Dynamic Characteristics and Damage Detection of a Metallic Thermal Protection System Panel Using a Three-Dimensional Point Tracking Method and a Modal Assurance Criterion

Abstract

1. Introduction

2. Theoretical Background

3. Material and Methods

3.1. Material Preparation

3.2. Experimental Setup

3.3. Validation

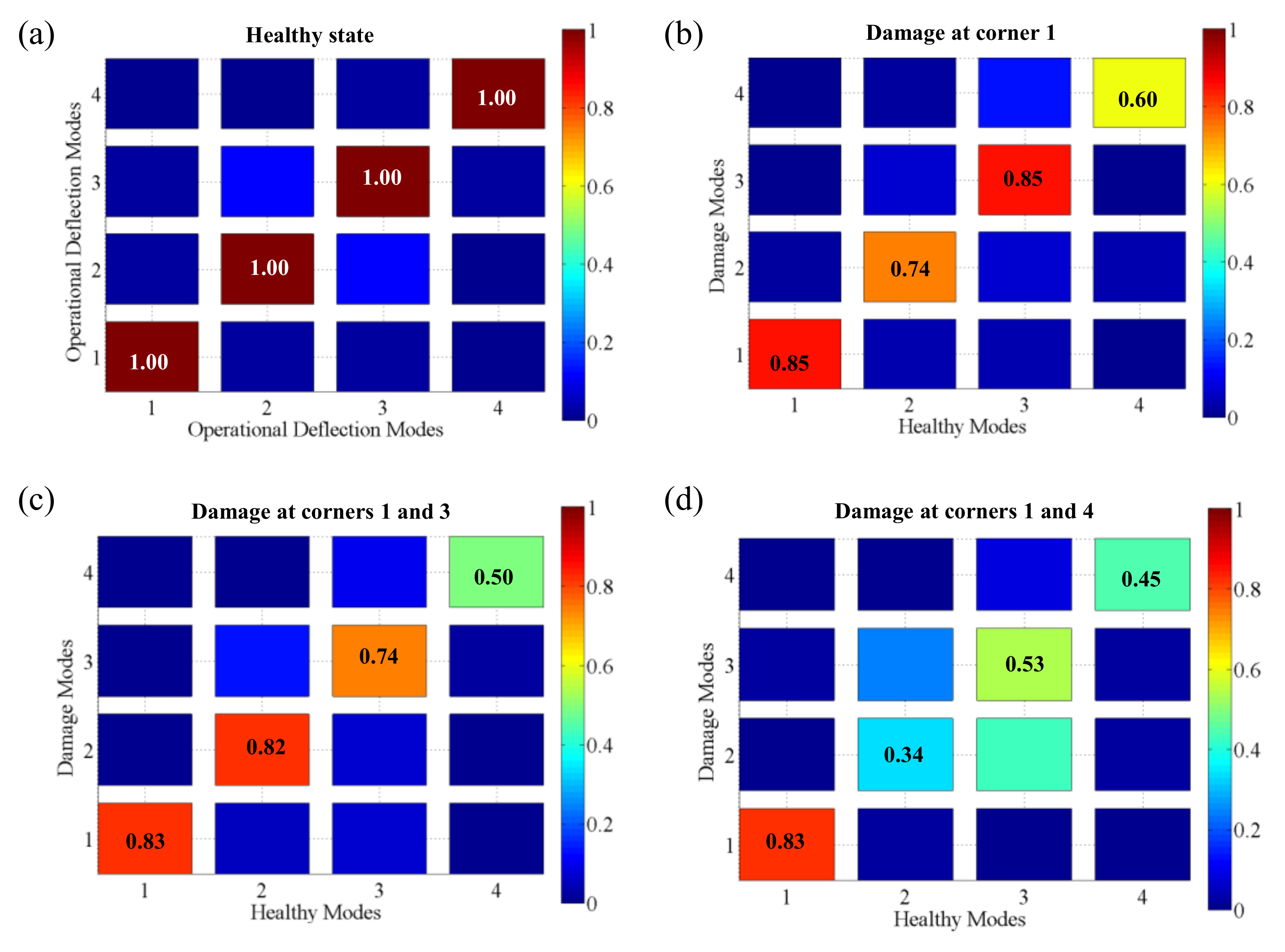

3.4. Damage Detection Method

4. Results and Discussion

4.1. Dynamic Characteristics of a Healthy Fully-Assembled TPS Panel

4.2. Damage Detection

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Dorsey, J.; Poteet, C.; Chen, R.; Wurster, K. Metallic thermal protection system technology development-Concepts, requirements and assessment overview. In Proceedings of the 40th AIAA Aerospace Sciences Meeting & Exhibit, Reno, NV, USA, 14–17 January 2002. [Google Scholar] [CrossRef][Green Version]

- Le, V.T.; Goo, N.S. Thermomechanical performance of bio-inspired corrugated-core sandwich structure for a thermal protection system panel. Appl. Sci. 2019, 9, 5541. [Google Scholar] [CrossRef]

- Blosser, M.L.; Poteet, C.C.; Chen, R.R.; Dorsey, J.T.; Schmidt, I.H.; Bird, R.K.; Wurster, K.E. Development of advanced metallic-thermal-protection system prototype hardware. J. Spacecr. Rocket. 2004, 41, 183–194. [Google Scholar] [CrossRef]

- Xu, Y.; Xu, N.; Zhang, W.; Zhu, J. A multi-layer integrated thermal protection system with C/SiC composite and Ti alloy lattice sandwich. Compos. Struct. 2019, 111507. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, L.; He, R.; Ma, Y.; Zhang, K.; Bai, X.; Xu, B.; Chen, Y. Integrated thermal protection system based on C/SiC composite corrugated core sandwich plane structure. Aerosp. Sci. Technol. 2019, 91, 607–616. [Google Scholar] [CrossRef]

- Le, V.T.; Ha, N.S.; Goo, N.S. Thermal protective properties of the allomyrina dichotoma beetle forewing for thermal protection systems. Heat Transf. Eng. 2019, 40, 1539–1549. [Google Scholar] [CrossRef]

- Le, V.T.; Goo, N.S.; Kim, J.Y. Experimental investigation on thermal contact resistance of alumina fibrous insulation material with Ti-6Al-4V alloy at high temperature and its effective thermal conductivity. Heat Mass Transf. 2019, 55, 1705–1721. [Google Scholar] [CrossRef]

- Le, V.T.; Ha, N.S.; Goo, N.S.; Kim, J.Y. Insulation system using high-temperature fibrous insulation materials. Heat Transf. Eng. 2019, 40, 1523–1538. [Google Scholar] [CrossRef]

- Blosser, M.L. Fundamental modeling and thermal performance issues for metallic thermal protection system concept. J. Spacecr. Rocket. 2004, 41, 195–206. [Google Scholar] [CrossRef]

- Le, V.T.; Goo, N.S.; Kim, J.Y. Thermomechanical behavior of superalloy thermal protection system under aerodynamic heating. J. Spacecr. Rocket. 2019, 56, 1432–1448. [Google Scholar] [CrossRef]

- Ng, W.; McNamara, J.; Friedmann, P.; Waas, A. Thermomechanical behavior of damaged TPS including hypersonic flow effects. In Proceedings of the 14th AIAA/AHI space planes and hypersonic systems and technologies conference, Canberra, Australia, 6–9 November 2006. [Google Scholar] [CrossRef][Green Version]

- Ng, W.H.; Friedmann, P.; Waas, A. Thermomechanical analysis of a thermal protection system with defects and heat shorts. In Proceedings of the 47th AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference, Newport, RL, USA, 1–4 May 2006. [Google Scholar] [CrossRef]

- Ng, W.; Friedmann, P.; Waas, A.; McNamara, J. Thermomechanical behavior of a thermal protection system with different levels of damage-experiments and simulation. In Proceedings of the 48th AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference, Honolulu, HI, USA, 23–26 April 2007. [Google Scholar] [CrossRef]

- Derriso, M.; Braisted, W.; Rosenstengel, J.; DeSimio, M. The structural health monitoring of a mechanically attached thermal protection system. JOM 2004, 56, 36–39. [Google Scholar] [CrossRef]

- Chen, R.R.; Blosser, M.L. Metallic thermal-protection-system panel flutter study. J. Spacecr. Rocket. 2004, 41, 207–212. [Google Scholar] [CrossRef]

- Tobe, R.J.; Grandhi, R.V. Hypersonic vehicle thermal protection system model optimization and validation with vibration tests. Aerosp. Sci. Technol. 2013, 28, 208–213. [Google Scholar] [CrossRef]

- Jiang, X.; Mahadevan, S.; Guratzsch, R. Bayesian wavelet methodology for damage detection of thermal protection system panels. AIAA J. 2009, 47, 942–952. [Google Scholar] [CrossRef]

- Myers, D.E.; Martin, C.J.; Blosser, M.L. Parametric Weight Comparison of Advanced Metallic, Ceramic Tile, and Ceramic Blanket Thermal Protection Systems; NASA TM 2000-210289; NASA: Washington, DC, USA, 2000; p. 49.

- Boehrk, H.; Weihs, H.; Elsäßer, H. Hot structure flight data of a faceted atmospheric reentry thermal protection system. Int. J. Aerosp. Eng. 2019, 2019, 9754739. [Google Scholar] [CrossRef]

- Pau, A.; Greco, A.; Vestroni, F. Numerical and experimental detection of concentrated damage in a parabolic arch by measured frequency variations. J. Vib. Control 2011, 17, 605–614. [Google Scholar] [CrossRef]

- Yamaguchi, H.; Matsumoto, Y.; Kawarai, K.; Dammika, A.J.; Shahzad, S.; Takanami, R. Damage detection based on modal damping change in bridges. In Proceedings of the ICSBE’12, Kandt, Sri Lanka, 14–16 December 2013. [Google Scholar]

- Farrar, C.R.; James Iii, G.H. System identification from ambient vibration measurements on a bridge. J. Sound Vib. 1997, 205, 1–18. [Google Scholar] [CrossRef]

- Allemang, R.J. The modal assurance criterion–twenty years of use and abuse. In Proceedings of the 20th International Modal Analysis Conference (IMAC 20), Los Angeles, CA, USA, 4–7 February 2002. [Google Scholar]

- Orlowitz, E.; Brandt, A. Comparison of experimental and operational modal analysis on a laboratory test plate. Measurement 2017, 102, 121–130. [Google Scholar] [CrossRef]

- Nguyen, M.; Filippatos, A.; Langkamp, A.; Gude, M. Modal identification of output-only systems of composite discs using Zernike modes and MAC. Sensors 2019, 19, 660. [Google Scholar] [CrossRef]

- Allemang, R.J.; Brown, D.L. A correlation coefficient for modal vector analysis. In Proceedings of the 1st International Modal Analysis Conference, Orlando, FL, USA, 8–10 November 1982. [Google Scholar]

- Zhong, H.; Yang, M. Damage detection for plate-like structures using generalized curvature mode shape method. J. Civ. Struct. Health Monit. 2016, 6, 141–152. [Google Scholar] [CrossRef]

- Pandey, A.; Biswas, M. Damage detection in structures using changes in flexibility. J. Sound Vib. 1994, 169, 3–17. [Google Scholar] [CrossRef]

- Pandey, A.K.; Biswas, M.; Samman, M.M. Damage detection from changes in curvature mode shapes. J. Sound Vib. 1991, 145, 321–332. [Google Scholar] [CrossRef]

- Altunışık, A.C.; Okur, F.Y.; Karaca, S.; Kahya, V. Vibration-based damage detection in beam structures with multiple cracks: Modal curvature vs. modal flexibility methods. Nondestruct. Test. Eval. 2019, 34, 33–53. [Google Scholar] [CrossRef]

- Sazonov, E.; Klinkhachorn, P. Optimal spatial sampling interval for damage detection by curvature or strain energy mode shapes. J. Sound Vib. 2005, 285, 783–801. [Google Scholar] [CrossRef]

- Capecchi, D.; Ciambella, J.; Pau, A.; Vestroni, F. Damage identification in a parabolic arch by means of natural frequencies, modal shapes and curvatures. Meccanica 2016, 51, 2847–2859. [Google Scholar] [CrossRef]

- Bae, W.; Kyong, Y.; Dayou, J.; Park, K.-h.; Wang, S. Scaling the operating deflection shapes obtained from scanning laser doppler vibrometer. J. Nondestruct. Eval. 2011, 30, 91–98. [Google Scholar] [CrossRef]

- Pai, P.F.; Young, L.G. Damage detection of beams using operational deflection shapes. Int. J. Solids Struct. 2001, 38, 3161–3192. [Google Scholar] [CrossRef]

- Waldron, K.; Ghoshal, A.; Schulz, M.J.; Sundaresan, M.J.; Ferguson, F.; Pai, P.F.; Chung, J.H. Damage detection using finite element and laser operational deflection shapes. Finite Elem. Anal. Des. 2002, 38, 193–226. [Google Scholar] [CrossRef]

- Xu, Y. Photogrammetry-based structural damage detection by tracking a visible laser line. Struct. Health Monit. 2020, 19, 322–336. [Google Scholar] [CrossRef]

- Molina-Viedma, Á.; López-Alba, E.; Felipe-Sesé, L.; Díaz, F.; Rodríguez-Ahlquist, J.; Iglesias-Vallejo, M. Modal parameters evaluation in a full-scale aircraft demonstrator under different environmental conditions using HS 3D-DIC. Materials 2018, 11, 230. [Google Scholar] [CrossRef]

- Civera, M.; Zanotti Fragonara, L.; Surace, C. Using video processing for the full-field identification of backbone curves in case of large vibrations. Sensors 2019, 19, 2345. [Google Scholar] [CrossRef]

- Civera, M.; Zanotti Fragonara, L.; Surace, C. Video Processing Techniques for the Contactless Investigation of Large Oscillations. J. Phys. Conf. Ser. 2019, 1249, 012004. [Google Scholar] [CrossRef]

- Tashan, J.; Al-Mahaidi, R. Detection of cracks in concrete strengthened with CFRP systems using infra-red thermography. Compos. Part B Eng. 2014, 64, 116–125. [Google Scholar] [CrossRef]

- Liu, Y.; Yang, S.; Liu, X. Detection and quantification of damage in metallic structures by laser-generated ultrasonics. Appl. Sci. 2018, 8, 824. [Google Scholar] [CrossRef]

- Hwang, S.; An, Y.-K.; Yang, J.; Sohn, H. Remote Inspection of Internal Delamination in Wind Turbine Blades using Continuous Line Laser Scanning Thermography. Int. J. Precis. Eng. Manuf.-Green Technol. 2020, 7, 699–712. [Google Scholar] [CrossRef]

- Hu, Y.; Guo, W.; Zhu, W.; Xu, Y. Local damage detection of membranes based on Bayesian operational modal analysis and three-dimensional digital image correlation. Mech. Syst. Signal Process. 2019, 131, 633–648. [Google Scholar] [CrossRef]

- Ha, N.; Vang, H.; Goo, N. Modal analysis using digital image correlation technique: An application to artificial wing mimicking beetle’s hind wing. Exp. Mech. 2015, 55, 989–998. [Google Scholar] [CrossRef]

- Zhang, F.; Zarate Garnica, G.I.; Yang, Y.; Lantsoght, E.; Sliedrecht, H. Monitoring Shear Behavior of Prestressed Concrete Bridge Girders Using Acoustic Emission and Digital Image Correlation. Sensors 2020, 20, 5622. [Google Scholar] [CrossRef]

- Feito, N.; Calvo, J.V.; Belda, R.; Giner, E. An Experimental and Numerical Investigation to Characterize an Aerospace Composite Material with Open-Hole Using Non-Destructive Techniques. Sensors 2020, 20, 4148. [Google Scholar] [CrossRef]

- Zhao, T.; Le, V.T.; Goo, N.S. Global-local deformation measurement of stress concentration structures using a multi-digital image correlation system. J. Mech. Sci. Technol. 2020, 34, 1655–1665. [Google Scholar] [CrossRef]

- Le, V.T.; Ha, N.S.; Jin, T.; Goo, N.S.; Kim, J.Y. Thermal interaction of a circular plate-ring structure using digital image correlation technique and infrared heating system. J. Mech. Sci. Technol. 2016, 30, 4363–4372. [Google Scholar] [CrossRef]

- Ha, N.S.; Le, V.T.; Goo, N.S.; Kim, J.Y. Thermal strain measurement of austin stainless steel (ss304) during a heating-cooling process. Int. J. Aeronaut. Space Sci. 2017, 18, 206–214. [Google Scholar] [CrossRef]

- Jin, T.; Ha, N.S.; Le, V.T.; Goo, N.S.; Jeon, H.C. Thermal buckling measurement of a laminated composite plate under a uniform temperature distribution using the digital image correlation method. Compos. Struct. 2015, 123, 420–429. [Google Scholar] [CrossRef]

- Pham, V.; Wang, H.; Xu, J.; Wang, J.; Singh, C.; Park, S. A Study of substrate models and its effect on package warpage prediction. In Proceedings of the 2019 IEEE 69th Electronic Components and Technology Conference (ECTC), Las Vegas, NV, USA, 28–31 May 2019. [Google Scholar] [CrossRef]

- Pham, V.-L.; Niu, Y.; Wang, J.; Wang, H.; Singh, C.; Park, S.; Zhong, C.; Koh, S.W.; Wang, J.; Shao, S. Experimentally Minimizing the Gap Distance Between Extra Tall Packages and PCB Using the Digital Image Correlation (DIC) Method. In Proceedings of the 2018 IEEE 68th Electronic Components and Technology Conference (ECTC), San Diego, CA, USA, 29 May–1 June 2018. [Google Scholar] [CrossRef]

- Pham, V.-L.; Xu, J.; Pan, K.; Wang, J.; Park, S.; Singh, C.; Wang, H. Investigation of underfilling BGAs packages – Thermal fatigue. In Proceedings of the 2020 IEEE 70th Electronic Components and Technology Conference (ECTC), Orlando, FL, USA, 3–30 June 2020. [Google Scholar] [CrossRef]

- Ha, N.S.; Le, V.T.; Goo, N.S. Investigation of punch resistance of the Allomyrira dichtoloma beetle forewing. J. Bionic Eng. 2018, 15, 57–68. [Google Scholar] [CrossRef]

- Ha, N.S.; Le, V.T.; Goo, N.S. Investigation of fracture properties of a piezoelectric stack actuator using the digital image correlation technique. Int. J. Fatigue 2017, 101, 106–111. [Google Scholar] [CrossRef]

- Srivastava, V.; Baqersad, J. An optical-based technique to obtain operating deflection shapes of structures with complex geometries. Mech. Syst. Signal Process. 2019, 128, 69–81. [Google Scholar] [CrossRef]

- Beberniss, T.J.; Ehrhardt, D.A. High-speed 3D digital image correlation vibration measurement: Recent advancements and noted limitations. Mech. Syst. Signal Process. 2017, 86, 35–48. [Google Scholar] [CrossRef]

- Wu, R.; Zhang, D.; Yu, Q.; Jiang, Y.; Arola, D. Health monitoring of wind turbine blades in operation using three-dimensional digital image correlation. Mech. Syst. Signal Process. 2019, 130, 470–483. [Google Scholar] [CrossRef]

- Helfrick, M.N.; Niezrecki, C.; Avitabile, P. Curvature methods of damage detection using digital image correlation. In Proceedings of the Health Monitoring of Structural and Biological Systems 2009, San Diego, CA, USA, 8–12 March 2009. [Google Scholar] [CrossRef]

- Poozesh, P.; Baqersad, J.; Niezrecki, C.; Avitabile, P.; Harvey, E.; Yarala, R. Large-area photogrammetry based testing of wind turbine blades. Mech. Syst. Signal Process. 2017, 86, 98–115. [Google Scholar] [CrossRef]

- Warren, C.; Niezrecki, C.; Avitabile, P.; Pingle, P. Comparison of FRF measurements and mode shapes determined using optically image based, laser, and accelerometer measurements. Mech. Syst. Signal Process. 2011, 25, 2191–2202. [Google Scholar] [CrossRef]

- Ozbek, M.; Rixen, D.J.; Erne, O.; Sanow, G. Feasibility of monitoring large wind turbines using photogrammetry. Energy 2010, 35, 4802–4811. [Google Scholar] [CrossRef]

- Schwarz, B.J.; Richardson, M.H. Introduction to operating deflection shapes. In Proceedings of the CSI Reliability Week, Orlando, FL, USA, October 1999; pp. 121–126. [Google Scholar]

- Maia, N.; Silva, J. Modal analysis identification techniques. Philos. Trans. R. Soc. Lond. Ser. A: Math. Phys. Eng. Sci. 2001, 359, 29–40. [Google Scholar] [CrossRef]

- Schwarz, B.; Richardson, S.; Richardson, M. Curve Fitting Analytical Mode Shapes to Experimental Data. In Topics in Modal Analysis & Testing; Springer: New York, NY, USA, 2016; Volume 10, pp. 45–59. [Google Scholar] [CrossRef]

- Avitabile, P. Experimental modal analysis-a simple non-mathematical presentation. Sound Vib. 2001, 35, 20–31. [Google Scholar]

- Richardson, M.H.; Formenti, D.L. Global curve fitting of frequency response measurements using the rational fraction polynomial method. In Proceedings of the Third International Modal Analysis Conference, Orlando, FL, USA, January 1985; pp. 390–397. [Google Scholar]

- GOMGmbH. ARAMIS Software. Available online: https://www.gom.com/3d-software/gom-system-software/aramis-professional.html (accessed on 11 November 2020).

- Richardson, M.H. Is it a mode shape, or an operating deflection shape. J. Sound Vib. 1997, 31, 54–61. [Google Scholar]

- MacDonald, S. OMG! What Is OMA? Operational Modal Analysis. Available online: https://community.sw.siemens.com/s/article/OMG-What-is-OMA-Operating-Modal-Analysis (accessed on 10 December 2020).

- Norbar Torque Tools Ltd. Catalogue 2020-Torque Wrench Section; Norbar Torque Tools Ltd.: Banbury, Oxfordshire, UK, 2020. [Google Scholar]

- Jones, E.M.; Iadicola, M.A. A good practices guide for digital image correlation. Int. Digit. Image Correl. Soc. 2018. [Google Scholar]

- Schmidt, T.; Tyson, J.; Galanulis, K. Full-field dynamic displacement and strain measurement using advanced 3d image correlation photogrammetry: Part 1. Exp. Tech. 2003, 27, 47–50. [Google Scholar] [CrossRef]

- Wolf, J.A. The Influence of mounting stiffness on frequencies measured in a vibration test. In Proceedings of the SAE International Congress and Exposition, Detroit, MI, USA, 27 February–2 March 1984. SAE-840480. [Google Scholar] [CrossRef]

- Carne, T.G.; Dohrmann, C.R. Support conditions, their effect on measured modal parameters. In Proceedings of the 16th International Modal Analysis Conference, Santa Barbara, CA, USA, 2–5 February 1998; Volume 3243, pp. 477–483. [Google Scholar]

- Ewins, D.J. Modal Testing: Theory, Practice and Application, 2nd ed.; Research Studies Press LTD: Herfordshire, UK, 2009; p. 574. [Google Scholar]

- Devriendt, C.; Steenackers, G.; De Sitter, G.; Guillaume, P. From operating deflection shapes towards mode shapes using transmissibility measurements. Mech. Syst. Signal Process. 2010, 24, 665–677. [Google Scholar] [CrossRef]

- Richardson, M.H.; McHargue, P.L. Operating deflection shapes from time versus frequency domain measurements. In Proceedings of the 11th International Modal Analysis Conference. Society for experimental mechanics, Kissimmee, FL, USA, 1–4 February 1993. [Google Scholar]

- Brincker, R.; Ventura, C.E. Introduction to Operational Modal Analysis; John Wiley & Sons Ltd.: Chichester, UK, 2015. [Google Scholar]

- Molina-Viedma, Á.; López-Alba, E.; Felipe-Sesé, L.; Díaz, F. Modal Identification in an Automotive Multi-Component System Using HS 3D-DIC. Materials 2018, 11, 241. [Google Scholar] [CrossRef]

- Thibault, L.; Marinone, T.; Avitabile, P.; Van Karsen, C. Comparison of modal parameters estimated from operational and experimental modal analysis approaches. In Topics in Modal Analysis I, Volume 5; Springer: New York, NY, USA, 2012; pp. 77–88. [Google Scholar] [CrossRef]

- Wadhwa, N.; Rubinstein, M.; Durand, F.; Freeman, W.T. Phase-based video motion processing. Acm Trans. Graph. 2013, 32, 80. [Google Scholar] [CrossRef]

- Wadhwa, N.; Rubinstein, M.; Durand, F.; Freeman, W.T. Riesz pyramids for fast phase-based video magnification. In Proceedings of the 2014 IEEE International Conference on Computational Photography (ICCP), Santa Clara, CA, USA, 2–4 May 2014; pp. 1–10. [Google Scholar] [CrossRef]

- Chen, J.G.; Wadhwa, N.; Cha, Y.-J.; Durand, F.; Freeman, W.T.; Buyukozturk, O. Modal identification of simple structures with high-speed video using motion magnification. J. Sound Vib. 2015, 345, 58–71. [Google Scholar] [CrossRef]

- Poozesh, P.; Sarrafi, A.; Mao, Z.; Avitabile, P.; Niezrecki, C. Feasibility of extracting operating shapes using phase-based motion magnification technique and stereo-photogrammetry. J. Sound Vib. 2017, 407, 350–366. [Google Scholar] [CrossRef]

- Sarrafi, A.; Mao, Z.; Niezrecki, C.; Poozesh, P. Vibration-based damage detection in wind turbine blades using Phase-based Motion Estimation and motion magnification. J. Sound Vib. 2018, 421, 300–318. [Google Scholar] [CrossRef]

- Civera, M.; Zanotti Fragonara, L.; Surace, C. An experimental study of the feasibility of phase-based video magnification for damage detection and localisation in operational deflection shapes. Strain 2020, 56, e12336. [Google Scholar] [CrossRef]

- Fatemi, J.; Lemmen, M. Effective thermal/mechanical properties of honeycomb core panels for hot structure applications. J. Spacecr. Rocket. 2009, 46, 514–525. [Google Scholar] [CrossRef]

- Schaldenbrand, P. Window Types: Hanning, Flattop, Uniform, Tukey, and Exponential. Available online: https://community.sw.siemens.com/s/article/window-types-hanning-flattop-uniform-tukey-and-exponential (accessed on 10 December 2020).

- Zhang, J.; Gungor, M.N.; Lavernia, E.J. The effect of porosity on the microstructural damping response of 6061 aluminium alloy. J. Mater. Sci. 1993, 28, 1515–1524. [Google Scholar] [CrossRef]

| Components | Load-Carrying Plate | Back Plate | Fibrous Insulation Layer | Fully-Assembled TPS Panel |

|---|---|---|---|---|

| Size (mm) | 240 × 240 | 170 × 170 | 170 × 170 | |

| Weight (g) | 1229 | 137 | 72 | 1547 |

| Case | Load-carrying Plate | Assembled TPS Panel without Fibrous Insulation Material | Assembled TPS Panel with Fibrous Insulation Material | |||

|---|---|---|---|---|---|---|

| State | Single plate | Healthy condition | Healthy condition | Damage at specific corners(#) | ||

| #1 | #1 and #3 | #1 and #4 | ||||

| Mode | Load-Carrying Plate (Hz) | Assembled Panel with Insulation (Hz) | Assembled Panel without Insulation (Hz) | Damage at Specific Corners (#) | |||||

|---|---|---|---|---|---|---|---|---|---|

| #1 | #1 and #3 | #1 and #4 | |||||||

| (Hz) | % diff. | (Hz) | % diff. | (Hz) | % diff. | ||||

| 1 | 151 | 192 | 196 | 173 | 9.9 | 165 | 14 | 142 | 26 |

| 2 | 220 | 332 | 337 | 248 | 25.3 | 216 | 34.9 | 214 | 35.5 |

| 3 | 256 | 362 | 363 | 312 | 13.8 | 310 | 14.3 | 281 | 22.3 |

| 4 | 380 | 467 | 477 | 442 | 5.3 | 342 | 26.7 | 424 | 9.2 |

| Mode | Load-Carrying Plate | Assembled Panel with Insulation | Assembled Panel without Insulation | Damage at Corner #1 | Damage at Corners #1 and #3 | Damage at Corners #1 and #4 |

|---|---|---|---|---|---|---|

| 1 | 0.9% | 1.1% | 1.3% | 1.63% | 1.7% | 2.4% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Le, V.T.; Goo, N.S. Dynamic Characteristics and Damage Detection of a Metallic Thermal Protection System Panel Using a Three-Dimensional Point Tracking Method and a Modal Assurance Criterion. Sensors 2020, 20, 7185. https://doi.org/10.3390/s20247185

Le VT, Goo NS. Dynamic Characteristics and Damage Detection of a Metallic Thermal Protection System Panel Using a Three-Dimensional Point Tracking Method and a Modal Assurance Criterion. Sensors. 2020; 20(24):7185. https://doi.org/10.3390/s20247185

Chicago/Turabian StyleLe, Vinh Tung, and Nam Seo Goo. 2020. "Dynamic Characteristics and Damage Detection of a Metallic Thermal Protection System Panel Using a Three-Dimensional Point Tracking Method and a Modal Assurance Criterion" Sensors 20, no. 24: 7185. https://doi.org/10.3390/s20247185

APA StyleLe, V. T., & Goo, N. S. (2020). Dynamic Characteristics and Damage Detection of a Metallic Thermal Protection System Panel Using a Three-Dimensional Point Tracking Method and a Modal Assurance Criterion. Sensors, 20(24), 7185. https://doi.org/10.3390/s20247185