Vibration Control of Scanning Electron Microscopes with Experimental Approaches for Performance Enhancement

Abstract

1. Introduction

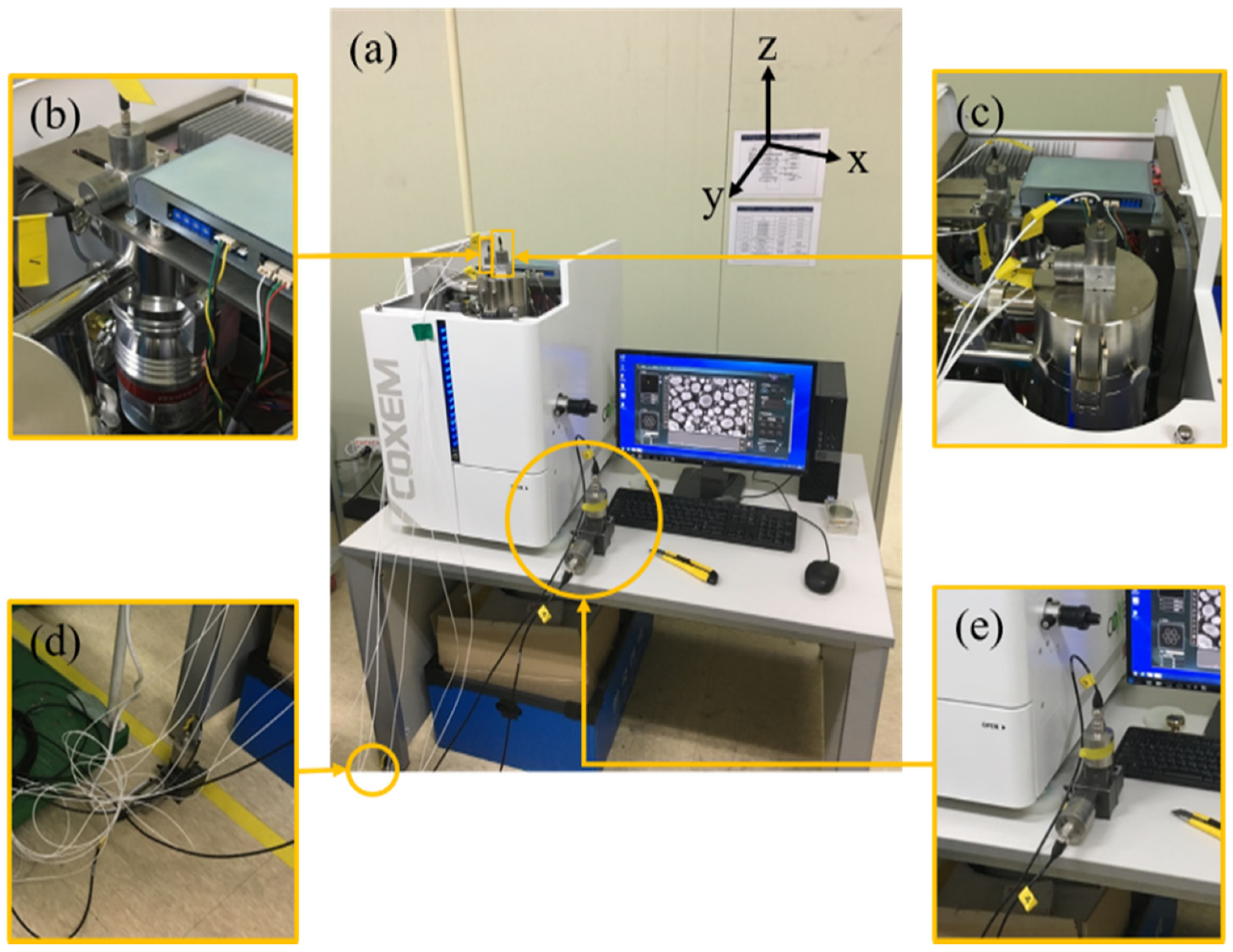

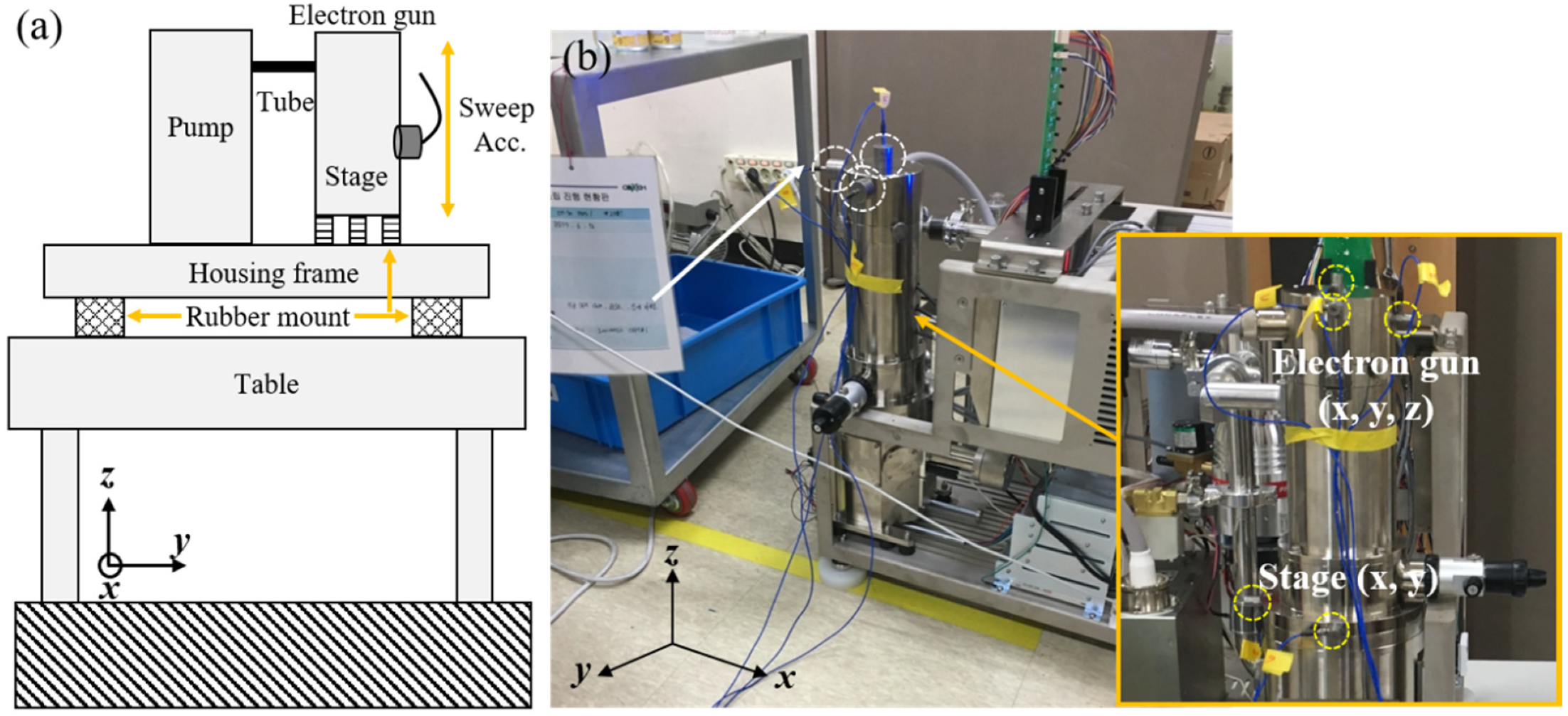

2. Experiments

2.1. Vibration Measurement Conditions for the Environment and Equipment Operation

2.2. Vibration Measurement

3. Results and Suggestions

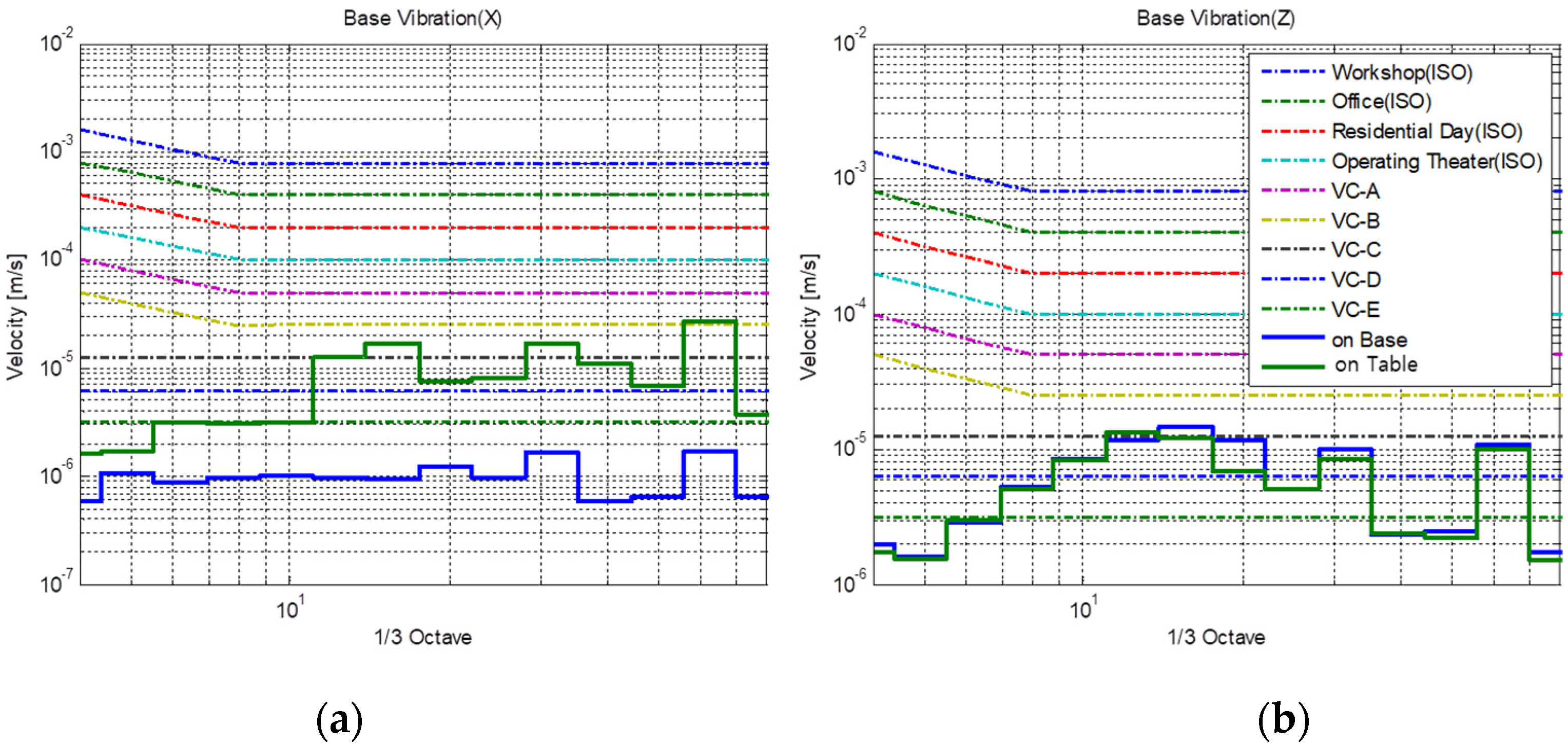

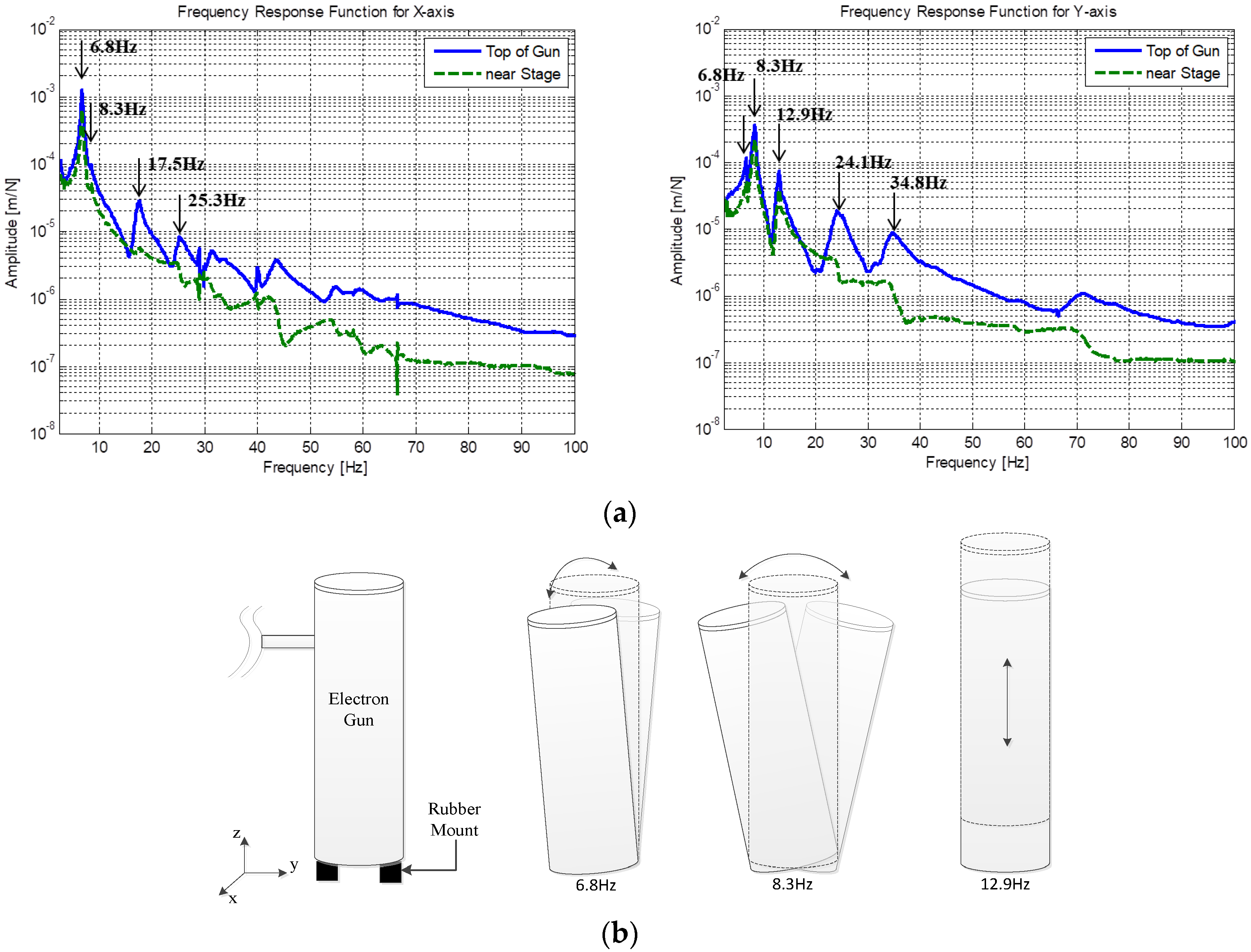

3.1. Characterization of Vibration

3.2. Design Suggestions

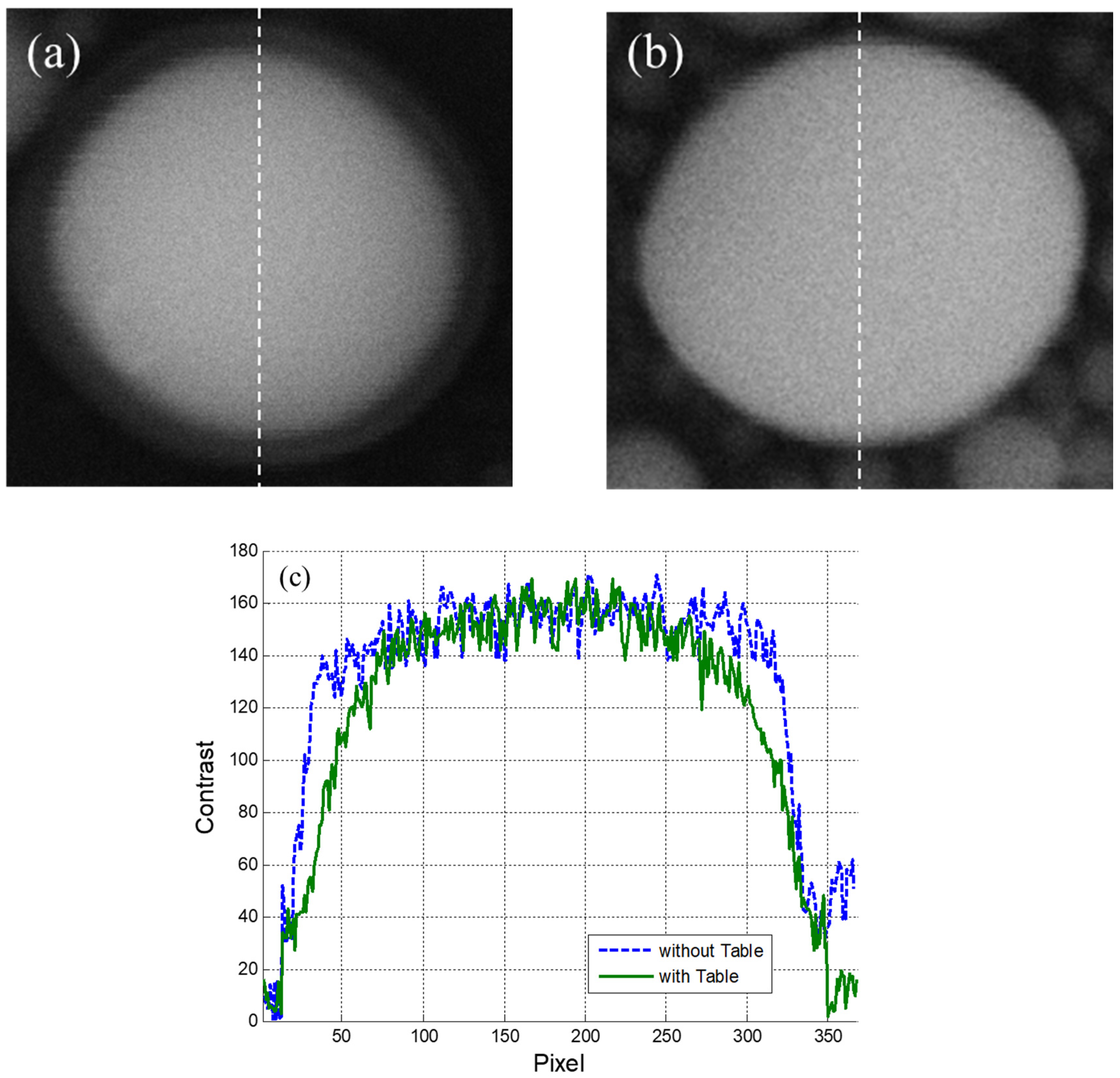

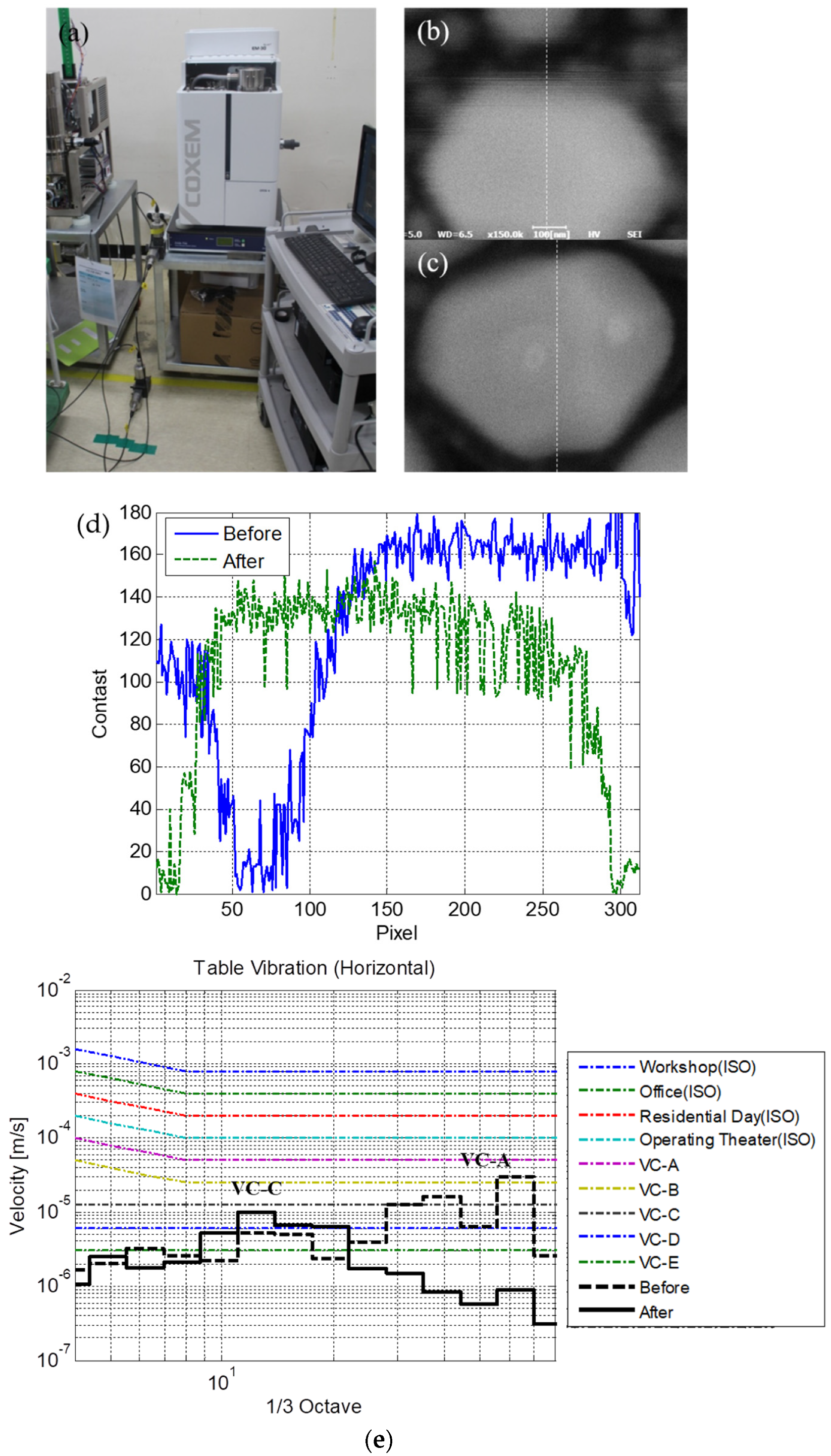

3.2.1. Environmental Vibration Control

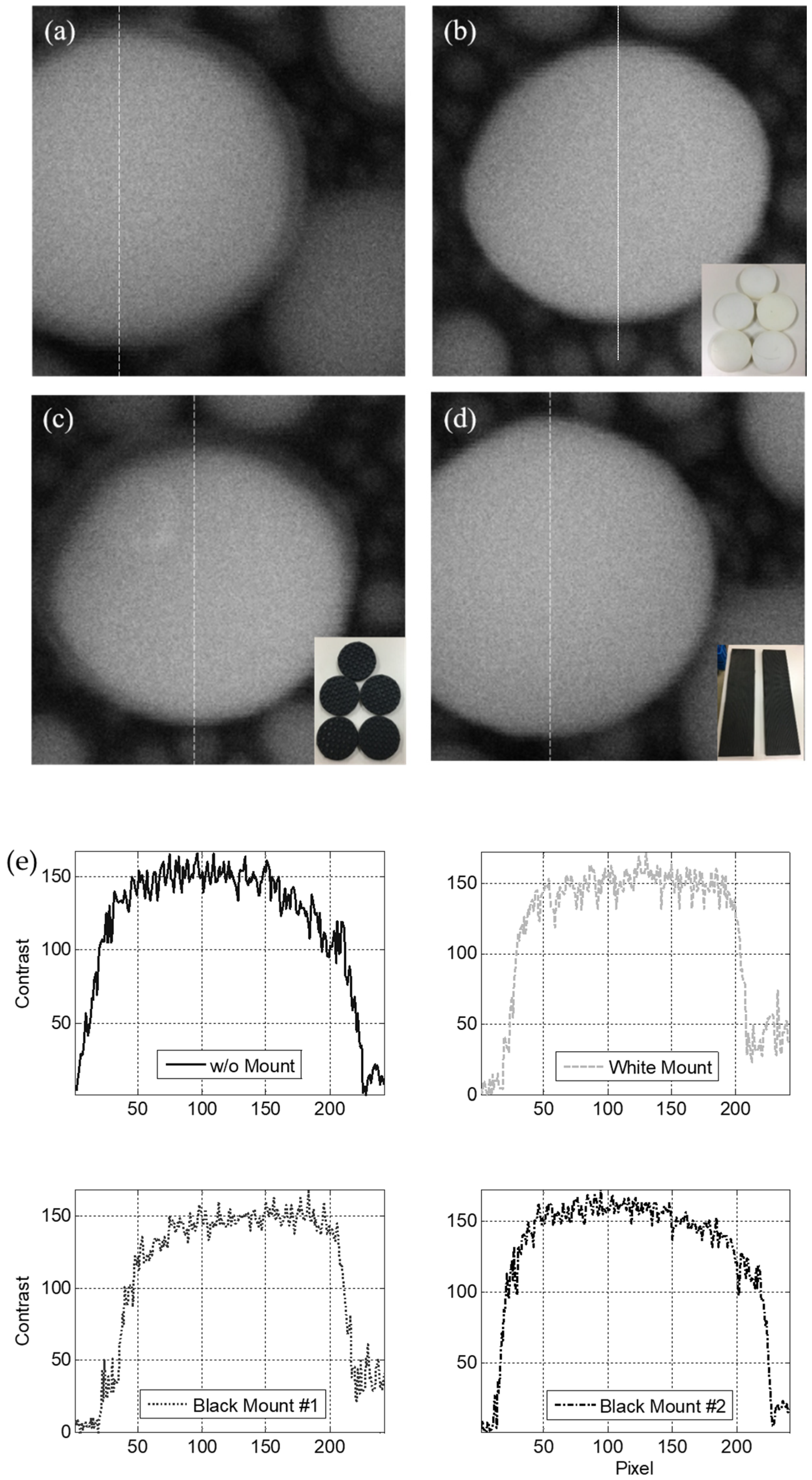

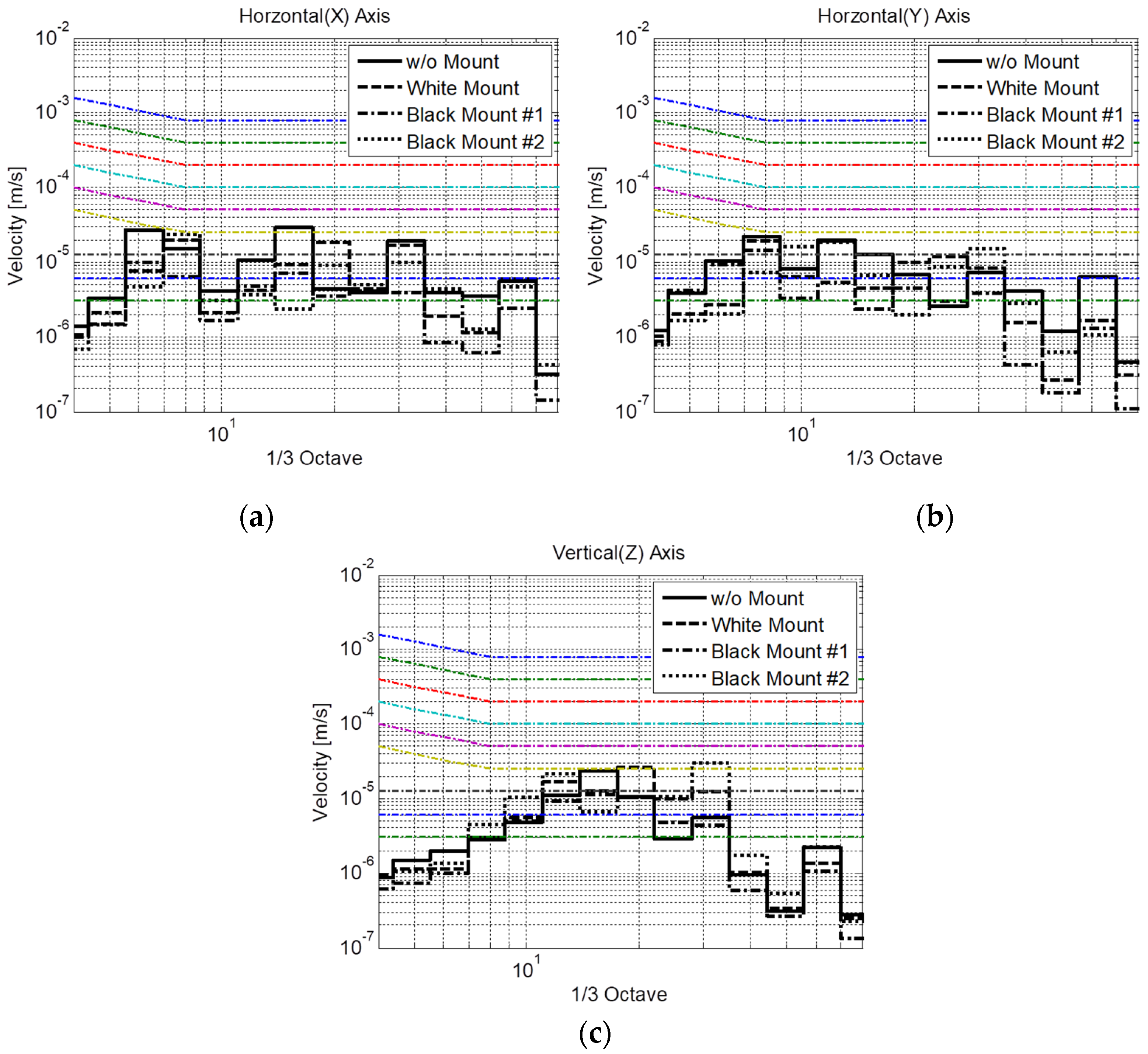

3.2.2. Internal Vibration Control

4. Conclusions

- The configuration of the measuring instruments and the selection of sensors are discussed to measure the extremely small vibrations in an SEM and its environment, and an improved arrangement of the general configuration of the SEM equipment is proposed.

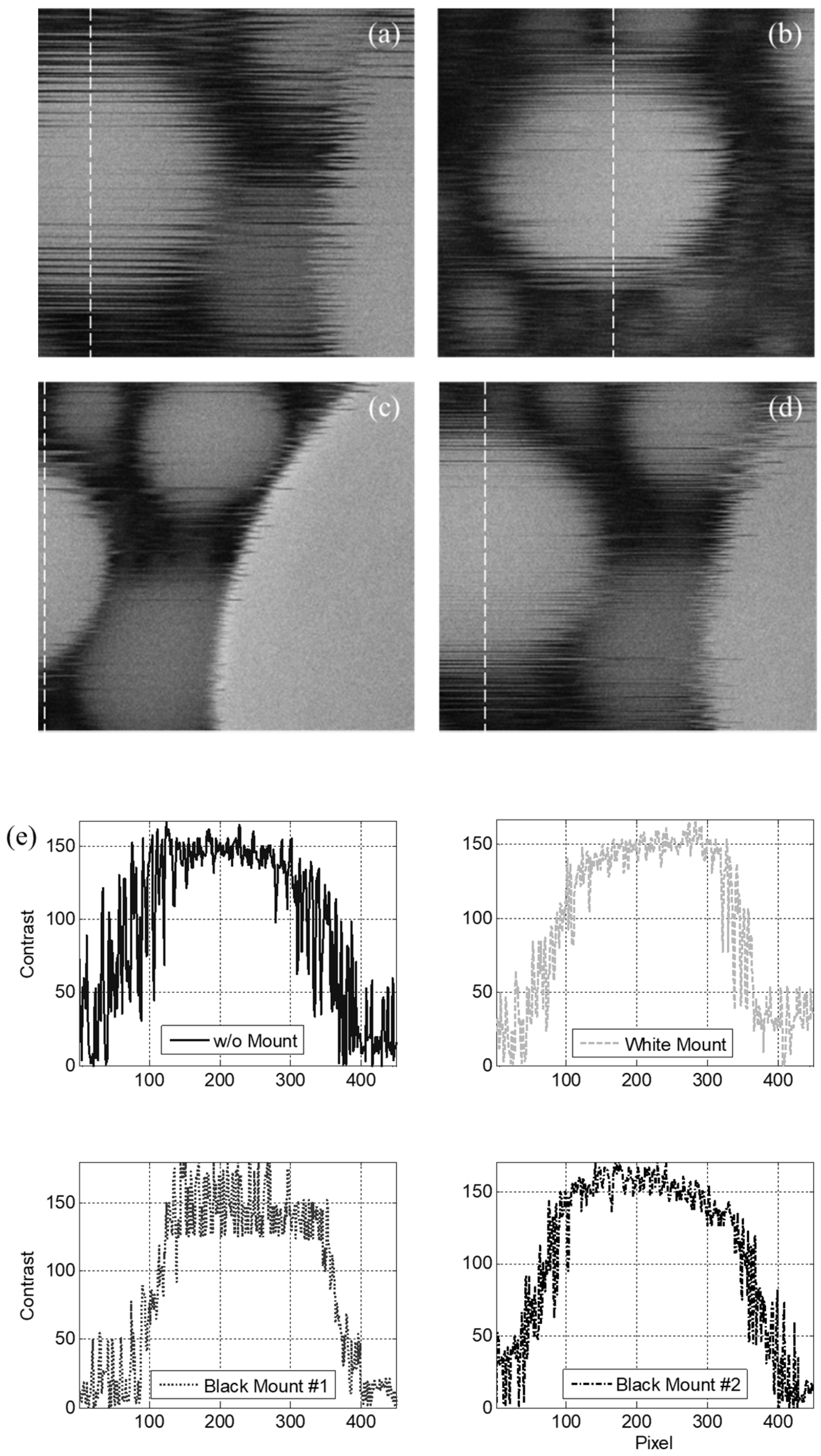

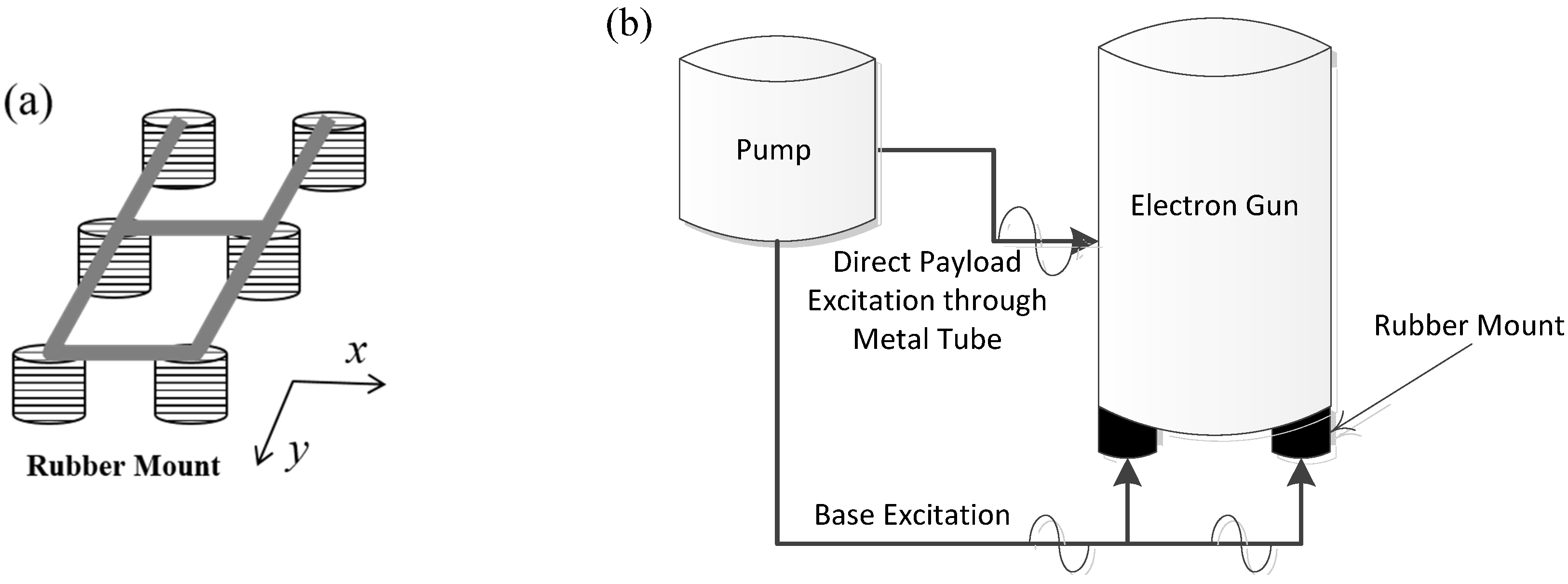

- An attempt is made to quantify the image patterns measured with the SEM; the post-processing computer and the main body of the SEM are separated, and the lower structure supporting the main body of the SEM are reinforced to reduce vibrations in this study. A mount selection guide for the dual elastic mount configuration is also presented. The proposed configuration is obtained by analyzing the measured image patterns and vibrations of the lower mount on the SEM.

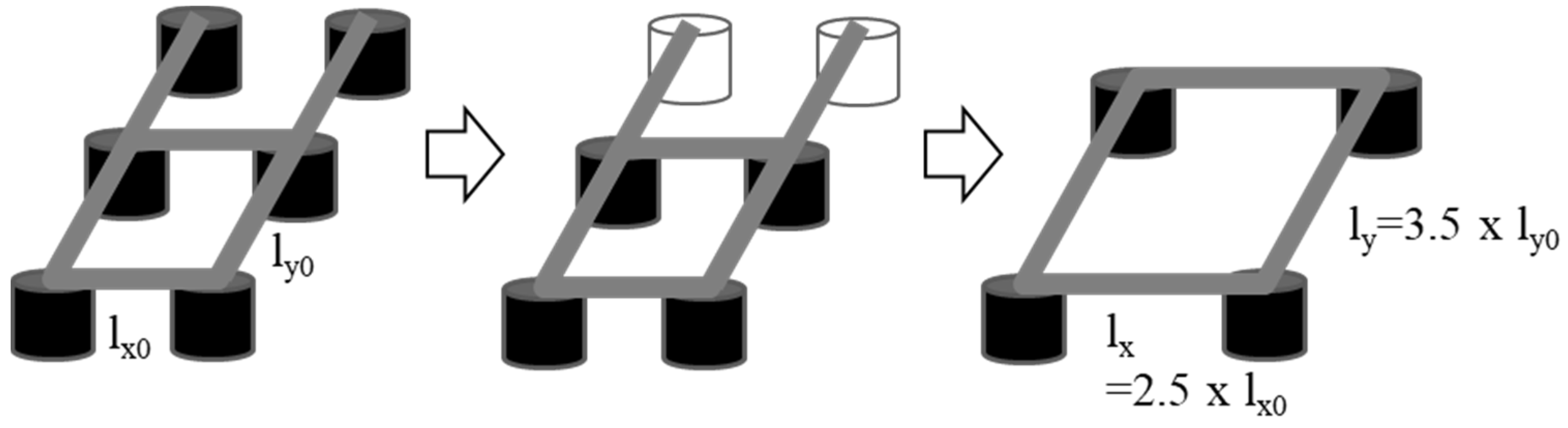

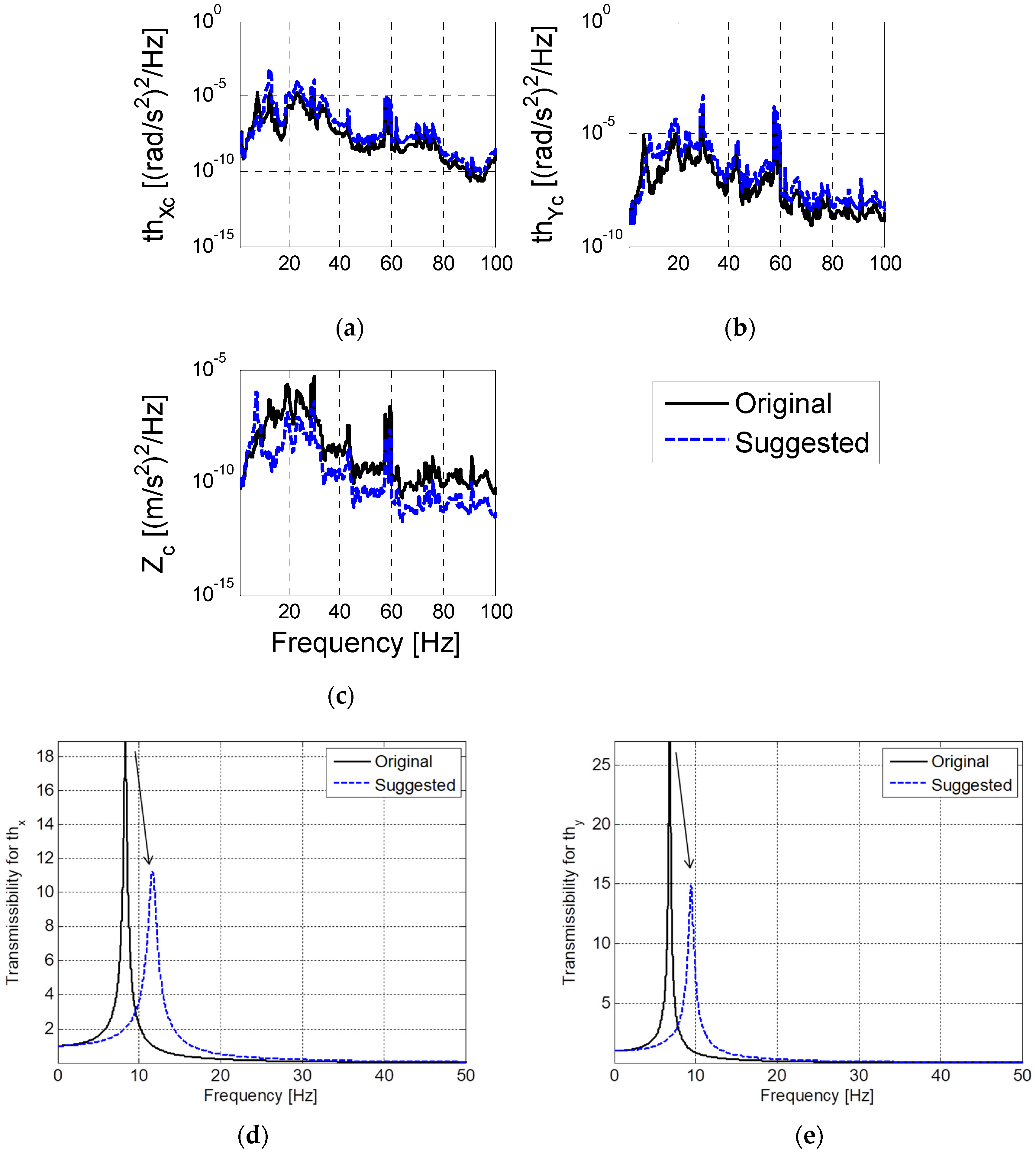

- Design changes and mounting placements are proposed based on a review of the results of impact tests and simulations performed on the top mounted electron gun and mounting supports for the dual elastic mounting configuration. Based on the current design, structural changes are proposed such that the natural frequency in the direction of rotation will occur after the natural frequency in the vertical direction.

Author Contributions

Funding

Conflicts of Interest

Appendix A. Selection of Accelerometer for Measurement of Environmental Vibration

Appendix B. VC-Curve

| Curve Criterion | Amplitude (1) μm/s (μin/s) | Detail Size (2) μm | Description of Use |

|---|---|---|---|

| Workshop (ISO) | 800 (32,000) | N/A | Distinctly perceptible vibration. Appropriate for workshops and non-sensitive areas. |

| Office (ISO) | 400 (16,000) | N/A | Perceptible vibration. Appropriate for offices and non-sensitive areas. |

| Residential Day (ISO) | 200 (8000) | 75 | Barely perceptible vibration. Appropriate for sleep areas in most instances. Usually adequate for computer equipment, hospital recovery rooms, semiconductor probe test equipment, and microscopes less than 40×. |

| Op. Theatre (ISO) | 100 (4000) | 25 | Vibration not perceptible. Suitable in most instances for surgical suites, microscopes to 100×, and for other equipment with low sensitivity. |

| VC-A | 50 (2000) | 8 | Adequate in most instances for optical microscopes up to 400×, microbalances, optical balances, proximity, and projection aligners, etc. |

| VC-B | 25 (1000) | 3 | Appropriate for inspection and lithography (including steppers) to line widths of 3 μm. |

| VC-C | 12.5 (500) | 1–3 | Appropriate standard for optical microscopes up to 1000×, inspection and lithography inspection equipment (including moderately sensitive electron microscopes), to 1 μm detail size, and thin film transistor liquid crystal display (TFT-LCD) stepper/scanner processes. |

| VC-D | 6.25 (250) | 0.1–0.3 | Suitable in most instances for the most demanding equipment including electron microscopes (transmission electron microscopes (TEMs) and scanning electron microscopes (SEMs)) and E-Beam systems. |

| VC-E | 3.12 (125) | <0.1 | A challenging criterion to achieve. Assumed to be adequate for the most demanding sensitive systems including long path, laser-based, and small target systems; E-Beam lithography systems working at nanometer scales; and other systems requiring extraordinary dynamic stability. |

References

- Lian, X.; Chen, J.; Zhang, Y.; Qin, M.; Li, J.; Tian, S.; Yang, W.; Lu, X.; Wu, G.; Chen, H. Highly efficient Sn/Pb binary perovskite solar cell via precursor engineering: A two-step fabrication process. Adv. Funct. Mater. 2019, 29, 1807024. [Google Scholar]

- Derakhshani, M.; Allgeier, B.E.; Berfield, T.A. Study on the fabrication process of MEMS bistable energy harvester based on coupled component structures. In Mechanics of Biological Systems & Micro- and Nanomechanics; Grady, M., Minary, M., Starman, L.V., Hay, J., Notbohm, J., Eds.; Springer: Cham, Switzerland, 2019; Volume 4, pp. 75–79. [Google Scholar]

- Mishra, M.K.; Dubey, V.; Mishra, P.M.; Khan, I. MEMS technology: A review. J. Eng. Res. Rep. 2019, 4, 1–24. [Google Scholar] [CrossRef]

- Totsu, K.; Moriyama, M.; Esashi, M. MEMS research is better together. Nat. Electron. 2019, 2, 134–136. [Google Scholar] [CrossRef]

- Gordon, C.G. Generic Vibration Criteria for Vibration-Sensitive Equipment. In Proceedings of the SPIE Conference On Current Developments In Vibration Control For Optomechanical Systems, Denver, CO, USA, 28 September 1999. [Google Scholar] [CrossRef]

- Amick, H. On generic vibration criteria for advanced technology facilities. J. Inst. Environ. Sci. 1997, 40, 35–44. [Google Scholar]

- International Standards Organization, ISO 2631. Mechanical Vibration and Shock—Evaluation of Human Exposure to Whole-Body Vibration, Parts 1: General Requirements and 2: Vibration in Building; ISO: Geneva, Switzerland, 1997. [Google Scholar]

- Amick, H.; Hichael, G.; Busch, T.; Gordon, C. Evolving Criteria for Research Facilities: I-Vibration. In Proceedings of the SPIE Conference: Buildings for Nanoscale Research and Beyond, San Diego, CA, USA, 31 July 2005; Volume 5933. [Google Scholar]

- Lee, J.H.; Kim, K.J. Modeling of nonlinear complex stiffness of dual-chamber pneumatic spring for precision vibration isolations. J. Sound Vib. 2007, 301, 909–926. [Google Scholar] [CrossRef]

- Lee, J.H.; Kim, K.J. A method of transmissibility design for dual-chamber pneumatic vibration isolator. J. Sound Vib. 2009, 323, 67–92. [Google Scholar] [CrossRef]

- Xu, D.; Yu, Q.; Shen, F.; Zhu, Y.; Guan, G. An analytical model for a pneumatic vibration isolator with the stiffness effect of the elastomeric diaphragm. Shock Vib. 2018, 2018, 8209290. [Google Scholar] [CrossRef]

- Meiritz Seiki Co., Ltd. Meiritz Active Pneumatic Suspension, Product Name: MAPS Series, Japan. Available online: http://http://www.meiritz.jp/eng/product/vibration-isolation/maps.html (accessed on 14 April 2020).

- Technical Manufacturing Corporation (TMC). Active Vibration Cancellation System, Product Name: TMC Eletro-Damp II, United States. Available online: https://www.techmfg.com/products/active-and-passive-vibratoin-isolators-for-oem-integration/electro-damp-ii (accessed on 14 April 2020).

- Bilz Vibration Technology. Active Vibration Isolation Stage, Product Name: AISTM, United States. Available online: https://www.bilz.ag/en/ais-active-isolation-system/ (accessed on 14 April 2020).

- Palomares, E.; Nieto, A.J.; Morales, A.L.; Chicharro, J.M.; Pintado, P. Numerical and experimental analysis of a vibration isolator equipped with a negative stiffness system. J. Sound Vib. 2018, 414, 31–42. [Google Scholar] [CrossRef]

- Kerber, F.; Beadle, B.M.; Hurlebaus, S.; Stöbener, U. Control concepts for an active vibration isolation system. Mech. Syst. Signal Process. 2007, 21, 3042–3059. [Google Scholar] [CrossRef]

- Kato, T.; Kawashima, K.; Sawamoto, K.; Kagawa, T. Active control of a pneumatic isolation table using model following control and a pressure differentiator. Precis. Eng. 2007, 31, 269–275. [Google Scholar] [CrossRef]

- Shin, Y.H.; Kim, K.J. Performance enhancement of pneumatic vibration isolation tables in low frequency range by time delay control. J. Sound Vib. 2009, 321, 537–553. [Google Scholar] [CrossRef]

- Chen, H.Y.; Liang, J.W.; Wu, J.W. Active pneumatic vibration control by using pressure and velocity measurements and adaptive fuzzy sliding-mode controller. Sensors 2013, 13, 8431–8444. [Google Scholar] [CrossRef] [PubMed]

- Hong, D.P.; Hwang, H.Y.; Lee, M.Y.; Jo, Y.K.; Vu, D.T.; Lee, D.Y. New electro-magnetic actuator for active vibration isolators. Int. J. Precis. Eng. Manuf. 2015, 16, 209–212. [Google Scholar] [CrossRef]

- Nagaya, N.; Ishikawa, M. A noncontact permanent magnet levitation table with electromagnetic control and its vibration isolation method using direct disturbance cancellation combining optimal regulators. IEEE Trans. Magn. 1995, 31, 885–896. [Google Scholar] [CrossRef]

- Jang, D.D.; Jung, H.J.; Shin, Y.H. Feasibility study on a hybrid mount system with air springs and piezo-stack actuators for microvibration control. J. Intell. Mater. Syst. Struct. 2012, 23, 515–526. [Google Scholar] [CrossRef]

- Bendat, J.S.; Piersol, A.G. Random Data: Analysis and Measurement Procedures, 4th ed.; John Wiley & Sons, Inc.: New York, NY, USA, 2010. [Google Scholar]

- Ewins, D.J. Modal Testing Theory, Practice and Application, 2nd ed.; Research Studies Press Ltd.: Baldock, UK, 2000. [Google Scholar]

| Normal Operational Vibration | Extreme Environmental Vibration | |||||

|---|---|---|---|---|---|---|

| x-axis | y-axis | z-axis | x-axis | y-axis | z-axis | |

| w/o mount | VC-A | VC-B | VC-B | Workshop | Workshop | Workshop |

| White (9.8 × 105 N/m) | VC-B | VC-B | VC-A | Office | Office | Workshop |

| Black #1 (8.8 × 105 N/m) | VC-C | VC-B | VC-C | Residential | Residential | Office |

| Black #2 (10.1 × 105 N/m) | VC-B | VC-B | VC-A | Office | Residential | Office |

| Electron Gun | Rubber Mount | Tube | ||||

|---|---|---|---|---|---|---|

| Stiffness | Damping | Stiffness | Damping | |||

| Mass, M | 40 kg | Vertical Direction, (kv, cv) | 4.38 × 104 N/m | 62.9 N·s/m | - | - |

| Moment of Inertia, Ixx | 0.65 kgm2 | X-Rotational Direction, (kϴx, cϴx) | 1.58 × 103 Nm/rad | 2.3 Nm·s/rad | 1.89 × 102 Nm/rad | 0.1 Nm·s/rad |

| Moment of Inertia, Iyy | 0.65 kgm2 | Y-Rotational Direction, (kϴy, cϴy) | 0.84 × 103 Nm/rad | 1.2 Nm·s/rad | 3.44 × 102 Nm/rad | 0.1 Nm·s/rad |

| Original | Suggested | |||

|---|---|---|---|---|

| Resonance | Rank | Resonance | Rank | |

| ϴy | 6.8 Hz | 1 | 9.4 Hz | 2 |

| ϴx | 8.3 Hz | 2 | 11.6 Hz | 3 |

| z | 12.9 Hz | 3 | 7.4 Hz | 1 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shin, Y.-H.; Moon, S.-J.; Kim, Y.-J.; Oh, K.-Y. Vibration Control of Scanning Electron Microscopes with Experimental Approaches for Performance Enhancement. Sensors 2020, 20, 2277. https://doi.org/10.3390/s20082277

Shin Y-H, Moon S-J, Kim Y-J, Oh K-Y. Vibration Control of Scanning Electron Microscopes with Experimental Approaches for Performance Enhancement. Sensors. 2020; 20(8):2277. https://doi.org/10.3390/s20082277

Chicago/Turabian StyleShin, Yun-Ho, Seok-Jun Moon, Yong-Ju Kim, and Ki-Yong Oh. 2020. "Vibration Control of Scanning Electron Microscopes with Experimental Approaches for Performance Enhancement" Sensors 20, no. 8: 2277. https://doi.org/10.3390/s20082277

APA StyleShin, Y.-H., Moon, S.-J., Kim, Y.-J., & Oh, K.-Y. (2020). Vibration Control of Scanning Electron Microscopes with Experimental Approaches for Performance Enhancement. Sensors, 20(8), 2277. https://doi.org/10.3390/s20082277