Printed Smart Devices on Cellulose-Based Materials by means of Aerosol-Jet Printing and Photonic Curing

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Manufacturing of Conductive Tracks and Insulating Coatings

2.2.1. Ag ink Deposition and Photonic Curing

2.2.2. Insulator Printing and UV Polymerization

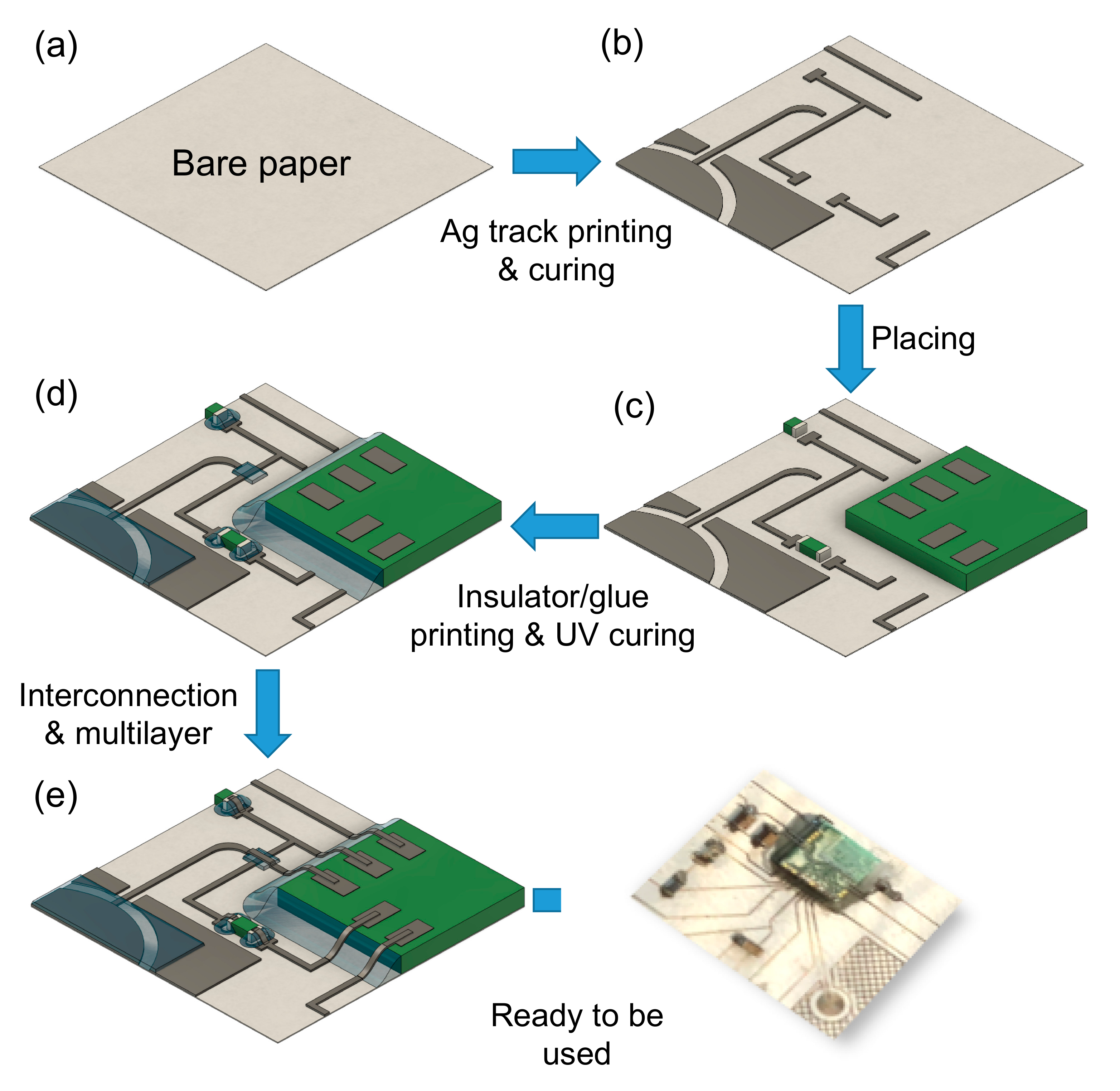

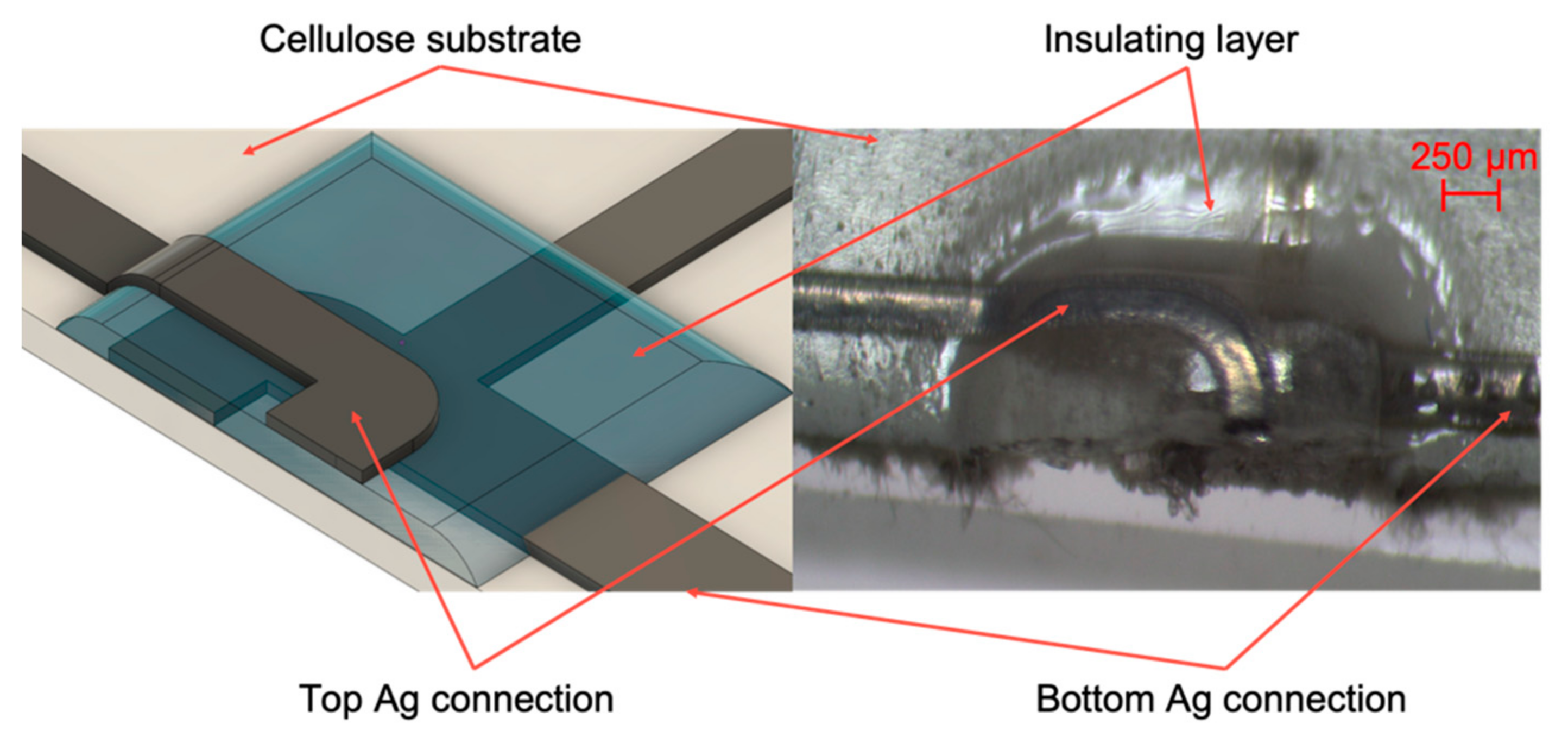

2.2.3. Multilayer and Interconnections

3. Results

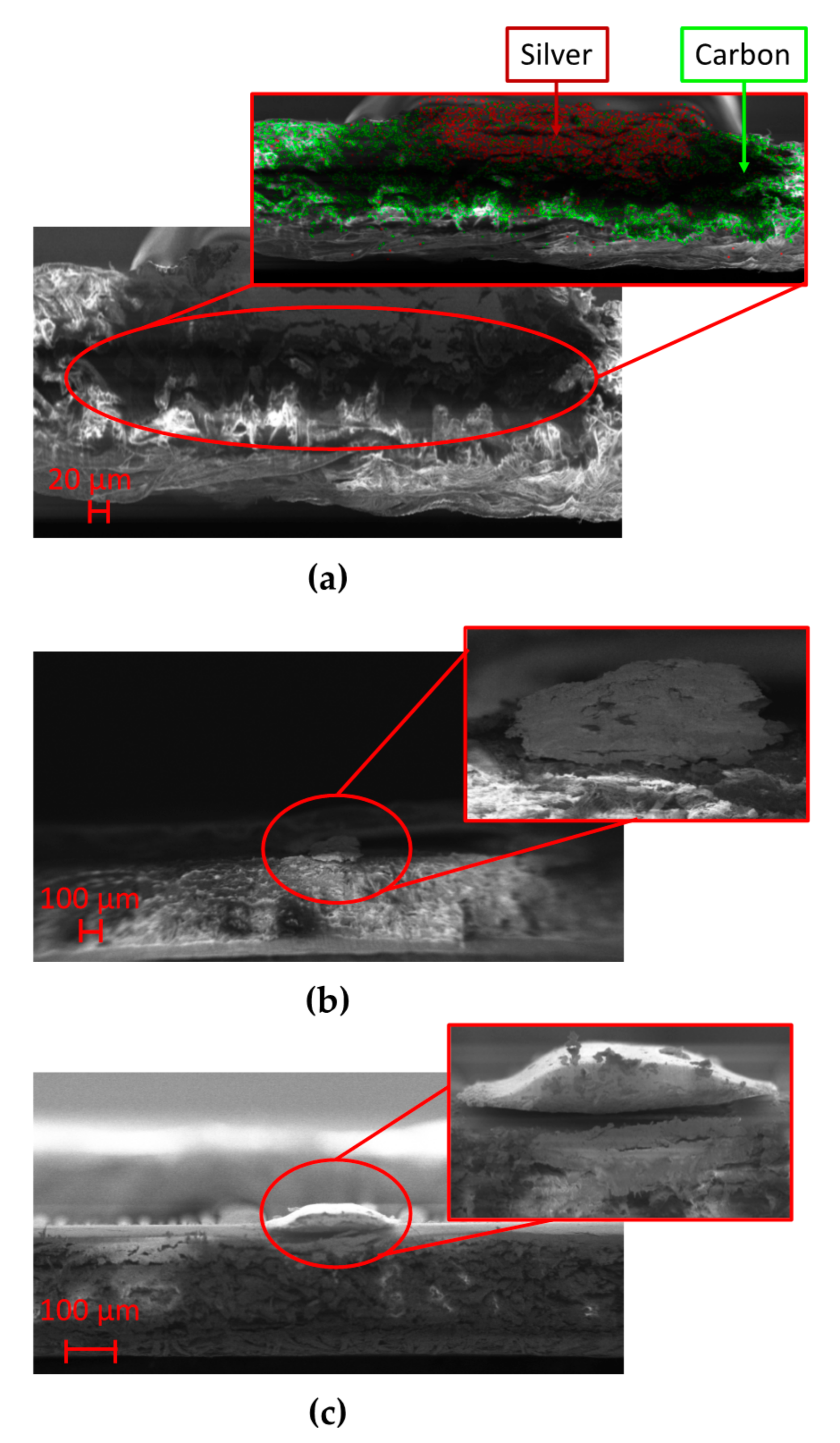

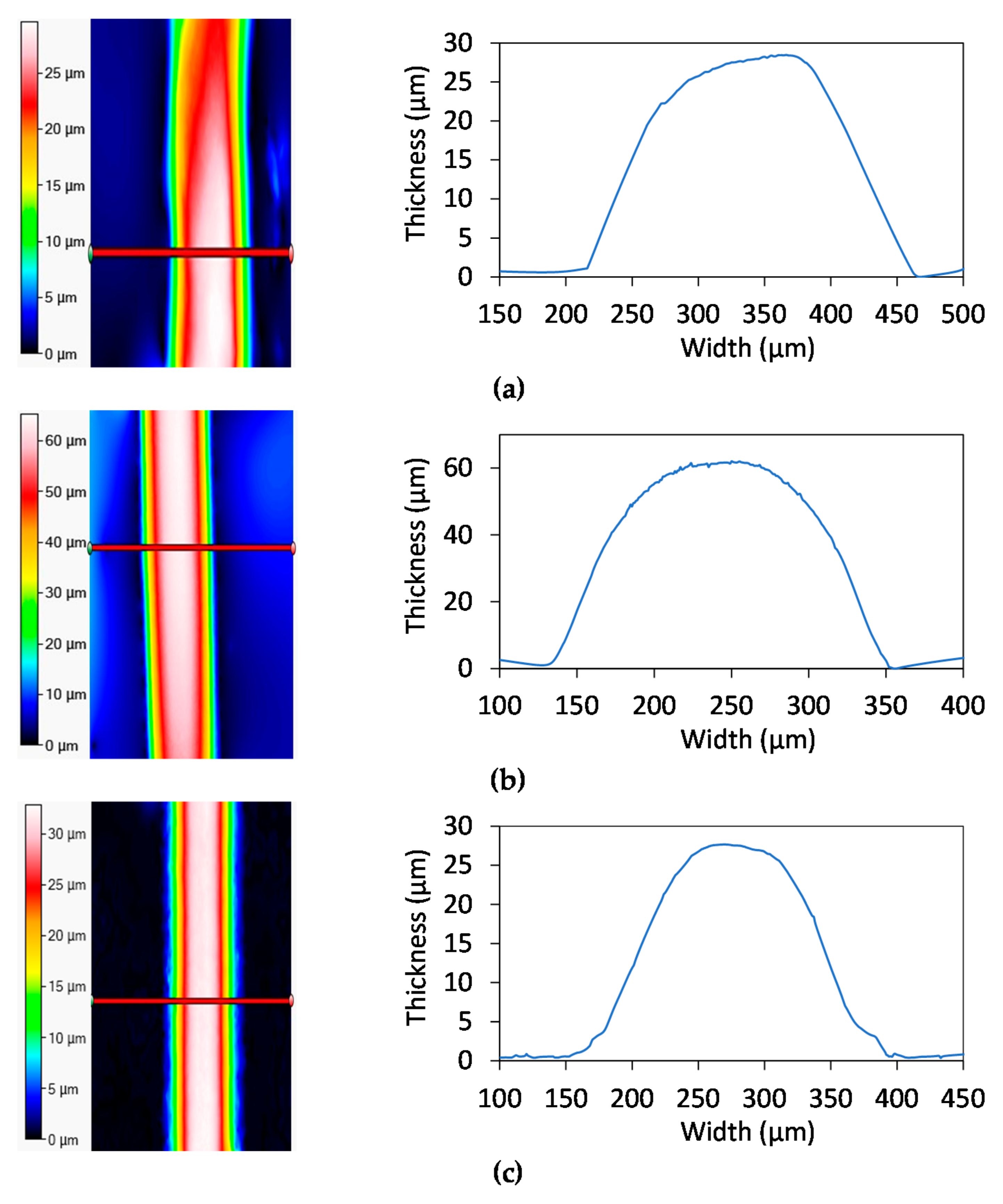

3.1. Resistivity Analysis

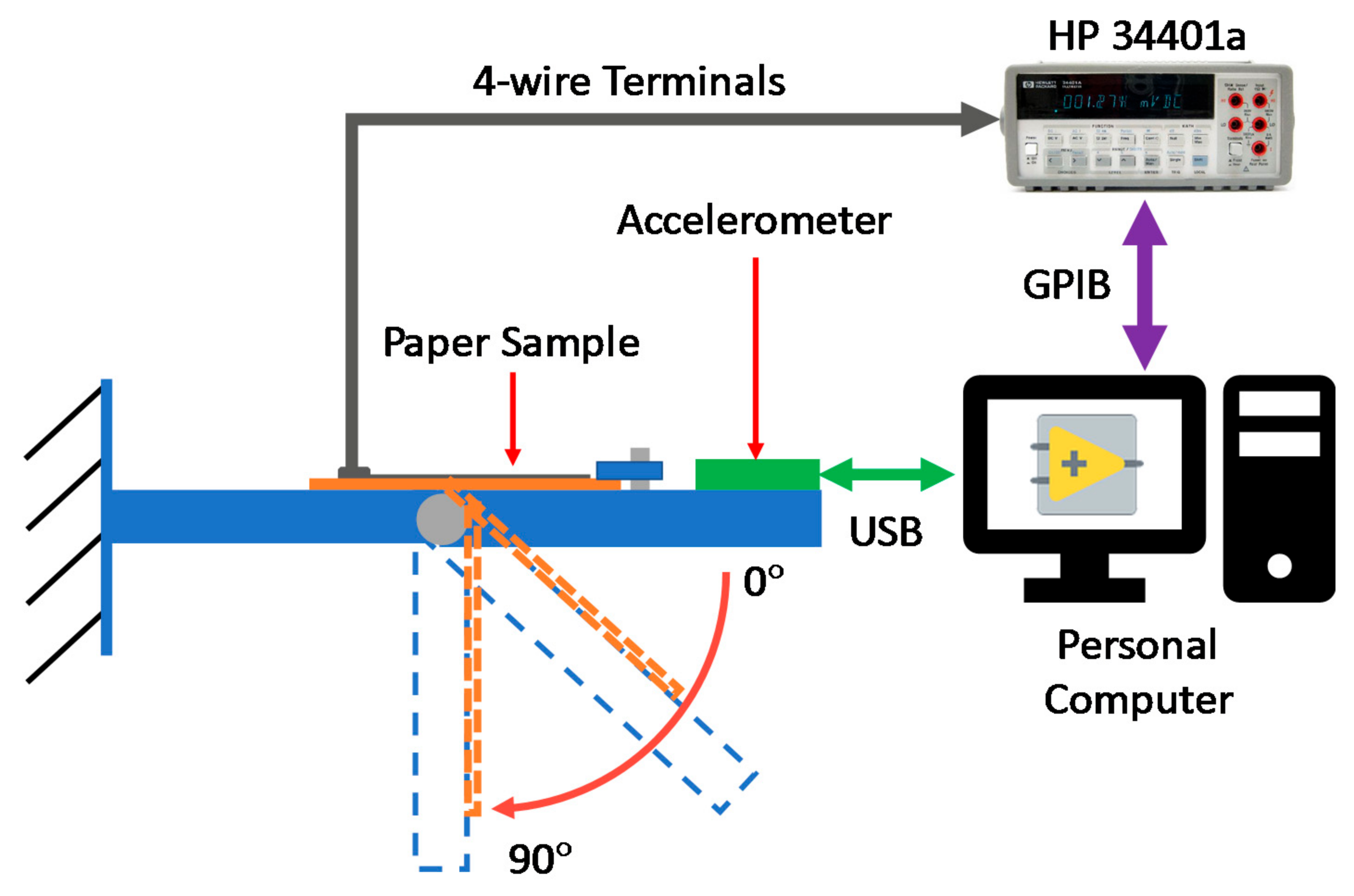

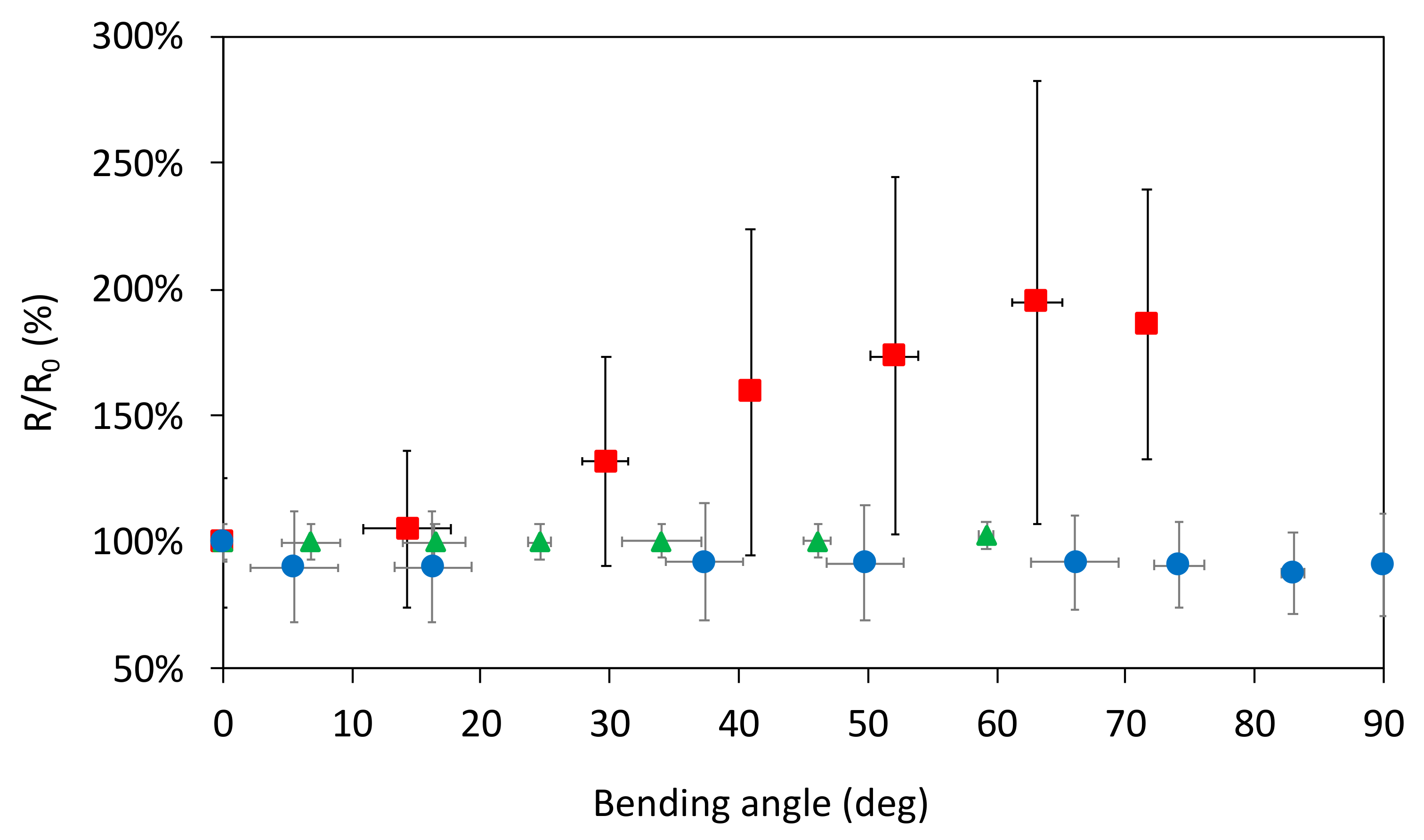

3.2. Electrical and Mechanical Stability under Bending Conditions

3.3. Electrical Stability in Damp Environment

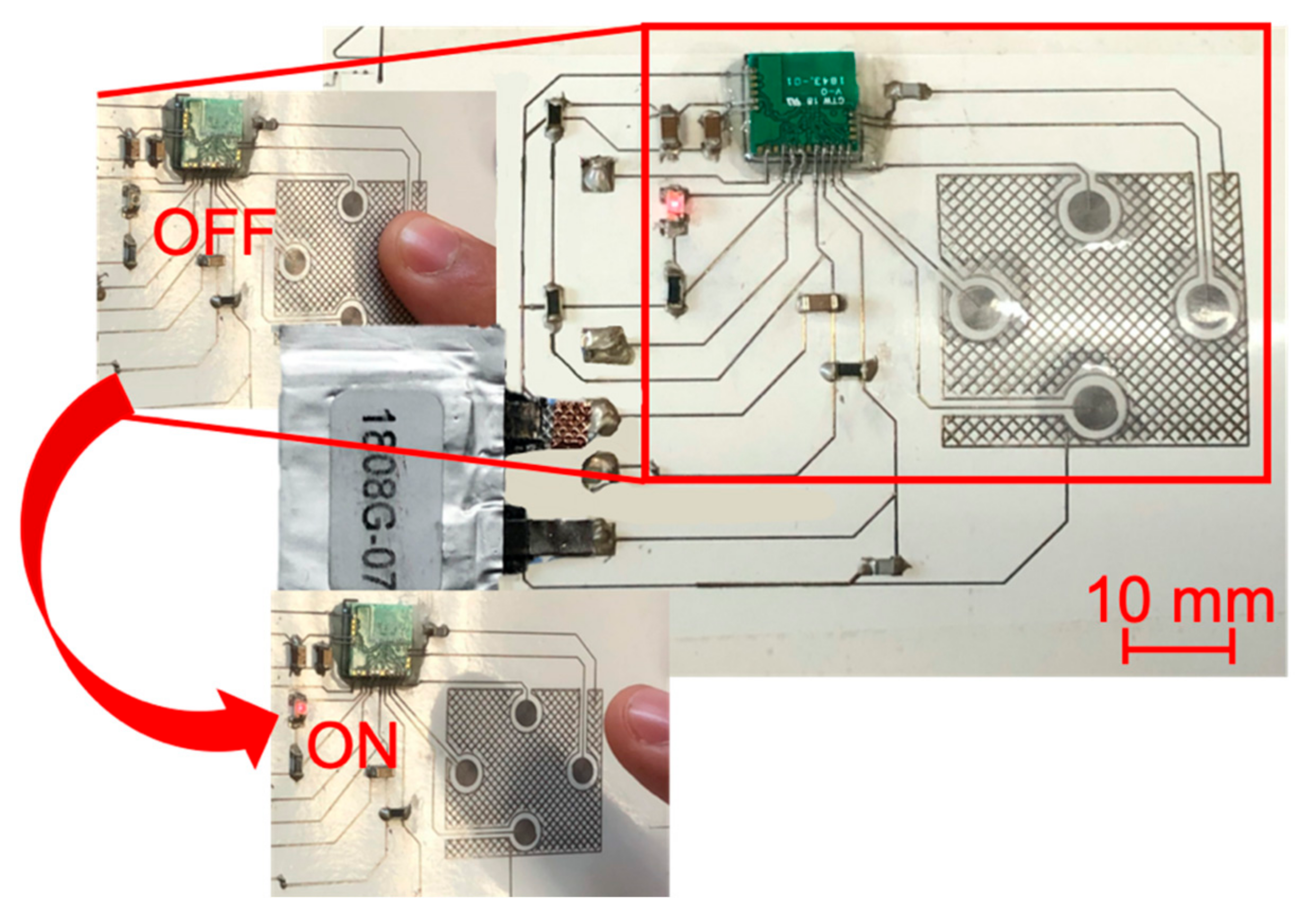

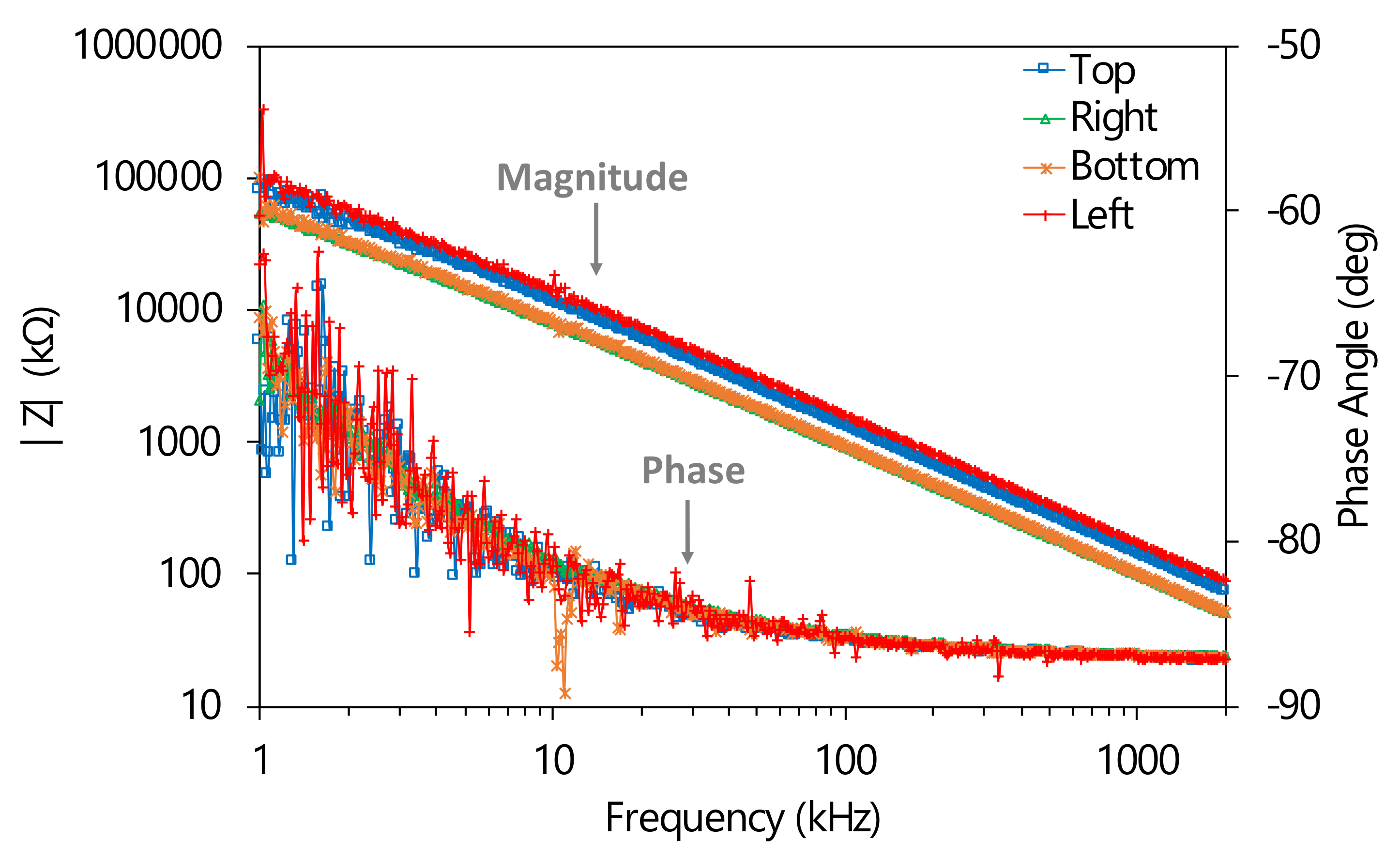

3.4. Multilayer Smart-3d-Device

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Liu, J.; Yang, C.; Wu, H.; Lin, Z.; Zhang, Z.; Wang, R.; Li, B.; Kang, F.; Shi, L.; Wong, C.P. Future paper based printed circuit boards for green electronics: Fabrication and life cycle assessment. Energy Environ. Sci. 2014, 7, 3674–3682. [Google Scholar] [CrossRef]

- Chang, H.; Guo, R.; Sun, Z.; Wang, H.; Hou, Y.; Wang, Q.; Rao, W.; Liu, J. Direct Writing and Repairable Paper Flexible Electronics Using Nickel–Liquid Metal Ink. Adv. Mater. Interfaces 2018, 5, 1800571. [Google Scholar] [CrossRef]

- Zou, X.; Chen, C.; Liang, T.; Xie, J.; Gillette-Henao, E.; Oh, J.; Tumalle, J.; Mazzeo, A.D. Paper-Based Resistive Networks for Scalable Skin-Like Sensing. Adv. Electron. Mater. 2018, 4, 1800131. [Google Scholar] [CrossRef]

- Wang, Z.; Fu, X.; Zhang, Z.; Jiang, Y.; Waqar, M.; Xie, P.; Bi, K.; Liu, Y.; Yin, X.; Fan, R. Paper-based metasurface: Turning waste-paper into a solution for electromagnetic pollution. J. Clean. Prod. 2019, 234, 588–596. [Google Scholar] [CrossRef]

- Bezuidenhout, P.; Smith, S.; Land, K.; Joubert, T.H. Inkjet-printed interconnects for unpackaged dies in printed electronics. Electron. Lett. 2019, 55, 252–254. [Google Scholar] [CrossRef]

- Guo, Z.; Jiao, Y.; Wang, H.; Zhang, C.; Liang, F.; Liu, J.L.; Yu, H.D.; Li, C.; Zhu, G.; Wang, Z.L. Self-Powered Electrowetting Valve for Instantaneous and Simultaneous Actuation of Paper-Based Microfluidic Assays. Adv. Funct. Mater. 2019, 29, 1808974. [Google Scholar] [CrossRef]

- Hu, J.; Wang, S.; Wang, L.; Li, F.; Pingguan-Murphy, B.; Lu, T.J.; Xu, F. Advances in paper-based point-of-care diagnostics. Biosens. Bioelectron. 2014, 54, 585–597. [Google Scholar] [CrossRef]

- Sun, X.; Wang, H.; Jian, Y.; Lan, F.; Zhang, L.; Liu, H.; Ge, S.; Yu, J. Ultrasensitive microfluidic paper-based electrochemical/visual biosensor based on spherical-like cerium dioxide catalyst for miR-21 detection. Biosens. Bioelectron. 2018, 105, 218–225. [Google Scholar] [CrossRef]

- Hayat, A.; Marty, J.L. Disposable screen printed electrochemical sensors: Tools for environmental monitoring. Sensors 2014, 14, 10432–10453. [Google Scholar] [CrossRef]

- Tee-Ngam, P.; Nunant, N.; Rattanarat, P.; Siangproh, W.; Chailapakul, O. Simple and rapid determination of ferulic acid levels in food and cosmetic samples using paper-based platforms. Sensors 2013, 13, 13039–13053. [Google Scholar] [CrossRef]

- Bezuidenhout, P.; Smith, S.; Joubert, T.H. A low-cost inkjet-printed paper-based potentiostat. Appl. Sci. 2018, 8, 968. [Google Scholar] [CrossRef]

- Wang, Y.; Guo, H.; Chen, J.J.; Sowade, E.; Wang, Y.; Liang, K.; Marcus, K.; Baumann, R.R.; Feng, Z.S. Paper-Based Inkjet-Printed Flexible Electronic Circuits. ACS Appl. Mater. Interfaces 2016, 8, 26112–26118. [Google Scholar] [CrossRef] [PubMed]

- Lee, C.J.; Chang, Y.C.; Wang, L.W.; Wang, Y.H. Biodegradable Materials for Organic Field-Effect Transistors on a Paper Substrate. IEEE Electron. Device Lett. 2019, 40, 236–239. [Google Scholar] [CrossRef]

- Xie, M.Z.; Wang, L.F.; Dong, L.; Deng, W.J.; Huang, Q.A. Low Cost Paper-Based LC Wireless Humidity Sensors and Distance-Insensitive Readout System. IEEE Sens. J. 2019, 19, 4717–4725. [Google Scholar] [CrossRef]

- Shamkhalichenar, H.; Choi, J.W. An inkjet-printed non-enzymatic hydrogen peroxide sensor on paper. J. Electrochem. Soc. 2017, 164, B3101–B3106. [Google Scholar] [CrossRef]

- Cinti, S.; Colozza, N.; Cacciotti, I.; Moscone, D.; Polomoshnov, M.; Sowade, E.; Baumann, R.R.; Arduini, F. Electroanalysis moves towards paper-based printed electronics: Carbon black nanomodified inkjet-printed sensor for ascorbic acid detection as a case study. Sens. Actuators B Chem. 2018, 265, 155–160. [Google Scholar] [CrossRef]

- Klem, M.d.S.; Morais, R.M.; Rubira, R.J.G.; Alves, N. Paper-based supercapacitor with screen-printed poly (3, 4-ethylene dioxythiophene)-poly (styrene sulfonate)/multiwall carbon nanotube films actuating both as electrodes and current collectors. Thin Solid Films 2019, 669, 96–102. [Google Scholar] [CrossRef]

- Chinnadayyala, S.R.; Park, J.; Le, H.T.N.; Santhosh, M.; Kadam, A.N.; Cho, S. Recent advances in microfluidic paper-based electrochemiluminescence analytical devices for point-of-care testing applications. Biosens. Bioelectron. 2019, 126, 68–81. [Google Scholar] [CrossRef]

- Kit, W.; Olarnwanich, A.; Sriprachuabwong, C.; Karuwan, C.; Tuantranont, A.; Wisitsoraat, A.; Srituravanich, W.; Pimpin, A. Disposable paper-based electrochemical sensor utilizing inkjet-printed Polyaniline modified screen-printed carbon electrode for Ascorbic acid detection. J. Electroanal. Chem. 2012, 685, 72–78. [Google Scholar]

- Tonello, S.; Abate, G.; Borghetti, M.; Marziano, M.; Serpelloni, M.; Uberti, D.L.; Lopomo, N.F.; Memo, M.; Sardini, E. Wireless Point-of-Care Platform with Screen-Printed Sensors for Biomarkers Detection. IEEE Trans. Instrum. Meas. 2017, 66, 2448–2455. [Google Scholar] [CrossRef]

- Borghetti, M.; Sardini, E.; Serpelloni, M. Preliminary study of resistive sensors in inkjet technology for force measurements in biomedical applications. In Proceedings of the 2014 IEEE 11th International Multi-Conference on Systems, Signals and Devices, SSD 2014, Barcelona, Spain, 11–14 February 2014. [Google Scholar]

- Borghetti, M.; Ghittorelli, M.; Sardini, E.; Serpelloni, M.; Torricelli, F. Electrical characterization of PEDOT: PSS strips deposited by inkjet printing on plastic foil for sensor manufacturing. IEEE Trans. Instrum. Meas. 2016, 65, 2137–2144. [Google Scholar] [CrossRef]

- Jo, Y.; Jeong, D.W.; Lee, J.O.; Choi, Y.; Jeong, S. 3D-printed origami electronics using percolative conductors. RSC Adv. 2018, 8, 22755–22762. [Google Scholar] [CrossRef]

- Ren’ai, L.; Zhang, K.; Chen, G.; Su, B.; Tian, J.; He, M.; Lu, F. Green polymerizable deep eutectic solvent (PDES) type conductive paper for origami 3D circuits. Chem. Commun. 2018, 54, 2304–2307. [Google Scholar] [CrossRef]

- Turner, N. A Review of Origami and its Applications in Mechanical Engineering. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2016, 230, 18. [Google Scholar]

- Linghu, C.; Zhang, S.; Wang, C.; Song, J. Transfer printing techniques for flexible and stretchable inorganic electronics. NPJ Flex. Electron. 2018, 2, 26. [Google Scholar] [CrossRef]

- Bian, J.; Zhou, L.; Wan, X.; Zhu, C.; Yang, B.; Huang, Y. Laser Transfer, Printing, and Assembly Techniques for Flexible Electronics. Adv. Electron. Mater. 2019, 5, 1800900. [Google Scholar] [CrossRef]

- Luo, H.; Wang, C.; Linghu, C.; Yu, K.; Wang, C.; Song, J. Laser-Driven Programmable Non-Contact Transfer Printing of Objects onto Arbitrary Receivers via an Active Elastomeric Micro-Structured Stamp. Natl. Sci. Rev. 2019. [Google Scholar] [CrossRef]

- Huang, Q.; Zhu, Y. Printing Conductive Nanomaterials for Flexible and Stretchable Electronics: A Review of Materials, Processes, and Applications. Adv. Mater. Technol. 2019, 4, 1800546. [Google Scholar] [CrossRef]

- Tan, H.W.; Tran, T.; Chua, C.K. A review of printed passive electronic components through fully additive manufacturing methods. Virtual Phys. Prototyp. 2016, 11, 271–288. [Google Scholar] [CrossRef]

- Hoey, J.M.; Lutfurakhmanov, A.; Schulz, D.L.; Akhatov, I.S. A review on aerosol-based direct-write and its applications for microelectronics. J. Nanotechnol. 2012, 2012, 324380. [Google Scholar] [CrossRef]

- Binder, S.; Glatthaar, M.; Rädlein, E. Analytical investigation of aerosol jet printing. Aerosol Sci. Technol. 2014, 48, 924–929. [Google Scholar] [CrossRef]

- OPTOMEC. Aerosol Jet ® Printed Electronics Overview; OPTOMEC: Albuquerque, NM, USA, 2018; p. 6. [Google Scholar]

- Gupta, A.A.; Arunachalam, S.; Cloutier, S.G.; Izquierdo, R. Fully Aerosol-Jet Printed, High-Performance Nanoporous ZnO Ultraviolet Photodetectors. ACS Photonics 2018, 5, 3923–3929. [Google Scholar] [CrossRef]

- Agarwala, S.; Goh, G.L.; Le, T.D.; An, J.; Peh, Z.K.; Yeong, W.Y.; Kim, Y. Wearable Bandage-Based Strain Sensor for Home Healthcare: Combining 3D Aerosol Jet Printing and Laser Sintering. ACS Sens. 2019, 4, 218–226. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.; Hong, G.Y.; Li, K.M.; Young, H.T. A miniaturized nickel oxide thermistor via aerosol jet technology. Sensors 2017, 17, 2602. [Google Scholar] [CrossRef] [PubMed]

- Yang, H.; Rahman, M.T.; Du, D.; Panat, R.; Lin, Y. 3-D printed adjustable microelectrode arrays for electrochemical sensing and biosensing. Sens. Actuators B Chem. 2016, 230, 600–606. [Google Scholar] [CrossRef] [PubMed]

- Habermehl, A.; Strobel, N.; Eckstein, R.; Bolse, N.; Mertens, A.; Hernandez-Sosa, G.; Eschenbaum, C.; Lemmer, U. Lab-on-chip, surface-enhanced Raman analysis by aerosol jet printing and roll-to-roll hot embossing. Sensors 2017, 17, 2401. [Google Scholar] [CrossRef]

- Cantù, E.; Tonello, S.; Abate, G.; Uberti, D.; Sardini, E.; Serpelloni, M. Aerosol jet printed 3D electrochemical sensors for protein detection. Sensors 2018, 18, 3719. [Google Scholar] [CrossRef]

- Di Novo, N.G.; Cantù, E.; Tonello, S.; Sardini, E.; Serpelloni, M. Support-material-free microfluidics on an electrochemical sensors platform by aerosol jet printing. Sensors 2019, 19, 1842. [Google Scholar] [CrossRef]

- Park, B.G.; Lee, C.J.; Jung, S.B. Enhancing adhesion strength of photonic sintered screen-printed Ag circuit by atmospheric pressure plasma. Microelectron. Eng. 2018, 202, 37–41. [Google Scholar] [CrossRef]

- West, J.; Carter, M.; Smith, S.; Sears, J. Photonic Curing of Silver Nanoparticle Based Inks. TechConnect Briefs 2010, 2, 210–213. [Google Scholar]

- Das, S.; Cormier, D.; Williams, S. Potential for Multi-functional Additive Manufacturing Using Pulsed Photonic Sintering. Procedia Manuf. 2015, 1, 366–377. [Google Scholar] [CrossRef]

- Mudgal, T.; Bhadrachalam, K.; Bischoff, P.; Cormier, D.; Manley, R.G.; Hirschman, K.D. Communication—CMOS Thin-Film Transistors via Xe Flash-Lamp Crystallization of Patterned Amorphous Si. ECS J. Solid State Sci. Technol. 2017, 6, Q179–Q181. [Google Scholar] [CrossRef]

- Schube, J.; Fellmeth, T.; Maier, F.; Keding, R. Applicability of photonic sintering and autoclaving as alternative contact formation methods for silicon solar cells with passivating contacts Applicability of Photonic Sintering and Autoclaving as Alternative Contact Formation Methods for Silicon Solar C. AIP Conf. Proc. 2018, 040019. [Google Scholar] [CrossRef]

- Bobinger, M.; Haider, M.; Goliya, Y.; Albrecht, A.; Becherer, M.; Lugli, P.; Rivadeneyra, A.; Russer, J.A. On the sintering of solution-based silver nanoparticle thin-films for sprayed and flexible antennas. Nanotechnology 2018, 29, 48. [Google Scholar] [CrossRef] [PubMed]

- Akbari, M.; He, H.; Juuti, J.; Tentzeris, M.M.; Virkki, J.; Ukkonen, L. 3D Printed and Photonically Cured Graphene UHF RFID Tags on Textile, Wood, and Cardboard Substrates. Int. J. Antennas Propag. 2017, 2017, 7327398. [Google Scholar] [CrossRef]

- Rizwan, M.; Kutty, A.A.; Kgwadi, M.; Drysdale, T.D.; Sydänheimo, L.; Ukkonen, L.; Virkki, J. Possibilities of Fabricating Copper-Based RFID Tags with Photonic-Sintered Inkjet Printing and Thermal Transfer Printing. IEEE Antennas Wirel. Propag. Lett. 2017, 16, 1828–1831. [Google Scholar] [CrossRef]

- Cronin, H.M.; Stoeva, Z.; Brown, M.; Shkunov, M.; Silva, S.R.P. Photonic Curing of Low-Cost Aqueous Silver Flake Inks for Printed Conductors with Increased Yield. ACS Appl. Mater. Interfaces 2018, 10, 21398–21410. [Google Scholar] [CrossRef] [PubMed]

- Mahajan, B.K.; Ludwig, B.; Shou, W.; Yu, X.; Fregene, E.; Xu, H.; Pan, H.; Huang, X. Aerosol printing and photonic sintering of bioresorbable zinc nanoparticle ink for transient electronics manufacturing. Sci. China Inf. Sci. 2018, 61, 060412. [Google Scholar] [CrossRef]

- Mahajan, B.K.; Yu, X.; Shou, W.; Pan, H.; Huang, X. Mechanically Milled Irregular Zinc Nanoparticles for Printable Bioresorbable Electronics. Small 2017, 13, 1700065. [Google Scholar] [CrossRef] [PubMed]

| Process Parameters | HPS 108-AE1 |

|---|---|

| Sheath gas flow (SCCM) | 500 |

| Atomizer gas flow (SCCM) | 1350 |

| Exhaust gas flow (SCCM) | 1000 |

| Plate temperature (°C) | 35 |

| Process speed (mm/s) | 1 |

| Process Parameters | NOA 81 |

|---|---|

| Sheath gas flow (SCCM) | 600 |

| Atomizer gas flow (SCCM) | 1350 |

| Exhaust gas flow (SCCM) | 1000 |

| Plate temperature (°C) | / |

| Process speed (mm/s) | 1 |

| Number of depositions | 4 |

| %RH | R/R35 (%) | ||

|---|---|---|---|

| Chromatographic Paper | Cardboard | Photopaper | |

| 35 | 100 ± 6 | 100 ± 4 | 100 ± 9 |

| 45 | 101 ± 9 | 95.3 ± 6 | 99.3 ± 8 |

| 55 | 102 ± 8 | 102 ± 6 | 99.7 ± 9 |

| 65 | 103 ± 6 | 95.7 ± 3 | 98.6 ± 8 |

| 80 | 96 ± 7 | 94.4 ± 8 | 97.3 ± 8 |

| Key Position | Capacitance (pF) | |

|---|---|---|

| No Finger | Finger in Touch | |

| Top | 1.32 ± 0.08 | 1.86 ± 0.19 |

| Right | 1.92 ± 0.08 | 2.85 ± 0.35 |

| Bottom | 1.87 ± 0.09 | 2.72 ± 0.21 |

| Left | 1.13 ± 0.09 | 1.55 ± 0.15 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Serpelloni, M.; Cantù, E.; Borghetti, M.; Sardini, E. Printed Smart Devices on Cellulose-Based Materials by means of Aerosol-Jet Printing and Photonic Curing. Sensors 2020, 20, 841. https://doi.org/10.3390/s20030841

Serpelloni M, Cantù E, Borghetti M, Sardini E. Printed Smart Devices on Cellulose-Based Materials by means of Aerosol-Jet Printing and Photonic Curing. Sensors. 2020; 20(3):841. https://doi.org/10.3390/s20030841

Chicago/Turabian StyleSerpelloni, Mauro, Edoardo Cantù, Michela Borghetti, and Emilio Sardini. 2020. "Printed Smart Devices on Cellulose-Based Materials by means of Aerosol-Jet Printing and Photonic Curing" Sensors 20, no. 3: 841. https://doi.org/10.3390/s20030841

APA StyleSerpelloni, M., Cantù, E., Borghetti, M., & Sardini, E. (2020). Printed Smart Devices on Cellulose-Based Materials by means of Aerosol-Jet Printing and Photonic Curing. Sensors, 20(3), 841. https://doi.org/10.3390/s20030841