber Bragg Grating Sensors for Laser Ablation of Hepatic Tissue. Sensors 2020, 20, 6496. [Google Scholar] [CrossRef]

- Lorenc, Z.; Paśko, S.; Kursa, O.; Pakuła, A.; Sałbut, L. Spectral technique for detection of changes in eggshells caused by Mycoplasma synoviae. Poult. Sci. 2019, 98, 3481–3487. [Google Scholar] [CrossRef] [PubMed]

- Łuczak, S. Tilt Measurements in BMW Motorcycles. In Recent Global Research and Education: Technological Challenges; Jabłoński, R., Szewczyk, R., Eds.; Springer International Publishing: Cham, Switzerland, 2017; pp. 287–293. [Google Scholar]

- Łuczak, S.; Ekwińska, M. Electric-Contact Tilt Sensors: A Review. Sensors 2021, 21, 1097. [Google Scholar] [CrossRef] [PubMed]

- Post, D.; Han, B.; Ifju, P. High Sensitivity Moire; Springer: New York, NY, USA, 1994. [Google Scholar]

- Walker, C.A. A historical review of moire interferometry. Exp. Mech. 1994, 34, 281–299. [Google Scholar] [CrossRef]

- Minjin, T.; Huimin, X.; Jianguo, Z.; Xiaojun, L.; Yanjie, L. Study of moiré grating fabrication on metal samples using nanoimprint lithography. Opt. Express 2012, 20, 2942–2955. [Google Scholar]

- Servin, M.; Quiroga, A.; Padilla, J.M. Fringe Pattern Analysis for Optical Metrology: Theory, Algorithms, and Applications; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2014. [Google Scholar] [CrossRef]

- Malesa, M.; Kowalczyk, P.; Dymny, G.; Skrzypczak, P.; Sałbut, L.; Pakuła, A. Hybrid GI-DIC measurement procedure for hierarchical assessment of strain fields. Measurement 2019, 134, 83–88. [Google Scholar] [CrossRef]

- Ifju, P.G.; John, E.; Masters, J.E.; Jackson, W.C. The use of moiré interferometry as an aid to standard test-method development for textile composite materials. Compos. Sci. Technol. 1995, 53, 155–163. [Google Scholar] [CrossRef]

- Chen, L.; Bhavani, V.; Sankar, G.V.; Ifju, G.P. Application of Moire Interferometry for Mode II Testing of Stitched Composites. J. ASTM Int. 2004, 1, 1–16. [Google Scholar]

- Han, B. Higher sensitivity moire interferometry for micromechanics studies. Opt. Eng. 1992, 31, 1517–1526. [Google Scholar] [CrossRef]

- Ifju, P.; Post, D. Zero thickness specimen gratings for moiré interferometry. Exp. Tech. 1991, 15, 45–47. [Google Scholar] [CrossRef]

- Sałbut, L. Waveguide grating (moiré) microinterferometer for in-plane displacement/strain field investigation. Opt. Eng. 2002, 41, 626–631. [Google Scholar] [CrossRef]

- Liu, H.; Cartwright, A.N.; Cemal Basaran, C.; Casey, W. Moiré Interferometry for Microelectronics Packaging Interface Fatigue Reliability. In Proceedings of the International Conference on Compound Semiconductor Manufacturing Technology, GaAs Conference, San Diego, CA, USA, 8–11 April 2002. [Google Scholar]

- Holstein, D.; Salbut, L.; Kujawinska, M.; Jüptner, W. Hybrid Experimental-numerical concept of residual stress analysis in laser weldments. Exp. Mech. 2001, 41, 343–348. [Google Scholar] [CrossRef]

- Wang, M.; Drews, M.J.; Wood, J. Utilization of moiré interferometry to study the strain distribution within multi-layer thermoplastic elastomers, J. Biomaterials Science, Polymer Edition 2002, 13, 1051–1065. [Google Scholar] [CrossRef] [PubMed]

- Walker, C.A. Handbook of Moire Measurement; IOP: Bristol, UK; Philadelphia, PA, USA, 2004. [Google Scholar]

- Czarnek, R. High sensitivity moire interferometry with compact achromatic inferometer. Opt. Las. Eng. 1990, 13, 93–101. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sałbut, L.; Łuczak, S. Concept of an In-Plane Displacement Sensor Based on Grating Interferometry with a Stepwise Change of Sensitivity. Sensors 2021, 21, 4894. https://doi.org/10.3390/s21144894

Sałbut L, Łuczak S. Concept of an In-Plane Displacement Sensor Based on Grating Interferometry with a Stepwise Change of Sensitivity. Sensors. 2021; 21(14):4894. https://doi.org/10.3390/s21144894

Chicago/Turabian StyleSałbut, Leszek, and Sergiusz Łuczak. 2021. "Concept of an In-Plane Displacement Sensor Based on Grating Interferometry with a Stepwise Change of Sensitivity" Sensors 21, no. 14: 4894. https://doi.org/10.3390/s21144894

APA StyleSałbut, L., & Łuczak, S. (2021). Concept of an In-Plane Displacement Sensor Based on Grating Interferometry with a Stepwise Change of Sensitivity. Sensors, 21(14), 4894. https://doi.org/10.3390/s21144894