Cross-Correlation Algorithm-Based Optimization of Aliasing Signals for Inductive Debris Sensors

Abstract

1. Introduction

2. Model Analysis of Debris Aliasing Signal

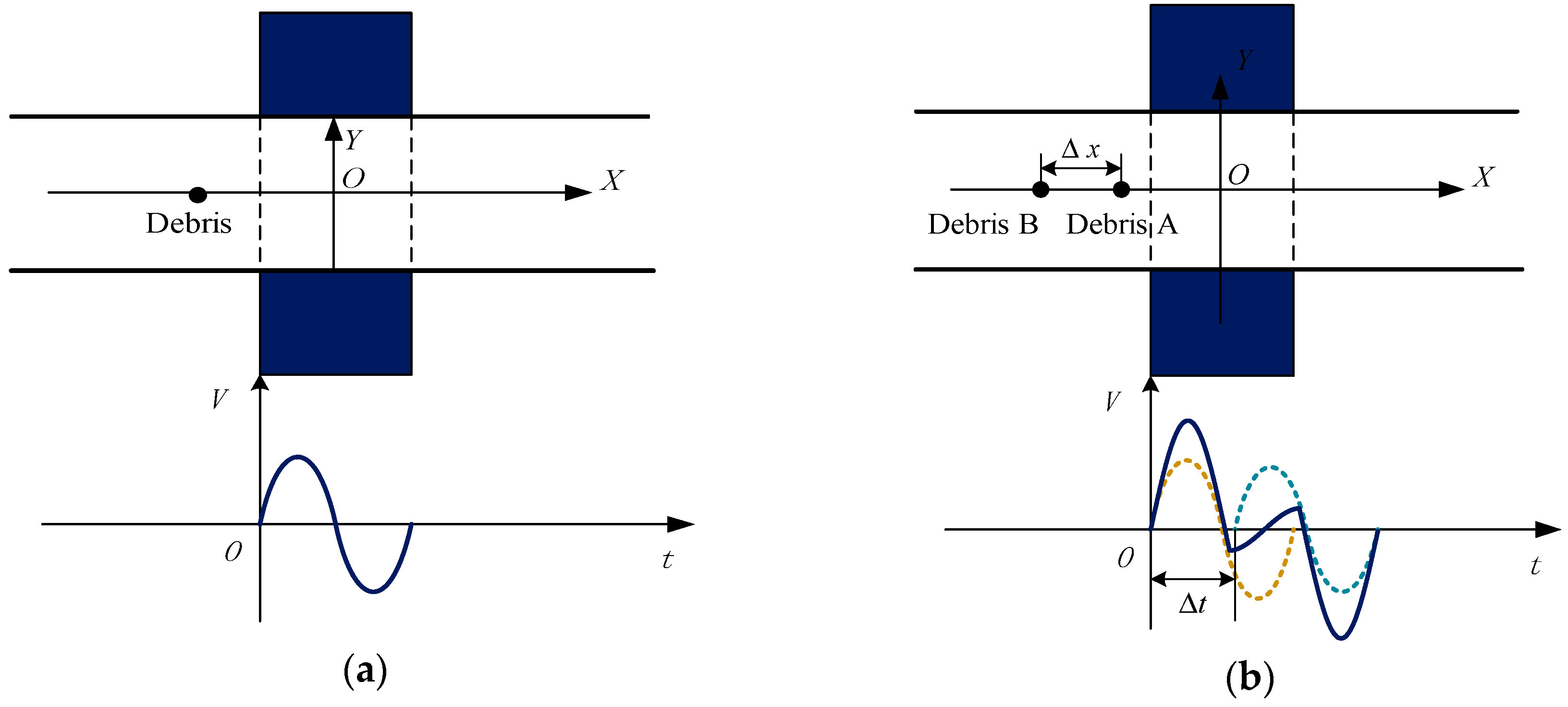

2.1. Aliasing Signal Model of Debris Aliasing Behavior

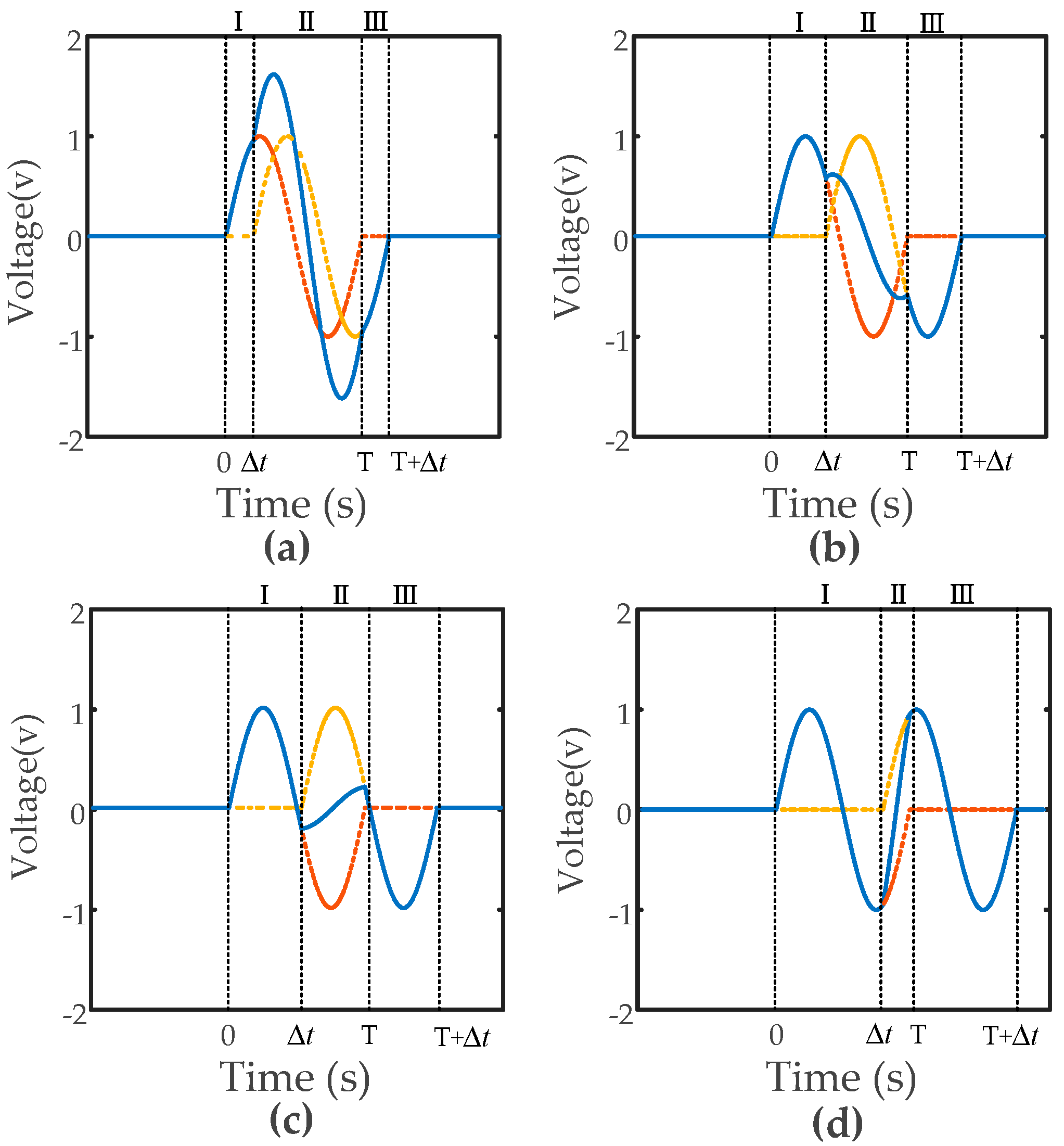

2.2. Analysis of the Aliasing Signal Model

- When

- When

- When

- When

3. Cross-Correlation Algorithm-Based Optimization

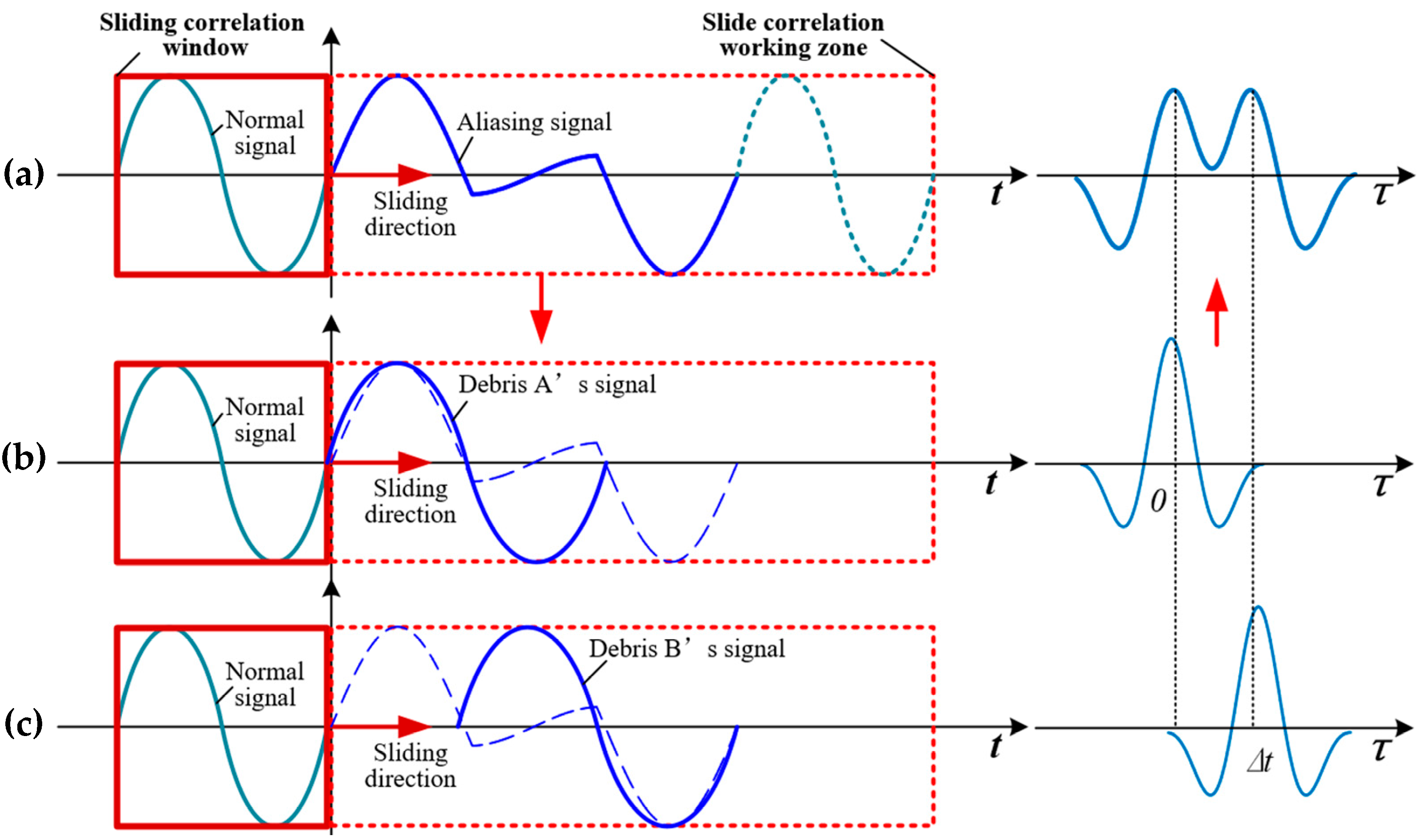

3.1. Cross-Correlation Analysis of Aliasing Signal

- When

- When

- When

- When

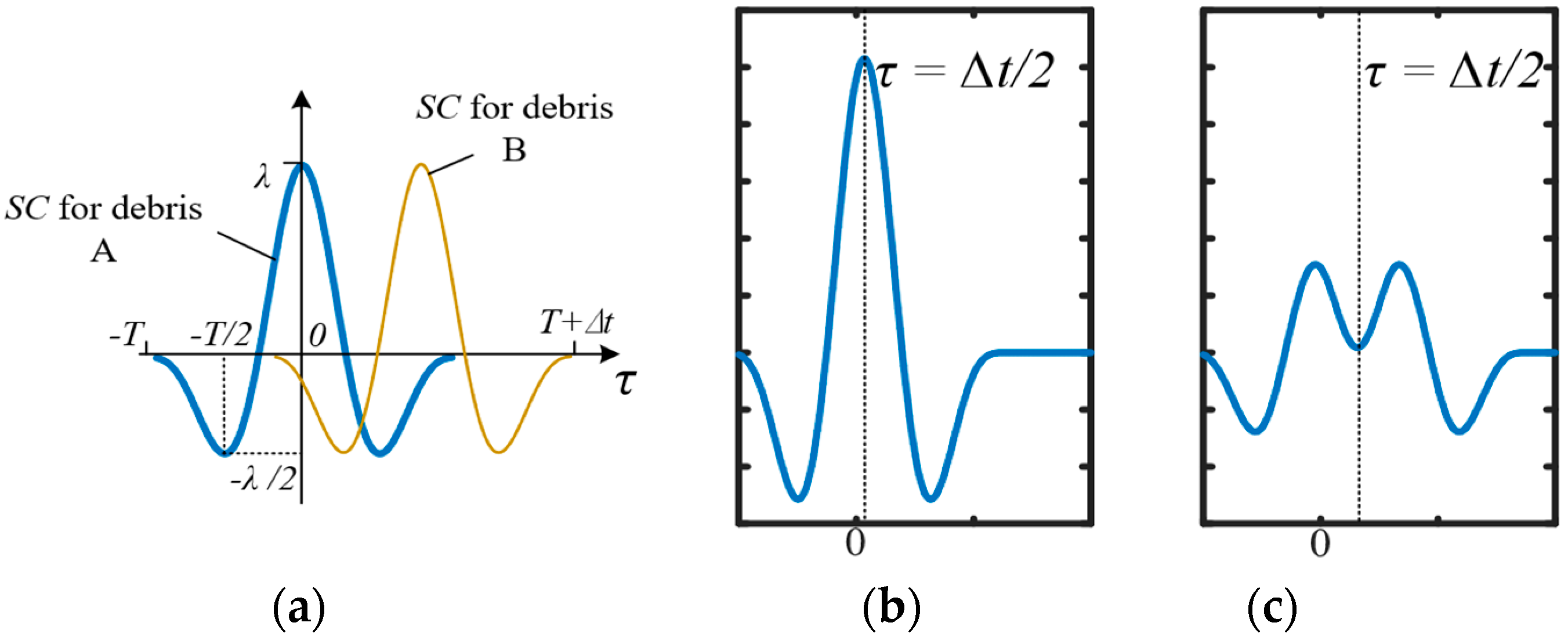

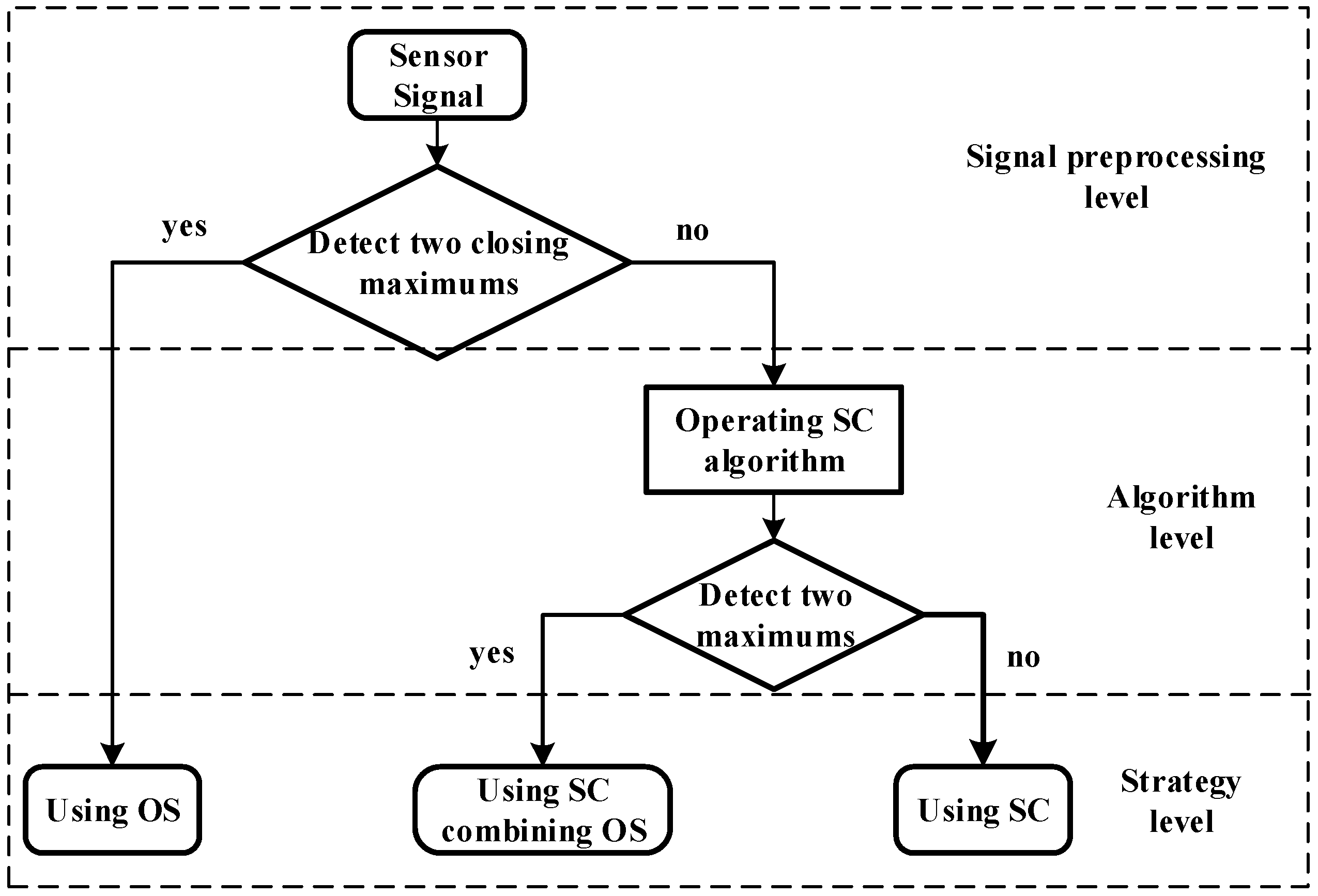

3.2. Optimization Strategy for Aliasing Signal Processing

4. Experiment Validation

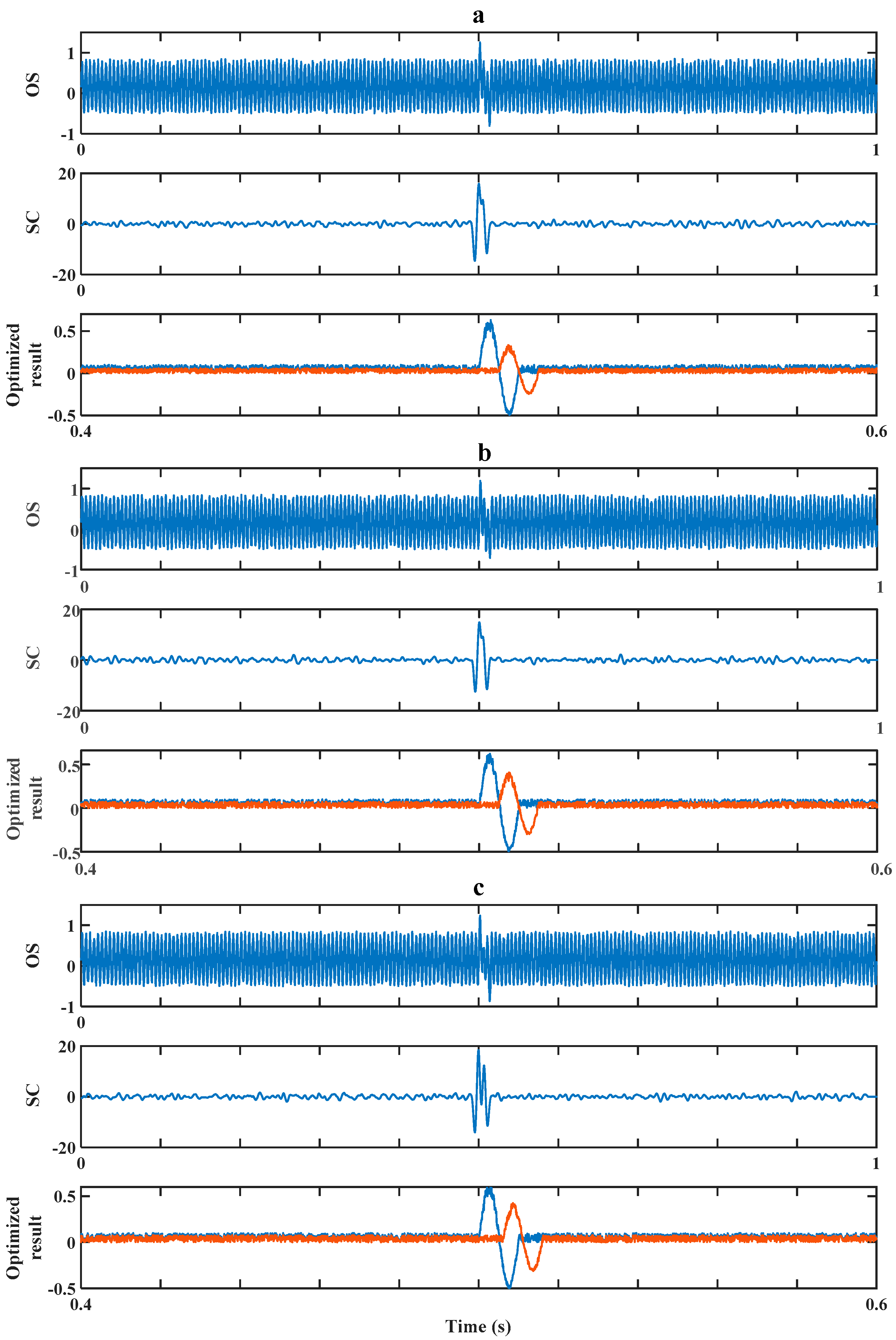

4.1. Simulation Experiment

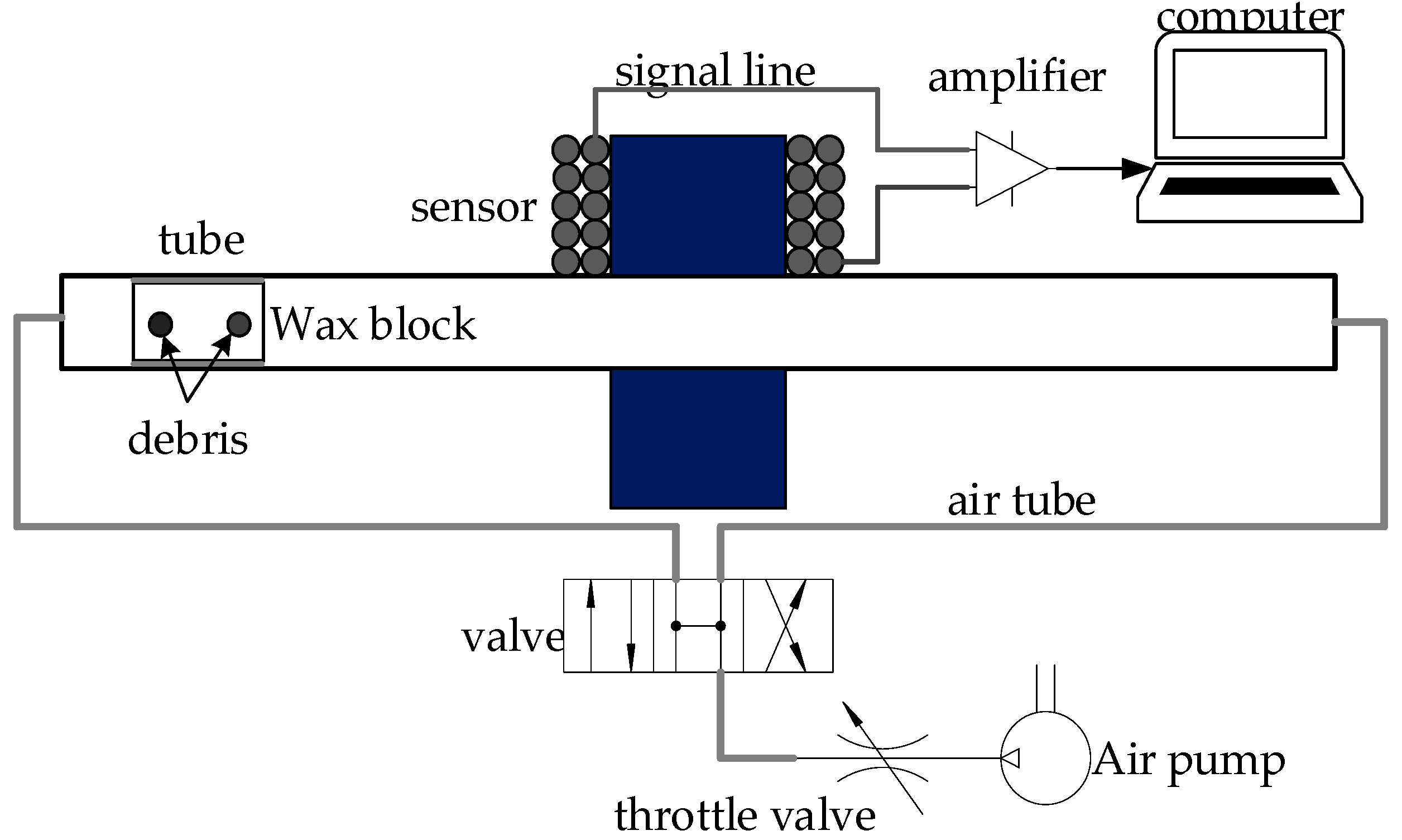

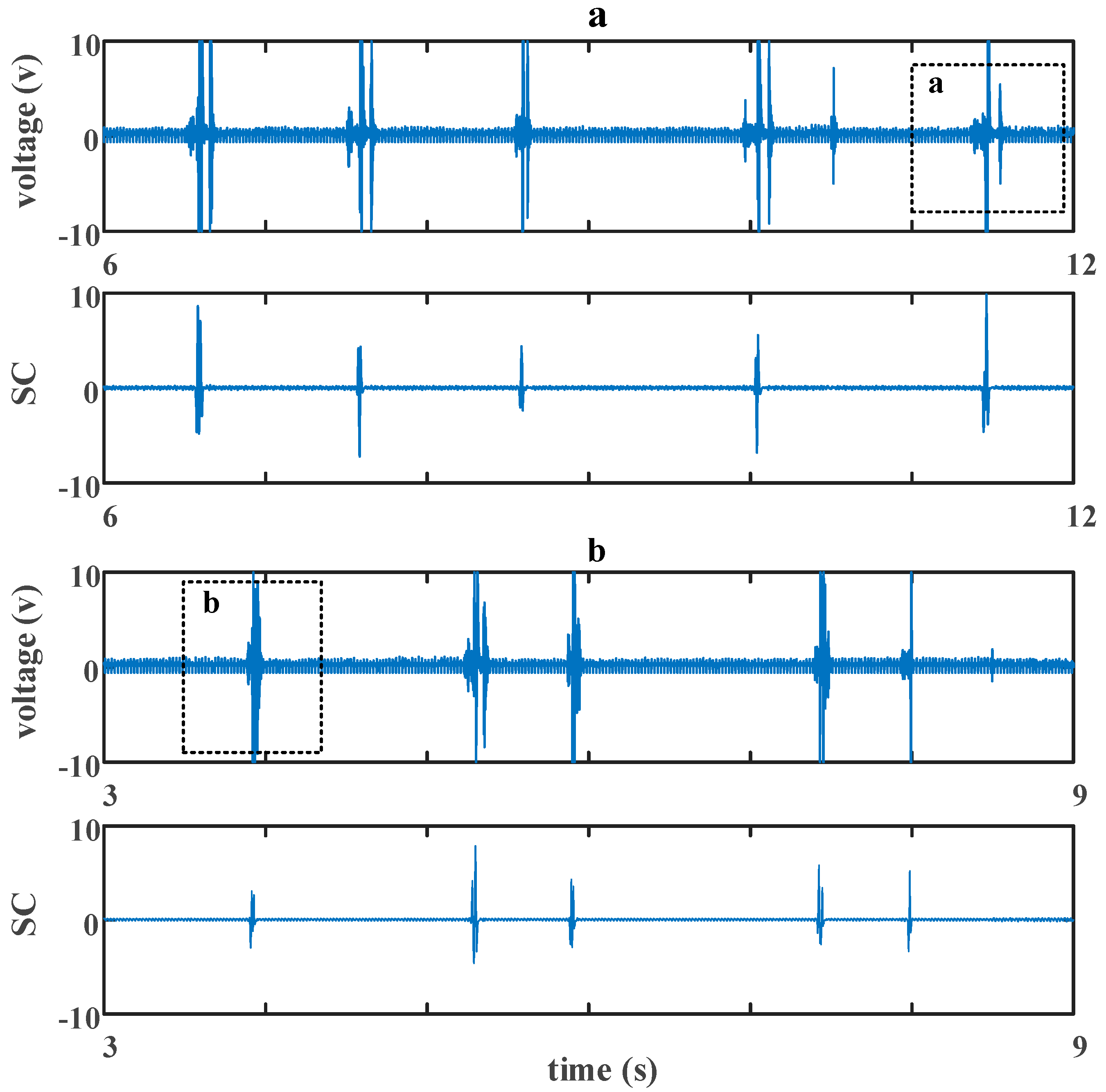

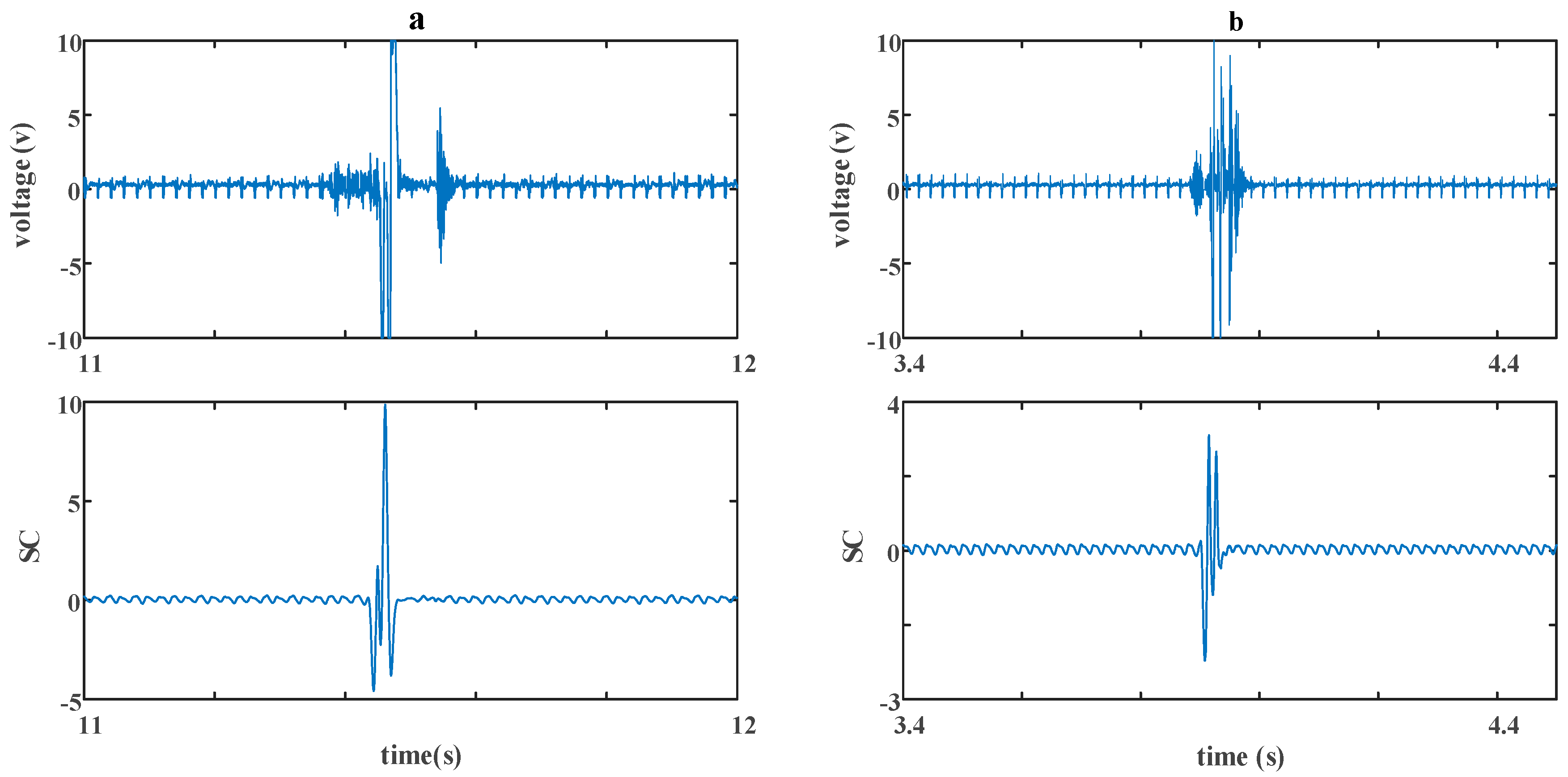

4.2. Wax Block Experiment

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Amiri, M.; Khonsari, M. On the Thermodynamics of Friction and Wear—A Review. Entropy 2010, 12, 1021–1049. [Google Scholar] [CrossRef]

- Wu, T.; Peng, Y.; Wu, H.; Zhang, X.; Wang, J. Full-life dynamic identification of wear state based on on-line wear debris image features. Meas. Sci. Technol. 2014, 42, 404–414. [Google Scholar] [CrossRef]

- Wang, X.; Lin, S.; Wang, S.; He, Z.; Zhang, C. Remaining useful life prediction based on the Wiener process for an aviation axial piston pump. Chin. J. Aeronaut. 2016, 29, 779–788. [Google Scholar] [CrossRef]

- Dwyer-Joyce, R.; Williams, J.A.; Roylance, B.J. Wear debris and associated wear phenomena-fundamental research and practice. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2000, 214, 79–105. [Google Scholar]

- Seifert, W.W.; Westcott, V.C. A method for the study of wear particles in lubricating oil. Wear 1972, 21, 27–42. [Google Scholar] [CrossRef]

- Zhu, X.; Zhong, C.; Zhe, J. Lubricating oil conditioning sensors for online machine health monitoring—A review. Tribol. Int. 2017, 109, 473–484. [Google Scholar] [CrossRef]

- Edmonds, J.; Resner, M.S.; Shkarlet, K. Detection of precursor wear debris in lubrication systems. In Proceedings of the 2000 IEEE Aerospace Proceedings, Big Sky, MT, USA, 25–25 March 2000; Volume 76, pp. 73–77. [Google Scholar]

- Tucker, J.E.; Reintjes, J.; Galie, T.R.; Schultz, A.; Lu, C.; Tankersley, L.L.; Sebok, T.; Holloway, C.; Howard, P.L. Lasernet fines optical wear debris monitor: A Navy shipboard evaluation of CBM enabling technology. In Proceedings of the 54th Meeting of the Society for Machinery Failure Prevention Technology, Virginia Beach, VA, USA, 1–4 May 2000. [Google Scholar]

- Centers, P.W.; Price, F.D. Real time simultaneous in-line wear and lubricant condition monitoring. Wear 1998, 123, 303–312. [Google Scholar] [CrossRef]

- Hong, W.; Wang, S.; Tomovic, M.M.; Liu, H.; Shi, J.; Wang, X. A Novel Indicator for Mechanical Failure and Life Prediction Based on Debris Monitoring. IEEE Trans. Reliab. 2017, 66, 161–169. [Google Scholar] [CrossRef]

- Kumar, P.; Hirani, H.; Agrawal, A.K.; Gachot, C. Online condition monitoring of misaligned meshing gears using wear debris and oil quality sensors. Ind. Lubr. Tribol. 2018, 70, 645–655. [Google Scholar] [CrossRef]

- Gorritxategi, E.; García-Arribas, A.; Aranzabe, A. Innovative on-Line Oil Sensor Technologies for the Condition Monitoring of Wind Turbines. Key Eng. Mater. 2015, 644, 53–56. [Google Scholar] [CrossRef]

- Hong, W.; Wang, S.; Tomovic, M.M.; Han, L.; Shi, J. Radial inductive debris detection sensor and performance analysis. Meas. Sci. Technol. 2013, 24, 125103. [Google Scholar] [CrossRef]

- Miller, J.L.; Kitaljevich, D. In-line oil debris monitor for aircraft engine condition assessment. In Proceedings of the 2000 IEEE Aerospace Proceedings, Big Sky, MT, USA, 25 March 2000; Volume 76, pp. 49–56. [Google Scholar]

- Kempster, R.W.; George, D.B. Detection and Discrimination between Ferromagnetic and Non-Ferromagnetic Conductive Particles in a Fluid. U.S. Patent 5,315,243, 24 May 1994. [Google Scholar]

- Chambers, K.W.; Arneson, M.C.; Waggoner, C.A. An on-line ferromagnetic wear debris sensor for machinery condition monitoring and failure detection. Wear 1988, 128, 325–337. [Google Scholar] [CrossRef]

- Hong, W.; Wang, S.; Tomovic, M.M.; Liu, H.; Wang, X. A new debris sensor based on dual excitation sources for online debris monitoring. Meas. Sci. Technol. 2015, 26, 095101. [Google Scholar] [CrossRef]

- Zhong, Z.; Wang, S.; Hong, W.; Tomovic, M. Aliasing signal separation of oil debris monitoring. In Proceedings of the 2016 IEEE 11th Conference on Industrial Electronics and Applications, Hefei, China, 5–7 June 2016; pp. 1682–1687. [Google Scholar]

- Li, T.; Wang, S.; Zio, E.; Shi, J.; Hong, W. Aliasing signal separation of superimposed abrasive debris based on degenerate unmixing estimation technique. Sensors 2018, 18, 866. [Google Scholar] [CrossRef] [PubMed]

- Bozchalooi, I.S.; Liang, M. In-line identification of oil debris signals: An adaptive subband filtering approach. Meas. Sci. Technol. 2010, 21, 015104. [Google Scholar] [CrossRef]

- Liu, H.; Wang, S.; Hong, W.; Zhang, C.; Wang, X.; Haokuo, L.; Shaoping, W.; Wei, H.; Chao, Z.; Xingjian, W. Design and experimental test of an on-line particle detection sensor based on symmetrical magnetic field. In Proceedings of the 2015 International Conference on Fluid Power and Mechatronics (FPM), Harbin, China, 4–6 August 2015; pp. 241–245. [Google Scholar] [CrossRef]

- Podobnik, B.; Stanley, H.E. Detrended Cross-Correlation Analysis: A New Method for Analyzing Two Non-stationary Time Series. Phys. Rev. Lett. 2008, 100, 084102. [Google Scholar] [CrossRef] [PubMed]

| Number of Detected Debris | RSO (Overall Size) | RSB (Debris B) | |

|---|---|---|---|

| 1 | ↓ | —— | |

| 2 | ↓ | ↓ | |

| 1 | 1/2 | 0 | |

| (T/2, 3T/4) | 2 | ↑ | ↑ |

| 2 | 1 | 1 |

| Number of Detected Debris | |||

|---|---|---|---|

| 1 | ↓ | —— | |

| 2 | ↑ | ↑ |

| Number of Detected Debris Particles | RS of Overall Size | RS of Debris B | Preferred | ||||

|---|---|---|---|---|---|---|---|

| OS | SC | ||||||

| I | 1 | 1 | > | - | - | SC | |

| II | 2 | 1 | < | >50% | - | OS | |

| III | 1 | 2 | < | - | >50% | SC and OS | |

| IV | 2 | 2 | < | 1 | <1 | OS | |

| Parameter | Value |

|---|---|

| Frequency of debris signal w | 100 Hz |

| Amplitude of inference | 0.5 |

| Amplifier of noise | 0.2 |

| Length of correlation T | 0.01 s |

| Sampling frequency | 10 kHz |

| Parameter | Value |

|---|---|

| Velocity of debris particle | 5 m/s |

| Size of particle | 200 μm |

| Amplifier magnification | 900 times |

| Space between two debris particles | 3 cm/6 cm |

| Sampling frequency | 10 kHz |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, X.; Sun, H.; Wang, S.; Huang, W. Cross-Correlation Algorithm-Based Optimization of Aliasing Signals for Inductive Debris Sensors. Sensors 2020, 20, 5949. https://doi.org/10.3390/s20205949

Wang X, Sun H, Wang S, Huang W. Cross-Correlation Algorithm-Based Optimization of Aliasing Signals for Inductive Debris Sensors. Sensors. 2020; 20(20):5949. https://doi.org/10.3390/s20205949

Chicago/Turabian StyleWang, Xingjian, Hanyu Sun, Shaoping Wang, and Wenhao Huang. 2020. "Cross-Correlation Algorithm-Based Optimization of Aliasing Signals for Inductive Debris Sensors" Sensors 20, no. 20: 5949. https://doi.org/10.3390/s20205949

APA StyleWang, X., Sun, H., Wang, S., & Huang, W. (2020). Cross-Correlation Algorithm-Based Optimization of Aliasing Signals for Inductive Debris Sensors. Sensors, 20(20), 5949. https://doi.org/10.3390/s20205949