Reflective Properties of a Polymer Micro-Transducer for an Optical Fiber Refractive Index Sensor

Abstract

1. Introduction

2. Manufacturing Technology of a Polymer Micro-Transducer

2.1. Photopolymerization Process and Monomer Mixtures

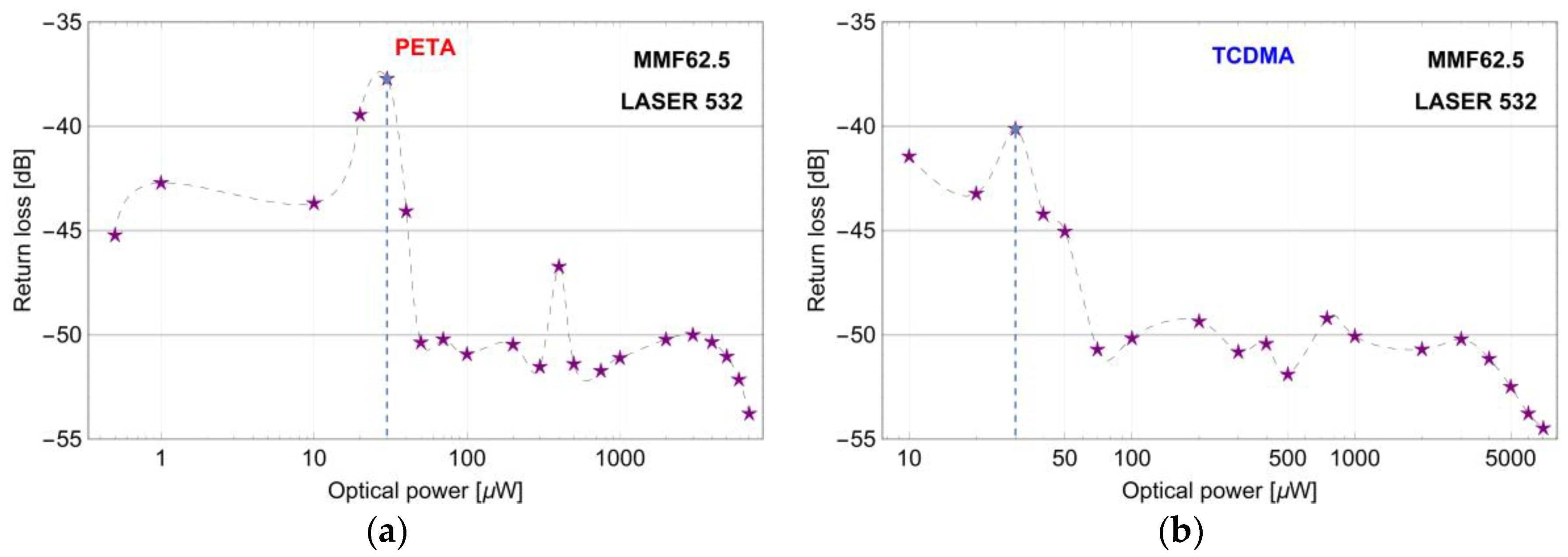

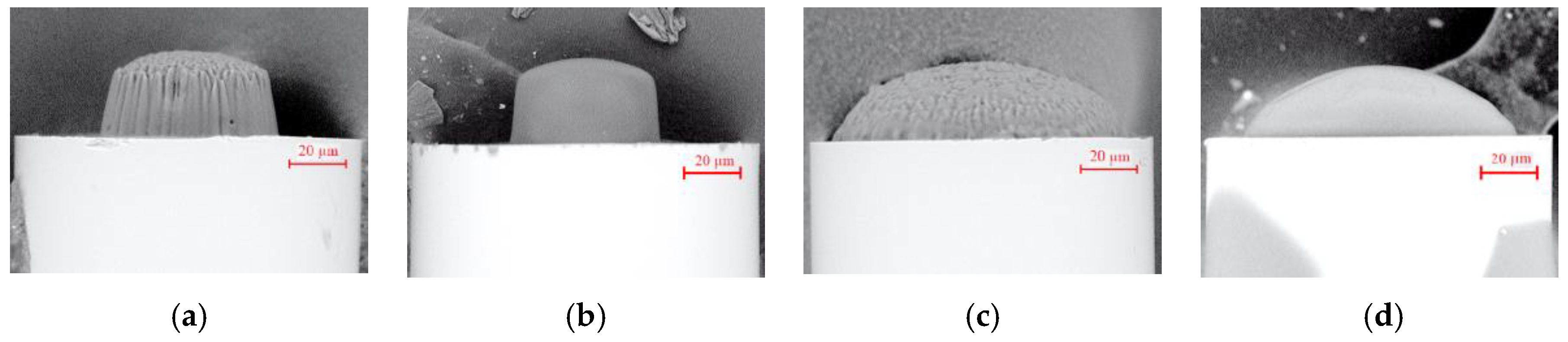

2.2. Technology and Optimization of a Polymer Micro-Transducer

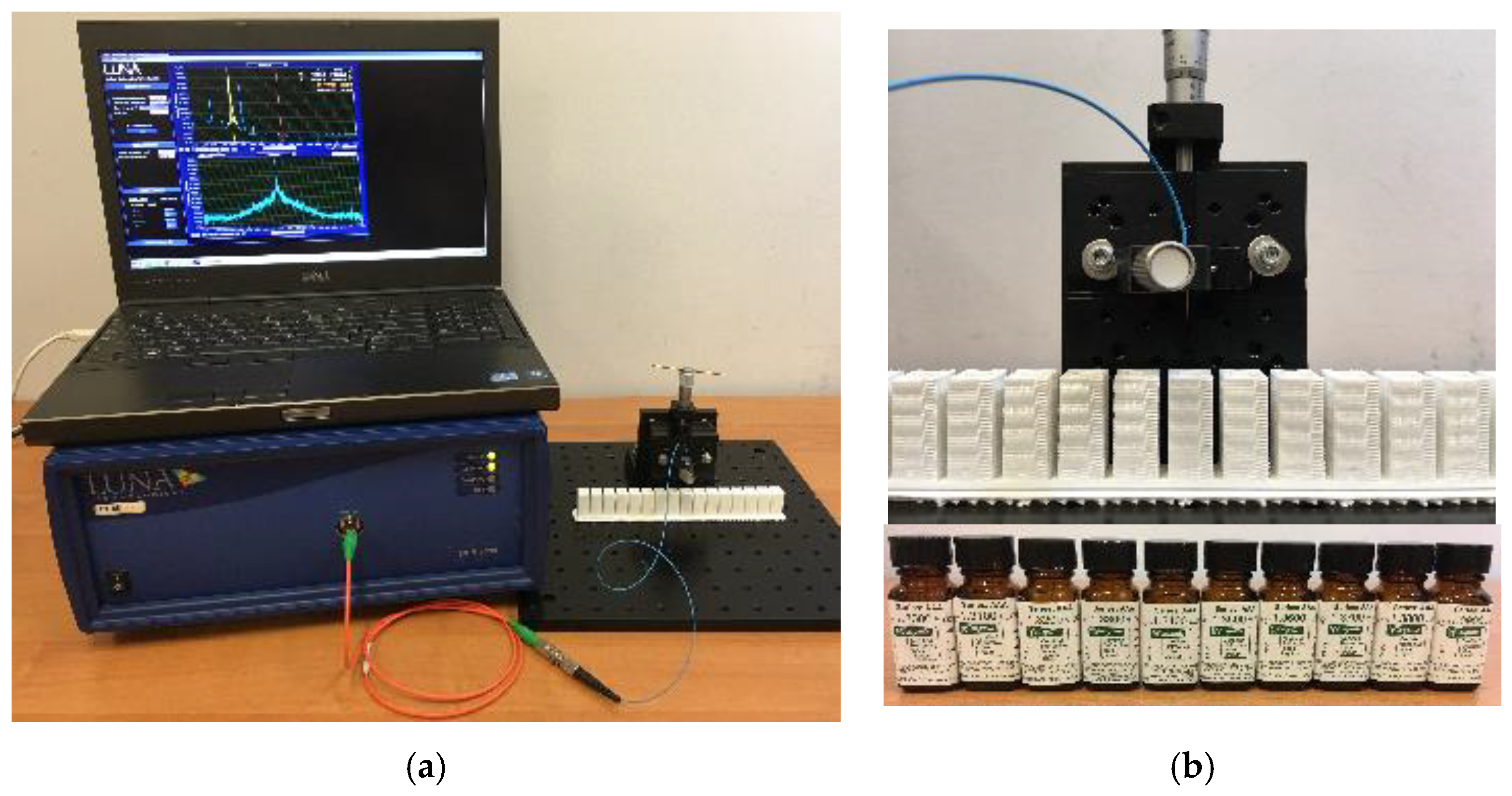

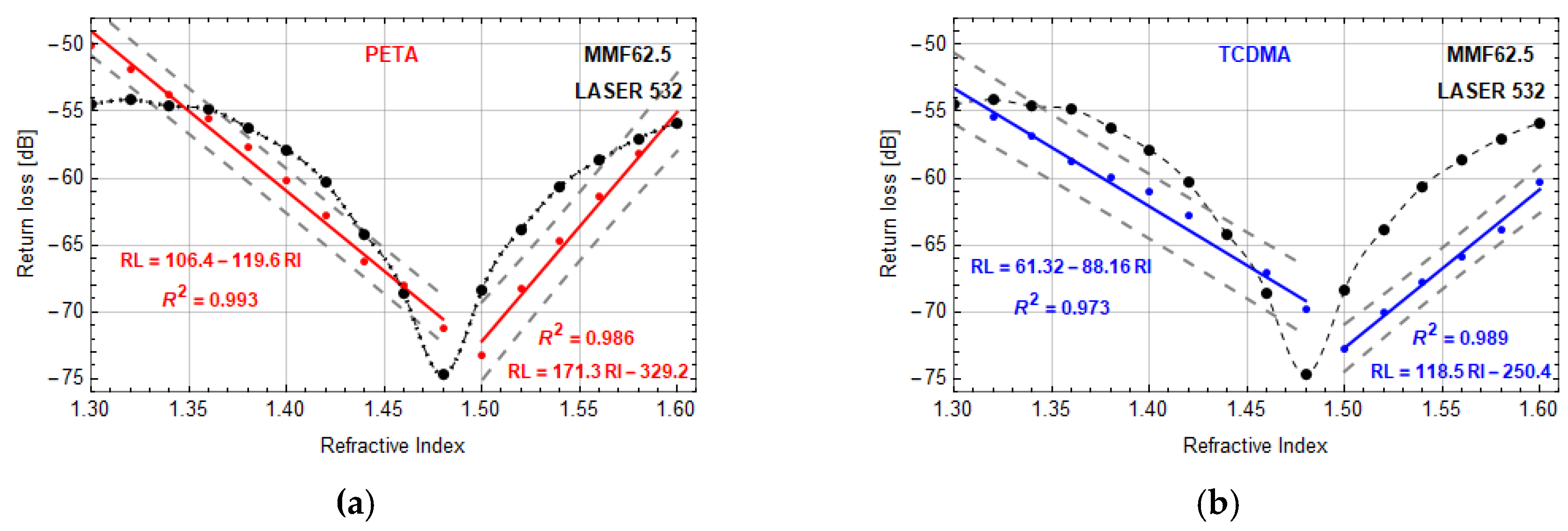

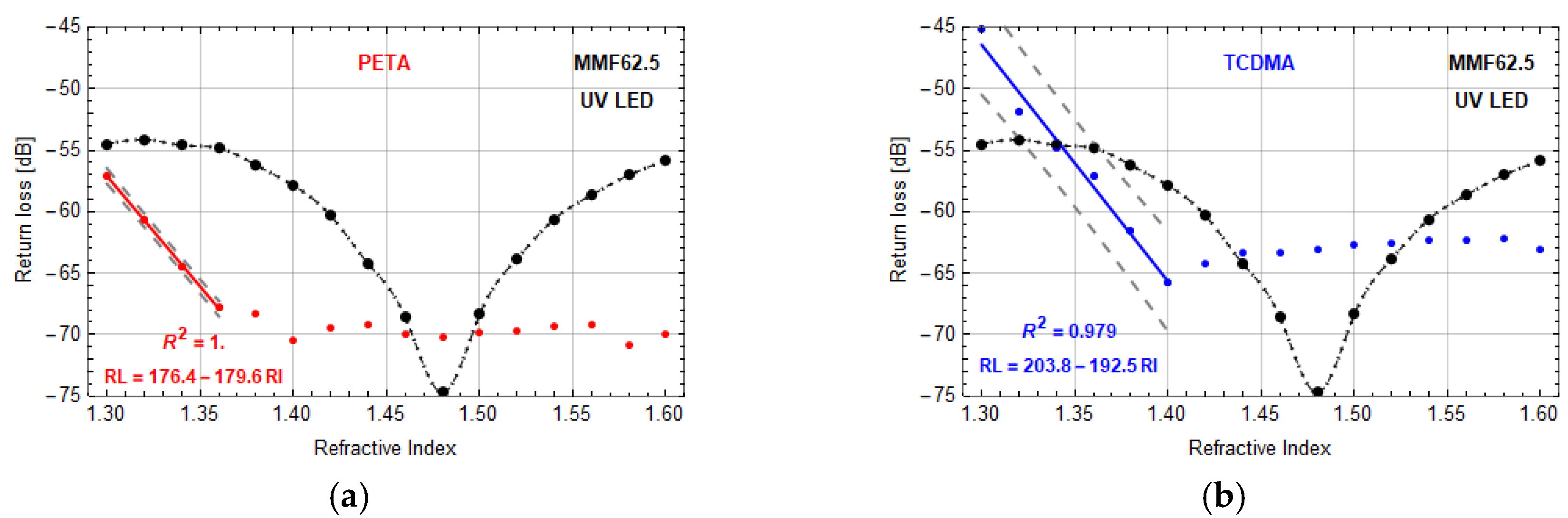

3. Reflective Properties of a Micro-Transducer under RI Changes

4. Discussion

Author Contributions

Funding

Conflicts of Interest

References

- Hecht, B.; Sick, B.; Wild, U.P. Scanning near-field optical microscopy with aperture probes: Fundamentals and applications. J. Chem. Phys. 2000, 112, 7761–7774. [Google Scholar] [CrossRef]

- Pura-Pawlikowska, P.; Dudek, M.; Wonko, R.; Marć, P.; Kujawińska, M.; Jaroszewicz, L.R. The polymer converter for effectively connecting polymer with silica optical fibers. Opto-Electron. Rev. 2016, 24, 126–133. [Google Scholar] [CrossRef]

- Żuchowska (Chruściel), M.; Marć, P.; Jakubowska, I.; Jaroszewicz, L.R. Technology of Polymer Microtips’ Manufacturing on the Ends of Multi-Mode Optical Fibers. Materials 2020, 13, 416. [Google Scholar] [CrossRef] [PubMed]

- Pura, P.; Szymański, M.; Dudek, M.; Jaroszewicz, L.R.; Marć, P.; Kujawińska, M. Polymer microtips at different types of optical fibers as functional elements for sensing applications. J. Lightwave Technol. 2015, 33, 2398–2404. [Google Scholar] [CrossRef]

- Chruściel, M.; Marć, P.; Dudek, M.; Pura-Pawlikowska, P.; Wonko, R.; Jaroszewicz, L.R. Technology of a photopolymer microtip as an optical fiber sensor’s transducer. Proc. SPIE 2017, 10325, 103250E. [Google Scholar]

- Chruściel, M.; Marć, P.; Jaroszewicz, L.R. Reflective type optical fiber sensors’ transducer based on a photopolymer microtip. Proc. SPIE 2019, 11199, 111992X. [Google Scholar]

- Zawisza, R.; Eftimov, T.; Mikulic, P.; Bock, W.J.; Jaroszewicz, L.R. Ambient Refractive-Index Measurement with Simultaneous Temperature Monitoring Based on a Dual-Resonance Long-Period Grating Inside a Fiber Loop Mirror Structure. Sensors 2018, 18, 2370. [Google Scholar] [CrossRef]

- Zawisza, R.; Eftimov, T.; Mikulic, P.; Chinifooroshan, Y.; Celebańska, A.; Bock, W.J.; Jaroszewicz, L.R. Dual-resonance long-period grating in fiber loop mirror structure for liquid refractive index measurement. Opto-Electron. Rev. 2018, 26, 24–28. [Google Scholar] [CrossRef]

- Śmietana, M.; Koba, M.; Mikulic, P.; Bock, W.J. Towards refractive index sensitivity of long period gratings at level of tens of μm per refractive index unit: Fiber cladding etching and nano-coating deposition. Opt. Express 2016, 24, 11897–11904. [Google Scholar]

- Tian, Z.; Yam, S.S.-H. In-Line Single-Mode Optical Fiber Interferometric Refractive Index Sensors. J. Lightwave Technol. 2009, 27, 2296–2306. [Google Scholar] [CrossRef]

- Chu, J.; Shen, C.; Zhong, C.; Zou, X.; Li, K.; Dong, X. Optical Fiber Refractometer Based on a Long-Period Grating inscribed in a fiber loop mirror. In Proceedings of the Symposium on Photonics and Optoelectronics, Shanghai, China, 21–23 May 2012. [Google Scholar]

- Shu, X.; Bashir, A.; Liu, Y.; Zhang, L.; Bennion, I. Sampled fiber Bragg grating for simultaneous refractive index and temperature measurement. Opt. Lett. 2001, 26, 774–776. [Google Scholar] [CrossRef] [PubMed]

- Schroeder, K.; Ecke, W.; Mueller, R.; Willsch, R.; Andreev, A. A fiber Bragg grating refractometer. Meas. Sci. Technol. 2001, 12, 757–764. [Google Scholar] [CrossRef]

- Yan, B.; Sun, L.; Luo, Y.; Yang, L.; Qi, H.; Chen, X.; Wang, K.; Yuan, J.; Sang, X.; Wang, C.; et al. Temperature Self-Compensated Refractive Index Sensor Based on Fiber Bragg Grating and the Ellipsoid Structure. Sensors 2019, 19, 5211. [Google Scholar] [CrossRef] [PubMed]

- Ahsani, V.; Ahmed, F.; Jun, M.B.G.; Bradley, C. Tapered Fiber-Optic Mach-Zehnder Interferometer for Ultra-High Sensitivity Measurement of Refractive Index. Sensors 2019, 19, 1652. [Google Scholar] [CrossRef] [PubMed]

- Wong, Y.; Scully, R.; Kadim, H.; Alexiou, V.; Bartlett, R. Automation and dynamic characterization of light intensity with applications to tapered plastic optical fiber. Appl. Opt. 2003, 5, S51–S58. [Google Scholar]

- Kumar, A.; Subrahmonium, T.; Sharma, A.; Thyagarajan, K.; Pal, B.; Goyal, I. Novel refractometer using a tapered optical fiber. Electron. Lett. 1984, 20, 534. [Google Scholar] [CrossRef]

- Villiatoro, J.; Monzoon-Hernandez, D.; Talavera, D. High resolution refractive index sensing with cladded multimode tapered optical fiber. Electron. Lett. 2004, 40, 106–107. [Google Scholar] [CrossRef]

- Śmietana, M.; Janiak, M.; Koba, M.; Bock, W.J. Transition between bulk and surface refractive index sensitivity of micro-cavity in-line Mach-Zehnder interferometer induced by thin film deposition. Opt. Express 2017, 25, 26118. [Google Scholar] [CrossRef]

- Li, Z.; Hou, L.; Ran, L.; Kang, J.; Yang, J. Ultra-Sensitive Fiber Refractive Index Sensor with Intensity Modulation and Self-Temperature Compensation. Sensors 2019, 19, 3820. [Google Scholar] [CrossRef]

- Sequeira, F.; Cennamo, N.; Rudnitskaya, A.; Nogueira, R.; Zeni, L.; Bilro, L. D-Shaped POF Sensors for Refractive Index Sensing—The Importance of Surface Roughness. Sensors 2019, 19, 2476. [Google Scholar] [CrossRef]

- Cusano, A.; Cutolo, A.; Giordano, M.; Nicolais, L. Optoelectronic refractive index measurements: Application to smart processing. IEEE Sens. J. 2003, 3, 781–787. [Google Scholar] [CrossRef]

- Mukherjee, A.; Munsi, D.; Saxena, V.; Rajput, R.; Tewari, P.; Singh, V.; Ghosh, A.K.; John, J.; Wanare, H.; Gupta-Bhaya, P. Characterization of a fiber optic liquid refractive index sensor. Sens. Actuators B-Chem. 2010, 145, 265–271. [Google Scholar] [CrossRef]

- Śmietana, M.; Koba, M.; Sezemsky, P.; Szot-Karpińska, K.; Burnat, D.; Stranak, V.; Niedziółka-Jönssond, J.; Bogdanowicz, R. Simultaneous optical and electrochemical label-free biosensing with ITO-coated lossy-mode resonance sensor. Biosens. Bioelectron. 2020, 154, 112050. [Google Scholar] [CrossRef] [PubMed]

- Xu, W.; Huang, X.G.; Pan, J.S. Simple Fiber-Optic Refractive Index Sensor Based On Fresnel Reflection and Optical Switch. IEEE Sens. J. 2013, 13, 1571–1574. [Google Scholar] [CrossRef]

- Zhou, X.; Chen, K.; Mao, X.; Peng, W.; Yu, Q. A reflective fiber-optic refractive index sensor based on multimode interference in a coreless silica fiber. Opt. Com. 2015, 340, 50–55. [Google Scholar] [CrossRef]

- Kong, Y.; Shu, X.; Cao, H.; Deng, J. Thin-Core Fiber Taper-Based Multi-Mode Interferometer for Refractive Index Sensing. IEEE Sens. J. 2018, 18, 8747–8754. [Google Scholar] [CrossRef]

- Ma, Y.; Qiao, X.; Guo, T.; Wang, R.; Zhang, J.; Weng, Y.; Rong, Q.; Hu, M.; Feng, Z. Reflective fiber-optic refractometer based on a thin-core fiber tailored Bragg grating reflection. Opt. Lett. 2012, 37, 323–325. [Google Scholar] [CrossRef]

- Bachelot, R.; Ecoffet, C.; Deloeil, D.; Royer, P.; Lougnot, D.J. Integration of micrometer-sized polymer elements at the end of optical fibers by free-radical photopolymerization. Appl. Opt. 2001, 40, 5860–5871. [Google Scholar] [CrossRef]

- Soppera, O.; Turck, C.; Lougnot, D.J. Fabrication of micro-optical devices by self-guiding photopolymerization in the near IR. Opt. Lett. 2009, 34, 461–463. [Google Scholar] [CrossRef]

- Zheng, S.; Zeng, X.; Luo, W.; Jradi, S.; Plain, J.; Li, M.; Renaud-Goud, P.; Deturche, R.; Wang, Z.; Kou, J.; et al. Rapid fabrication of micro-nanometric tapered fiber lens and characterization by a novel scanning optical microscope with submicron resolution. Opt. Express 2013, 21, 30–38. [Google Scholar] [CrossRef]

- Pura, P.; Szymański, M.; Wiśniowski, B.; Dudek, M.; Jaroszewicz, L.R.; Napierała, M.; Spadło, A.; Marć, P.; Kujawińska, M. Polymer microtips fabricated at the extremity of photonic crystal fibers. J. Matter. Sci. Eng. B 2013, 3, 749–758. [Google Scholar]

- Chruściel, M.; Marć, P.; Jakubowska, I.; Jaroszewicz, L.R. UV polymerized microtips on multimode optical fibers. Proc. SPIE 2018, 11045, 110450G. [Google Scholar]

- Soller, B.J.; Wolfe, M.; Froggatt, M.E. Polarization resolved measurement of Rayleigh backscatter in fiber-optic components. In Proceedings of the Optical Fiber Communication Conference Technical Digest 2005, NWD3, Anaheim, CA, USA, 6 March 2005. [Google Scholar]

| Source | PETA | TCDMA |

|---|---|---|

| Microtip Base Diameter [µm] | Microtip Base Diameter [µm] | |

| LASER 532 | 50 ± 1 | 35 ± 1 |

| UV LED | 53 ± 1 | 50 ± 1 |

| VIS LED | 51 ± 1 | 50 ± 1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Marć, P.; Żuchowska, M.; Jaroszewicz, L.R. Reflective Properties of a Polymer Micro-Transducer for an Optical Fiber Refractive Index Sensor. Sensors 2020, 20, 6964. https://doi.org/10.3390/s20236964

Marć P, Żuchowska M, Jaroszewicz LR. Reflective Properties of a Polymer Micro-Transducer for an Optical Fiber Refractive Index Sensor. Sensors. 2020; 20(23):6964. https://doi.org/10.3390/s20236964

Chicago/Turabian StyleMarć, Paweł, Monika Żuchowska, and Leszek R. Jaroszewicz. 2020. "Reflective Properties of a Polymer Micro-Transducer for an Optical Fiber Refractive Index Sensor" Sensors 20, no. 23: 6964. https://doi.org/10.3390/s20236964

APA StyleMarć, P., Żuchowska, M., & Jaroszewicz, L. R. (2020). Reflective Properties of a Polymer Micro-Transducer for an Optical Fiber Refractive Index Sensor. Sensors, 20(23), 6964. https://doi.org/10.3390/s20236964