Photonic Integrated Interrogator for Monitoring the Patient Condition during MRI Diagnosis

Abstract

:1. Introduction

2. Interrogator Design and Implementation

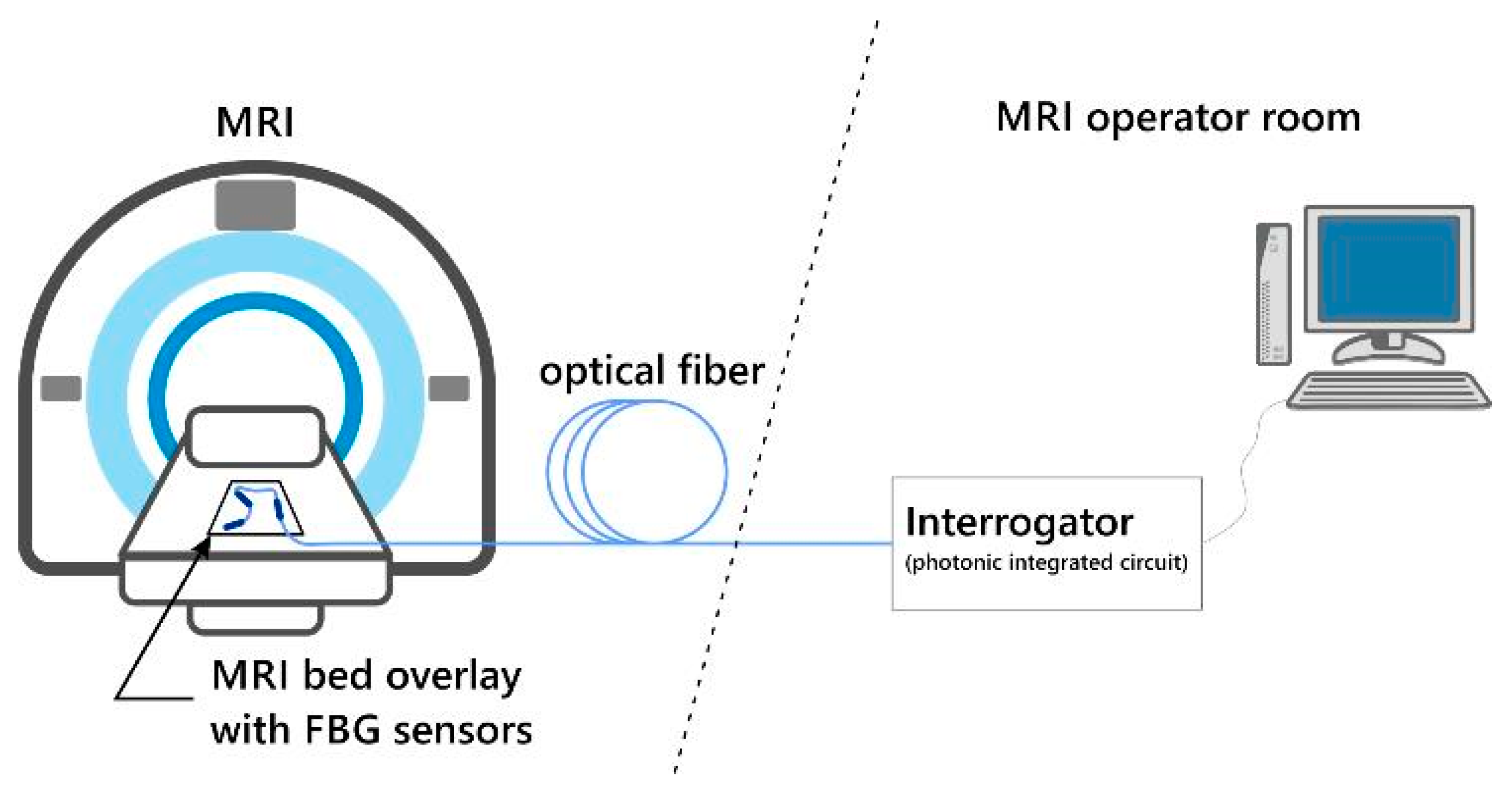

2.1. General Concept of the System

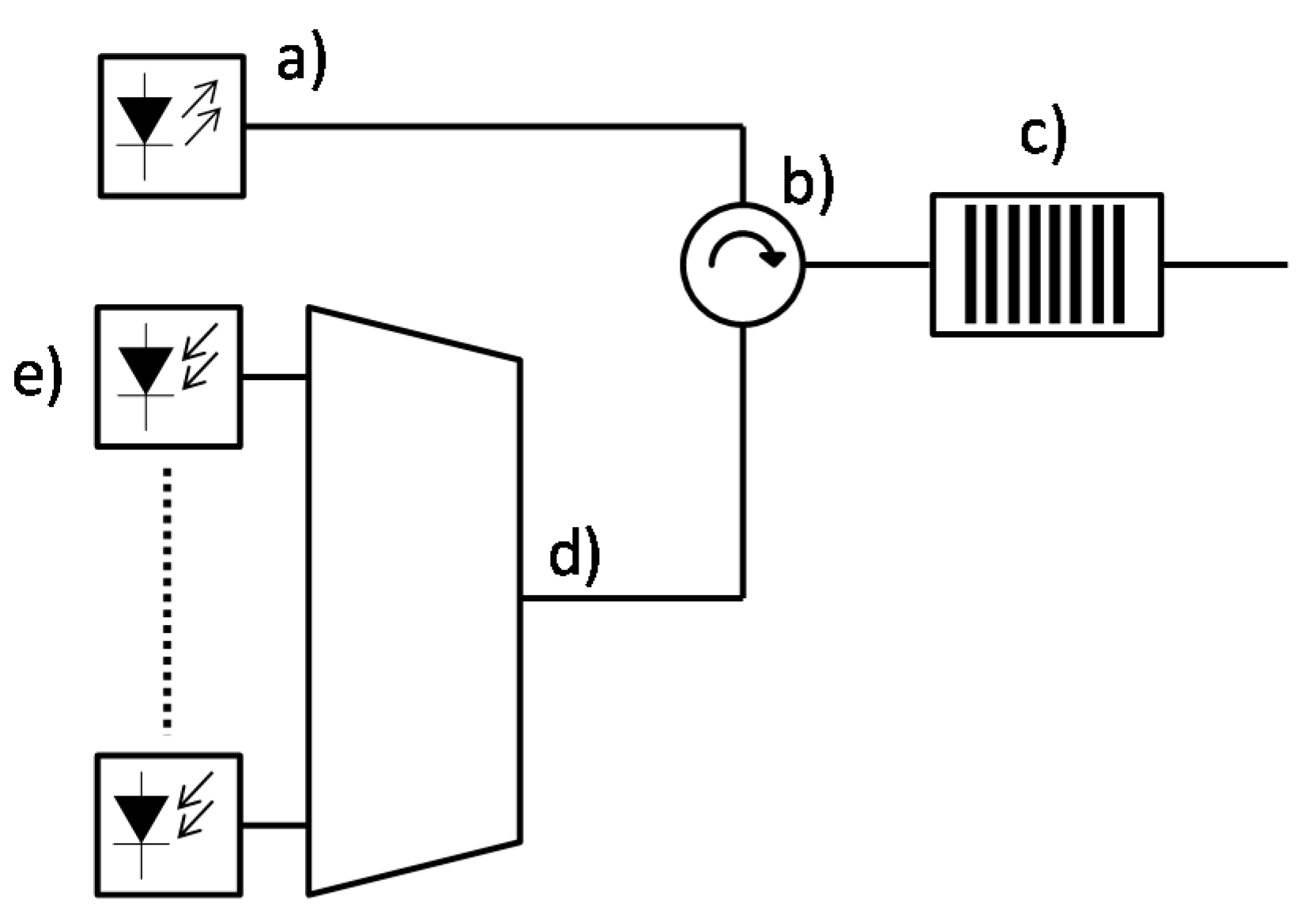

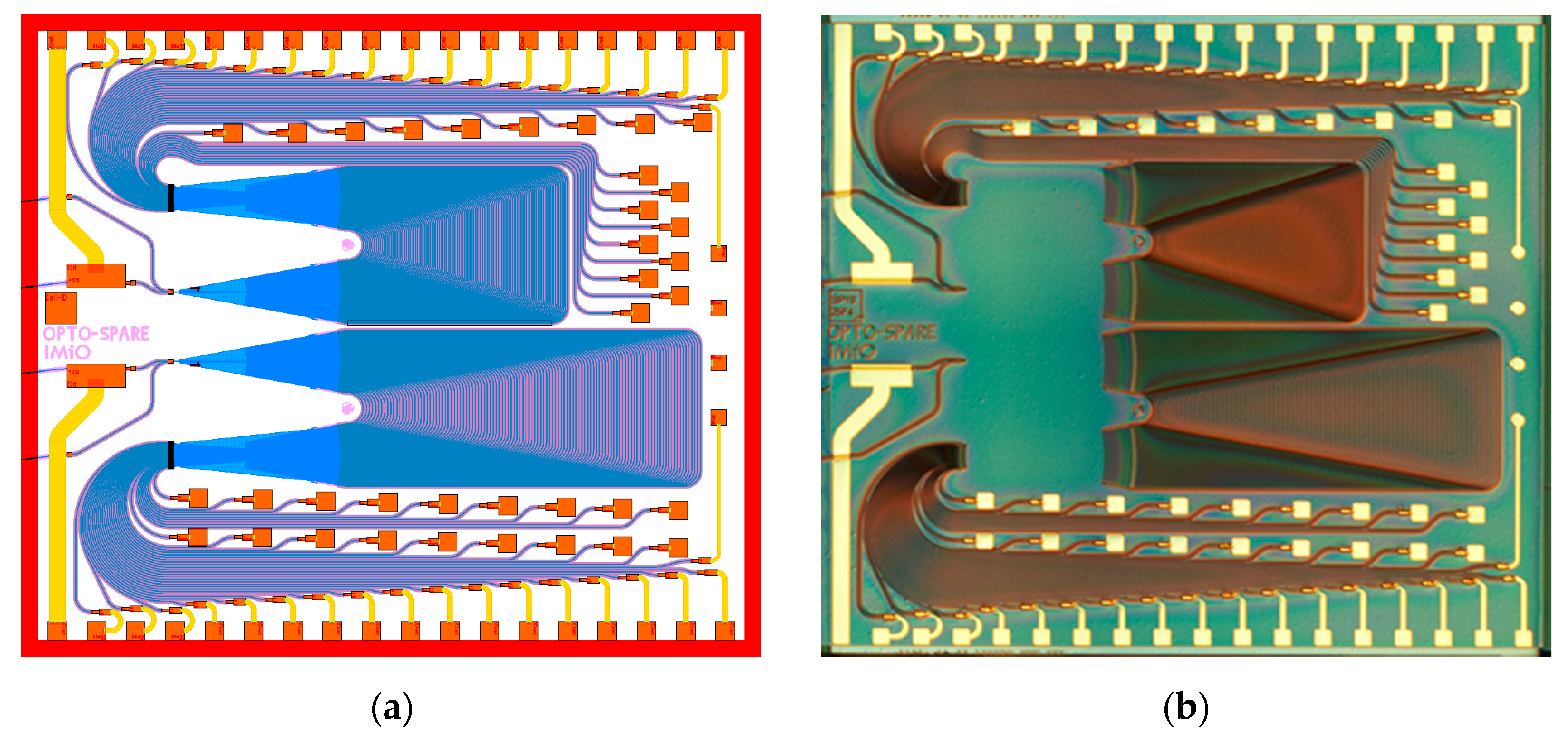

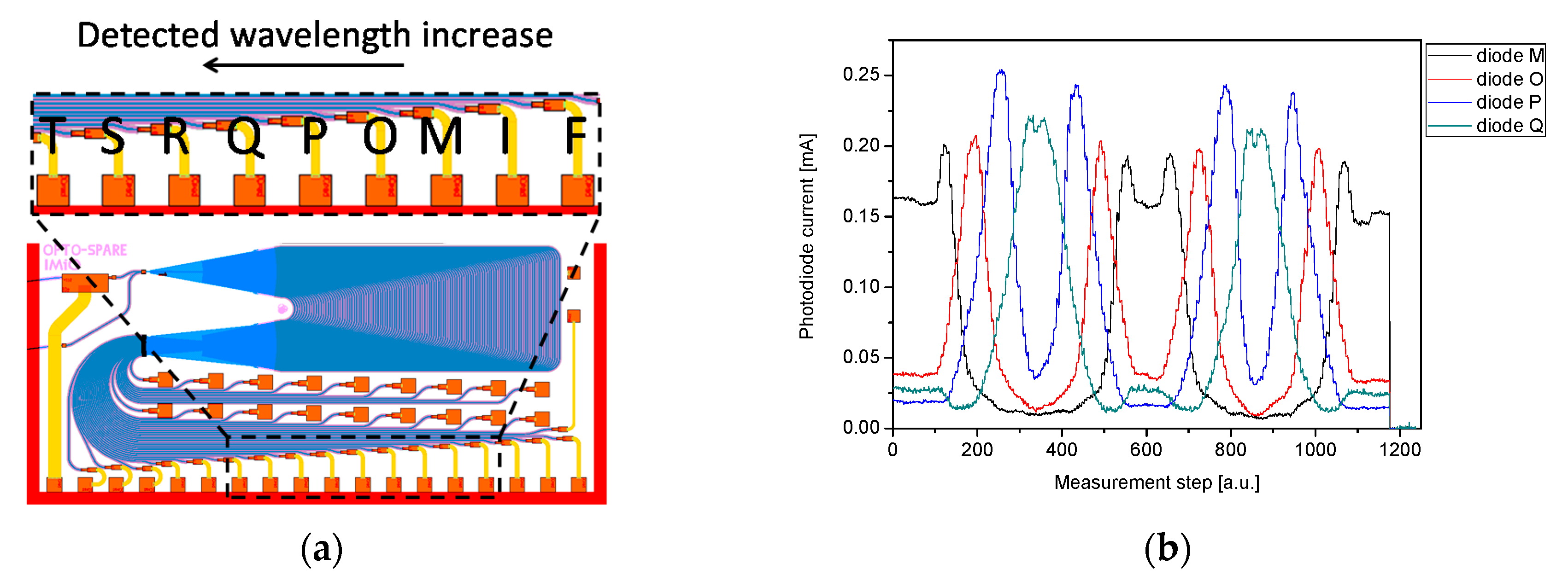

2.2. Integrated Interrogator Design

3. Interrogator Validation

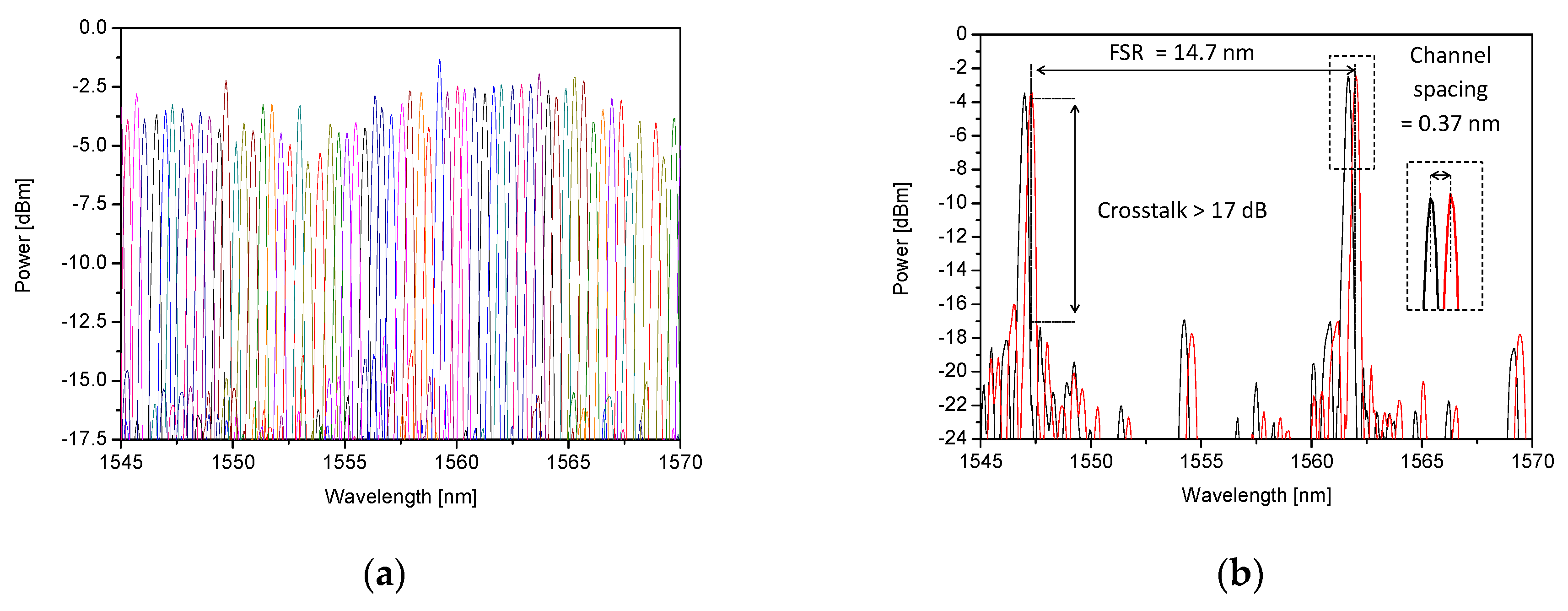

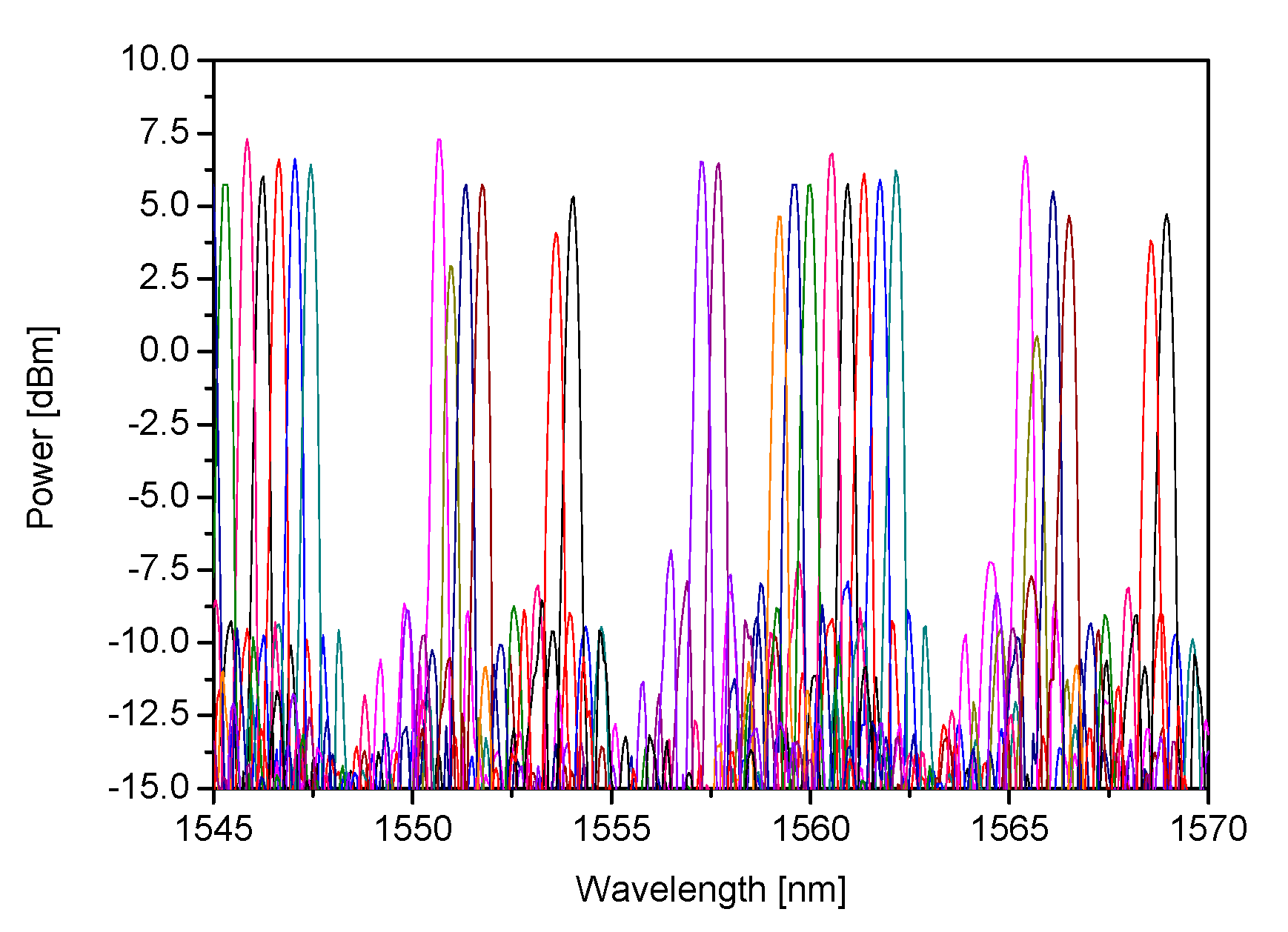

3.1. Characterization Results

3.2. Interrogation of FBG Sensors

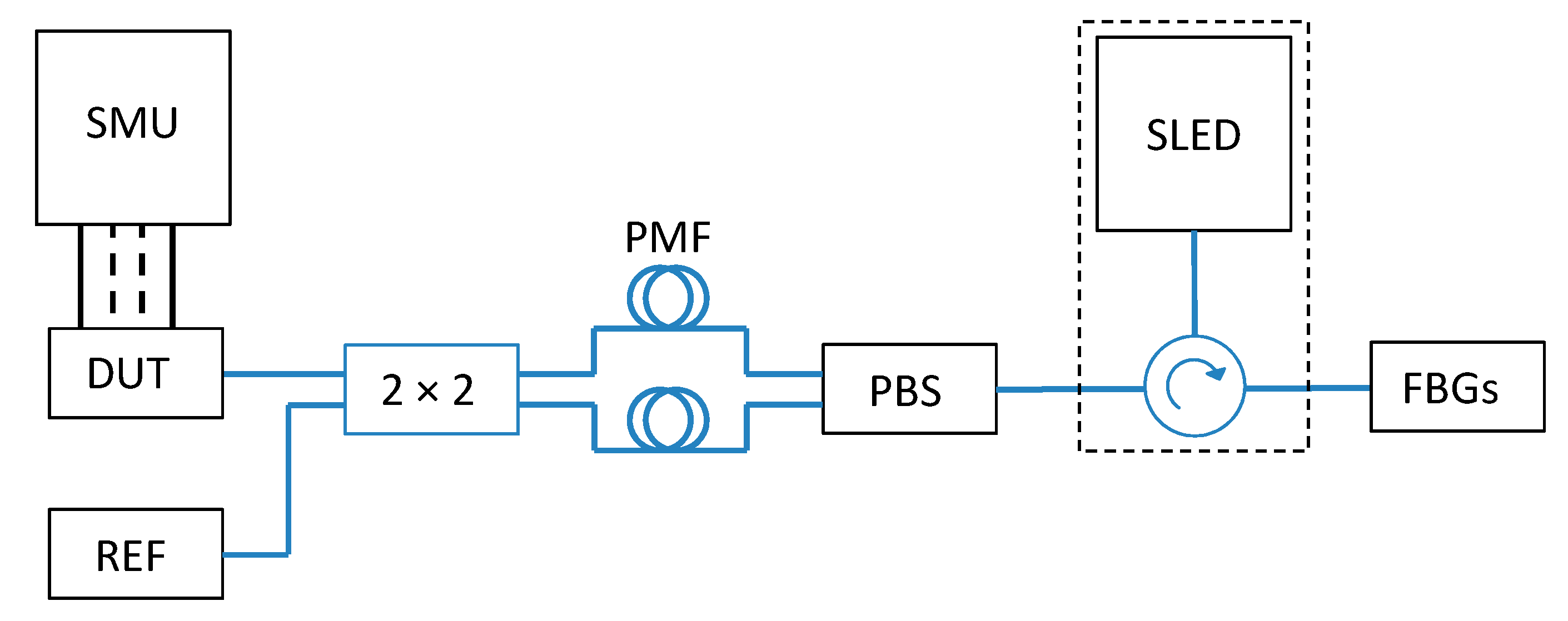

3.2.1. Experimental System Configuration

3.2.2. FBG Reflection Spectrum Reconstruction

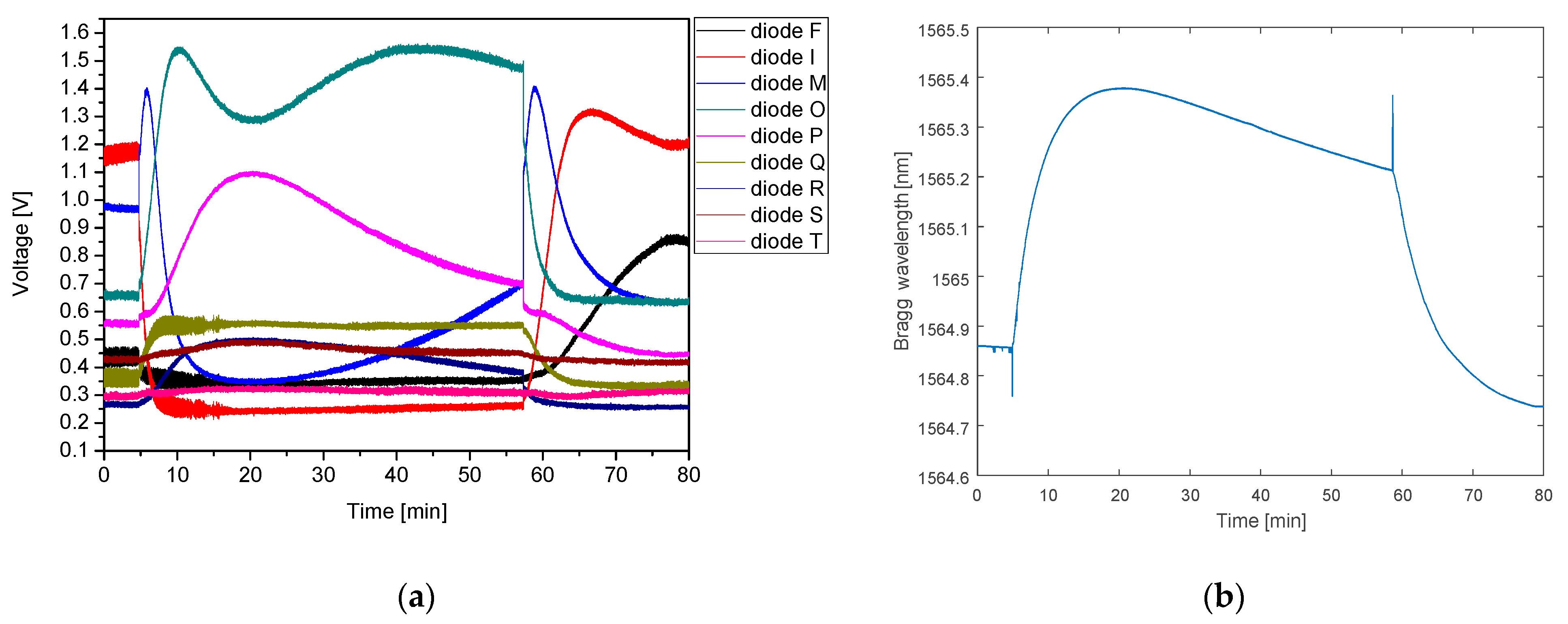

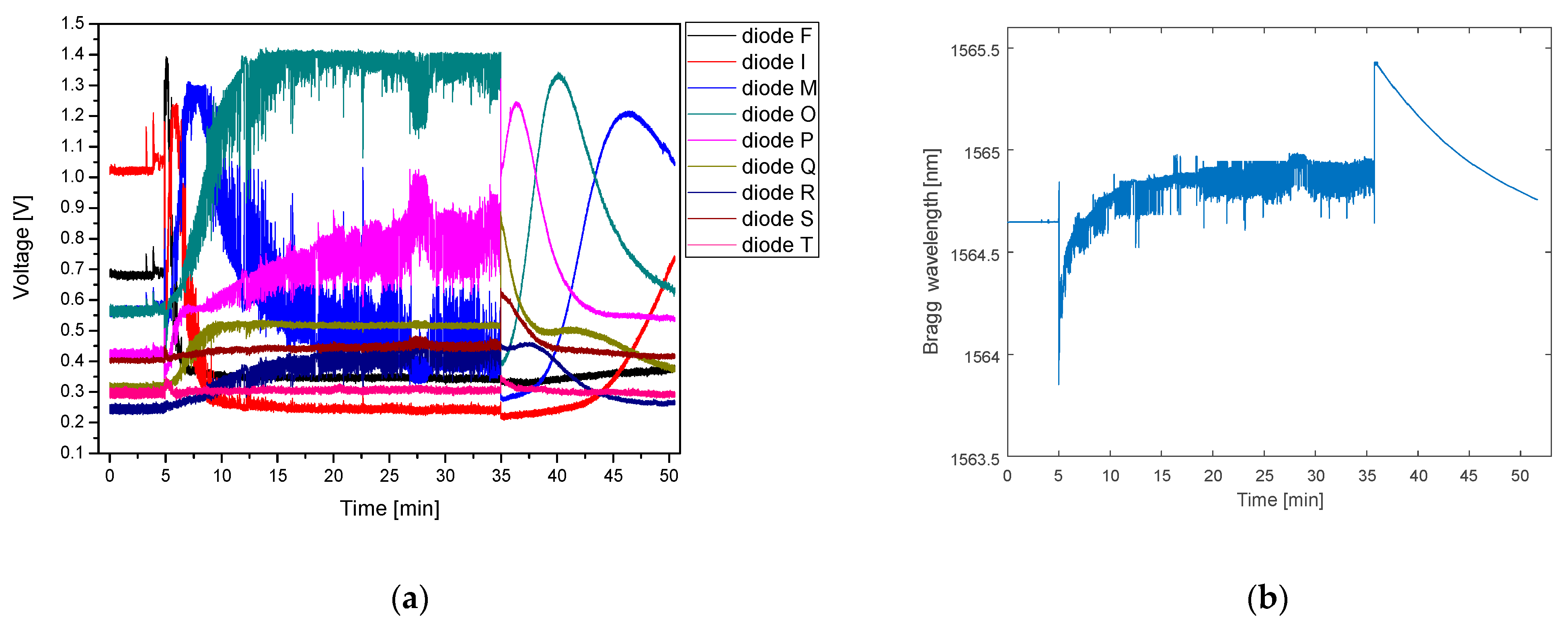

3.2.3. FBG Elongation Testing

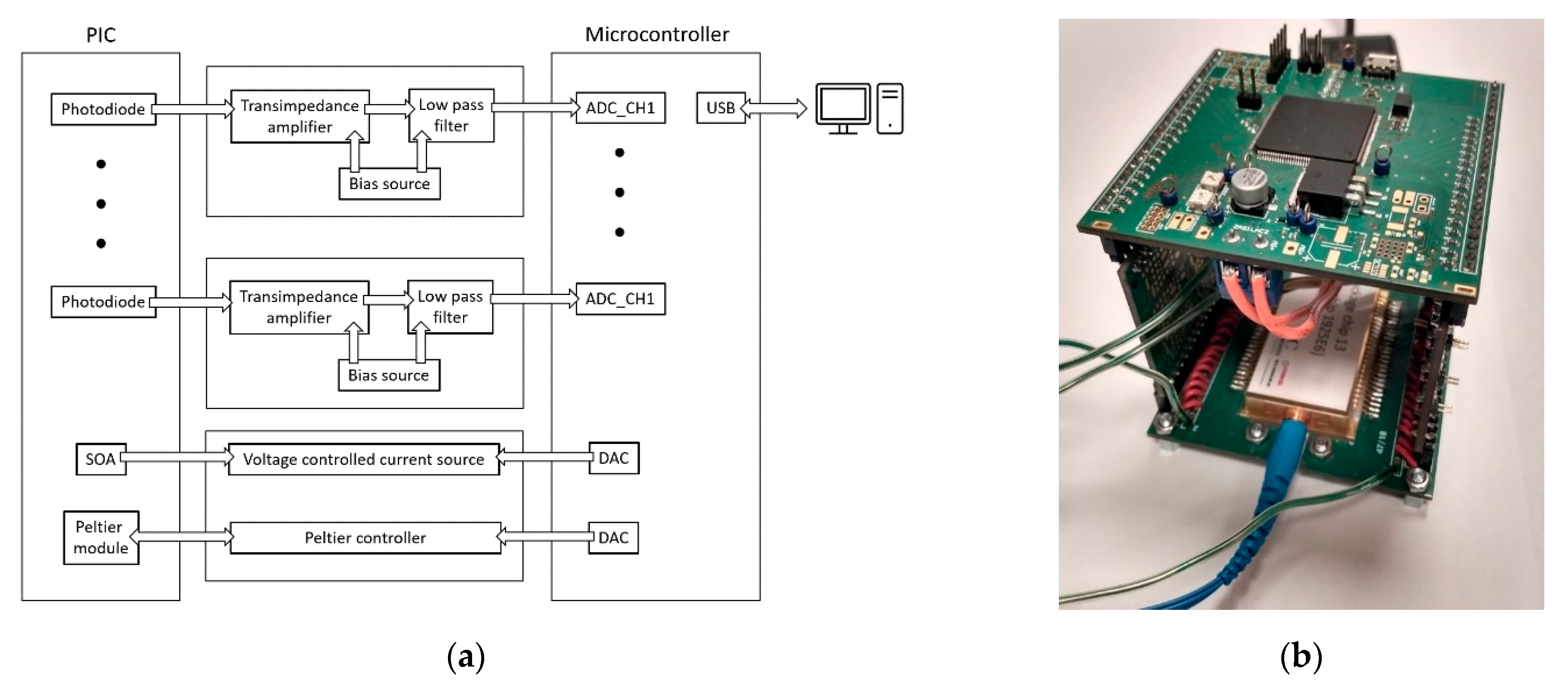

3.2.4. Electronic Readout Circuit Design and Implementation

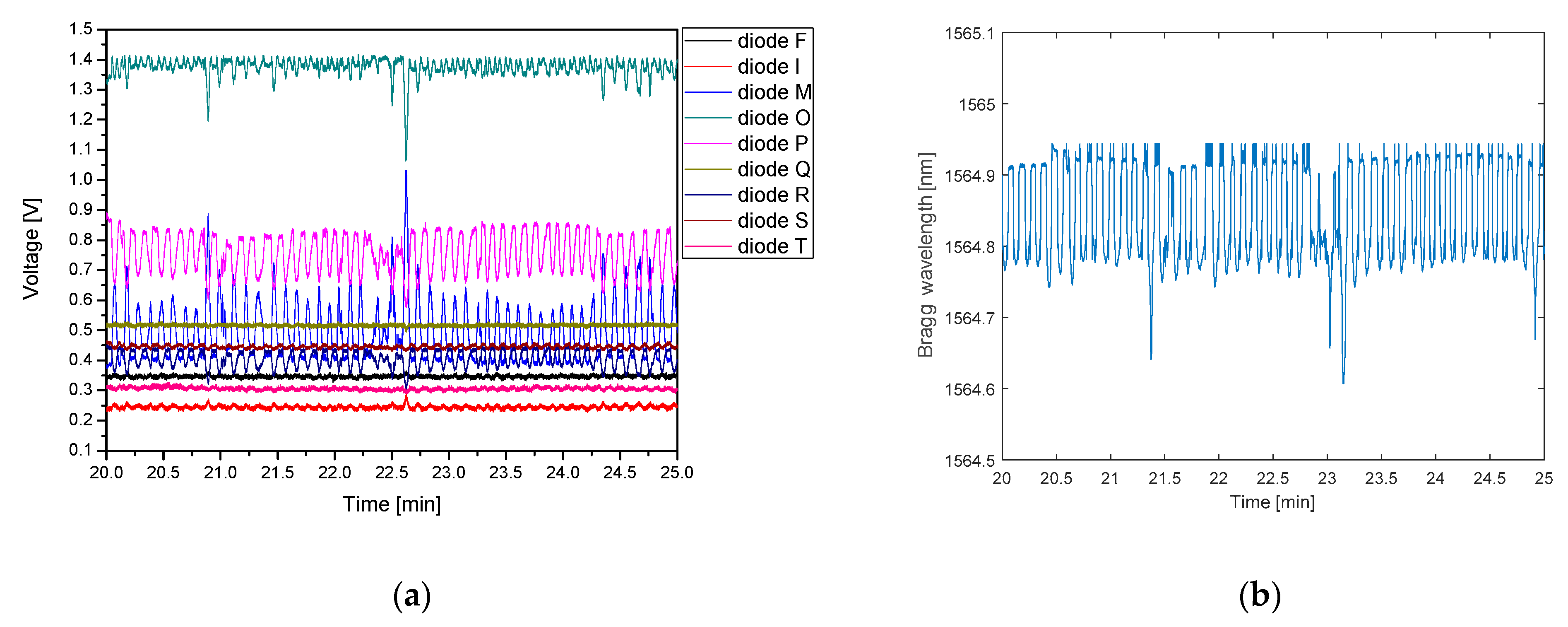

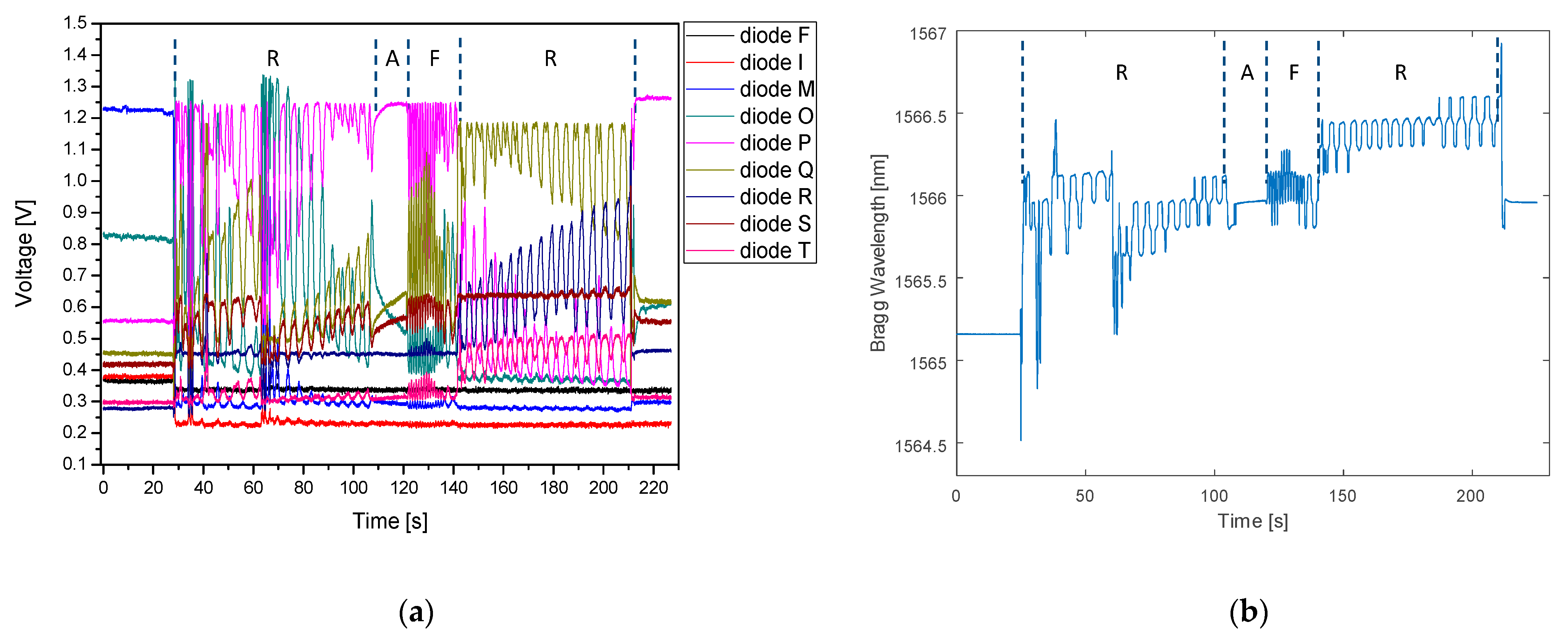

3.2.5. Human Respiratory Rate Detection Testing

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Moerman, K.M.; Sprengers, A.M.J.; Nederveen, A.J.; Simms, C.K. A Novel MRI Compatible Soft Tissue Indentor and Fibre Bragg Grating Force Sensor. Med. Eng. Phys. 2013, 35, 486–499. [Google Scholar] [CrossRef] [Green Version]

- Nedoma, J.; Kepak, S.; Fajkus, M.; Cubik, J.; Siska, P.; Martinek, R.; Krupa, P. Magnetic Resonance Imaging Compatible Non-Invasive Fibre-Optic Sensors Based on the Bragg Gratings and Interferometers in the Application of Monitoring Heart and Respiration Rate of the Human Body: A Comparative Study. Sensors 2018, 18, 3713. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Dziuda, L.; Skibniewski, F.W.; Krej, M.; Lewandowski, J. Monitoring Respiration and Cardiac Activity Using Fiber Bragg Grating-Based Sensor. IEEE Trans. Biomed. Eng. 2012, 59, 1934–1942. [Google Scholar] [CrossRef] [PubMed]

- Tosi, D.; Olivero, M.; Perrone, G. Low-Cost Fiber Bragg Grating Vibroacoustic Sensor for Voice and Heartbeat Detection. Appl. Opt. 2008, 47, 5123–5129. [Google Scholar] [CrossRef] [Green Version]

- Wehrle, G.; Nohama, P.; Kalinowski, H.J.; Torres, P.I.; Valente, L.C.G. A Fibre Optic Bragg Grating Strain Sensor for Monitoring Ventilatory Movements. Meas. Sci. Technol. 2001, 12, 805–809. [Google Scholar] [CrossRef]

- Chethana, K.; Guru Prasad, A.S.; Omkar, S.N.; Asokan, S. Fiber Bragg Grating Sensor Based Device for Simultaneous Measurement of Respiratory and Cardiac Activities. J. Biophotonics 2017, 10, 278–285. [Google Scholar] [CrossRef] [PubMed]

- Presti, D.L.; Massaroni, C.; Formica, D.; Saccomandi, P.; Giurazza, F.; Caponero, M.A.; Schena, E. Smart Textile Based on 12 Fiber Bragg Gratings Array for Vital Signs Monitoring. IEEE Sens. J. 2017, 17, 6037–6043. [Google Scholar] [CrossRef]

- Fajkus, M.; Nedoma, J.; Martinek, R.; Vasinek, V.; Nazeran, H.; Siska, P. A Non-Invasive Multichannel Hybrid Fiber-Optic Sensor System for Vital Sign Monitoring. Sensors 2017, 17, 111. [Google Scholar] [CrossRef] [PubMed]

- Nedoma, J.; Fajkus, M.; Martinek, R.; Nazeran, H. Vital Sign Monitoring and Cardiac Triggering at 1.5 Tesla: A Practical Solution by an Mr-Ballistocardiography Fiber-Optic Sensor. Sensors 2019, 19, 470. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Perezcampos Mayoral, C.; Gutiérrez Gutiérrez, J.; Cano Pérez, J.L.; Vargas Treviño, M.; Gallegos Velasco, I.B.; Hernández Cruz, P.A.; Torres Rosas, R.; Tepech Carrillo, L.; Arnaud Ríos, J.; Apreza, E.L.; et al. Fiber Optic Sensors for Vital Signs Monitoring. A Review of Its Practicality in the Health Field. Biosensors 2021, 11, 58. [Google Scholar] [CrossRef] [PubMed]

- Kaźmierczak, A.; Jusza, A.; Slowikowski, M.; Stopiński, S.; Piramidowicz, R. Integrated Interrogator Circuits for Fiber Optic Sensor Network in Generic InP Photonic Integrated Circuit Technology. Opt. Sens. Detect. V 2018, 10680, 106800M. [Google Scholar] [CrossRef]

- Smit, M.; Williams, K.; Van Der Tol, J. Past, Present, and Future of InP-Based Photonic Integration. APL Photonics 2019, 4, 050901. [Google Scholar] [CrossRef] [Green Version]

- Augustin, L.M.; Santos, R.; Den Haan, E.; Kleijn, S.; Thijs, P.J.A.; Latkowski, S.; Zhao, D.; Yao, W.; Bolk, J.; Ambrosius, H.; et al. InP-Based Generic Foundry Platform for Photonic Integrated Circuits. IEEE J. Sel. Top. Quantum Electron. 2018, 24, 1–10. [Google Scholar] [CrossRef]

- Soares, F.M.; Baier, M.; Gaertner, T.; Grote, N.; Moehrle, M.; Beckerwerth, T.; Runge, P.; Schell, M. InP-Based Foundry PICs for Optical Interconnects. Appl. Sci. 2019, 9, 1588. [Google Scholar] [CrossRef] [Green Version]

- SMART Photonics. Available online: https://smartphotonics.nl/ (accessed on 20 April 2021).

- Smit, M.K.; van Dam, C. PHASAR-Based WDM-Devices: Principles, Design and Applications. IEEE J. Sel. Top. Quantum Electron. 1996, 2, 236–250. [Google Scholar] [CrossRef] [Green Version]

- Dziuda, L.; Krej, M.; Skibniewski, F.W. Fiber Bragg Grating Strain Sensor Incorporated to Monitor Patient Vital Signs during MRI. IEEE Sens. J. 2013, 13, 4986–4991. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Słowikowski, M.; Kaźmierczak, A.; Stopiński, S.; Bieniek, M.; Szostak, S.; Matuk, K.; Augustin, L.; Piramidowicz, R. Photonic Integrated Interrogator for Monitoring the Patient Condition during MRI Diagnosis. Sensors 2021, 21, 4238. https://doi.org/10.3390/s21124238

Słowikowski M, Kaźmierczak A, Stopiński S, Bieniek M, Szostak S, Matuk K, Augustin L, Piramidowicz R. Photonic Integrated Interrogator for Monitoring the Patient Condition during MRI Diagnosis. Sensors. 2021; 21(12):4238. https://doi.org/10.3390/s21124238

Chicago/Turabian StyleSłowikowski, Mateusz, Andrzej Kaźmierczak, Stanisław Stopiński, Mateusz Bieniek, Sławomir Szostak, Krzysztof Matuk, Luc Augustin, and Ryszard Piramidowicz. 2021. "Photonic Integrated Interrogator for Monitoring the Patient Condition during MRI Diagnosis" Sensors 21, no. 12: 4238. https://doi.org/10.3390/s21124238

APA StyleSłowikowski, M., Kaźmierczak, A., Stopiński, S., Bieniek, M., Szostak, S., Matuk, K., Augustin, L., & Piramidowicz, R. (2021). Photonic Integrated Interrogator for Monitoring the Patient Condition during MRI Diagnosis. Sensors, 21(12), 4238. https://doi.org/10.3390/s21124238