Characteristic Evaluation of Chameleon Luminophore Dispersed in Polymer

Abstract

1. Introduction

2. Materials and Methods

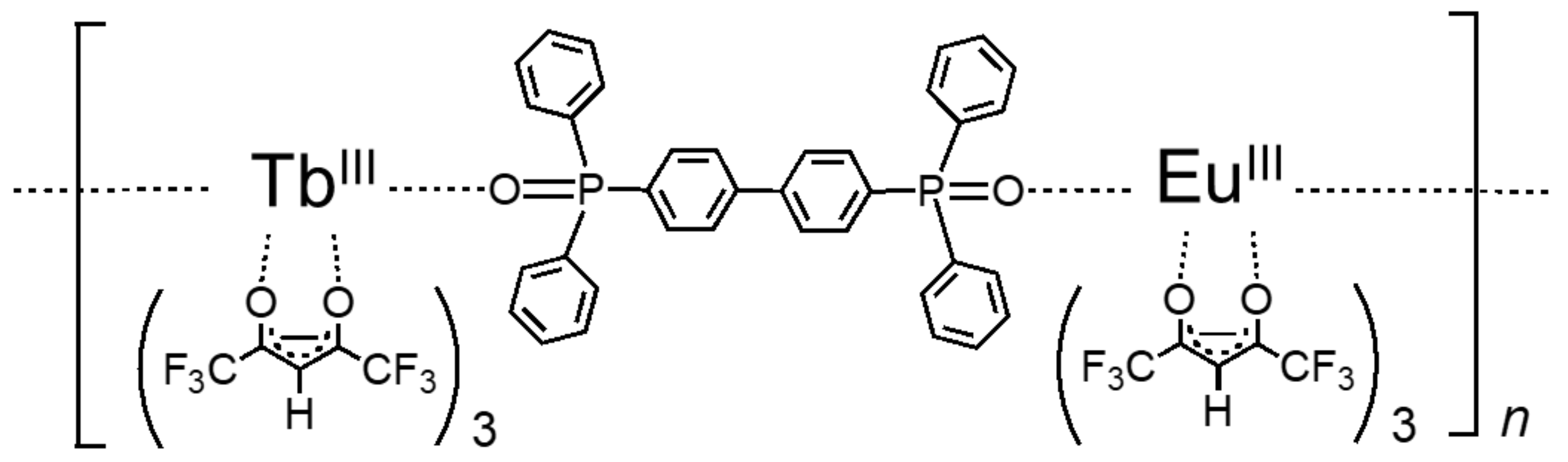

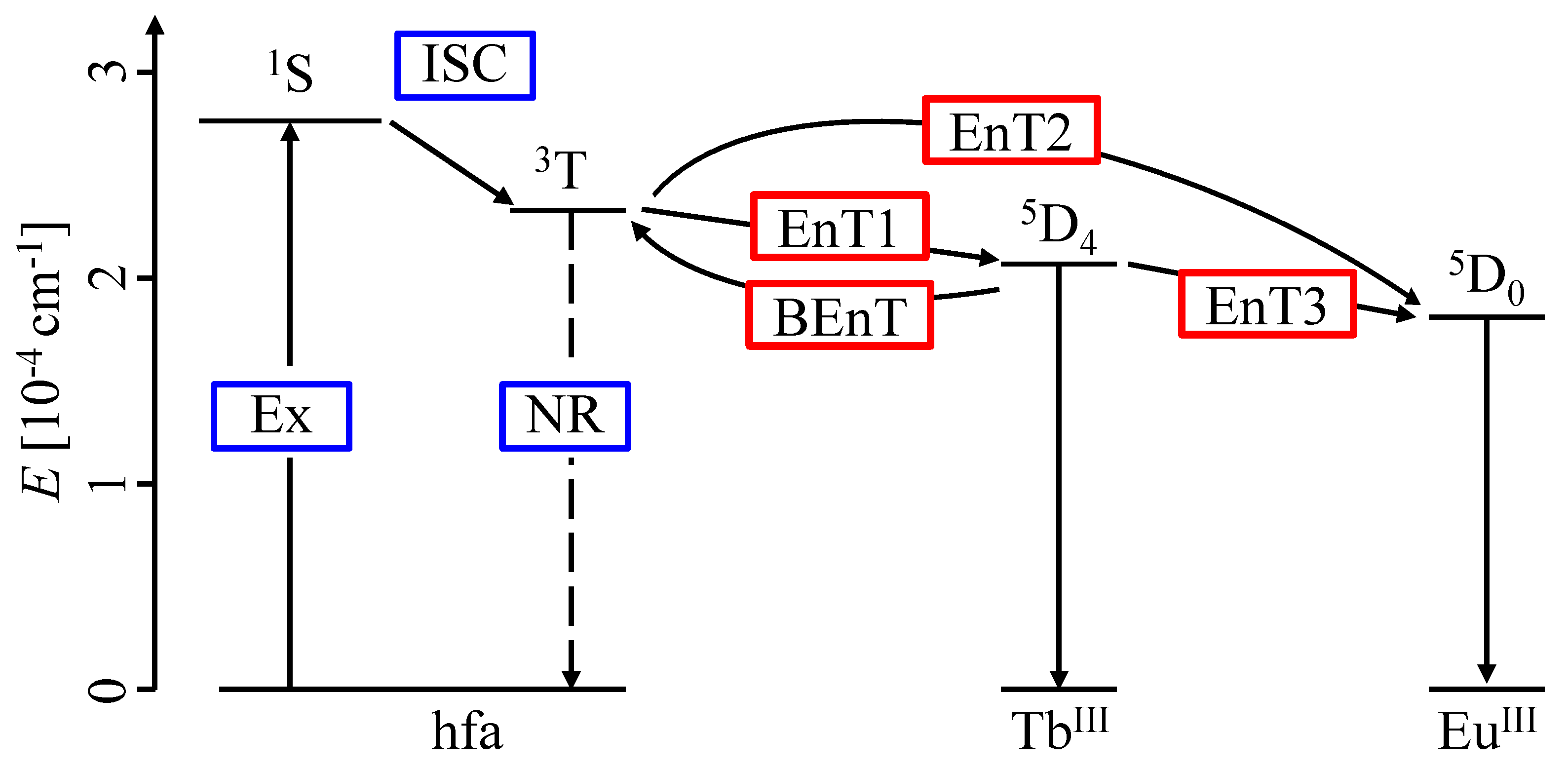

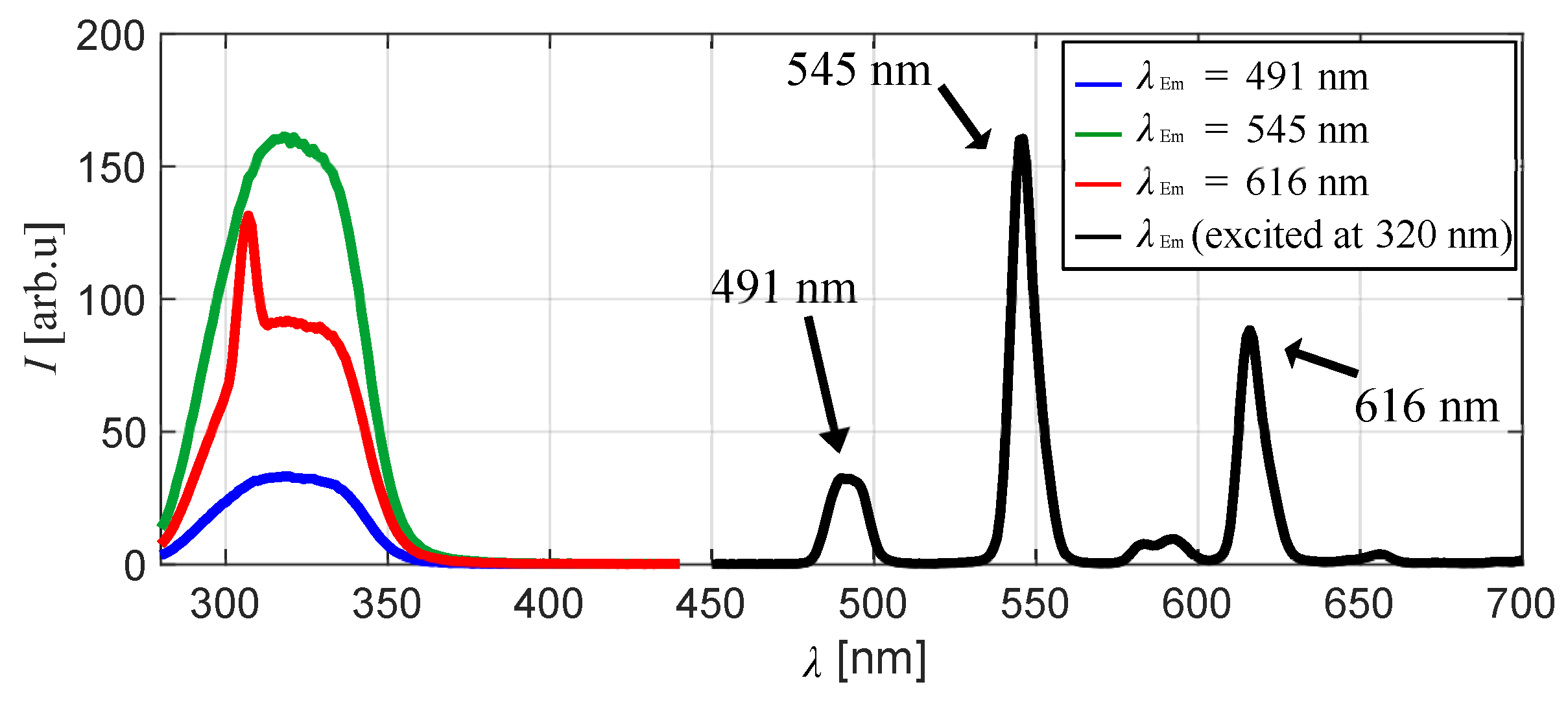

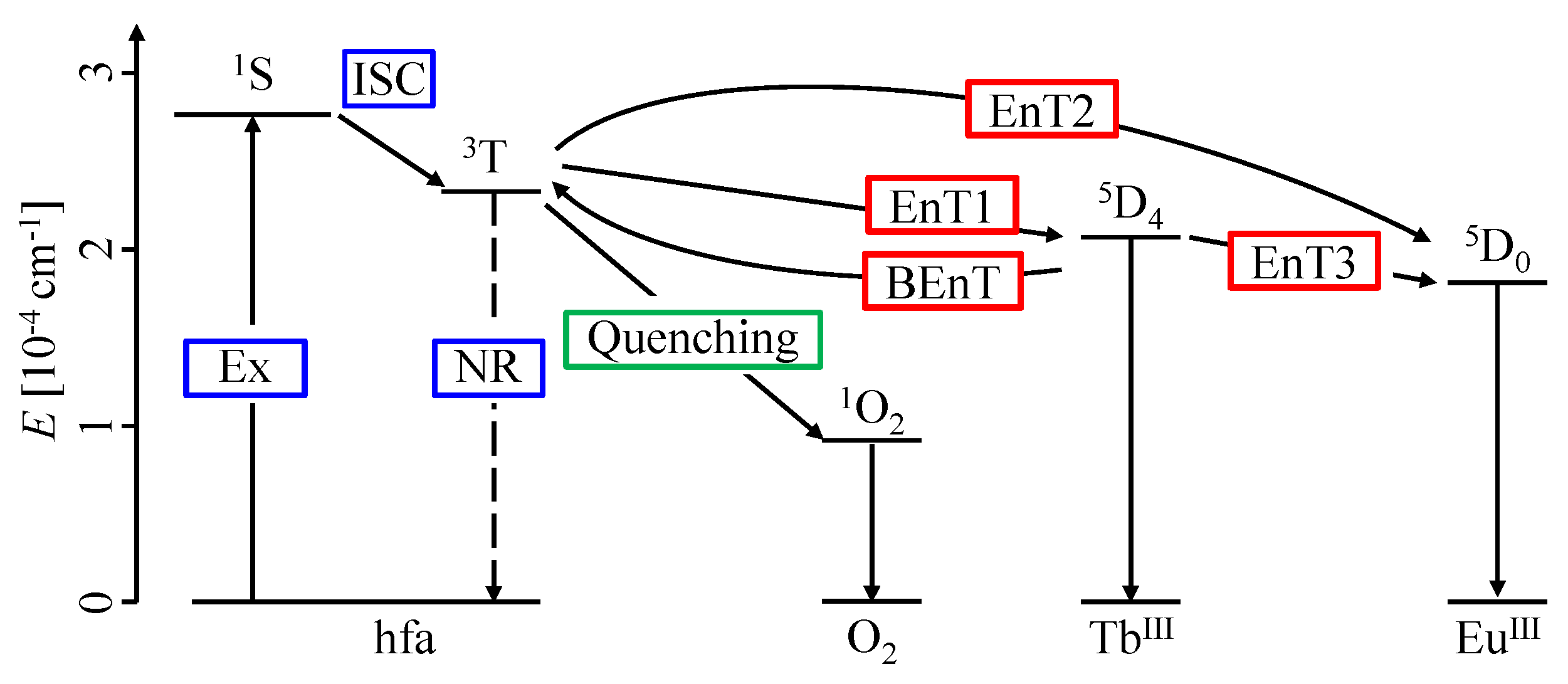

2.1. The Probe and Its Emission Mechanism

2.2. Sensor Fabrication

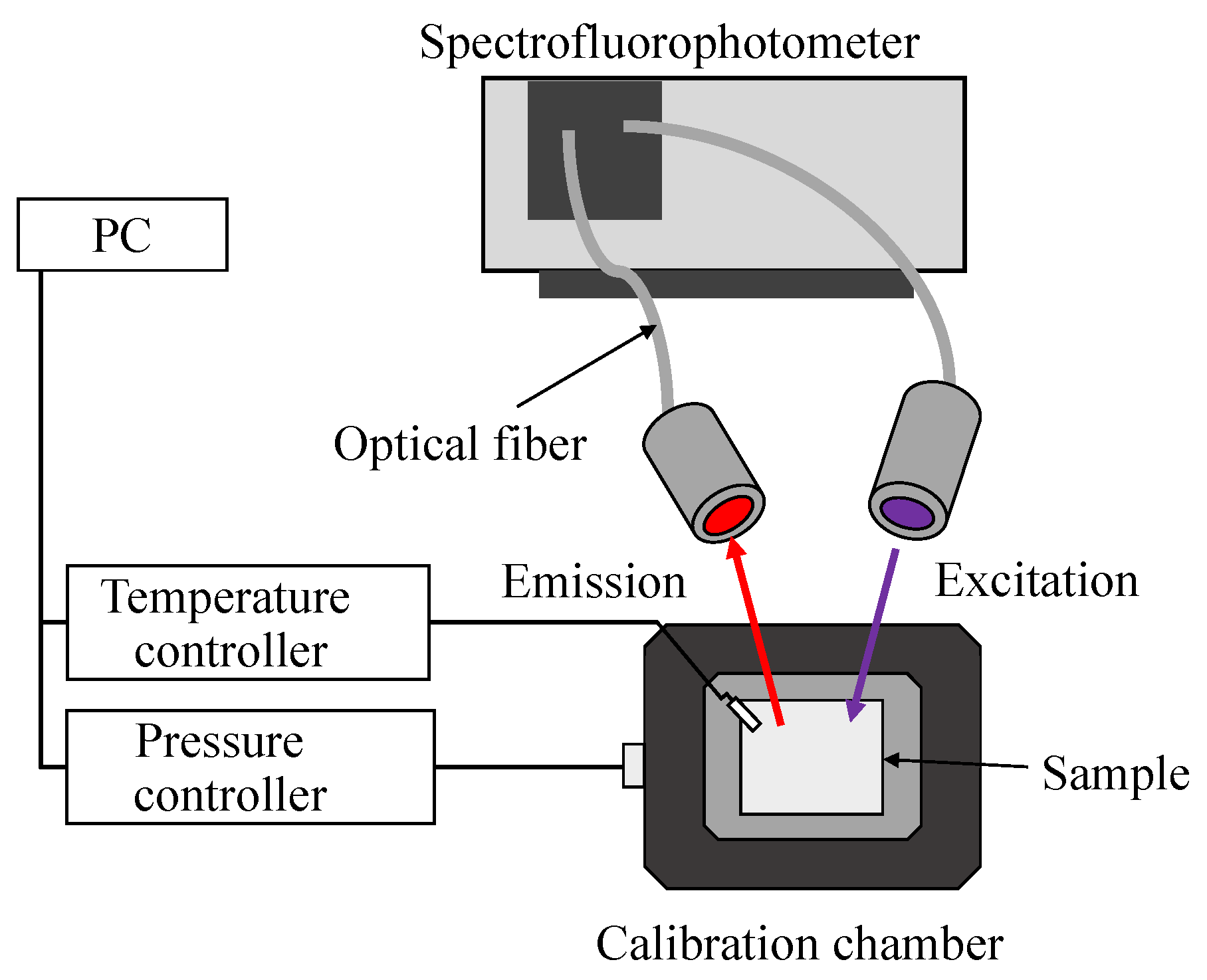

2.3. Experimental Setup

2.4. Analysis Method

3. Results and Discussion

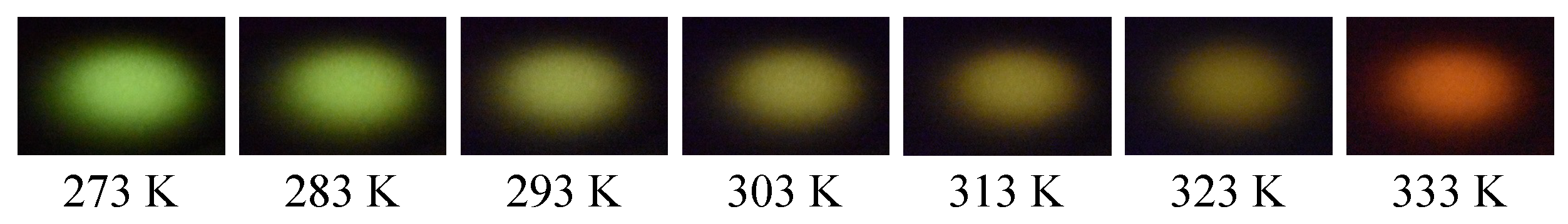

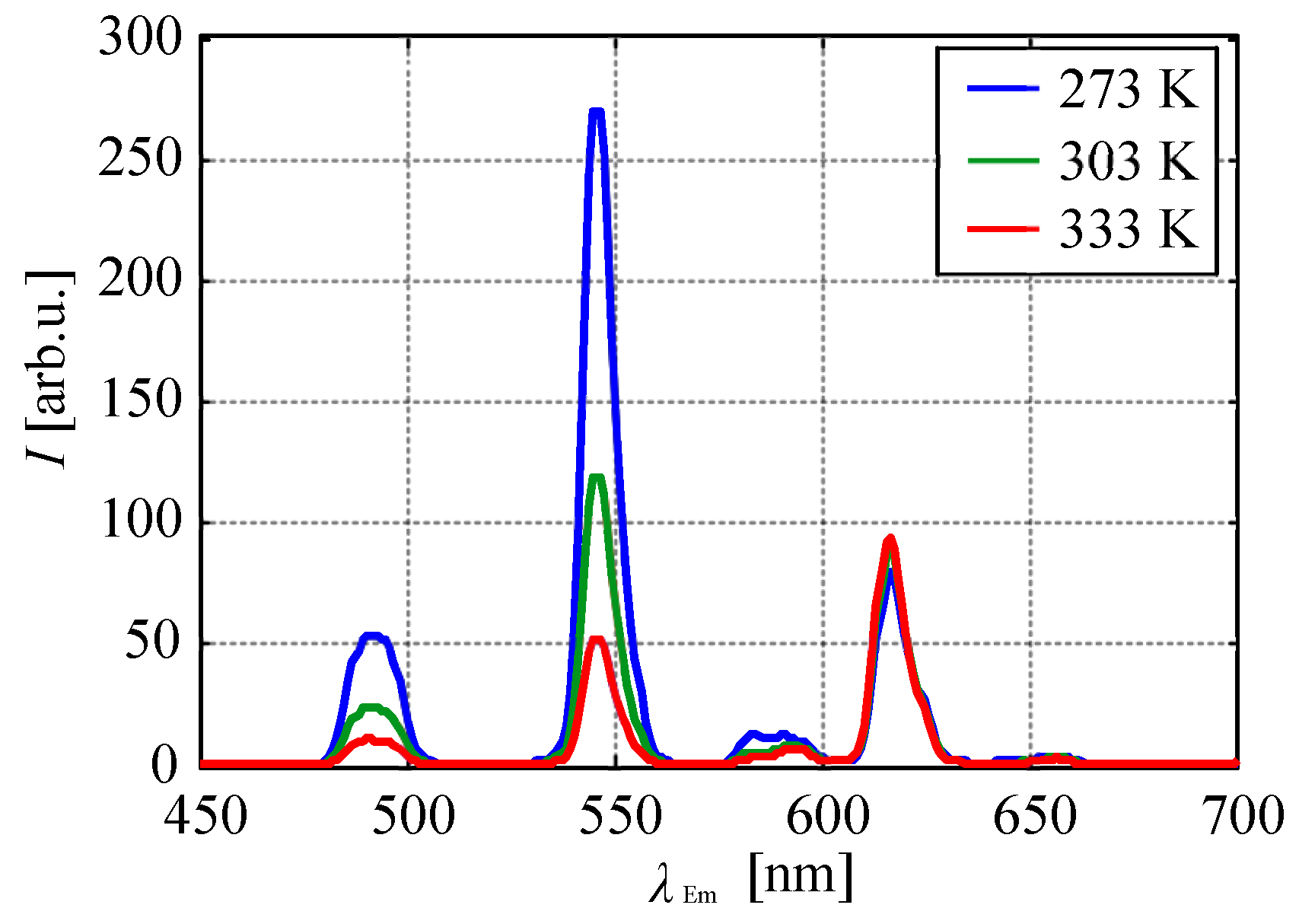

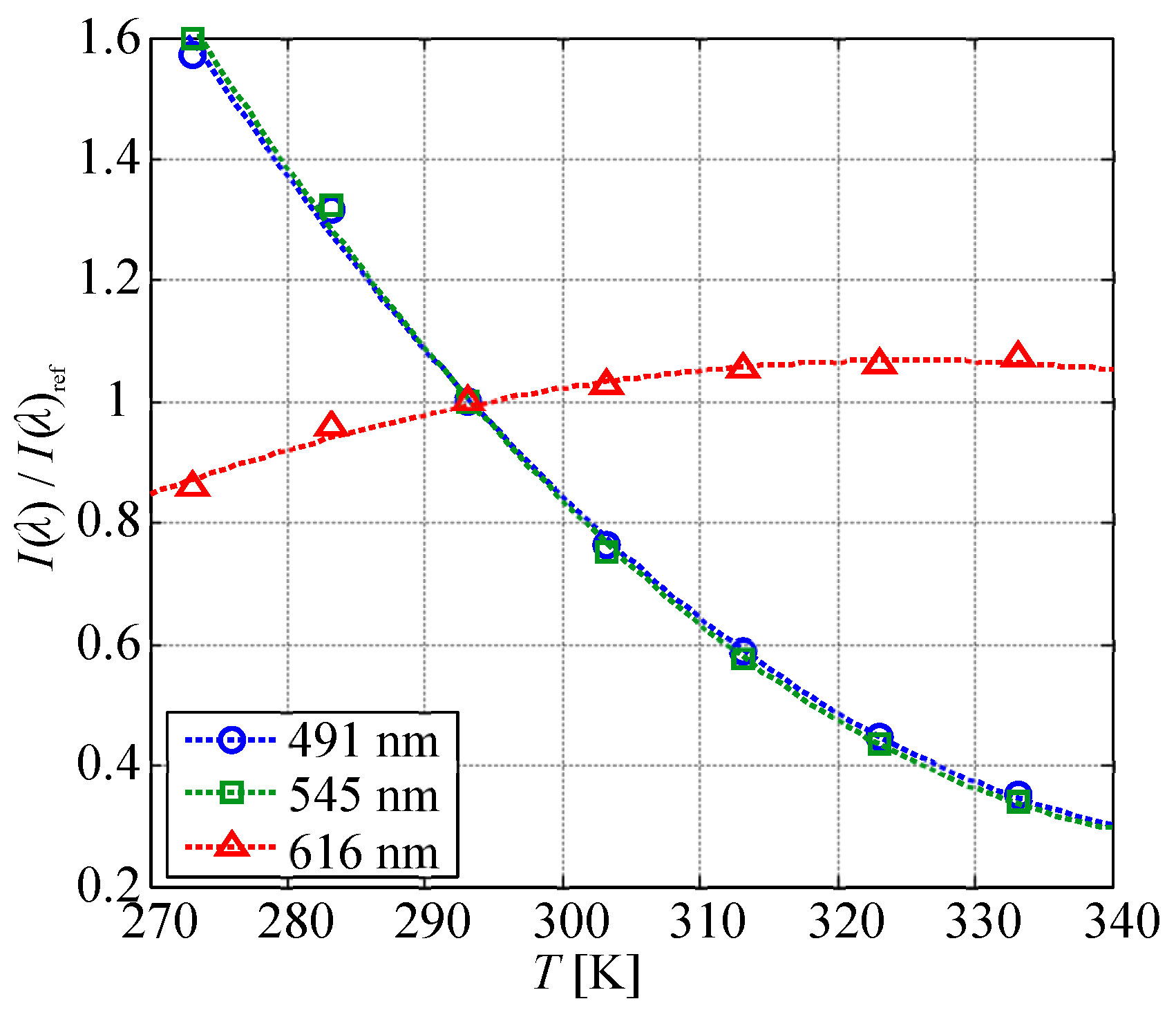

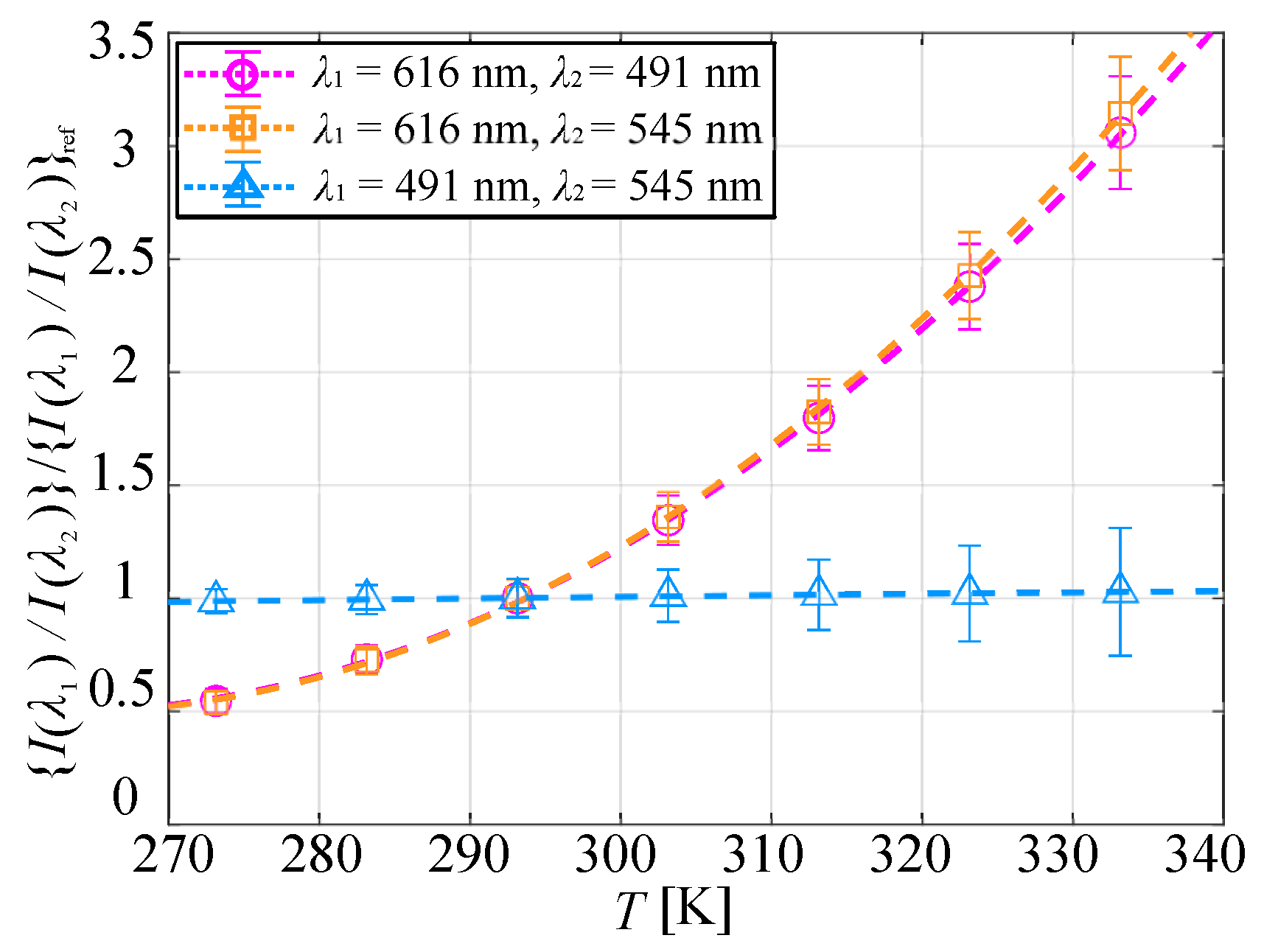

3.1. Temperature Characteristics

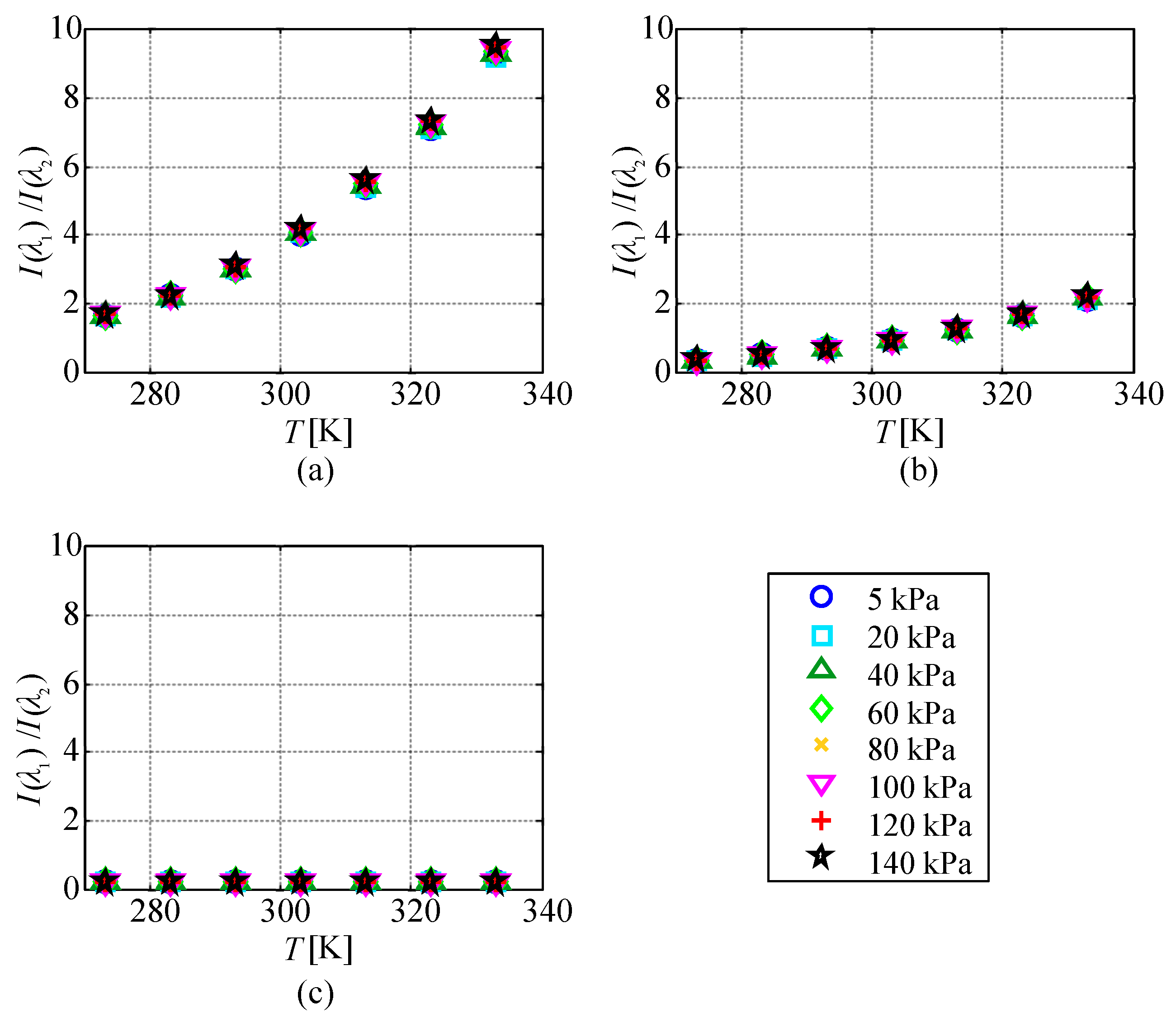

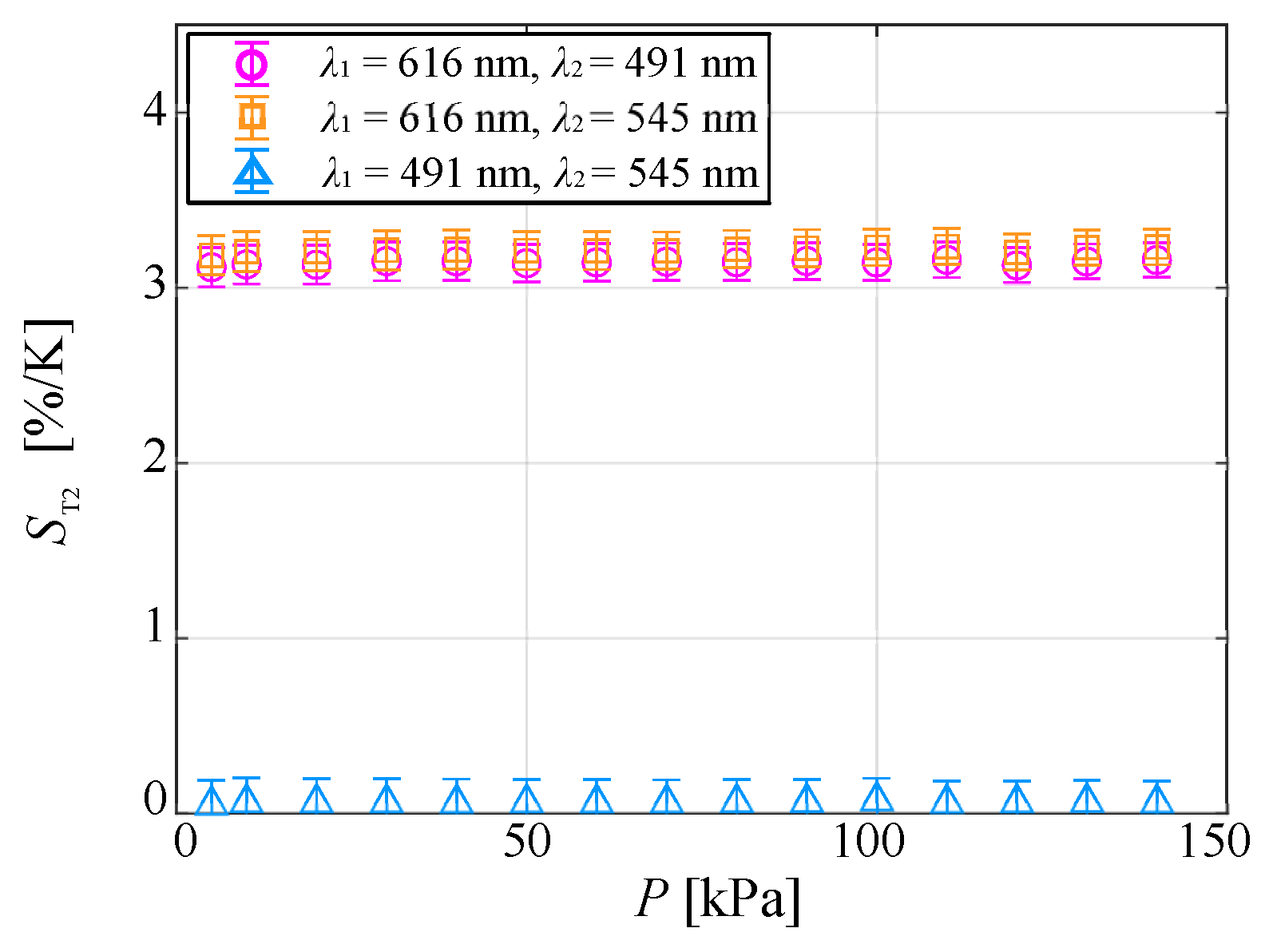

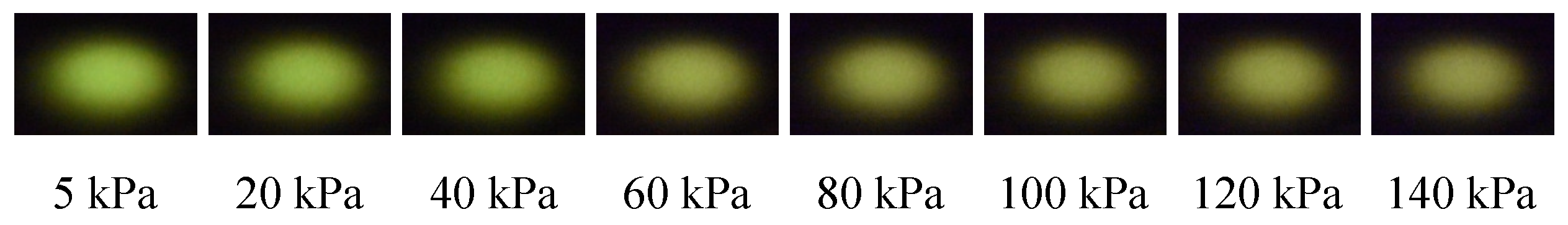

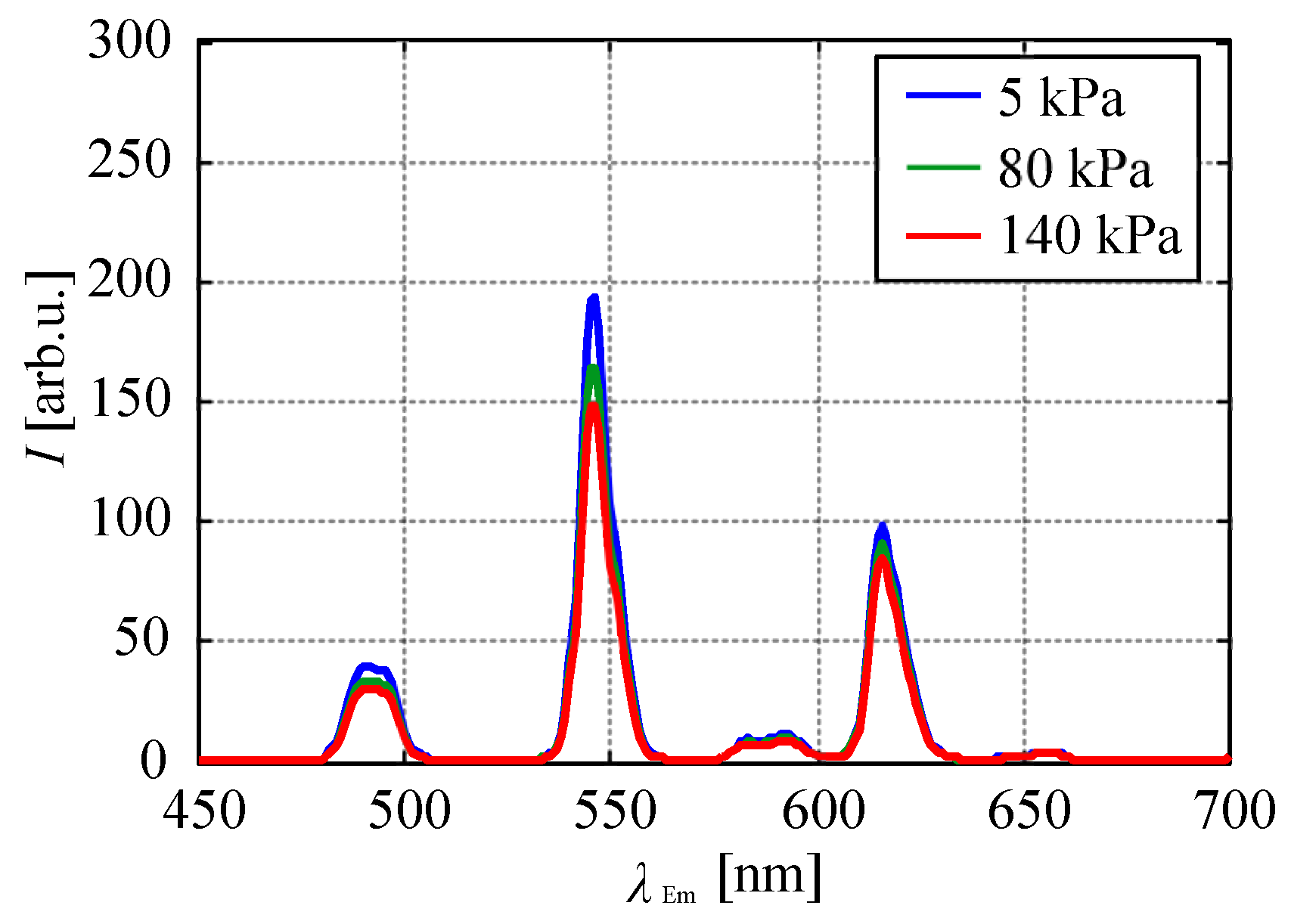

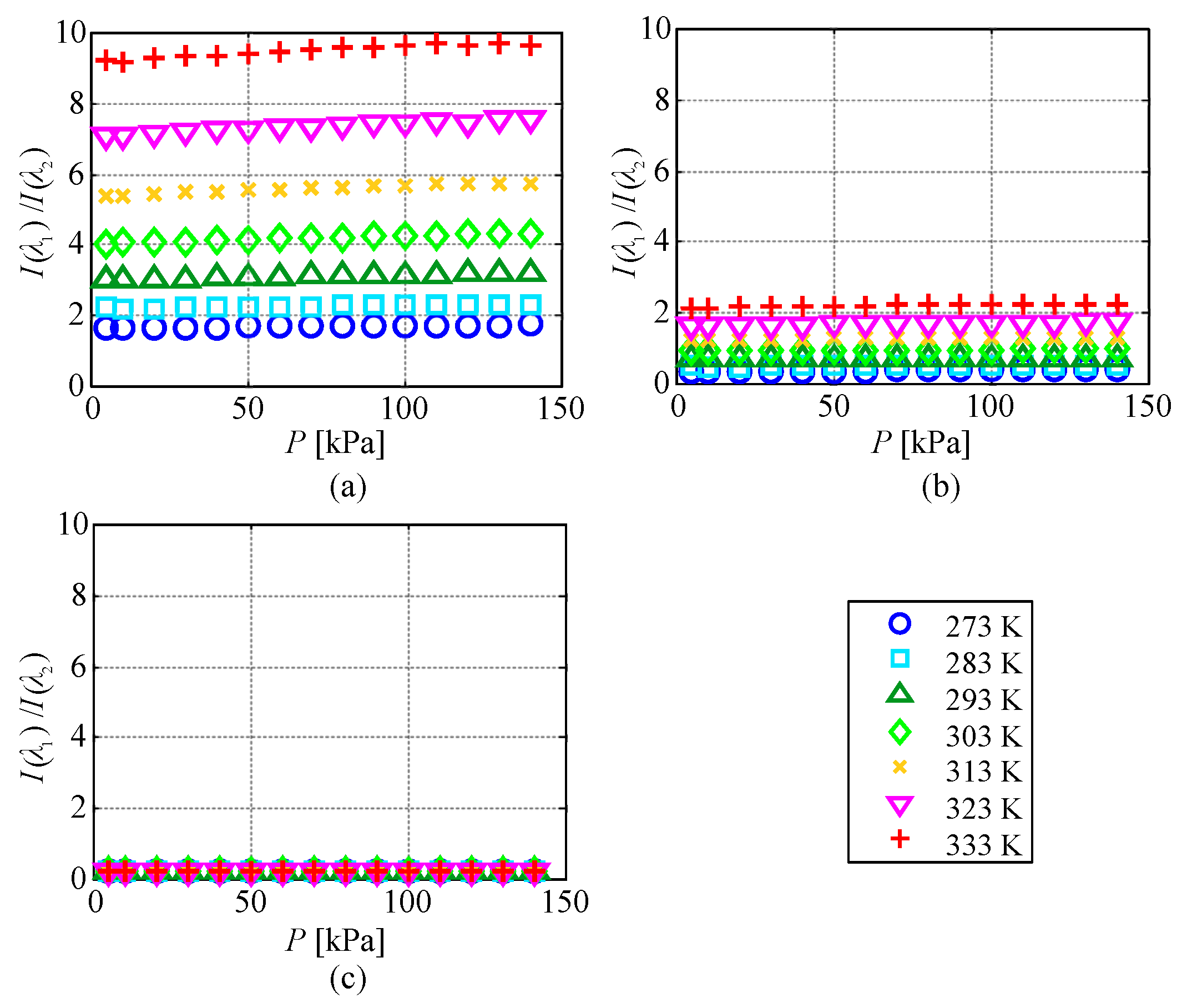

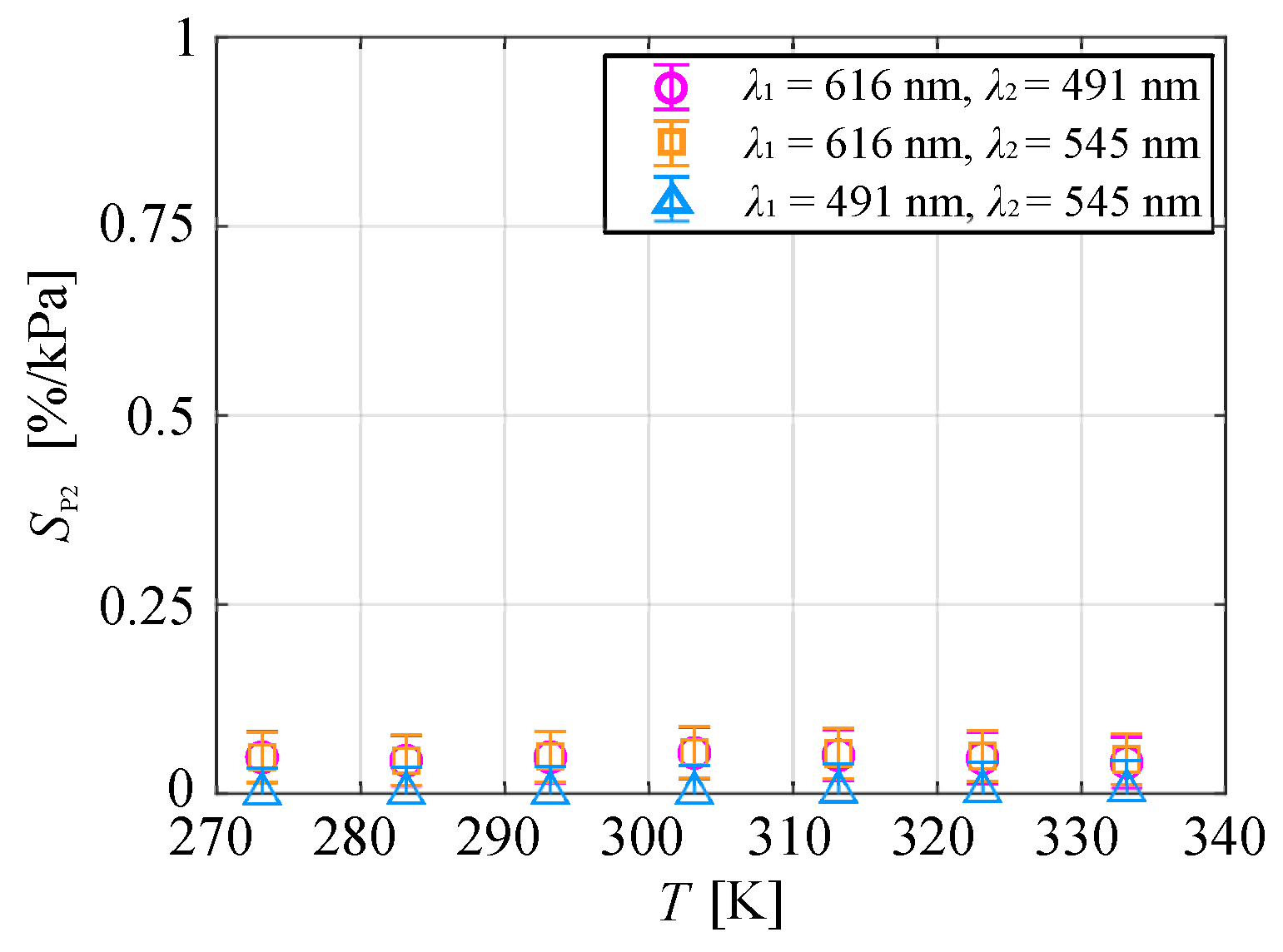

3.2. Pressure Characteristics

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Liu, T.; Campbell, B.; Sullivan, J.; Lafferty, J.; Yanta, W. Heat transfer measurement on a waverider at Mach 10 using fluorescent paint. J. Thermophys. Heat Transf. 1995, 9, 605–611. [Google Scholar] [CrossRef]

- Nagai, H.; Ohmi, S.; Asai, K.; Nakakita, K. Effect of temperature-sensitive-paint thickness on global heat transfer measurement in hypersonic flow. J. Thermophys. Heat Transf. 2008, 22, 373–381. [Google Scholar] [CrossRef]

- Kurits, I.; Lewis, M.J. Global temperature-sensitive paint system for heat transfer measurements in long-duration hypersonic flows. J. Thermophys. Heat Transf. 2009, 23, 256–266. [Google Scholar] [CrossRef]

- Fuata, J. Quantifying the eFfects of Convective Aerodynamic Heating Over a Double Swept-Wedge Configuration at Mach 6; University of Southern Queensland: Toowoomba, Australia, 2014. [Google Scholar]

- Le Sant, Y.; Marchand, M.; Millan, P.; Fontaine, J. An overview of infrared thermography techniques used in large wind tunnels. Aerosp. Sci. Technol. 2002, 6, 355–366. [Google Scholar] [CrossRef]

- Rhee, H.; Koseff, J.; Street, R. Flow visualization of a recirculating flow by rheoscopic liquid and liquid crystal techniques. Exp. Fluids 1984, 2, 57–64. [Google Scholar] [CrossRef]

- Babinsky, H.; Edwards, J. Automatic liquid crystal thermography for transient heat transfer measurements in hypersonic flow. Exp. Fluids 1996, 21, 227–236. [Google Scholar] [CrossRef]

- Aleksic, J.; Zielke, P.; Szymczyk, J.A. Temperature and Flow Visualization In A Simulation Of The Czochralski Process Using Temperature-Sensitive Liquid Crystals (TLCS). Ann. N. Y. Acad. Sci. 2002. [Google Scholar] [CrossRef]

- Ireland, P.; Jones, T. Liquid crystal measurements of heat transfer and surface shear stress. Meas. Sci. Technol. 2000, 11, 969. [Google Scholar] [CrossRef]

- Bell, J.H.; Schairer, E.T.; Hand, L.A.; Mehta, R.D. Surface pressure measurements using luminescent coatings. Annu. Rev. Fluid Mech. 2001, 33, 155–206. [Google Scholar] [CrossRef]

- Liu, T.; Sullivan, J.P. Pressure and Temperature Sensitive Paints; Springer: Berlin/Heidelberg, Germany, 2005. [Google Scholar]

- Liu, T.; Cai, Z.; Lai, J.; Rubal, J.; Sullivan, J.P. Analytical method for determining heat flux from temperature-sensitive-paint measurements in hypersonic tunnels. J. Thermophys. Heat Transf. 2010, 24, 85–94. [Google Scholar] [CrossRef]

- Peng, D.; Jiao, L.; Sun, Z.; Gu, Y.; Liu, Y. Simultaneous PSP and TSP measurements of transient flow in a long-duration hypersonic tunnel. Exp. Fluids 2016, 57, 188. [Google Scholar] [CrossRef]

- Risius, S.; Beck, W.H.; Klein, C.; Henne, U.; Wagner, A. Determination of heat transfer into a wedge model in a hypersonic flow using temperature-sensitive paint. Exp. Fluids 2017, 58, 117. [Google Scholar] [CrossRef]

- Asai, K.; Kanda, H.; Kunimasu, T.; Liu, T.; Sullivan, J.P. Boundary-layer transition detection in a cryogenic wind tunnel using luminescent paint. J. Aircr. 1997, 34, 34–42. [Google Scholar] [CrossRef]

- Fey, U.; Egami, Y. Transition detection by temperature-sensitive paint. In Springer Handbook of Experimental Fluid Mechanics; Springer: Berlin/Heidelberg, Germany, 2007; pp. 537–552. [Google Scholar]

- Egami, Y.; Fey, U.; Klein, C.; Quest, J.; Ondrus, V.; Beifuss, U. Development of new two-component temperature-sensitive paint (TSP) for cryogenic testing. Meas. Sci. Technol. 2012, 23, 115301. [Google Scholar] [CrossRef]

- Disotell, K.J.; Peng, D.; Juliano, T.J.; Gregory, J.W.; Crafton, J.W.; Komerath, N.M. Single-shot temperature-and pressure-sensitive paint measurements on an unsteady helicopter blade. Exp. Fluids 2014, 55, 1671. [Google Scholar] [CrossRef]

- Peng, D.; Jiao, L.; Yu, Y.; Liu, Y.; Oshio, T.; Kawakubo, T.; Yakushiji, A. Single-shot lifetime-based PSP and TSP measurements on turbocharger compressor blades. Exp. Fluids 2017, 58, 127. [Google Scholar] [CrossRef]

- Chandrasekharan, N.; Kelly, L.A. A dual fluorescence temperature sensor based on perylene/exciplex interconversion. J. Am. Chem. Soc. 2001, 123, 9898–9899. [Google Scholar] [CrossRef]

- Basu, B.J.; Venkatraman, S. Fabrication of a bi-luminophore temperature sensitive coating by embedding europium thenoyltrifluoroacetonate (EuTTA) and perylene in polystyrene. J. Fluoresc. 2009, 19, 479. [Google Scholar] [CrossRef]

- Miyata, K.; Konno, Y.; Nakanishi, T.; Kobayashi, A.; Kato, M.; Fushimi, K.; Hasegawa, Y. Chameleon luminophore for sensing temperatures: Control of metal-to-metal and energy back transfer in lanthanide coordination polymers. Angew. Chem. Int. Ed. 2013, 52, 6413–6416. [Google Scholar] [CrossRef]

- Hatanaka, M.; Hirai, Y.; Kitagawa, Y.; Nakanishi, T.; Hasegawa, Y.; Morokuma, K. Organic linkers control the thermosensitivity of the emission intensities from Tb (III) and Eu (III) in a chameleon polymer. Chem. Sci. 2017, 8, 423–429. [Google Scholar] [CrossRef]

- Hirai, Y. Study on Assembled Structures and Physical Properties of Luminescent Lanthanide (III) Complexes. Ph.D. Thesis, Hokkaido University, Sapporo, Japan, 2017. [Google Scholar]

- Egami, Y.; Matsuda, Y.; Yamaguchi, H.; Niimi, T. Property changes of temperature-sensitive paint immobilized in acrylic polymer matrices. Sens. Actuators B Chem. 2014, 195, 677–681. [Google Scholar] [CrossRef]

- Ondrus, V.; Meier, R.J.; Klein, C.; Henne, U.; Schäferling, M.; Beifuss, U. Europium 1, 3-di (thienyl) propane-1, 3-diones with outstanding properties for temperature sensing. Sens. Actuators A Phys. 2015, 233, 434–441. [Google Scholar] [CrossRef]

| Excitation wavelength (nm) | 320 |

| Fluorescence spectrum range (nm) | 450–700 |

| Slit width of excitation/fluorescence spectroscope (nm) | 5 |

| Sampling interval (nm) | 1 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kasai, M.; Sugioka, Y.; Yamamoto, M.; Nagata, T.; Nonomura, T.; Asai, K.; Hasegawa, Y. Characteristic Evaluation of Chameleon Luminophore Dispersed in Polymer. Sensors 2020, 20, 2623. https://doi.org/10.3390/s20092623

Kasai M, Sugioka Y, Yamamoto M, Nagata T, Nonomura T, Asai K, Hasegawa Y. Characteristic Evaluation of Chameleon Luminophore Dispersed in Polymer. Sensors. 2020; 20(9):2623. https://doi.org/10.3390/s20092623

Chicago/Turabian StyleKasai, Miku, Yosuke Sugioka, Masanori Yamamoto, Takayuki Nagata, Taku Nonomura, Keisuke Asai, and Yasuchika Hasegawa. 2020. "Characteristic Evaluation of Chameleon Luminophore Dispersed in Polymer" Sensors 20, no. 9: 2623. https://doi.org/10.3390/s20092623

APA StyleKasai, M., Sugioka, Y., Yamamoto, M., Nagata, T., Nonomura, T., Asai, K., & Hasegawa, Y. (2020). Characteristic Evaluation of Chameleon Luminophore Dispersed in Polymer. Sensors, 20(9), 2623. https://doi.org/10.3390/s20092623