Real-Time Mine Road Boundary Detection and Tracking for Autonomous Truck

Abstract

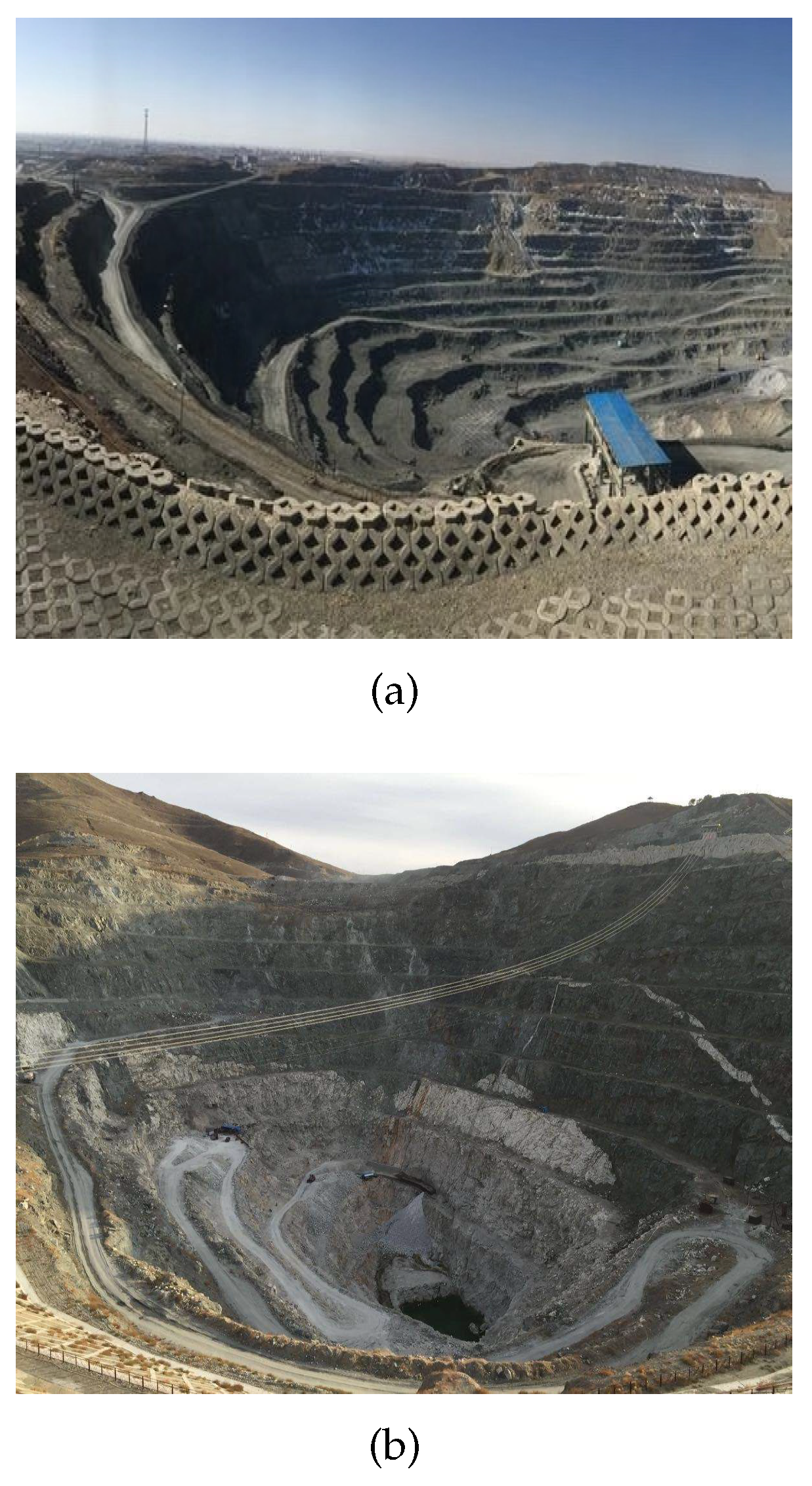

1. Introduction

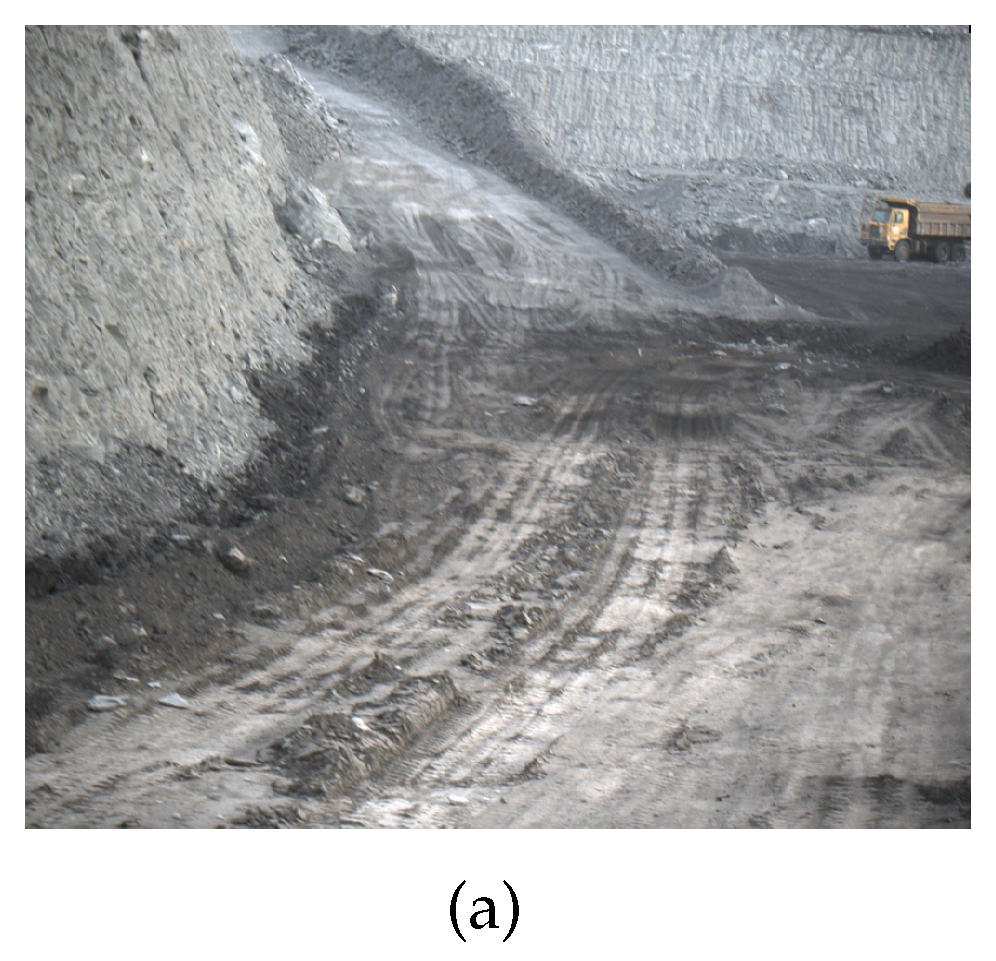

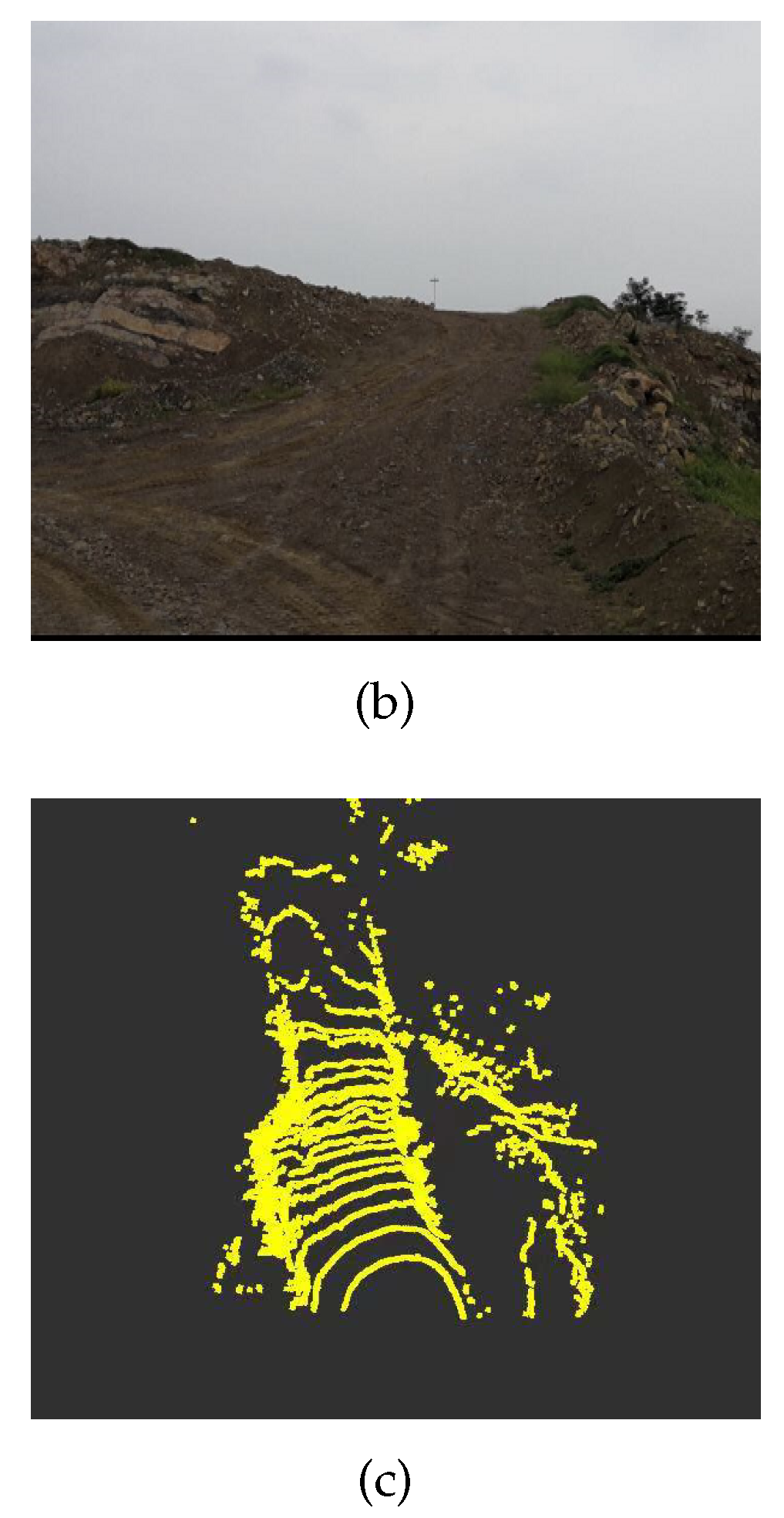

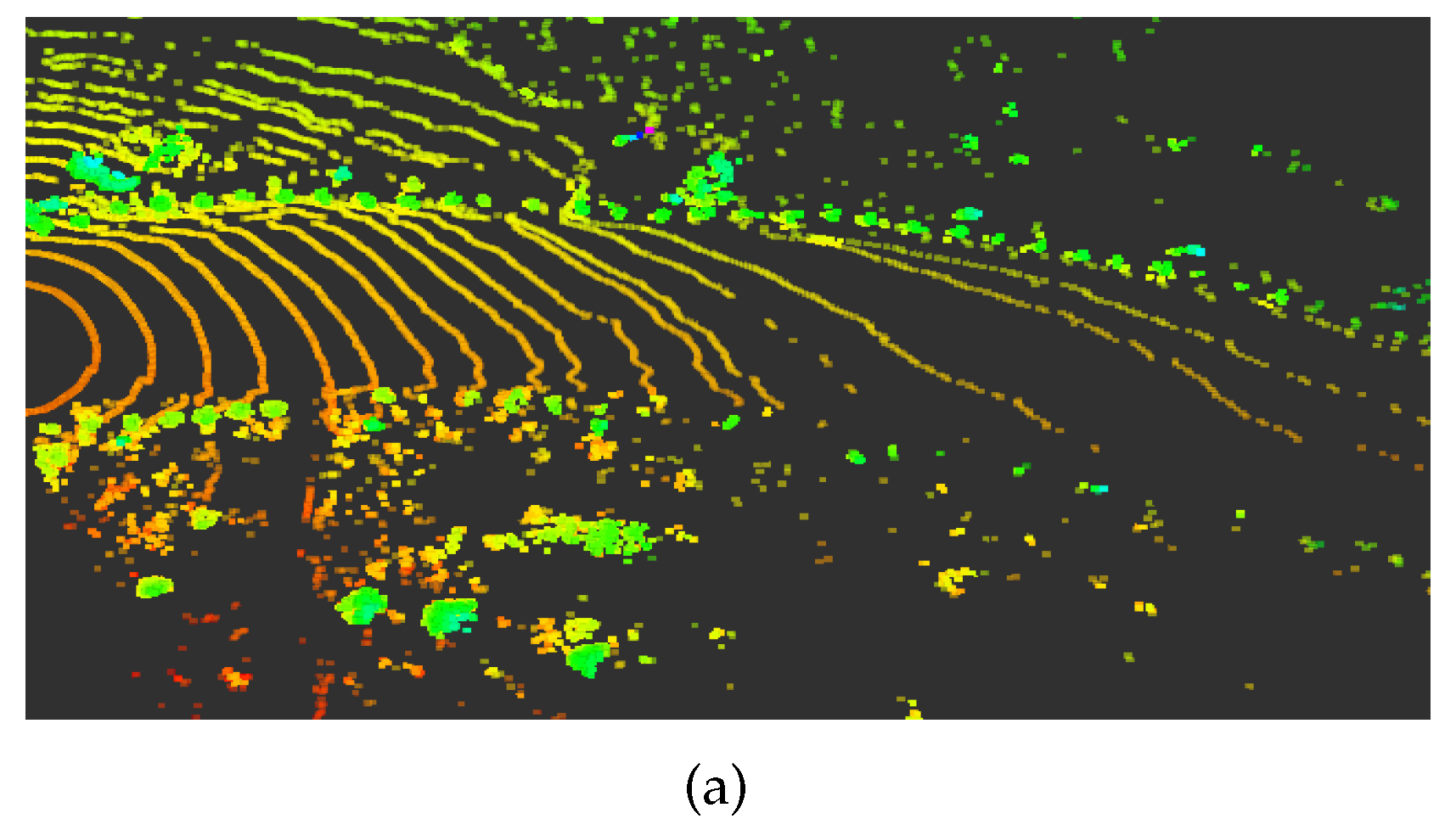

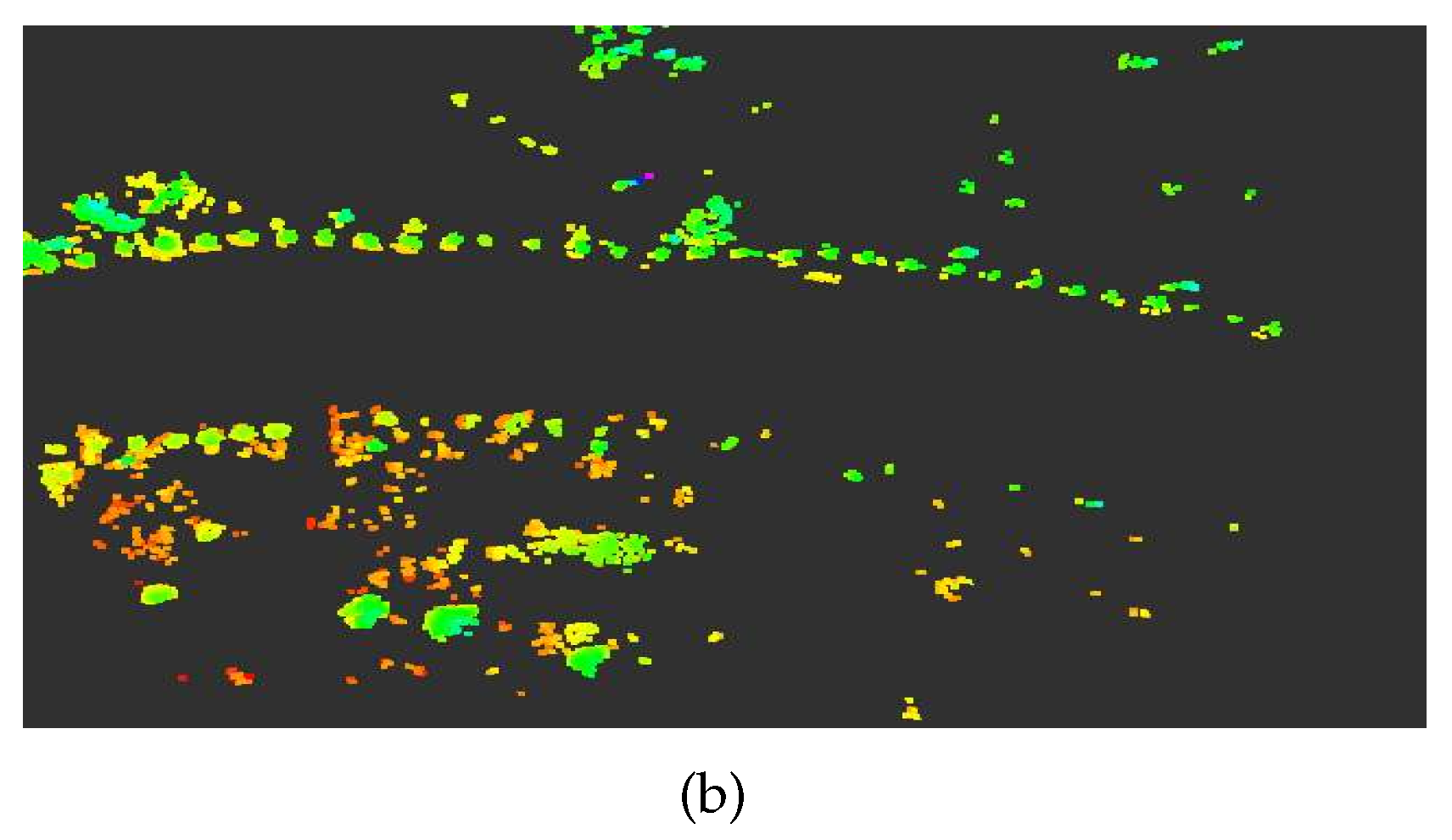

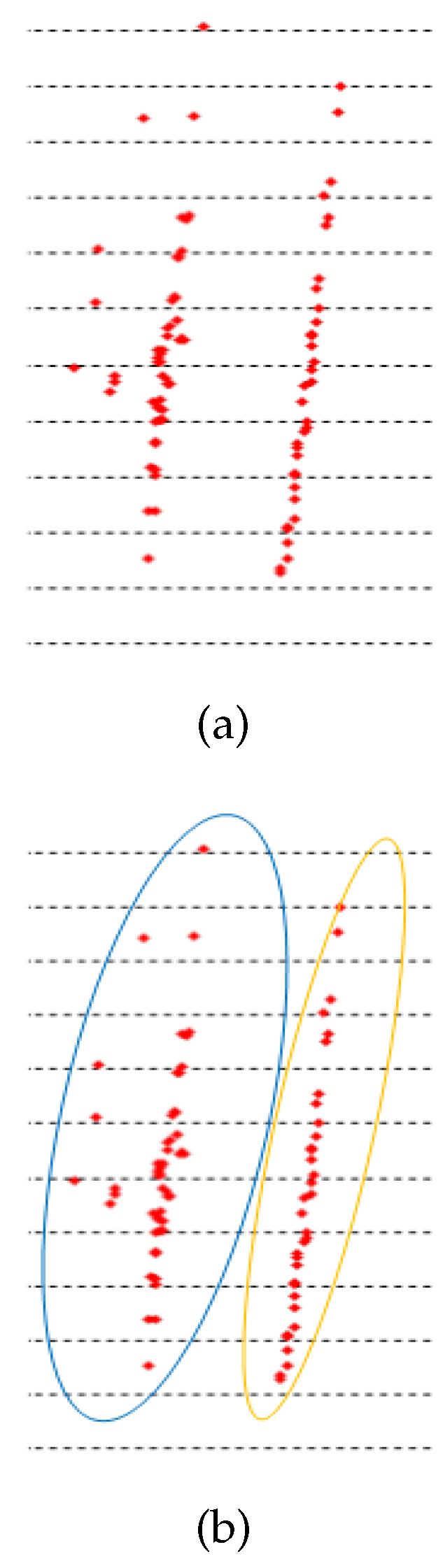

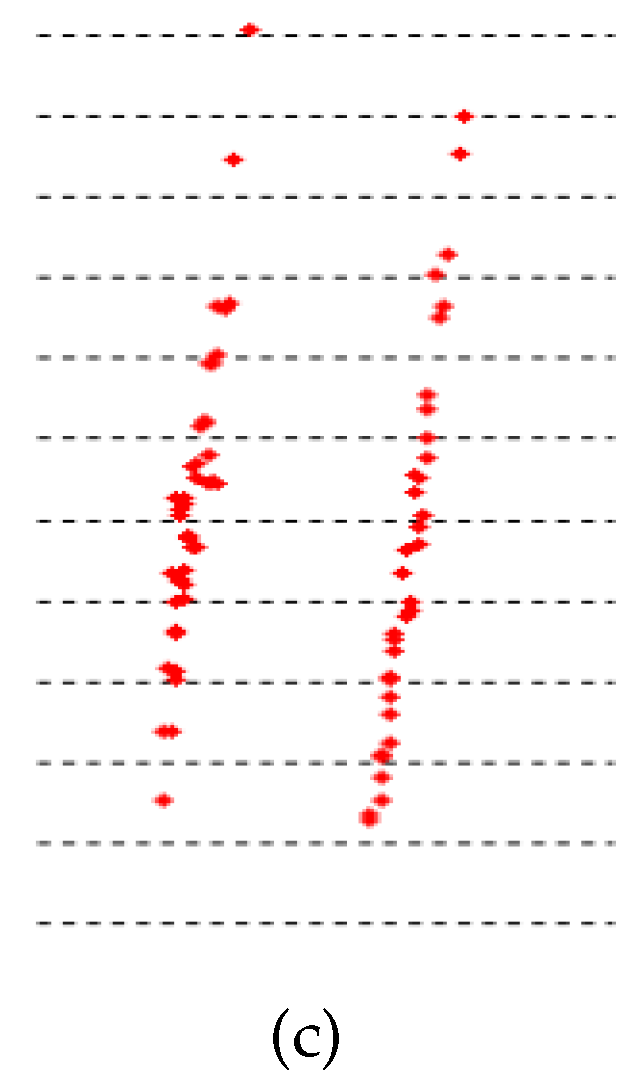

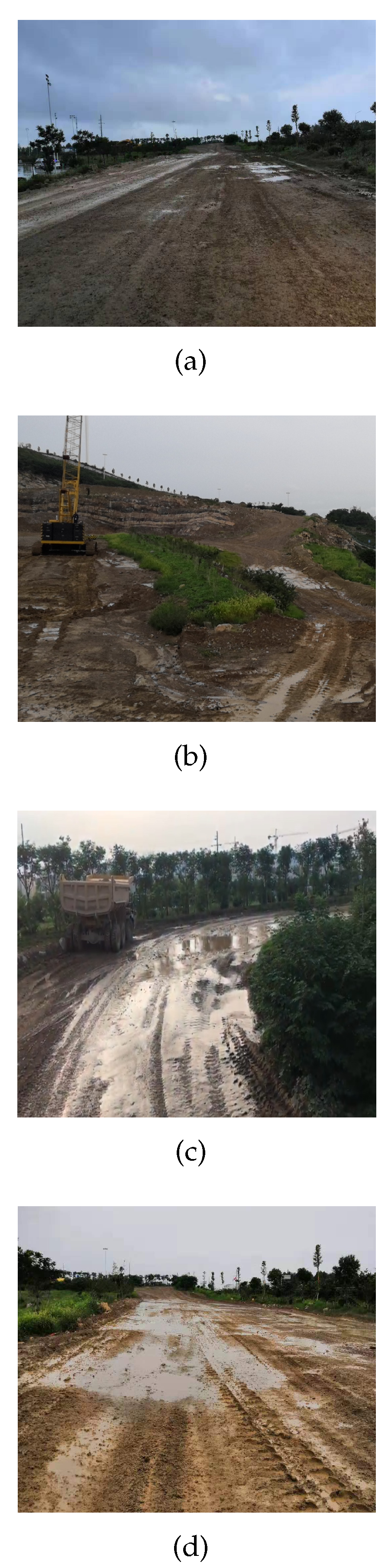

- There is a small slope on the road surface of the mine, as shown in Figure 2a. It is difficult to find which are the ground points and which are the elevated points by the height information of the point cloud.

- There is no boundary between the road surface and the non-road surface in the mine road, as shown in Figure 2b. The road boundary is determined based on the analysis and judgment of obstacles on the roadside. However, the location of obstacles on the roadside of the mine is irregular and discontinuous. Therefore, many of the extracted road candidate points are invalid.

- Compared with ordinary rural roads and suburban roads, there are potholes and convex hulls on the road surface of mine roads. Figure 2c shows the raw data of the mine point cloud and the status of the scanning line. The LiDAR scanning line is broken up by the clod or interrupted by the mound, thus it is difficult to extract the road boundary points.

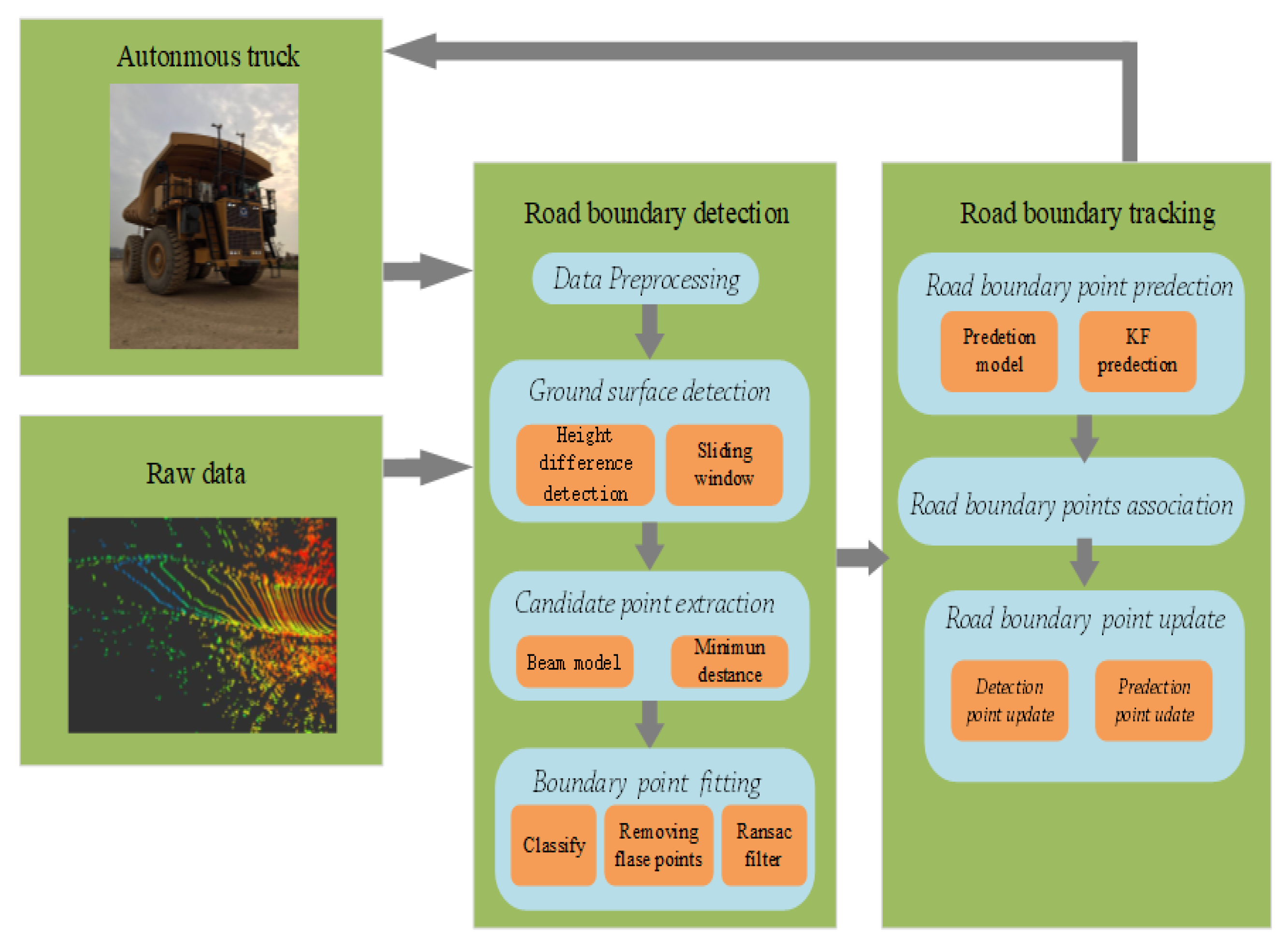

- We propose a method that can effectively detect the boundaries of mine roads.

- We design a road boundary point extraction method to filter false points that are outside the road.

- We propose a road boundary point tracking method based on Kalman filter, which can improve the stability and accuracy of detection results.

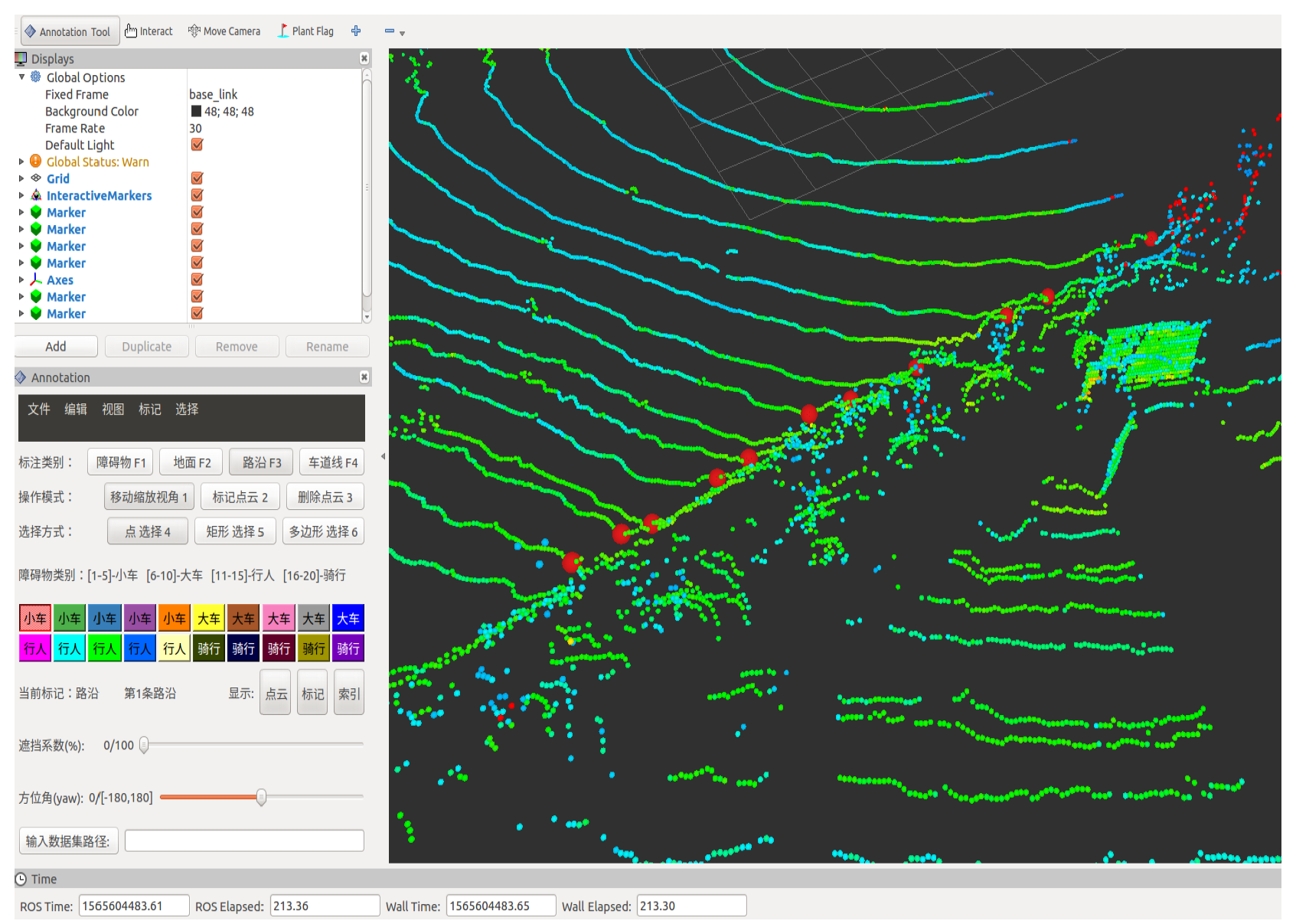

- We built a dataset for a mine scene. We collected point cloud data for multiple different types of roads. The calibration of the ground and road boundary points was performed for each frame of data.

2. Related Work

2.1. Road Boundary Points Extraction

2.2. Road Boundary Points Filtering

3. Road Boundary Detection

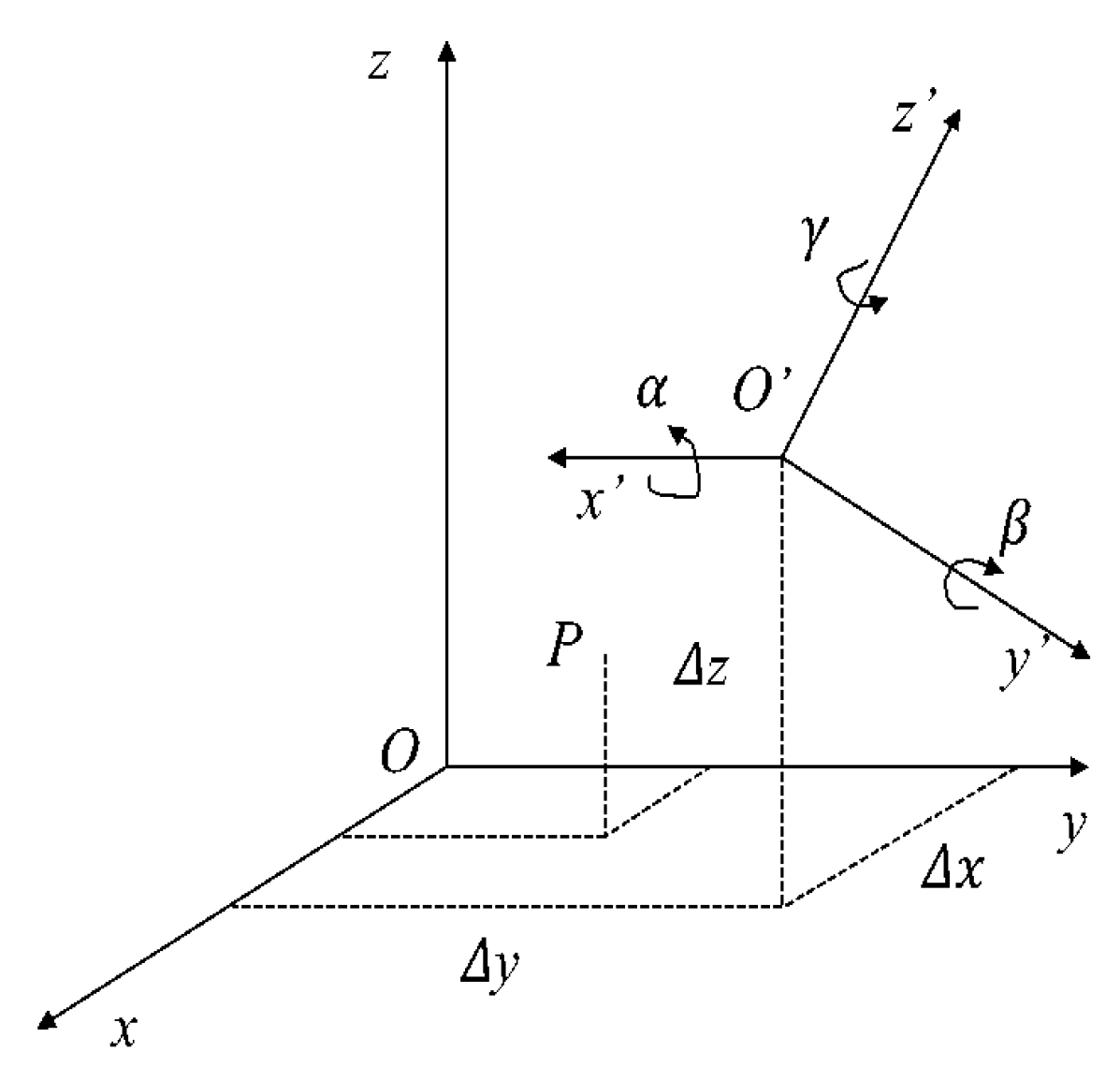

3.1. Data Preprocessing

3.2. Ground Surface Detection

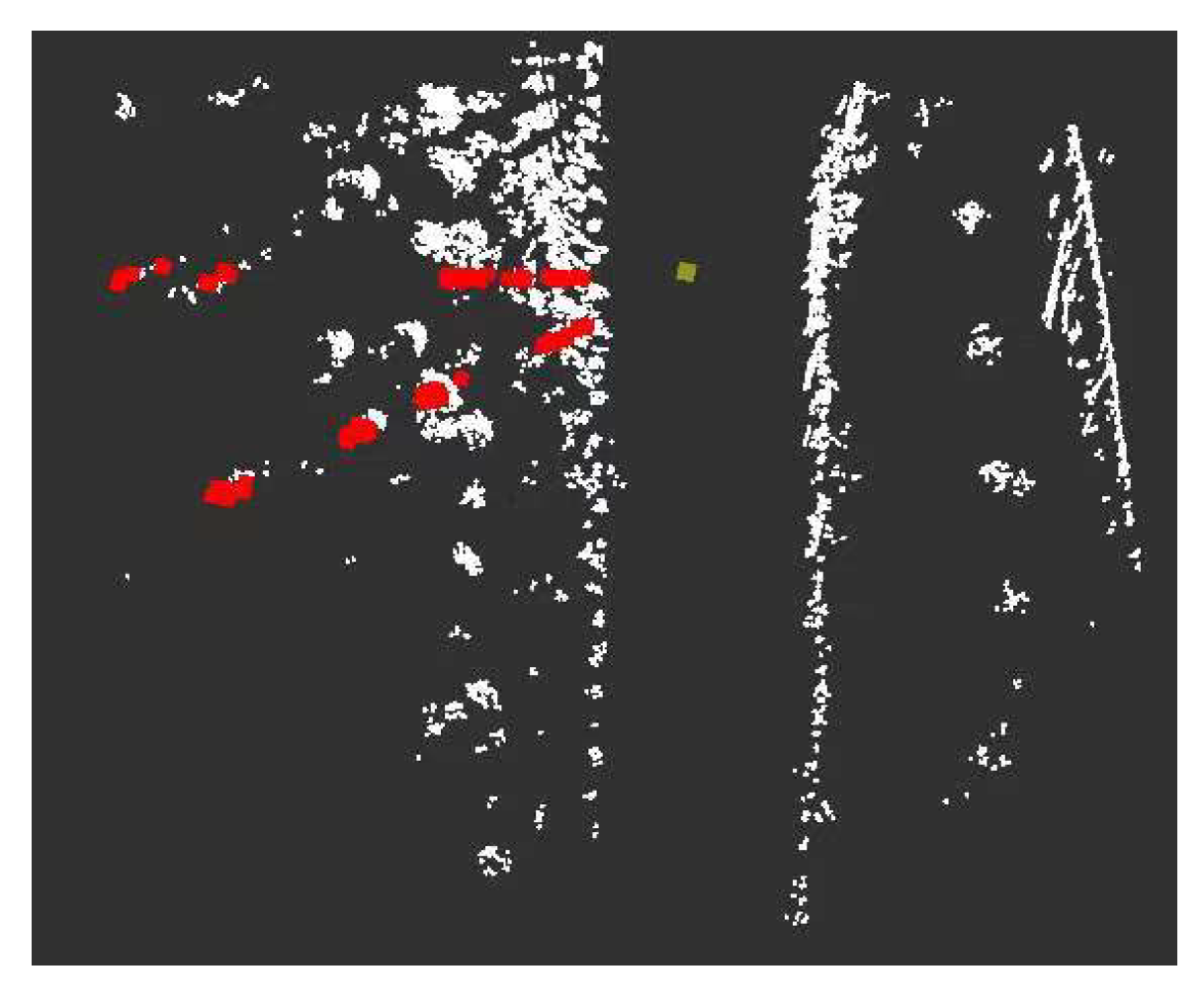

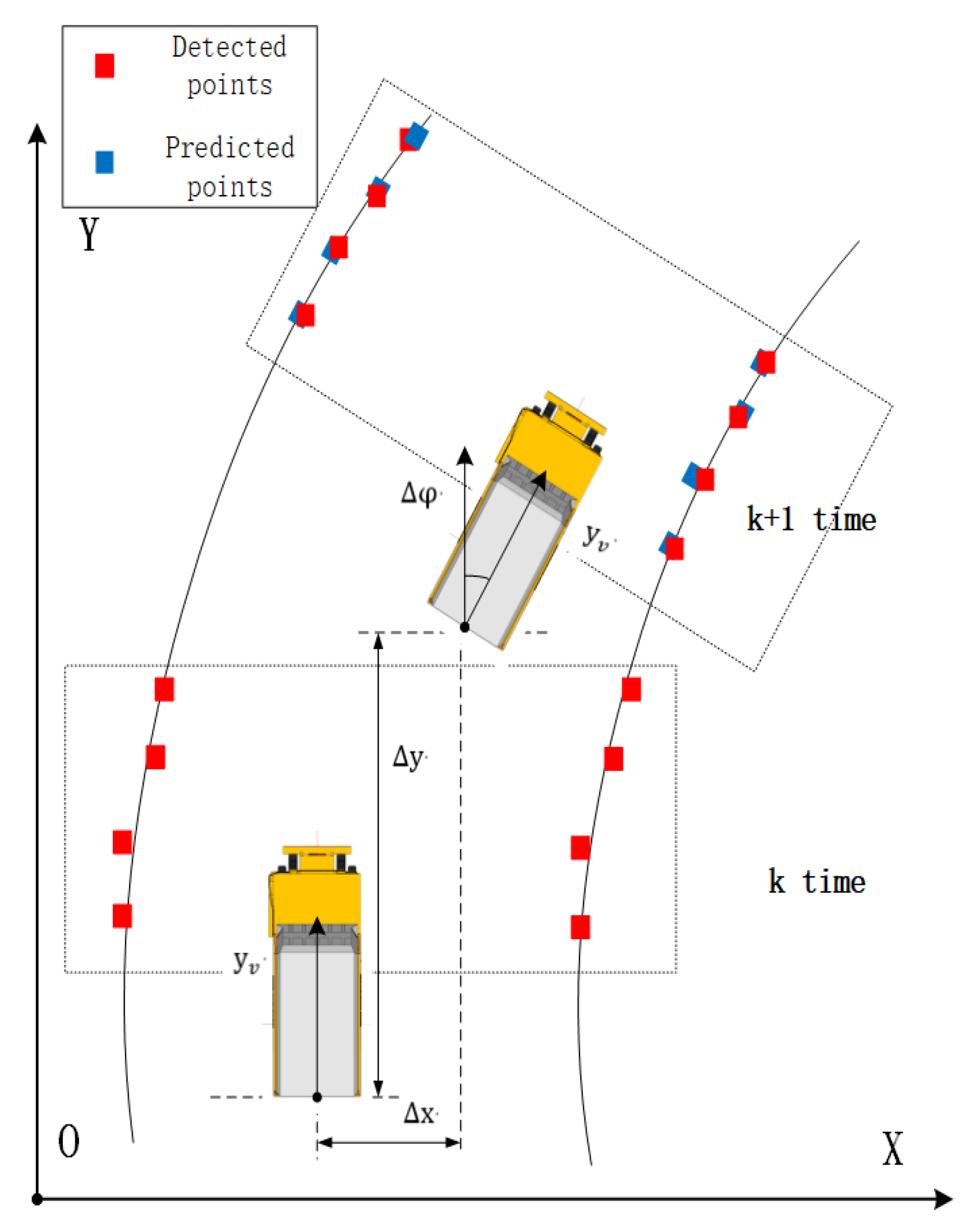

3.3. Candidate Points Extraction

3.4. Boundary Points Fitting

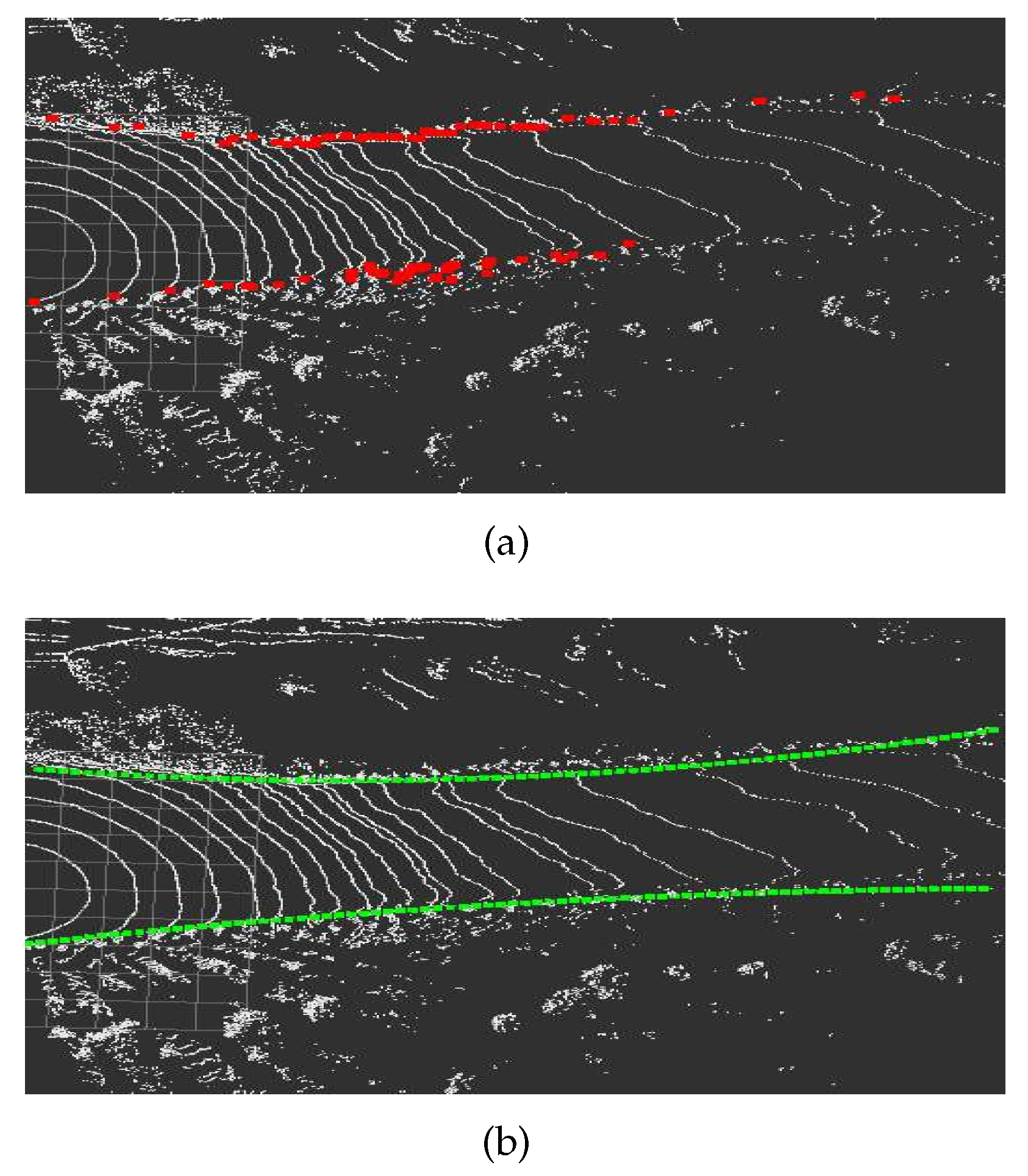

4. Road Boundary Tracking

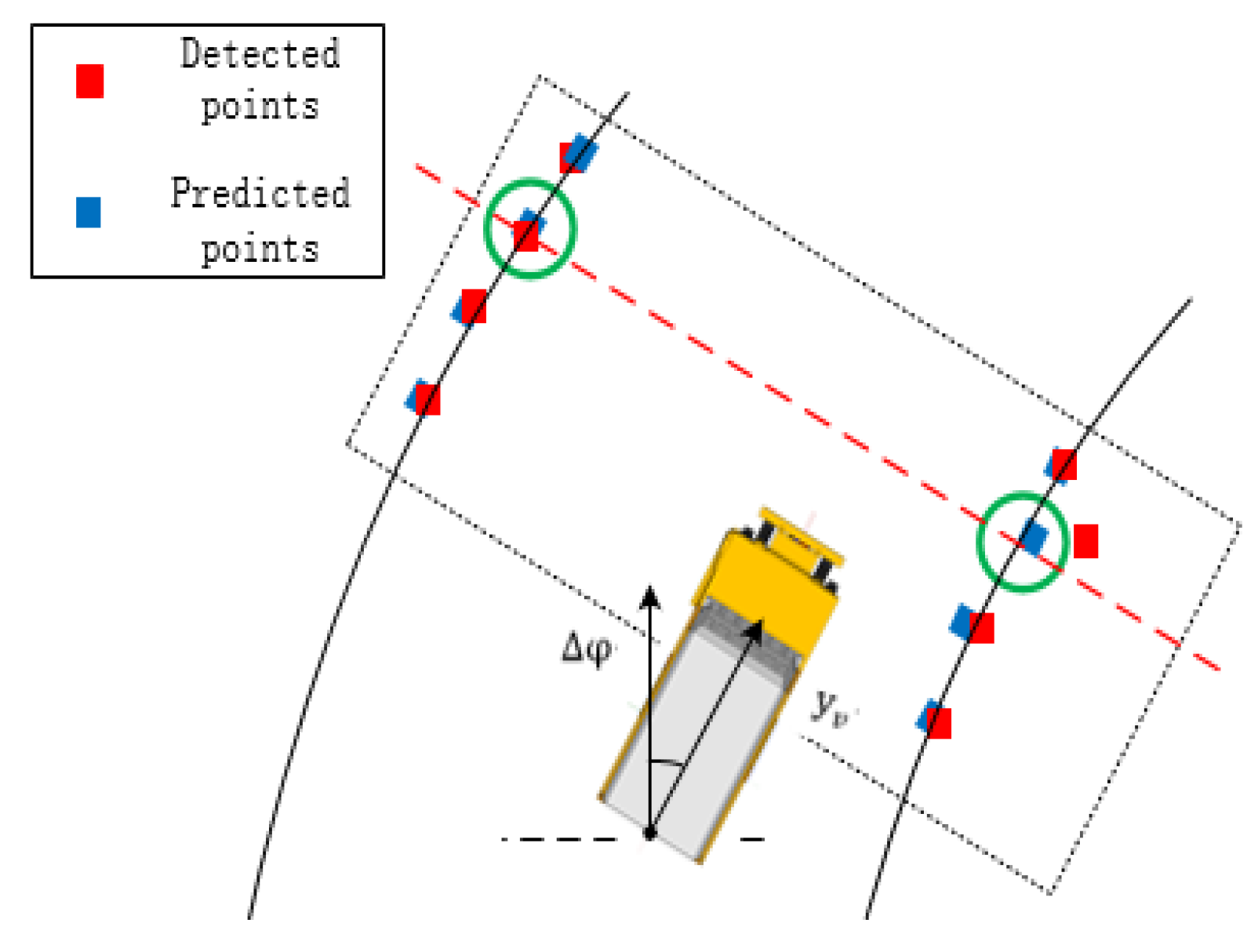

4.1. Road Boundary Point Prediction

4.2. Road Boundary Points Association

4.3. Road Boundary Points Update

5. Experiment Results

5.1. Experimental Setup

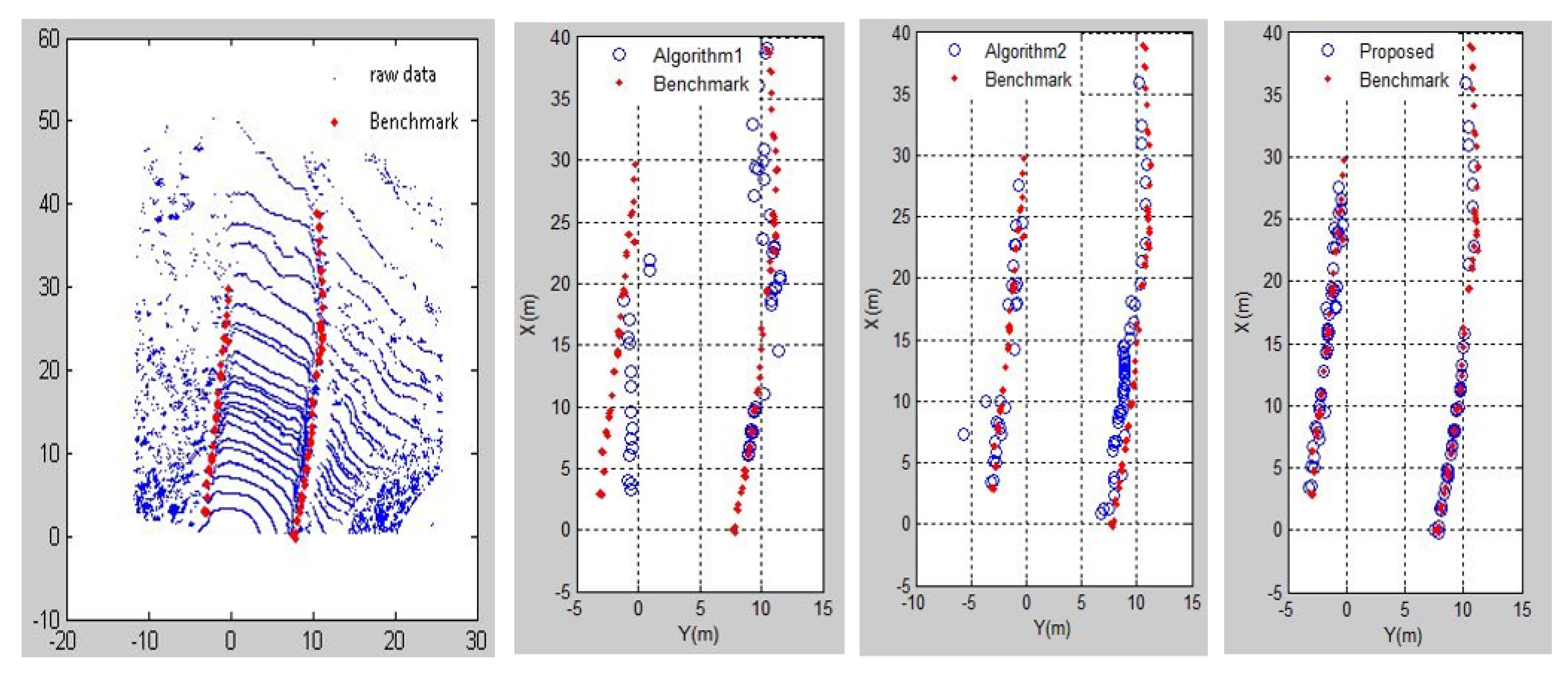

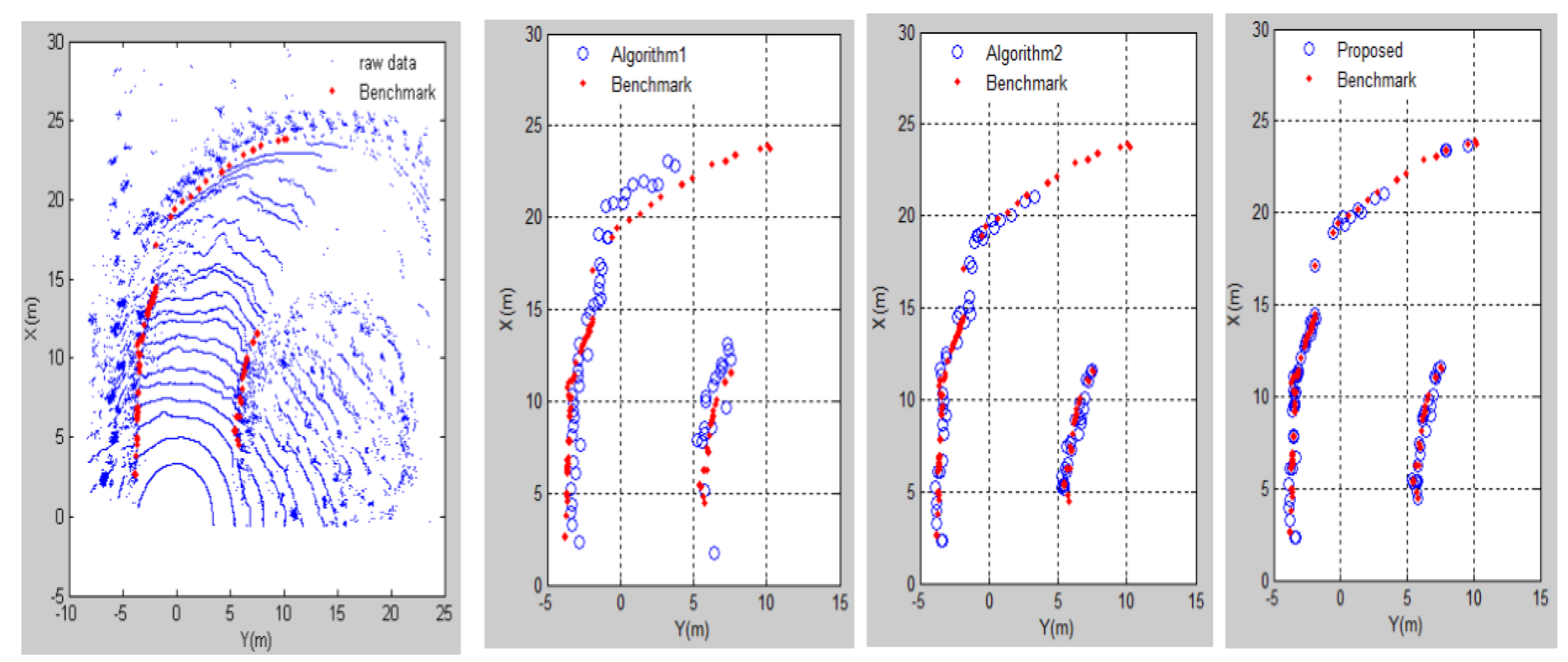

5.2. Evaluation of the Road Detection Algorithm

- Precision denotes the fraction of the road boundary points detected correctly out of all the road boundary points detected in one frame:where TP is the true positive numbers and FP is the false positive numbers (false alarm).

- Recall denotes the fraction of the road boundary points detected correctly out of all the labeled road boundary points:where FN means false negative (missed detection).

- denotes the harmonic average of precision and recall:

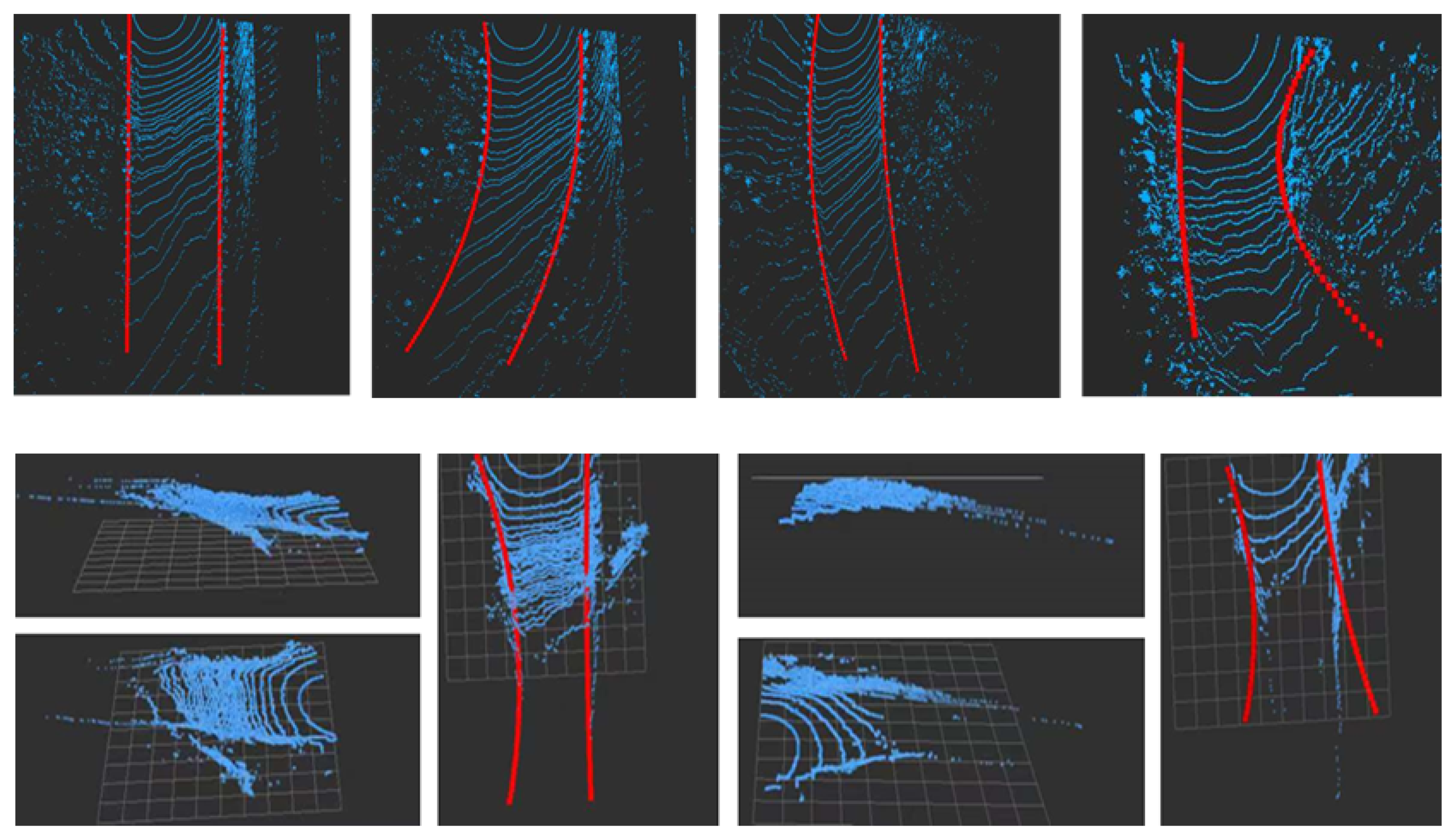

5.3. Detection Results for Autonomous Truck

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Nuchter, A.; Surmann, H.; Lingemann, K.; Hertzberg, J.; Thrun, S. 6D SLAM with an application in autonomous mine mapping. In Proceedings of the IEEE International Conference on Robotics & Automation, New Orleans, LA, USA, 26 April–1 May 2004; pp. 1998–2003. [Google Scholar]

- Caltagirone, L.; Scheidegger, S.; Svensson, L.; Wahde, M. Fast lidar-based road detection using fully convolutional neural networks. In Proceedings of the 2017 IEEE Intelligent Vehicles Symposium (IV), Los Angeles, CA, USA, 11–14 June 2017; pp. 1019–1024. [Google Scholar]

- Nikolova, M.; Hero, A. Segmentation of a road from a vehicle mounted radar and accuracy of the estimation. In Proceedings of the 2000 IEEE Intelligent Vehicles Symposium, Dearborn, MI, USA, 5 October 2000; pp. 284–289. [Google Scholar]

- Siegemund, J.; Pfeiffer, D.; Franke, U.; Forstner, W. Curb reconstruction using conditional random fields. In Proceedings of the 2010 IEEE Intelligent Vehicles Symposium, San Diego, CA, USA, 21–24 June 2010; pp. 203–210. [Google Scholar]

- Wang, X.; Wang, J.; Zhang, Y.; Li, C.; Wang, L. 3d lidar-based intersection recognition and road boundary detection method for unmanned ground vehicle. In Proceedings of the IEEE International Conference on Intelligent Transportation Systems (ITSC), Las Palmas, Spain, 15–18 September 2015; pp. 499–504. [Google Scholar]

- Wang, G.; Wu, J.; He, R.; Yang, S. A Point Cloud-Based Robust Road Curb Detection and Tracking Method. IEEE Access 2019, 3, 24611–24625. [Google Scholar] [CrossRef]

- Hu, K.; Wang, T.; Li, Z.; Chen, D.; Li, X. Real-time extraction method of road boundary based on three-dimensional lidar. J. Phys. Conf. Ser. 2018, 1074, 1–8. [Google Scholar] [CrossRef]

- Shin, Y.; Jung, C.; Chung, W. Drivable road region detection using a single laser range finder for outdoor patrol robots. In Proceedings of the IEEE Intelligent Vehicles Symposium, San Diego, CA, USA, 21–24 June 2010; pp. 877–882. [Google Scholar]

- Han, J.; Kim, D.; Lee, M.; Sunwoo, M. Road boundary detection and tracking for structured and unstructured roads using a 2d lidar sensor. Int. J. Automot. Technol. 2014, 4, 611–623. [Google Scholar] [CrossRef]

- Chen, T.; Dai, B.; Liu, D.; Liu, Z. LiDAR-based Long Range Road Intersection Detection. In Proceedings of the IEEE International Conference on Image and Graphics(ICIG), Hefei, China, 12–15 August 2011; pp. 754–759. [Google Scholar]

- Weiss, T.; Schiele, B.; Dietmayer, K. Robust driving path detection in urban and highway scenarios using a laser scanner and online occupancy grids. In Proceedings of the IEEE Intelligent Vehicles Symposium, Istanbul, Turkey, 13–15 June 2007; pp. 184–189. [Google Scholar]

- Vu, T.-D.; Aycard, O.; Appenrodt, N. Online localization and mapping with moving object tracking in dynamic outdoor environments. In Proceedings of the IEEE Intelligent Vehicles Symposium, Istanbul, Turkey, 13–15 June 2007; pp. 190–195. [Google Scholar]

- Homm, F.; Kaempchen, N.; Ota, J.; Burschka, D. Efficient occupancy grid computation on the GPU with lidar and radar for road boundary detection. In Proceedings of the IEEE Intelligent Vehicles Symposium, San Diego, CA, USA, 21–24 June 2010; pp. 1006–1013. [Google Scholar]

- Zhu, Q.; Chen, L.; Li, Q.; Li, M.; Nuchter, A.; Wang, J. 3d lidar point cloud based intersection recognition for autonomous driving. In Proceedings of the IEEE Intelligent Vehicles Symposium(IV), Alcala de Henares, Spain, 3–7 June 2012; pp. 456–461. [Google Scholar]

- Zhang, Y.; Wang, J.; Wang, X. Road-Segmentation-Based Curb Detection Method for Self-Driving via a 3D-LiDAR Sensor. IEEE Trans. Intell. Transp. Syst. 2018, 10, 3981–3991. [Google Scholar] [CrossRef]

- Wang, H.; Luo, H.; Wen, C.; Cheng, J.; Li, P.; Chen, Y.; Li, J. Road boundaries detection based on local normal aliency from mobile laser scanning data. IEEE Geosci. Remote Sens. Lett. 2015, 12, 2085–2089. [Google Scholar] [CrossRef]

- Zai, D.; Li, J.; Guo, Y.; Cheng, M.; Lin, Y.; Luo, H.; Wang, C. 3-D road boundary extraction from mobile laser scanning data via supervoxels and graph cuts. IEEE Trans. Intell. Transp. Syst. 2017, 19, 802–813. [Google Scholar] [CrossRef]

- Smadja, L.; Ninot, J.; Gavrilovic, T. Road extraction and environment interpretation from LiDAR sensors. IAPRS 2010, 38, 281–286. [Google Scholar]

- Yang, B.; Fang, L.; Li, J. Semi-automated extraction and delineation of 3D roads of street scene from mobile laser scanning point clouds. ISPRS 2013, 79, 80–93. [Google Scholar] [CrossRef]

- Yao, W.; Deng, Z.; Zhou, L. Road curb detection using 3D lidar and integral laser points for intelligent vehicles. In Proceedings of the IEEE International Conference on Soft Computing and Intelligent Systems, Kobe, Japan, 20–24 November 2012; pp. 100–105. [Google Scholar]

- Liu, Z.; Tang, Z.; Ren, M. Algorithm of real-time road boundary detection based on 3D lidar. J. Huazhong Univ. Sci. Technol. (Nat. Sci. Ed.) 2011, 39, 360–363. [Google Scholar]

- Pfeiffer, D.; Franke, U. Efficient representation of traffic scenes by means of dynamic stixels. In Proceedings of the IEEE Intelligent Vehicles Symposium, San Diego, CA, USA, 21–24 June 2010; pp. 217–224. [Google Scholar]

- Hata, A.Y.; Wolf, D.F. Feature detection for vehicle localization in urban environments using a multilayer LiDAR. IEEE Trans. Intell. Transp. Syst. 2015, 17, 420–429. [Google Scholar] [CrossRef]

- Chen, T.; Dai, B.; Liu, D.; Song, J.; Liu, Z. Velodyne-based curb detection up to 50 meters away. In Proceedings of the 2015 IEEE Intelligent Vehicles Symposium (IV), Seoul, Korea, 28 June–1 July 2015; pp. 241–248. [Google Scholar]

- Yang, B.; Fang, L.; Li, J. A full-3d voxel-based dynamic obstacle detection for urban scenario using stereo vision. In Proceedings of the International IEEE Conference on Intelligent Transportation Systems, The Hague, The Netherlands, 6–9 October 2013; pp. 71–76. [Google Scholar]

- Azim, A.; Aycard, O. Layer-based supervised classification of moving objects in outdoor dynamic environment using 3d laser scanner. In Proceedings of the IEEE Intelligent Vehicles Symposium Proceedings, Dearborn, MI, USA, 8–11 June 2014; pp. 1408–1414. [Google Scholar]

- Oniga, F.; Nedevschi, S. Processing Dense Stereo Data Using Elevation Maps: Road Surface, Traffic Isle, and Obstacle Detection. IEEE Trans. Veh. Technol. 2009, 59, 1172–1182. [Google Scholar]

- Asvadi, A.; Premebida, C.; Peixoto, P.; Nunes, U. 3D LiDAR-based static and moving obstacle detection in driving environments: An approach based on voxels and multi-region ground planes. Robot. Auton. Syst. 2016, 83, 299–311. [Google Scholar] [CrossRef]

- Tang, J.L.; Lu, X.W.; Ai, Y.F.; Tian, T.; Chen, L. Road Detection for autonomous truck in mine environment. In Proceedings of the 2019 IEEE Intelligent Transportation Systems Conference (ITSC), Auckland, New Zealand, 27–30 October 2019. [Google Scholar]

- Kim, Z.; Whan, Z. Robust lane detection and tracking in challenging scenarios. IEEE Trans. Intell. Transp. Syst. 2008, 9, 16–26. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, J.; Wang, X.; Li, C.; Wang, L. A real-time curb detection and tracking method for UGVs by using a 3D-LiDAR sensor. In Proceedings of the 2015 IEEE Conference on Control Applications (CCA), Sydney, NSW, Australia, 21–23 September 2015; pp. 1020–1025. [Google Scholar]

- Bar-Shalom, Y.; Daum, F.; Huang, J. The Probabilistic Data Association Filter ESTIMATION IN THE PRESENCE OF MEASUREMENT ORIGIN UNCERTAINTY. Control Syst. 2012, 29, 82–100. [Google Scholar]

- Fortmann, T.; Bar-Shalom, Y.; Scheffe, M. Sonar tracking of multiple targets using joint probabilistic data association. IEEE J. Ocean. Eng. 2003, 8, 173–184. [Google Scholar] [CrossRef]

| Methods | Straight Road | Curved Road | |

|---|---|---|---|

| Precision | Algorithm 1 | 75.44% | 71.88% |

| Algorithm 2 | 87.93% | 86.89% | |

| Proposal | 93.65% | 91.14% | |

| Recall | Algorithm 1 | 54.32% | 46.48% |

| Algorithm 2 | 62.96% | 53.54% | |

| Proposal | 72.84% | 77.78% | |

| F1 | Algorithm 1 | 63.16% | 56.45% |

| Algorithm 2 | 73.38% | 66.26% | |

| Proposal | 81.94% | 83.932% |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, X.; Ai, Y.; Tian, B. Real-Time Mine Road Boundary Detection and Tracking for Autonomous Truck. Sensors 2020, 20, 1121. https://doi.org/10.3390/s20041121

Lu X, Ai Y, Tian B. Real-Time Mine Road Boundary Detection and Tracking for Autonomous Truck. Sensors. 2020; 20(4):1121. https://doi.org/10.3390/s20041121

Chicago/Turabian StyleLu, Xiaowei, Yunfeng Ai, and Bin Tian. 2020. "Real-Time Mine Road Boundary Detection and Tracking for Autonomous Truck" Sensors 20, no. 4: 1121. https://doi.org/10.3390/s20041121

APA StyleLu, X., Ai, Y., & Tian, B. (2020). Real-Time Mine Road Boundary Detection and Tracking for Autonomous Truck. Sensors, 20(4), 1121. https://doi.org/10.3390/s20041121