1. Introduction

The most critical risk factor for food quality and safety during the cold chain stages is the temperature deviation from the maximum allowed limits. Therefore, it is necessary to continuously monitor and record the temperature, starting from the production process and continuing to the distribution until the end consumer. The term cold chain refers to the equipment, procedures, and information management used for food protection.

According to article 5 of the European Commission regulation 852/2004 [

1], all health interest companies must keep a temperature file for documenting the temperature in all stages of their operation. According to article 2 of the European Commission regulation 37/2005 [

2], all-temperature measurement devices must fully comply with the EN12830 standard, which sets two basic specifications for temperature sensors. The first specification defines the maximum acceptable measurement error, i.e., the maximum deviation of ±1.0 °C from the actual value. The second specification assumes that the area range for each sensor in which it can take measurements with an acceptable variation is greater or equal to 50 °C.

The experimental part of this work is based on the DS18B20 temperature sensor. This sensor is widely popular, due to its low cost, support of the 1-wire protocol, and good precision over a wide range of temperatures (ranging from −55 °C to 125 °C). The 1-wire serial protocol provides a convenient way to add multiple sensors in a single data line where the master device activates and controls the communication with one or more slave devices [

3]. According to the manufacturer’s specifications, the measurement error is determined to be within ±0.5 °C in the range of −10 °C to +85 °C, which increases to ±2.0 °C for the rest of the temperature range [

4]. The DS18B20 digital sensors are prevalent, due to their low cost and their ability to communicate via the 1-wire communication protocol. These two characteristics created the conditions for the design and implementation of significantly more economical temperature monitoring and recording systems. Each microcontroller can connect with multiple sensors and simultaneously monitor an equal number of points [

4].

In combination with their wide operation range, the above factors have contributed to their rapid implementation of many applications. A significant drawback lies in their usage in temperature monitoring and recording systems intended for the European common market (ECM), due to legal and regulatory requirements restrictions. According to the current regulatory framework, the temperature monitoring devices for refrigerators and freezers must comply with the following EN12830 standard conditions:

Based on the manufacturer’s specifications, the DS18B20 sensor does not satisfy the EN12830 standard requirement, since the measurement uncertainty between −22 °C and −10 °C increases from ±0.5 °C to ±2.0 °C.

In this work, the proposed technique is based on applying Simple Linear Regression on a DS18B20 (SLR-DS18B20) sensor system, with the goal to improve the DS18B20 digital temperature sensor’s accuracy. SLR-DS18B20 can correct the nonlinear response of the DS18B20 digital temperature sensor using a regression for temperatures below −10 °C to satisfy the EN12830 standard requirements. The proposed technique will develop the systems for temperature monitoring and recording based on the DS18B20 temperature sensor for commercial use inside the European Union (EU).

Several existing methods use linear regression (LR) to calibrate the DS18B20 sensors. Agrimson et al. [

5] developed a calibration protocol for the DS18B20 digital temperature sensors used during thermal wake boom experiments. This method utilized a two-point technique to correct each sensor for slope and offset errors. It also used a national institute of standards and technology (NIST) certified thermocouple as standard for the temperature. Hafiz et al. [

6] created a control system for receiving real-time height and temperature data regarding crude palm oil (CPO) inside a storage tank. Koestoer et al. [

7] proposed a calibration method for the DS18B20 temperature sensor based on Arduino Uno and linear regression. Finally, Chamberlin [

8] also used linear regression to calibrate the temperature measurement network based on DS18B20 sensors. Although the above methods use linear regression to calibrate the DS18B20 sensors, they do not conform with the EN12830 standard requirements. The above calibration techniques utilize different temperature ranges than the −22 °C to −10 °C range of the EN12830 standard. This study aims to correct the nonlinear response using linear regression for temperatures below −10 °C to satisfy the EN12830 standard requirements.

A significant number of existing works are trying to improve fiber-optics sensors (which include temperature monitoring amongst their measured data) using various methods. The algorithm proposed by Sun et al. [

9] approaches the temperature accuracy problem caused by the Rayleigh noise in optic fiber Raman distributed temperature sensor systems. Lee et al. [

10] proposed Gaussian line fitting for improving the accuracy of spectrally distorted Bragg grating sensors. He et al. [

11] utilized a signal processing method for reducing the measurement error in a Brillouin distributed optical fiber sensing system. Lalam et al. [

12] used a signal-to-noise ratio enhancement in a Brillouin optical time-domain reflectometry system. Soto et al. [

13] proposed optical pulse coding as a signal-to-noise ratio improvement, allowing the acquisition of accurate Brillouin intensity and frequency shift measurements at low peak power levels. This is a cost-effective method that avoids high peak power levels utilization. Park and Song [

14] designed a fiber Bragg grating (FBG) sensor system having 15 FBGs in its sensor array for distributed temperature monitoring in electrical power systems. In this system, the calculation of the FBG wavelengths took place using interpolation in the temporal Fabry-Perot ITU filter (FPIF) peaks, with the purpose of minimizing the effect of nonlinear wavelength scanning. Loranger et al. [

15] utilized the frequency domain Rayleigh scatter to improve the signal strength and the sensitivity in distributed temperature and strain sensing (DTSS). Jin et al. [

16] used a calibration method in a distributed optical fiber Raman temperature sensor system for dealing with the measurement error caused by detector nonlinearities. Yan et al. [

17] proposed a tunnel fire detection method that utilizes an optical dynamic difference compensation algorithm and visual localization technology for increasing the temperature measurement accuracy. Laarossi et al. [

18] studied a high temperature distributed optical fiber sensor based on Raman optical time domain with optical fibers having different coatings. This study aimed to determine the most suitable optical fiber for use in an industrial environment with high temperatures according to distributed temperature sensor measurements. Pan et al. [

19] proposed an ensemble empirical mode decomposition denoising algorithm for Raman-based distributed temperature sensors. This approach can enhance the signal to noise ratio without changing spatial resolution. The above methods are focused on improving the accuracy of fiber optic sensors and cannot apply to non-fiber optic-based sensors like the DS18B20 temperature sensor.

Other sensor types improvements include the work from Marinov et al. [

20], which investigated the possibilities of improving the accuracy of non-dispersive infrared (NDIR) sensors used in ventilation systems for CO

2 detection. This research aimed to examine and evaluate the impact of these approaches regarding the accuracy improvement of NDIR CO

2 sensors. This investigation focused on NDIR sensors without taking into consideration non-NDIR sensors.

A significant number of researchers designed new and novel temperature sensor types. Tang et al. [

21] proposed a smart complementary metal-oxide-semiconductor (CMOS) temperature sensor having a digital-assisted readout solution. The digital-assisted readout solution introduces the advantages of increasing the circuit’s compatibility, while achieving high accuracy. Amador et al. [

22] utilized a compensation circuit for the design of a Celsius temperature sensor with a purpose to increase its accuracy. Chen et al. [

23] used an all-digital linearity enhancement for improving the accuracy of the CMOS smart temperature sensor. Finally, Chen et al. [

24] presented a CMOS time-domain smart temperature sensor having one homogeneous delay line and curvature compensation to increase its accuracy. Tan et al. [

25] designed and implemented an entirely passive radio-frequency identification (RFID) wireless sensor. This sensor utilizes a power-efficient CMOS circuitry and can achieve on-chip temperature sensing using time-domain signal processing. Heidari et al. [

26] proposed a CMOS-based bipolar junction transistor (BJT), optimized for noise-power performance. Wang et al. [

27] designed a CMOS-based temperature sensor having thermistor linear calibration and equipped with a circuit for automatic temperature range selection. Shan et al. [

28] developed a CMOS-based temperature sensor frontend for thermal monitoring equipped with a dual-slope analog to digital converter (DSADC). Pan et al. [

29] designed a high-resolution CMOS temperature sensor for MEMS/quartz frequency references’ temperature compensation. Saffari et al. [

30] designed a radio frequency (RF) powered temperature sensor having a non-intermittent operation. Cao et al. [

31] designed a physical unclonable function (PUF) based temperature sensor for secure remote temperature sensing environments. Li et al. [

32] designed a microprocessor-based system-on-chip (SoC) capable of transforming static random-access memory (SRAM) in the instruction cache to an ambient temperature sensor and a PUF. Although the above sensors provide accurate temperature measurements, they are not low-cost solutions, since they are new sensor types and are not improving the accuracy of already existing low-cost commercial sensors.

The paper structure contains seven main sections (Introduction, Simple Linear Regression, The SLR-DS18B20 Sensor, Experimental Procedure, Simulation Results, Discussion, and Conclusion). The Introduction section contains the description and motivation behind the problem of increasing the DS18B20 temperature sensor’s accuracy to conform with the EN12830 standard, followed by a literature review of other existing methods. The Simple Linear Regression section contains a detailed description of the simple linear regression (SLR) algorithm used to calibrate the DS18B20 temperature sensor. The SLR-DS18B20 sensor architecture section contains a thorough analysis of the proposed system. The Experimental Procedure section describes the process of obtaining the temperature measurements and the parameters that affect measurement accuracy. The Simulation Results section compares the proposed method with a sensor complying with the EN12830 standard. Finally, the last two sections contain the discussion and conclusion of the proposed system.

2. Simple Linear Regression

SLR describes the relationship between a dependent variable and an independent variable using a linear model [

33]. A simple linear regression model contains one independent variable

for

subjects. This variable has a linear relationship to the dependent variable

and the regression parameters, as seen in the following formula [

34]:

In this equation,

denotes the

y-axis intercept,

is the slope, and

is a random error term. The error term

is expected to be uncorrelated. The latter’s mean is expected to equal 0, while having a constant variance. Additionally, the SLR algorithm’s efficiency increases when the errors follow the normal distribution [

34].

The least-squares method is one of the most commonly used methods for calculating the parameters (i.e., intercept and slope), which define the line that fits the data and can predict

according to

. Its goal is to find the proper regression parameters which minimize the sum of squared residuals, where value

is predicted according to the following linear equation:

In this equation,

is the independent variable,

denotes the intercept, and

is the slope [

34,

35,

36]. The slope

is calculated according to Equation (3)

while the intercept is calculated according to Equation (4).

The mathematical proof for the calculation of

and

parameters’ values can be seen below. It is based in the following sum of squares error formula where

is the actual value.

Using Equation (5), the following calculation can be done.

The overbar denotes the average, while

denotes the total number of data. The sum of squares error has been split into a sum of three terms that will be minimized. It can be seen that the first term contains both parameters, while the second term contains parameter

Moreover, both terms are squared, and they cannot have a value lower than zero, while the third term contains a function of the data and not any parameters. In order to minimize the equation

the first two terms must be set to zero. The first term takes the form:

and defines the slope as seen in formula (3). The second term takes the form:

0

and defines the intercept

, as seen in Formula (4) [

34,

35,

36,

37].

3. The SLR-DS18B20 System Architecture

The proposed SLR-DS18B20 sensor system utilizes the Raspberry Pi Zero W microcontroller, which connects to a series of DS18B20 sensors using the 1-wire communication protocol.

Figure 1 shows the system’s architecture.

The system connects a series of DS18B20 sensors to the Raspberry Pi Zero W microcontroller exploiting 3 of the microcontroller’s pins. The Raspbian operating system that operates on the Raspberry Pi Zero W is implemented with a 1-wire protocol driver for the microcontroller to be able to communicate with the other peripheral devices. The communication is achieved through pin 7 of the microcontroller, while pin 17 provides the device with the appropriate 3.3 voltage, and pin 25 grounds the circuit [

38,

39].

The reason that led to this choice, compared to other low-cost microcontrollers (Arduino, Esp8266, Esp32, etc.), is that these simple, low-power computers can only run one program at a time. These alternative microcontrollers are designed with ease-of-use in mind, and they are widely utilized in various automation tasks. In addition, Raspberry Pi Zero W is a general-purpose, Linux-based computer system that can run multiple programs simultaneously; thus, providing more features than conventional alternative microcontrollers. Conventional microcontrollers can communicate with personal computers (PCs) via the universal serial bus (USB) port to provide the user with access to their available features, but their use is limited to simple repetitive tasks (e.g., reading the value of various sensors) [

38,

39]. To be more precise, in cases where multi-tasking or more complex calculations are needed, the utilization of a microcontroller equipped with an operating system with the ability to distribute available resources is necessary. As a result, a more advanced microcontroller like the Raspberry Pi Zero W is the ideal solution for embedded systems or projects requiring more interactivity and processing power. Note that having the abilities of a fully functional computer in a small size offers features that do not exist in conventional microcontrollers [

38,

39].

Due to a large amount of output data from sampling, available storage space is required. As an indication of the data amount that needs to be stored, note that the experimental part required collecting 650 temperature values from 10 DS18B20 sensors for sequential experiments. The Raspberry Pi Zero W holds a secure digital (SD) memory card and can store all the output data. On the other hand, alternative conventional microcontrollers can maintain only one measurement each time with its value replaced from the next measurement [

38,

39]

The Raspberry Pi Zero W has a built-in wireless network adapter and can provide network capabilities. This feature is significant for the current project because it allows for data exchange between Raspberry Pi Zero W and the computer, which will perform the statistical processing of the measured values [

38,

39].

The absence of keyboard, mouse, and screen support does not allow for user interaction with conventional microcontrollers’ applications. Moreover, Raspberry Pi Zero W supports connection with keyboard and mouse via USB or wireless Bluetooth communication protocol. It also holds a graphics processor unit (GPU) equipped with a high-definition multimedia interface (HDMI) output, providing the ability to connect to a screen. All of the above features offer significantly increased user interaction [

38,

39]. The Raspberry Pi Zero W costs 10

$ and is 5

$ more expensive than Raspberry Pi Zero, but it offers built-in wireless connectivity that provides ease-of-use for transferring the data between the device and a PC. Moreover, the cheapest version would require the purchase of an adapter for transferring the data, which would exceed the purchase cost of the Raspberry Pi Zero W. A tradeoff regarding the selected microcontroller is its size (65.0 mm × 31.0 mm), which is slightly larger than alternative microcontrollers (e.g., Arduino Nano with size 45 mm × 18 mm [

40]) [

41].

Conventional microprocessors cannot download the current time and date as they do not have a complete real-time clock (RTC) chip. The absence of RTC makes them unsuitable for this project, since they must record each sample’s time and date. One significant limitation of the Raspberry Pi Zero W is that all software implementation must be done in a Linux environment, which requires substantial knowledge of this operating system.

5. Experimental Measurements and Simulation Results

This section presents the analysis of the values taken from each sensor. The purpose of this analysis is to determine if the application of linear regression results in the reduction of the relative error, which will make the DS18B20 sensor comply with the EN12830 standard. The measurement process has been split into two parts, with each part corresponding to the following temperature ranges:

Ten DS18B20 temperature sensors are employed at each temperature area, along with a single high accuracy reference sensor. The sampling procedure, regarding the DS18B20 sensors, used five samples for each measured temperature. The reference sensor used 50 samples for each measured temperature with the purpose of having the same number of entries for both sensor types. The latter configuration’s goal is to evaluate the repeatability and accuracy of the low-cost sensors. The measurements regarding the first part contained 250 entries, while for the second part, the measurements contained 400 entries, forming a dataset of 650 input vectors in total. The reason for using ten DS18B20 temperature sensors instead of one was because the accuracy of each sensor varies slightly, due to the manufacturing process. It was desirable to consider this variability when the dataset was created with the purpose of making the model as accurate as possible.

The sensor accuracy for each temperature measurement was estimated by calculating the absolute error (AE) before and after applying linear regression in comparison to the actual values taken from the reference sensor. The calculation of the AE took place under Formula (7). There,

is the value taken from the reference sensor, and

denotes the value taken from the DS18B20 sensor.

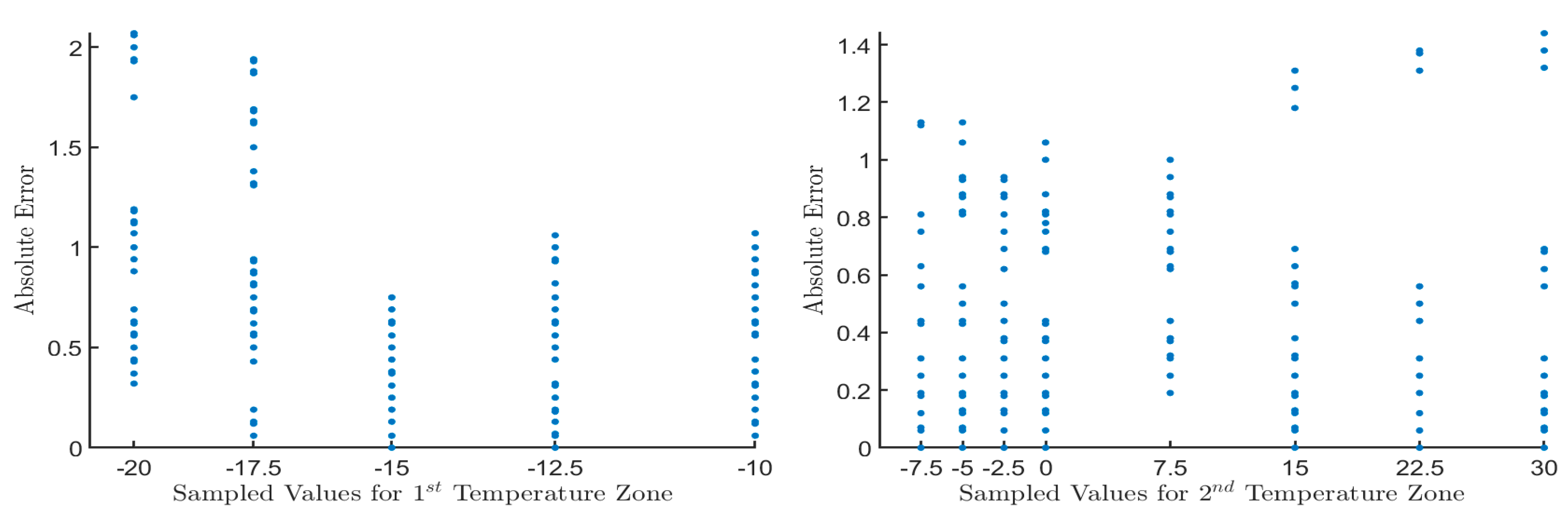

The AE regarding the sampled values taken from the DS18B20 sensor for both temperature zones before applying linear regression is shown in

Figure 3. It is observed there that in the first temperature area, the AE ranged from 0 °C to 2.07 °C, while for the second temperature area, the AE ranged from 0 °C to 1.44 °C.

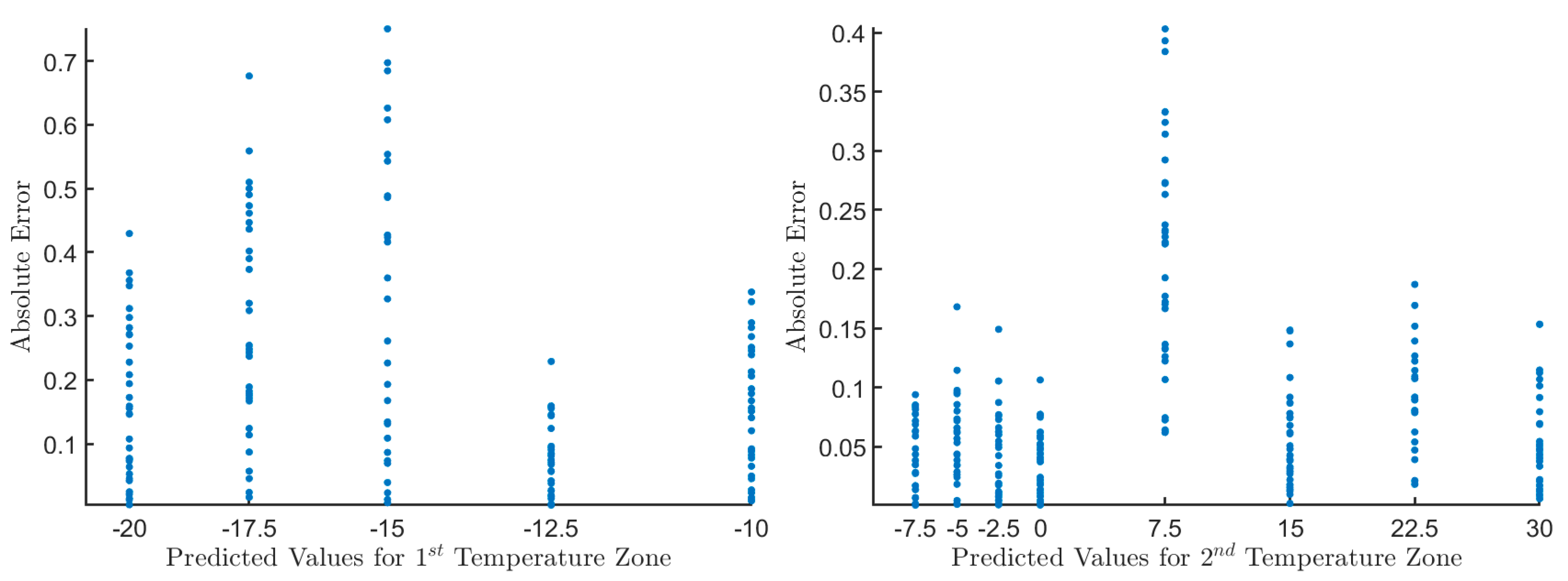

The AE regarding the predicted values taken from the DS18B20 sensor for both temperature zones after applying linear regression is shown in

Figure 4. It can be seen in

Figure 4 that in the first temperature area, the AE ranged from 0 °C to 0.75 °C, while for the second temperature area, the AE ranged from 0 °C to 0.4 °C. This outcome experimentally verifies that linear regression managed to improve the sensor’s accuracy and now can fully comply with the EN12830 standard.

The information in

Table 1 shows the mean absolute error (MAE) regarding the sampled and predicted measurements for both temperature zones. The MAE was calculated using Formula (7), where

is the number of entries,

is the actual value, and

is the predicted value.

This table shows that the linear regression method reduced the MAE by 69% in the first temperature zone and 82% in the second temperature zone. The reduction of the MAE enables the DS18B20 sensor to conform to the EN12830 standard.

The next step is to perform a statistical test to verify if the above error reductions are statistically significant. The statistical test involved creating 95% confidence intervals (Cis) before and after applying linear regression. Then, these Cis were checked for overlapping. The case where no overlaps between the two Cis exists can be understood as strong evidence that the results after applying linear regression are statistically significant [

46]. The equation which calculated the 95% CI could be seen below.

In this equation,

is the sample mean,

is the standard deviation of the sample,

is the sample size, and

is the standard error of the mean (SEM). The standard deviation was calculated based on the sampled and predicted coefficient of determination

values for each temperature zone.

In this formula, is the number of entries, Y is the reference value, is either the sampled or predicted values, and is the average of all reference values.

The average

for the actual and predicted values of the 1st temperature zone can be seen in

Figure 5. The

for the sample values was 0.949, which increased to 0.995 for the predicted values. Both Cis do not overlap, which can be understood as strong evidence that the results after applying linear regression are statistically significant.

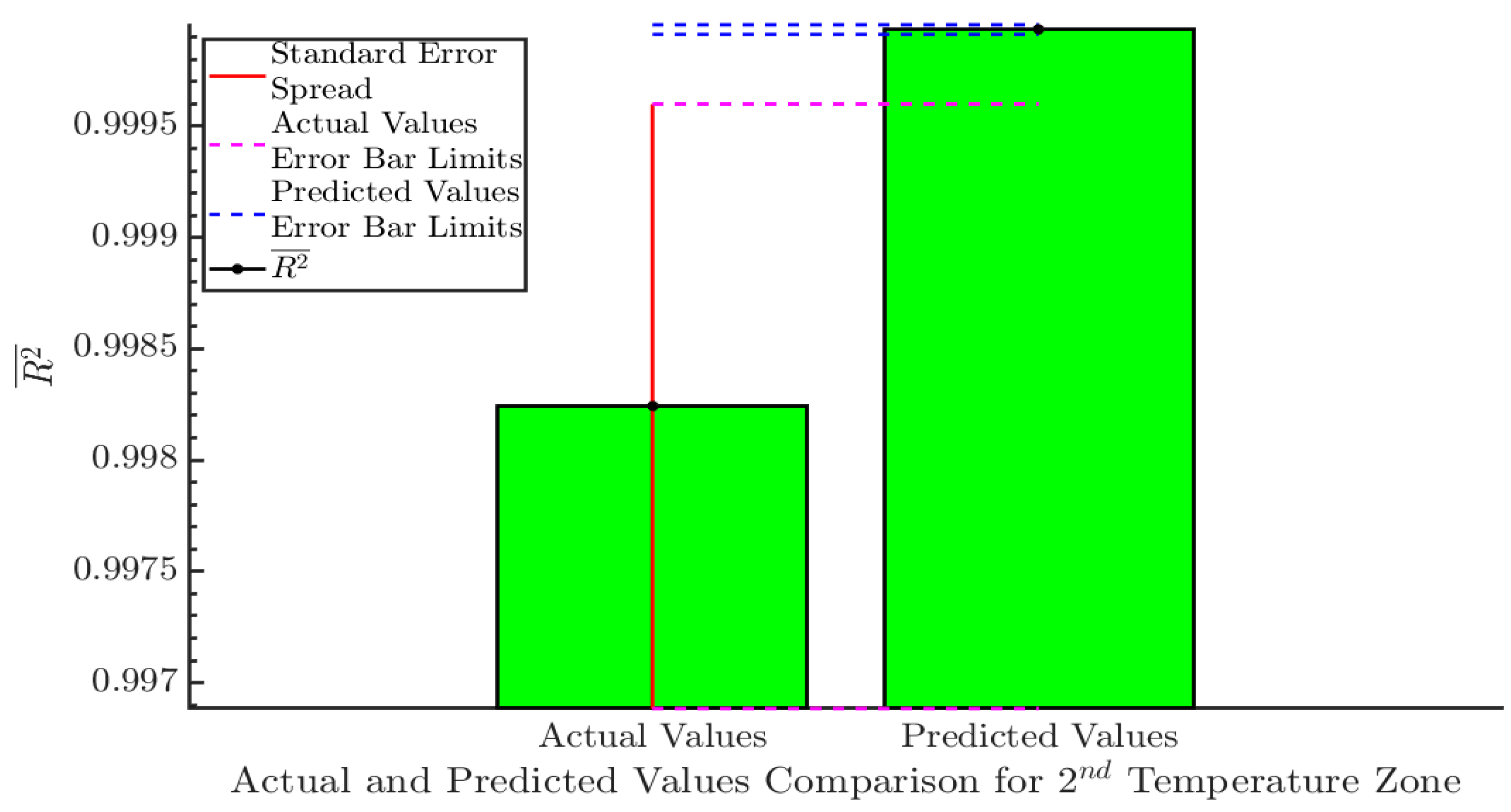

The average

for the actual and predicted values of the 2nd temperature zone can be seen in

Figure 6. The

for the sample values was 0.99824, which increased to 0.99994 for the predicted values. Both Cis do not overlap, which can be understood as strong evidence that the results after applying linear regression are statistically significant.

6. Comparative Study

The SLR has been tested against three existing machine learning techniques. These techniques are support vector machine (SVM) and two variations of the extreme learning machine (ELM) algorithm: Bidirectional extreme learning machine (B-ELM) and on-line sequential extreme learning machine (OS-ELM). SVM is a supervised learning algorithm created in 1963 by Vladimir N. Vapnik and Alexey Ya. Chervonenkis. The original SVM algorithm has been improved, since its creation in 1963, with the current standard incarnation being proposed by Cortes and Vapnik [

47]. The SVM algorithm constructs a separating hyperplane or a series of hyperplanes in a high or infinite-dimensional space for use in various tasks, including classification and regression [

48]. The ELM algorithm was created by Huang et al. [

49] and can train a single layer neural network (SLNN) very fast. Initially, it randomly chooses the hidden layer neurons’ weights and thresholds, and with the help of the Moore-Penrose pseudo-inverse, is able to calculate the output node weights. One characteristic of ELM is that it tends to reach a low training error with a small norm of output weights, which according to Bartlett’s theory [

50], leads to better generalization performance [

51]. The Bi-directional ELM (B-ELM) proposed by Yang et al. [

52] can reduce the number of hidden layer units by incrementally updating some hidden layer nodes during the network growth. OS-ELM proposed by Huang et al. [

53] is a modified version of the ELM algorithm, which can work with sequential data.

The experimental part includes comparing the proposed SLR-DS18B20 systems and three machine learning methods (SVM, B-ELM, and OS-ELM). The design of these experiments involved using 10-fold cross-validation to estimate the performance of SLR-DS18B20 on unseen data. The parameters used for each compared method can be seen in

Table 2.

The SVM method used linear and radial basis function (RBF) kernel types. B-ELM used sigmoid and sinusoid activation functions, while OS-ELM used sigmoid, sinusoid, and RBF activation functions. The ELM-based methods used random hidden weights and thresholds () taken from the uniform distribution, the number of hidden neurons was set to 100, and the experiments were repeated ten times.

As seen in the comparison results of

Table 3, the proposed SLR-DS18B20 method was able to achieve a lower mean square error (MSE) than the other compared methods (the lowest MSE value is shown in bold). The calculation of MSE is done according to the following formula.

In this formula, defines the number of folds, defines the number of validation patterns, defines the current pattern target network output value for the current fold and defines the current pattern network output value for the current fold.

7. Discussion

The proposed system can improve the DS18B20 digital temperature sensor’s accuracy to satisfy the EN12830 standard requirements. The accuracy improvement will create temperature monitoring and recording systems based on the low-cost DS18B20 temperature sensor for commercial use inside the EU.

As seen from the experimental results in

Section 5, the proposed method managed to get significantly lower

than the other compared methods, which, in most cases, was at least one order less. One exception was the SVM method, which produced a higher error than SLR-DS18B20, but it had the same order. The 0.0003505

of the proposed method was derived by averaging the MSE from all input test patterns for each fold. Then, the experiments regarding the ELM-based methods were repeated ten times with different values for the hidden layer weights and thresholds to avoid any bias, due to the randomization of the hidden units. The overall

involved averaging the

from all experiment runs. One typical value regarding the

formula is to set the number of folds to 10 (for relatively large datasets) or 5 (for small datasets).

The experimental procedure involved comparing the low-cost EN12830 temperature sensor with a high accuracy reference temperature sensor before and after applying linear regression. The experimental procedure followed a basic calibration principle where the temperature values obtained from the sensors had been compared with some known reference values. The experimental results in

Section 6 showed that the proposed linear regression calibration method could increase the DS18B20 sensor’s accuracy in two temperature zones to comply with the EN12830 standard requirements. The temperature zones are: (i) The refrigeration area, which must operate between 1 °C and 7 °C; and (ii) the freezer area, which must operate between −22 °C and −10 °C. These results were statistically significant since the 95% CIs from the actual and predicted values for both temperature zones did not overlap. In

Section 7, a comparative study of the proposed SLR-DS18B20 sensor system with three existing machine learning methods was conducted. The outcome from this comparison experimentally verified that the proposed SLR-DS18B20 system could provide a fast, low-cost solution for improving the accuracy of the DS18B20 temperature sensor because it was able to achieve a lower MSE than the other three alternative methods.