Classification of Bee Pollen and Prediction of Sensory and Colorimetric Attributes—A Sensometric Fusion Approach by e-Nose, e-Tongue and NIR

Abstract

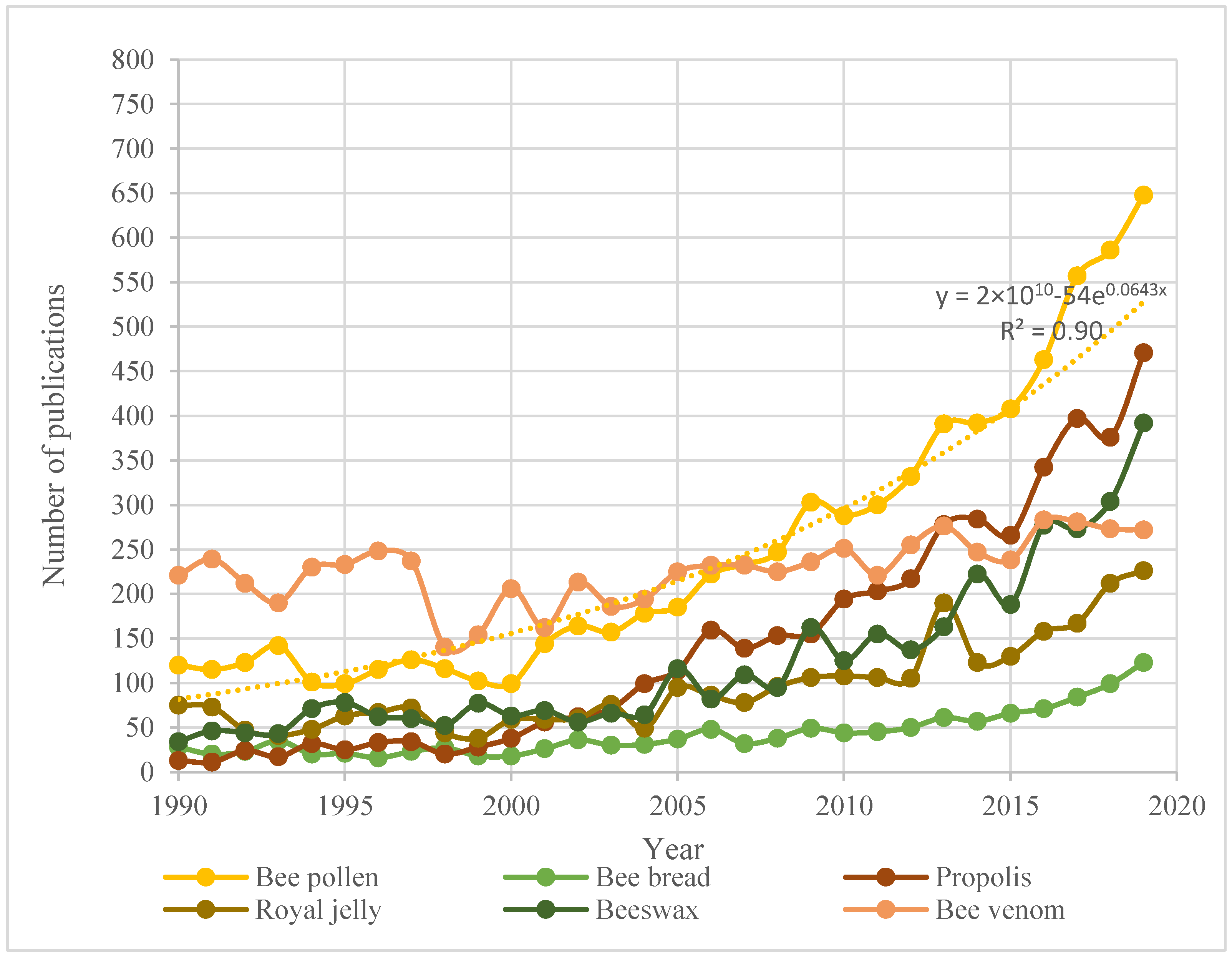

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Microscopic Pollen Analysis

2.3. Spectral Colour Measurement (L*a*b* System)

2.4. Sensory Analysis

2.5. Near Infrared Spectroscopy Measurements (NIR)

2.6. Electronic Nose Measurements

2.7. Electronic Tongue Measurements

2.8. Statistical Analysis

3. Results

3.1. Results of the Microscopic Pollen Analysis

3.2. Results of Bee Pollen the Colour Measurement

3.3. Results of the Sensory Evaluation

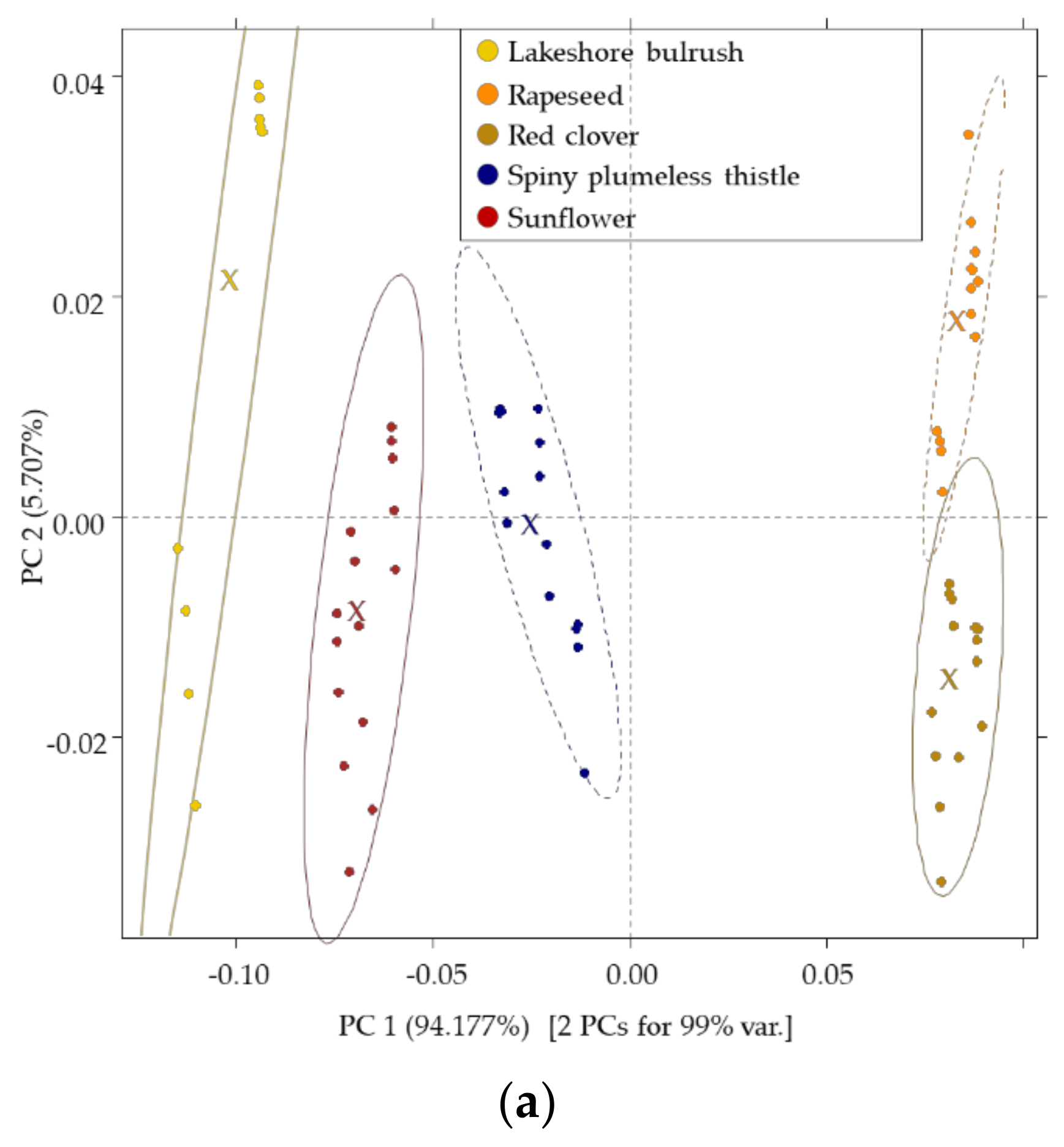

3.4. Results of the NIR

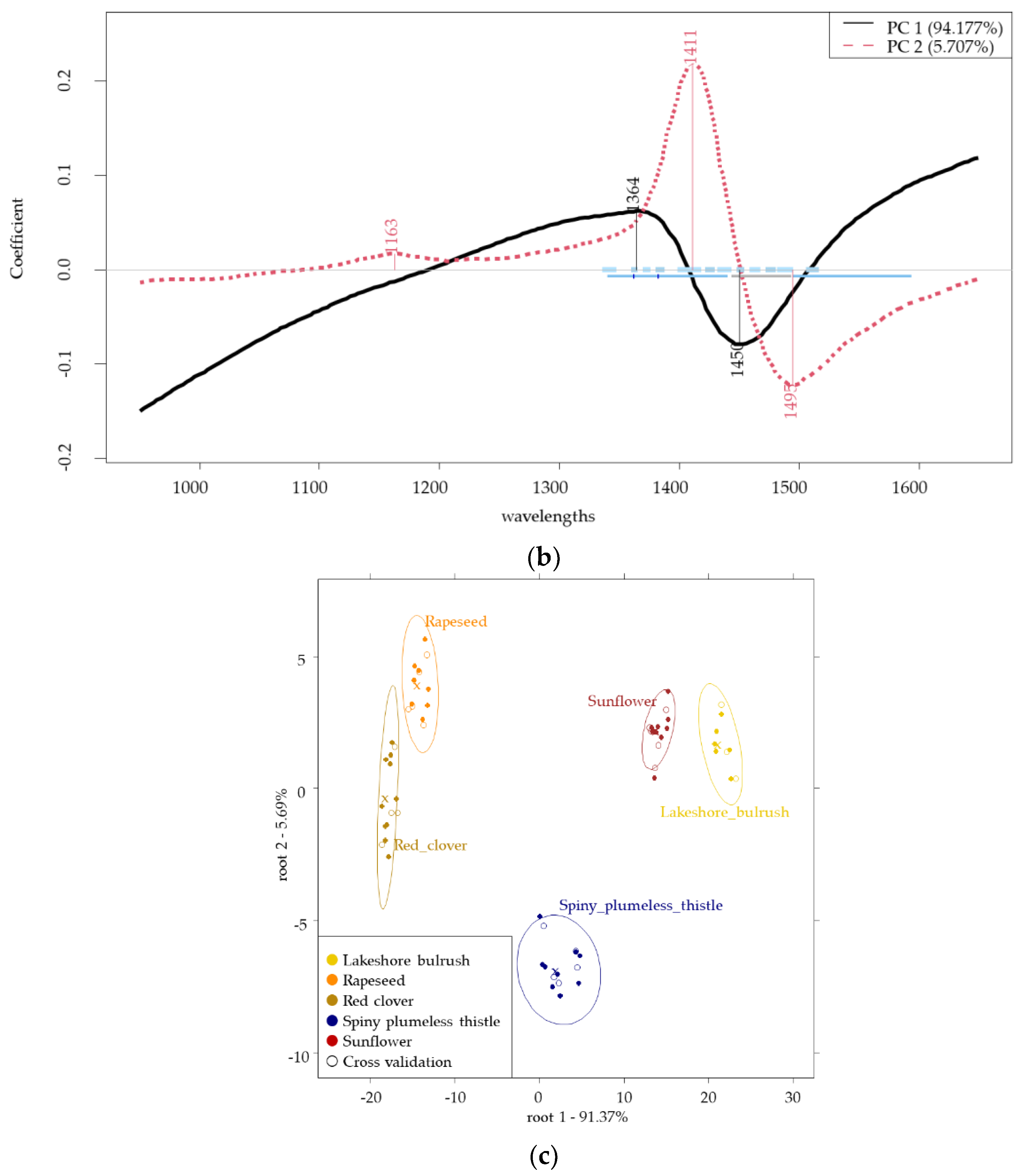

3.5. Results of the Electronic Nose

3.6. Results of the Electronic Tongue

3.7. Partial least Square Regression Results of the Fusion of NIR Spectroscopy, e-Nose, e-Tongue Methods to Regress on the Sensory Attributes and Colour Parameters

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Bargańska, Ż.; Ślebioda, M.; Namieśnik, J. Honey bees and their products: Bioindicators of environmental contamination. Crit. Rev. Environ. Sci. Technol. 2016, 46, 235–248. [Google Scholar] [CrossRef]

- Sciencedirect.com. Available online: https://www.sciencedirect.com/ (accessed on 14 March 2019).

- Kieliszek, M.; Piwowarek, K.; Kot, A.M.; Błażejak, S.; Chlebowska-Śmigiel, A.; Wolska, I. Pollen and bee bread as new health-oriented products: A review. Trends Food Sci. Technol. 2018, 71, 170–180. [Google Scholar] [CrossRef]

- Ulbricht, C.; Conquer, J.; Giese, N.; Khalsa, K.P.S.; Sklar, J.; Weissner, W.; Woods, J. An Evidence-based systematic review of bee pollen by the natural standard research collaboration. J. Diet. Suppl. 2019, 6, 290–312. [Google Scholar] [CrossRef]

- Thakur, M.; Nanda, V. Exploring the physical, functional, thermal, and textural properties of bee pollen from different botanical origins of India. J. Food Process. Eng. 2018, 43, e12935. [Google Scholar] [CrossRef]

- Mayda, N.; Özkök, A.; Bayram, N.E.; Gerçek, Y.C.; Sorkun, K. Bee bread and bee pollen of different plant sources: Determination of phenolic content, antioxidant activity, fatty acid and element profiles. J. Food Meas. Charact. 2020, 14, 1795–1809. [Google Scholar] [CrossRef]

- Liolios, V.; Tananaki, C.; Papaioannou, A.; Kanelis, D.; Rodopoulou, M.-A.; Argena, N. Mineral content in monofloral bee pollen: Investigation of the effect of the botanical and geographical origin. J. Food Meas. Charact. 2019, 13, 1674–1682. [Google Scholar] [CrossRef]

- Spulber, R.; Doğaroğlu, M.; Băbeanu, N.; Popa, O. Physicochemical characteristics of fresh bee pollen from different botanical origins. Rom. Biotechnol. Lett. 2018, 23, 13357–13365. [Google Scholar]

- Li, Q.Q.; Wang, K.; Marcucci, M.C.; Sawaya, A.C.H.F.; Hu, L.; Xue, X.F.; Wu, L.M.; Hu, F.L. Nutrient-rich bee pollen: A treasure trove of active natural metabolites. J. Funct. Foods 2018, 49, 472–484. [Google Scholar] [CrossRef]

- Ares, A.M.; Valverde, S.; Bernal, J.L.; Nozal, M.J. Extraction and determination of bioactive compounds from bee pollen. J. Pharm. Biomed. Anal. 2018, 147, 110–124. [Google Scholar] [CrossRef]

- Saraiva, L.; Cunha, F.; Léllis, D.; Nunes, L. Composition, biological activity and toxicity of bee pollen: State of the art. Bol. Latinoam. Caribe Plantas Med. Aromát. 2018, 17, 426–440. [Google Scholar]

- Böhme, F.; Bischoff, G.; Zebitz, C.P.W.; Rosenkranz, P.; Wallner, K. Pesticide residue survey of pollen loads collected by honeybees (Apis mellifera) in daily intervals at three agricultural sites in South Germany. PLoS ONE 2018, 13, e0199995. [Google Scholar] [CrossRef] [PubMed]

- Altunatmaz, S.S.; Tarhan, D.; Aksu, F.; Barutçu, U.B.; Or, M.E. Mineral element and heavy metal (cadmium, lead and arsenic) levels of bee pollen in Turkey. Food Sci. Technol. 2017, 37, 136–141. [Google Scholar] [CrossRef]

- Roman, A. Concentration of chosen trace elements of toxic properties in bee pollen loads. Pol. J. Environ. Stud. 2009, 18, 265–272. [Google Scholar]

- Kostić, A.Ž.; Milinčić, D.D.; Petrović, T.; Krnjaja, V.; Stanojevic, S.P.; Barać, M.B.; Tešić, Ž.L.; Pešić, M.B. Mycotoxins and mycotoxin producing fungi in pollen: Review. Toxins 2019, 11, 64. [Google Scholar] [CrossRef]

- Sari, M.F.; Ayyildiz, E.G.; Esen, F. Determination of polychlorinated biphenyls in honeybee, pollen, and honey samples from urban and semi-urban areas in Turkey. Environ. Sci. Pollut. Res. 2020, 27, 4414–4422. [Google Scholar] [CrossRef]

- Roszko, M.Ł.; Kamińska, M.; Szymczyk, K.; Jędrzejczak, R. Levels of selected persistent organic pollutants (PCB, PBDE) and pesticides in honey bee pollen sampled in Poland. PLoS ONE 2016, 11, e0167487. [Google Scholar] [CrossRef]

- Wei, Y.; Chen, F.; Xue, X.; Li, Y.; Zhao, L.; Cao, W.; Yu, L.; Wu, L. Determination of Persistent Environmental Pollutants in Bee Pollen by Gas Chromatography–Mass Spectrometry Using a Modified QuEChERS Approach. Curr. Anal. Chem. 2016, 12, 366–377. [Google Scholar] [CrossRef]

- Papa, G.; Capitani, G.; Capri, E.; Pellecchia, M.; Negri, I. Vehicle-derived ultrafine particulate contaminating bees and bee products. Sci. Total. Environ. 2020, 750, e141700. [Google Scholar] [CrossRef]

- Guzman, A.; Gaines-Day, H.; Lois, A.; Steffan, S.; Brunet, J.; Zalapa, J.; Guédot, C. Surrounding landscape and spatial arrangement of honey bee hives affect pollen foraging and yield in cranberry. Agric. Ecosyst. Environ. 2019, 286, 106624. [Google Scholar] [CrossRef]

- Danner, N.; Molitor, A.M.; Schiele, S.; Härtel, S.; Steffan-Dewenter, I. Season and landscape composition affect pollen foraging distances and habitat use of honey bees. Ecol. Appl. 2016, 26, 1920–1929. [Google Scholar] [CrossRef]

- Ghosh, S.; Jeon, H.; Jung, C. Foraging behaviour and preference of pollen sources by honey bee (Apis mellifera) relative to protein contents. J. Ecol. Environ. 2020, 44, 4. [Google Scholar] [CrossRef]

- Wilmer, P. Pollination and Floral Ecology, 1st ed.; Princeton University Press: Princeton, NJ, USA, 2011; p. 778. [Google Scholar]

- Ferguson, J.A.; Northfield, T.D.; Lach, L. Honey bee (Apis mellifera) pollen foraging reflects benefits dependent on individual infection status. Microb. Ecol. 2018, 76, 482–491. [Google Scholar] [CrossRef] [PubMed]

- Arenas, A.; Kohlmaier, M.G. Nectar source profitability influences individual foraging preferences for pollen and pollen-foraging activity of honeybee colonies. Behav. Ecol. Sociobiol. 2019, 73, 34. [Google Scholar] [CrossRef]

- Castiglioni, S.; Astolfi, P.; Conti, C.; Monaci, E.; Stefano, M.; Carloni, P. Morphological, physicochemical and ftir spectroscopic properties of bee pollen loads from different botanical origin. Molecules 2019, 24, 3974. [Google Scholar] [CrossRef]

- Anklam, E. A review of the analytical methods to determine the geographical and botanical origin of honey. Food Chem. 1998, 63, 549–562. [Google Scholar] [CrossRef]

- Oddo, L.P.; Bogdanov, S. Determination of honey botanical origin: Problems and issues. Apidologie 2004, 35, 1–3. [Google Scholar] [CrossRef]

- Marcos, J.V.; Nava, R.; Cristóbal, G.; Redondo, R.; Escalante-Ramírez, B.; Bueno, G.; Déniz, Ó.; González-Porto, A.V.; Pardo, C.; Chung, F.; et al. Automated pollen identification using microscopic imaging and texture analysis. Micron 2015, 68, 36–46. [Google Scholar] [CrossRef]

- Palynological Database. Available online: https://www.paldat.org/ (accessed on 12 October 2020).

- Global Pollen Database. Available online: https://ecologicaldata.org/wiki/global-pollen-database (accessed on 20 September 2020).

- European Pollen Database. Available online: http://www.europeanpollendatabase.net/index.php (accessed on 20 September 2020).

- Pollen Databases and Collections, Georg-August-Universität Göttingen. Available online: https://www.uni-goettingen.de/en/databases+and+collections/97306.html (accessed on 12 October 2020).

- Kovács, Z.; Dalmadi, I.; Lukács, L.; Sipos, L.; Szántai-Kőhegyi, K.; Kókai, Z.; Fekete, A. Geographical origin identification of pure Sri Lanka tea infusions with electronic nose, electronic tongue and sensory profile analysis. J. Chemom. 2009, 24, 121–130. [Google Scholar] [CrossRef]

- Sipos, L.; Gere, A.; Szöllősi, D.; Kovacs, Z.; Kókai, Z.; Fekete, A. Sensory evaluation and electronic tongue for sensing flavored mineral water taste attributes. J. Food Sci. 2013, 78, S1602–S1608. [Google Scholar] [CrossRef]

- Gere, A.; Losó, V.; Györey, A.; Kovács, S.; Huzsvai, L.; Nábrádi, A.; Kókai, Z.; Sipos, L. Applying parallel factor analysis and Tucker-3 methods on sensory and instrumental data to establish preference maps: Case study on sweet corn varieties. J. Sci. Food Agric. 2014, 94, 3213–3225. [Google Scholar] [CrossRef]

- ISO 13299. Sensory Analysis—Methodology—General Guidance for Establishing a Sensory Profile; ISO: Geneva, Switzerland, 2016. [Google Scholar]

- Nicolaï, B.M.; Beullens, K.; Bobelyn, E.; Peirs, A.; Saeys, W.; Theron, K.I.; Lammertyn, J. Nondestructive measurement of fruit and vegetable quality by means of NIR spectroscopy: A review. Annu. Rev. Food. Sci. Technol. 2007, 46, 99–118. [Google Scholar] [CrossRef]

- Zaukuu, J.L.Z.; Bodor, Z.; Vitalis, F.; Zsom-Muha, V.; Kovacs, Z. Near infrared spectroscopy as a rapid method for detecting paprika powder adulteration with corn flour. Acta Period. Technol. 2019, 50, 346–352. [Google Scholar] [CrossRef]

- Pasquini, C. Near Infrared Spectroscopy: Fundamentals, practical aspects and analytical applications. J. Braz. Chem. Soc. 2003, 14, 198–219. [Google Scholar] [CrossRef]

- Pathare, P.B.; Opara, U.L.; Al-Said, F.A.J. Colour measurement and analysis in fresh and processed foods: A review. Food Bioprocess. Technol. 2013, 6, 36–60. [Google Scholar] [CrossRef]

- Gonnet, J.F. CIELab measurement, a precise communication in flower colour: An example with carnation (Dianthus caryophyllus) cultivars. J. Hortic. Sci. 2015, 68, 499–510. [Google Scholar] [CrossRef]

- Kuchmenko, T.A.; Lvova, L.B. A perspective on recent advances in piezoelectric chemical sensors for environmental monitoring and foodstuffs analysis. Chemosensors 2019, 7, 39. [Google Scholar] [CrossRef]

- Peris, M.; Escuder-Gilabert, L. Electronic noses and tongues to assess food authenticity and adulteration. Trends Food Sci. Technol. 2016, 58, 40–54. [Google Scholar] [CrossRef]

- Rodríguez-Méndez, M.L.; Apetrei, C.; Saja, J.A. Electronic tongues purposely designed for the organoleptic characterization of olive oils. In Olives and Olive Oil in Health and Disease Prevention; Preedy, V.R., Watson, R.R., Eds.; Academic Press: London, UK, 2010; pp. 525–532. [Google Scholar]

- Baldwin, E.; Bai, J.; Plotto, A.; Dea, S. Electronic noses and tongues: Applications for the food and pharmaceutical industries. IEEE Sens. J. 2011, 11, 4744–4766. [Google Scholar] [CrossRef]

- Borràs, E.; Ferré, J.; Boqué, R.; Mestres, M.; Aceña, L.; Busto, O. Data fusion methodologies for food and beverage authentication and quality assessment—A review. Anal. Chim. Acta 2015, 891, 1–14. [Google Scholar] [CrossRef]

- Xu, M.; Wang, J.; Zhu, L. The qualitative and quantitative assessment of tea quality based on E-nose, E-tongue and E-eye combined with chemometrics. Food Chem. 2019, 289, 482–489. [Google Scholar] [CrossRef]

- Rodriguez-Mendez, M.L. Electronic Nose and Tongue in Food Science, 1st ed.; Academic Press: London, UK, 2016; 332p. [Google Scholar]

- Salazar-González, C.Y.; Rodríguez-Pulido, F.J.; Terrab, A.; Díaz-Moreno, C.; Fuenmayor, C.A.; Heredia, F.J. Analysis of multifloral bee pollen pellets by advanced digital imaging applied to functional food ingredients. Plant. Foods Hum. Nutr. 2018, 73, 328–335. [Google Scholar] [CrossRef] [PubMed]

- Thakur, M.; Nanda, V. Composition and functionality of bee pollen: A review. Trends Food Sci. Technol. 2020, 98, 82–106. [Google Scholar] [CrossRef]

- Commission Internationale de l’Éclairage. Colorimetry: Technical Report; Central Bureau of the CIE: Vienna, Austria, 2004; pp. 12–18. [Google Scholar]

- Juhász, R.; Penksza, P.; Sipos, L. Effect of xylo-oligosaccharides (XOS) addition on technological and sensory attributes of cookies. Food Sci. Nutr. 2020, 10, 5452–5460. [Google Scholar] [CrossRef]

- ISO 8589. Sensory Analysis—General Guidance for the Design of Test Rooms; ISO: Geneva, Switzerland, 2007. [Google Scholar]

- ISO 8586. Sensory Analysis—General Guidelines for the Selection, Training and Monitoring of Selected Assessors and Expert Sensory Assessors; ISO: Geneva, Switzerland, 2012. [Google Scholar]

- ISO 6658. Sensory Analysis—Methodology—General Guidance; ISO: Geneva, Switzerland, 2017. [Google Scholar]

- Zenkevich, I.G. Kovats retention index system. In Encyclopedia of Chromatography; Cazes, J., Ed.; Marcel Dekker Inc.: New York, NY, USA, 2002. [Google Scholar]

- AlphaM.O.S. Heracles Manual. Available online: https://www.alpha-mos.com/heracles-smell-analysis (accessed on 30 September 2020).

- AlphaM.O.S. aAstree Electronic Tongue User Manual. Available online: https://www.alpha-mos.com/astree-taste-analysis#electronic-tongue (accessed on 30 September 2020).

- ISO 11132. Sensory Analysis—Methodology—Guidelines for Monitoring the Performance of a Quantitative Sensory Panel; ISO: Geneva, Switzerland, 2012. [Google Scholar]

- Tomic, O.; Luciano, G.; Nilsen, A.; Hyldig, G.; Lorensen, K.; Næs, T. Analysing sensory panel performance in a proficiency test using the PanelCheck software. Eur. Food Res. Technol. 2009, 230, 497–511. [Google Scholar] [CrossRef]

- Peltier, C.; Brockhoff, P.; Visalli, M.; Schlich, P. The MAM-CAP table: A new tool for monitoring panel performances. Food Qual. Prefer. 2013, 32, 24–27. [Google Scholar] [CrossRef]

- R Core Team. R: A Language and Environment for Statistical Computing; R Foundation for Statistical Computing: Vienna, Austria, 2013; Available online: http://www.R-project.org/ (accessed on 30 September 2020).

- Kovacs, Z.; Szöllősi, D.; Zaukuu, J.-L.Z.; Bodor, Z.; Vitalis, F.; Aouadi, B.; Zsom-Muha, V.; Gillay, Z. Factors influencing the long-term stability of electronic tongue and application of improved drift correction methods. Biosensors 2020, 10, 74. [Google Scholar] [CrossRef] [PubMed]

- Williams, P.C.; Sobering, D. Comparison of commercial near infrared transmittance and reflectance instruments for analysis of whole grains and seeds. J. Near Infrared Spectrosc. 1993, 1, 25–32. [Google Scholar] [CrossRef]

- Mokrzycki, W.S.; Tatol, S. Color difference Delta E—A survey. Mach. Graph. Vis. 2011, 20, 383–411. [Google Scholar]

- Barth, O.M.; Munhoz, M.C.; Luz, C.F.P. Botanical origin of Apis pollen loads using colour, weight and pollen morphology data. Acta Alim. 2009, 38, 133–139. [Google Scholar] [CrossRef]

- Almeida-Muradian, L.; Pamplona, L.C.; Coimbra, S.; Barth, O.M. Chemical composition and botanical evaluation of dried bee pollen pellets. J. Food Compos. Anal. 2005, 18, 105–111. [Google Scholar] [CrossRef]

- Bazar, G.; Romvári, R.; Szabó, A.; Somogyi, T.; Éles, V.; Tsenkova, R. NIR detection of honey adulteration reveals differences in water spectral pattern. Food Chem. 2016, 194, 873–880. [Google Scholar] [CrossRef] [PubMed]

- Mouazen, A.M.; Al-Walaan, N. Glucose Adulteration in Saudi Honey with Visible and Near Infrared Spectroscopy. Int. J. Food Prop. 2014, 17, 2263–2274. [Google Scholar] [CrossRef]

- Węglińska, M.; Szostak, R.; Kita, A.; Nemś, A.; Mazurek, S. Determination of nutritional parameters of bee pollen by Raman and infrared spectroscopy. Talanta 2020, 212, 120790. [Google Scholar] [CrossRef] [PubMed]

- Neto, J.M.M.; Lopes, J.A.D.; De Lima, S.G.; Da Luz, C.F.P.; Citó, A.M.D.G.L. Volatile compounds and palynological analysis from pollen pots of stingless bees from the mid-north region of Brazil. Braz. J. Pharm. Sci. 2017, 53, 1–9. [Google Scholar] [CrossRef]

- Kaškonienė, V.; Ruočkuvienė, G.; Kaškonas, P.; Akuneca, I.; Maruška, A. Chemometric analysis of bee pollen based on volatile and phenolic compound compositions and antioxidant properties. Food Anal. Methods 2015, 8, 1150–1163. [Google Scholar] [CrossRef]

- Kaškonienė, V.; Kaškonas, P.; Maruška, A. Volatile compounds composition and antioxidant activity of bee pollen collected in Lithuania. Chem. Pap. 2015, 69, 291–299. [Google Scholar] [CrossRef]

- ISO 5492. Sensory Analysis—Vocabulary; ISO: Geneva, Switzerland, 2008. [Google Scholar]

| Sample | Main Plant Species | Proportion of Main Plant Species | Minor Plant Species | |

|---|---|---|---|---|

| Common Name | Scientific Name | |||

| 1 | Lakeshore bulrush | Schoenoplectus lacustris (L.) Palla | 80% | Cornus sanguinea |

| Plantago lanceolata | ||||

| Zea mays | ||||

| Robinia pseudoacacia | ||||

| Carduus acanthoides | ||||

| Convolvulus arvensis | ||||

| 2 | Sunflower | Helianthus annuus | 100% | − |

| 3 | Red clover | Trifolium pretense | 100% | − |

| 4 | Rapeseed | Brassica napus | 100% | − |

| 5 | Spiny plumeless thistle | Carduus acanthoides L. | 85% | Trifolium pratense |

| Samples | L* | a* | b* | C*ab | hab |

|---|---|---|---|---|---|

| Lakeshore bulrush | 59.6 ± 0.4 b | 6.0 ± 0.1 c | 44.2 ± 0.9 c | 44.6 | 82.3 |

| Sunflower | 58.1 ± 0.2 c | 12.2 ± 0.1 b | 64.5 ± 0.2 a | 65.6 | 79.3 |

| Red clover | 50.7 ± 0.4 d | 5.8 ± 0.1 c | 40.7 ± 0.4 d | 41.1 | 81.9 |

| Rapeseed | 66.3 ± 0.5 a | 0.9 ± 0.2 d | 54.6 ± 0.4 b | 54.6 | 89.1 |

| Spiny plumeless thistle | 33.4 ± 0.3 e | 15.6 ± 0.2 a | 17.1 ± 0.3 e | 23.1 | 47.6 |

| Lakeshore Bulrush | Sunflower | Red Clover | Rapeseed | Spiny Plumeless Thistle | |

|---|---|---|---|---|---|

| Lakeshore bulrush | – | 21.28 * | 9.57 * | 13.38 * | 38.90 * |

| 21.03 ** | 3.50 ** | 10.00 ** | 21.46 ** | ||

| 3.0 *** | 0.4 *** | 6.8 *** | 34.7 *** | ||

| Sunflower | – | 25.73 * | 17.12 * | 53.56 * | |

| 24.53 ** | 11.03 ** | 42.49 ** | |||

| 2.6 *** | 9.8 *** | 31.7 *** | |||

| Red clover | – | 21.46 * | 30.86 * | ||

| 13.50 ** | 17.96 ** | ||||

| 7.2 *** | 34.3 *** | ||||

| Rapeseed | – | 52.01 * | |||

| 41.5 *** | |||||

| 31.46 ** | |||||

| Spiny plumeless thistle | – |

| Attribute | F-Prod | F-Scal | F-Disag | RMSE |

|---|---|---|---|---|

| brightness | 1360.05 | 0.42 | 1.55 | 2.33 |

| colour hue | 7303.81 | 1.70 | 0.84 | 2.21 |

| homogeniety of surface | 275.96 | 1.25 | 1.06 | 3.27 |

| global odour intensity | 252.87 | 0.66 | 1.50 | 2.89 |

| sweet odour intensity | 279.68 | 0.39 | 1.38 | 2.58 |

| sour odour intensity | 116.52 | 1.70 | 1.35 | 1.56 |

| floral odour intensity | 46.71 | 1.07 | 1.24 | 1.95 |

| hay odour intensity | 208.2 | 1.00 | 1.50 | 2.15 |

| global taste intensity | 44.47 | 1.24 | 1.48 | 3.12 |

| sweet taste intensity | 120.03 | 1.11 | 1.42 | 3.35 |

| sour taste intensity | 844.91 | 1.20 | 1.37 | 2.33 |

| floral taste intensity | 8.83 | 1.10 | 1.66 | 2.37 |

| hay taste intensity | 162.88 | 1.60 | 1.15 | 1.85 |

| off-taste intensity | 344.46 | 0.65 | 1.29 | 3.45 |

| aftertaste intensity | 4.68 | 106.95 | 0.32 | 0.64 |

| hardness | 81.91 | 1.61 | 1.01 | 2.21 |

| cohesiveness | 3572.56 | 7.19 | 1.55 | 2.08 |

| mouthcoating | 579.97 | 1.10 | 1.37 | 66.86 |

| Attributes | Lakeshore Bulrush (Mean ± Std.) | Sunflower (Mean ± Std.) | Red Clover (Mean ± Std.) | Rapeseed (Mean ± Std.) | Spiny Plumeless Thistle (Mean ± Std.) |

|---|---|---|---|---|---|

| brightness | 45.5 ± 3.9 c | 29.6 ± 3.7 d | 68.9 ± 2.1 b | 11.5 ± 2.0 e | 84.3 ± 3.5 a |

| colour hue | 40.9 ± 2.7 c | 23.9 ± 2.4 d | 61.7 ± 2.0 b | 11.4 ± 2.0 e | 94.1 ± 1.9 a |

| homogeniety of surface | 62.9 ±3.0 c | 64.5 ± 5.1 c | 80.8 ± 1.7 b | 85.6 ± 3.5 a | 81.3 ± 1.9 b |

| global odour intensity | 85.6 ± 3.4 b | 63.8 ± 2.9 d | 70.0 ± 3.4 c | 88.0 ± 3.2 a | 86.5 ± 3.4 a,b |

| sweet odour intensity | 63.0 ± 3.0 d | 67.0 ± 2.8 c | 56.7 ± 2.7 e | 71.3 ± 2.6 b | 82.4 ± 2.2 a |

| sour odour intensity | 17.3 ± 3.2 a | 5.5 ± 1.7 c | 6.0 ± 2.1 c | 10.4 ± 1.1 b | 7.1 ± 2.5 c |

| floral odour intensity | 11.8 ± 2.4 a | 6.3 ± 2.3 c | 3.2 ± 2.8 d | 8.7 ± 1.8 b | 2.8 ± 2.7 d |

| hay odour intensity | 20.3 ± 3.7 a | 11.7 ± 2.9 c | 2.8 ± 2.5 d | 14.8 ± 2.5 b | 2.4 ± 2.0 d |

| global taste intensity | 87.8 ± 3.9 b | 92.0 ± 2.8 a | 83.3 ± 4.1 c | 81.8 ± 3.8 c,d | 79.8 ± 2.8 d |

| sweet taste intensity | 86.2 ± 4.8 a | 64.4 ± 3.5 d | 72.8 ± 5.0 b | 68.4 ± 2.8 c | 84.1 ± 3.9 a |

| sour taste intensity | 7.4 ± 3.5 e | 14.4 ± 3.6 d | 47.7 ± 4.1 c | 69.1 ± 2.4 a | 63.4 ± 5.5 b |

| floral taste intensity | 5.5 ± 2.8 b | 5.5 ± 3.0 b | 8.3 ± 2.3 a | 9.0 ± 1.8 a | 8.3 ± 3.3 a |

| hay taste intensity | 4.4 ± 1.6 c | 15.5 ± 3.0 a | 7.6 ± 2.5 b | 4.0 ± 2.6 c | 4.8 ± 0.6 c |

| off-taste intensity | 42.3 ± 5.5 b | 64.6 ± 5.6 a | 32.8 ± 4.6 c | 32.5 ± 5.8 c | 0.0 ± 0.0 d |

| aftertaste intensity | 0.1 ± 0.4 a | 0.0 ± 0.0 a | 0.0 ± 0.4 a | 0.0 ± 0.0 a | 0.4 ± 1.3 a |

| hardness | 10.5 ± 1.0 c | 8.4 ± 2.3 d | 11.0 ± 1.8 c | 13.4 ± 2.0 b | 18.4 ± 3.6 a |

| cohesiveness | 10.4 ± 0.8 b,c | 8.9 ± 3.3 c | 12.1 ± 2.3 b | 5.9 ± 2.0 d | 74.6 ± 5.9 a |

| mouthcoating | 76.8 ± 3.4 b | 86.8 ± 3.6 a | 35.9 ± 4.8 e | 63.8 ± 2.5 d | 71.0 ± 4.1 c |

| Predicted Variable | R2Tr | RMSEC | R2CV | RMSECV | RPD | Number of Latent Variables | Number of Observations |

|---|---|---|---|---|---|---|---|

| brightness | 0.81 | 11.53 | 0.54 | 17.75 | 1.49 | 3 | 58 |

| colour hue | 0.85 | 11.14 | 0.7 | 15.87 | 1.84 | 3 | 58 |

| homogeneity of surface | 0.98 | 1.26 | 0.85 | 3.53 | 2.62 | 5 | 57 |

| global odour intensity | 0.9 | 3.15 | 0.49 | 7.08 | 1.41 | 5 | 59 |

| sweet odour intensity | 0.06 | 8.47 | −0.25 | 9.75 | 0.90 | 1 | 63 |

| sour odour intensity | 0.59 | 2.49 | 0.14 | 3.61 | 1.09 | 3 | 57 |

| floral odour intensity | 0.95 | 0.7 | 0.75 | 1.62 | 2.03 | 5 | 55 |

| hay odour intensity | 0.96 | 1.28 | 0.84 | 2.75 | 2.48 | 5 | 56 |

| global taste intensity | 0.95 | 0.95 | 0.75 | 2.19 | 2.03 | 5 | 59 |

| sweet taste intensity | 0.61 | 5.11 | 0.2 | 7.33 | 1.13 | 3 | 61 |

| sour taste intensity | 0.96 | 5.11 | 0.67 | 14.2 | 1.75 | 5 | 55 |

| floral taste intensity | 0.96 | 0.3 | 0.84 | 0.62 | 2.5 | 4 | 61 |

| hay taste intensity | 0.77 | 2.08 | 0.2 | 3.91 | 1.13 | 4 | 61 |

| off-taste intensity | 0.95 | 4.83 | 0.74 | 10.64 | 2.00 | 5 | 58 |

| aftertaste intensity | 0.84 | 0.05 | 0.7 | 0.07 | 1.84 | 3 | 61 |

| hardness | 0.95 | 0.81 | 0.69 | 1.97 | 1.8 | 5 | 59 |

| cohesiveness | 0.95 | 6.17 | 0.68 | 15.39 | 1.79 | 5 | 58 |

| mouthcoating | 0.66 | 10.34 | 0.52 | 12.36 | 1.45 | 1 | 65 |

| L* | 0.94 | 2.76 | 0.80 | 4.9 | 2.27 | 4 | 57 |

| a* | 0.85 | 1.78 | 0.50 | 3.57 | 1.42 | 4 | 55 |

| b* | 0.94 | 4.28 | 0.65 | 9.94 | 1.71 | 5 | 59 |

| ∆C*ab | 0.78 | 6.92 | 0.59 | 9.43 | 1.58 | 3 | 61 |

| ∆hab | 0.93 | 3.68 | 0.61 | 8.96 | 1.61 | 5 | 58 |

| Predicted Variable | R2Tr | RMSEC | R2CV | RMSECV | RPD | Number of Latent Variables | Number of Observations |

|---|---|---|---|---|---|---|---|

| brightness | 0.66 | 15.38 | 0.44 | 19.44 | 1.39 | 2 | 15 |

| colour hue | 0.65 | 17.42 | 0.42 | 22.12 | 1.36 | 2 | 15 |

| homogeneity of surface | 0.69 | 5.23 | 0.00 | 9.22 | 1.03 | 2 | 15 |

| global odour intensity | 0.74 | 5.02 | 0.62 | 6.25 | 1.69 | 2 | 15 |

| sweet odour intensity | 0.68 | 4.86 | 0.53 | 5.85 | 1.52 | 2 | 15 |

| sour odour intensity | 0.56 | 2.88 | 0.37 | 3.46 | 1.31 | 2 | 15 |

| floral odour intensity | 0.72 | 1.79 | 0.27 | 2.84 | 1.21 | 2 | 15 |

| hay odour intensity | 0.87 | 2.46 | 0.26 | 5.52 | 1.21 | 2 | 15 |

| global taste intensity | 0.49 | 3.17 | 0.27 | 3.76 | 1.21 | 2 | 15 |

| sweet taste intensity | 0.92 | 2.39 | 0.89 | 2.81 | 3.16 | 2 | 15 |

| sour taste intensity | 0.48 | 18.2 | −0.06 | 26.65 | 1.00 | 2 | 15 |

| floral taste intensity | 0.58 | 1.00 | 0.06 | 1.52 | 1.07 | 2 | 15 |

| hay taste intensity | 0.78 | 2.02 | 0.69 | 2.39 | 1.86 | 2 | 15 |

| off-taste intensity | 0.62 | 12.87 | 0.38 | 16.55 | 1.31 | 2 | 15 |

| aftertaste intensity | 0.67 | 0.08 | 0.49 | 0.09 | 1.45 | 2 | 15 |

| hardness | 0.54 | 2.31 | 0.32 | 2.81 | 1.25 | 2 | 15 |

| cohesiveness | 0.61 | 16.33 | 0.41 | 20.12 | 1.34 | 2 | 15 |

| mouthcoating | 0.97 | 2.91 | 0.87 | 5.66 | 2.88 | 2 | 15 |

| L* | 0.68 | 6.38 | 0.5 | 8.25 | 1.46 | 2 | 15 |

| a* | 0.81 | 2.26 | 0.62 | 3.15 | 1.69 | 2 | 15 |

| b* | 0.76 | 7.84 | 0.61 | 9.92 | 1.65 | 2 | 15 |

| ∆C*ab | 0.79 | 6.45 | 0.67 | 8.14 | 1.79 | 2 | 15 |

| ∆hab | 0.62 | 9.04 | 0.41 | 11.14 | 1.35 | 2 | 15 |

| Predicted Variable | R2Tr | RMSEC | R2CV | RMSECV | RPD | Number of Latent Variables | Number of Observations |

|---|---|---|---|---|---|---|---|

| brightness | 0.68 | 14.91 | 0.22 | 22.88 | 1.14 | 5 | 46 |

| colour hue | 0.44 | 21.84 | 0.09 | 27.56 | 1.06 | 3 | 43 |

| homogeneity of surface | 0.73 | 4.87 | 0.54 | 6.26 | 1.49 | 4 | 50 |

| global odour intensity | 0.95 | 2.31 | 0.91 | 3.02 | 3.32 | 4 | 47 |

| sweet odour intensity | 0.76 | 4.39 | 0.58 | 5.83 | 1.55 | 4 | 45 |

| sour odour intensity | 0.78 | 1.92 | 0.57 | 2.67 | 1.54 | 5 | 49 |

| floral odour intensity | 0.66 | 1.97 | 0.16 | 3.05 | 1.11 | 5 | 47 |

| hay odour intensity | 0.54 | 4.75 | 0.16 | 6.37 | 1.11 | 4 | 45 |

| global taste intensity | 0.85 | 1.71 | 0.61 | 2.69 | 1.62 | 5 | 51 |

| sweet taste intensity | 0.88 | 2.96 | 0.77 | 4.11 | 2.10 | 4 | 44 |

| sour taste intensity | 0.65 | 14.47 | 0.43 | 18.4 | 1.34 | 4 | 51 |

| floral taste intensity | 0.90 | 0.46 | 0.85 | 0.57 | 2.61 | 4 | 44 |

| hay taste intensity | 0.98 | 0.55 | 0.97 | 0.69 | 5.94 | 4 | 44 |

| off-taste intensity | 0.88 | 6.96 | 0.68 | 10.88 | 1.80 | 5 | 49 |

| aftertaste intensity | 0.50 | 0.09 | 0.04 | 0.12 | 1.03 | 3 | 44 |

| hardness | 0.83 | 1.34 | 0.66 | 1.87 | 1.74 | 5 | 49 |

| cohesiveness | 0.59 | 16.76 | 0.21 | 22.94 | 1.14 | 4 | 45 |

| mouthcoating | 0.98 | 2.16 | 0.97 | 3.20 | 5.42 | 4 | 44 |

| L* | 0.62 | 6.46 | 0.00 | 10.27 | 1.01 | 5 | 46 |

| a* | 0.72 | 2.67 | 0.56 | 3.32 | 1.53 | 3 | 41 |

| b* | 0.77 | 7.57 | 0.44 | 11.73 | 1.35 | 5 | 46 |

| ∆C*ab | 0.72 | 7.64 | 0.46 | 10.47 | 1.37 | 3 | 45 |

| ∆hab | 0.67 | 7.62 | 0.14 | 12.00 | 1.09 | 5 | 46 |

| Predicted Variable | R2Tr | RMSEC | R2CV | RMSECV | RPD | Number of Latent Variables | Number of Observations |

|---|---|---|---|---|---|---|---|

| brightness | 0.99 | 2.14 | 0.96 | 4.61 | 5.06 | 5 | 70 |

| colour hue | 0.97 | 4.80 | 0.90 | 9.08 | 3.20 | 5 | 70 |

| homogeniety of surface | 0.99 | 0.77 | 0.98 | 1.40 | 6.67 | 5 | 70 |

| global odour intensity | 0.99 | 1.09 | 0.96 | 2.05 | 4.82 | 5 | 70 |

| sweet odour intensity | 0.98 | 1.21 | 0.94 | 2.13 | 3.99 | 5 | 70 |

| sour odour intensity | 0.98 | 0.66 | 0.94 | 1.07 | 4.09 | 5 | 70 |

| floral odour intensity | 0.97 | 0.58 | 0.91 | 1.02 | 3.34 | 5 | 70 |

| hay odour intensity | 0.97 | 1.15 | 0.91 | 2.03 | 3.42 | 5 | 70 |

| global taste intensity | 0.99 | 0.46 | 0.96 | 0.90 | 4.95 | 5 | 70 |

| sweet taste intensity | 0.99 | 0.87 | 0.96 | 1.69 | 5.12 | 5 | 70 |

| sour taste intensity | 0.99 | 2.45 | 0.97 | 4.41 | 5.65 | 5 | 70 |

| floral taste intensity | 0.99 | 0.14 | 0.97 | 0.24 | 6.25 | 4 | 70 |

| hay taste intensity | 0.99 | 0.47 | 0.96 | 0.88 | 4.92 | 5 | 70 |

| off-taste intensity | 0.98 | 2.96 | 0.93 | 5.62 | 3.73 | 5 | 70 |

| aftertaste intensity | 0.80 | 0.06 | 0.55 | 0.09 | 1.49 | 3 | 70 |

| hardness | 0.98 | 0.51 | 0.92 | 0.94 | 3.61 | 5 | 70 |

| cohesiveness | 0.97 | 4.87 | 0.89 | 8.72 | 2.98 | 5 | 70 |

| mouthcoating | 0.99 | 0.81 | 0.99 | 1.43 | 12.10 | 5 | 70 |

| L* | 0.96 | 2.14 | 0.88 | 3.85 | 2.89 | 5 | 70 |

| a* | 0.97 | 0.91 | 0.90 | 1.57 | 3.27 | 5 | 70 |

| b* | 0.98 | 2.41 | 0.91 | 4.63 | 3.44 | 5 | 70 |

| ∆C*ab | 0.98 | 1.99 | 0.92 | 3.91 | 3.64 | 5 | 70 |

| ∆hab | 0.96 | 2.77 | 0.88 | 4.92 | 2.93 | 5 | 70 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sipos, L.; Végh, R.; Bodor, Z.; Zaukuu, J.-L.Z.; Hitka, G.; Bázár, G.; Kovacs, Z. Classification of Bee Pollen and Prediction of Sensory and Colorimetric Attributes—A Sensometric Fusion Approach by e-Nose, e-Tongue and NIR. Sensors 2020, 20, 6768. https://doi.org/10.3390/s20236768

Sipos L, Végh R, Bodor Z, Zaukuu J-LZ, Hitka G, Bázár G, Kovacs Z. Classification of Bee Pollen and Prediction of Sensory and Colorimetric Attributes—A Sensometric Fusion Approach by e-Nose, e-Tongue and NIR. Sensors. 2020; 20(23):6768. https://doi.org/10.3390/s20236768

Chicago/Turabian StyleSipos, László, Rita Végh, Zsanett Bodor, John-Lewis Zinia Zaukuu, Géza Hitka, György Bázár, and Zoltan Kovacs. 2020. "Classification of Bee Pollen and Prediction of Sensory and Colorimetric Attributes—A Sensometric Fusion Approach by e-Nose, e-Tongue and NIR" Sensors 20, no. 23: 6768. https://doi.org/10.3390/s20236768

APA StyleSipos, L., Végh, R., Bodor, Z., Zaukuu, J.-L. Z., Hitka, G., Bázár, G., & Kovacs, Z. (2020). Classification of Bee Pollen and Prediction of Sensory and Colorimetric Attributes—A Sensometric Fusion Approach by e-Nose, e-Tongue and NIR. Sensors, 20(23), 6768. https://doi.org/10.3390/s20236768