Classifying the Biological Status of Honeybee Workers Using Gas Sensors

Abstract

1. Introduction

1.1. Biological Status of Worker Bees vs. Odor

1.2. The Context of the Problem in Practical Beekeeping

1.3. Achievements to Date in the Use of Gas Sensors for this Type of Task

2. Materials and Methods

2.1. Characteristics of the Studied Objects

- Young workers—class 5

- Old workers—class 6

- Workers from colonies with physiological laying worker bees—class 7 (Table 1)

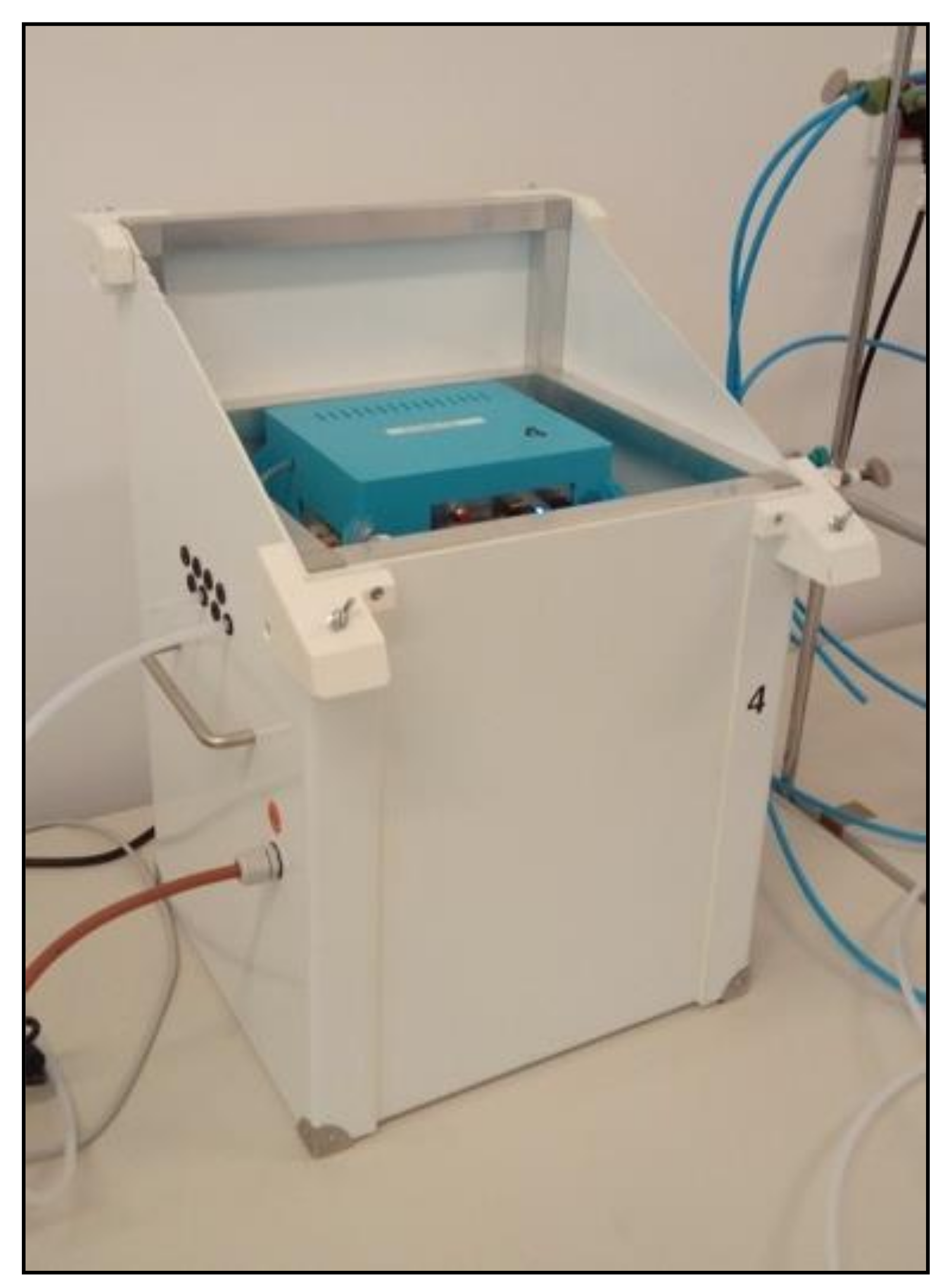

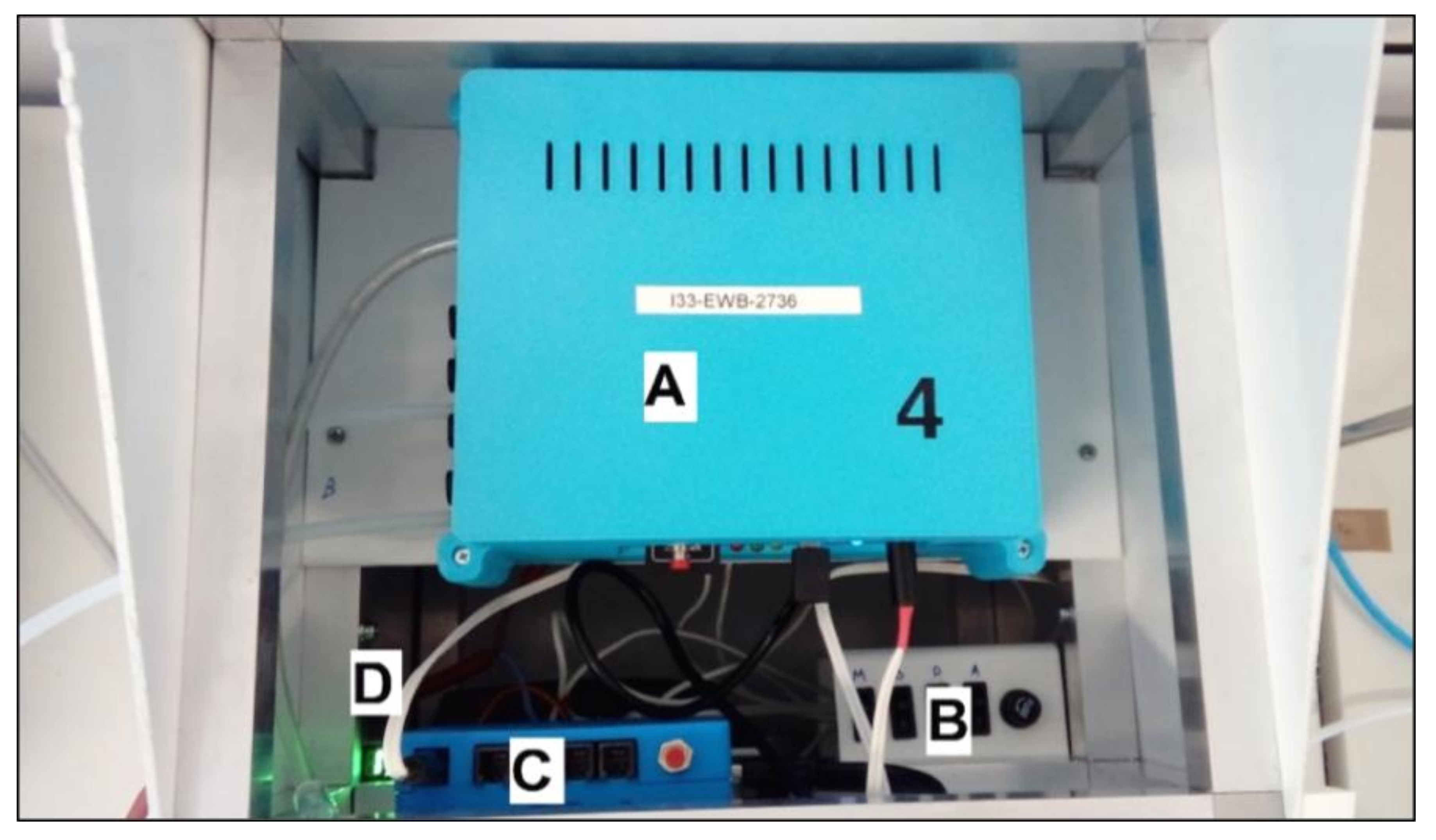

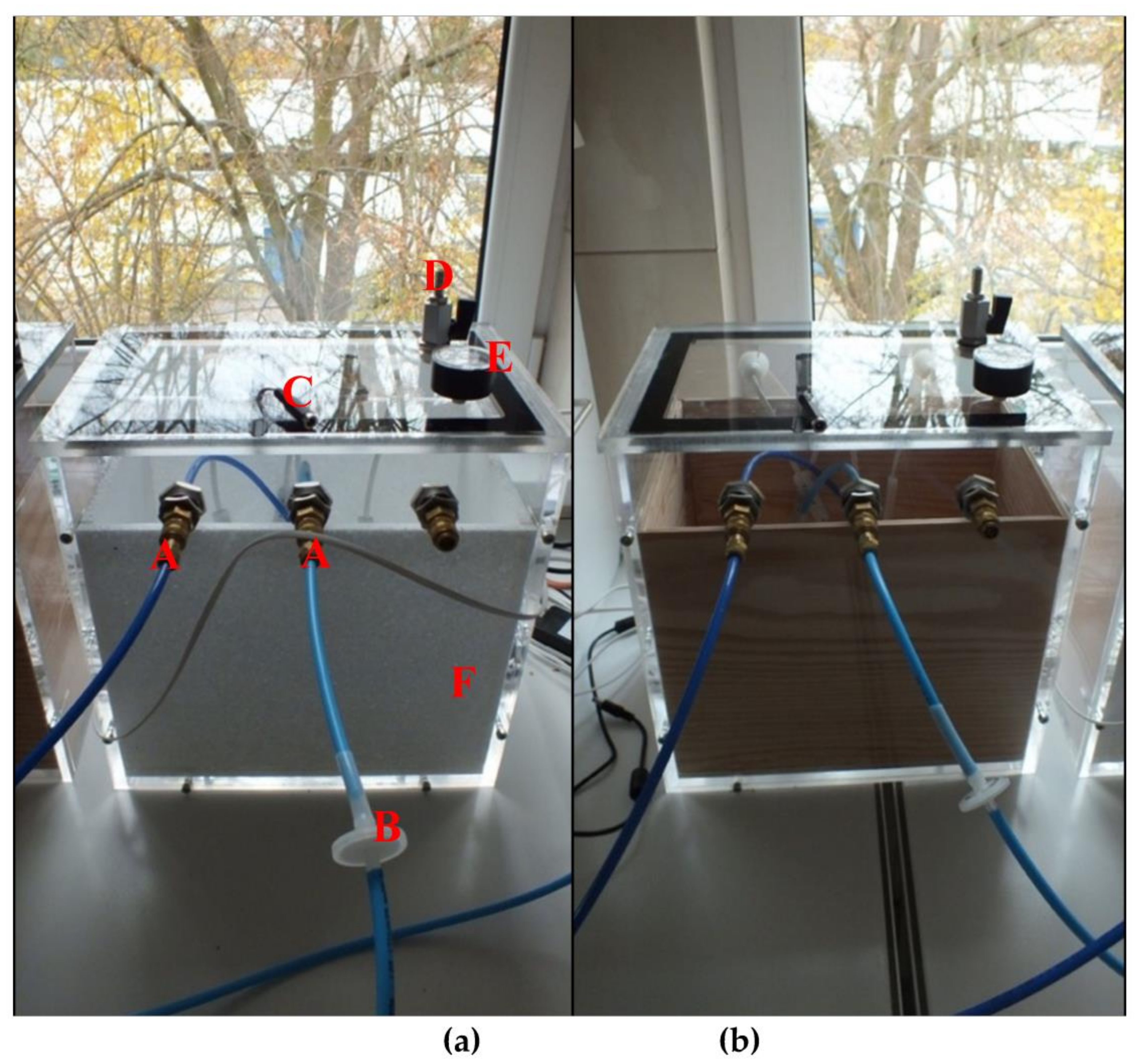

2.2. Construction of a Laboratory Measuring Stand—Multi-Sensor Signal Recorder

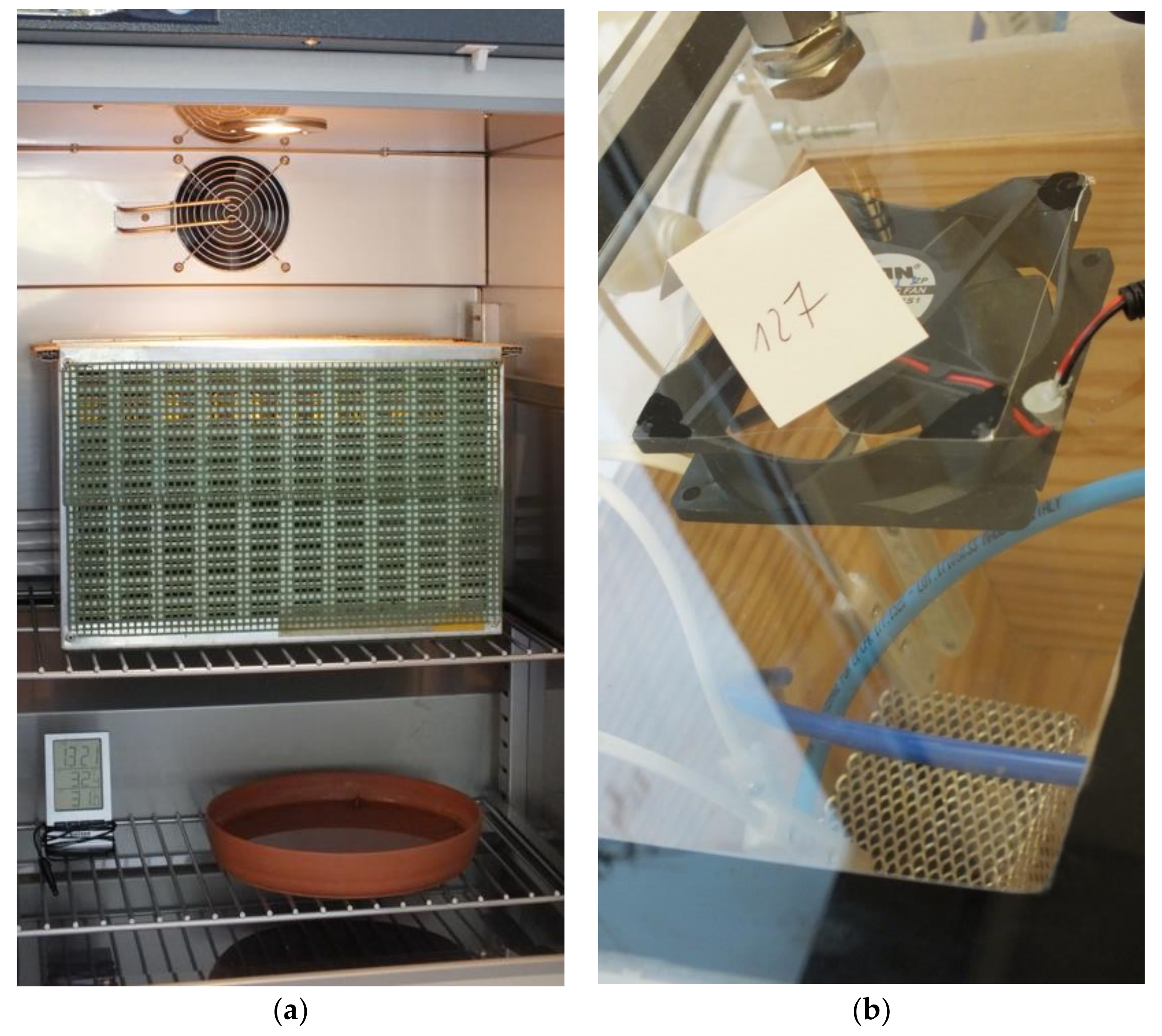

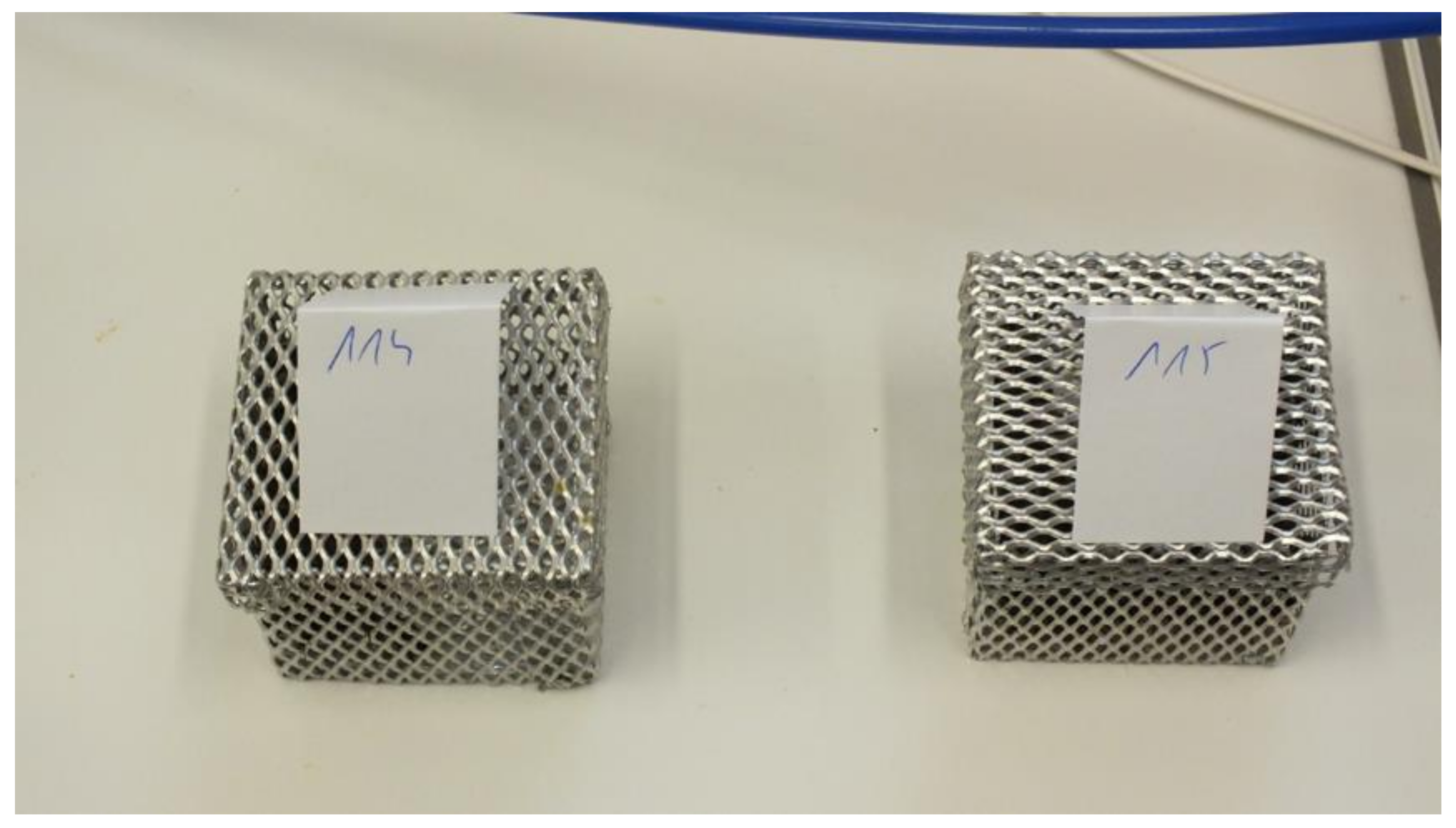

2.3. Construction of a Laboratory Measuring Stand—Resarch Chamber

- a tight structure, aimed at eliminating factors that may interfere with the odor of the tested objects,

- small dimensions, maximizing the concentration of volatile substances around the sensors,

- adjustable tightness of test chambers in terms of the possibility of external gas inflow,

- using neutral, odorless materials to build the chambers, with removable inserts,

- the possibility of measuring the pressure in the chamber,

- the possibility of mechanical equalization of the level of volatile substances from the tested object in the entire volume of the chamber through use of the fan, and

- the possibility of simultaneous measurement of a given object with at least two devices.

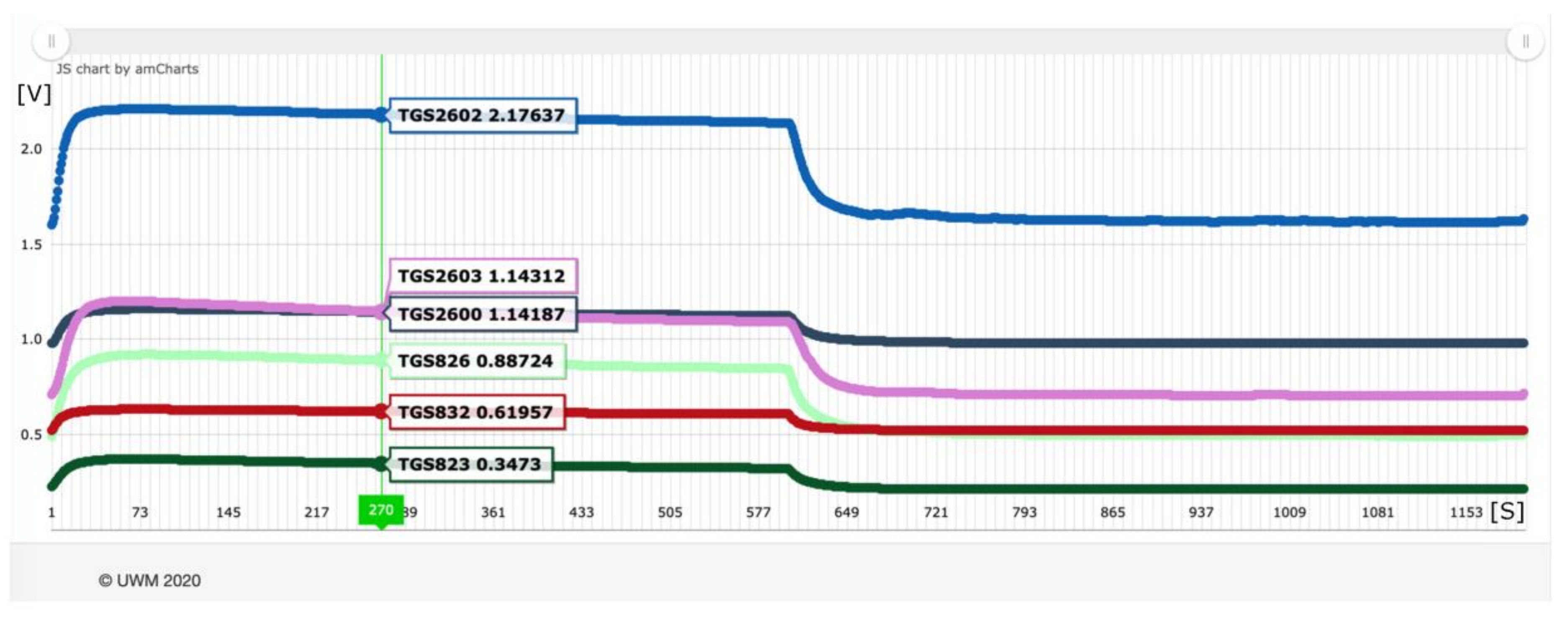

2.4. Measurement Procedure

2.5. Data Analysis Procedure

3. Results

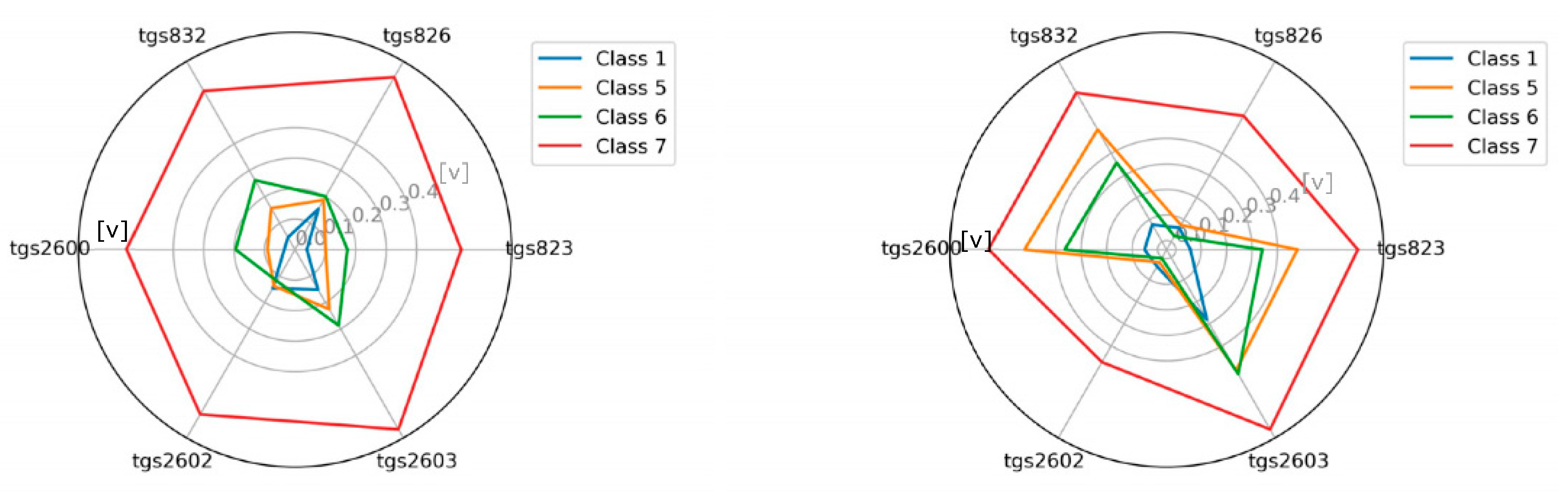

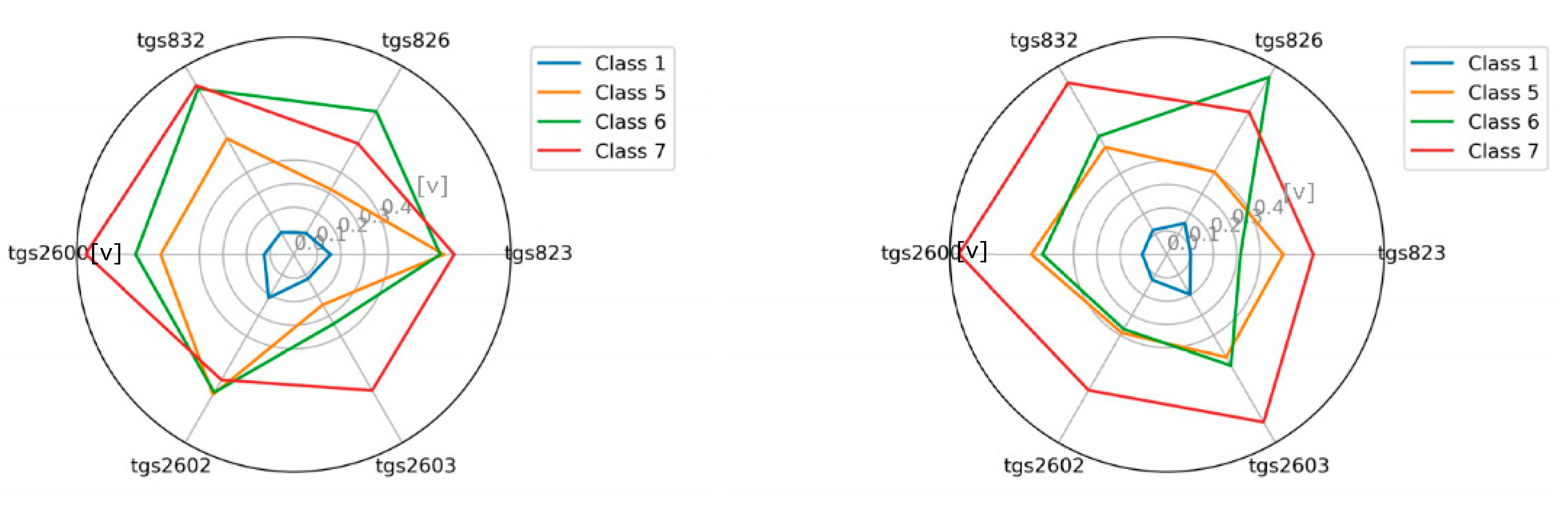

3.1. The Visualization of the Tested Classes

3.2. Searching for the Dedicated Method—Selected Results

- (I)

- M1 device in a wooden box,

- (II)

- M1 device in a polystyrene box,

- (III)

- M2 device in a wooden box,

- (IV)

- M2 device in a polystyrene box,

- (V)

- M1 device in a wooden box using baseline correction,

- (VI)

- M1 device in a polystyrene box using baseline correction,

- (VII)

- M2 device in a wooden box using baseline correction, and

- (VIII)

- M2 device in a polystyrene box using baseline correction.

- all classes together,

- 1 vs. 5,6,7,

- 5 vs. 1,6,7,

- 6 vs. 1,5,7, and

- 7 vs. 1,5,6.

- canberra.1nn,

- canberra.811,

- eps = 0.01.nb,

- eps = 0.01.nb2,

- euclidean.1nn,

- euclidean.811,

- manhattan.1nn,

- manhattan.811,

- maxminnormalized.1nn, and

- maxminnormalized.811.

- Accuracy balanced, the best classifier is m5, in five options, reaching the value of 0.646 for Option III,

- True positive rate for class 1, the best classifier is m2, in four options, in three options reaching the value of 1,

- True positive rate for class 5, the best classifiers are m5 and m10 pari passu, each in two options, while the m1 classifier reaches the highest value of up to 0.674 in Option VII,

- True positive rate for class 6, the best classifiers are m4 and m5 pari passu, each in two options, while the m5 classifier reaches the highest value of up to 0.684 for Option VI, and

- True positive rate for class 7, the best classifier is m5 in three options, with m10 reaching the highest value of 0.844 for Option V.

4. Discussion

4.1. Four-Class Problem

4.2. Choosing the Best Classifier to Distinguish Class 7

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Van Zweden, J.S.; D’Ettorre, P. Nestmate recognition in social insects and the role of hydrocarbons. In Insect Hydrocarbons; Blomquist, G.J., Bagneres, A.-G., Eds.; Cambridge University Press: Cambridge, UK, 2010; pp. 222–243. [Google Scholar] [CrossRef]

- Vernier, C.; Krupp, J.; Marcus, K.; Hefetz, A.; Levine, J.; Ben-Shahar, Y. The cuticular hydrocarbon profiles of honey bee workers develop via a socially-modulated innate process. eLife 2019, 8, e41855. [Google Scholar] [CrossRef] [PubMed]

- Butler, C.G. Queen Substance. Bee World 1959, 40, 269–275. [Google Scholar] [CrossRef]

- Hoover, S.; Keeling, C.; Winston, M.; Slessor, K. The effect of queen pheromones on worker honey bee ovary development. Naturwissenschaften 2003, 90, 477–480. [Google Scholar] [CrossRef] [PubMed]

- Rojek, W.; Kuszewska, K.; Ostap-Chęć, M.; Woyciechowski, M. Do rebel workers in the honeybee Apis mellifera avoid worker policing? Apidologie 2019, 50, 821–832. [Google Scholar] [CrossRef]

- Gregg, A.L. The Unexplained Queen. Bee World 1939, 20, 133–134. [Google Scholar] [CrossRef]

- Woyke, J. Drones from fertilized eggs and biology of sex determination in the honeybee. Bull. Acad. Polon. Sci. Cl. 1963, 9, 251–254. [Google Scholar]

- Gardner, J.W.; Bartlett, P.N. A brief history of electronic noses. Sens. Actuators B Chem. 1994, 18, 210–211. [Google Scholar] [CrossRef]

- Dymerski, T.; Gebicki, J.; Wardencki, W.; Namieśnik, J. Application of an Electronic Nose Instrument to Fast Classification of Polish Honey Types. Sensors 2014, 14, 10709–10724. [Google Scholar] [CrossRef]

- Szczurek, A.; Maciejewska, M.; Bąk, B.; Wilk, J.; Wilde, J.; Siuda, M. Gas sensor array and classifier as a means of varroosis detection. Sensors 2020, 20, 117. [Google Scholar] [CrossRef] [PubMed]

- Schaller, E.; Bosset, J.; Escher, F. “Electronic Noses” and Their Application to Food. LWT Food Sci. Technol. 1998, 31, 305–316. [Google Scholar] [CrossRef]

- Benedetti, S.; Mannino, S.; Sabatini, A.G.; Marcazzan, G.L. Original article electronic nose and neural network use for the classification of honey. Apidologie 2004, 35, 397–402. [Google Scholar] [CrossRef]

- Ampuero, S.; Bogdanov, S.; Bosset, J.O. Classification of unifloral honeys with an MS-based electronic nose using different sampling modes: SHS, SPME and INDEX. Eur. Food Res. Technol. 2004, 218, 198–207. [Google Scholar] [CrossRef]

- Abellán, J.; Castellano, J.G. Improving the Naive Bayes Classifier via a Quick Variable Selection Method Using Maximum of Entropy. Entropy 2017, 19, 247. [Google Scholar] [CrossRef]

- Saadatfar, H.; Khosravi, S.; Joloudari, J.H.; Mosavi, A.; Shamshirband, S. A New K-Nearest Neighbors Classifier for Big Data Based on Efficient Data Pruning. Mathematics 2020, 8, 286. [Google Scholar] [CrossRef]

- Szczurek, A.; Maciejewska, M.; Bąk, B.; Wilde, J.; Siuda, M. Semiconductor gas sensor as a detector of Varroa destructor infestation of honeybee colonies—Statistical evaluation. Comput. Electron. Agric. 2019, 162, 405–411. [Google Scholar] [CrossRef]

- Polkowski, L.; Artiemjew, P. Granular Computing in Decision Approximation, An Application of Rough Mereology. In Series: Intelligent Systems Reference Library; Springer: Berlin/Heidelberg, Germany, 2015; Volume 77, p. 452. [Google Scholar]

| Class 5—Young Workers | Class 6—Old Workers | Class 7—Workers from Colonies with Physiological Laying Worker Bees | ||||||

|---|---|---|---|---|---|---|---|---|

| Object No. | Object Origin (Colony ID) | Test Date | Object No. | Object Origin (Colony ID) | Test Date | Object No. | Object Origin (Colony ID) | Test Date |

| 106 | 38 | 18 October 2018 | 96 | 51 | 17 October 2018 | 18 | 10 | 24 September 2018 |

| 108 | 68 | 18 October 2018 | 97 | 51 | 17 October 2018 | 19 | 10 | 25 September 2018 |

| 110 | 51 | 18 October 2018 | 98 | 51 | 17 October 2018 | 20 | 10 | 25 September 2018 |

| 111 | 322 | 18 October 2018 | 99 | 51 | 17 October 2018 | 22 | 10 | 25 September 2018 |

| 112 | 68 | 18 October 2018 | 100 | 38 | 17 October 2018 | 68 | 66 | 4 October 2018 |

| 125 | 44 | 23 October 2018 | 101 | 68 | 17 October 2018 | 69 | 66 | 4 October 2018 |

| 126 | 73 | 23 October 2018 | 102 | 322 | 17 October 2018 | 77 | 66 | 5 October 2018 |

| 127 | 73 | 23 October 2018 | 103 | 322 | 17 October 2018 | 78 | 66 | 5 October 2018 |

| 128 | 73 | 23 October 2018 | 105 | 38 | 18 October 2018 | 114 | 66 | 23 October 2018 |

| 129 | 68 | 23 October 2018 | 107 | 44 | 18 October 2018 | 115 | 66 | 23 October 2018 |

| 109 | 68 | 18 October 2018 | ||||||

| Sensor | Substances Detected | Detection Range | Heater Power Consumption [mW] |

|---|---|---|---|

| TGS 823 | Organic solvent vapors | 50 ppm~5000 ppm Ethanol, n-Hexane, Benzene, Acetone | 660 |

| TGS 826 | Ammonia | 30 ppm~300 ppm Ethanol, Ammonia, Isobutane | 835 |

| TGS 832 | Chlorofluorocarbons | 100 ppm~3000 ppm R-407c, R-134a, R-410a, R-404a, R-22 | 835 |

| TGS 2600 | Gaseous air contaminants | 1 ppm~100 ppm | 210 |

| TGS 2602 | VOCs and odorous gases | 1~30 ppm Ethanol, Ammonia, Toluene | 280 |

| TGS 2603 | Amine-series and sulfurous odor gases | 1 ppm–30 ppm Ethanol 0.1 ppm–3 ppm Trimethylamine, 0.3 ppm–2 ppm Methyl mercaptan | 240 |

| Option I | Option II | Option III | Option IV | Option V | Option VI | Option VII | Option VIII | Best Classifier/ Parameter | ||

|---|---|---|---|---|---|---|---|---|---|---|

| Acc balanced | Classifier | m5 | m5 | m5 | m7 | m5 | m5 | m1 | m6 | m5 |

| Value | 0.585 | 0.576 | 0.646 | 0.564 | 0.57 | 0.583 | 0.598 | 0.567 | ||

| Tpr 1 | Classifier | m6 | m9 | m2 | m2, m6, m8, m10 | m2 | m10 | m1 | m2, m6, m8 | m2 |

| Value | 0.969 | 0.883 | 0.993 | 1 | 0.78 | 1 | 0.899 | 1 | ||

| Tpr 5 | Classifier | m7 | m5 | m10 | m10 | m5 | m6 | m1 | m8 | m5, m10 |

| Value | 0.462 | 0.544 | 0.581 | 0.473 | 0.442 | 0.308 | 0.674 | 0.483 | ||

| Tpr 6 | Classifier | m7 | m9 | m4 | m1 | m5 | m5 | m4 | m6 | m4, m5 |

| Value | 0.32 | 0.422 | 0.533 | 0.576 | 0.476 | 0.684 | 0.43 | 0.452 | ||

| Tpr 7 | Classifier | m5 | m5 | m5 | m6 | m10 | m6 | m1 | m9 | m5 |

| Value | 0.73 | 0.47 | 0.678 | 0.483 | 0.844 | 0.768 | 0.54 | 0.721 | ||

| Best classifier/option-Tpr parameter | m7 | m5 | m2, m4, m5, m10 | m6, m10 | m5 | m6 | m1 | m6, m8 | ||

| Classifier | acc global | cov global | acc 156 | acc 7 | acc balanced | tpr 156 | tpr 7 |

|---|---|---|---|---|---|---|---|

| m1 | 0.804204 | 1 | 0.941696 | 0.421144 | 0.681416 | 0.831952 | 0.718668 |

| m2 | 0.59578 | 1 | 0.46676 | 1 | 0.73338 | 1 | 0.386401 |

| m3 | 0.639988 | 1 | 0.436116 | 0.57086 | 0.631352 | 0.831816 | 0.385934 |

| m4 | 0.522104 | 1 | 0.930472 | 0.838284 | 0.6372 | 0.903864 | 0.331623 |

| m5 | 0.835788 | 1 | 0.930472 | 0.59462 | 0.762544 | 0.871184 | 0.742336 |

| m6 | 0.66526 | 1 | 0.589488 | 0.892668 | 0.741072 | 0.962496 | 0.42656 |

| m7 | 0.802104 | 1 | 0.928148 | 0.488048 | 0.708096 | 0.840752 | 0.637808 |

| m8 | 0.61894 | 1 | 0.50308 | 0.968668 | 0.73588 | 0.989336 | 0.395088 |

| m9 | 0.776836 | 1 | 0.941556 | 0.324333 | 0.632944 | 0.806192 | 0.580668 |

| m10 | 0.59578 | 1 | 0.474112 | 0.978668 | 0.726392 | 0.989848 | 0.38302 |

| Classifier | acc global | cov global | acc 156 | acc 7 | acc balanced | tpr 156 | tpr 7 |

|---|---|---|---|---|---|---|---|

| m1 | 0.757892 | 1 | 0.881348 | 0.434096 | 0.65772 | 0.808972 | 0.589808 |

| m2 | 0.469476 | 1 | 0.408336 | 0.65762 | 0.532972 | 0.673972 | 0.302018 |

| m3 | 0.635784 | 1 | 0.818772 | 0.157048 | 0.487912 | 0.726604 | 0.195856 |

| m4 | 0.477892 | 1 | 0.471108 | 0.51562 | 0.493364 | 0.737268 | 0.250017 |

| m5 | 0.766312 | 1 | 0.858332 | 0.53524 | 0.696788 | 0.834828 | 0.608952 |

| m6 | 0.50316 | 1 | 0.409024 | 0.763432 | 0.586228 | 0.808416 | 0.360549 |

| m7 | 0.732632 | 1 | 0.841324 | 0.45848 | 0.649904 | 0.809468 | 0.527712 |

| m8 | 0.4779 | 1 | 0.391062 | 0.720764 | 0.555908 | 0.749288 | 0.32875 |

| m9 | 0.741056 | 1 | 0.85872 | 0.434096 | 0.646404 | 0.804592 | 0.515332 |

| m10 | 0.503164 | 1 | 0.467176 | 0.603336 | 0.535252 | 0.739672 | 0.326092 |

| Classifier | acc global | cov global | acc 156 | acc 7 | acc balanced | tpr 156 | tpr 7 |

|---|---|---|---|---|---|---|---|

| m1 | 0.770524 | 1 | 0.944852 | 0.347047 | 0.645948 | 0.790696 | 0.622 |

| m2 | 0.604212 | 1 | 0.465928 | 0.984 | 0.724968 | 0.994668 | 0.404204 |

| m3 | 0.621048 | 1 | 0.692736 | 0.524856 | 0.6088 | 0.795492 | 0.367568 |

| m4 | 0.543152 | 1 | 0.469512 | 0.804 | 0.636764 | 0.867452 | 0.341942 |

| m5 | 0.80842 | 1 | 0.934388 | 0.51124 | 0.722808 | 0.837764 | 0.710188 |

| m6 | 0.669476 | 1 | 0.592276 | 0.881712 | 0.736984 | 0.943892 | 0.450932 |

| m7 | 0.778948 | 1 | 0.942352 | 0.383333 | 0.662844 | 0.800552 | 0.654 |

| m8 | 0.658944 | 1 | 0.543292 | 0.978284 | 0.76078 | 0.990224 | 0.442968 |

| m9 | 0.755788 | 1 | 0.938508 | 0.306285 | 0.622388 | 0.780056 | 0.562004 |

| m10 | 0.610528 | 1 | 0.485748 | 0.957904 | 0.721832 | 0.980056 | 0.403856 |

| Classifier | acc global | cov global | acc 156 | acc 7 | acc balanced | tpr 156 | tpr 7 |

|---|---|---|---|---|---|---|---|

| m1 | 0.732624 | 1 | 0.850236 | 0.454 | 0.65212 | 0.798528 | 0.594572 |

| m2 | 0.59158 | 1 | 0.447148 | 0.975 | 0.711076 | 0.986668 | 0.428288 |

| m3 | 0.654732 | 1 | 0.826652 | 0.253952 | 0.540308 | 0.735512 | 0.396762 |

| m4 | 0.532628 | 1 | 0.483588 | 0.67662 | 0.580104 | 0.786232 | 0.342526 |

| m5 | 0.751572 | 1 | 0.843516 | 0.55976 | 0.70164 | 0.833768 | 0.559636 |

| m6 | 0.738944 | 1 | 0.85024 | 0.450952 | 0.6506 | 0.81728 | 0.650192 |

| m7 | 0.74526 | 1 | 0.820408 | 0.588192 | 0.704296 | 0.840516 | 0.588724 |

| m8 | 0.730524 | 1 | 0.810488 | 0.540284 | 0.675384 | 0.832588 | 0.589084 |

| m9 | 0.741048 | 1 | 0.85594 | 0.469048 | 0.662496 | 0.803396 | 0.612092 |

| m10 | 0.71368 | 1 | 0.694484 | 0.789996 | 0.74224 | 0.915252 | 0.5277 |

| Option I | Option II | Option III | Option IV | Option V | Option VI | Option VII | Option VIII | Best Classifier/ parameter | ||

|---|---|---|---|---|---|---|---|---|---|---|

| Tpr 1 vs. 5, 6, 7 | Classifier | m2 | m5 | m2 | m2, m5, m6, m7, m10 | m2, m10 | m2 | m1 | m1, m9 | m2 |

| Value | 0.981 | 0.817 | 0.948 | 1 | 0.975 | 0.995 | 0.902 | 1 | ||

| Tpr 5 vs. 1, 6, 7 | Classifier | m6 | m5 | m6 | m6 | m6 | m10 | m1 | m6 | m6 |

| Value | 0.544 | 0.55 | 0.51 | 0.51 | 0.525 | 0.284 | 0.582 | 0.530 | ||

| Tpr 6 vs. 1, 5, 7 | Classifier | m5 | m9 | m1 | m1 | m5 | m6 | m5 | m1, m9 | m1, m5 |

| Value | 0.532 | 0.514 | 0.489 | 0.563 | 0.372 | 0.619 | 0.542 | 0.413 | ||

| Tpr 7 vs. 1, 5, 6 | Classifier | m5 | m5 | m5 | m5 | m5 | m5 | m9 | m5 | m5 |

| Value | 0.742 | 0.61 | 0.417 | 0.376 | 0.710 | 0.650 | 0.427 | 0.489 | ||

| Best classifier/Option | m5 | m5 | m1, m2, m5, m6 | m5, m6 | m5 | m2, m5, m6, m10 | m1 | m1, m9 |

| Option I | Option II | Option III | Option IV | Option V | Option VI | Option VII | Option VIII | Best Classifier/ Parameter | ||

|---|---|---|---|---|---|---|---|---|---|---|

| Acc balanced 1 vs. 5, 6, 7 | Classifier | m7 | m9 | m10 | m6 | m10 | m9 | m1 | m1 | m1, m9, m10 |

| Value | 0.864 | 0.788 | 0.887 | 0.925 | 0.866 | 0.886 | 0.896 | 0.964 | ||

| Acc balanced 5 vs. 1, 6, 7 | Classifier | m6 | m5 | m6 | m10 | m6 | m10 | m1 | m6 | m6 |

| Value | 0.752 | 0.741 | 0.725 | 0.663 | 0.713 | 0.638 | 0.736 | 0.707 | ||

| Acc balanced 6 vs. 1, 5, 7 | Classifier | m6 | m5 | m10 | m1 | m10 | m5 | m10 | m10 | m10 |

| Value | 0.819 | 0.814 | 0.758 | 0.822 | 0.652 | 0.775 | 0.792 | 0.697 | ||

| Acc balanced 7 vs. 1, 5, 6 | Classifier | m5 | m5 | m5 | m5 | m1 | m10 | m9 | m5 | m5 |

| Value | 0.763 | 0.697 | 0.652 | 0.665 | 0.696 | 0.742 | 0.427 | 0.656 | ||

| Best classifier/ option | m6 | m5 | m10 | m1, m5, m6, m10 | m10 | m10 | m1 | m1, m5, m6, m10 |

| Option I | Option II | Option III | Option IV | Option V | Option VI | Option VII | Option VIII | |

|---|---|---|---|---|---|---|---|---|

| Acc balanced True positive rate class 7 | 0.763 | 0.697 | 0.651 | 0.558 | 0.723 | 0.702 | 0.612 | 0.601 |

| 0.742 | 0.609 | 0.417 | 0.36 | 0.612 | 0.56 | 0.349 | 0.47 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wilk, J.T.; Bąk, B.; Artiemjew, P.; Wilde, J.; Siuda, M. Classifying the Biological Status of Honeybee Workers Using Gas Sensors. Sensors 2021, 21, 166. https://doi.org/10.3390/s21010166

Wilk JT, Bąk B, Artiemjew P, Wilde J, Siuda M. Classifying the Biological Status of Honeybee Workers Using Gas Sensors. Sensors. 2021; 21(1):166. https://doi.org/10.3390/s21010166

Chicago/Turabian StyleWilk, Jakub T., Beata Bąk, Piotr Artiemjew, Jerzy Wilde, and Maciej Siuda. 2021. "Classifying the Biological Status of Honeybee Workers Using Gas Sensors" Sensors 21, no. 1: 166. https://doi.org/10.3390/s21010166

APA StyleWilk, J. T., Bąk, B., Artiemjew, P., Wilde, J., & Siuda, M. (2021). Classifying the Biological Status of Honeybee Workers Using Gas Sensors. Sensors, 21(1), 166. https://doi.org/10.3390/s21010166