Development of a Flex and Stretchy Conductive Cotton Fabric Via Flat Screen Printing of PEDOT:PSS/PDMS Conductive Polymer Composite

Abstract

1. Introduction

2. Materials and Methods

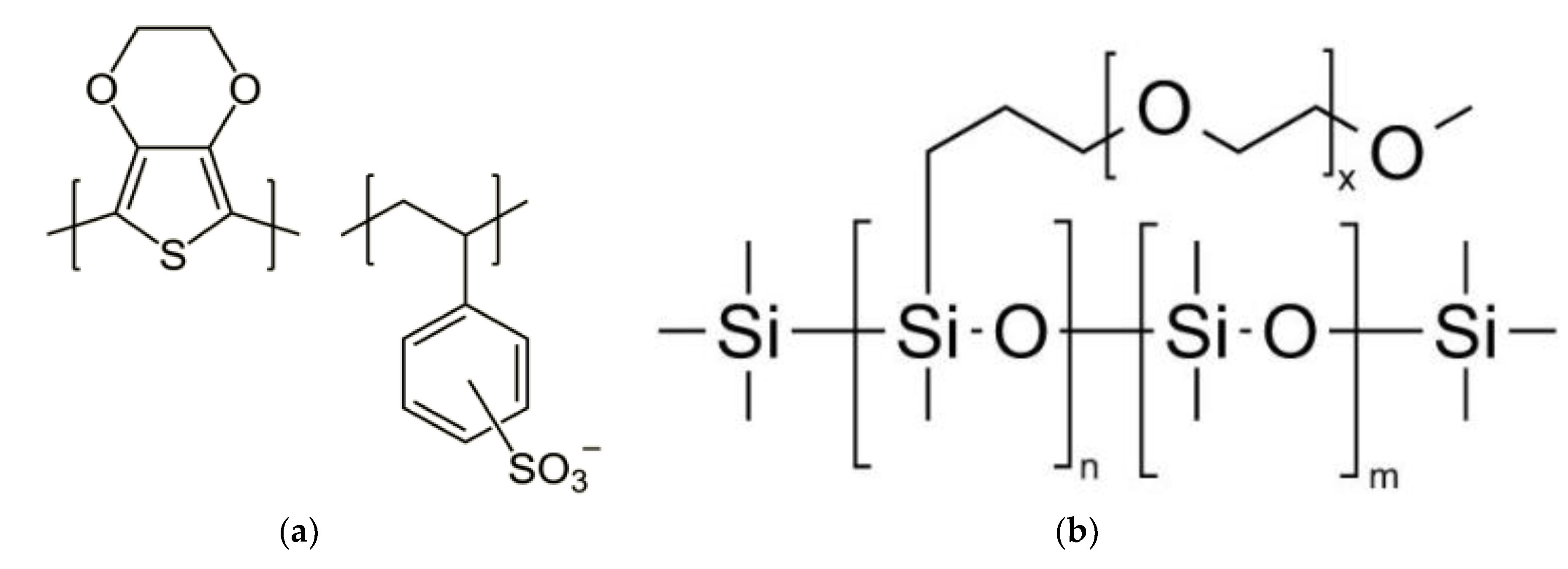

2.1. Material and Chemicals

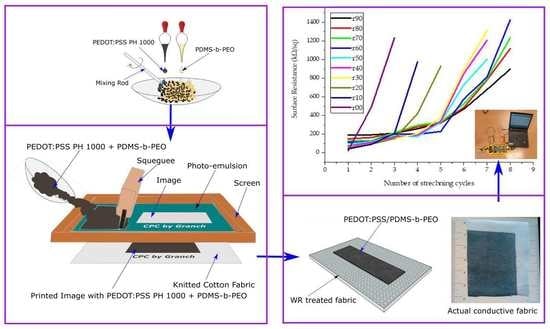

2.2. Methods

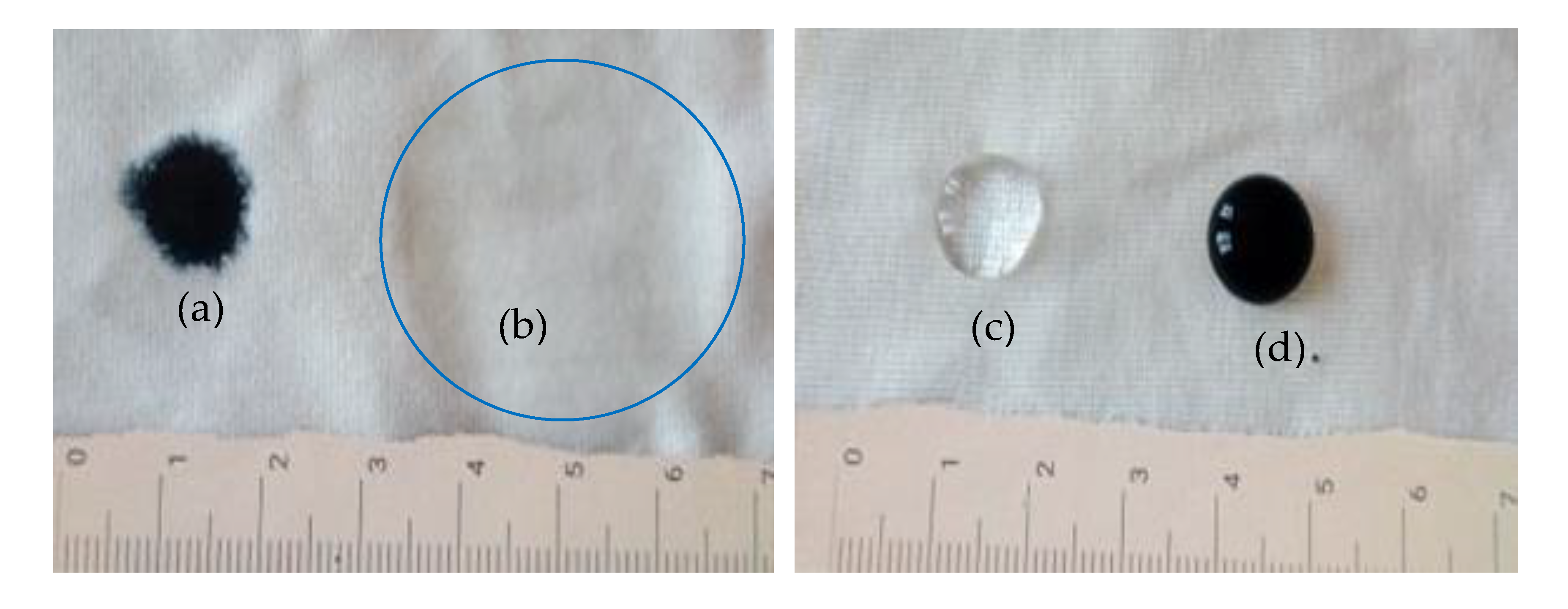

2.1.1. Fabric Water Repellency Pre-Treatment

2.2.2. Flat Screen Printing

2.2.3. Mechanical Characterization

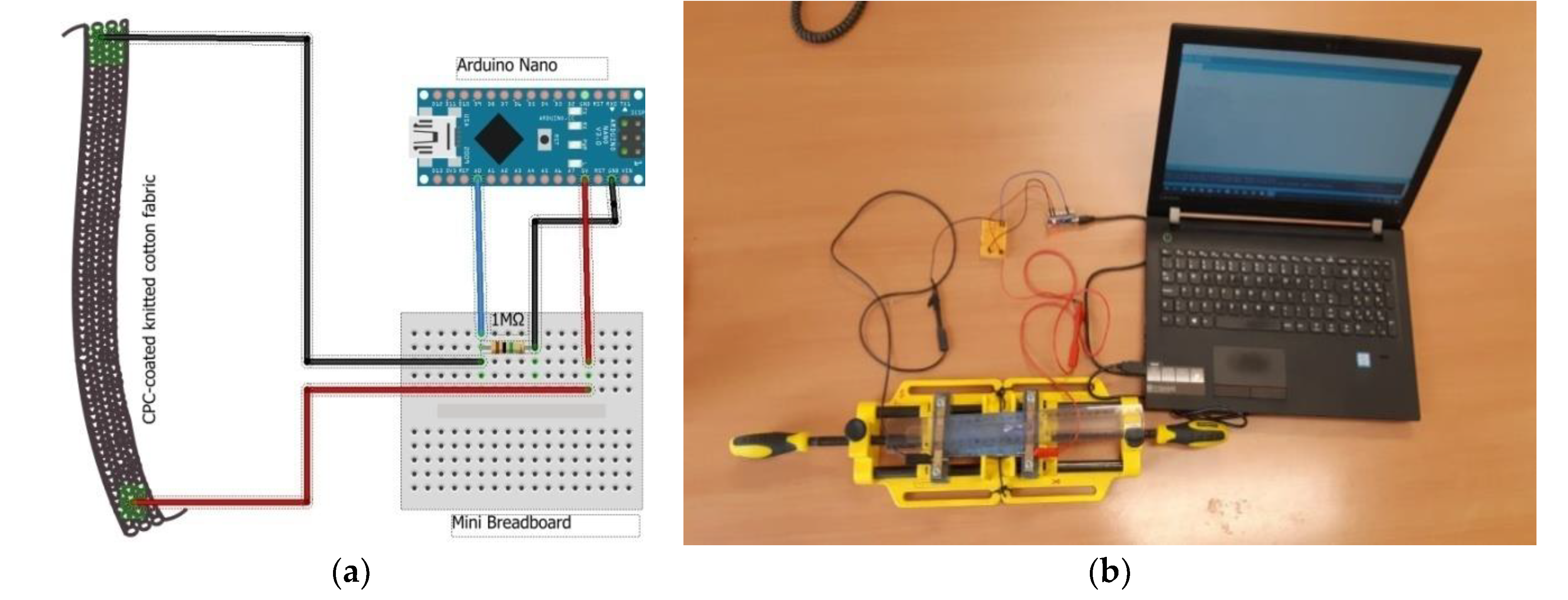

2.2.4. Electrical Characterization

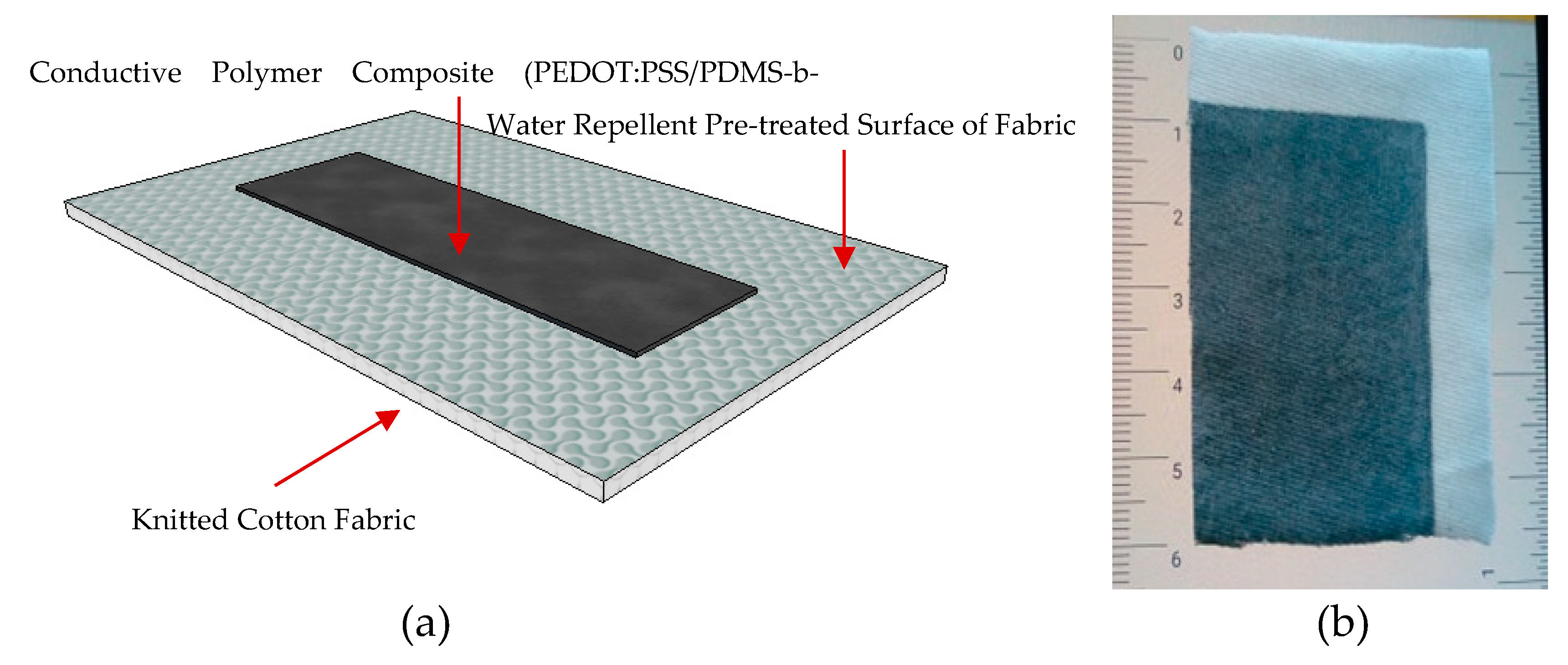

3. Result and Discussion

3.1. Mechanical Property Analysis

3.1.1. Solid Add-on

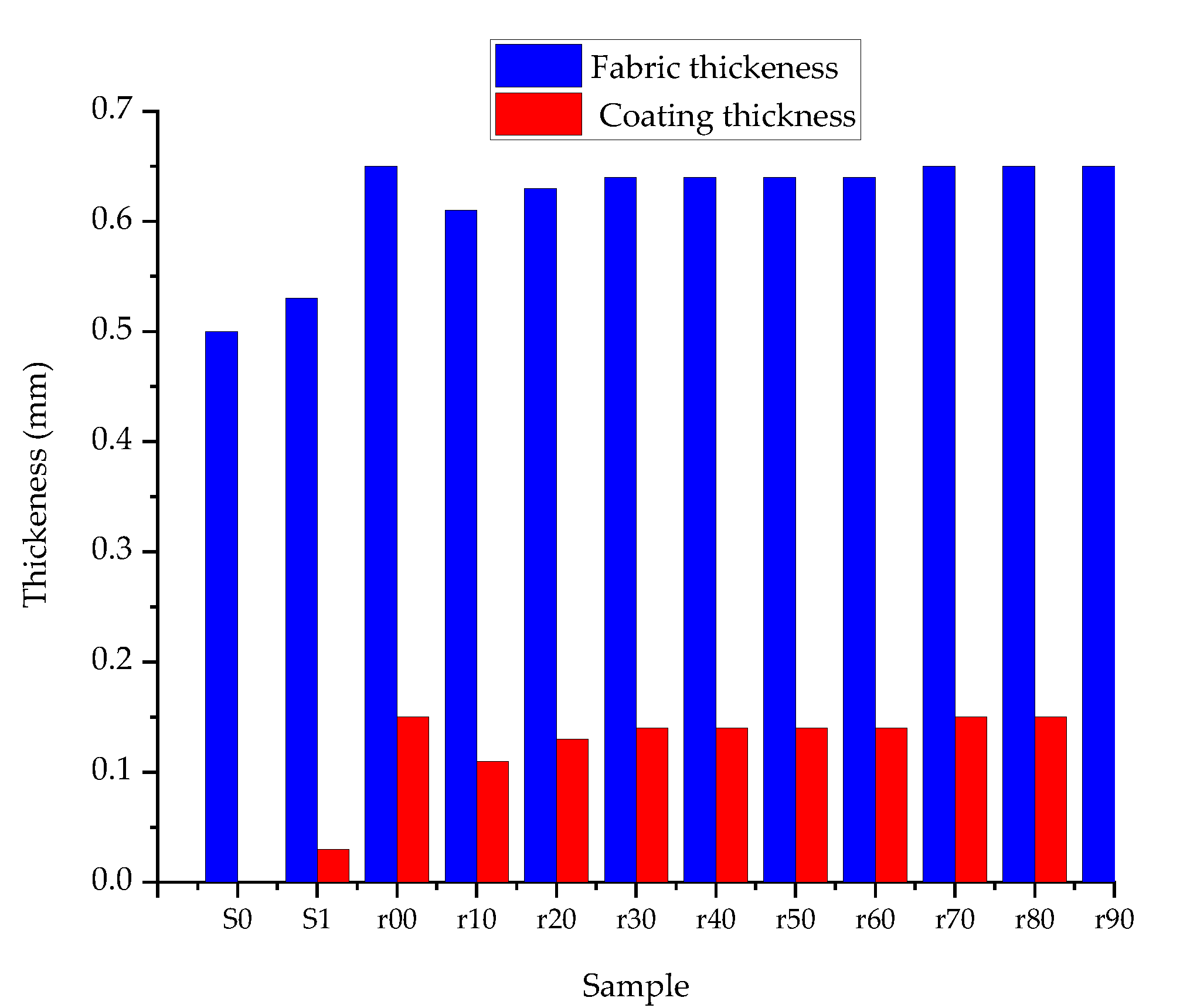

3.1.2. Thickness Analysis

3.1.3. Bending Length Analysis

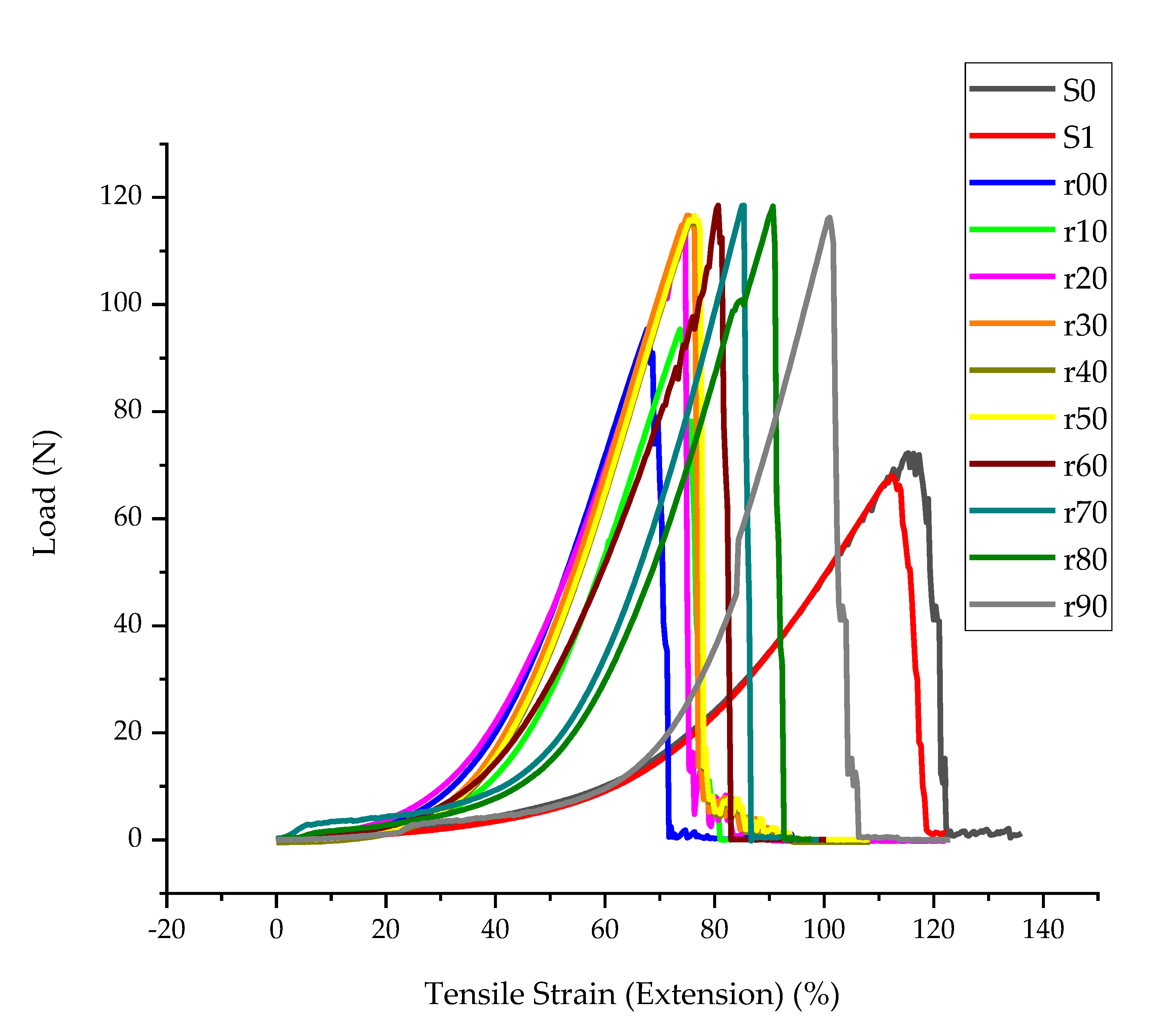

3.1.4. Tensile Strength

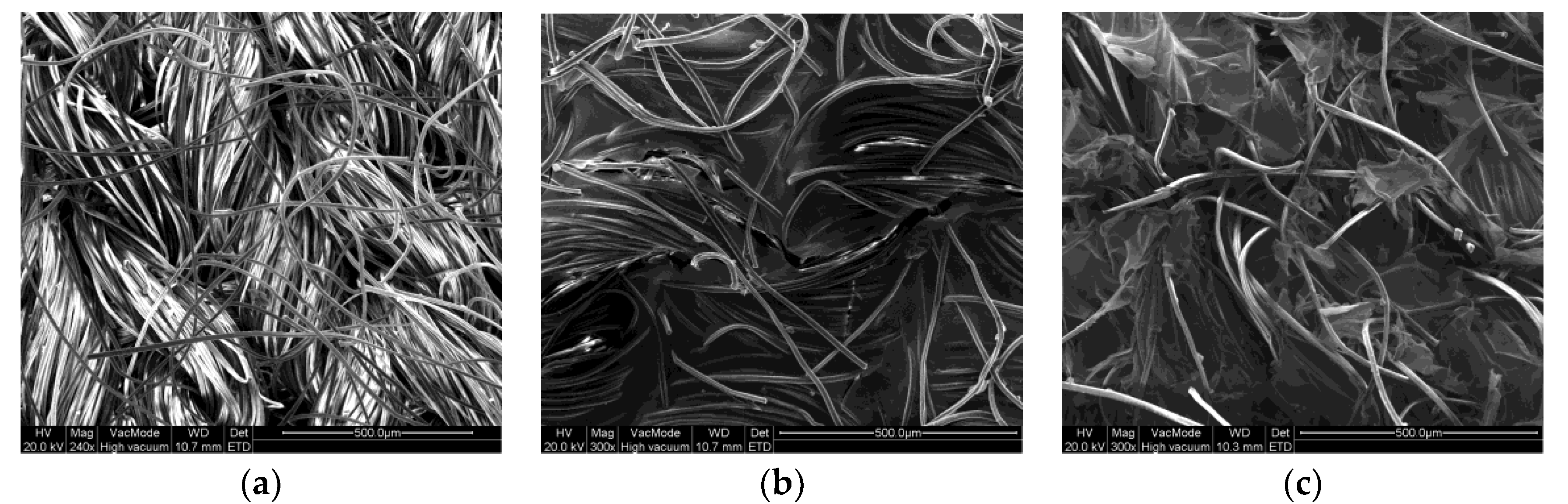

3.1.5. SEM Characteristics of the Conductive Polymer Composite

3.2. Electrical Characteristics Analysis

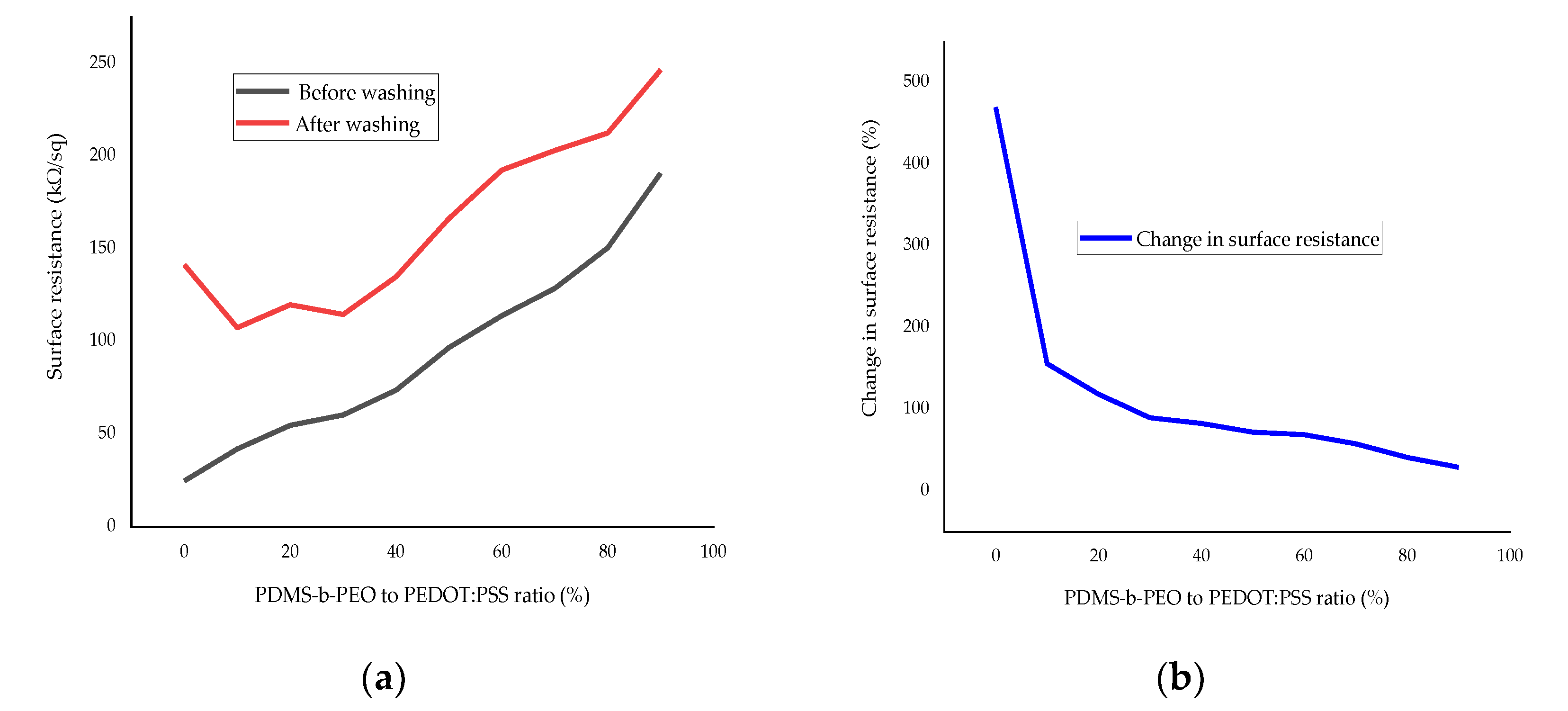

3.2.1. Effect of PDMS-b-PEO to PEDOT:PSS Ratio on Resistance

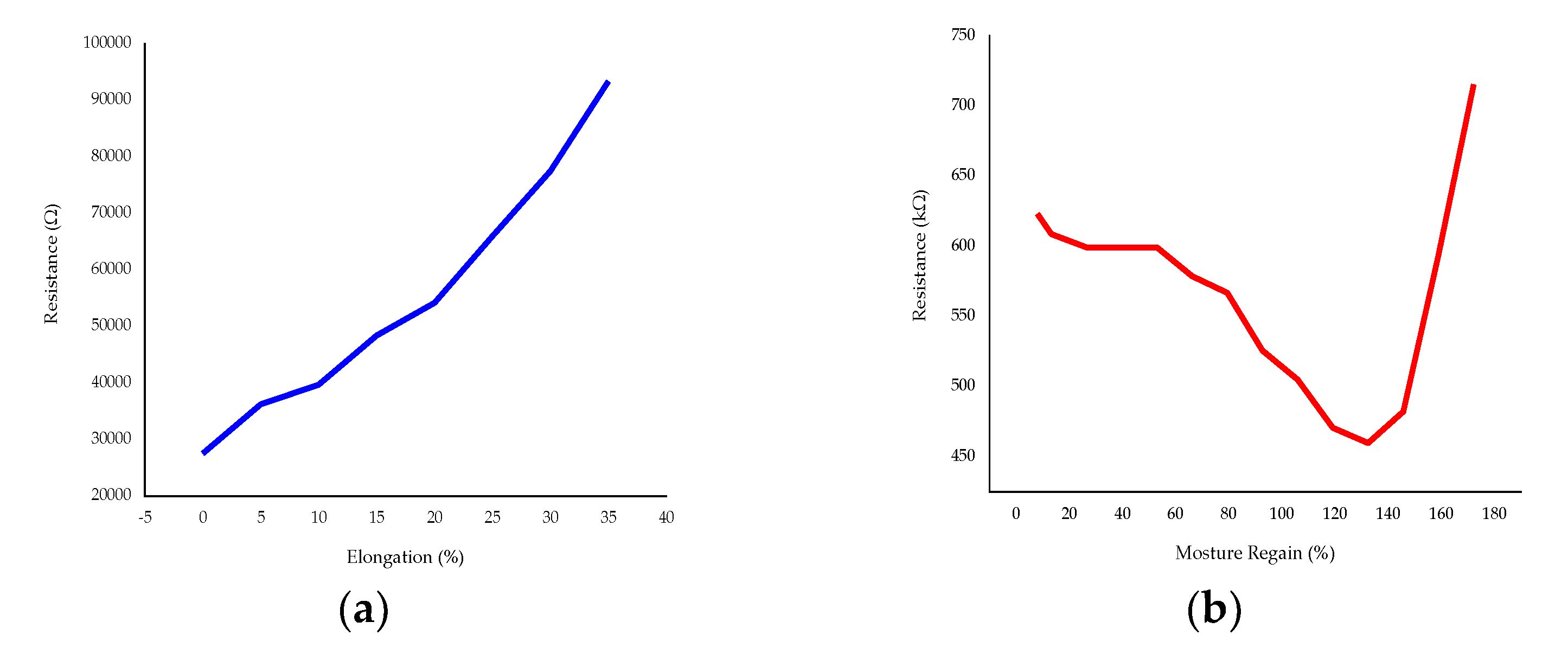

3.2.2. Effect of Stretching on Sensing Stability

3.2.3. Effect of Washing on Surface Resistance

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Borges, B.G.A.; Holakoei, S.; das Neves, M.F.; de Menezes, L.C.; de Matos, C.F.; Zarbin, A.J.; Roman, L.S.; Rocco, M.L.M. Molecular orientation and femtosecond charge transfer dynamics in transparent and conductive electrodes based on graphene oxide and PEDOT:PSS composites. Phys. Chem. Chem. Phys. 2019, 21, 736–743. [Google Scholar] [CrossRef]

- Güney, H.Y.; Avdan, Z.; Yetkin, H. Optimization of annealing temperature and the annealing effect on life time and stability of P3HT:PCBM-based organic solar cells. Mater. Res. Express 2019, 6, 045103. [Google Scholar] [CrossRef]

- Hebbar, V.; Bhajantri, R.F.; Ravikumar, H.B.; Ningaraju, S. Role of free volumes in conducting properties of GO and rGO filled PVA PEDOT:PSS composite free standing films: A positron annihilation lifetime study. J. Phys. Chem. Solids 2018, 126, 242–256. [Google Scholar] [CrossRef]

- Ding, Y.; Xu, W.; Wang, W.; Fong, H.; Zhu, Z. Scalable and Facile Preparation of Highly Stretchable Electrospun PEDOT:PSS@PU Fibrous Nonwovens toward Wearable Conductive Textile Applications. ACS Appl. Mater. Interfaces 2017, 9, 30014–30023. [Google Scholar] [CrossRef] [PubMed]

- Sedighi, A.; Montazer, M.; Mazinani, S. Fabrication of electrically conductive superparamagnetic fabric with microwave attenuation, antibacterial properties and UV protection using PEDOT/magnetite nanoparticles. Mater. Des. 2018, 160, 34–47. [Google Scholar] [CrossRef]

- Giuri, A.; Colella, S.; Listorti, A.; Rizzo, A.; Mele, C.; Corcione, C.E. GO/glucose/PEDOT:PSS ternary nanocomposites for flexible supercapacitors. Compos. Part B 2018, 148, 149–155. [Google Scholar] [CrossRef]

- Hilal, M.; Han, J.I. Interface engineering of G-PEDOT:PSS hole transport layer via interlayer chemical functionalization for enhanced efficiency of large-area hybrid solar cells and their charge transport investigation. Sol. Energy 2018, 174, 743–756. [Google Scholar] [CrossRef]

- Zajdel, T.J.; Baruch, M.; Méhes, G.; Stavrinidou, E.; Berggren, M.; Maharbiz, M.M.; Simon, D.T.; Ajo-Franklin, C.M. OPEN PEDOT:PSS-based Multilayer Bacterial-Composite Films for Bioelectronics. Sci. Rep. 2018, 8, 1–12. [Google Scholar] [CrossRef]

- Taroni, P.J.; Santagiuliana, G.; Wan, K.; Calado, P.; Qiu, M.; Zhang, H.; Pugno, N.M.; Palma, M.; Stingelin-Stutzman, N.; Heeney, M.; Fenwick, O.; Baxendale, M.; Bilotti, E. Toward Stretchable Self-Powered Sensors Based on the Thermoelectric Response of PEDOT:PSS/Polyurethane Blends. Adv. Funct. Mater. 2018, 28, 1704285. [Google Scholar] [CrossRef]

- Rafique, S.; Roslan, N.A.; Abdullah, S.M.; Li, L.; Supangat, A.; Jilani, A.; Iwamoto, M. UV- ozone treated graphene oxide/PEDOT:PSS bilayer as a novel hole transport layer in highly efficient and stable organic solar cells. Org. Electrons. 2019, 66, 32–42. [Google Scholar] [CrossRef]

- Zahid, M.; Papadopoulou, E.L.; Athanassiou, A.; Bayer, I.S. Strain-responsive mercerized conductive cotton fabrics based on PEDOT:PSS/graphene. Mater. Des. 2017, 135, 213–222. [Google Scholar] [CrossRef]

- Houghton, T.; Vanjaria, J.; Yu, H. Conductive and Stretchable Silver-Polymer Blend for Electronic Applications. In Proceedings of the 2016 IEEE 66th Electronic Components and Technology Conference (ECTC), Las Vegas, NV, USA, 31 May–3 June 2016; pp. 812–816. [Google Scholar]

- Chen, M.; Duan, S.; Zhang, L.; Wang, Z.; Li, C. Conductive polymer composites based on graphene networks grown by chemical vapour deposition and PEDOT:PSS coating. Chem. Commun. 2015, 51, 3169–3172. [Google Scholar] [CrossRef] [PubMed]

- Meng, Q.; Cai, K.; Du, Y.; Chen, L. Preparation and thermoelectric properties of SWCNT/PEDOT:PSS coated tellurium nanorod composite films. J. Alloys. Compd. 2019, 778, 163–169. [Google Scholar] [CrossRef]

- Lei, K.F.; Lee, K.F.; Lee, M.Y. Development of a flexible PDMS capacitive pressure sensor for plantar pressure measurment. Microelectron. Eng. 2012, 99, 1–5. [Google Scholar] [CrossRef]

- Lee, C.; Jug, L.; Meng, E. High strain iocompatible polydimethylsiloxane-based conductive graphene and multiwalled carbon nanotube nanocomposite strain sensors. Appl. Phys. Lett. 2013, 102, 183511. [Google Scholar] [CrossRef]

- Kong, J.; Tong, Y.; Sun, J.; Wei, Y.; Thitsartarn, W.; Jayven, C.C.Y.; Muiruri, J.K.; Wong, S.Y.; He, C. Electrically conductive PDMS-grafted CNTs-reinforced silicone elastomer. Compos. Sci. Technol. 2018, 159, 208–215. [Google Scholar] [CrossRef]

- Kong, K.T.S.; Mariatti, M.; Rashid, A.A.; Busfield, J.J.C. Composites: Part B Enhanced conductivity behavior of polydimethylsiloxane (PDMS) hybrid composites containing exfoliated graphite nanoplatelets and carbon nanotubes. Compos. Part B 2014, 58, 457–462. [Google Scholar] [CrossRef]

- Gao, X.; Huang, Y.; Liu, Y.; Kormakov, S.; Zheng, X.; Wu, D.; Wu, D. Improved electrical conductivity of PDMS/SCF composite sheets with bolting cloth prepared by a spatial con fi ning forced network assembly. RSC Adv. 2017, 7, 14761–14768. [Google Scholar] [CrossRef]

- Kim, J.; Park, J.; Jeong, U.; Park, J.W. Silver nanowire network embedded in polydimethylsiloxane as stretchable, transparent, and conductive substrates. J. Appl. Polym. Sci. 2016, 133, 43830. [Google Scholar] [CrossRef]

- Xu, Q.; Kobayashi, S.; Ye, X.; Meng, X. Ag-PDMS composites. Sci. Rep. 2014, 4, 1–7. [Google Scholar]

- Bian, J.; Zhou, L.; Wan, X.; Zhu, C.; Yang, B.; Huang, Y. Laser Transfer, Printing, and Assembly Techniques for Flexible Electronics. Adv. Electron. Mater. 2019, 5, 1800900. [Google Scholar] [CrossRef]

- Cai, M.; Nie, S.; Du, Y.; Wang, C.; Song, J. Soft Elastomers with Programmable Stiffness as Strain-Isolating Substrates for Stretchable Electronics. ACS Appl. Mater. Interfaces 2019, 11, 14340–14346. [Google Scholar] [CrossRef] [PubMed]

| Sample | r [%] | Vc [ml] | Ve [ml] | Wb [g] | A [cm2] |

| r00 | 0 | 4 | 0 | 1.655 | 5 × 12.5 |

| r10 | 10 | 4 | 0.4 | 1.653 | 5 × 12.5 |

| r20 | 20 | 4 | 0.8 | 1.629 | 5 × 12.5 |

| r30 | 30 | 4 | 1.2 | 1.608 | 5 × 12.5 |

| r40 | 40 | 4 | 1.6 | 1.578 | 5 × 12.5 |

| r50 | 50 | 4 | 2 | 1.645 | 5 × 12.5 |

| r60 | 60 | 4 | 2.4 | 1.678 | 5 × 12.5 |

| r70 | 70 | 4 | 2.8 | 1.661 | 5 × 12.5 |

| r80 | 80 | 4 | 3.2 | 1.622 | 5 × 12.5 |

| r90 | 90 | 4 | 3.6 | 1.628 | 5 × 12.5 |

| Sample | Vc [ml] | Ve [ml] | Wb [g] | Wa [g] | A [cm2] | w [g/cm2] |

| r00 | 4 | 0 | 1.655 | 1.913 | 5 × 12.5 | 0.0041 |

| r10 | 4 | 0.4 | 1.653 | 2.142 | 5 × 12.5 | 0.0078 |

| r20 | 4 | 0.8 | 1.629 | 2.344 | 5 × 12.5 | 0.0114 |

| r30 | 4 | 1.2 | 1.608 | 2.401 | 5 × 12.5 | 0.0127 |

| r40 | 4 | 1.6 | 1.578 | 2.462 | 5 × 12.5 | 0.0141 |

| r50 | 4 | 2 | 1.645 | 2.44 | 5 × 12.5 | 0.0144 |

| r60 | 4 | 2.4 | 1.678 | 2.646 | 5 × 12.5 | 0.0155 |

| r70 | 4 | 2.8 | 1.661 | 2.671 | 5 × 12.5 | 0.0162 |

| r80 | 4 | 3.2 | 1.622 | 2.688 | 5 × 12.5 | 0.0171 |

| r90 | 4 | 3.6 | 1.628 | 2.733 | 5 × 12.5 | 0.0177 |

| Fabric | Weight (g/m2) | Bending Length (cm) | Flexural Rigidity (mg cm) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Wale Direction | Course Direction | Average | Wale Direction | Course Direction | Average | ||||||

| Face | Back | Face | Back | Face | Back | Face | Back | ||||

| S0 | 140.0 | 1.3 | 1.2 | 1.3 | 1.7 | 1.4 | 27.3 | 24.2 | 27.3 | 71.2 | 34.8 |

| S1 | 146.0 | 1.8 | 1.7 | 1.7 | 1.9 | 1.8 | 78.2 | 65.6 | 71.7 | 100.1 | 78.2 |

| r00 | 176.0 | 3.0 | 2.9 | 2.9 | 2.5 | 2.8 | 475.2 | 407.4 | 407.4 | 262.0 | 382.2 |

| r10 | 191.0 | 2.9 | 2.8 | 2.8 | 2.4 | 2.7 | 456.3 | 397.2 | 428.3 | 247.9 | 375.9 |

| r20 | 199.0 | 2.9 | 2.7 | 2.7 | 2.3 | 2.7 | 460.7 | 396.1 | 409.4 | 245.3 | 371.4 |

| r30 | 205.0 | 2.8 | 2.7 | 2.7 | 2.2 | 2.6 | 454.9 | 394.6 | 408.0 | 230.4 | 364.5 |

| r40 | 209.0 | 2.8 | 2.7 | 2.6 | 2.2 | 2.6 | 453.9 | 388.9 | 371.6 | 219.5 | 350.6 |

| r50 | 213.0 | 2.7 | 2.6 | 2.6 | 2.1 | 2.5 | 433.4 | 383.1 | 353.2 | 200.1 | 333.8 |

| r60 | 216.0 | 2.7 | 2.6 | 2.5 | 2.1 | 2.5 | 415.8 | 370.9 | 341.6 | 191.6 | 321.6 |

| r70 | 221.0 | 2.6 | 2.5 | 2.5 | 2.0 | 2.4 | 392.9 | 349.5 | 341.2 | 179.5 | 307.4 |

| r80 | 224.0 | 2.5 | 2.5 | 2.5 | 1.9 | 2.3 | 362.8 | 337.6 | 333.5 | 153.6 | 287.0 |

| r90 | 228.0 | 2.5 | 2.5 | 2.4 | 1.9 | 2.3 | 356.3 | 335.3 | 315.2 | 149.1 | 279.2 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tseghai, G.B.; Malengier, B.; Fante, K.A.; Nigusse, A.B.; Van Langenhove, L. Development of a Flex and Stretchy Conductive Cotton Fabric Via Flat Screen Printing of PEDOT:PSS/PDMS Conductive Polymer Composite. Sensors 2020, 20, 1742. https://doi.org/10.3390/s20061742

Tseghai GB, Malengier B, Fante KA, Nigusse AB, Van Langenhove L. Development of a Flex and Stretchy Conductive Cotton Fabric Via Flat Screen Printing of PEDOT:PSS/PDMS Conductive Polymer Composite. Sensors. 2020; 20(6):1742. https://doi.org/10.3390/s20061742

Chicago/Turabian StyleTseghai, Granch Berhe, Benny Malengier, Kinde Anlay Fante, Abreha Bayrau Nigusse, and Lieva Van Langenhove. 2020. "Development of a Flex and Stretchy Conductive Cotton Fabric Via Flat Screen Printing of PEDOT:PSS/PDMS Conductive Polymer Composite" Sensors 20, no. 6: 1742. https://doi.org/10.3390/s20061742

APA StyleTseghai, G. B., Malengier, B., Fante, K. A., Nigusse, A. B., & Van Langenhove, L. (2020). Development of a Flex and Stretchy Conductive Cotton Fabric Via Flat Screen Printing of PEDOT:PSS/PDMS Conductive Polymer Composite. Sensors, 20(6), 1742. https://doi.org/10.3390/s20061742