Intelligent Diagnosis towards Hydraulic Axial Piston Pump Using a Novel Integrated CNN Model

Abstract

1. Introduction

- (1)

- The proposed diagnosis method can compensate for the deficiencies of the conventional fault diagnosis methods, and will provide a solid foundation for the exploitation of the novel intelligent methods for a hydraulic pump.

- (2)

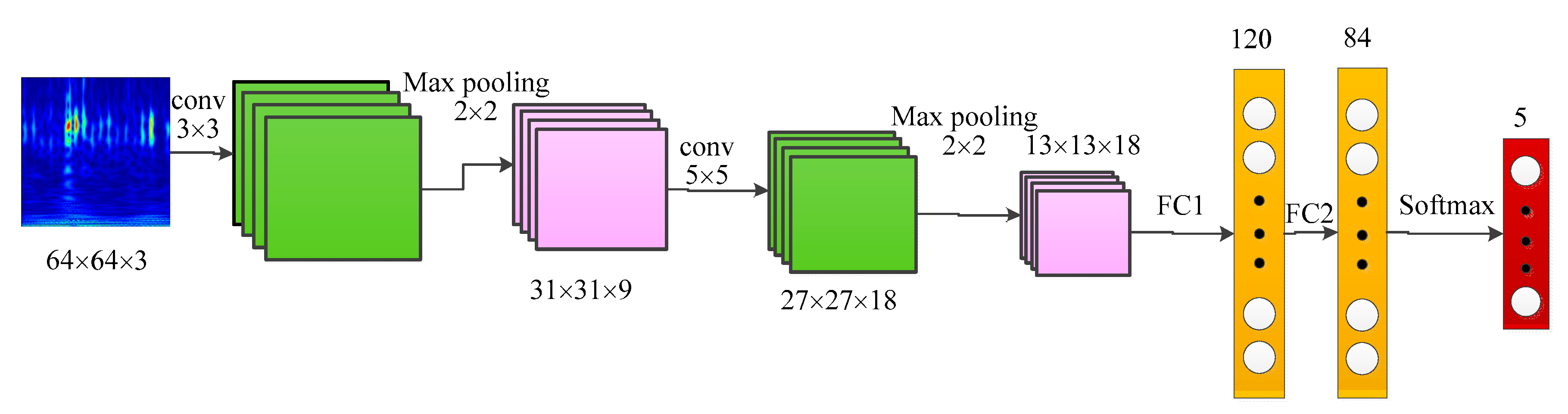

- The structure of the proposed model is greatly simplified. The deep model in this research only includes two convolutional layers, and the corresponding parameters to be trained are greatly reduced. In comparison to the traditional LeNet 5, the number of the channels and the input size of the images are improved to enhance the performance of the diagnostic method.

- (3)

- In light of the structural simplicity and fast computation of the method, it is more conducive to the practical operation and application.

2. Basic Theory

2.1. Brief Introduction of Convolutional Neural Network (CNN)

2.1.1. Convolution Layer

2.1.2. Rectified Linear Unit (ReLU) Layer

2.1.3. Pooling Layer

2.1.4. Fully Connected Layer

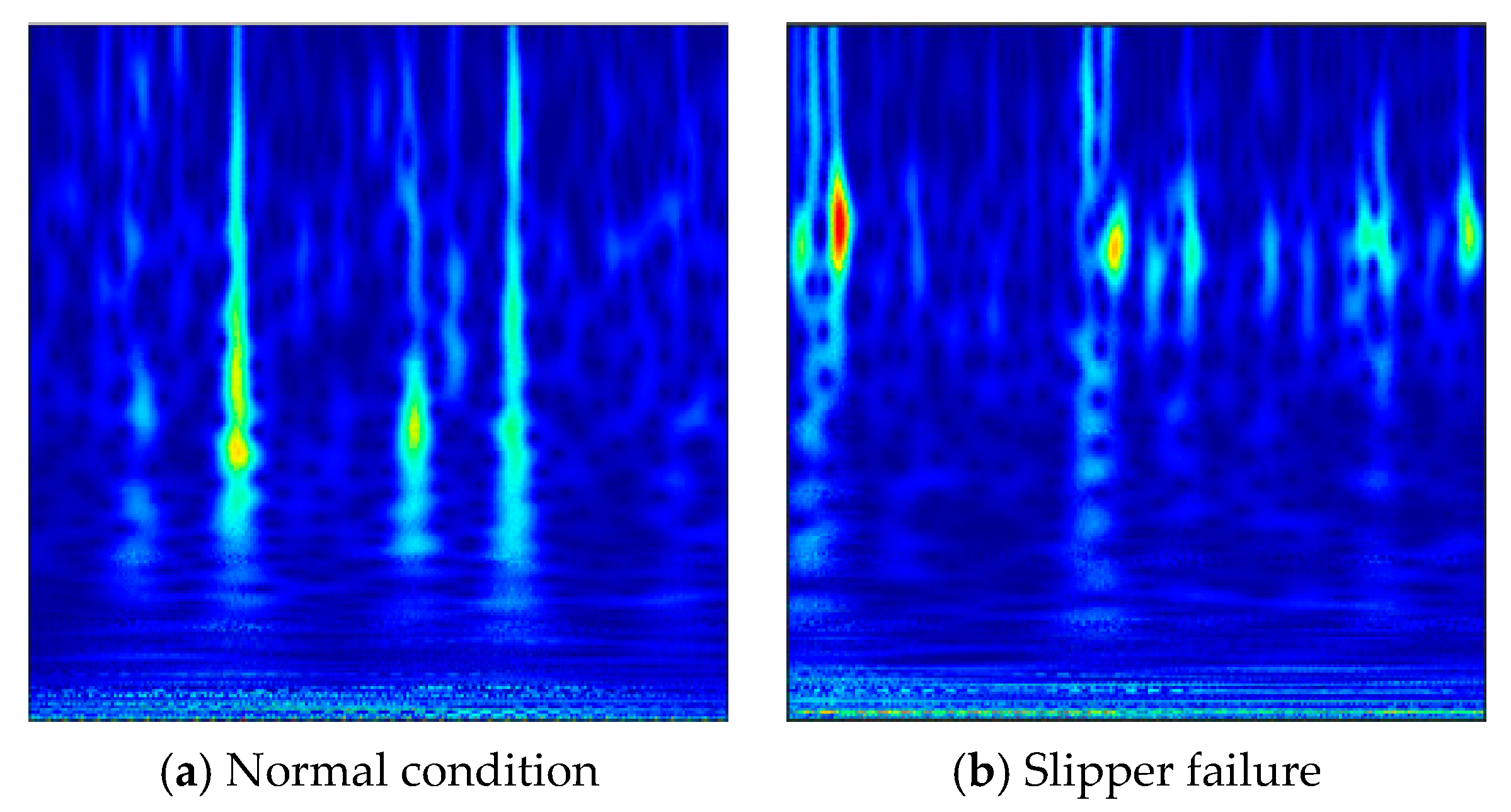

2.2. Continuous Wavelet Transform

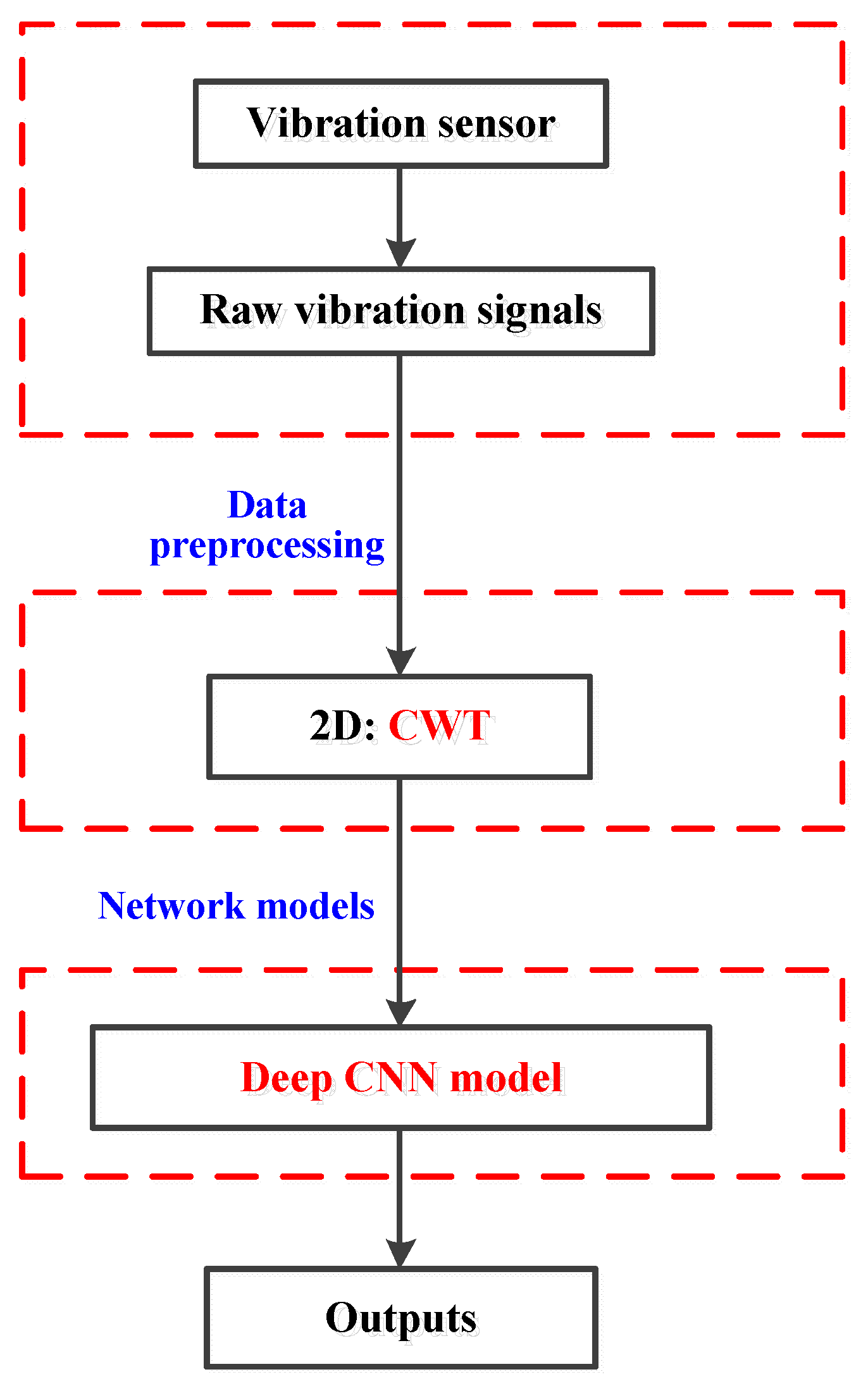

3. Proposed Intelligent Fault-Diagnosis Method

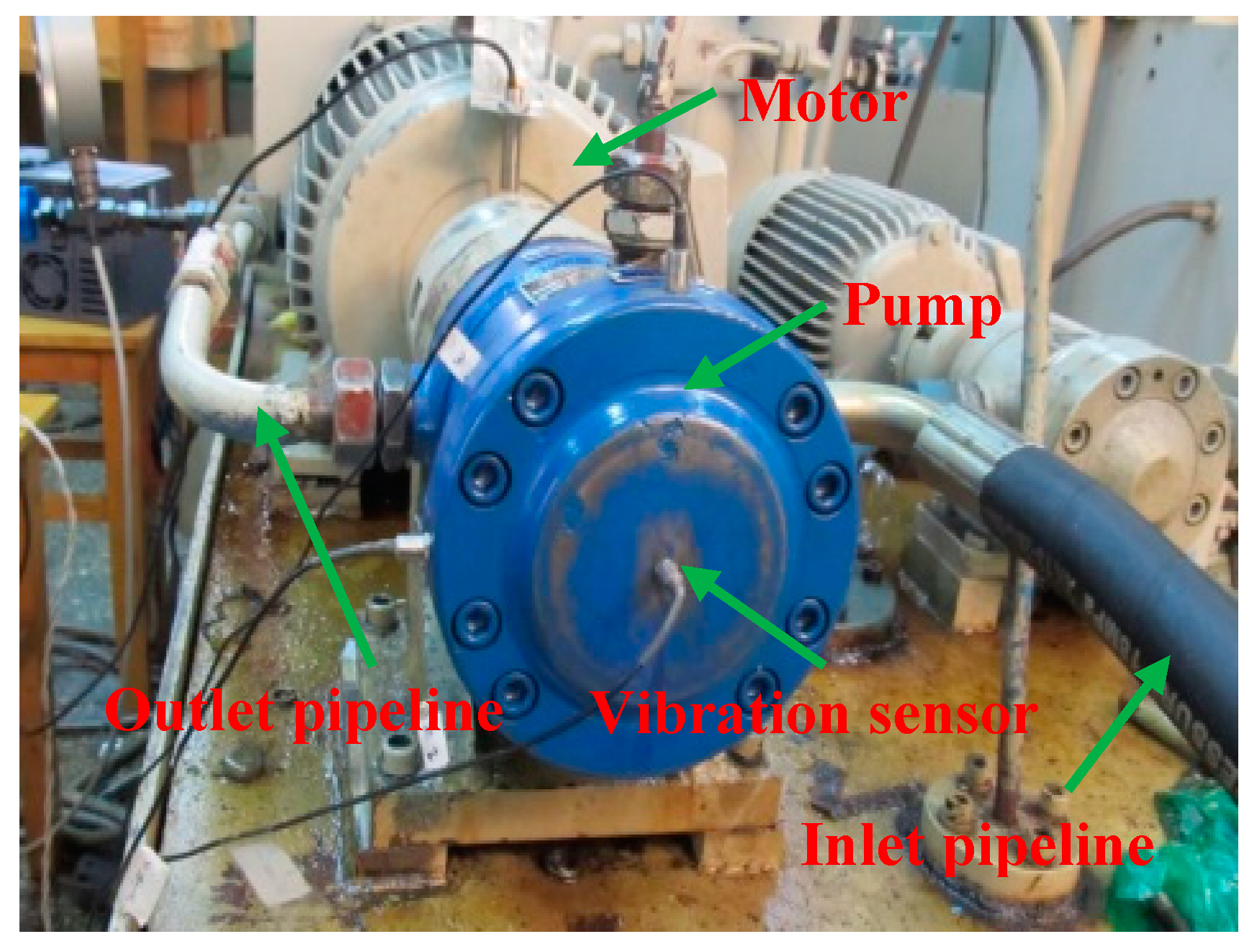

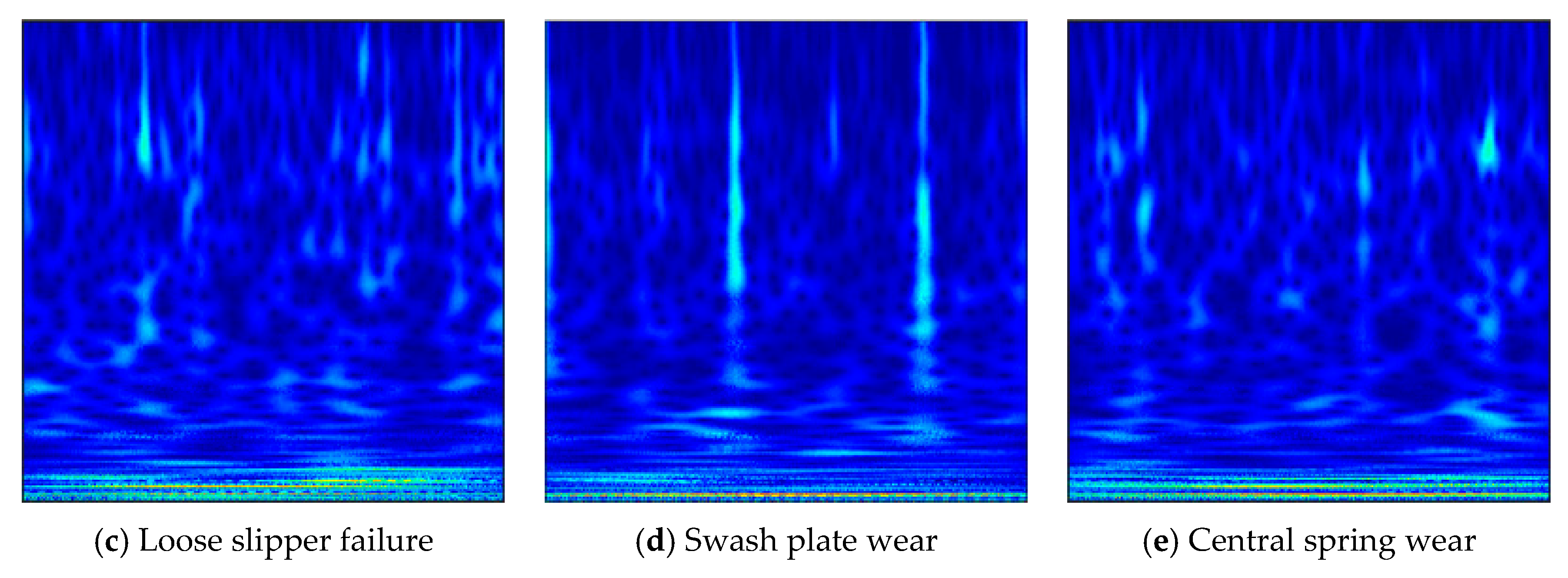

3.1. Data Description

3.2. Data Preprocessing

3.3. Proposed CNN-Based Intelligent Diagnosis Method

4. Verification of Proposed CNN Model

4.1. Input Data Description

4.2. Parameter Selection for the Proposed Model

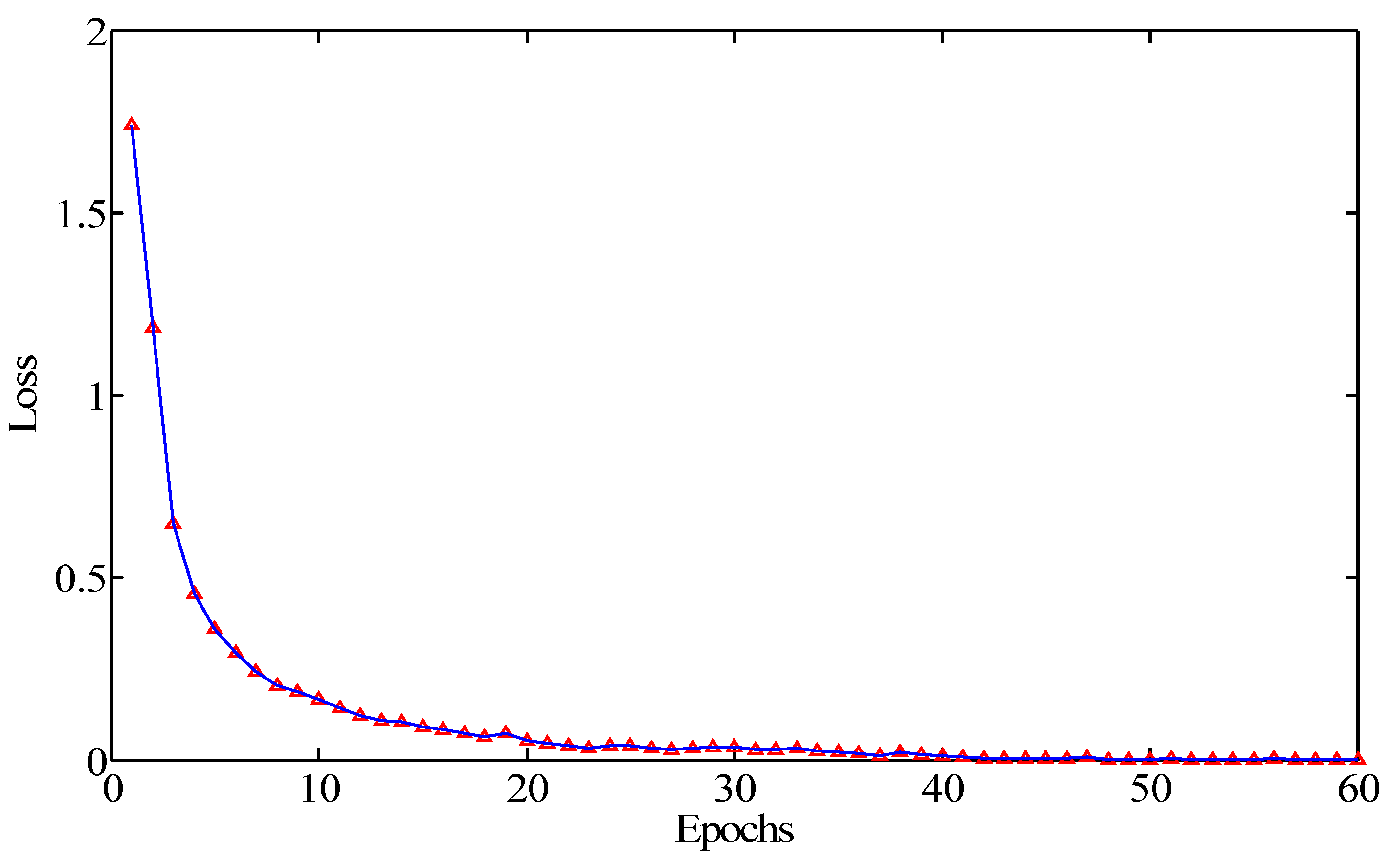

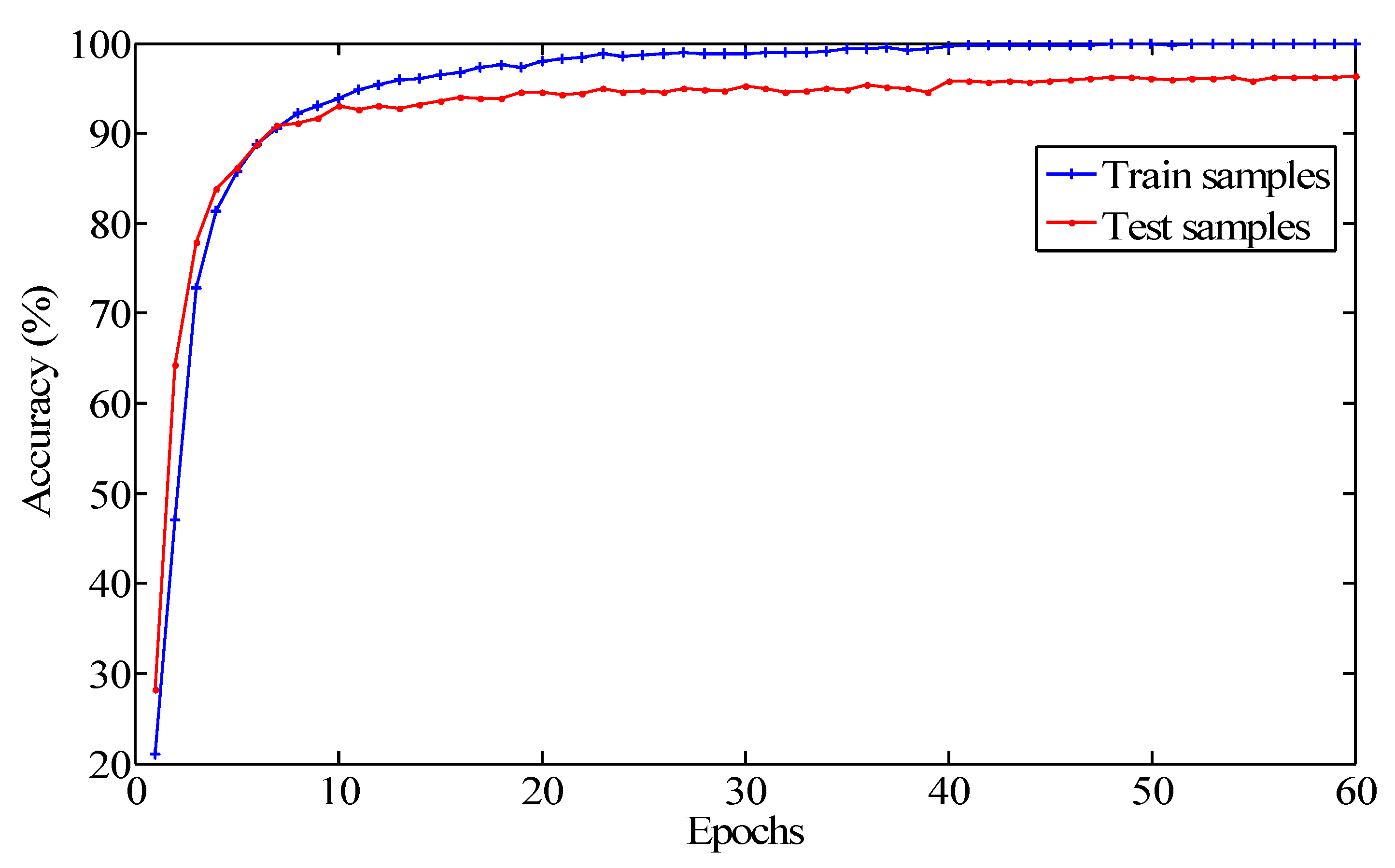

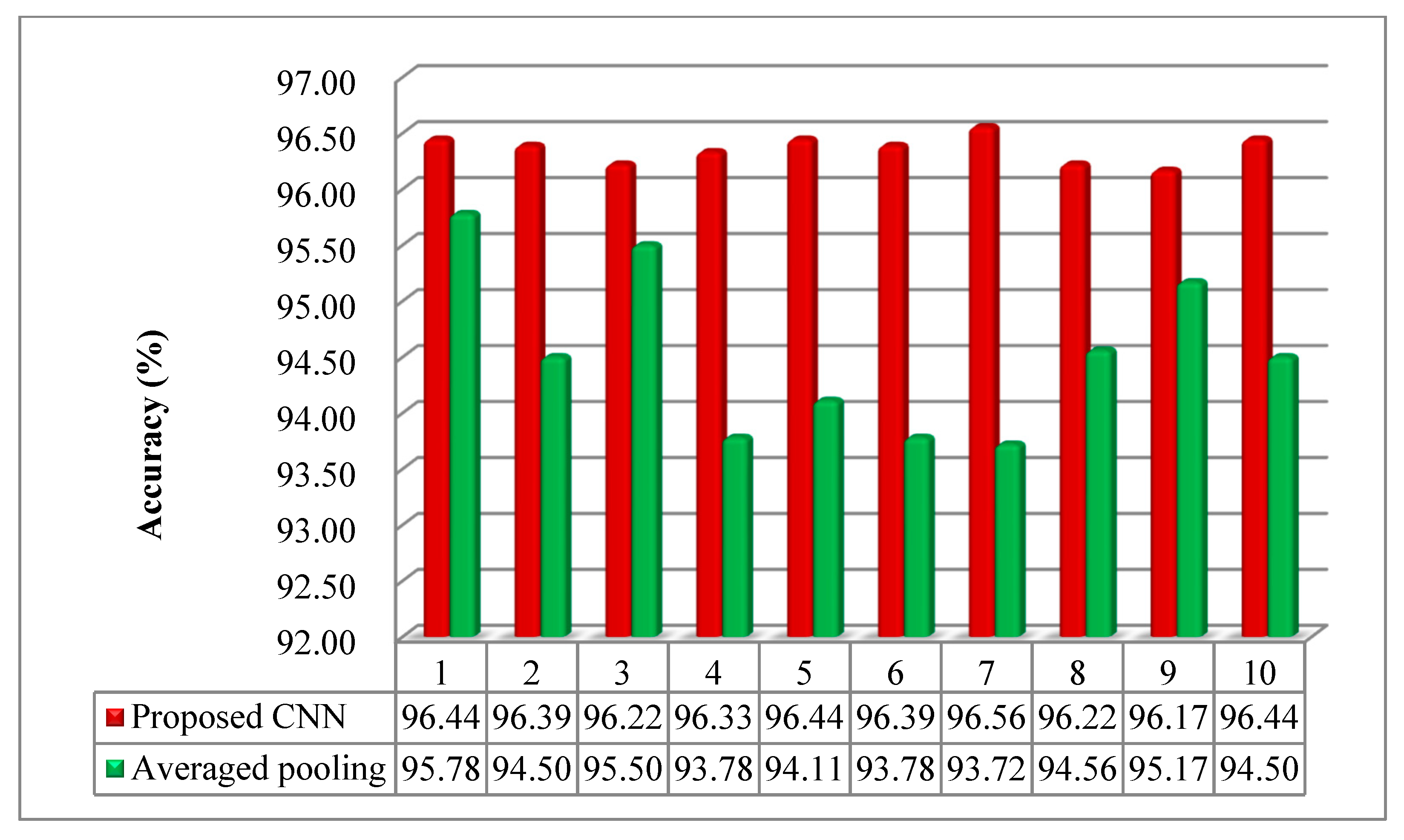

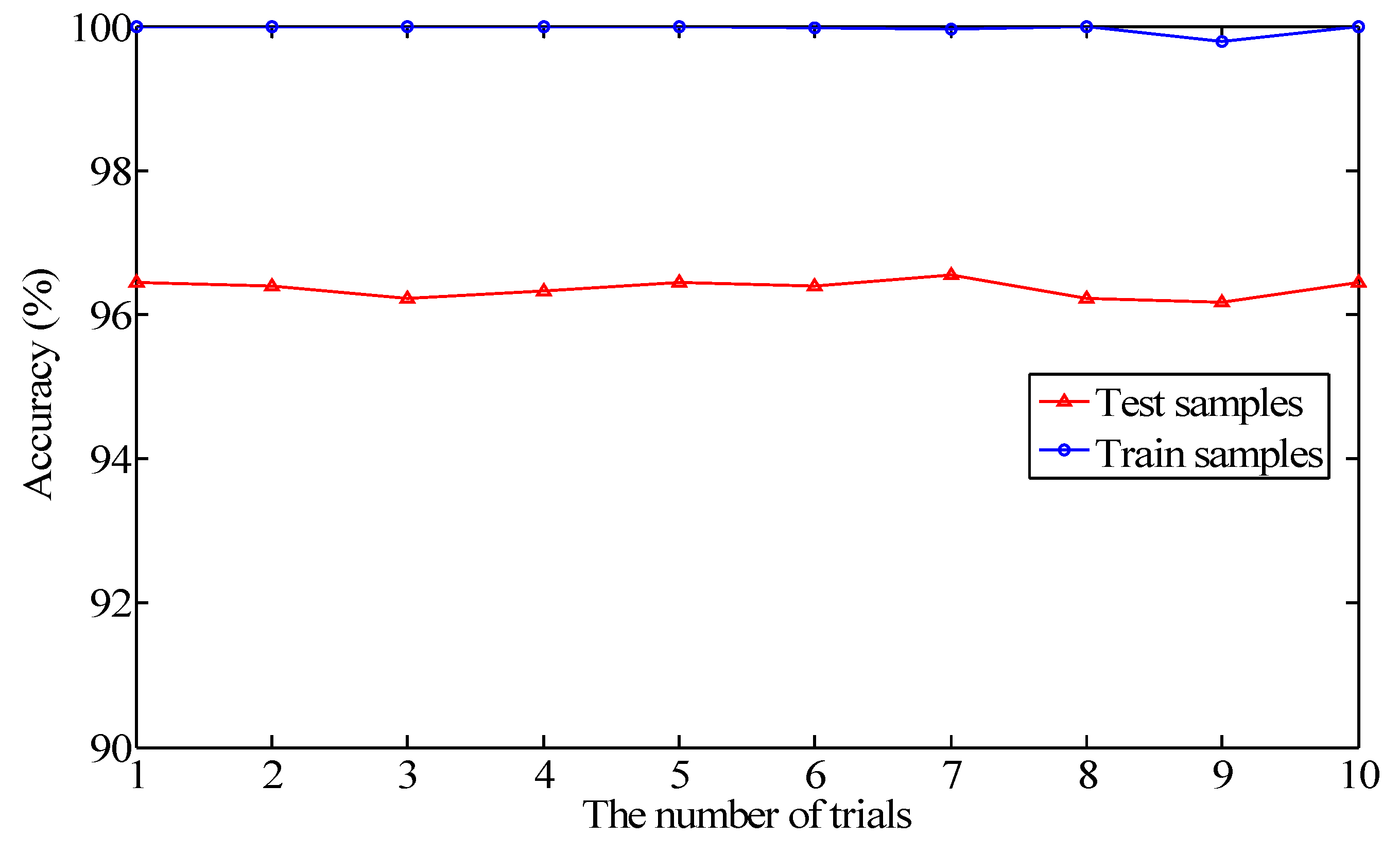

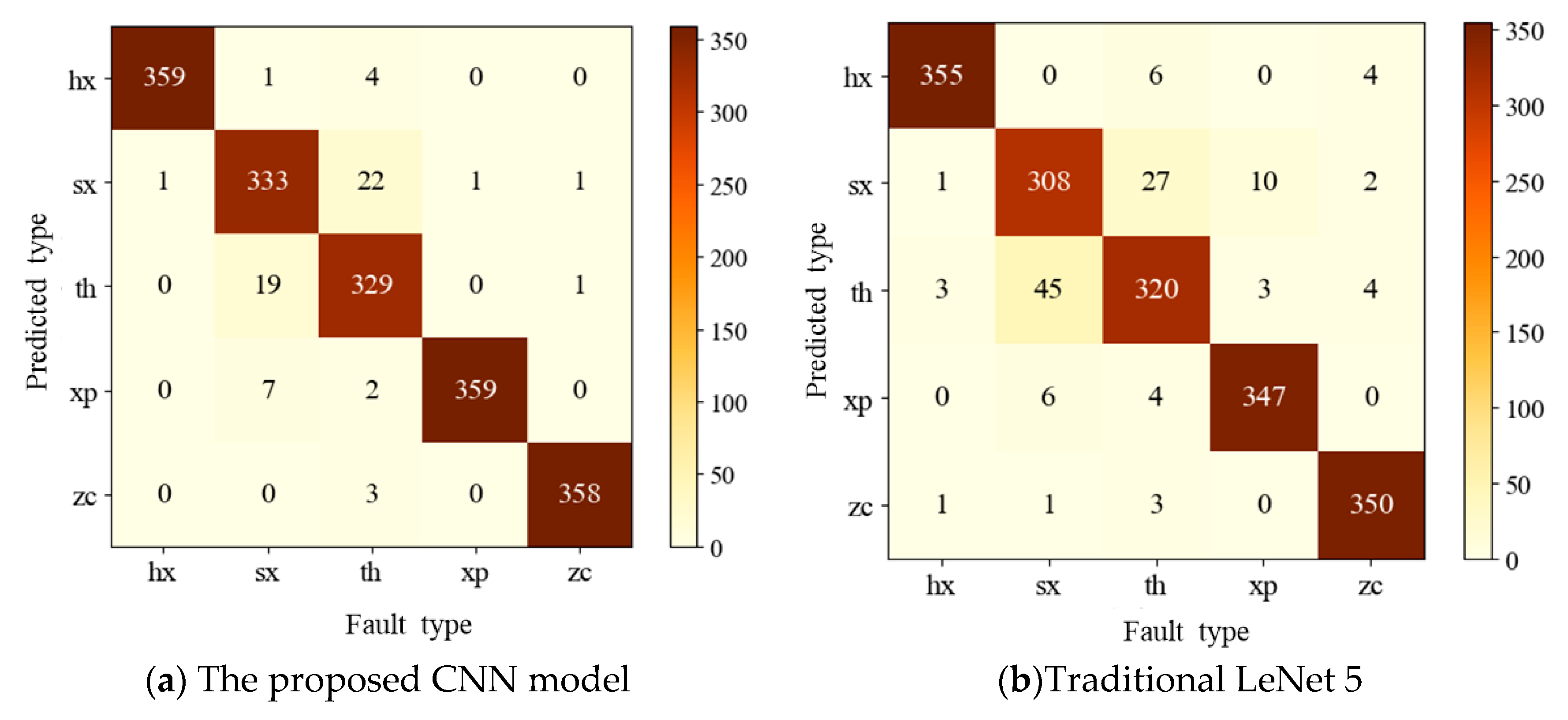

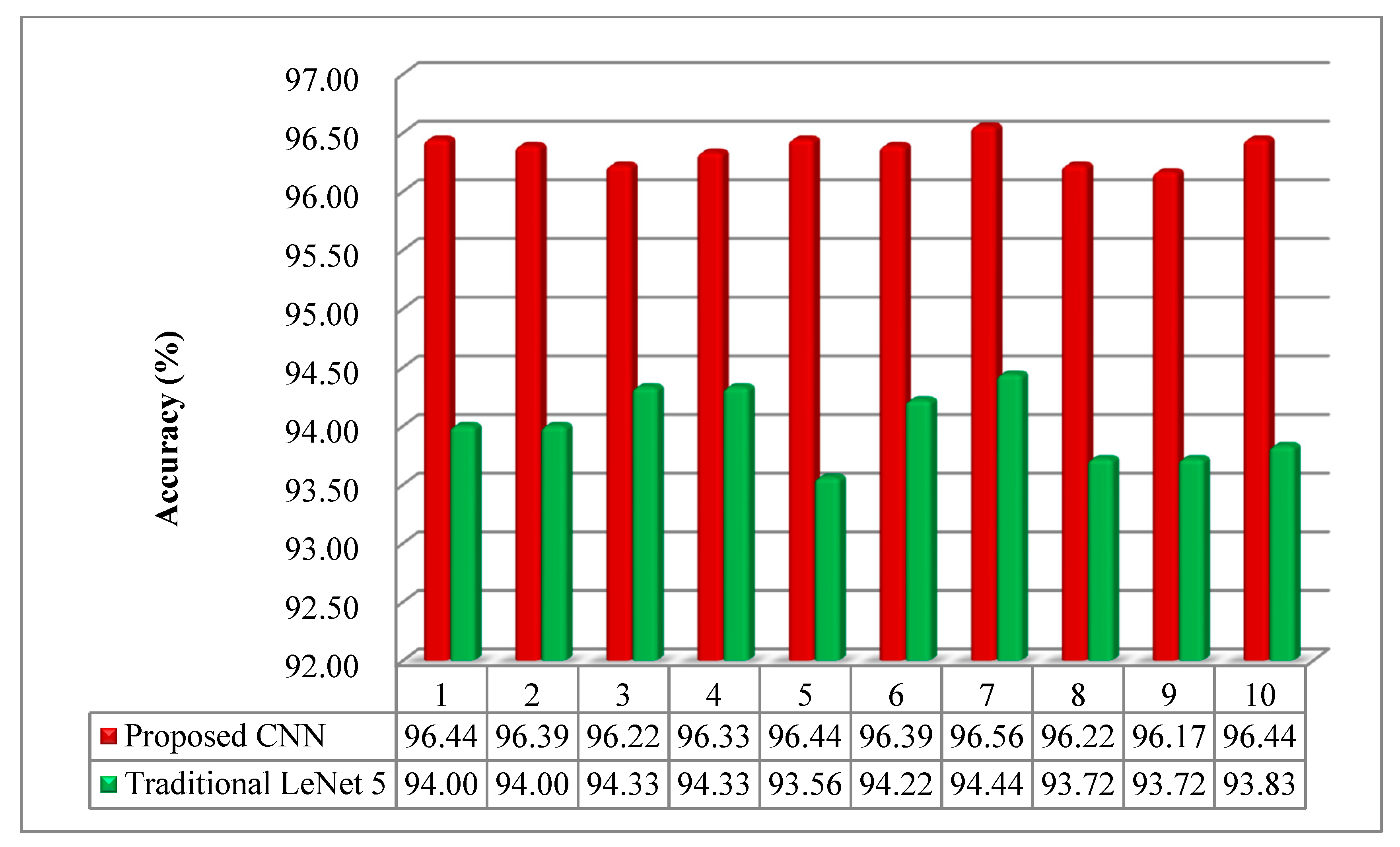

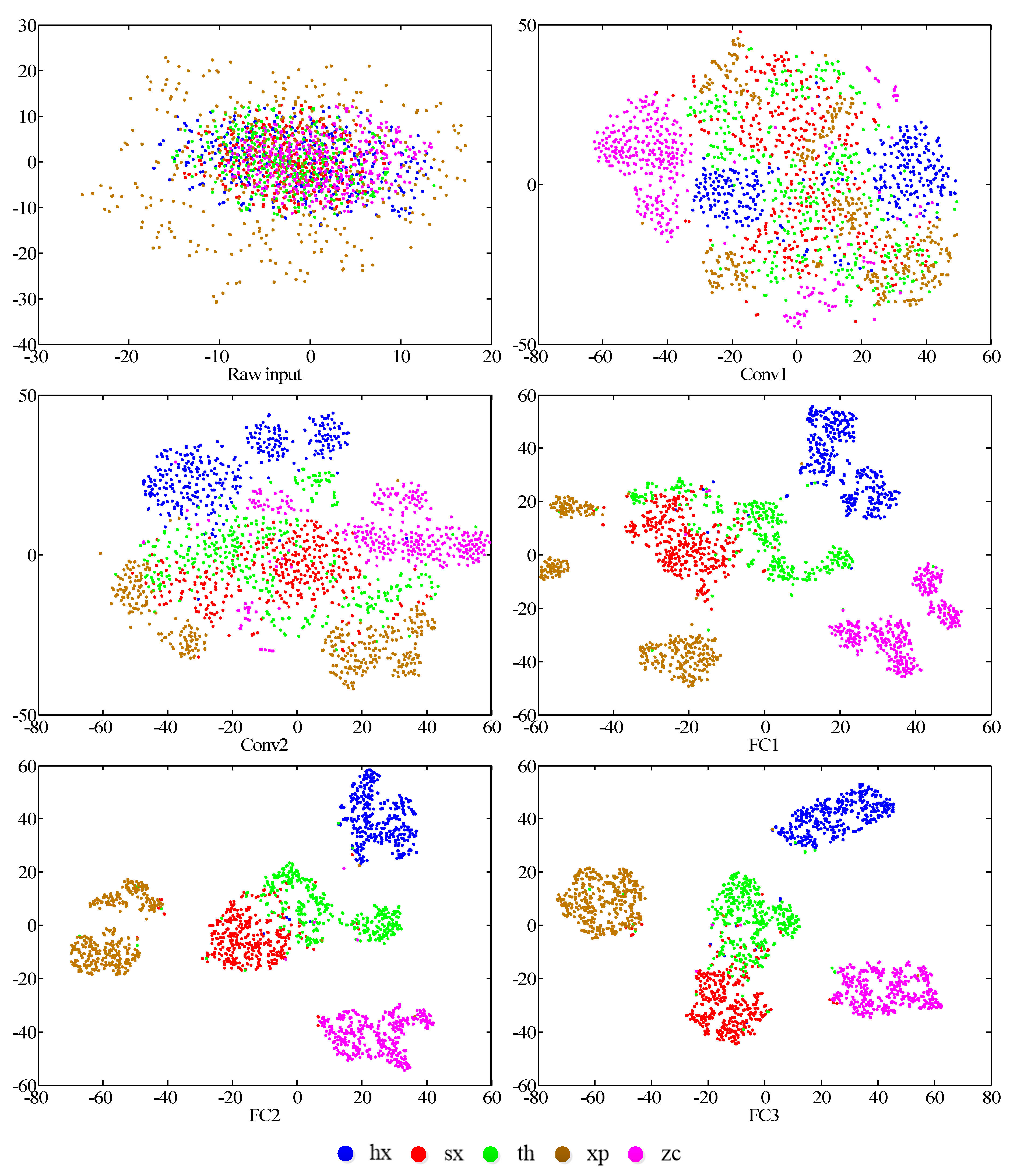

4.3. Performance Validation of the Proposed Model

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- He, X.; Xiao, G.; Hu, B.; Tan, L.; Tang, H.; He, S.; He, Z. The applications of energy regeneration and conversion technologies based on hydraulic transmission systems: A review. Energy Convers. Manag. 2020, 205, 112413. [Google Scholar] [CrossRef]

- Wang, S.; Xiang, J.; Tang, H.; Liu, X.; Zhong, Y. Minimum entropy deconvolution based on simulation-determined band pass filter to detect faults in axial piston pump bearings. ISA Trans. 2019, 88, 186–198. [Google Scholar] [CrossRef]

- Liu, F.; Wu, W.; Hu, J.; Yuan, S. Design of multi-range hydro-mechanical transmission using modular method. Mech. Syst. Signal. Process. 2019, 126, 1–20. [Google Scholar] [CrossRef]

- Ye, S.; Zhang, J.; Xu, B.; Hou, L.; Xiang, J.; Tang, H. A theoretical dynamic model to study the vibration response characteristics of an axial piston pump. Mech. Syst. Signal. Process. 2020, 150, 107237. [Google Scholar] [CrossRef]

- Sun, B.; Li, Y.; Wang, Z.; Ren, Y.; Feng, Q.; Yang, D. An improved inverse Gaussian process with random effects and measurement errors for RUL prediction of hydraulic piston pump. Measurement 2020, 108604. [Google Scholar] [CrossRef]

- Kumar, S.; Bergada, J.M. The effect of piston grooves performance in an axial piston pumps via CFD analysis. Int. J. Mech. Sci. 2013, 66, 168–179. [Google Scholar] [CrossRef]

- Lu, C.; Wang, S.; Zhang, C. Fault diagnosis of hydraulic piston pumps based on a two-step EMD method and fuzzy C-means clustering. Proc. Inst. Mech. Eng. Part. C J. Mech. Eng. Sci. 2016, 230, 2913–2928. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, F.; Yuan, S. Effect of unrans and hybrid rans-les turbulence models on unsteady turbulent flows inside a side channel pump. ASME J. Fluids Eng. 2020, 142, 061503. [Google Scholar] [CrossRef]

- Gao, Q.; Xiang, J.; Hou, S.; Tang, H.; Zhong, Y.; Ye, S. Method using L-kurtosis and enhanced clustering-based segmentation to detect faults in axial piston pumps. Mech. Syst. Signal. Process. 2021, 147, 107130. [Google Scholar] [CrossRef]

- Zhao, R.; Yan, R.; Chen, Z.; Mao, K.; Wang, P.; Gao, R.X. Deep learning and its applications to machine health monitoring. Mech. Syst. Signal. Process. 2019, 115, 213–237. [Google Scholar] [CrossRef]

- Zhang, F.; Appiah, D.; Hong, F.; Zhang, J.; Yuan, S.; Adu-Poku, K.A.; Wei, X. Energy loss evaluation in a side channel pump under different wrapping angles using entropy production method. Int. Commun. Heat Mass Transf. 2020, 113, 104526. [Google Scholar] [CrossRef]

- Li, C.; Zhang, S.; Qin, Y.; Estupinan, E. A systematic review of deep transfer learning for machinery fault diagnosis. Neurocomputing 2020, 407, 121–135. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, W.; Xiong, Q.; Luo, D.; Mei, G.; Zhang, T. A rolling bearing fault diagnosis strategy based on improved multiscale permutation entropy and least squares SVM. J. Mech. Sci. Technol. 2017, 31, 2711–2722. [Google Scholar] [CrossRef]

- Wang, Z.; Yao, L.; Cai, Y.; Zhang, J. Mahalanobis semi-supervised mapping and beetle antennae search based support vector machine for wind turbine rolling bearings fault diagnosis. Renew. Energy 2020, 155, 1312–1327. [Google Scholar] [CrossRef]

- Wei, J.; Huang, H.; Yao, L.; Hu, Y.; Fan, Q.; Huang, D. New imbalanced fault diagnosis framework based on Cluster-MWMOTE and MFO-optimized LS-SVM using limited and complex bearing data. Eng. Appl. Artif. Intell. 2020, 96, 103966. [Google Scholar] [CrossRef]

- Li, X.; Yang, Y.; Pan, H.; Cheng, J.; Cheng, J. A novel deep stacking least squares support vector machine for rolling bearing fault diagnosis. Comput. Ind. 2019, 110, 36–47. [Google Scholar] [CrossRef]

- Long, B.; Tian, S.; Miao, Q.; Pecht, M.G. Research on features for diagnostics of filtered analog circuits based on LS-SVM. In 2011 IEEE AUTOTESTCON; Institute of Electrical and Electronics Engineers (IEEE): New York, NY, USA, 2011; pp. 360–366. [Google Scholar]

- Mao, W.; Feng, W.; Liang, X. A novel deep output kernel learning method for bearing fault structural diagnosis. Mech. Syst. Signal. Process. 2019, 117, 293–318. [Google Scholar] [CrossRef]

- Xiong, S.; Zhou, H.; He, S.; Zhang, L.; Xia, Q.; Xuan, J.; Shi, T. A Novel End-To-End Fault Diagnosis Approach for Rolling Bearings by Integrating Wavelet Packet Transform into Convolutional Neural Network Structures. Sensors 2020, 20, 4965. [Google Scholar] [CrossRef]

- Luo, B.; Wang, H.; Liu, H.; Li, B.; Peng, F. Early Fault Detection of Machine Tools Based on Deep Learning and Dynamic Identification. IEEE Trans. Ind. Electron. 2019, 66, 509–518. [Google Scholar] [CrossRef]

- Cao, X.; Chen, B.; Zeng, N. A deep domain adaption model with multi-task networks for planetary gearbox fault diagnosis. Neurocomputing 2020, 409, 173–190. [Google Scholar] [CrossRef]

- Zhong, S.; Fu, S.; Lin, L. A novel method based on transfer learning with CNN. Measurement 2019, 137, 435–453. [Google Scholar] [CrossRef]

- Li, F.; Tang, T.; Tang, B.; He, Q. Deep convolution domain-adversarial transfer learning for fault diagnosis of rolling bearings. Measurement 2021, 169, 108339. [Google Scholar] [CrossRef]

- He, Z.; Shao, H.; Wang, P.; Lin, J.; Cheng, J.; Yang, Y. Deep transfer multi-wavelet auto-encoder for intelligent fault diagnosis of gearbox with few target training samples. Knowl. Based Syst. 2020, 191, 105313. [Google Scholar] [CrossRef]

- Guo, S.; Yang, T.; Gao, W.; Yang, T. A Novel Fault Diagnosis Method for Rotating Machinery Based on a Convolutional Neural Network. Sensors 2018, 18, 1429. [Google Scholar] [CrossRef]

- Xu, Y.; Li, Z.; Wang, S.; Li, W.; Sarkodie-Gyan, T.; Feng, S. A Hybrid Deep-Learning Model for Fault Diagnosis of Rolling Bearings. Measurement 2020, 169, 108502. [Google Scholar] [CrossRef]

- Liang, P.; Deng, C.; Cheng, Y.; Yang, Z. Intelligent fault diagnosis of rotating machinery via wavelet transform, generative adversarial nets and convolutional neural network. Measurement 2020, 159, 107768. [Google Scholar] [CrossRef]

- Kumar, A.; Gandhi, C.; Zhou, Y.; Kumar, R.; Xiang, J. Improved deep convolution neural network (CNN) for the identification of defects in the centrifugal pump using acoustic images. Appl. Acoust. 2020, 167, 107399. [Google Scholar] [CrossRef]

- Gao, T.; Sheng, W.; Zhou, M.; Fang, B.; Luo, F.; Li, J. Method for Fault Diagnosis of Temperature-Related MEMS Inertial Sensors by Combining Hilbert–Huang Transform and Deep Learning. Sensors 2020, 20, 5633. [Google Scholar] [CrossRef]

- Jiao, J.; Lin, J.; Zhao, M.; Liang, K. Double-level adversarial domain adaptation network for intelligent fault diagnosis. Knowl. Based Syst. 2020, 205, 106236. [Google Scholar] [CrossRef]

- Liao, Y.; Huang, R.; Li, J.; Chen, Z.; Li, W. Deep Semi-supervised Domain Generalization Network for Rotary Machinery Fault Diagnosis under Variable Speed. IEEE Trans. Instrum. Meas. 2020, 69, 1. [Google Scholar] [CrossRef]

- Jia, F.; Lei, Y.; Lu, N.; Xing, S. Deep normalized convolutional neural network for imbalanced fault classification of machinery and its understanding via visualization. Mech. Syst. Signal. Process. 2018, 110, 349–367. [Google Scholar] [CrossRef]

- He, Z.; Shao, H.; Zhong, X.; Zhao, X. Ensemble transfer CNNs driven by multi-channel signals for fault diagnosis of rotating machinery cross working conditions. Knowl. Based Syst. 2020, 207, 106396. [Google Scholar] [CrossRef]

- Li, X.; Jiang, H.; Niu, M.; Wang, R. An enhanced selective ensemble deep learning method for rolling bearing fault diagnosis with beetle antennae search algorithm. Mech. Syst. Signal. Process. 2020, 142, 106752. [Google Scholar] [CrossRef]

- Wu, Z.; Jiang, H.; Zhao, K.; Li, X. An adaptive deep transfer learning method for bearing fault diagnosis. Measurement 2020, 151, 107227. [Google Scholar] [CrossRef]

- Qiu, G.; Gu, Y.; Cai, Q. A deep convolutional neural networks model for intelligent fault diagnosis of a gearbox under different operational conditions. Measurement 2019, 145, 94–107. [Google Scholar] [CrossRef]

- Li, X.; Zhang, W.; Ding, Q. Cross-Domain Fault Diagnosis of Rolling Element Bearings Using Deep Generative Neural Networks. IEEE Trans. Ind. Electron. 2019, 66, 5525–5534. [Google Scholar] [CrossRef]

- Tang, S.; Yuan, S.; Zhu, Y. Convolutional Neural Network in Intelligent Fault Diagnosis toward Rotatory Machinery. IEEE Access 2020, 8, 86510–86519. [Google Scholar] [CrossRef]

- Chen, Z.; Li, C.; Sanchez, R.-V. Gearbox Fault Identification and Classification with Convolutional Neural Networks. Shock. Vib. 2015, 2015, 1–10. [Google Scholar] [CrossRef]

- Goodfellow, I.; Bengio, Y.; Courville, A. Deep Learning; The MIT Press: Cambridge, MA, USA, 2016. [Google Scholar]

- Glorot, X.; Bordes, A.; Bengio, Y. Deep Sparse Rectifier Neural Networks. In Proceedings of the 14th International Conference on Artificial Intelligence and Statistics, Ft. Lauderdale, FL, USA, 11–13 April 2011; pp. 315–323. [Google Scholar]

- Ji, S.; Xu, W.; Yang, M.; Yu, K. 3D convolutional neural networks for human action recognition. IEEE Trans. Pattern Anal. Mach. Intell. 2013, 35, 221–231. [Google Scholar] [CrossRef]

- LeCun, Y.; Kavukcuoglu, K.; Farabet, C. Convolutional Networks and Applications in Vision. In Proceedings of the 2010 IEEE International Symposium on Circuits and Systems, Paris, France, 30 May–2 June 2010; pp. 253–256. [Google Scholar]

- Zhu, X.; Zhang, Z.; Gao, J.; Li, W. Two robust approaches to multicomponent signal reconstruction from STFT ridges. Mech. Syst. Signal. Process. 2019, 115, 720–735. [Google Scholar] [CrossRef]

- Sun, H.; Si, Q.; Chen, N.; Yuan, S. HHT-based feature extraction of pump operation instability under cavitation conditions through motor current signal analysis. Mech. Syst. Signal. Process. 2020, 139, 106613. [Google Scholar] [CrossRef]

- Miao, R.; Gao, Y.; Ge, L.; Jiang, Z.; Zhang, J. Online defect recognition of narrow overlap weld based on two-stage recognition model combining continuous wavelet transform and convolutional neural network. Comput. Ind. 2019, 112, 103115. [Google Scholar] [CrossRef]

- Qin, S.; Zhong, Y. Research on the unified mathematical model for FT, STFT and WT and its applications. Mech. Syst. Signal. Process. 2004, 18, 1335–1347. [Google Scholar] [CrossRef]

- Tang, S.; Yuan, S.; Zhu, Y. Data Preprocessing Techniques in Convolutional Neural Network Based on Fault Diagnosis towards Rotating Machinery. IEEE Access 2020, 8, 149487–149496. [Google Scholar] [CrossRef]

- Sinha, S.; Routh, P.S.; Anno, P.D.; Castagna, J.P. Spectral decomposition of seismic data with continuous wavelet transform. Geophysics 2005, 70, 6. [Google Scholar] [CrossRef]

- Jadhav, P.; Rajguru, G.; Datta, D.; Mukhopadhyay, S. Automatic sleep stage classification using time–frequency images of CWT and transfer learning using convolution neural network. Biocybern. Biomed. Eng. 2020, 40, 494–504. [Google Scholar] [CrossRef]

- Kant, P.; Laskar, S.H.; Hazarika, J.; Mahamune, R. CWT Based Transfer Learning for Motor Imagery Classification for Brain computer Interfaces. J. Neurosci. Methods 2020, 345, 108886. [Google Scholar] [CrossRef]

- Wang, J.; Du, G.; Zhu, Z.; Shen, C.; He, Q. Fault diagnosis of rotating machines based on the EMD manifold. Mech. Syst. Signal. Process. 2020, 135, 106443. [Google Scholar] [CrossRef]

- Sun, C.; Wang, P.; Yan, R.; Gao, R.X.; Chen, X. Machine health monitoring based on locally linear embedding with kernel sparse representation for neighborhood optimization. Mech. Syst. Signal. Process. 2019, 114, 25–34. [Google Scholar] [CrossRef]

- Tang, B.; Song, T.; Li, F.; Deng, L. Fault diagnosis for a wind turbine transmission system based on manifold learning and Shannon wavelet support vector machine. Renew. Energy 2014, 62, 1–9. [Google Scholar] [CrossRef]

- Tang, S.; Yuan, S.; Zhu, Y. Deep Learning-Based Intelligent Fault Diagnosis Methods toward Rotating Machinery. IEEE Access 2020, 8, 9335–9346. [Google Scholar] [CrossRef]

- Wang, D.-F.; Guo, Y.; Wu, X.; Na, J.; Litak, G. Planetary-Gearbox Fault Classification by Convolutional Neural Network and Recurrence Plot. Appl. Sci. 2020, 10, 932. [Google Scholar] [CrossRef]

- Guo, X.; Chen, L.; Shen, C. Hierarchical adaptive deep convolution neural network and its application to bearing fault diagnosis. Measurement 2016, 93, 490–502. [Google Scholar] [CrossRef]

- Zeng, X.; Liao, Y.; Li, W. Gearbox Fault Classification Using S-Transform and Convolutional Neural Network. In Proceedings of the 2016 10th International Conference on Sensing Technology (ICST), Nanjing, China, 11–13 November 2016; pp. 1–5. [Google Scholar]

- Chen, Z.; Mauricio, A.; Li, W.; Gryllias, K. A deep learning method for bearing fault diagnosis based on Cyclic Spectral Coherence and Convolutional Neural Networks. Mech. Syst. Signal. Process. 2020, 140, 106683. [Google Scholar] [CrossRef]

- Zhou, Q.; Li, Y.; Tian, Y.; Jiang, L. A novel method based on nonlinear auto-regression neural network and convolutional neural network for imbalanced fault diagnosis of rotating machinery. Measurement 2020, 161, 107880. [Google Scholar] [CrossRef]

- Gu, X.; Yang, S.; Liu, Y.; Deng, F.; Ren, B. Compound faults detection of the rolling element bearing based on the optimal complex Morlet wavelet filter. Proc. Inst. Mech. Eng. Part. C J. Mech. Eng. Sci. 2017, 232, 1786–1801. [Google Scholar] [CrossRef]

- LeCun, Y.; Bottou, L.; Bengio, Y.; Haffner, P. Gradient-based learning applied to document recognition. Proc. IEEE 1998, 86, 2278–2324. [Google Scholar] [CrossRef]

- Xu, X.; Tao, Z.; Ming, W.; An, Q.; Chen, M. Intelligent monitoring and diagnostics using a novel integrated model based on deep learning and multi-sensor feature fusion. Measurement 2020, 165, 108086. [Google Scholar] [CrossRef]

- Luque-Sendra, A.; Carrasco, A.; Martín, A.; Heras, A.D.L. The impact of class imbalance in classification performance metrics based on the binary confusion matrix. Pattern Recognit. 2019, 91, 216–231. [Google Scholar] [CrossRef]

- Deng, X.; Liu, Q.; Deng, Y.; Mahadevan, S. An improved method to construct basic probability assignment based on the confusion matrix for classification problem. Inf. Sci. 2016, 340-341, 250–261. [Google Scholar] [CrossRef]

- van der Maaten, L.J.P.; Hinton, G.E. Visualizing high-dimensional data using t-SNE. J. Mach. Learn. Res. 2008, 9, 2579–2605. [Google Scholar]

| Health Condition | Description | Index | Type Label |

|---|---|---|---|

| Normal | no any fault in hydraulic pump | zc | 0 |

| Faulty | swash plate wear | xp | 1 |

| loose slipper failure | sx | 2 | |

| slipper wear | hx | 3 | |

| central spring wear | th | 4 |

| Fault Type | Train Dataset | Test Dataset | Type Label |

|---|---|---|---|

| hx | 840 | 360 | 0 |

| sx | 840 | 360 | 1 |

| th | 840 | 360 | 2 |

| xp | 840 | 360 | 3 |

| zc | 840 | 360 | 4 |

| total | 4200 | 1800 | — |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tang, S.; Zhu, Y.; Yuan, S.; Li, G. Intelligent Diagnosis towards Hydraulic Axial Piston Pump Using a Novel Integrated CNN Model. Sensors 2020, 20, 7152. https://doi.org/10.3390/s20247152

Tang S, Zhu Y, Yuan S, Li G. Intelligent Diagnosis towards Hydraulic Axial Piston Pump Using a Novel Integrated CNN Model. Sensors. 2020; 20(24):7152. https://doi.org/10.3390/s20247152

Chicago/Turabian StyleTang, Shengnan, Yong Zhu, Shouqi Yuan, and Guangpeng Li. 2020. "Intelligent Diagnosis towards Hydraulic Axial Piston Pump Using a Novel Integrated CNN Model" Sensors 20, no. 24: 7152. https://doi.org/10.3390/s20247152

APA StyleTang, S., Zhu, Y., Yuan, S., & Li, G. (2020). Intelligent Diagnosis towards Hydraulic Axial Piston Pump Using a Novel Integrated CNN Model. Sensors, 20(24), 7152. https://doi.org/10.3390/s20247152