Microbial Nanocellulose Printed Circuit Boards for Medical Sensing

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials and Components

2.2. Nanocellulose Growth and Sheet Formation

2.3. AFM Characterization

2.4. Thickness Measurements

2.5. Electroless Plating on Nanocellulose Sheets

2.6. Soldering of Surface Mount Electronics and Electrodes on Nanocellulose

2.7. Electrical Testing

2.8. Notes

3. Results and Discussion

3.1. Synthesis of Ultra-Thin Nanocellulose Sheets

3.2. Nanocellulose Characteristics for Flexible Electronics

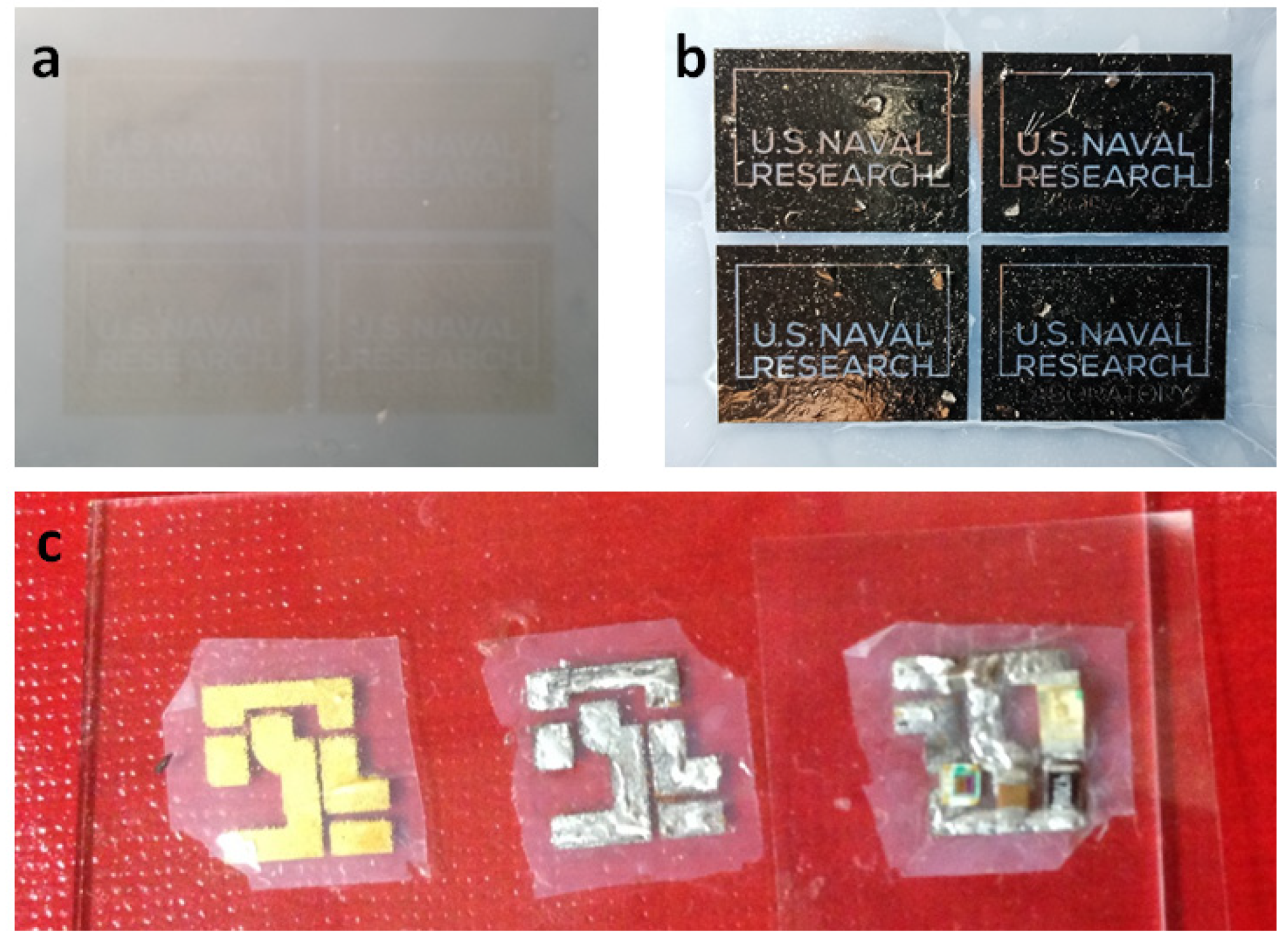

3.3. Nanocellulose PCB Fabrication

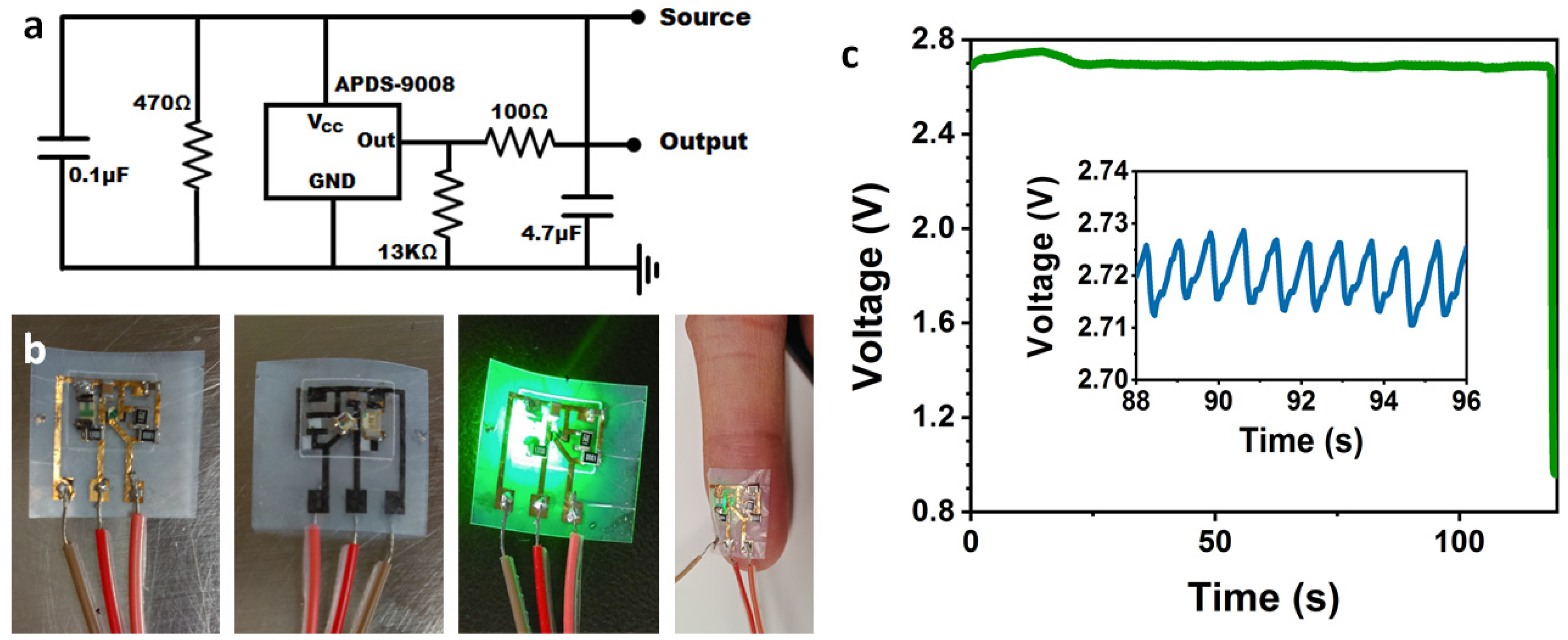

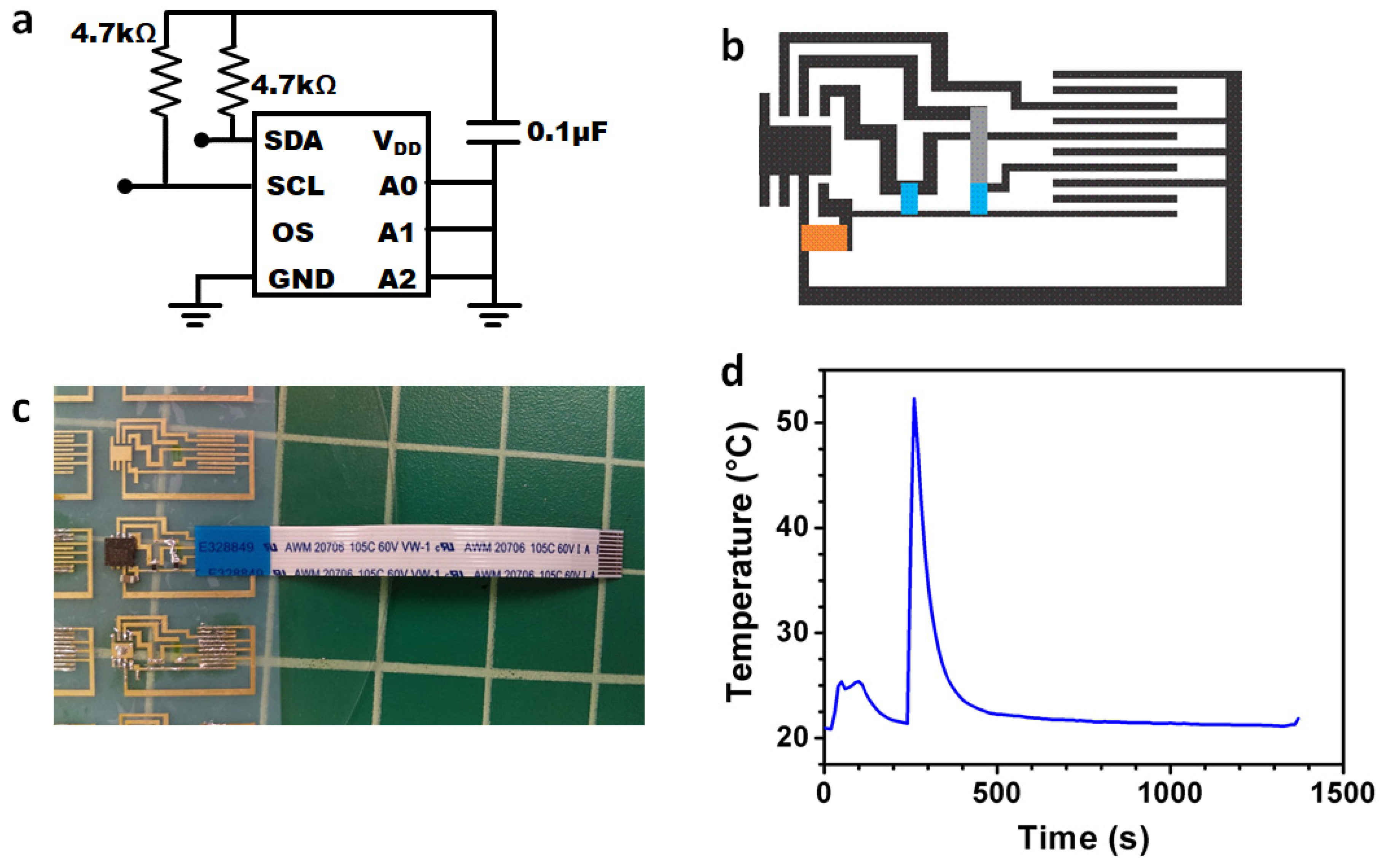

3.4. Examples of Medical Application of Nanocellulose PCBs

4. Conclusions

Supplementary Materials

Author Contributions

Acknowledgments

Conflicts of Interest

Appendix A. Thickness Profile and Thickness Distribution Data of Nanocellulose Sheets

Appendix B. Adhesion Tape Tests Experimental and Video Description

References

- Khan, Y.; Ostfeld, A.E.; Lochner, C.M.; Pierre, A.; Arias, A.C. Monitoring of Vital Signs with Flexible and Wearable Medical Devices. Adv. Mater. 2016, 28, 4373–4395. [Google Scholar] [CrossRef]

- Liu, Y.; Pharr, M.; Salvatore, G.A. Lab-on-Skin: A Review of Flexible and Stretchable Electronics for Wearable Health Monitoring. ACS Nano 2017, 11, 9614–9635. [Google Scholar] [CrossRef]

- Ling, H.; Liu, S.; Zheng, Z.; Yan, F. Organic Flexible Electronics. Small Methods 2018, 2, 70. [Google Scholar] [CrossRef]

- Gao, W.; Ota, H.; Kiriya, D.; Takei, K.; Javey, A. Flexible Electronics toward Wearable Sensing. Acc. Chem. Res. 2019, 52, 523–533. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Gao, W. Wearable and flexible electronics for continuous molecular monitoring. Chem. Soc. Rev. 2019, 48, 1465–1491. [Google Scholar] [CrossRef] [PubMed]

- Kaltenbrunner, M.; White, M.S.; Głowacki, E.D.; Sekitani, T.; Someya, T.; Sariciftci, N.S.; Bauer, S. Ultrathin and lightweight organic solar cells with high flexibility. Nat. Commun. 2012, 3, 770. [Google Scholar] [CrossRef]

- Kaltenbrunner, M.; Sekitani, T.; Reeder, J.; Yokota, T.; Kuribara, K.; Tokuhara, T.; Drack, M.; Schwödiauer, R.; Graz, I.; Bauer-Gogonea, S.; et al. An ultra-lightweight design for imperceptible plastic electronics. Nature 2013, 499, 458–463. [Google Scholar] [CrossRef]

- Someya, T.; Bauer, S.; Kaltenbrunner, M. Imperceptible organic electronics. MRS Bull. 2017, 42, 124–130. [Google Scholar] [CrossRef]

- Wang, X.; Dong, L.; Zhang, H.; Yu, R.; Pan, C.; Wang, Z.L. Recent Progress in Electronic Skin. Adv. Sci. 2015, 2, 169. [Google Scholar] [CrossRef]

- Biji, K.B.; Ravishankar, C.N.; Mohan, C.O.; Srinivasa Gopal, T.K. Smart packaging systems for food applications: A review. J. Food Sci. Technol. 2015, 52, 6125–6135. [Google Scholar] [CrossRef]

- Son, M.; Park, T.H. The bioelectronic nose and tongue using olfactory and taste receptors: Analytical tools for food quality and safety assessment. Biotechnol. Adv. 2018, 36, 371–379. [Google Scholar] [CrossRef] [PubMed]

- Takei, K.; Gao, W.; Wang, C.; Javey, A. Physical and Chemical Sensing With Electronic Skin. Proc. IEEE 2019, 107, 2155–2167. [Google Scholar] [CrossRef]

- Yang, J.C.; Mun, J.; Kwon, S.Y.; Park, S.; Bao, Z.; Park, S. Electronic Skin: Recent Progress and Future Prospects for Skin-Attachable Devices for Health Monitoring, Robotics, and Prosthetics. Adv. Mater. 2019, 31, 4765. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Yu, J.; Wang, T.; Li, C.; Wei, Y.; Deng, X.; Chen, X. Emerging Intraoral Biosensors. J. Mater. Chem. B 2020. [Google Scholar] [CrossRef]

- Magliulo, M.; Mulla, M.Y.; Singh, M.; Macchia, E.; Tiwari, A.; Torsi, L.; Manoli, K. Printable and flexible electronics: From TFTs to bioelectronic devices. J. Mater. Chem. C 2015, 3, 12347–12363. [Google Scholar] [CrossRef]

- Someya, T.; Bao, Z.; Malliaras, G.G. The rise of plastic bioelectronics. Nature 2016, 540, 379–385. [Google Scholar] [CrossRef]

- Inal, S.; Rivnay, J.; Suiu, A.-O.; Malliaras, G.G.; McCulloch, I. Conjugated Polymers in Bioelectronics. Acc. Chem. Res. 2018, 51, 1368–1376. [Google Scholar] [CrossRef]

- Yu, Y.; Nyein, H.Y.Y.; Gao, W.; Javey, A. Flexible Electrochemical Bioelectronics: The Rise of In Situ Bioanalysis. Adv. Mater. 2019, 2083. [Google Scholar] [CrossRef]

- Gershenfeld, N.; Krikorian, R.; Cohen, D. The Internet of Things. Sci. Am. 2004, 291, 76–81. [Google Scholar] [CrossRef]

- Atzori, L.; Iera, A.; Morabito, G. The Internet of Things: A survey. Comput. Netw. 2010, 54, 2787–2805. [Google Scholar] [CrossRef]

- Gubbi, J.; Buyya, R.; Marusic, S.; Palaniswami, M. Internet of Things (IoT): A vision, architectural elements, and future directions. Future Gener. Comput. Syst. 2013, 29, 1645–1660. [Google Scholar] [CrossRef]

- Hsu, C.-L.; Lin, J.C.-C. An empirical examination of consumer adoption of Internet of Things services: Network externalities and concern for information privacy perspectives. Comput. Hum. Behav. 2016, 62, 516–527. [Google Scholar] [CrossRef]

- Halden, R.U. Plastics and Health Risks. Annu. Rev. Public Health 2010, 31, 179–194. [Google Scholar] [CrossRef] [PubMed]

- Köhler, A.R. Challenges for eco-design of emerging technologies: The case of electronic textiles. Mater. Des. 2013, 51, 51–60. [Google Scholar] [CrossRef]

- Ceballos, D.M.; Dong, Z. The formal electronic recycling industry: Challenges and opportunities in occupational and environmental health research. Environ. Int. 2016, 95, 157–166. [Google Scholar] [CrossRef] [PubMed]

- Kargarzadeh, H.; Ahmad, I.; Thomas, S.; Dufresne, A. Handbook of Nanocellulose and Cellulose Nanocomposites; Wiley-VCH: Weinheim, Germany, 2017. [Google Scholar]

- Ainla, A.; Xu, S.; Sanchez, N.; Jeffries, G.D.M.; Jesorka, A. Single-cell electroporation using a multifunctional pipette. Lab Chip 2012, 12, 4605–4609. [Google Scholar] [CrossRef] [PubMed]

- Paglia, D.N.; Wey, A.; Hreha, J.; Park, A.G.; Cunningham, C.; Uko, L.; Benevenia, J.; O’Connor, J.P.; Lin, S.S. Local vanadium release from a calcium sulfate carrier accelerates fracture healing. J. Orthop. Res. 2014, 32, 727–734. [Google Scholar] [CrossRef]

- Khan, W.; Jia, Y.; Madi, F.; Weber, A.; Ghovanloo, M.; Li, W. A Miniaturized, Wirelessly-Powered, Reflector-Coupled Single Channel Opto Neurostimulator. In Proceedings of the 2018 IEEE Micro Electro Mechanical Systems (MEMS), Belfast, UK, 21–25 January 2018; pp. 174–177. [Google Scholar]

- Panwar, J.; Roy, R. Integrated Field’s metal microelectrodes based microfluidic impedance cytometry for cell-in-droplet quantification. Microelectron. Eng. 2019, 215, 111010. [Google Scholar] [CrossRef]

- Naskar, S.; Kumaran, V.; Markandeya, Y.S.; Mehta, B.; Basu, B. Neurogenesis-on-Chip: Electric field modulated transdifferentiation of human mesenchymal stem cell and mouse muscle precursor cell coculture. Biomaterials 2020, 226, 119522. [Google Scholar] [CrossRef]

- Yuen, J.D.; Walper, S.A.; Melde, B.J.; Daniele, M.A.; Stenger, D.A. Electrolyte-Sensing Transistor Decals Enabled by Ultrathin Microbial Nanocellulose. Sci. Rep. 2017, 7, 40867. [Google Scholar] [CrossRef]

- Yuen, J.D.; Baingane, A.; Hasan, Q.; Shriver-Lake, L.C.; Walper, S.A.; Zabetakis, D.; Breger, J.C.; Stenger, D.A.; Slaughter, G. A Fully-Flexible Solution-Processed Autonomous Glucose Indicator. Sci. Rep. 2019, 9, 6931. [Google Scholar] [CrossRef] [PubMed]

- Yamanaka, S.; Watanabe, K.; Kitamura, N.; Iguchi, M.; Mitsuhashi, S.; Nishi, Y.; Uryu, M. The structure and mechanical properties of sheets prepared from bacterial cellulose. J. Mater. Sci. 1989, 24, 3141–3145. [Google Scholar] [CrossRef]

- Gatenholm, P.; Klemm, D. Bacterial Nanocellulose as a Renewable Material for Biomedical Applications. MRS Bull. 2010, 35, 208–213. [Google Scholar] [CrossRef]

- Gea, S.; Bilotti, E.; Reynolds, C.T.; Soykeabkeaw, N.; Peijs, T. Bacterial cellulose–poly(vinyl alcohol) nanocomposites prepared by an in-situ process. Mater. Lett. 2010, 64, 901–904. [Google Scholar] [CrossRef]

- Iguchi, M.; Yamanaka, S.; Budhiono, A. Bacterial cellulose—A masterpiece of nature’s arts. J. Mater. Sci. 2000, 35, 261–270. [Google Scholar] [CrossRef]

- Gromet, Z.; Schramm, M.; Hestrin, S. Synthesis of cellulose by Acetobacter xylinum. 4. Enzyme systems present in a crude extract of glucose-grown cells. Biochem. J. 1957, 67, 679–689. [Google Scholar] [CrossRef]

- Klemm, D.; Schumann, D.; Kramer, F.; Heßler, N.; Hornung, M.; Schmauder, H.P.; Marsch, S. Nanocelluloses As Innovative Polymers in Research and Application; Polysaccharides II; Springer: Berlin/Heidelberg, Germany, 2006; pp. 49–96. [Google Scholar]

- Gama, M.; Dourado, F.; Bielecki, S. Bacterial Nanocellulose: From Biotechnology to Bio-Economy; Elsevier: Amsterdam, The Netherlands, 2016. [Google Scholar]

- Shi, Z.; Zhang, Y.; Phillips, G.O.; Yang, G. Utilization of bacterial cellulose in food. Food Hydrocoll. 2014, 35, 539–545. [Google Scholar] [CrossRef]

- Ullah, H.; Santos, H.A.; Khan, T. Applications of bacterial cellulose in food, cosmetics and drug delivery. Cellulose 2016, 23, 2291–2314. [Google Scholar] [CrossRef]

- Petersen, N.; Gatenholm, P. Bacterial cellulose-based materials and medical devices: Current state and perspectives. Appl. Microbiol. Biotechnol. 2011, 91, 1277–1286. [Google Scholar] [CrossRef]

- Mohite, B.V.; Patil, S.V. A novel biomaterial: Bacterial cellulose and its new era applications: BC and Its New Era Applications. Biotechnol. Appl. Biochem. 2014, 61, 101–110. [Google Scholar] [CrossRef]

- Lee, C.K.; Hsu, K.C.; Cho, J.C.; Kim, Y.J.; Han, S.H.; Amorepacific Corp. Method for Manufacturing a Cosmetic Bio-Cellulose Mask Pack Sheet and Use Thereof. U.S. Patent 9,226,886, 5 January 2016. [Google Scholar]

- Morganti, P.; Morganti, G.; Chen, H.D.; Gagliardini, A. Beauty Mask: Market and Environment. J. Clin. Cosmet. Derm. 2019, 3. [Google Scholar] [CrossRef]

- Gardner, D.J.; Oporto, G.S.; Mills, R.; Samir, M.A.S.A. Adhesion and Surface Issues in Cellulose and Nanocellulose. J. Adhes. Sci. Technol. 2008, 22, 545–567. [Google Scholar] [CrossRef]

- Daniele, M.A.; Yuen, J.D. Pattern Definition of Nanocellulose Sheets Through Selective Ashing via Lithographic Masking. U.S. Patent 9,720,318, 1 August 2017. [Google Scholar]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yuen, J.D.; Shriver-Lake, L.C.; Walper, S.A.; Zabetakis, D.; Breger, J.C.; Stenger, D.A. Microbial Nanocellulose Printed Circuit Boards for Medical Sensing. Sensors 2020, 20, 2047. https://doi.org/10.3390/s20072047

Yuen JD, Shriver-Lake LC, Walper SA, Zabetakis D, Breger JC, Stenger DA. Microbial Nanocellulose Printed Circuit Boards for Medical Sensing. Sensors. 2020; 20(7):2047. https://doi.org/10.3390/s20072047

Chicago/Turabian StyleYuen, Jonathan D., Lisa C. Shriver-Lake, Scott A. Walper, Daniel Zabetakis, Joyce C. Breger, and David A. Stenger. 2020. "Microbial Nanocellulose Printed Circuit Boards for Medical Sensing" Sensors 20, no. 7: 2047. https://doi.org/10.3390/s20072047

APA StyleYuen, J. D., Shriver-Lake, L. C., Walper, S. A., Zabetakis, D., Breger, J. C., & Stenger, D. A. (2020). Microbial Nanocellulose Printed Circuit Boards for Medical Sensing. Sensors, 20(7), 2047. https://doi.org/10.3390/s20072047