1. Introduction

Recently, many studies have been attempted to increase productivity by building smart factories through the convergence of the Internet of Things (IoT) and information and communication technology (ICT) in traditional manufacturing systems [

1,

2]. As the IoT technology is used to connect machines, sensors, and facilities seamlessly, smartization can be realized, and the role of the worker has been changed from an operator to a smart manager [

3,

4]. Therefore, it is essential to provide the right manufacturing information to the smart manager concerning his or her role for practical task assistance.

Augmented reality is considered to provide user-centric information more easily in various environments by embedding visual information onto the real objects directly. In particular, the AR-based visualization of manufacturing information, called industrial AR, can provide more effective task assistance, which can reduce a worker’s cognitive load and increase work efficiency [

5,

6,

7].

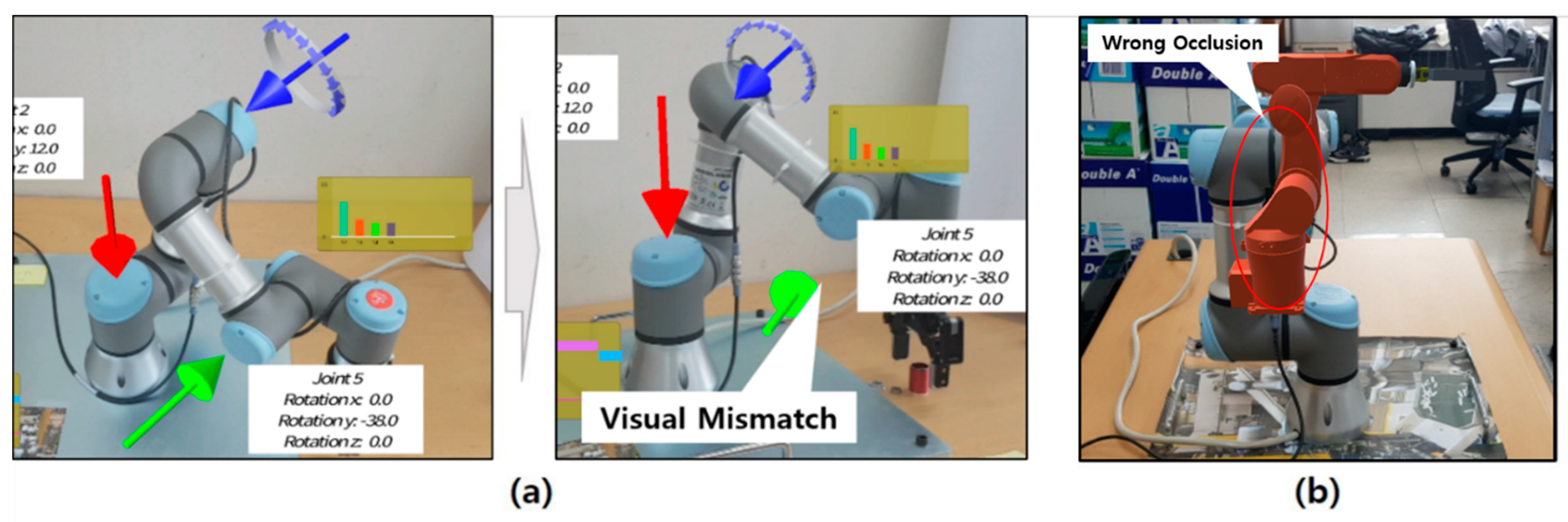

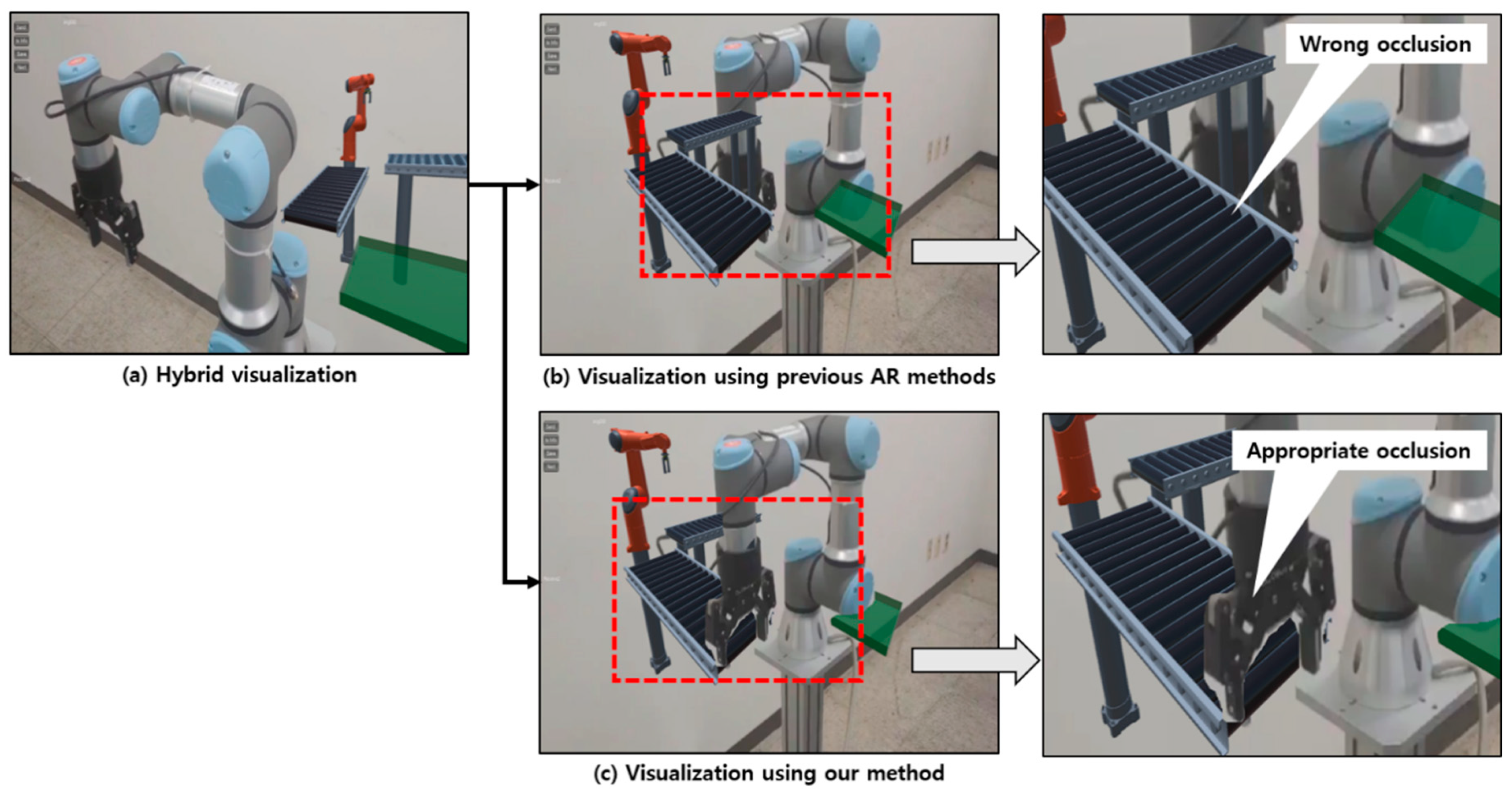

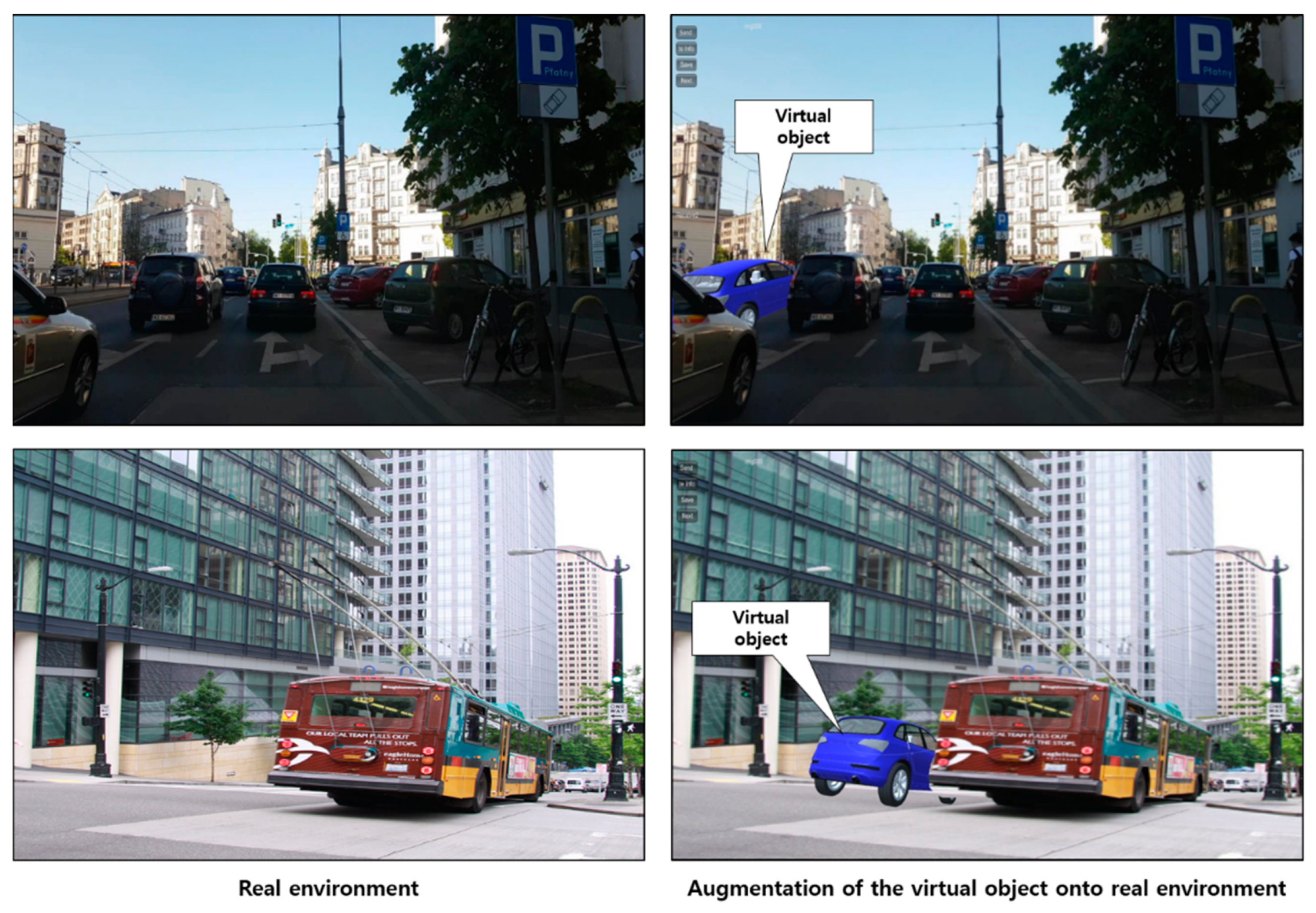

Typical industrial AR superimposes necessary manufacturing data around real equipment using AR markers for indirect object detection and visual registration. However, it is difficult to attach AR markers on the physical objects such as machines and facilities whose shapes are complicated. It is much more difficult to attach them if the configuration of the facility or equipment is dynamically moving during the operation. Note that it is challenging to acquire a 3D spatial relationship between physical objects from an RGB image using only one AR marker. Thus, it is necessary to attach multiple AR markers to them to solve this problem. However, it is sometimes infeasible to attach multiple markers. In addition, some of the markers cannot be adequately detected due to spatial occlusion when the viewpoint is changed. Therefore, visual mismatch and incorrect occlusion problems still occur in industrial AR environments, as shown in

Figure 1. These visual problems increase cognitive load and prevent the worker from understanding the required task quickly and accurately at the right time.

For example, although the manufacturing information can be visualized correctly from a particular viewpoint of the worker, as shown in

Figure 1a, the visual mismatch occurs when the viewpoint is changed. Besides, when the physical configuration of a facility such as a robot is changed, incorrect information is displayed to the worker. Furthermore, as shown in

Figure 1b, the equipment located near the worker is occluded by the AR view related to the far-off object irrespective of the distance between the worker and the actual equipment. Both examples indicate the inherent limitation of currently available AR systems.

For this reason, several previous studies have been conducted to support effective and user-friendly visualization by solving these problems in industrial AR [

8,

9,

10,

11]. However, most of them could not conduct object detection and find 3D spatial relations among different physical objects effectively in industrial AR. In particular, they could not correctly recognize the configuration of a dynamically moving object even if the AR marker was attached or area learning-based AR was used [

10]. One way to figure out the 3D spatial relations among facilities is to use a depth camera to scan them and acquire a 3D point cloud. However, most of the smart devices, such as smartphones and tablets, do not have depth cameras. While a depth camera is attached, AR markers are still required to recognize real objects [

12].

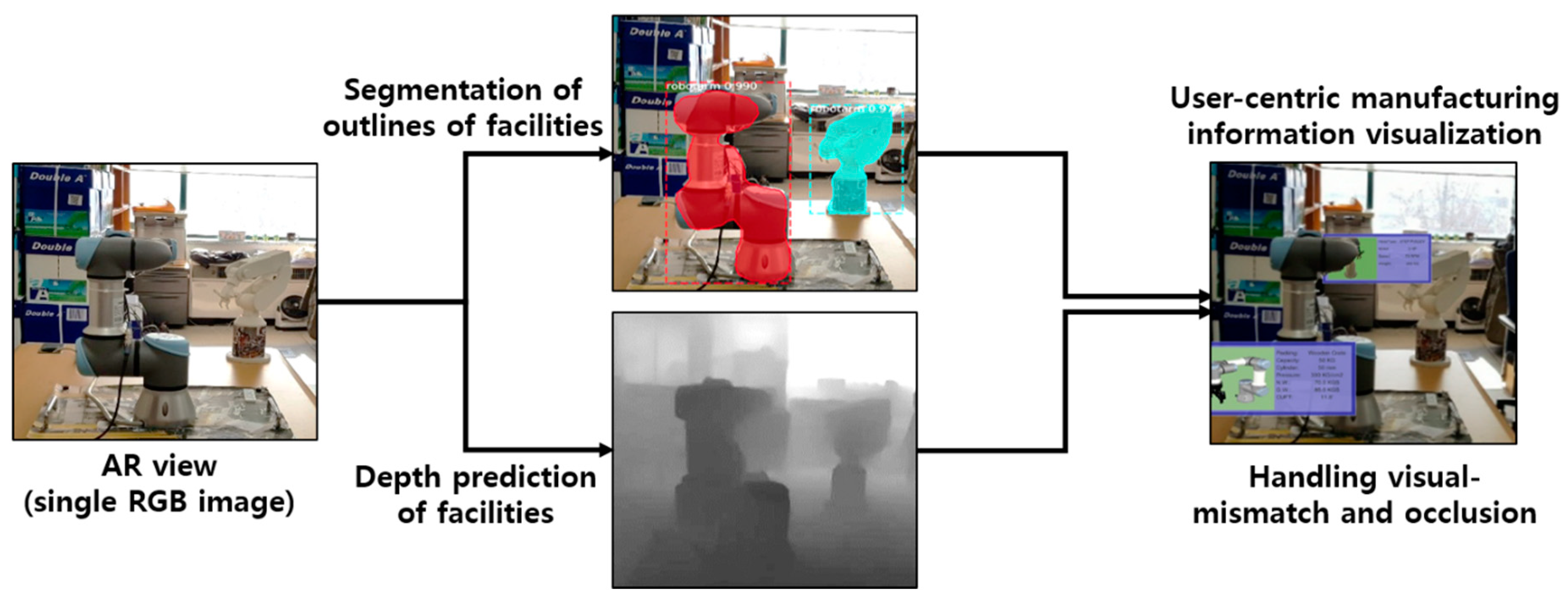

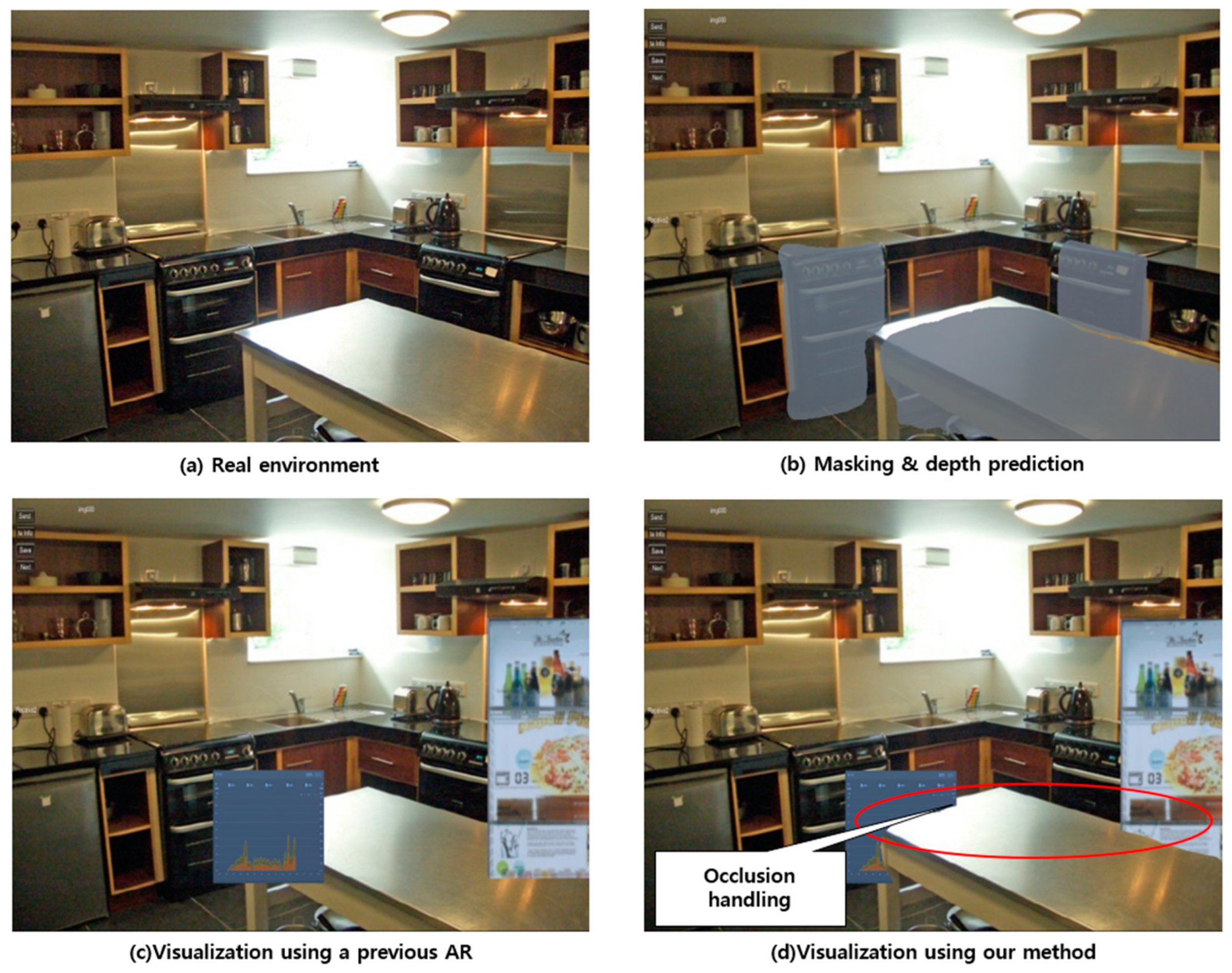

In this study, we propose a hybrid approach to industrial AR, which can complement existing AR methods and provide manufacturing information more effectively through the deep learning-based instance segmentation and depth prediction of physical objects in the AR scene. Deep learning-based instance segmentation is performed to recognize physical facilities and to outline their regions in the AR view (e.g., 2D RGB image), and the depth prediction using another deep learning is simultaneously conducted to predict a 3D depth map of those facilities from the same AR view, as shown in

Figure 2. Then, by combining the segmented regions of the real facilities and the 3D depth map, the 3D point clouds of the facilities and their 3D spatial relations are also segmented and constructed. Thus, the proposed industrial AR approach can not only solve the visual mismatch problem between manufacturing information and actual facilities, but also can handle occlusion properly, which is used to provide more user-friendly manufacturing visualization to improve the worker’s understanding of the environment. In addition to stationary objects, dynamically moving objects such as robots can also be handled to provide occlusion-free manufacturing visualization through facility segmentation and depth prediction.

The contributions of this study are as follows.

- (1)

A new industrial AR method is proposed to provide manufacturing information more intuitively and accurately by solving visual mismatch and occlusion problems through the deep learning-based instance segmentation and depth prediction.

- (2)

It is possible to handle dynamically moving facilities and visualize the manufacturing information more effectively.

- (3)

The proposed approach can complement existing AR methods. Thus, it can be utilized as a hybrid or complementing function to existing AR methods, since it can be activated whenever the industrial worker requires handing of visual mismatches or occlusions.

- (4)

The applicability and extensibility of this study can be confirmed through experiments and various viable implementations.

The paper is organized as follows.

Section 2 describes related research.

Section 3 presents the proposed industrial AR method.

Section 4 describes several implementation results of the proposed approach. Quantitative and qualitative analyses are conducted and evaluated in

Section 5.

Section 6 discusses the proposed approach. Finally,

Section 7 concludes the paper and presents future studies.

3. Industrial AR Using Deep Learning-Based Facility Segmentation and Depth Prediction

3.1. Overview of the Proposed Approach

This study proposes a new hybrid approach to industrial AR that can provide user-friendly manufacturing information to the worker more effectively and naturally by combining deep learning and augmented reality, which can complement existing AR methods. Instance segmentation is applied to the image of the AR view to detect actual equipment and tools and to segment their outlines from the AR image. Besides, depth information is predicted at the same time, using another deep learning approach. Then, the relative 3D spatial relationship between objects is calculated using the segmented object instances and predicted depth information. Finally, the manufacturing information is augmented on physical objects so that the worker can easily understand their tasks through AR scenes.

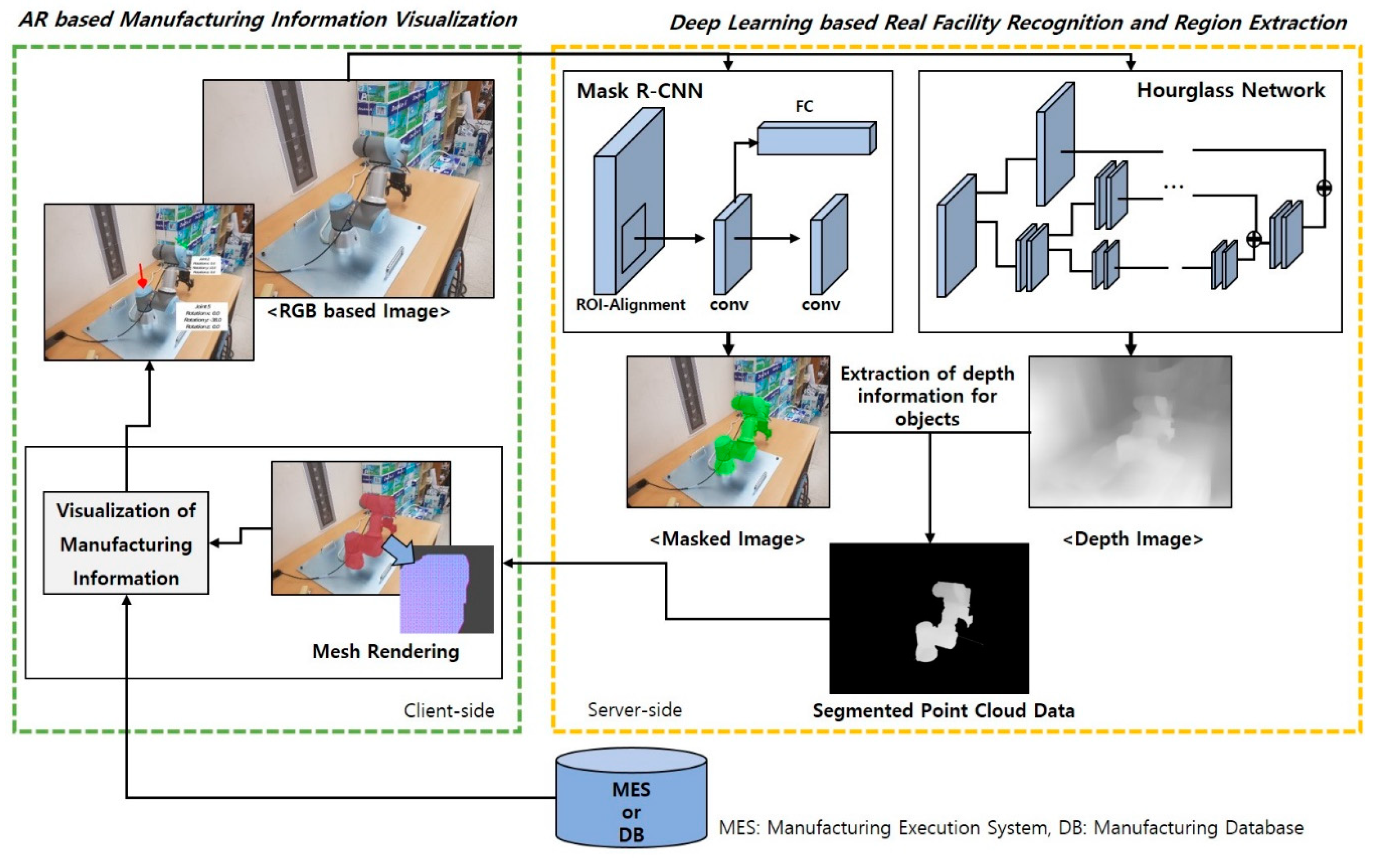

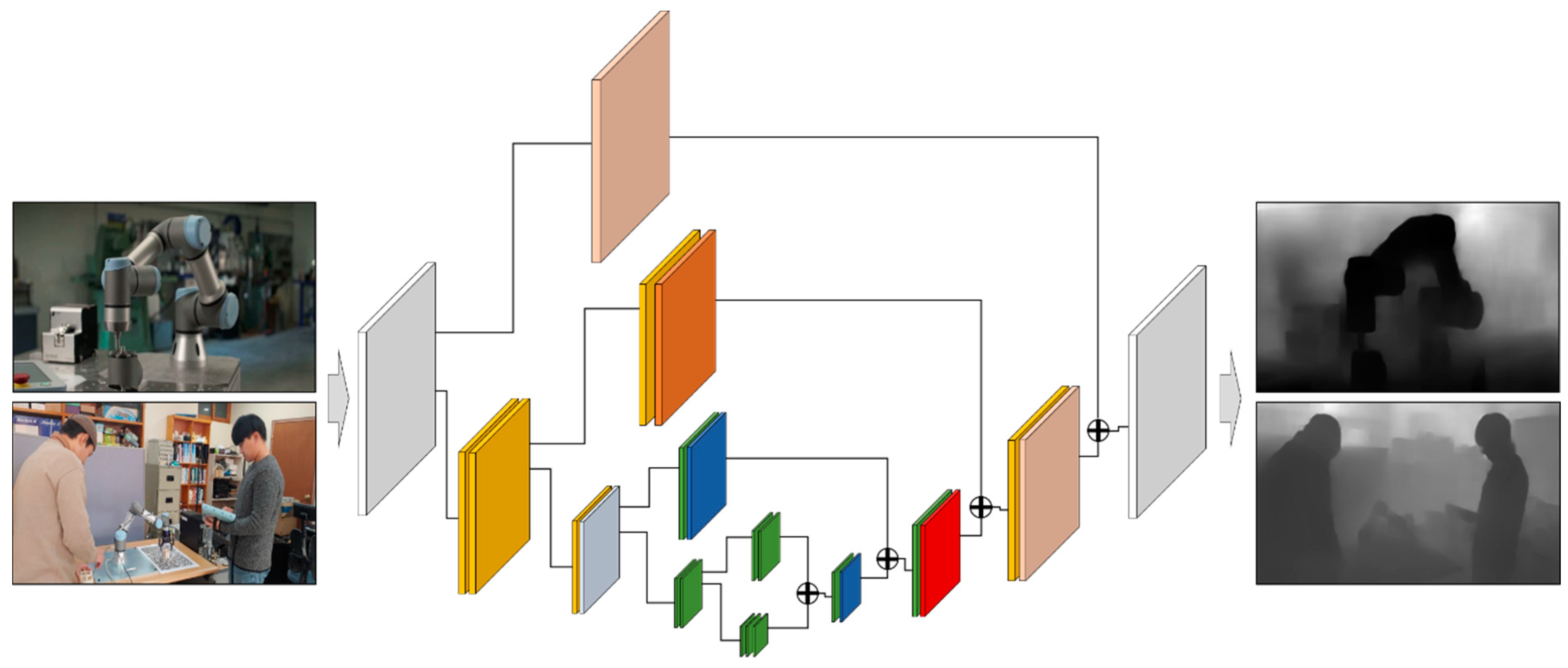

Figure 3 shows a schematic diagram of the proposed industrial AR, which consists of (1) deep learning-based facility recognition and region extraction and (2) AR-based manufacturing information visualization modules.

The deep learning-based facility recognition and region extraction module applies the mask region-based convolutional neural network (Mask R-CNN [

37]) to the RGB image captured by the AR camera, which detects actual facilities or tools and then segments the surrounding regions of the detected objects from the RGB image. At the same time, depth prediction is conducted to estimate the 3D depth map of the same AR image [

38,

39]. Then, the results of instance segmentation and depth prediction are combined to obtain a 3D point cloud of the detected facilities and spatial relationship among them.

The AR-based manufacturing information visualization module superimposes the required information onto the detected objects for task assistance. Firstly, it creates triangle meshes using the segmented and predicted 3D point cloud data. Then, a 3D spatial relation among real facilities is calculated from the constructed 3D meshes as the 3D meshes can be sorted in the ascending order in the depth map. Finally, a meshing rendering using a depth mask shader is applied to the 3D meshes for occlusion rendering, which makes the region of the object in the AR view depth-aware transparent. For example, the far object instance can be occluded by the near object instance, although there is no such information in the AR scene.

The deep learning methods used in this study are difficult to be executed in mobile or wearable devices directly because of their hardware and software restrictions. For this reason, a client-server module was developed to solve this problem. The module consists of the AR client and the remote deep learning server, as shown in

Figure 4. Smart devices or wearable devices play the role of the AR client. Firstly, the RGB-based AR image captured from the smart device is transmitted to the remote deep learning server through a network connection. The remote deep learning server is used to achieve instance segmentation and depth prediction of the physical facility in the AR image. Results are combined to generate the segmented 3D point cloud data of the physical object. Then, they are transmitted to the AR client. The AR client generates 3D meshes based on the segmented 3D point cloud. It also conducts the occlusion rendering to handle incorrect occlusions and solve visual mismatches. Finally, the AR client overlays manufacturing information on the AR display.

Although this study can solve the problems of existing AR, such as visual mismatches and incorrect occlusions, with deep learning it is difficult to guarantee real-time performance regarding providing manufacturing information to users. Therefore, the proposed approach can be utilized as a hybrid or complementing function to existing AR methods since it can be activated whenever the industrial worker requires handing of visual mismatches or occlusions. In other words, the proposed method and the existing AR method can be used at the same time, so that they can be switched with each other as needed, thereby complementing each other. Since the technology of deep learning and the performances of mobile devices are rapidly developing, it is expected that deep learning will be executed in real time on smart devices rather than via server–client connections sooner or later.

Note that the proposed approach can not only detect physical object instances but also segment the outlines of the objects whose configurations are dynamically moving and changing. Most of the previous AR works have not considered this issue. In addition, manufacturing information is augmented in the right position by overcoming visual mismatches and incorrect occlusions. For example, visual information of a certain facility that is far from the worker can be obscured by nearby facilities. Besides, manufacturing information of a nearby facility can be displayed in a larger and detailed form, and that of a remote facility can be displayed in a simplified and small form, which can provide a more intuitive and user-centric visual form.

3.2. Detection, Segmentation, and Depth Prediction of Real Facilities

It is crucial to acquire 3D spatial information and the class and position of each equipment to provide manufacturing information appropriate for task assistance in mobile AR.

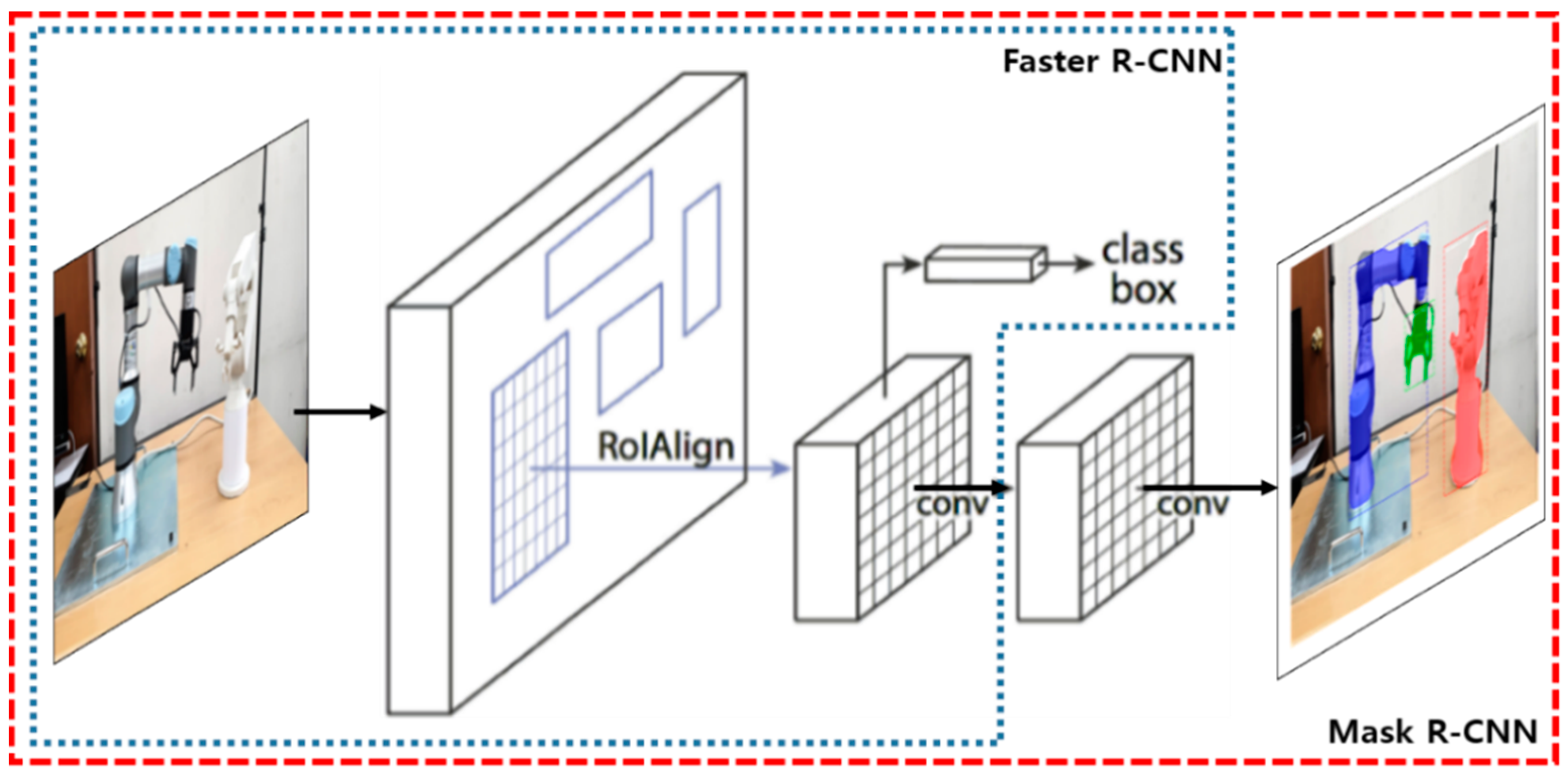

3.2.1. Object Detection and Facility Instance Segmentation

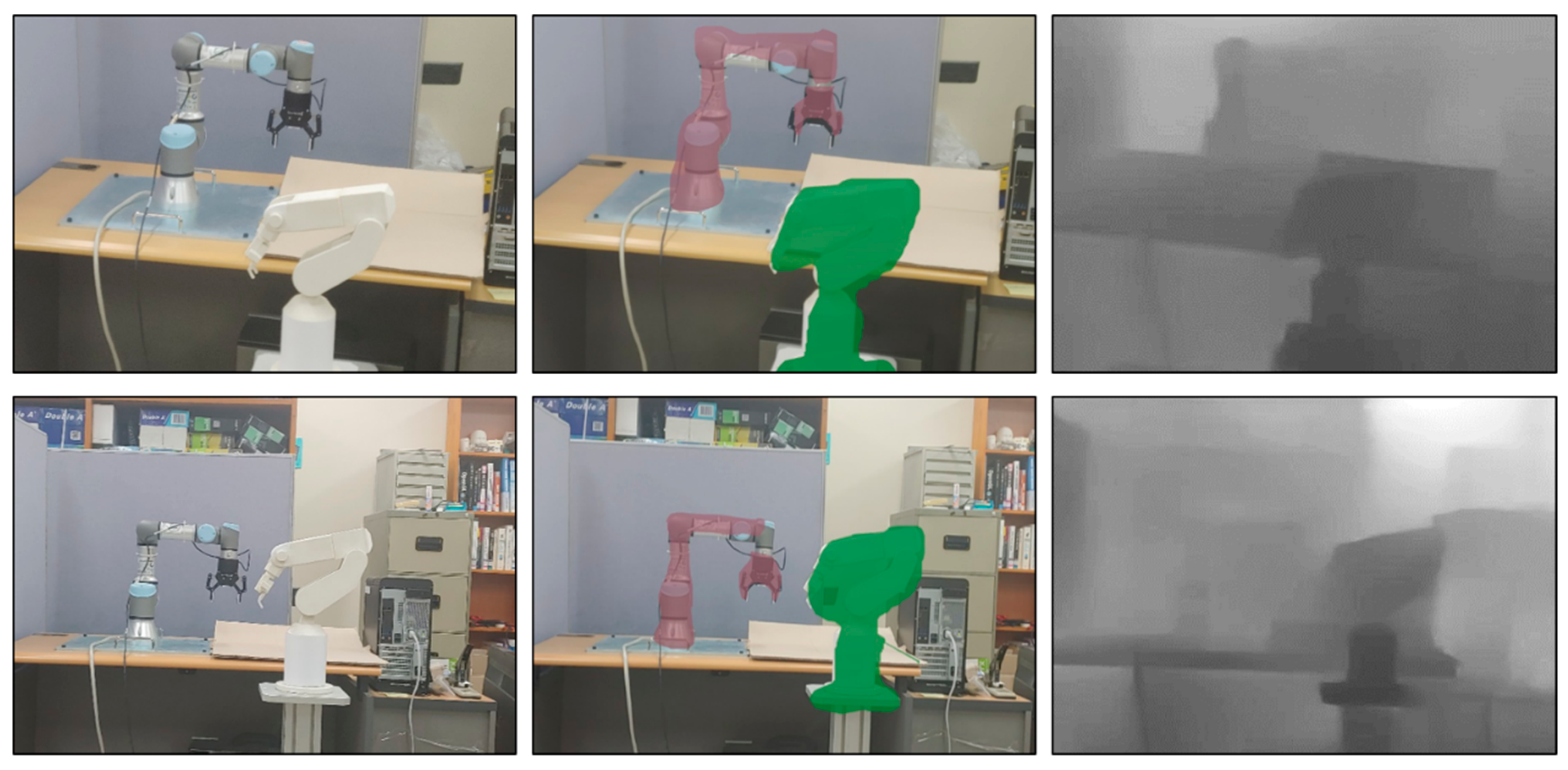

Object instance segmentation identifies object outlines at the pixel level by detecting objects and segmenting their regions in the RGB image, as shown in

Figure 5. Then, the object can be rendered in the pixel level according to the outline of the recognized object shape. For example, it can segment Universal Robot-3

TM (UR3) and its gripper from the AR view. Unlike object detection, which displays a detected object as a bounding box, instance segmentation accurately can render the region corresponding to the outline of the detected object. In particular, it recognizes the region as another object, even if it is classified into the same class. In this study, instance segmentation was conducted using the Mask R-CNN [

37] to outline the regions for real facilities from the AR image acquired through smart devices, as shown in

Figure 5.

Mask R-CNN extends Faster R-CNN [

40] by adding a branch for predicting segmentation masks on each region of interest (RoI), in parallel with the existing branch for classification and bounding box regression [

37]. The mask branch is a fully convolutional network (FCN) applied to each RoI, predicting a segmentation mask in a pixel-to-pixel manner. Mask R-CNN has two stages for instance segmentation. The first stage scans the image and generates region proposals. The second stage classifies the proposals and generates bounding boxes and masks. In the first stage, the region proposal network (RPN), like Faster R-CNN, is used to predict the bounding box for the object. However, in Mask R-CNN, RoIAlign was used instead of RoIPool for accurate segmentation and fixing misalignment.

Mask R-CNN defines a multi-task loss on each sampled RoI as follows (Equation (1)).

The classification loss

and the bounding-box loss

(Equation (2)) are identical as those defined in Faster R-CNN [

40] as follows.

where

p and

t represent the size and position of the predicted classes and bounding box, and

u and

v represent the size and position of the real class and bounding box.

Finally, the mask loss is defined as the average binary cross-entropy.

3.2.2. Depth Prediction

By conducting the instance segmentation mentioned above, it is possible to calculate 2D spatial relations, such as relative positions between real objects. However, since the depth information is unknown, a 3D spatial relation cannot be derived, which can cause visual mismatch and occlusion problems. To calculate the 3D spatial relationships between objects from the AR view, depth information must be predictable. Note that mobile AR also utilizes a single image so that it cannot percept depth information from the single image without AR markers. In this study, depth information was predicted through an hourglass network by training MageDepth Dataset [

38,

39]. Depth prediction aims to recover depth information from a single RGB image taken from a camera. As shown in

Figure 6, the hourglass network consists of a series of convolutions using a variant of the inception model and down-sampling, followed by a series of convolutions and up-sampling, interleaved with skip connections that add back features. The symmetric shape of the network resembles an hourglass. Through this process, the depth information of the RGB image can be acquired, and the resolution of the depth information is the same as that of the RGB image.

The scale-invariant loss function

L (Equation (3)) combines three terms as follows [

38].

The scale-invariant data loss

(Equation (4)) calculates the mean square error of the difference between all pairs of log-depths. Let

L be a predicted log-depth map and

a ground truth long-depth map.

and

denote corresponding individual log-depth values indexed by pixel position

i.

where

and

n is the number of valid depths in the ground truth depth map.

The scale-invariable gradient matching loss

(Equation (5)) makes gradient changes smoother and depth discontinuities sharper in the predicted depth map. It is defined as an

L1 penalty on differences in log-depth gradients between the predicted and ground truth depth map as follows.

where

is the value of the log-depth difference map at position

i and scale

k.

The ordinal depth loss

(Equation (6)) encourages the predicted depth map to agree with the ground-truth ordinal relations as follows.

where

and

is the automatically labeled ordinal depth relation between

i and

j (

if pixel

i is further than

j and −1 otherwise).

As a result, the segmented 3D point cloud data of the detected facilities can be acquired by combining the predicted depth information with the outcome of instance segmentation. Since the dimension of the predicted information is the same as that of the RGB image, the segmentation of 3D point clouds corresponding to the detected facilities from the predicted depth map is straightforward.

3.3. Industrial AR-Based Manufacturing Information Visualization

When information on the segmented 3D point cloud data is transmitted to the mobile device of the worker together with the classification information of the detected facilities, all the information is combined to handle visual mismatches and incorrect occlusions in manufacturing information visualization. Since segmented point cloud data do not contain surface information for rendering and occlusion handling, a triangular mesh is constructed from the segmented point cloud of each object instance. If there are multiple detected object instances, several triangular meshes are generated. Each triangular mesh can represent a detected object in the 3D AR space. A Delaunay triangulation was applied to construct a triangular mesh of the segmented 3D point cloud of each object instance [

41,

42], as shown in

Figure 7. A meshing rendering using a depth mask shader is applied to the triangular mesh for occlusion rendering, which makes the region of the object in the AR view depth-aware transparent.

As 3D spatial relation can be derived from the 3D meshes of segmented instances, the location and orientation of a visual information panel or object can be easily synchronized with the detected real facility.

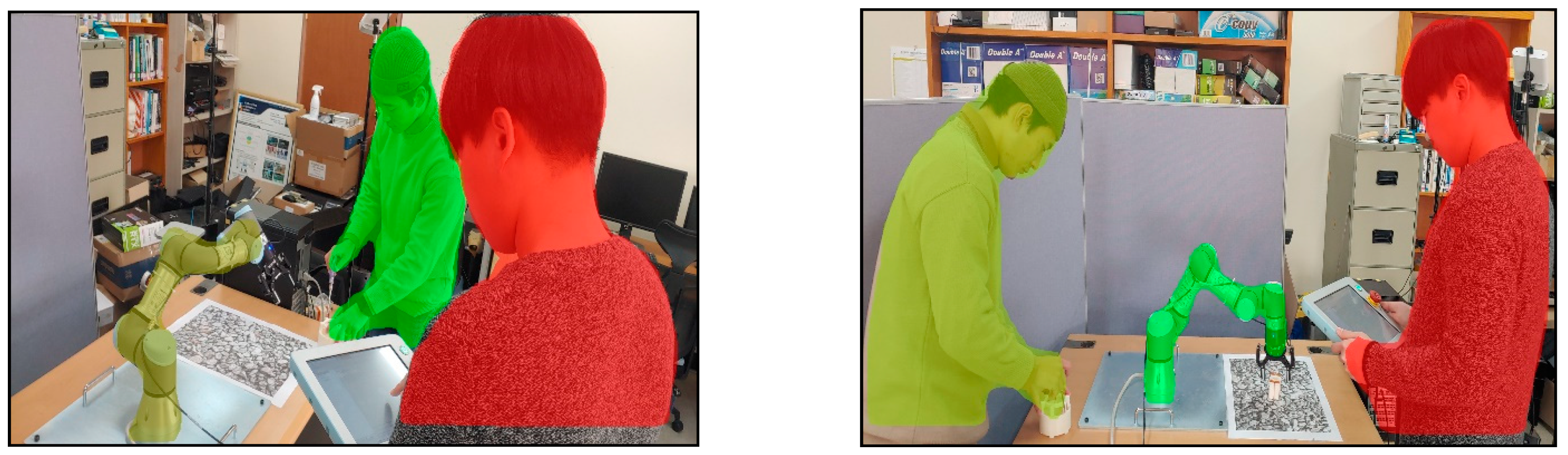

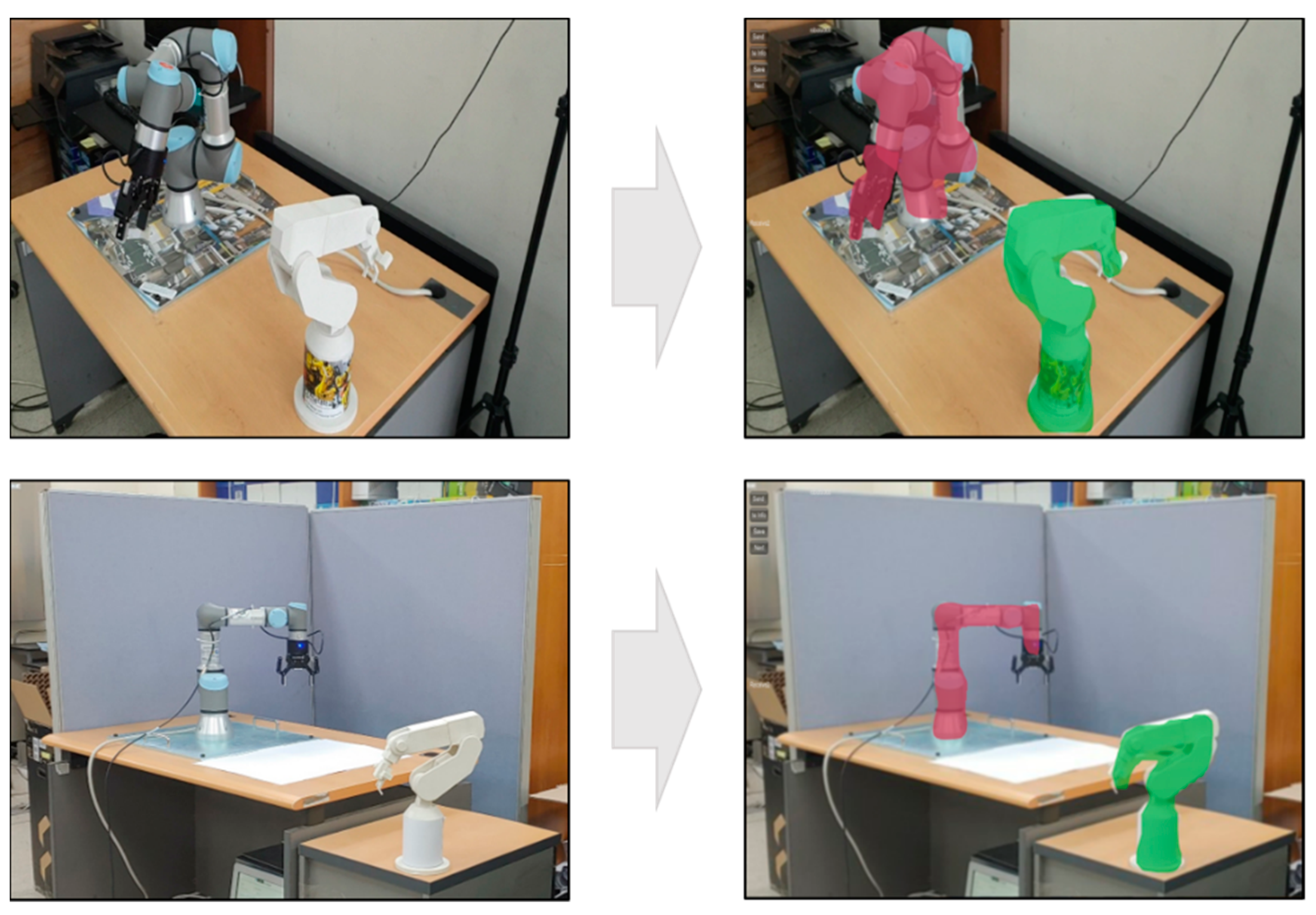

Figure 8 shows the segmented objects and their spatial relations according to the different viewpoints of the worker. The segmented object with the red color is located near the worker, and that with the green color is located far from the worker.

Figure 9 and

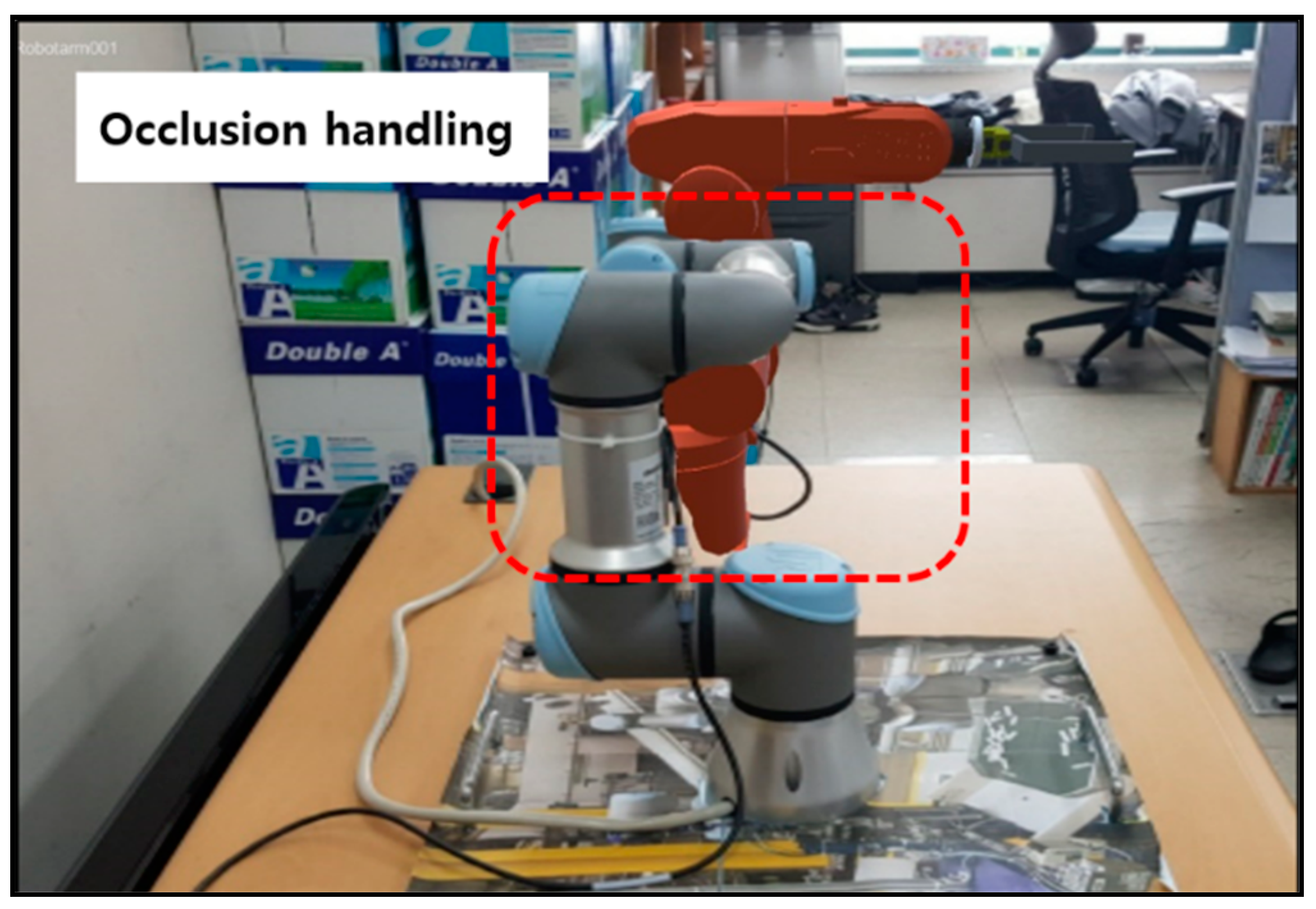

Figure 10 show how the proposed AR can handle the occlusion properly and can provide depth-aware and intuitive visualization to the worker. The manufacturing information corresponding to the actual facility can be visualized dynamically and adaptively around the facility according to its location and spatial relation. As shown in

Figure 9, the virtual object (robot) on the rear side is occluded adequately by the UR3 robot closer to the worker.

In particular, even if the actual equipment is dynamically operating or moving by changing its configuration, the manufacturing information can be positioned around the equipment properly by updating its location, as the proposed approach can detect and segment facilities and predict their 3D depths and spatial information. On the other hand, when the existing AR marker is used, there is no problem in visualizing fixed and stationary equipment, but visual mismatching occurs when the position and configuration of the equipment are changed.

Figure 10 shows how to effectively perform the manufacturing information visualization for the gripper attached to the UR3 robot using the proposed AR method. As the UR3 robot moves to grip a product or a component, the configuration of the robot changes the position and orientation of the gripper. Nevertheless, the proposed approach can recognize the movement of the gripper and consistently augments the relevant information, which can solve the common visual mismatch in the AR environment. These examples prove the effectiveness and advantage of the proposed approach.

4. System Implementation and Comparative Evaluation

We implemented the proposed industrial AR, which can segment actual facilities and predict their 3D depths from the AR view for task assistance. Instance segmentation and depth prediction can run on either TensorFlow [

43] or Pytorch [

44] in Windows 10. Two GPUs with GTX 1080 Ti architecture were used for training and testing. One GPU is assigned to instance segmentation, and the other to depth prediction. The industrial AR application was developed using Unity3D [

45]. For the evaluation of the industrial AR, an additional seven classes based on pre-trained weights of the COCO dataset [

46] were trained and tested, including UR3 robot, gripper, press machine, etc. Each class was trained with 250 segmented images. The learning rate was 0.001, and the epoch was 100. For training depth prediction, 130,000 images were used [

38,

39]. The learning rate was 0.0002, and the epoch was set to 30. To verify the feasibility and viability of the proposed approach, it was implemented in two environments, a controlled laboratory environment and a testbed for a smart factory.

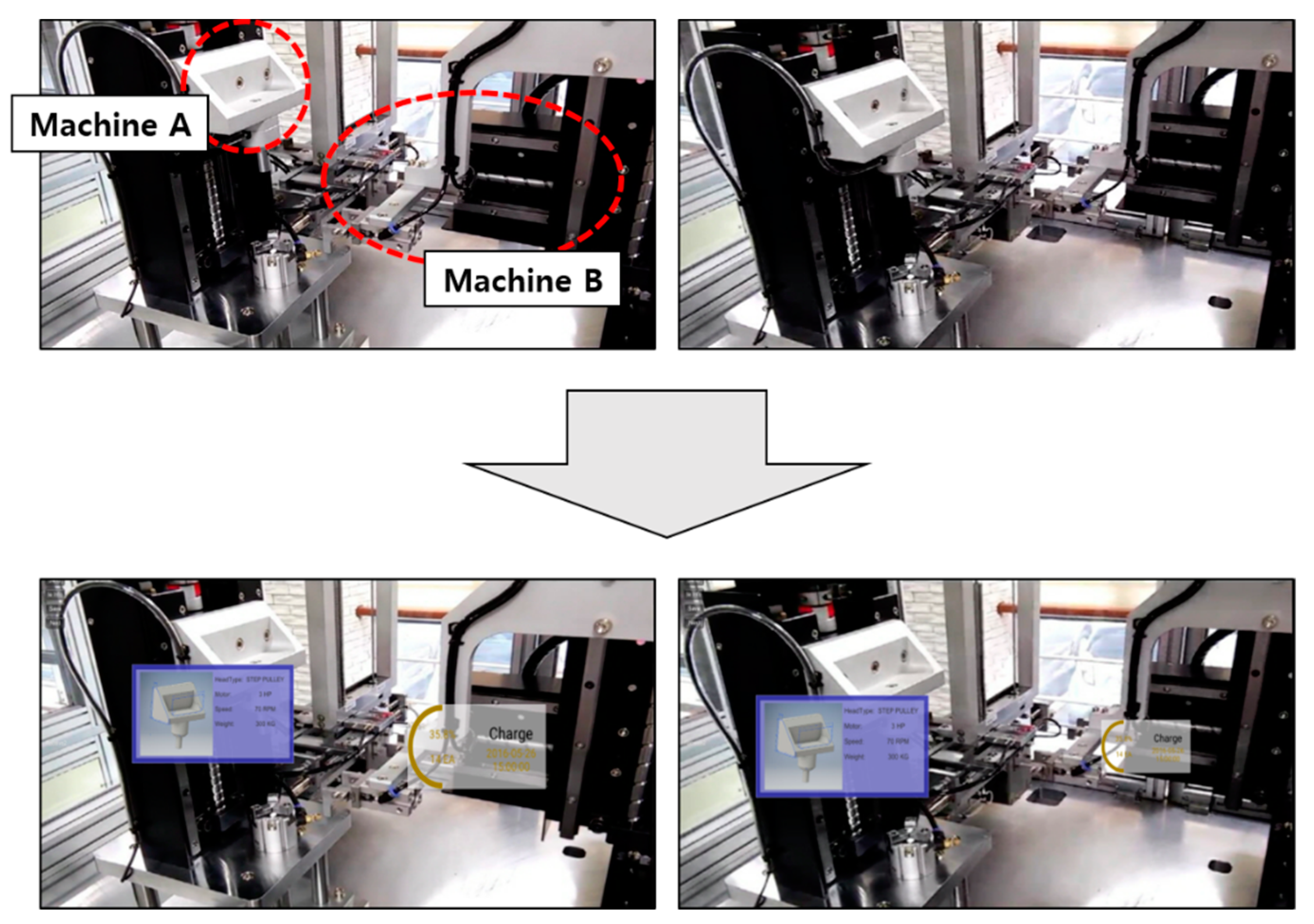

We compared the proposed industrial AR with conventional AR marker-based methods (e.g., planar and cylindrical markers) using a popular Android-based smartphone (Samsung Galaxy S9TM) and another AR method using a smartphone with an RGB-D camera (Google TangoTM). In the case of AR marker-based methods, the 3D model is overlaid on the AR marker when the AR method recognizes the marker. In the case of the method using the RGB-D camera, the outline of the facility is segmented using the Mask R-CNN used in the proposed approach, but only the point cloud data corresponding to the segmentation are extracted from among those obtained by the RGB-D camera. Two experiments were conducted to evaluate three methods. First, we examined the effectiveness of the recognition of real equipment according to the variable distance. Different color gradation is used to represent the distance from the AR system. For example, the color becomes darker when the detected object is far from the user. Second, we evaluated the recognition of dynamically moving equipment. Note that one of the main advantages of the proposed industrial AR visualization is that it does not require a depth sensor.

4.1. Recognizable Distances of Real Objects

We evaluated whether each method can detect and superimpose a virtual model onto corresponding real equipment consistently and effectively depending on the distance between the AR camera and the equipment. For this purpose, each AR system was located at a distance of 1, 3, or 5 m from the UR3 robot and another robot prototype created using a 3D printer, as shown in

Figure 11.

First, the cylindrical AR marker-based method showed the worst performance. On the other hand, the proposed method showed the best performance without AR markers and an RGB-D sensor. When a cylindrical AR marker was attached to the physical object, the marker was recognized at a distance of 1 m, but the marker was not identified at distances of 3 and 5 m (

Figure 11b). The size of the cylinder-shaped AR marker was 8.5 cm in diameter and 7 cm in height due to the geometric shape of the prototype. The rectangular AR marker was recognized at distances of 1 m and 3 m, but the AR marker was not recognized at a distance of 5 m. Note that the marker was attached to the perpendicular direction to the AR camera for easy recognition.

However, this attachment was not normal. When the marker was attached to the floor, its recognition rate became worse. As shown in

Figure 11c, when the real object was detected using the same instance segmentation using the RGB-D camera, depth information of the actual equipment was only acquired at distances of 1 m and 3 m. In the case of the RGB-D camera [

10], the range of obtaining the depth information is about 50 cm to 4.5 m. Furthermore, the accuracy of the depth perception depends on the material type and distance too much. Unlike the conventional AR marker-based and RGB-D sensor-based approaches, the method proposed in this study recognized real facilities more consistently and accurately at all distances, as shown in

Figure 11d. In addition, it can also construct the 3D spatial relations among the detected facilities.

Figure 12 shows that the proposed approach can effectively find the spatial relations, although the interesting objects are separated a lot concerning the spatial relation in

Figure 11.

Table 1 shows quantitative results for measuring the recognition rate and processing time of the experiment in

Figure 11. For 5 m, the marker-based method cannot recognize the objects at all, although it can run in real-time. In particular, the method cannot detect the cylindrical marker, even at 3 m. Furthermore, the existing marker-based methods cannot deal with occlusion and visual mismatch properly. The RGB-D camera cannot also recognize objects at a distance of 5 m. Only the proposed approach can recognize objects correctly. Note that most mobile devices such as smartphones and tablets on the market today do not have RGB-D cameras so that the proposed approach could be more practical. Due to the processing of deep learning and mesh generation, it takes about one second for AR visualization. Nevertheless, the proposed approach can deal with incorrect occlusion and visual mismatch that prohibit the worker from understanding the manufacturing situation correctly and effectively. Concerning the advantages of each approach, the proposed method and the existing AR method can be used at the same time so that they can be switched to each other as needed, thereby complementing each other.

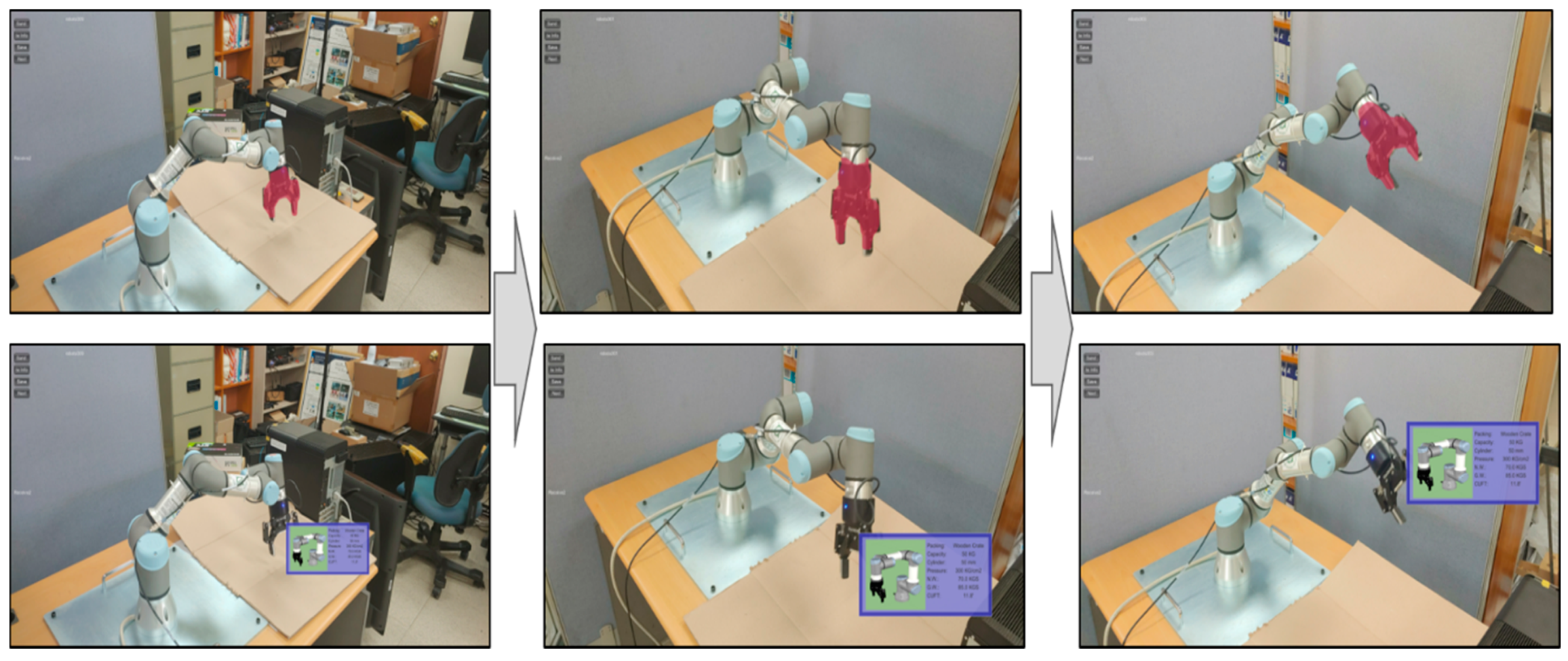

4.2. Handling Dynamically Moving Objects

We have also evaluated the capability for handling dynamically moving objects. As shown in

Figure 13, two AR markers were used in the marker-based method. The first marker was attached to the body of the UR3 robot, and the other was attached to the gripper to detect them separately during the movement. On the other hand, the proposed approach does not need any AR makers.

Note that one of the advantages of using the AR marker is to detect actual facility fast and accurately. However, when the configuration of the facility is changed, or the facility is moving, it is almost impossible to detect parts or components attached to the facility without receiving additional information through other sensors. Furthermore, it is still difficult to detect and segment the facility itself, and their components as AR markers might be occluded when the facility and their parts are moving, as shown in

Figure 13. Such problems make it difficult to attach AR markers on the dynamically moving equipment, which may prevent the industrial worker from performing the task properly. On the other hand, the proposed approach can detect and segment the dynamically moving equipment with only single AR images. Besides, the equipment can be recognized at various perspectives even if the worker’s position changes. These assessments prove the novelty and advantage of the proposed approach.

6. Discussion

Existing AR methods have difficulties in handling incorrect occlusions and visual mismatches and in estimating depth from AR images, which prevents the industrial worker from conducting manufacturing tasks effectively. To solve these inherent problems in existing AR methods, this study proposed a new hybrid approach to industrial AR for complementing existing AR methods using deep learning-based facility segmentation and depth prediction without AR markers and a depth camera.

Several case studies and experimental analysis in

Section 5 verified the advantage of the proposed approach compared with existing AR methods. In particular, handling incorrect occlusions and visual mismatches can make the worker understand the manufacturing situation more effectively and intuitively. Note that the proposed approach does not require the RGB-D camera.

Nevertheless, there is some room for improvement and investigation. The depth prediction does not always construct 3D depth maps accurately depending on the background color and its complexity, as shown in

Figure 19 (right). Nevertheless, by combining instance segmentation and depth prediction, it might be possible to estimate 3D spatial relations between detected objects correctly, since instance segmentation and depth prediction can complement each other. However, it is necessary to improve the capability of the depth prediction by training a variety of data and improving the deep learning network. In addition, since the mobile device has hardware and software limitations, the deep learning methods run remotely. Although it is expected that deep learning can run on a mobile device, it is still necessary to devise a more efficient deep learning architecture such as an end-to-end deep learning model that supports both instance segmentation and depth prediction to improve the speed and accuracy.

Nevertheless, the proposed approach and an existing AR method complement each other. That is, for ordinary situations, the existing AR method is used, since it can support real-time marker tracking. However, as the existing AR cannot handle incorrect occlusions and visual mismatches, the worker can switch to the proposed approach to understand the situation more effectively and intuitively.

7. Conclusions

This paper proposed a new industrial AR method that can handle visual mismatches and incorrect occlusions of previous AR methods in representing manufacturing information by applying deep learning-based facility segmentation and depth prediction. From a single AR image, object instances are detected and segmented. At the same time, depth prediction is applied to the same AR image. Then, a segmented 3D point cloud for each detected object can be easily generated. Besides, a 3D triangular mesh is constructed from the segmented 3D point cloud, which makes it possible to find 3D spatial relations among the detected objects and render them in the 3D AR space rather than the image-based AR space. The constructed 3D mesh and spatial relation are used to solve visual mismatch and occlusion problems. Furthermore, the proposed approach can provide consistent AR visualization regardless of the movement of the physical object. Therefore, manufacturing information can be provided to the worker more intuitively and situation-dependently based on the estimated 3D spatial relation and depth perception. Note that the proposed approach can be utilized as a hybrid or complementing function to existing AR methods, since it can be activated whenever the industrial worker requires handing of visual mismatches or occlusions. For another possible storyboard, a facility manager can utilize the proposed approach, since the manager has difficulty in monitoring and maintaining the facility by looking at its outside or surface. In such a case, it would be more helpful to combine various IoT sensor data with the proposed AR system.

In future research, we will improve the deep learning network architecture because it is affected by the performance of the deep learning network. In addition, the proposed approach will be applied to various industrial environments. Furthermore, we will also design more storyboards of actual and realistic industrial situations.