Impact-Driven Energy Harvesting: Piezoelectric Versus Triboelectric Energy Harvesters

Abstract

:1. Introduction

2. Construction and Mechanism of the Test Bench

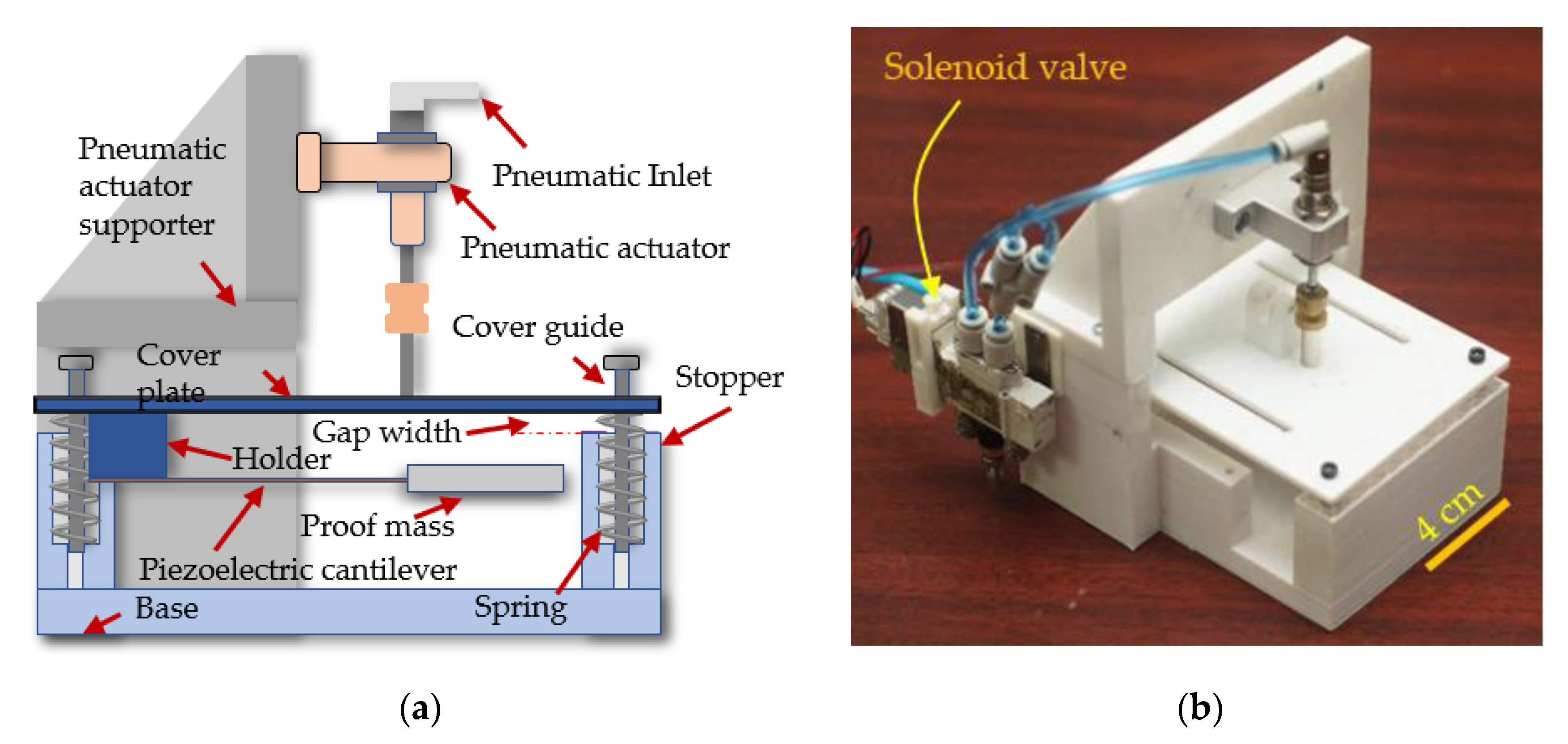

2.1. Piezoelectric Energy Harvester Test Bench

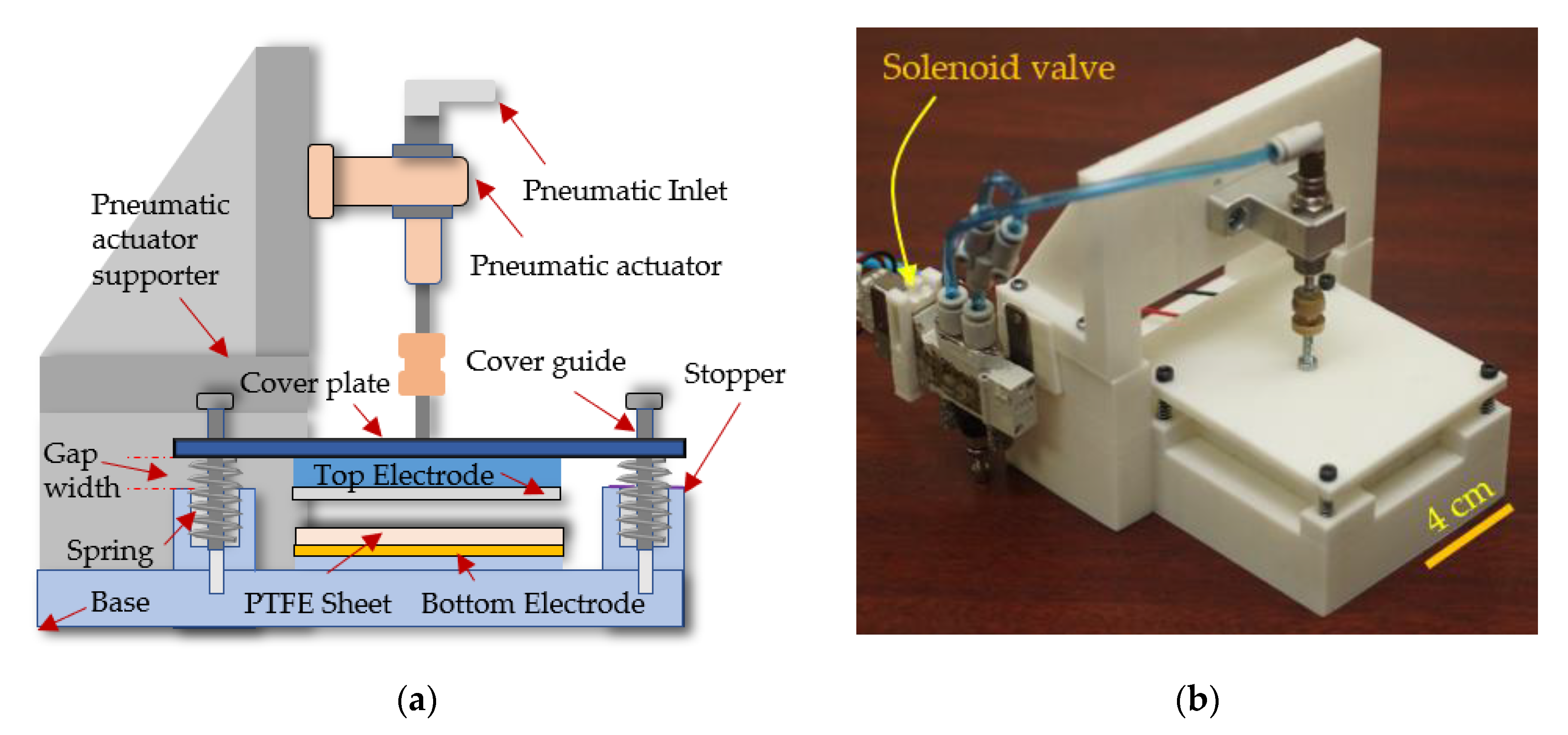

2.2. Triboelectric Energy Harvester Test Bench

3. Materials and Methods

3.1. Fabrication Materials

3.2. Experimental Set-up and Methods

- (1)

- Designing and fabricating test benches that used the same pneumatic actuator to apply a proper direct force to their cover plate and doing the same thing for the spring that pushed the cover plate away from the stopper. Images of actual PEH and TEH test benches are shown in Figure 1b and Figure 3b, respectively.

- (2)

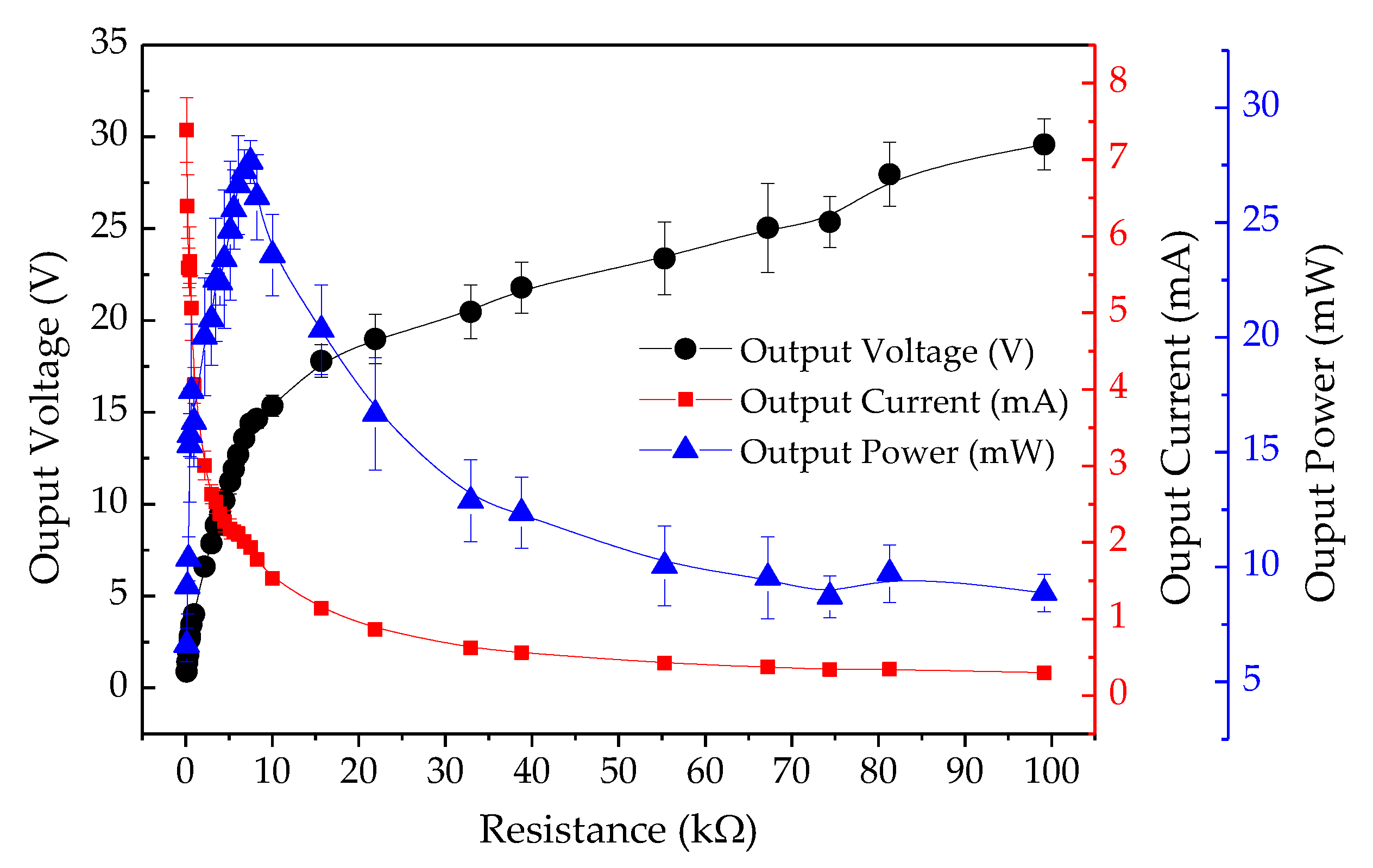

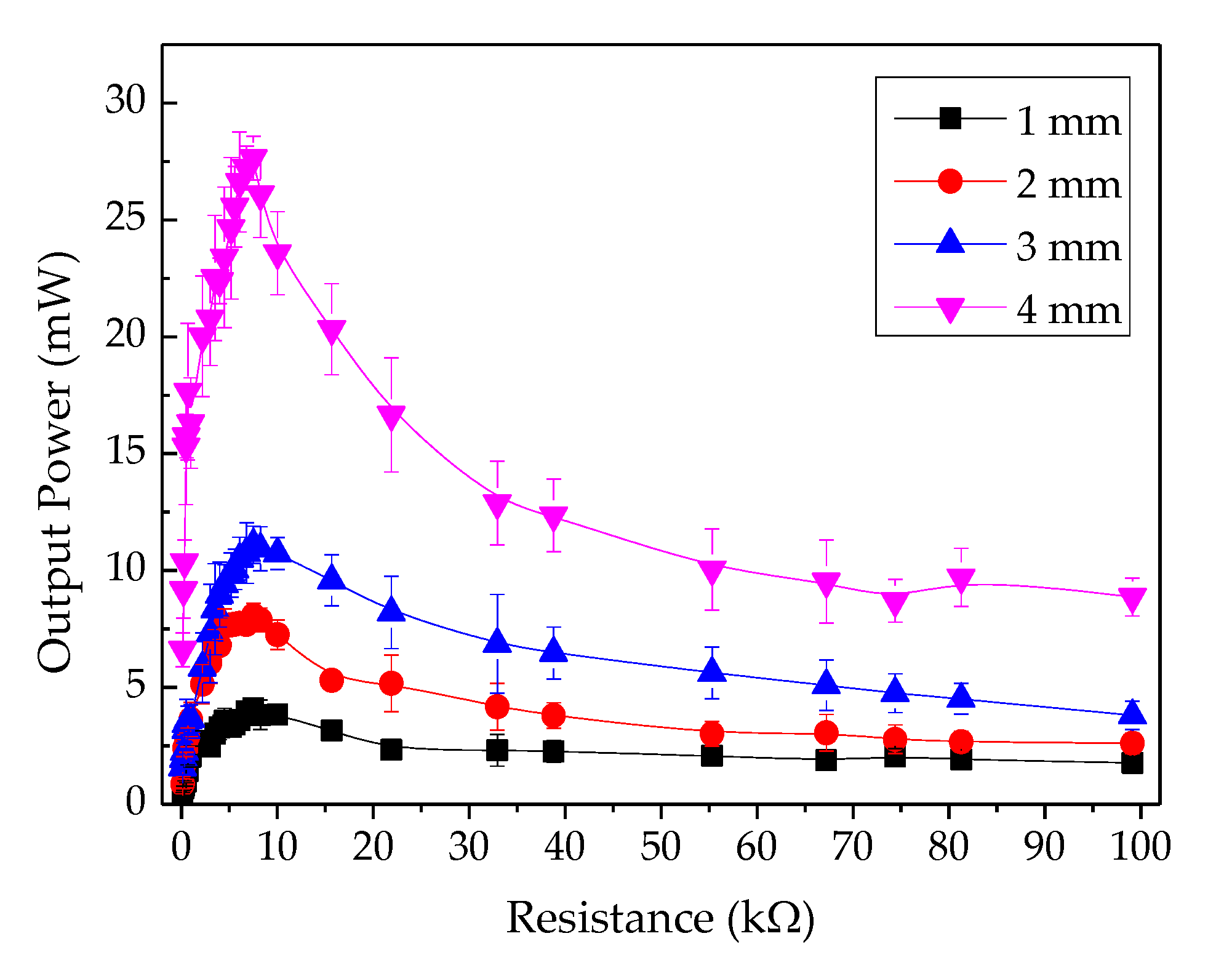

- Using resistive loads to connect the top electrode to the bottom electrode to identify their optimal load and peak power by measuring the peak output voltage across resistive load while varying the gap width between the cover plate and the stopper from 1 mm to 4 mm.

- (3)

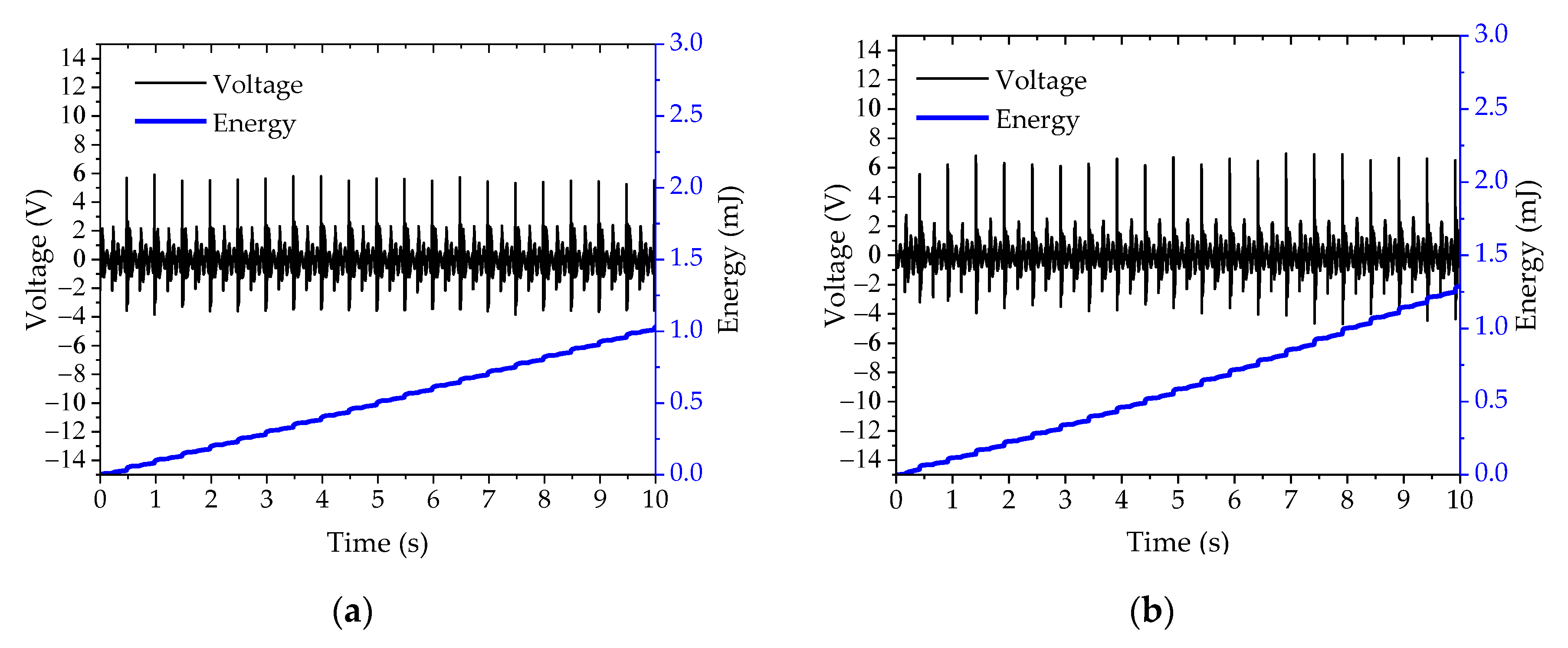

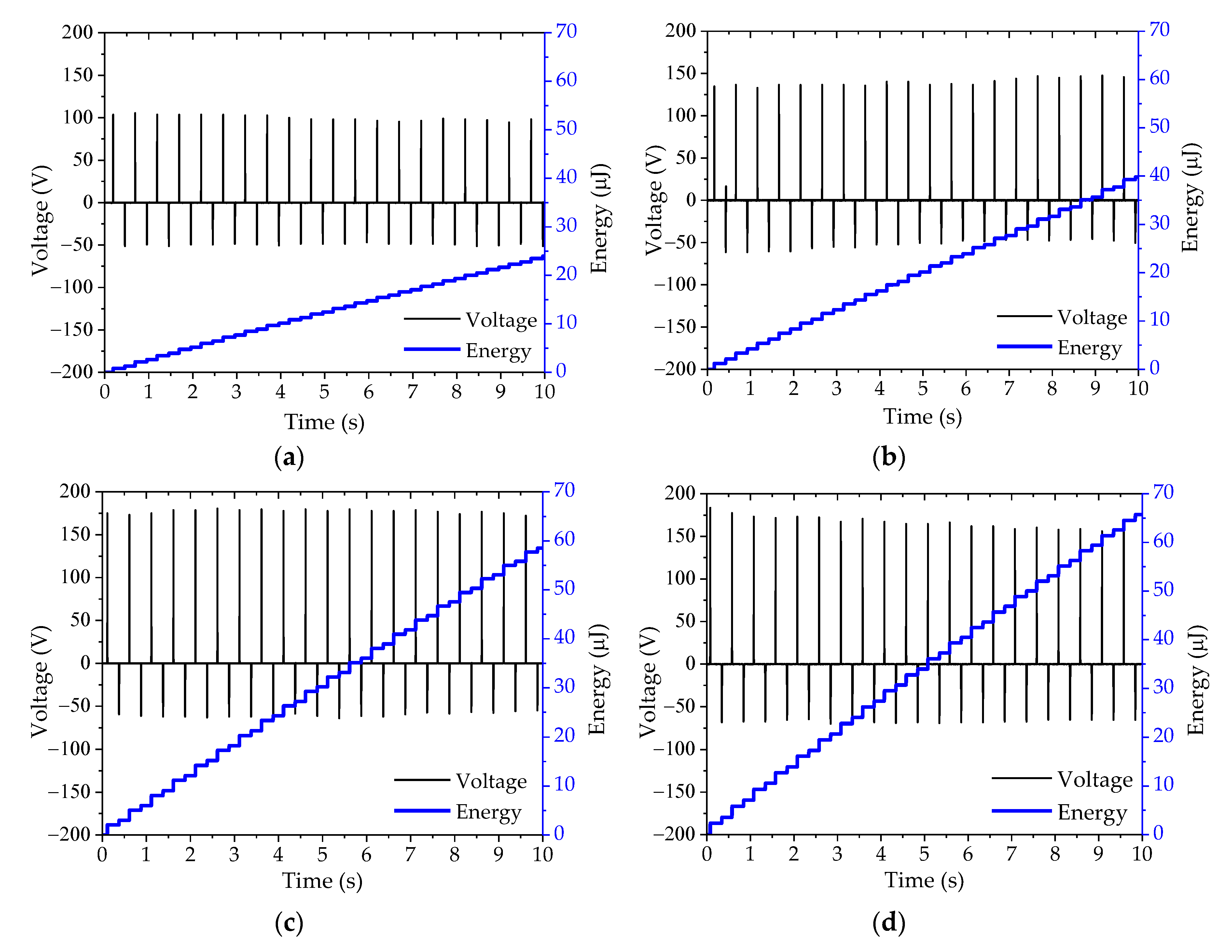

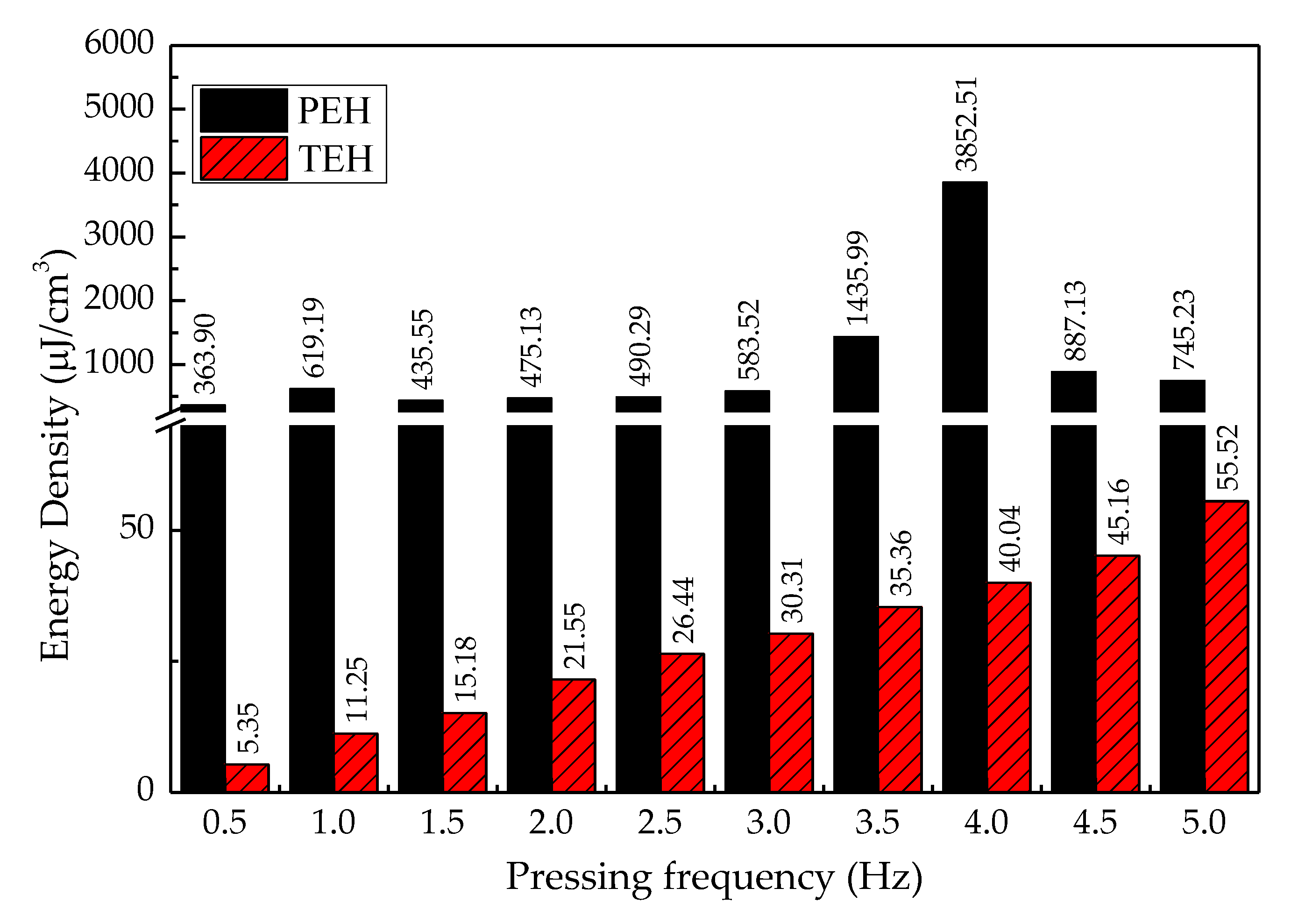

- Measuring and recording the output voltages of PEH and TEH for a 4 mm gap width while varying the cover plate pressing frequency from 0.5 Hz to 5 Hz in an increment of 0.5. The measured voltages were used in energy computation.

- (4)

- Calculating the electrical performances of the PEH and TEH normalized by material volume and cost into output voltage, power density, and energy density per unit cost, which would be immensely useful for designing and developing a practical energy harvesting device.

4. Experimental Results

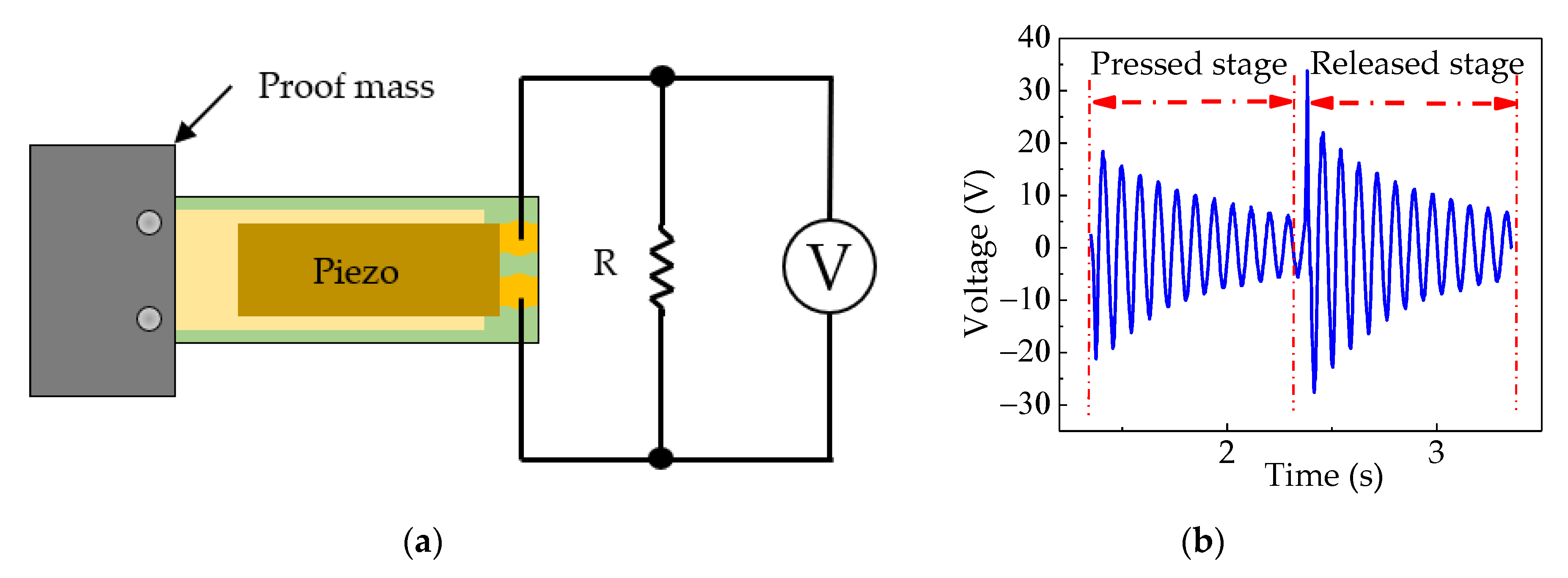

4.1. Electrical Output Characteristics of PEH Test Bench

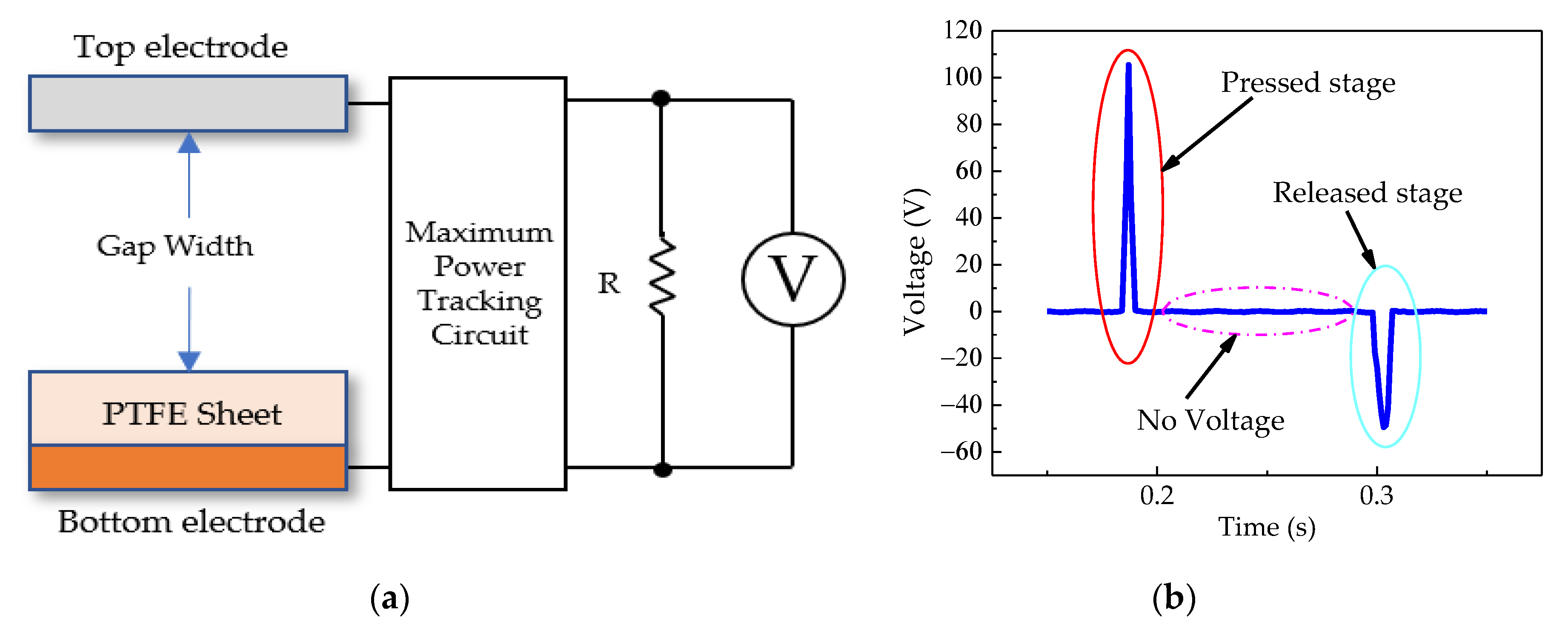

4.2. Electrical Output Characteristics of TEH Test Bench

4.3. Electrical Output Characteristics of PEH and TEH Test Benches

4.3.1. Output Voltage Comparison

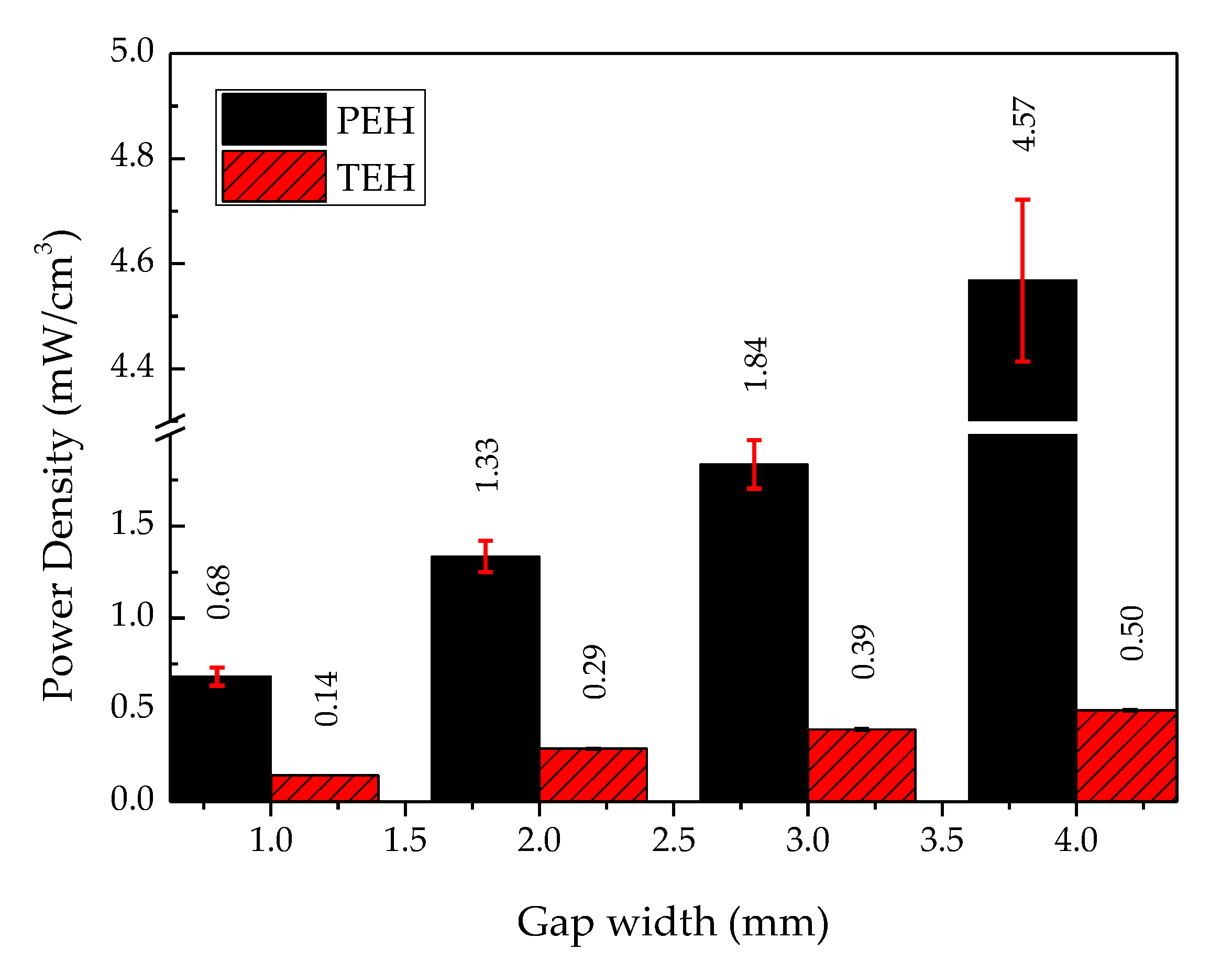

4.3.2. Power Density Comparison between PEH and TEH

4.3.3. Energy Density Comparison between PEH and TEH

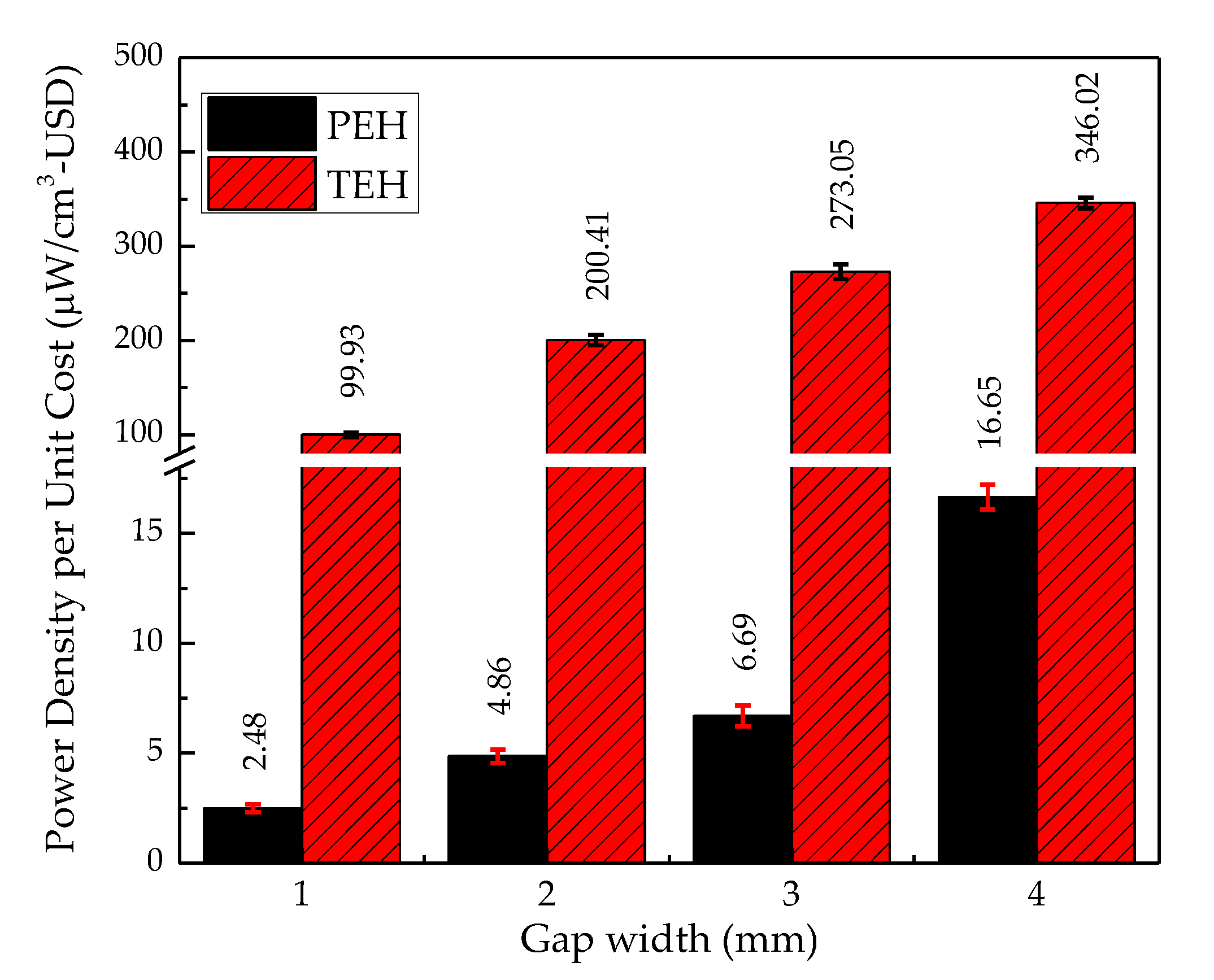

4.3.4. Power Density and Energy Density per Unit Cost

5. Discussion

5.1. Gap Width and Electrical Output

5.2. Power and Energy Densities per Unit Cost

5.3. Aspects to Be Considered in Realistic Implementation of the Energy Harvesters

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Panthongsy, P.; Isarakorn, D.; Hamamoto, K. A test bench for characterization of piezoelectric frequency up-converting energy harvesters. In Proceedings of the 2018 15th International Conference on Electrical Engineering/Electronics, Computer, Telecom-Munications and Information Technology (ECTI-CON), Chiang Rai, Thailand, 18–21 July 2018. [Google Scholar]

- Ruan, J.J.; Lackhart, R.A.; Janphuang, P.; Quintero, A.V.; Briand, D.; Rooij, N. An automatic test bench for complete characterization of vibration-energy harvesters. IEEE Trans. Instrum. Meas. 2013, 62, 2966–2973. [Google Scholar] [CrossRef]

- Yang, Z.; Zhou, S.; Zu, J.; Inman, D. High-performance piezoelectric energy harvesters and their application. Joule 2018, 2, 1–56. [Google Scholar] [CrossRef]

- Rase, M.S.; Halim, M.A.; Cho, H.O.; Park, J.Y. A wrist-band coupled, human skin based triboelectric generator for harvesting biomechanical energy. In Proceedings of the 2015 Transducers—2015 18th International Conference on Solid-State Sensors, Actuators and Microsystems (TRANSDUCERS), Anchorage, AK, USA, 21–25 June 2015. [Google Scholar]

- Zhang, X.; Guo, Y.; Wang, Y.; Zhang, H.; Brugger, J. A transparent silk-fibroin-based triboelectric microgenerator for airflow energy harvesting. In Proceedings of the 2017 IEEE 12th International Conference on Nano/Micro Engineered and Molecular Systems (NEMS), Los Angeles, CA, USA, 9–12 April 2017. [Google Scholar]

- Jurado, U.T.; Pu, S.H.; White, N.M. A contact-separation mode triboelectric nanogenerator for ocean wave impact energy harvesting. In Proceedings of the 2017 IEEE SENSORS, Glasgow, Scotland, UK, 29 October–1 November 2017. [Google Scholar]

- Kılkış, Ş.; Krajačić, G.; Duić, N.; Montorsi, L.; Wang, Q.; Rosen, M.A.; Al-Nimr, M.A. Research frontiers in sustainable development of energy, water and environment systems in a time of climate crisis. Energy Convers. Manag. 2019, 199, 1–21. [Google Scholar] [CrossRef]

- Unsal, O.F.; Bedeloglu, A.C. Recent trends in flexible nanogenerators: A review. Mater. Sci. Res. India 2018, 15, 114–130. [Google Scholar] [CrossRef]

- Rathore, S.; Sharma, S.; Swain, B.P.; Ghadai, R.K. A critical review on triboelectric nanogenerator. IOP Conf. Ser. Mater. Sci. Eng. 2018, 337, 1–16. [Google Scholar] [CrossRef]

- Askari, H.; Khajepour, A.; Khamesee, M.B.; Saadatnia, Z.; Wang, Z.L. Piezoelectric and triboelectric nanogenerators: Trends and impacts. Nano Today 2018, 22, 10–13. [Google Scholar] [CrossRef]

- Promsawat, N.; Wichaiwong, W.; Pimpawat, P.; Changsarn, K.; Phimol, K.; Promsawat, M.; Janphuang, P. A study of flexible piezoelectric generators by sputtering ZnO thin film on PET substrate. Integr. Ferroelectr. 2019, 195, 220–229. [Google Scholar] [CrossRef]

- Panthongsy, P.; Isarakorn, D.; Hamamoto, K.; Janphuang, P. Performance and behavior analysis of piezoelectric energy harvesting floor tiles. In Proceedings of the 2019 5th International Conference on Engineering, Applied Sciences and Technology (ICEAST), Luang Prabang, Laos, 2–5 July 2019. [Google Scholar]

- Isarakorn, D.; Jayasvasti, S.; Panthongsy, P.; Janphuang, P.; Hamamoto, K. Design and evaluation of double-stage energy harvesting floor tile. Sustainability 2019, 11, 5582. [Google Scholar] [CrossRef]

- Pachi, A.; Ji, T. Frequency and velocity of people walking. Struct. Eng. 2005, 83, 36–40. [Google Scholar]

- Salauddin, M.; Park, J.Y. A low frequency vibration driven, miniaturized and hybridized electromagnetic and triboelectric energy harvester using dual Halbach array. In Proceedings of the 2017 19th International Conference on Solid-State Sensors, Actuators and Microsystems (TRANSDUCERS), Kaohsiung, Taiwan, 1 February 2017. [Google Scholar]

- Niu, S.; Wang, Z.L. Theoretical systems of triboelectric nanogenerators. Nano Energy 2014, 14, 161–192. [Google Scholar] [CrossRef]

- Shamsuddin; Khan, S.A.; Rahimoon, A.Q.; Abro, A.; Ali, M.; Hussain, I.; Ahmed, F. Biomechanical Energy Harvesting by Single Electrode-based Triboelectric Nanogenerator. In Proceedings of the 2019 2nd International Conference on Computing, Mathematics and Engineering Technologies (iCoMET), Sukkur, Pakistan, 30–31 January 2019. [Google Scholar]

- Yang, B.; Zeng, W.; Peng, Z.H.; Liu, S.R.; Chen, K.; Tao, X.M. A fully verified theoretical analysis of contact-mode triboelectric nanogenerators as a wearable power source. Adv. Energy Mater. 2016, 6, 1–8. [Google Scholar] [CrossRef]

- Uddin, A.I.; Chung, G.S. A self-powered active hydrogen sensor using triboelectric effect. In Proceedings of the 2016 IEEE SENSORS, Orlando, FL, USA, 30 October–3 November 2016. [Google Scholar]

- Huang, H.; Li, X.; Liu, S.; Hu, S.; Sun, Y. TriboMotion: A self-powered triboelectric motion sensor in wearable Internet of Things for human activity recognition and energy harvesting. IEEE Internet Things J. 2018, 5, 4441–4453. [Google Scholar] [CrossRef]

- Wu, C.; Wang, A.C.; Ding, W.; Guo, H.; Wang, Z.L. Triboelectric nanogenerator: A foundation of the energy for the new era. Adv. Energy Mater. 2018, 9, 1–25. [Google Scholar] [CrossRef]

- Bertacchini, A.; Larcher, L.; Lasagni, M.; Pavan, P. Ultra-low-cost triboelectric energy harvesting solutions for embedded sensor systems. In Proceedings of the 15th IEEE International Conference on Nanotechnology, Rome, Italy, 27–30 July 2015. [Google Scholar]

- Zhou, T.; Zhang, L.; Xue, F.; Tang, W.; Zhang, C.; Wang, Z.L. Multilayered electret films based triboelectric nanogenerator. Nano Res. 2016, 9, 1442–1451. [Google Scholar] [CrossRef]

- Wen, R.; Guo, J.; Yu, A.; Zhai, J.; Wang, L.Z. Humidity-resistive triboelectric nanogenerator fabricated using metal organic framework composite. Adv. Funct. Mater. 2019, 9, 1–9. [Google Scholar] [CrossRef]

- Dharmasena, R.D.I.G.; Deane, J.H.B.; Silva, S.R.P. Nature of power generation and output optimization criteria for triboelectric nanogenerators. Adv. Energy Mater. 2018, 8, 1–11. [Google Scholar] [CrossRef]

- Xia, K.; Zhu, Z.; Zhang, H.; Du, C.; Wang, R.; Xu, Z. High output compound triboelectric nanogenerator based on paper for self-powered height sensing system. IEEE Trans. Nanotechnol. 2018, 17, 1217–1223. [Google Scholar] [CrossRef]

- Kim, K.; Song, G.; Park, C.; Yun, K.S. Multifunctional woven structure operating as triboelectric energy harvester, capacitive tactile sensor array, and piezoresistive strain sensor array. Sensors 2017, 17, 2582. [Google Scholar] [CrossRef]

- Lu, C.X.; Han, C.B.; Gu, G.Q.; Chen, J.; Yang, Z.W.; Jiang, T.; He, C.; Wang, Z.L. Temperature effect on performance of triboelectric nanogenerator. Adv. Eng. Mater. 2017, 19, 1–8. [Google Scholar] [CrossRef]

- Mule, A.R.; Dudem, B.; Graham, S.A.; Yu, J.S. Humidity sustained wearable pouch-type triboelectric nanogenerator for harvesting mechanical energy from human activities. Adv. Funct. Mater. 2019, 29, 1–11. [Google Scholar] [CrossRef]

- Sriphan, S.; Charoonsuk, T.; Maluangnont, T.; Vittayakorn, N. High-performance hybridized composited-based piezoelectric and triboelectric nanogenerators based on BaTiO3/PDMS composite film modified with Ti0.8O2 nanosheets and silver nanopowders cofillers. ACS Appl. Energy Mater. 2019, 2, 3840–3850. [Google Scholar] [CrossRef]

- Jung, W.S.; Kang, M.G.; Moon, H.G.; Baek, S.H.; Yoon, S.J.; Wang, Z.L.; Kim, S.W.; Kang, C.Y. High output piezo/triboelectric hybrid generator. Sci. Rep. 2015, 5, 1–6. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Yang, B.; Liu, J.; He, Q.; Guo, H.; Yang, C.; Chen, X. Flexible triboelectric and piezoelectric coupling nanogenerator based on electrospinning P(VDF-TRFE) nanowires. In Proceedings of the 2015 28th IEEE International Conference on Micro Electromechanical Systems (MEMS), Estoril, Portugal, 18–22 January 2015. [Google Scholar]

- Zhang, H.; Galayko, D.; Basset, P. A conditioning system for high-voltage electrostatic/triboelectric energy harvesters using bennet doubler and self-actuated hysteresis switch. In Proceedings of the Transducers 2019-Eurosensors XXXIII, Berlin, Germany, 23–27 June 2019. [Google Scholar]

- Isarakorn, D.; Jayasvasti, S.; Thainiramit, P.; Yingyong, P. Power Measurement Circuit for Energy Harvesting Devices. Thai Patent Application No. 2001005793, 2 September 2020. [Google Scholar]

- Mide Technology. Piezoelectric Bending Transducer (S230-J1FR-1808XB). Available online: https://piezo.com/-products/piezoelectric-bending-transducer-s230-j1fr-1808xb (accessed on 27 August 2020).

- Material Properties. Piezoelectric Materials-PZT-5H. Available online: https://support.piezo.com/article/62-material-properties (accessed on 27 August 2020).

- Wang, Z.L.; Lin, L.; Chen, J.; Niu, S.; Zi, Y. Triboelectric Nanogenerators; Springer International Publishing: Basel, Switzerland, 2016; pp. 1–19. [Google Scholar]

- Indyplastic. Engineering Plastic Sheets–PTFE. Available online: https://www.indyplasticsheet.com/th/pages/4645 (accessed on 27 August 2020).

- Carames, T.M.; Lamas, P.F. Towards the internet of smart clothing: A review on IoT wearables and garments for creating intelligent connected E-texiles. Electronic 2018, 7, 405. [Google Scholar] [CrossRef]

- Luis, J.A.; Galan, J.A.G.; Espigado, J.A. Low power wireless smoke alarm system in home fires. Sensors 2015, 15, 20717–20729. [Google Scholar] [CrossRef]

- Zeiser, R.; Fellner, T.; Wilde, J. Capacitive strain gauge on flexible polymer substrates for wireless, intelligent systems. J. Sens. Sens. Syst. 2014, 3, 77–86. [Google Scholar] [CrossRef]

- Hemminger, L.T.; Walters, E.G. Reducing hearing aid power consumption using truncated-matrix multipliers. Glob. J. Res. Eng. 2013, 13. [Google Scholar]

- Gibson, D.R.; MacGregor, C. Self-powered non-dispersive infra-red CO2 gas sensor. J. Phys. Conf. Ser. 2011, 307. [Google Scholar] [CrossRef]

- Torah, R.N.; Beeby, S.P.; Tudor, M.J.; O’Donnell, T.; Roy, S. Development of a Cantilever Beam Generator Employing Vibration Energy Harvesting. In Proceedings of the 6th International Workshop on Micro and Nanotechnology for Power Generation and Energy Conversion Applications (PowerMEMS 2006), Berkeley, CA, USA, 29 November—1 December 2006; pp. 181–184. [Google Scholar]

- Zhu, D.; Tudor, M.J.; Beeby, S.P. Strategies for increasing the operating frequency range of vibration energy harvesters: A review. Meas. Sci. Technol. 2010, 21, 2. [Google Scholar] [CrossRef]

- Wang, Z.L.; Lin, L.; Chen, J.; Niu, S.; Zi, Y. Triboelectric nanogenerator: Freestanding triboelectric-layer mode. In Triboelectric Nanogenerators; Green Energy and Technology; Springer International Publishing: Cham, Switzerland, 2016; pp. 109–153. ISBN 978-3-319-40038-9. [Google Scholar]

- Yingyong, P.; Thainiramit, P.; Vittayakorn, N.; Isarakorn, D. Performance and behavior analysis of single-electrode triboelectric nanogenerator for energy harvesting floor tiles. In Proceedings of the 17th International Conference on Electrical Engineering/Electronics, Computer, Telecommunications, and Information Technology (ECTI-CON), Phuket, Thailand, 24–27 June 2020; pp. 514–517. [Google Scholar]

- Kazmierski, T.J.; Beeby, S. 2011. Energy Harvesting Systems: Principles, Modeling and Applications; Springer Science & Business Media: Berlin, Germany, 2010. [Google Scholar]

- Niu, S.; Liu, Y.; Zhou, Y.S.; Wang, S.; Lin, L.; Wang, Z.L. Optimization of triboelectric nanogenerator charging systems for efficient energy harvesting and storage. IEEE Trans. Electron. Devices 2015, 62, 641–647. [Google Scholar]

- Yang, Z.; Wang, Y.Q.; Zuo, L.; Zu, J. Introducing arc-shaped piezoelectric elements into energy harvesters. Energy Convers. Manag. 2017, 148, 260–266. [Google Scholar] [CrossRef]

- Dai, X.; Wen, Y.; Li, P.; Yang, J.; Zhang, G. Modeling, characterization and fabrication of vibration energy harvester using Terfenol-D/PZT/Terfenol-D composite transducer. Sens. Actuators Phys. 2009, 156, 350–358. [Google Scholar] [CrossRef]

- Sriramdas, R.; Chiplunkar, S.; Cuduvally, R.M.; Pratap, R. Performance enhancement of piezoelectric energy harvesters using multilayer and multistep beam configurations. IEEE Sens. J. 2015, 15, 3338–3348. [Google Scholar] [CrossRef]

- Ma, M.; Xia, S.; Li, Z.; Xu, Z.; Yao, X. Enhanced energy harvesting performance of the piezoelectric unimorph with perpendicular electrodes. Appl. Phys. Lett. 2014, 105, 043905-1–043905-4. [Google Scholar] [CrossRef]

- Dhakar, L.; Liu, H.; Tay, F.E.H.; Lee, C. A new energy harvester design for high power output at low frequencies. Sens. Actuators Phys. 2013, 199, 344–352. [Google Scholar] [CrossRef]

- Lee, B.S.; Lin, S.C.; Wu, W.J.; Wang, X.Y.; Chang, P.Z.; Lee, C.K. Piezoelectric MEMS generators fabricated with an aerosol deposition PZT thin film. J. Micromech. Microeng. 2009, 19, 065014-1–065014-8. [Google Scholar] [CrossRef]

- Song, H.-C.; Kumar, P.; Maurya, D.; Kang, M.-G.; Reynolds, W.T.; Jeong, D.-Y.; Kang, C.-Y.; Priya, S. Ultra-low resonant piezoelectric MEMS energy harvester with high power density. J. Microelectromec. Syst. 2017, 26, 1226–1234. [Google Scholar] [CrossRef]

- Zou, H.-X.; Zhang, W.-M.; Li, W.-B.; Hu, K.-M.; Wei, K.-X.; Peng, Z.-K.; Meng, G. A broadband compressive-mode vibration energy harvester enhanced by magnetic force intervention approach. Appl. Phys. Lett. 2017, 110, 163–904. [Google Scholar] [CrossRef]

- Morimoto, K.; Kanno, I.; Wasa, K.; Kotera, H. High-efficiency piezoelectric energy harvesters of c-axis-oriented epitaxial PZT films transferred onto stainless steel cantilevers. Sens. Actuators Phys. 2010, 163, 428–432. [Google Scholar] [CrossRef]

- Ji, S.H.; Lee, W.; Yun, J.S. All-in-One Piezo-Triboelectric Energy Harvester Module Based on Piezoceramic Nanofibers for Wearable Devices. ACS Appl. Mater. Interfaces 2020, 12, 18609–18616. [Google Scholar] [CrossRef]

- Rodrigues, C.A.; Gomes, A.; Ghosh, A.; Pereira, A.; Ventura, J. Power-generating footwear based on a triboelectric-electromagnetic-piezoelectric hybrid nanogenerator. Nano Energy 2019, 62, 660–666. [Google Scholar] [CrossRef]

| Property (Unit) | Value |

|---|---|

| Density ρ (Kg/m3) | 7800 |

| Mechanical Q (Qm) | 60 |

| Elastic (Young’s modulus) YE3 (N/m2) | 5 × 1010 |

| Relative dielectric constant KT3 (@ 1 kHz) | 2100 |

| Piezoelectric coefficient d33 (pC/N) | 500 |

| Piezoelectric coefficient d31 (pC/N) | −210 |

| Piezoelectric voltage constant g33 (Vm/N) | 23 × 10−3 |

| Piezoelectric voltage constant g31 (V-m/N) | −10.4 × 10−3 |

| Coupling coefficient K33 | 0.74 |

| Coupling coefficient K31 | 0.37 |

| Polarizing field (Ep) V/m | >1.7 × 106 |

| Initial depolarizing field Ec (V/m) | ~4 × 105 |

| Coercive field Ec (V/m) | ~1.0 × 106 |

| Property (Unit) | Value |

|---|---|

| Density (g/cm3) | 2.3–2.45 |

| Water absorption (%) | >0.01 |

| Tensile strength (kg/cm2) | 140–350 |

| Flexural strength (kg/cm2) | 16.4 |

| Rockwell hardness | D55 |

| Izod impact strength (kg cm/ cm with notch) | 2.5–2.7 |

| Friction coefficients | 0.10–0.04 |

| Coefficient of linear thermal expansion (x 10−5/°C) | 7.0–10.0 |

| Thermal conductivity (kcal/m. Hr. °C) | 6.0 |

| Heat distortion temperature (°C) | 120 |

| Heat resistance (°C) | –70–260 |

| Dielectric breakdown strengths (kV/mm) | 19 |

| Coefficient of volume resistance (Ohm-cm) | 1018 |

| Device | Power Consumption | PEH | TEH |

|---|---|---|---|

| Watches [39] | 3–10 µW | applicable | applicable |

| Smoke detector [40] | 4.95 µW | applicable | applicable |

| Peacemakers [39] | 25–80 µW | applicable | applicable |

| Capacitive strain gauge [41] | 600 µW | applicable | applicable |

| Hearing aids [42] | <1.4 mW | applicable | applicable |

| CO2 sensor [43] | <3.5 mW | applicable | not applicable |

| Digital clocks [39] | 13 mW | applicable | not applicable |

| Light-emitting diode [39] | 25 mW–100 mW | applicable | not applicable |

| Reference | Harvester Size | Voltage (V) | Power | Power Density | Frequency (Hz) | Optimal Load |

|---|---|---|---|---|---|---|

| 1. Piezoelectric energy harvester | ||||||

| Panthongsy et al. [1] | 2.80 cm3 | 7.57 | 0.58 mW | 2.07 mW/cm3 | 20.83 | 99 kΩ |

| Yang et al. [50] | 241 mm3 | 22.50 | 2.53 mW | 10.50 mW/cm3 | 44.00 | 200 kΩ |

| Dai et al. [51] | 2.26 cm3 | 24.47 | 1.06 mW | 0.47 mW/cm3 | 51.00 | 564.7 kΩ |

| Sriramdas et al. [52] | 108 mm3 | 3.96 | 8.1 µW | 0.08 mW/cm3 | 30.80 | 1 MΩ |

| Ma et al. [53] | 270 mm3 | 1.46 | 3.18 µW | 0.012 mW/cm3 | 93.00 | 700 kΩ |

| Dhakar et al. [54] | 102.08 mm3 | 6.32 | 40 µW | 0.39 mW/cm3 | 36.00 | 1 MΩ |

| Lee et al. [55] | 0.023 mm3 | 0.84 | 1.38 µW | 61.3 mW/cm3 | 255.9. | 510 kΩ |

| Song et al. [56] | 0.11 mm3 | 0.03 | 0.023 µW | 0.209 mW/cm3 | 48.00 | 40 kΩ |

| Zou et al. [57] | 400 mm3 | 12.29 | 387 µW | 0.968 mW/cm3 | 9.90 | 390 kΩ |

| Morimoto et al. [58] | 0.26 mm3 | 0.51 | 5.3 µW | 20.46 mW/cm3 | 126.00 | 50 kΩ |

| 2. Triboelectric energy harvester | ||||||

| Zhang et al. [5] | 18.75 cm2 | 36 | 162 µW | 86.4 mW/cm2 | - | 8 MΩ |

| Jurado et al. [6] | 64 cm2 | 3.83 | 307.88 µW | 19.24 µW/cm2 | 150 | 10 MΩ |

| Shamsuddin et al. [17] | 118.16 cm2 | 40.00 | 17 µW | 0.14 µW/cm2 | - | 60 MΩ |

| Yang et al. [18] | 36 cm2 | 749.40 | 9.36 mW | 260 µW/cm2 | 3.2 | 60 MΩ |

| Uddin et al. [19] | 2.28 cm2 | 16.20 | 36 µW | 15.8 µW/cm2 | 3 | 1 MΩ |

| Xia et al. [26] | 6 cm2 | 48.00 | 2.88 mW | 480 µW/cm2 | - | 800 kΩ |

| Kim et al. [27] | 36 cm2 | 13 | 210 µW | 48 µW/cm2 | - | 20 MΩ |

| Mule et al. [29] | 4 cm2 | 774.59 | 10 mW | 2.54 mW/cm2 | - | 60 MΩ |

| Piezoelectric Energy Harvester | Triboelectric Energy Harvester | |

|---|---|---|

| Advantages |

|

|

| Disadvantages |

|

|

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Thainiramit, P.; Yingyong, P.; Isarakorn, D. Impact-Driven Energy Harvesting: Piezoelectric Versus Triboelectric Energy Harvesters. Sensors 2020, 20, 5828. https://doi.org/10.3390/s20205828

Thainiramit P, Yingyong P, Isarakorn D. Impact-Driven Energy Harvesting: Piezoelectric Versus Triboelectric Energy Harvesters. Sensors. 2020; 20(20):5828. https://doi.org/10.3390/s20205828

Chicago/Turabian StyleThainiramit, Panu, Phonexai Yingyong, and Don Isarakorn. 2020. "Impact-Driven Energy Harvesting: Piezoelectric Versus Triboelectric Energy Harvesters" Sensors 20, no. 20: 5828. https://doi.org/10.3390/s20205828

APA StyleThainiramit, P., Yingyong, P., & Isarakorn, D. (2020). Impact-Driven Energy Harvesting: Piezoelectric Versus Triboelectric Energy Harvesters. Sensors, 20(20), 5828. https://doi.org/10.3390/s20205828