1. Introduction

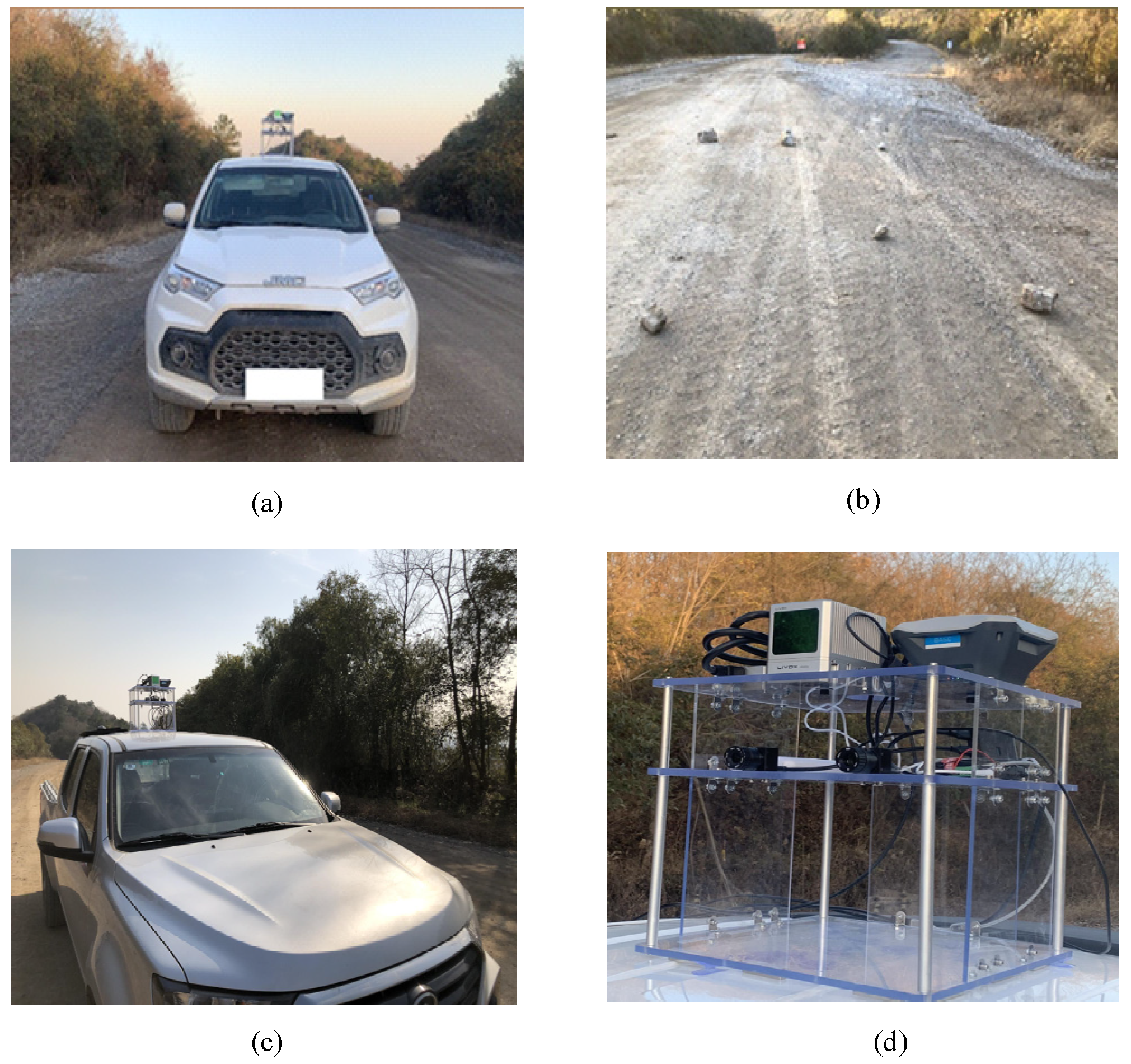

Reducing the cost of transportation is an important goal for open-pit mines [

1,

2]. With the application of unmanned vehicles and light detection and ranging (lidar) equipment in a variety of enclosed scenarios [

3,

4,

5], the transportation of open-pit mines is also expected to realize unmanned operations, but the literature [

6,

7,

8] has proposed that the current unmanned vehicles will cause extra tire wear when facing bad road conditions. In addition, in the path planning task, the passability of rough roads needs to be analyzed [

9,

10,

11,

12]. Therefore, it is of great significance to realize the automatic detection of rocks on the road while the truck is driving.

At present, there is a lack of mature methods for detecting rocks on transportation road in open-pit mines. Although scholars in the field of autonomous driving have proposed a variety of obstacle detection methods [

13,

14,

15,

16], they are different from the main obstacles on transportation roads in mining. These methods deal with the detection of common objects on urban structured roads, such as motor vehicles, pedestrians, bicycles, etc. These objects are characterized by large scale, regular shape, and high recognition. Therefore, the problem of detecting rocks on transportation road in open-pit mines is a new challenge.

Obstacle detection methods based on lidar sensors can be divided into methods based on deep learning and traditional methods. Scholars such as Minemura [

17] proposed an optimized convolutional neural network LMNet to handle point cloud target detection tasks, and expand the receptive field of the network by expanding convolution.

This method runs fast, but sacrifices accuracy. Scholars such as Beltran [

18] proposed a birdNet framework to process point cloud target detection tasks, projecting point cloud data into a cell code for bird’s-eye projection, and using a convolutional neural network to estimate the target position and direction. Scholars such as Abdelkarim [

19] extended the yolo(you only look once) framework to the task of 3D point cloud target detection, which balanced the detection accuracy and speed. Scholars such as ShaoshuaiShi [

20] proposed the PointRCNN framework, which divides the original point cloud into foreground and background, and directly generates a small amount of high-quality 3D region proposal from the point cloud in a bottom-up manner to perform accurate box refinement and confidence prediction. Deep learning-based methods require a large amount of labeled training data. The quality of the detection effect depends largely on the richness of the training data, and the principle is difficult to explain clearly.

Traditional methods generally assume that the road surface is locally flat. Scholars such as Tongtong Chen [

21] proposed a ground segmentation method based on Gaussian process, using one-dimensional Gaussian process regression to classify the midpoint of each segment. This method divides the space into independent fan-shaped areas and cannot guarantee the continuity of the overall ground. Scholars such as Rummelhard [

22] proposed a point cloud segmentation method based on spatio-temporal conditional random field, which considered the time sequence relationship between point cloud data. The estimated value of this method for each node is easily affected by its surrounding points. Scholars such as Thrun [

23,

24,

25] proposed a height map method, which processed a 3D point cloud into a 2D raster map, and used methods such as height difference for classification within the raster. Although this method is highly efficient, its accuracy is difficult to adapt to unstructured roads. Scholars such as Narksri [

26] proposed a ground segmentation method that is robust to slopes. This method deals with slopes on flat roads and cannot achieve satisfactory results for rough roads.

The above methods have been proved to be successful in some tasks, but the good results obtained by these methods are limited to the common obstacle types on structured roads. In the task of detecting small-scale and irregular-shaped obstacles on rough roads, it is difficult to obtain satisfactory results from these methods [

21].

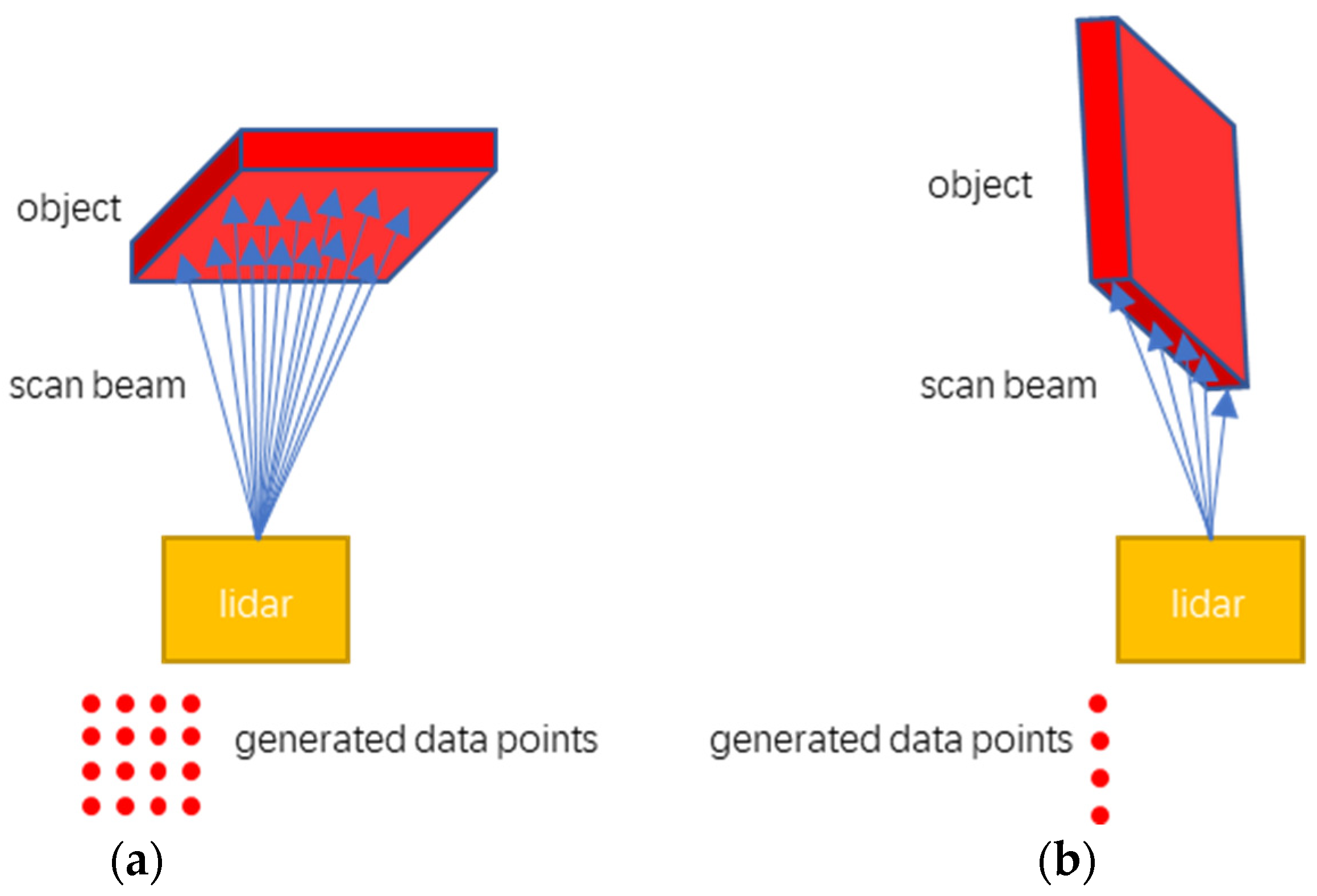

Transportation roads in open-pit mines are unstructured and rough, and the rocks on the roads are small and irregular in shape. These two characteristics require that the method of filtering ground points has strong generalization, and the accuracy of the method is high enough. This paper proposes a two-stage detection method for rock obstacles on transportation roads in open-pit mines. In the first stage, the cloth simulation method [

27] in the field of computer graphics is introduced and modified to obtain an approximate simulation of the rough surface of the road and realize the filtering of ground points. The following modifications have been made to the original cloth simulation method: (1) limiting the movement of particles to the vertical direction. The original cloth simulation method is used to deal with three-dimensional simulation problems. The purpose of this paper is to obtain the degree of protrusion of the obstacle relative to the ground. The method only focuses on the z-axis coordinates of the point cloud. Therefore, the method limits the movement of particles in the z-axis direction. (2) The collision detection of particles is modified to compare the height difference. When the height of a particle is lower than the height of its adjacent grounding point, the particle needs to be set to be immovable, and its height must be reset to the height of its adjacent grounding point. This collision detection is intuitive and is a simple but very effective method that can simplify calculations and reduce time consumption. (3) The internal constraints between particles are simplified to the spring force between the current particle and the particles in its 4 neighborhoods. It will not have an obvious effect on the results, but it can reduce the time complexity of the method and reduce the running time of the program. This is a reasonable and effective modification. In the second stage, after filtering the ground points the non-ground points are clustered by grid division based on the regional growth method, and the bounding box of the object is calculated. The method proposed in this paper does not require the assumption of local flat of the road, and it is easy to understand.

The remainder of this paper is organized as follows. A new detection Algorithm 1 is proposed in

Section 2.

Section 3 presents the experimental results, and the proposed Algorithm 1 is discussed in

Section 4. Finally,

Section 5 concludes this paper.

| Algorithm 1. Regional growth clustering based on grid division:

|

1: Input:

2: Point cloud = {}

3: Initialize:

4: {grid_pts} ← {}(project {} to grid unit according to the coordinate)

5: {bin_mat} ←

6: {use_mat} ←

7: {label_mat} ←

8: Label ←

9: Algorithm:

10: for i = 1 to N step 1; j = 1 to M step 1

11: if bin_mat[i][j]==0 or label_mat[i][j]≠0

12: continue

13: end if

14: Creating a variable neighborPoints, which is used to store the neighborhood unit that meet the conditions.

15: {neighborPoints}←

16: neighborPoints.push(grid_pts[i][j])

17: label + 1

18: label_mat[i][j]←label

19: while {neighboorPoints} is not empty

20: cur_voxel←neighborPoints.pop()

21: for k=1,2,3,4

22: getting the index m,n of the k-th neighborhood grid unit of cur_voxel

23: if bin_mat[m][n]==0 or use_mat[m][n]≠0

24: continue

25: end if

26: label_mat[m][n]←label

27: neighborPoints.push(grid_pts[m][n])

28: use_mat[m][n]←1

29: end for

30: end while

31: end for

32: Output:

33: {label_mat} |

2. Method

The method is divided into two stages. The first stage is to filter ground points. The original data are cropped and only the data in the valid range are retained. The z-axis coordinates of the point cloud are inverted and the modified cloth simulation method are used for ground recognition. The second stage is to cluster non-ground points. After filtering the ground points, the remaining points are projected into the grid unit according to its own coordinates. Setting a grid unit as the seed point, and the grid unit are clustered through the greedy search strategy. Finally, we calculate the bounding box for each clustered object. The code to implement this method is based on C++ and PCL(Point Cloud Library), and the technical route is shown in

Figure 1.

2.1. Modification of Cloth Simulation Method

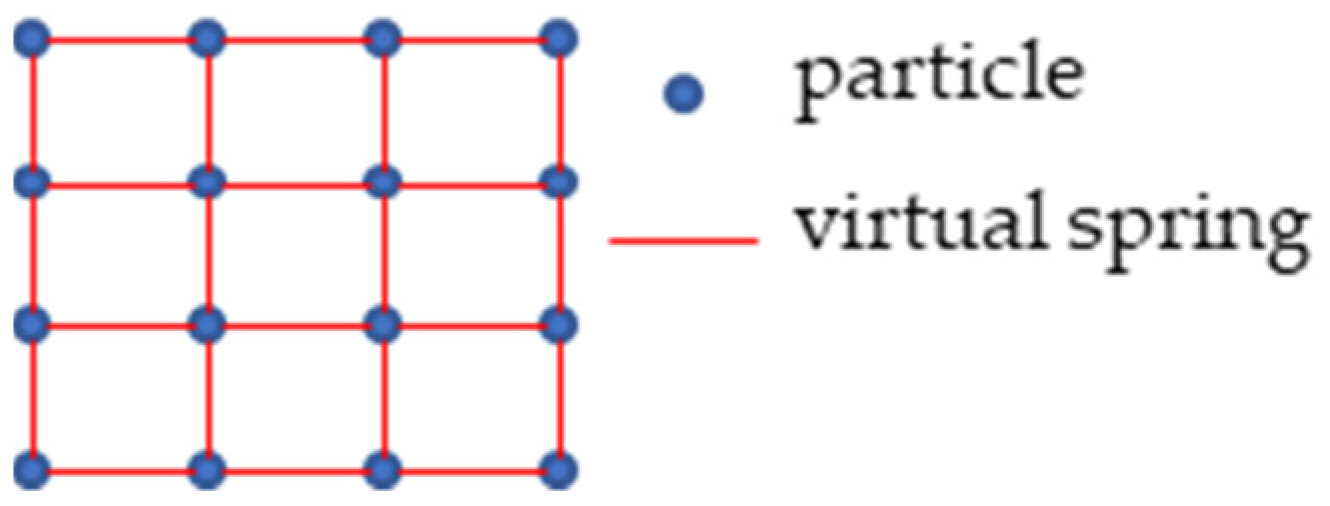

Cloth simulation is a method that is used to simulate cloth in computer programs. In fact, the cloth in the real world is represented in a computer program as a grid connected by particles. The particles have mass and the interaction between the particles is called the mass-spring model [

28],

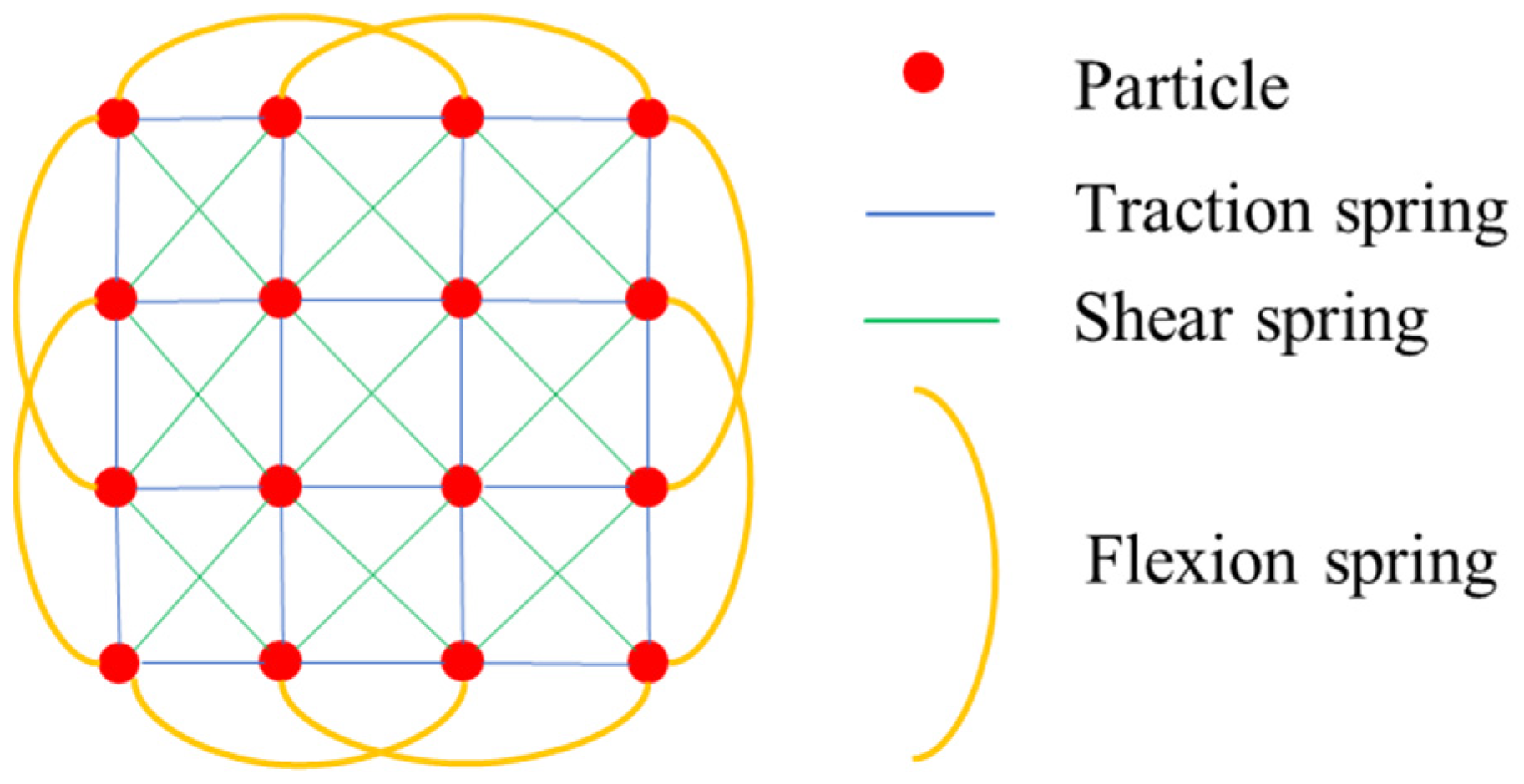

Figure 2 shows the structure of the grid. The particles represent the nodes of the grid. The nodes have no volume and are only given constant mass. Particles fall under the influence of gravity, and there is an interaction between connected particles during the falling process. The final position of the particles in space determines the final shape of the cloth.

To solve the problem of filtering ground, the following modifications have been made to the cloth simulation method: (1) the movement of particles is simplified to one direction movement. The method only focuses on the z-axis coordinate information of the point cloud. When updating the position of the particles in each iteration, only the vertical position change of the particles needs to be updated. (2) The collision detection of particles is modified to height difference comparison. The movement of the particles is restricted to the vertical direction, so when the height of the particle is lower than the height of the adjacent ground point, the particle is set to be unmovable and the height of the particle is reset to the ground height. (3) The internal constraint between particles is expressed as the spring force between the current particle and its four neighboring particles. The purpose of this modification is to simplify the calculation steps without affecting the results and reduce the running time of the program. By calculating the distance between the current particle and the surrounding four neighboring particles, it is compared with the distance between the particles when the cloth is initialized. According to the amount of change between these two distances, the internal force of the particle can be calculated simply.

Figure 3 shows the internal constraints between cloth particles.

In order to determine the shape of the cloth after each iteration, it is necessary to calculate the position of each particle after each iteration. The position of the particle is determined by the force on the particle. According to Newton’s Second Law, Formula (1) can be obtained:

where

represents the acceleration of the particle at time

;

represents the mass of the particle, which can be set as a constant;

represents the external force on the particle, usually referring to gravity, which can be expressed as a constant;

represents the internal force on the particle. The vertical component of spring force is used as the internal force constraint on the current particle.

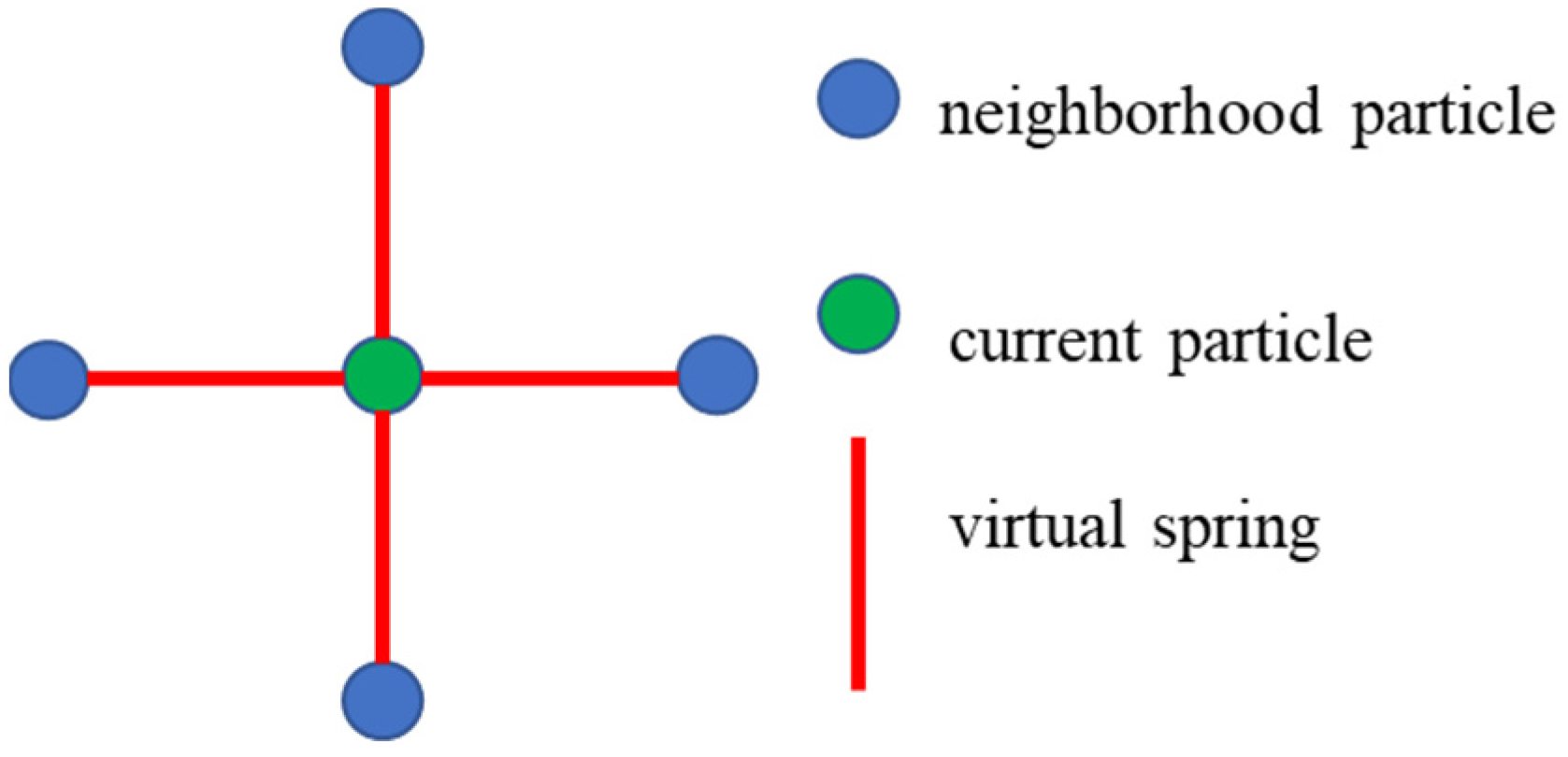

In this paper, the internal force between particles is expressed as a simple spring force model, calculated according to Formula (2):

where

represents the coefficient of elasticity between particles,

represents the change in the distance between particles during the falling process relative to the distance between particles when the cloth is initialized, and

represents the angle between the virtual spring and the horizontal plane.

The particle position after each iteration is obtained by the Taylor expansion method. We perform right Taylor expansion and left Taylor expansion on

, and omit the third term.

where

represents the velocity of the particle at time

.

The particle position after each iteration is obtained by adding Formulas (3) and (4):

The relationship between the position of the particle and the force exerted by the particle is obtained simultaneously by Formulas (1) and (5):

where

represents the sum of external and internal forces experienced by the particle.

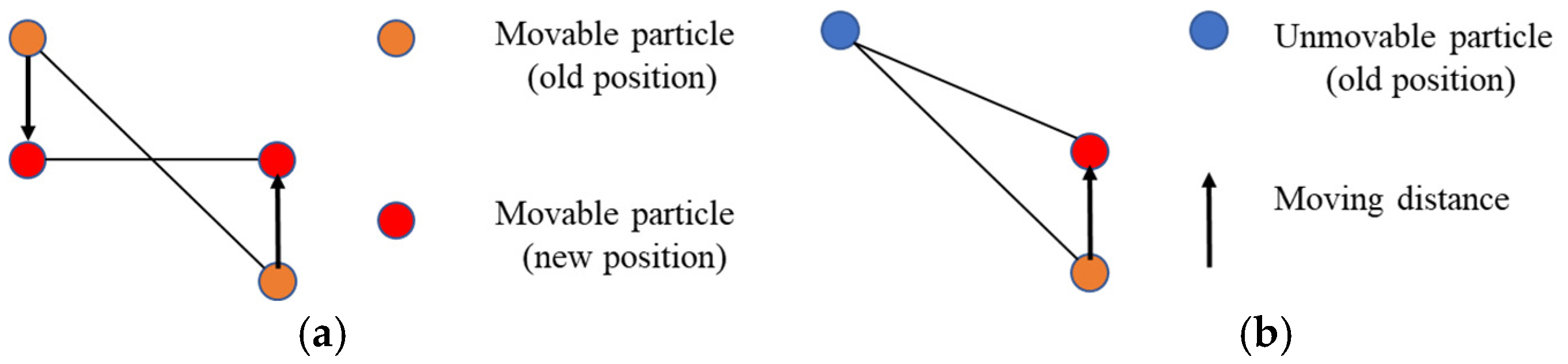

After inverting the original point cloud, small holes were formed by the bumps on the ground. Restricting the movement of particles in these holes [

29] can speed up the convergence of the iterative falling process of particles. By comparing the height difference between the current particle and the surrounding particles, the particles of different heights are moved the same distance in the opposite direction. According to the different cloth hardness values, the particles can be moved multiple times to ensure faster convergence of the iteration process. The process diagram is shown in

Figure 4. The moving distance can be calculated according to the following formula:

where

represents the distance, each particle should move,

is 0 or 1, when the particle type is movable,

is 1, and when the particle type is unmovable,

is 0, and

is the height value of the particle adjacent to the current particle, and

represents the height value of the current particle.

2.2. Ground Filtering Based on Modified Cloth Simulation Method

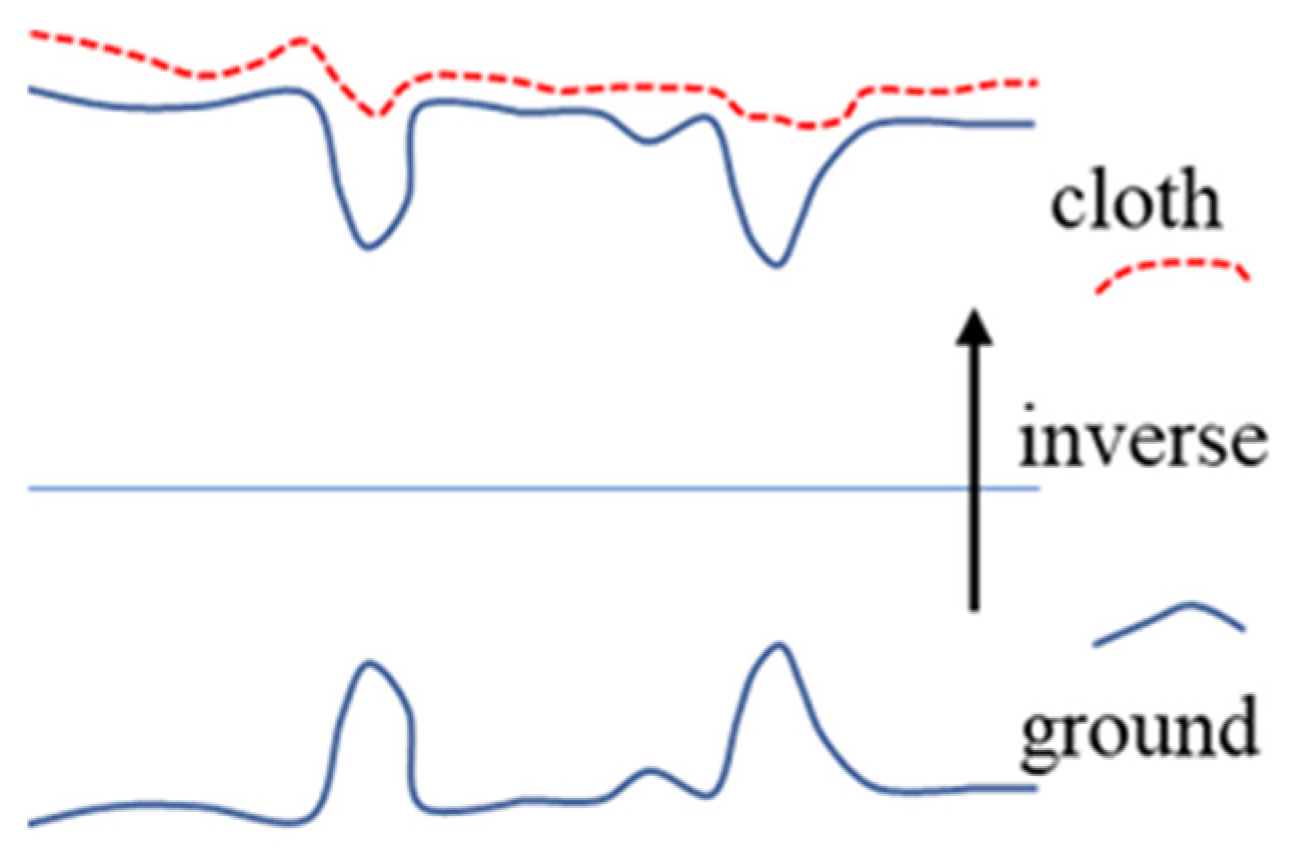

In order to accurately obtain the road surface from the point cloud, inspired by the cloth filtering method [

29], we imagine a piece of cloth placed on the road surface and falling due to gravity. The final shape of the cloth is the shape of the ground containing obstacles. If the ground is reversed in advance, the final shape of the cloth is a pure road surface without obstacles. Based on this method, we have realized the filtering of rough ground, and achieved satisfactory results.

Figure 5 shows the idea of this method.

First, we invert the z-axis coordinates of all points. Then, the cloth is simulated to fall under the constraints of external gravity and internal spring force. By affecting the interaction between particles and the iteration termination conditions, the final cloth shape can accurately represent the road surface. Finally, the cloth is used as a reference for classifying the original point cloud as ground points or non-ground points.

The ground point recognition based on the cloth simulation method can be summarized as the following steps:

Inverting the original point cloud.

Figure 5 shows the process.

Initiating the cloth grid and setting the height of all particles above the highest point of the point cloud.

Figure 6 shows the process.

Projecting the grid particles and point cloud to the same horizontal plane, and finding the nearest ground point for each grid particle.

For each particle, calculating the displacement under the constraints of gravity and internal spring force. When the height of the particle is lower than the height of its nearest neighboring ground point, setting the particle as an unmovable particle.

For the particles in the hole region, calculating their displacement under the constraint of the height difference of the neighboring particles.

Figure 4 shows the process.

Repeating 4–5, when the height change of all particles is small enough to reach the convergence condition, or the number of iterations exceeds the specified maximum number of iterations, the iteration process is terminated.

Comparing the distance between the points in the point cloud and the corresponding grid particles. Points smaller than the threshold are recognized as ground points; points greater than the threshold are recognized as non-ground points.

2.3. Grid Division Clustering Based on Regional Growth Method

After filtering ground points, non-ground points need to be clustered. The distribution of non-ground points in space is very discrete. At the same time, in order to speed up the search for neighboring points in space, this paper uses 2D grids to spatially divide the point cloud.

The core idea of the region growth method is to search from the seed point and merge the surrounding area with the target like the seed point according to the pre-defined rules, then forming a new seed point, and repeating the search process until there is no target that meets the conditions.

Before the greedy search, five variables need to be defined, which are the two-dimensional array grid_pts, bin_mat, use_mat, label_mat, and integer Label. Among them, grid_pts is used to describe the grid storing the point cloud, and the point cloud is projected to the corresponding grid unit according to their coordinates; bin_mat is used to indicate whether the current grid unit contains point cloud data, and its value is only 0 or 1; use_mat is used to indicate whether the current grid cell has been processed, and its value is only 0 or 1; label_mat is used to indicate which cluster the point cloud in the current grid cell belongs to; the integer Label is used to represent the total number of clusters.

First, the clustering algorithm needs to set the size of the grid, and project the points to be processed to the corresponding grid unit according to the coordinates. Cells that contain points inside are marked as real cells; cells that do not contain points inside are marked as empty cells. Then, the clustering algorithm uses a greedy search strategy to traverse and search all grid cells. The rule for judging whether a unit is added to the seed set is to judge whether the unit is a real unit and has not been processed. The pseudo code of the clustering algorithm is shown below.

After the clustering process, a bounding box needs to be calculated for each object. For each object after clustering, traversing all the points in the cluster, finding the coordinates of the points located on the boundary, and using them as the coordinates of the bounding box. For safety reasons, the bounding box can be appropriately enlarged. In other words, an expansion factor can be adopted to appropriately enlarge the bounding box.

2.4. Parameter Description

The method proposed in this paper has four parameters that need to be adjusted experimentally: the resolution of the cloth grid (grid resolution, GR); the height threshold (HT) that distinguishes ground points from non-ground points; the spring coefficient (SC); and the voxel resolution (VR) in the clustering process.

Due to the small volume of the falling rocks, there are few lidar points reflected by the rock itself, which is difficult to identify. This requires the resolution of the cloth grid to be set smaller. The height difference threshold depends on the size of the rocks, and it is necessary to ensure that the rocks are not mistakenly identified as ground points. The elastic coefficient between the cloth particles is determined by experiment. The grid resolution in the clustering process is related to the size of the rocks.

In addition to the above four parameters, there are three other parameters: the cloth hardness (CH), the max iteration times (MI), and the time step (TS) in the iteration process. But for all datasets, the values of these three parameters are the same. Through reference [

29] and the experimentals, for all datasets, the cloth hardness value is set to 3, the max iteration times is set to 500, and the time step is set to to 0.65. These three parameters are set to these values to ensure that the program reaches the convergence condition.

4. Discussion

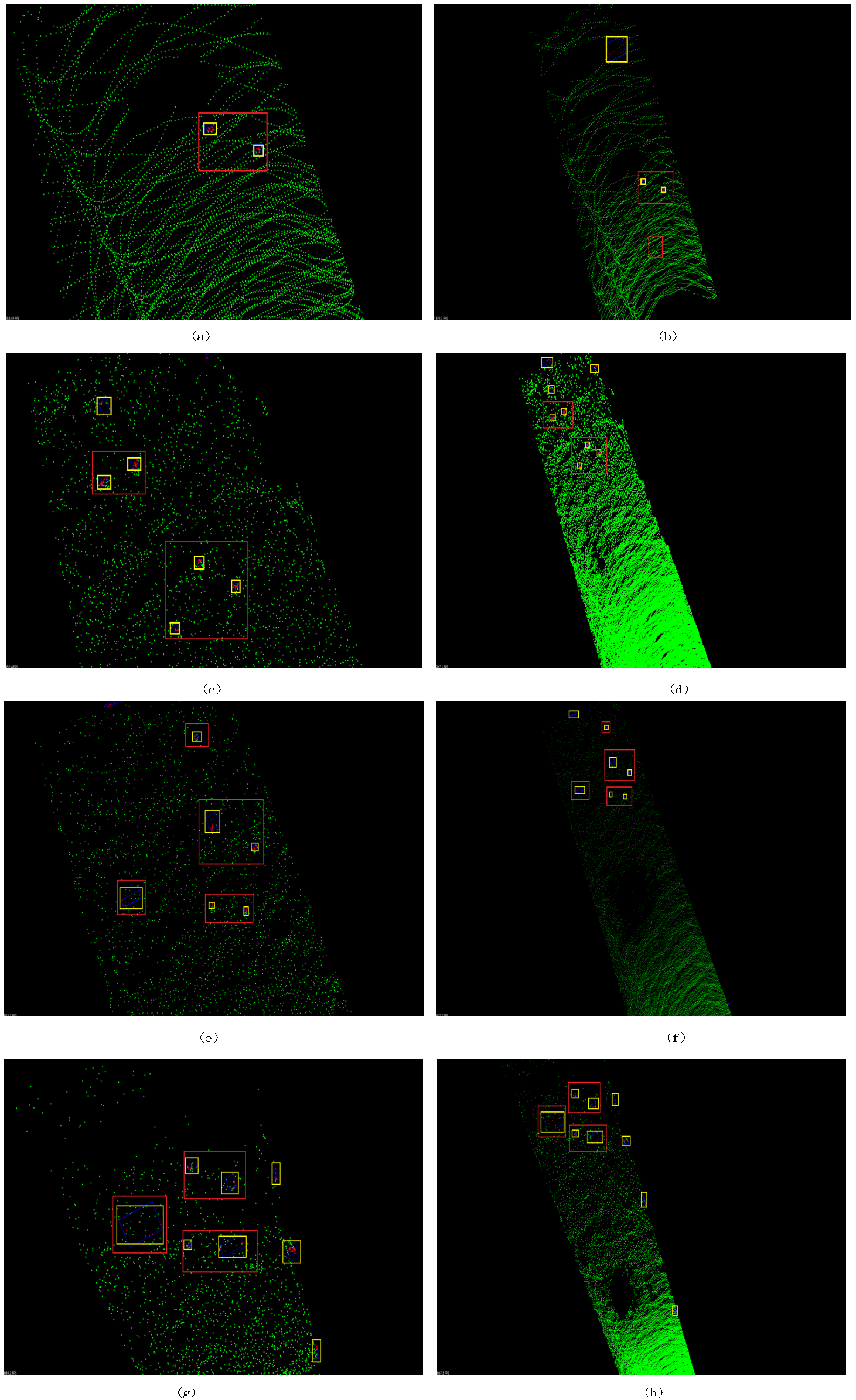

4.1. Result Analysis

The result is mainly affected by four factors, which are the resolution of the cloth grid, the threshold of the height difference between ground points and non-ground points, the elastic coefficient between cloth particles, and the grid resolution in the clustering process.

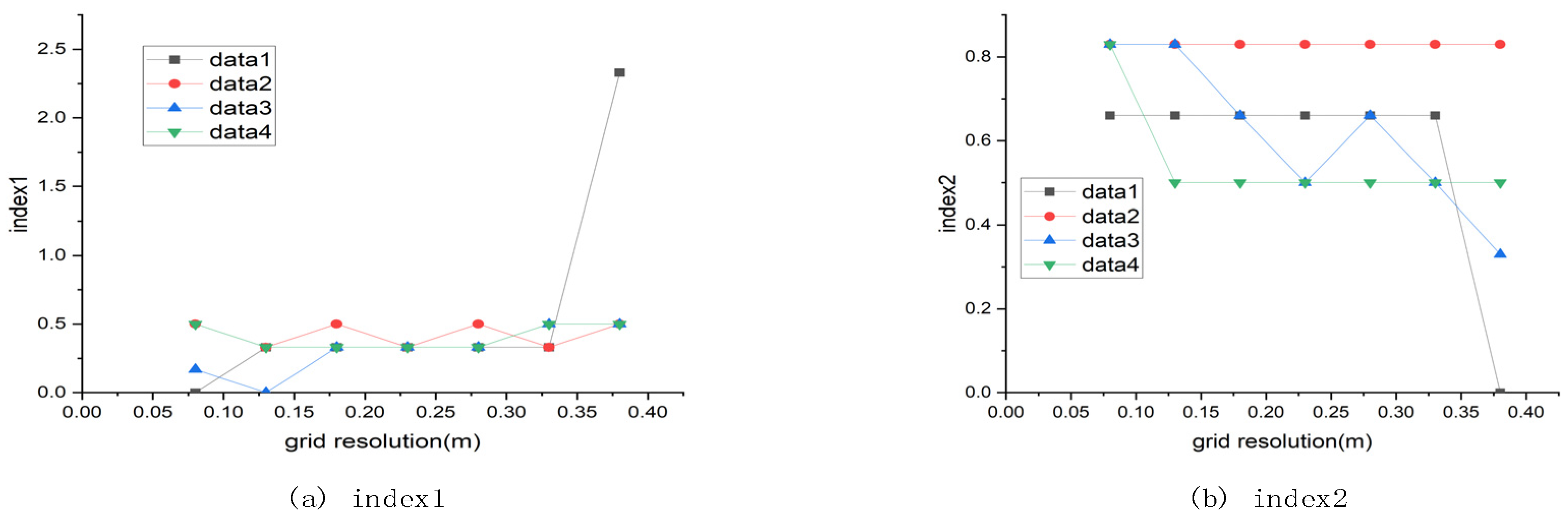

The higher the resolution of the cloth grid, the smaller the size of the grid and the greater the total number of particles. Considering the size of the rocks used in the experiment, the result is good when the cloth grid resolution is around 0.08 m after many experiments. The effect of different grid resolutions on the results is shown in

Figure 10.

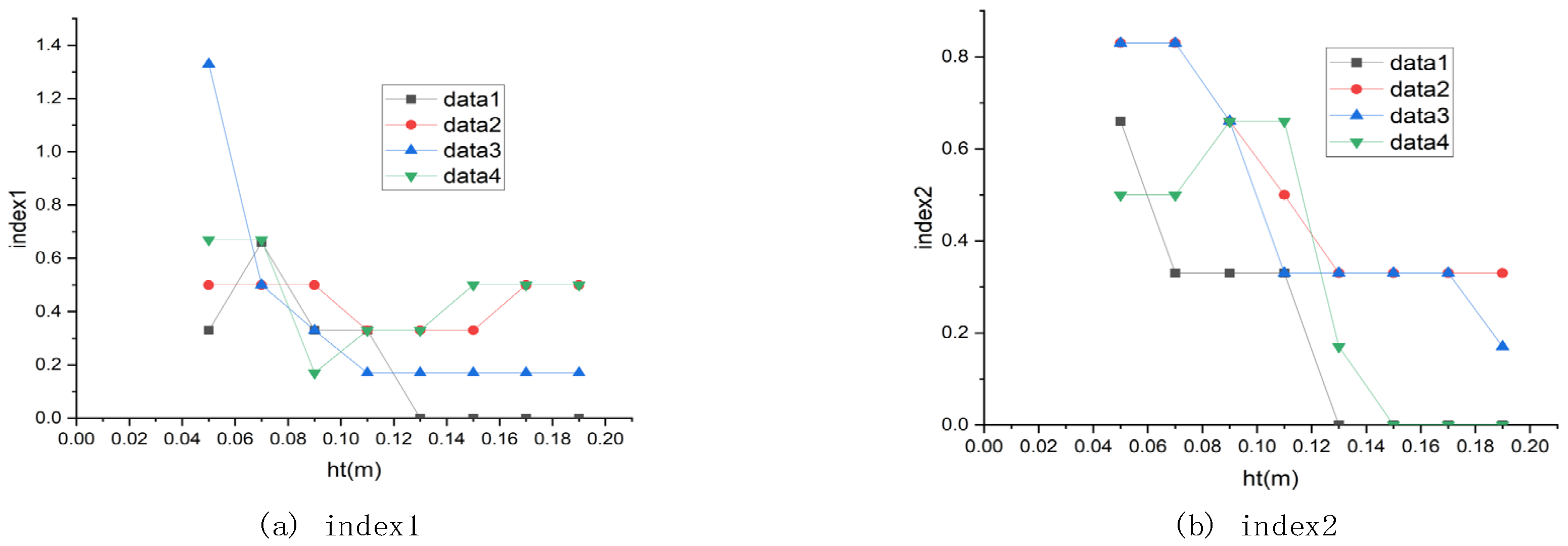

The height difference threshold that distinguishes ground points and non-ground points has an important influence on the results. After the iteration process is over, the final shape of the cloth grid represents the road surface. The height difference between the space point and its neighboring cloth particles is calculated and compared with the threshold. If the difference is less than the threshold, the space point is classified as a ground point; otherwise, the space point is classified as a non-ground point. If the height difference threshold is too large, the Algorithm 1 will incorrectly classify non-ground points as ground points; by contrast, if the height difference threshold is too small, the Algorithm 1 will incorrectly classify ground points as non-ground points. After many experiments, when the threshold value is around 0.08 m, the classification effect is good. The effect of different height difference threshold on the results is shown in

Figure 11.

The elastic coefficient between the cloth particles affects the internal spring force constraint. The function of the internal spring force constraint is to exert an upward force on the falling particles, which has an upward effect on the particles returning them to their correct positions. Considering an extreme case, if there is no spring force between the particles, the falling of the particles in the holes is only restricted by collision detection. The particles fall to a very deep position in the holes, which makes it impossible to accurately simulate the road surface. For different cloth grid resolution and height difference threshold, the best elastic coefficient can be determined through experiments. The effect of different elastic coefficients on the results is shown in

Figure 12.

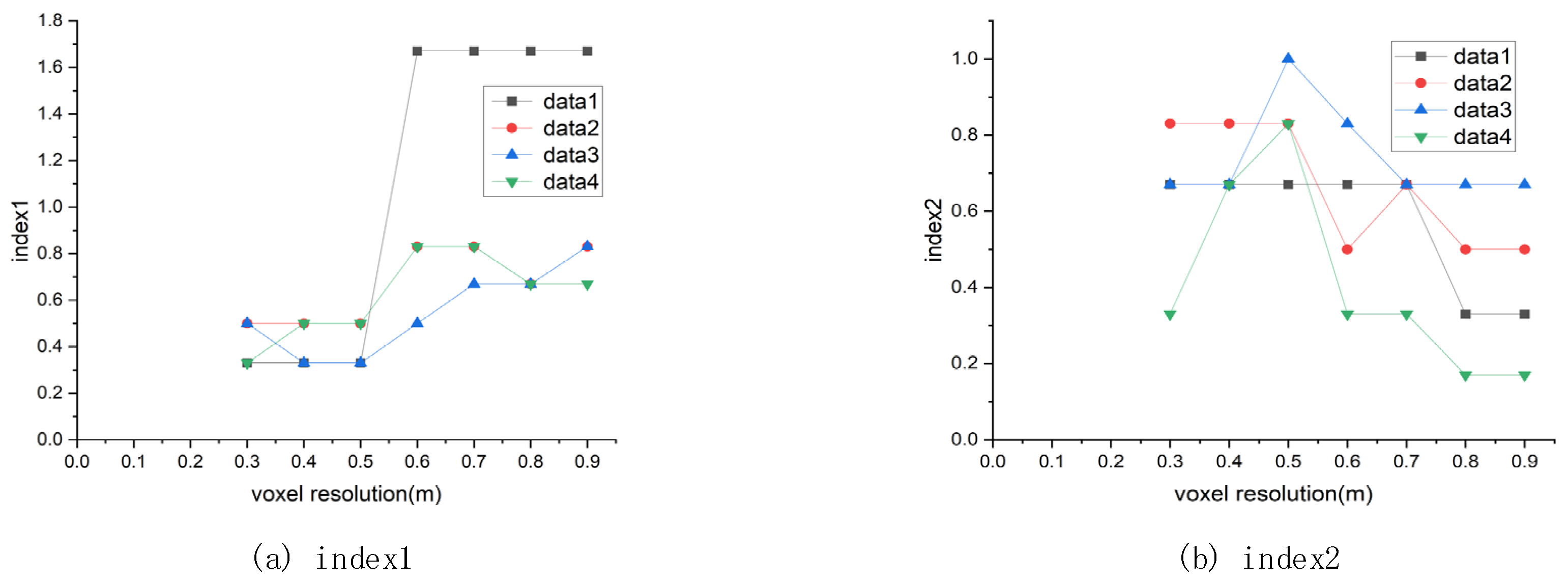

The grid resolution in the clustering process affects the result of the Algorithm 1 for clustering non-ground points belonging to different objects. In the clustering process, the neighborhood of the seed point is searched. This search method has a great relationship with the grid size. When the Algorithm 1 searches for the neighborhood, the points belonging to different objects will be merged. The grid resolution for spatial division of the point cloud during the clustering process also needs to be carefully set. In the clustering process, if the size of the grid resolution is set too large, then multiple adjacent objects will be merged, which will cause the area of the bounding box to expand and reduce the area of the road where the vehicle can travel. After many experiments, it is finally determined that the grid resolution is 0.5 m, and satisfactory results are obtained for all datasets. The effect of different grid resolutions on the results is shown in

Figure 13.

4.2. Further Analysis

The purpose of this paper was to detect rocks with a size of about 10–40 cm on the transportation roads of open-pit mines. Because the volume of these rocks is relatively small, and there is no fixed shape feature, the rocks are not easy to detect using conventional methods. At the same time, the transportation roads of open-pit mines are rough and unstructured, which requires a certain generalization of the method. A two-stage method proposed in this paper can effectively detect these rocks.

The first stage of the method uses a modified cloth simulation method to filter ground points from the original point cloud data. First, by reversing the original point cloud data, the convex part of the transportation road is transformed into a concave part, and the pure surface is located at the relatively highest point in the point cloud. Secondly, particles of constant mass fall from a height and, under the action of internal constraints, the particles will eventually stay near their corresponding actual ground points. Finally, the final shape of the cloth grid is determined, and the ground points can be identified by comparing them with the original point cloud data. This method is suitable for processing unstructured roads. After further modification, it can be used for rough road recognition in the field scene, and it has a certain versatility.

The second stage of the method uses grid division clustering based on area growth method to obtain the bounding box of each rock. In order to speed up the clustering process, this paper does not directly use a single point as the basic search unit, but uses a spatial grid division method to divide the point cloud into regular-sized grids unit. Each grid unit is used as the search unit of the area growth method, and the search process uses a greedy search strategy. The key to the clustering process is not to mistakenly identify multiple adjacent objects as one object, which will increase the volume of the bounding box and cause the truck’s drivable area to become smaller.

The physical properties of the object itself (such as density, material) also affect the scanning effect of the lidar sensor. The wavelength of the light beam emitted by the lidar is fixed, so the reflectivity of the light beam to objects of different densities is different, which will affect the density of the point cloud data and the detection results. The influence of the density of the scanned object on the reflectivity of the laser beam is complex, involving knowledge of optics and physics. Due to the lack of corresponding equipment and background knowledge, this paper does not undertake further research on this subject.

In addition, the method only uses the Z-axis coordinate information of the point cloud, and does not consider the local geometric characteristics of the point cloud. Future research may consider the X-axis and Y-axis coordinates of the point cloud, and then assist in the detection from the perspective of the local features of the point cloud.

4.3. Time Analysis

The machine used in the experiment is an ordinary personal computer (PC, (CPU-Intel Corei7, RAM-16G, OS-Ubuntu16). Under the best parameters, each group of data is tested multiple times, the fastest and slowest running time are counted, and the average time is calculated. The results are shown in

Table 4.

The source code of the Algorithm 1 proposed in this paper is written in C++ language and uses central processing unit (CPU) multi-thread acceleration. It can be seen from

Table 4 that the running time of the method is about 0.3 s. When the truck is loading ore, the driving speed is about 10 m/s. The running time of the method satisfies the reaction and avoidance time of the mining truck, so the method has a certain safety redundancy. Future research can use the graphics processing unit (GPU) parallel computing method to optimize the code, so that the program running speed is further accelerated to meet higher real-time requirements.

5. Conclusions

This paper proposes a new method for the detection of rock obstacles on rough roads during the driving process of mine trucks. First, the method modifies the cloth simulation method to make it applicable to the ground point filtering task of rough roads; secondly, the method uses the regional growth clustering method of grid division to achieve rapid clustering. The running speed of the method meets the real-time requirements of autonomous vehicles. Experiments show that for the high-density point cloud data scanned by lidar, the method can accurately detect rocks with a size of 20–30 cm and above at about 40 m within a safe time of 0.3 s. For a fully loaded mining truck with a driving speed of 30 km/h, this is sufficient time for the vehicle to avoid obstacles. The method is easy to understand, and there are fewer parameters that need to be adjusted. With high-precision lidar, the method can detect small-scale rocks on rough transportation roads in open-pit mines. This method can be extended to the detection of small-scale irregularly shaped obstacles on unstructured rough roads.

The effect of this method mainly depends on four parameters, which are the resolution of the cloth grid, the threshold of the height difference between ground points and non-ground points, the elasticity coefficient between cloth particles, and the grid resolution in the clustering process. The optimal values of these four parameters can be determined through experiments.

The problem discussed is a brand new research task, so there is a lack of mature and reliable methods. The method proposed in this paper also requires a lot of scenarios and data to verify it. The internal constraints between particles are simply expressed as spring forces in the method. Such a representation method cannot accurately simulate the internal interaction between particles. In addition, the effect of the method is related to the quality of the point cloud, which places higher requirements on the detection accuracy of the lidar. In order to improve the effect of the method, in the future we will try to extract features based on the geometric information of the object to optimize the detection process.