Influence of Temperature on the Natural Vibration Characteristics of Simply Supported Reinforced Concrete Beam

Abstract

:1. Introduction

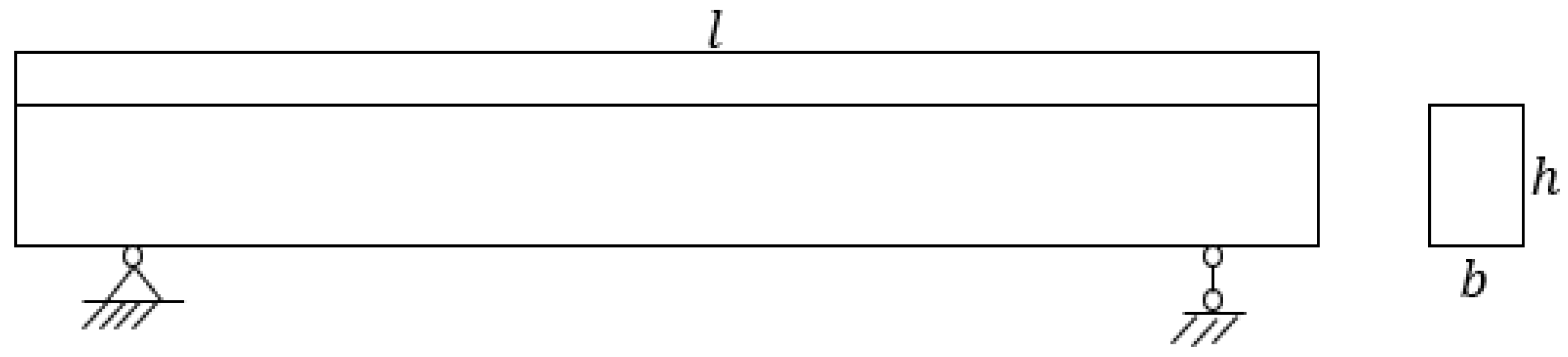

2. Theoretical Analysis on the Influence of Temperature on the Natural Frequency of Simply Supported Beam

2.1. Influence of Temperature on Elastic Modulus

- : Elastic modulus (Mpa) of concrete at T temperature;

- : Temperature of concrete (°C);

- : Elastic modulus of concrete (MPa) at 20 °C;

- : Temperature coefficient of elastic modulus, with a value of 0.003.

2.2. Influence of Temperature on Structure Size

- : Beam length after temperature change;

- : Linear expansion coefficient with reinforcement of 1.2 × 10−6 and concrete of 1.0 × 10−5;

- Temperature change;

- : Initial beam length;

2.3. Influence of Temperature on the Natural Frequency of Simply Supported Beam

- : nth order modal frequency

- : Calculated span lengths of beam

- : Young’s modulus

- : Second moment of area

- : Mass density

- : Sectional area

- : Influence coefficient of inertia moment,

- : Influence coefficient of beam length,

- : Influence coefficient of elastic modulus,

- Influence coefficient of elastic modulus: = 1.08628

- Influence coefficient of inertia moment: = 0.99976

- Influence coefficient of beam length: = 1.00120

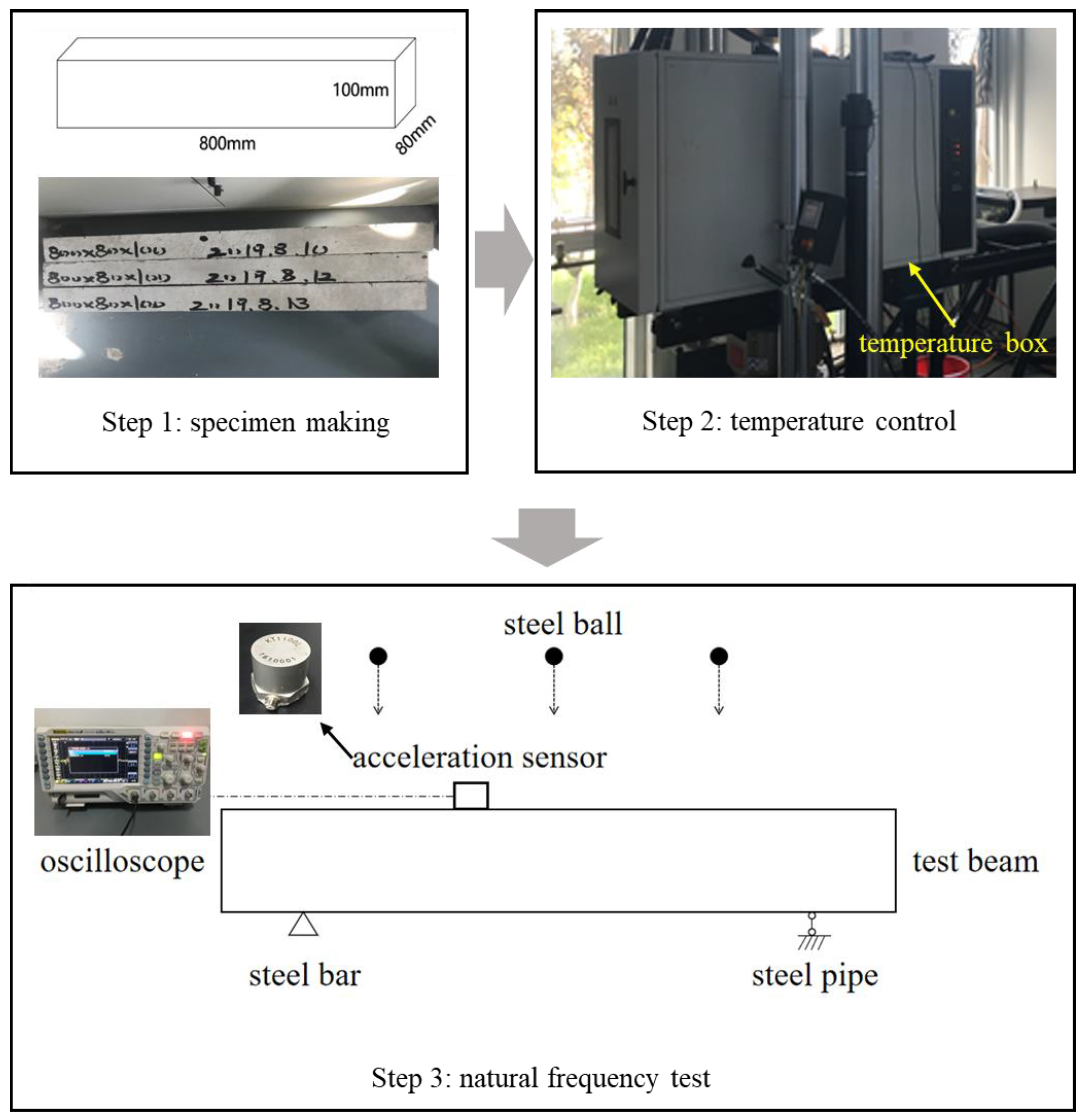

3. Experimental Study on the Influence of Temperature on the Natural Frequency of Simply Supported Beam

3.1. Test Scheme

3.2. Result Analysis

3.3. Method Verification

- : Concentrated loading (N);

- : Deflection (mm);

- : Testing beam effective span length (m);

- : Section inertia moment (m4);

4. Simulation Analysis on the Influence of Temperature on the Natural Frequency of Simply Supported Beam

4.1. Model Establishment

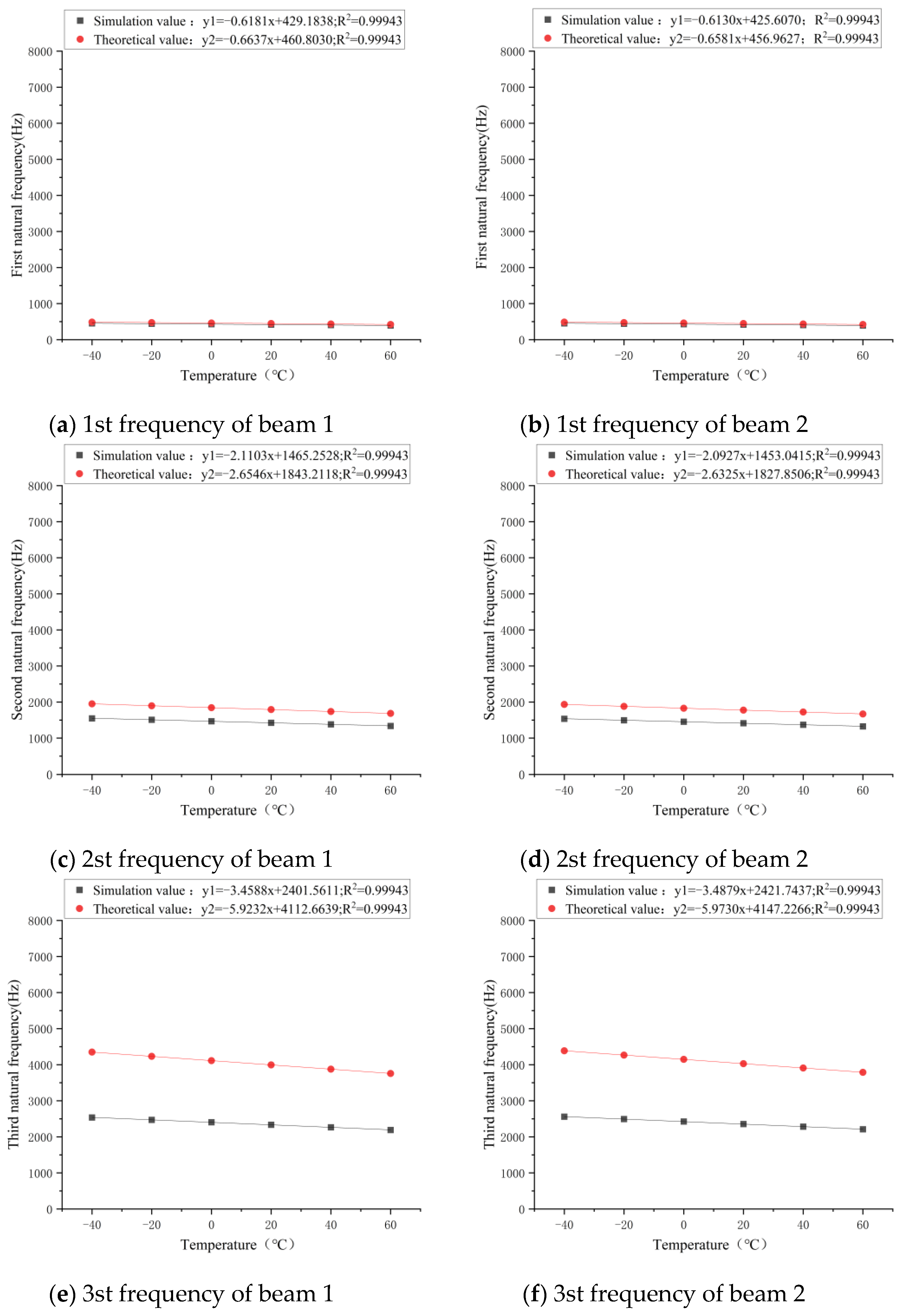

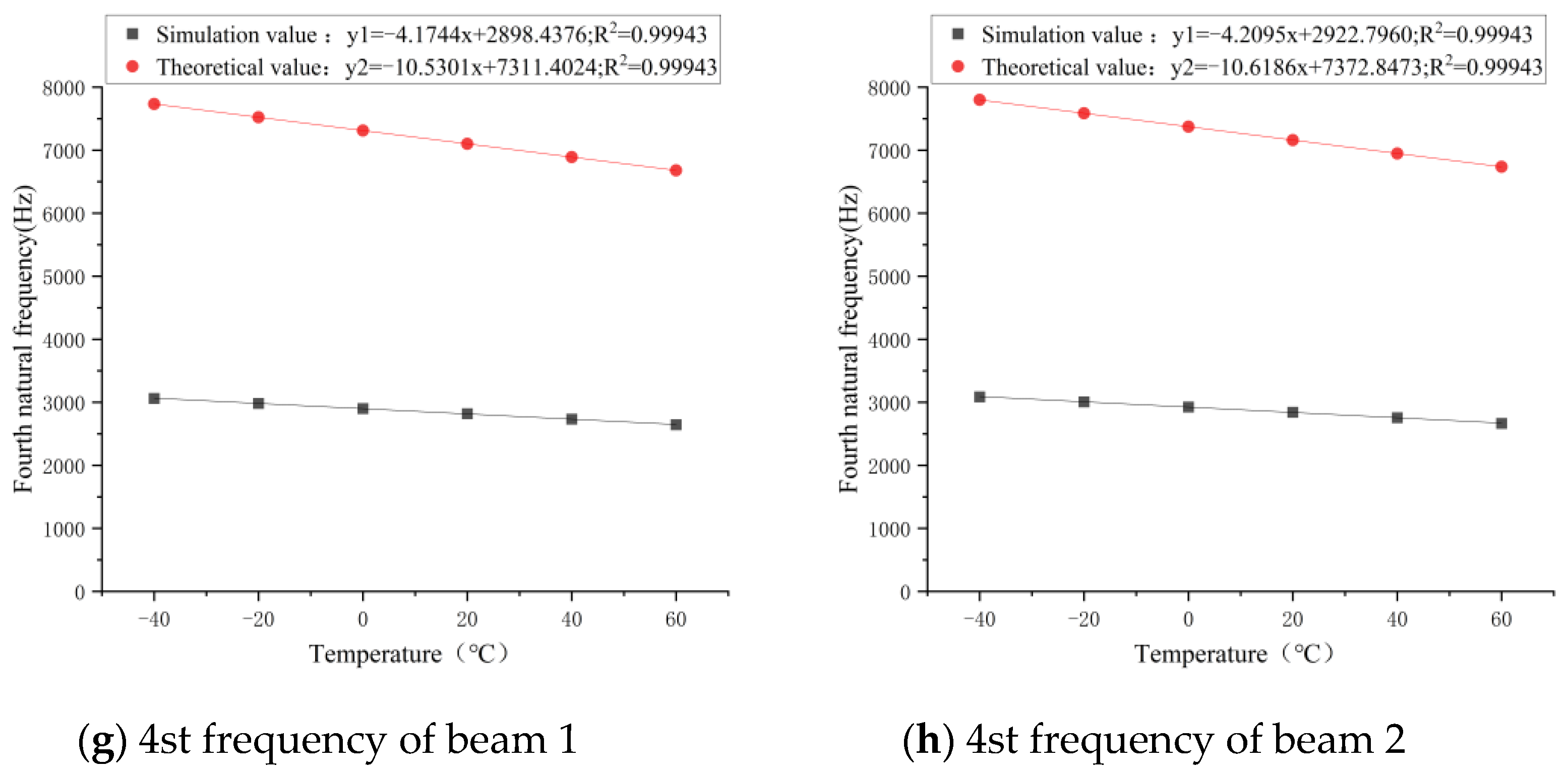

4.2. Result Analysis

5. Conclusions

- (1)

- The theoretical calculation formula for the change of natural frequency with temperature was obtained through the theoretical analysis of natural vibration characteristics of simply supported reinforced concrete beams. Theoretical analysis indicated that the effect of temperature on the natural frequency of the simply supported beam was mainly caused by the change of the elastic modulus of simply supported beam material. There was little influence of structure size on natural frequency.

- (2)

- The influence of temperature in the range of −40~60 °C on the natural frequency of the simply supported beam was analyzed through the small ball excitation test. The temperature range was so wide that it covered the conventional service temperature range of simply supported beam bridges. An acceleration sensor was used to monitor the natural frequency of the simply supported beam. The natural frequency-temperature change curve was obtained and verified. The curve showed that, for each 1 °C increase in temperature in the range of −40 °C to 60 °C, the natural frequency of the simply supported beam decreased by 0.148%.

- (3)

- The Midas/Civil finite-element simulation was applied to analyze the natural frequency of simply supported beams at different temperatures. By comparing with the theoretical values, the theoretical calculation formula for the natural frequency of the simply supported beam was only applicable to the fundamental frequency, rather than the frequencies above the first grade.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zong, Z.; Ren, W.; Zhen, Z. Load-carrying capacity assessment methods of existing bridges. Earthq. Eng. Eng. Dyn. 2005, 25, 147–152. [Google Scholar]

- Gillich, G.-R.; Furdui, H.; Wahab, M.A.; Korka, Z.-I. A robust damage detection method based on multi-modal analysis in variable temperature conditions. Mech. Syst. Signal Process. 2019, 115, 361–379. [Google Scholar] [CrossRef]

- Hu, W.-H.; Tang, D.-H.; Teng, J.; Said, S.; Rohrmann, R.G. Structural Health Monitoring of a Prestressed Concrete Bridge Based on Statistical Pattern Recognition of Continuous Dynamic Measurements over 14 years. Sensors 2018, 18, 4117. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wang, X.; Gao, Q.; Liu, Y. Damage Detection of Bridges under Environmental Temperature Changes Using a Hybrid Method. Sensors 2020, 20, 3999. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.; Wang, X.; Jiao, Y. Effect of Temperature Variation on Modal Frequency of Reinforced Concrete Slab and Beam in Cold Regions. Shock. Vib. 2016, 2016, 1–17. [Google Scholar] [CrossRef] [Green Version]

- Shan, W.; Wang, X.; Jiao, Y. Modeling of Temperature Effect on Modal Frequency of Concrete Beam Based on Field Monitoring Data. Shock. Vib. 2018, 2018, 1–13. [Google Scholar] [CrossRef] [Green Version]

- Jang, J.; Smyth, A.W. Data-driven models for temperature distribution effects on natural frequencies and thermal prestress modeling. Struct. Control Health Monit. 2020, 27, 2489. [Google Scholar] [CrossRef]

- Teng, J.; Tang, D.-H.; Zhang, X.; Hu, W.-H.; Said, S.; Rohrmann, R.G. Automated Modal Analysis for Tracking Structural Change during Construction and Operation Phases. Sensors 2019, 19, 927. [Google Scholar] [CrossRef] [Green Version]

- Liu, J.; Tang, K. Advances of Vibration-based Damage Identification Methods. Acta Sci. Nat. Univ. Sunyatseni 2004, 43, 57–61. [Google Scholar]

- Farrar, C.R.; Doebling, S.W.; Cornwell, P.J.; Straser, E.G. Variability of Modal Parameters Measured on the Alamosa Canyon Bridge; USDOE Assistant Secretary for Human Resources and Administration: Washington, DC, USA, 1997; pp. 257–263.

- Liu, C.; DeWolf, J.T. Effect of Temperature on Modal Variability of a Curved Concrete Bridge under Ambient Loads. J. Struct. Eng. 2007, 133, 1742–1751. [Google Scholar] [CrossRef]

- Sun, L.; Zhou, Y.; Min, Z. Experimental Study on the Effect of Temperature on Modal Frequencies of Bridges. Int. J. Struct. Stab. Dyn. 2018, 18, 1850155. [Google Scholar] [CrossRef]

- Zhou, Y.; Sun, L. Effects of environmental and operational actions on the modal frequency variations of a sea-crossing bridge: A periodicity perspective. Mech. Syst. Signal Process. 2019, 131, 505–523. [Google Scholar] [CrossRef]

- Peeters, B.; De Roeck, G. One-year monitoring of the Z24-Bridge: Environmental effects versus damage events. Earthq. Eng. Struct. Dyn. 2001, 30, 149–171. [Google Scholar] [CrossRef]

- Xia, Y.; Hao, H.; Zanardo, G.; Deeks, A. Long term vibration monitoring of an RC slab: Temperature and humidity effect. Eng. Struct. 2006, 28, 441–452. [Google Scholar] [CrossRef]

- Kim, J.-T.; Park, J.-H.; Lee, B.-J. Vibration-based damage monitoring in model plate-girder bridges under uncertain temperature conditions. Eng. Struct. 2007, 29, 1354–1365. [Google Scholar] [CrossRef]

- Hu, T. The Influence of Temperature on the Self Vibration Characteristics of Cfst Deck Arch Bridge and Seismic Response Analysis; Southwest Jiaotong University: Chengdu, China, 2018. [Google Scholar]

- Teng, J.; Tang, D.-H.; Hu, W.-H.; Lu, W.; Feng, Z.-W.; Ao, C.-F.; Liao, M.-H. Mechanism of the effect of temperature on frequency based on long-term monitoring of an arch bridge. Struct. Health Monit. 2020. [Google Scholar] [CrossRef]

- Cornwell, P.; Farrar, C.; Doebling, S.; Sohn, H. Environmental Variability of Modal Properties. Exp. Tech. 1999, 23, 45–48. [Google Scholar] [CrossRef]

- Xu, Y.; Zhu, S.; Zong, Z. Experimental study on effects of environmental temperature on dynamic characteristics of bridge structures. Earthq. Eng. Eng. Dyn. 2007, 27, 119–123. [Google Scholar]

- Zhang, J. Regression analysis of environmental temperature and humidity and the natural frequencies of composite beam. J. Hebei Univ. Eng. (Nat. Sci. Ed.) 2012, 29, 16–19. [Google Scholar]

- Li, X.; Chen, A.; Ma, R. Influence of temperature on modal parameters of bridge. J. South China Univ. Technol. (Nat. Sci. Ed.) 2012, 40, 138–143. [Google Scholar]

- Wang, J. Research on Natural Frequency of Simply Supported Beam Basis on Multiple Temperature Fields; Jilin University: Changchun, China, 2012. [Google Scholar]

- Yang, M. Evolvement of Nature Vibration Characteriscs of Concrete Girder Bridge Considering Environmental Temperature and Time-Depended Performance of Concrete; Beijing Jiaotong University: Beijing, China, 2014. [Google Scholar]

- Li, Y. Influence of the Temperature to the Evolvement of Dynamic Characteriscs of Concrete Girder Bridge; Beijing Jiaotong University: Beijing, China, 2016. [Google Scholar]

- CEB-FIP. Model Code 2010. In Fib Special Activity Group 5; The International Federation for Structural Concrete: Lausanne, Switzerland, 2010. [Google Scholar]

- CCCC Highway Consultants Co., Ltd. General Specifications for Design of Highway Bridges and Culverts, 1st ed.; China Communications Press: Beijing, China, 2015; ISBN 978-7-114-12506-5. [Google Scholar]

- Sharma, G.S.; Sarkar, A. Directivity based control of acoustic radiation. Appl. Acoust. 2019, 154, 226–235. [Google Scholar] [CrossRef]

- Sharma, G.S.; Sarkar, A. Directivity-Based Passive Barrier for Local Control of Low-Frequency Noise. J. Comput. Acoust. 2017, 26, 1850012. [Google Scholar] [CrossRef]

| Beam Number | Initial Deflection/ mm | Initial Load/ N | Deflection/ mm | Load/ N | Elastic Modulus/ 10^4 MPa |

|---|---|---|---|---|---|

| 1 | −0.0005 | 0 | −0.0180 | −803.36 | 3.0986 |

| 2 | 0 | 0 | −0.0195 | −910.26 | 3.1509 |

| Beam Number | Elastic Modulus/10^4 MPa | ||

|---|---|---|---|

| Frequency-Temperature Test Calculation Value | Three Point Bending Test Value | Relative Error | |

| 1 | 3.1569 | 3.0986 | 1.88% |

| 2 | 3.1626 | 3.1509 | 0.37% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cai, Y.; Zhang, K.; Ye, Z.; Liu, C.; Lu, K.; Wang, L. Influence of Temperature on the Natural Vibration Characteristics of Simply Supported Reinforced Concrete Beam. Sensors 2021, 21, 4242. https://doi.org/10.3390/s21124242

Cai Y, Zhang K, Ye Z, Liu C, Lu K, Wang L. Influence of Temperature on the Natural Vibration Characteristics of Simply Supported Reinforced Concrete Beam. Sensors. 2021; 21(12):4242. https://doi.org/10.3390/s21124242

Chicago/Turabian StyleCai, Yanxia, Kai Zhang, Zhoujing Ye, Chang Liu, Kaiji Lu, and Linbing Wang. 2021. "Influence of Temperature on the Natural Vibration Characteristics of Simply Supported Reinforced Concrete Beam" Sensors 21, no. 12: 4242. https://doi.org/10.3390/s21124242

APA StyleCai, Y., Zhang, K., Ye, Z., Liu, C., Lu, K., & Wang, L. (2021). Influence of Temperature on the Natural Vibration Characteristics of Simply Supported Reinforced Concrete Beam. Sensors, 21(12), 4242. https://doi.org/10.3390/s21124242