1. Introduction

The construction industry is one of the leading industries in the world, which spends

$10 trillion on construction-related goods and services every year [

1]. However, the construction industry is facing a massive workforce shortage of skilled craft workers [

2]. More than 8 out of 10 construction firms report having a hard time finding qualified workers. One of the significant causes of workforce shortage is the premature retirement of skilled craft workers due to safety and health issues. Due to a lack of proper safety training and monitoring systems, the construction workforce is exposed to various fatal and non-fatal injuries such as work-related musculoskeletal disorders (WMSDs). To overcome these challenges, various researchers have proposed wearable sensor-based systems in the area of construction safety and health [

3,

4,

5,

6,

7,

8]. Various applications in the area of safety and health involve preventing musculoskeletal disorders, fall prevention, mental and physical workload assessment, and fatigue monitoring [

3,

4,

5,

6,

7,

8]. All these applications can be categorized as a classification problem since they involve identifying different postures, classifying different physical and mental workloads, or detecting different motions or gestures using the sensor data. Moreover, classifying workers’ activity helps in monitoring and managing the productivity, safety, and quality of work [

9].

In the construction domain, the wearable sensor-based activity recognition models have gained increased attention due to low-cost, ease of use, high accuracy, and non-intrusiveness. Most of the previous studies have used accelerometers and gyroscopes embedded in smartphones to recognize construction workers’ activity [

10,

11,

12,

13]. A study by Cezar [

14] used an accelerometer and gyroscope embedded in the smartphone placed on the dominant hand to recognize hammering, sawing, sweeping, and drilling activities with an accuracy of 91% using quadratic discriminant analysis (QDA) algorithm. Lim, et al. [

15] and Akhavian and Behzadan [

16] have developed artificial neural network (ANN) based models for identifying falls and manual material handling activities with an accuracy of 94% and 90.74% using the smartphone placed in the hip pocket and upper arm respectively. The ironwork activities recognition models developed by [

17] and [

9] using support vector machine (SVM) and decision trees (DT) were able to recognize activities with 94.83% and 92.98% accuracy. Even though these smartphone sensors-based models have achieved considerable accuracy, there are practical implementation challenges. In order to overcome the smartphone challenges, inertial measurement unit (IMU), sensor-based activity recognition models have been proposed for various construction applications such as work sampling [

18,

19,

20] and fall detection [

21]. The wearable IMU sensor-based models have used various machine learning algorithms such as DT, random forest, and SVM to recognize ironwork [

18], fall detection [

19], and bricklaying [

20] with an accuracy of 90.4%, 93.90%, and 88.1% respectively. However, the current activity classification methods are that they are limited to a fewer number of activities involving either upper body or lower body, use of multiple sensors, and do not consider activities with multiple intensities. Moreover, none of these studies have discussed the reliability of sensor data and classification results. Therefore, there is a necessity for low-cost, easy to use, and non-obstructive sensors that can provide reliable data for complex construction activity classification.

Despite the fact that sensors provide rich and detailed information, not all sensors can be used for construction applications due to the dynamic nature of construction work [

3]. It was recommended that multisensory data fusion, which was applied in other domains, provides an opportunity for enhancing the accuracy of activity classification [

6,

22]. The sensor for construction applications should be simple and easy to wear, unobtrusive, affordable, and wireless. Moreover, the sensor should provide reliable data and involve minimal or no preprocessing for noise removal. Therefore, it is essential to identify a suitable and reliable sensor for construction activity classification, which helps in developing construction workers’ safety and health monitoring systems to prevent work-related injuries such as WMSDs, which is one of the significant reasons for the workforce shortage.

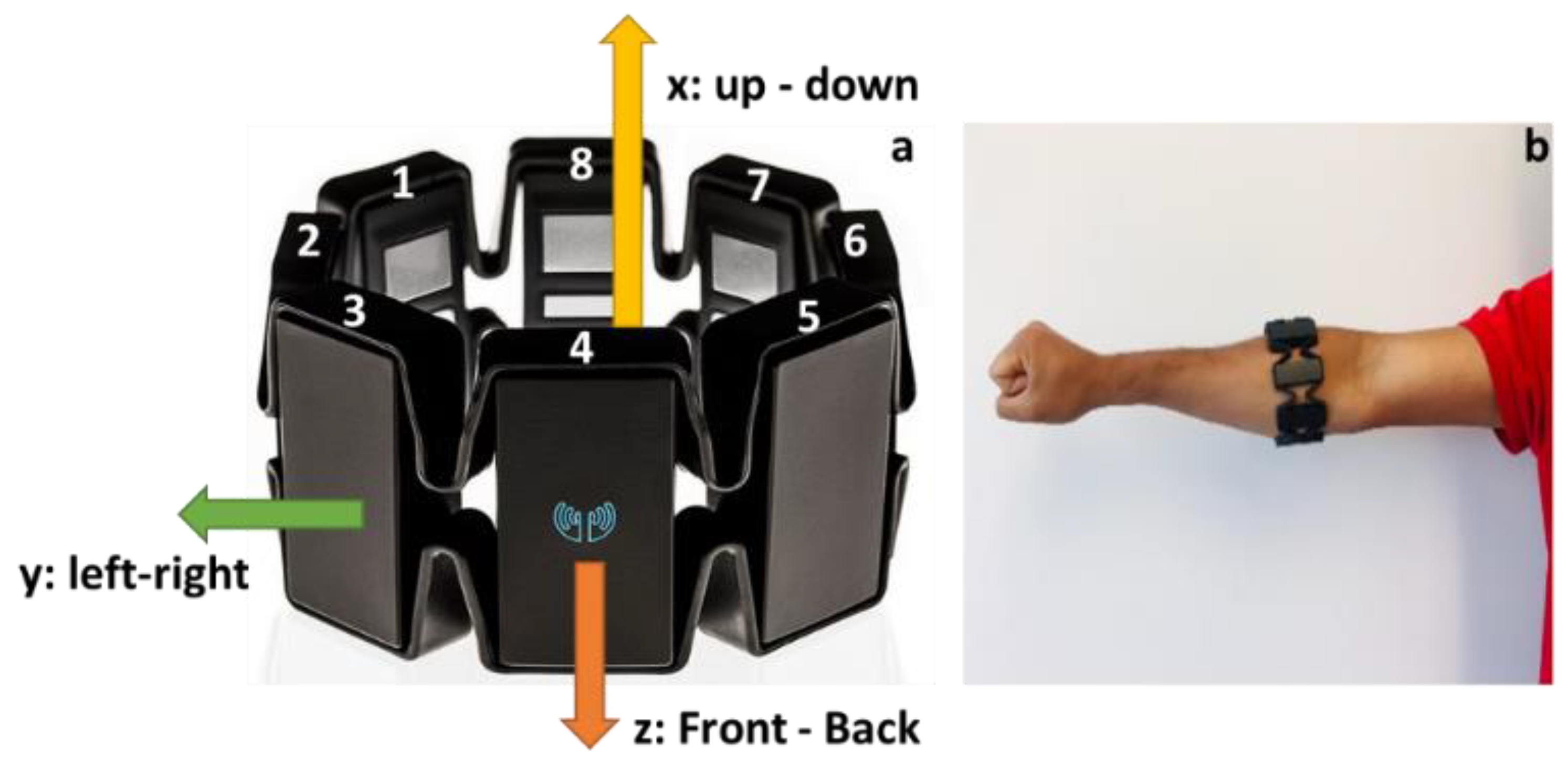

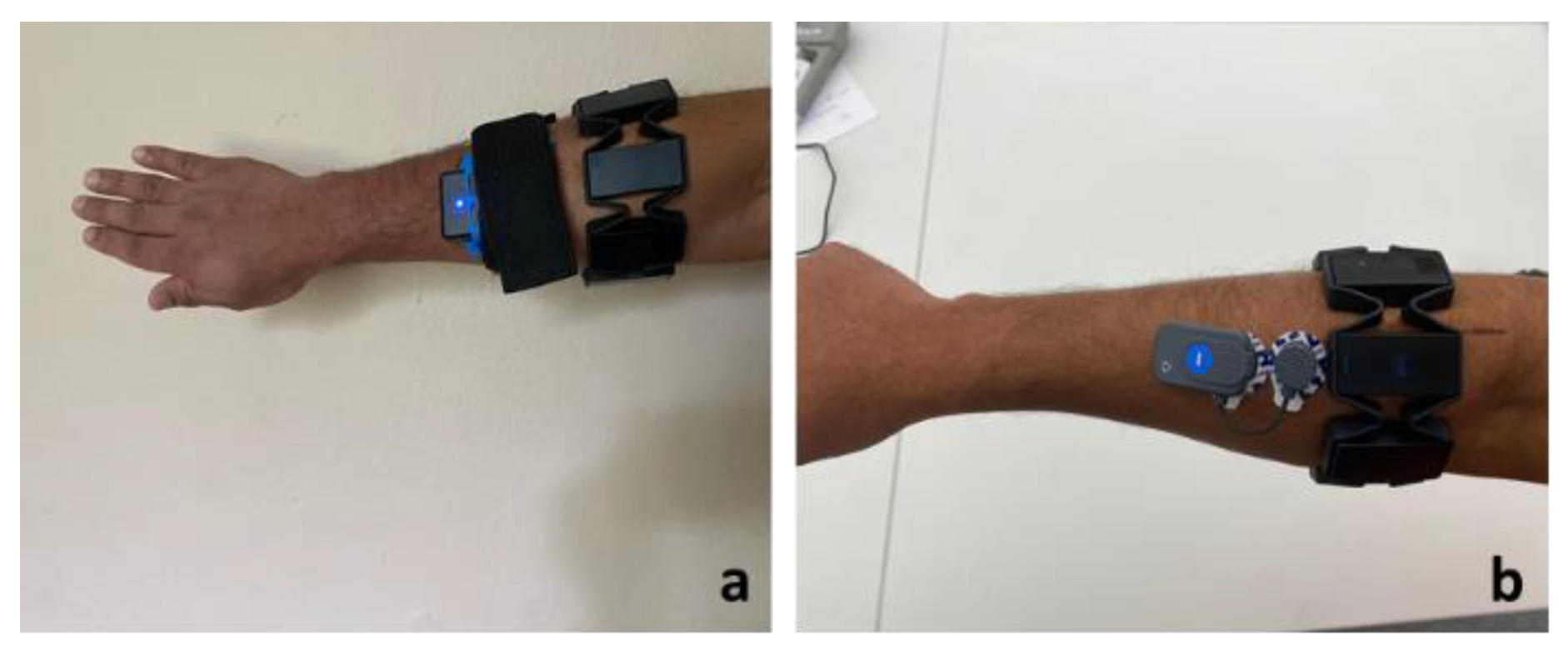

The armband sensor is an affordable, non-invasive, lightweight, and wireless wearable armband sensor that is available off-the-shelf to collect workers’ forearm electromyography (EMG) and inertial measurement unit (IMU) data [

23]. Many researchers have used these signal data for different applications in various domains. To the best of the authors’ knowledge, none of the studies in the construction domain have explored the use of armbands and a combination of EMG and IMU data for construction applications. Furthermore, investigating muscle activity and kinematic signals provides an understanding of workers’ physiological responses to workload. Furthermore, the signals facilitate activity analysis and workers’ behavior towards the work. In order to choose a wearable sensor for any construction applications specifically for activity classification, it is essential to investigate the data quality and reliability because the muscle activity and motion sensor signals from the forearm may inevitably be contaminated due to noise signals and artifacts that originate at the skin-electrode interface or due to external sources. A reduction in the noise and artifact contamination is required as well as preservation of the required information from the signals. Moreover, the sensor should provide consistent and reliable signals for activity throughout the data collection process. Therefore, the objective of this study is to assess the data quality and reliability of forearm EMG and IMU data for construction activity classification by following the guidelines, recommendations, and methods for data quality and reliability assessment proposed by previous studies on sensor [

24,

25,

26,

27,

28,

29].

In order to achieve the proposed objective, the whole study is divided into seven experiments. The first three experiments involve evaluating the data quality, understanding the effect of armband position on data quality, and reliability of forearm EMG and IMU data. Later, four experiments involve building and evaluating activity classification models, assessing the reliability of classification results, understanding the effect of lifting weights on classification results, and evaluating the classification performance of different sensor combinations. The results of these experiments answer various questions such as noise level in armband signal data, drift in the IMU sensor data, quality of EMG and IMU data for at-rest and in-motion activities, the effect of armband position on signal quality, the accuracy of construction activity classification using EMG and IMU, reliability of sensor data and classification results, effect of lifting weights on classification accuracy, and classification performance of different sensor combinations. It was hypothesized that the armband sensor provides reliable EMG and IMU data and activity classification results. The answers to the above questions establish the reliability and applicability of forearm EMG and IMU data for construction activity classification.

4. Discussion

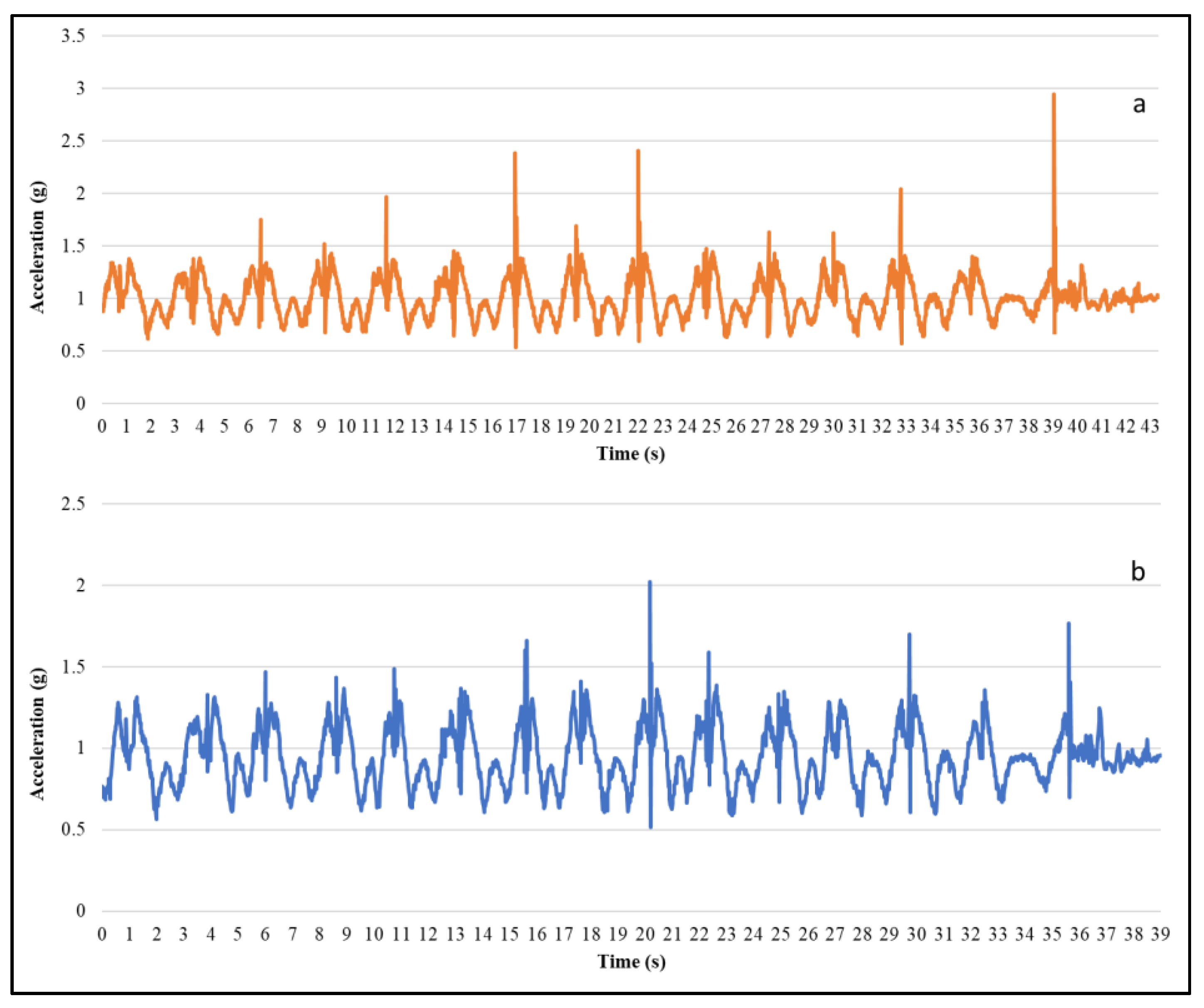

In this study, the data quality of low-cost forearm based wearable sensors were explored by comparing the standard deviation and signal to noise ratio of the armband sensor and the conventional sensor for at-rest and in-motion activities. The noise levels in the armband acceleration data (SD = 0.002) when lying on the floor are comparable to the high precision conventional IMU sensor (SD = 0.003), which is in agreement with the previous study (SD = 0.0019) [

25]. Similarly, the noise levels in the acceleration and gyroscope data for in-motion activities are comparable to conventional sensors. Besides, the signal quality of armband sensor data is higher compared to the conventional sensor, which shows that the armband sensor is less sensitive compared to high precision and high-frequency sensors. Moreover, the data quality test in the presence of confounding factors also proves that the armband data is not affected much by the confounding factors, environment, and inter-device variability. Drift is one of the most common issues of IMU when used to estimate position and orientation [

26]. The rotational drift of the armband sensor was assessed by observing the evolution of the yaw angle for at-rest activities. The yaw angle drifts at a rate of 0.17 deg/s before it reaches the steady orientation, which is in agreement with a previous study [

61]. This experiment proves that the drift reduced when the Myo was worn on the body compared to lying on the floor. Moreover, the rotational drift was highest in the initial frames and reached a steady state in a few seconds. Similar to the other studies [

25,

62], the in-motion (i.e., lifting) activity data of the armband and the conventional sensor was visually compared since the quantitative comparison of both sensor signal data would not be appropriate. For the comparison of EMG and accelerometer signals, RMS and absolute magnitude plots were considered, as shown in

Figure 5 and

Figure 6. The result shows that the armband data and conventional sensor both pick the same peaks and follow a similar trend for lifting activity. The qualitative assessment of armband sensor position on EMG and IMU data quality shows that accelerometer and gyroscope data is almost similar for three (rotated, standard, and slid down) sensor positions. A previous study [

63] reported similar results where the classification accuracy using accelerometer data at different sensor positions made no significant difference. However, the EMG data for three armband positions are significantly different, which conforms with the fact that the IMU sensor captures the motion of the forearm, whereas the EMG signal depends on the muscle contact.

The study assessed the relative and absolute reliability of forearm EMG and IMU data of construction activities. The test-retest evaluation of accelerometer data indicated an excellent trial-to-trial (ICC = 0.844 to 0.995 and SEM% = 0.087% to 0.258%) and day-to-day (ICC = 0.824 to 0.881 and SEM% = 0.245% to 0.526%) relative and absolute reliability for all the activities as shown in

Table 5. Whereas for the gyroscope data, an excellent relative reliability was observed for trial-to-trial (ICC = 0.824 to 0.987) and day-to-day (ICC = 0.801 to 0.844) except for lifting where ICC = 0.724 (

Table 6 and

Table 7). The absolute reliability of gyroscope data for day-to-day was slightly greater than 10% ranging from 5.224% to 16.322%. The EMG data has shown excellent relative (ICC = 0.864 to 0.988) and absolute (SEM% = 2.420% to 10.509%) reliability between trials but the absolute reliability between the days (SEM% = 7.75% to 16.21%) is slightly greater than 10% (

Table 8). Overall, the results show that armband sensor data (acceleration, gyroscope, and EMG) exhibited excellent relative reliability between trials and days, which indicates a strong correlation of the repeated measurements. Furthermore, the armband sensor data exhibited excellent absolute reliability between the trails and moderate absolute reliability between days, which is indicated with a slight increase in SEM% and SDD%. As shown in Equations (6) and (8), SEM% and SDD% are directly correlated to the ratio of SD and mean of the measurements. The higher SEM% and SDD% between days are due to the larger SD to mean ratio. Further investigation was performed to determine if the armband data obtained at this level of reliability is sufficient to yield accurate and reliable activity classification results.

The ML-based classification results using both days’ datasets show that the forearm EMG, acceleration, and gyroscope features are capable of classifying activities involving different body parts such as wrist, forearm, and whole-body and various motions such as repetitive motion, repeated impulsive motion, and free motion with high accuracy (Day-1

accuracy = 96.48% ± 0.0024 and Day-2

accuracy = 96.33% ± 0.0022). Furthermore, the overall classification accuracy of 98.13% achieved for nine uncontrolled activity datasets shows that the model is capable of recognizing activity with different intensities, which is one of the limitations of current construction activity recognition models [

10,

16,

20]. The accuracy of proposed activity recognition models using EMG and IMU forearm data (Accuracy

EMG + IMU = 98.13%) is higher than previously published construction activity recognition models such as carpentry activities (91%) [

14], fall identification (94%) [

15], manual material handling activities (90.74%) [

11], ironworker activities (94.83%, 92.98%) [

9,

17], and bricklaying activities (88.1%) [

20].

Moreover, the reliability assessment of classification results using Day-1 and Day-2 classifiers showed that there exists excellent reliability of classification results using the forearm EMG and IMU features. Later, the forearm EMG and IMU data were used to classify different weights of lifting activity, which is useful for various construction applications. The results showed that the overall classification accuracy of three classes (Lift10, Lift25, and Lift50) is 83.89% (0.0051), which is higher than the accuracy obtained by Ho, et al. [

64] (77.1%) in classifying barbell weights from 20 to 70 lbs using forearm EMG features. Moreover, for three lifting weights, the gyroscope and EMG features are highly correlated, which contributed to higher classification accuracy. The comparison of classification performance for different sensor combinations on controlled (Accuracy

EMG + IMU = 96.21%, Accuracy

IMU = 94.65%, Accuracy

EMG = 44.97%) and uncontrolled (Accuracy

EMG + IMU = 98.21%, Accuracy

IMU = 84.80%, Accuracy

EMG = 47.60%) dataset showed that the highest accuracy is obtained in case of EMG + IMU which is in agreement with the previous studies on forearm gym activities (Accuracy

EMG + IMU = 71.6%, Accuracy

IMU = 67.8%, Accuracy

EMG = 20.7%) [

38], forearm manufacturing activities (Accuracy

EMG + IMU = 87.4%, Accuracy

IMU = 85.0%, Accuracy

EMG = 50.7%) [

41], and gym exercises (Accuracy

EMG + IMU = 84.2%, Accuracy

IMU = 77.7%, Accuracy

EMG = 85.2%) [

47]. Further, the increase in classification accuracy due to combined features show that the gyroscope and EMG features obtained at higher SEM% and SDD% are suitable for activity classification. The fusion of forearm muscle activity (EMG) and kinematic (IMU) data have resulted in the highest classification accuracy for a greater number of complex activities with different intensities. The advantage of using an armband sensor is that both forearm muscle activity and motion data are obtained from the single device and avoids the use of multiple sensors that obstructs construction work.

Some of the limitations of the study worth mentioning are that the data quality of the sensor data was assessed only on at-rest activities. All the in-motion activities were performed in residential settings by participants with little to no construction experience. All the participants in this study were right-handed and male. In addition to acceleration, gyroscope, and EMG data, the armband sensor provides orientation quaternion and Euler angles of the forearm. However, the orientation angles were not assessed for reliability in this study. Moreover, one can consider performing validity assessment for forearm EMG and IMU data of armband sensor.

5. Conclusions

The current study assessed the data quality and reliability of forearm EMG and IMU data from a low-cost wearable sensor for activity classification. In order to achieve the objective, the whole study was divided into seven experiments. From the first experiment, the data was inferred that the armband sensor data is comparable to conventional EMG and IMU data. Moreover, there was a very minimal effect of environment, confounding factors (communication device, power tools, other sensors, and smartwatches), and inter-device variability. Secondly, a qualitative comparison was performed to understand the effect of armband position on forearm EMG and IMU data, and it was concluded that the armband position does not affect IMU data, but EMG data was affected due to the sensor position. Thirdly, the trial-to-trial and day-to-day reliability of acceleration, gyroscope, and EMG data were assessed for five construction activities. The results conclude that the forearm IMU and EMG data for all five activities have excellent relative and absolute reliability between the trials, and between the days except for EMG data between the days has SEM% slightly higher than 10%. Next, the EMG and IMU data for both days was used to build and evaluate building ML-based activity classification models. The most common classification models were compared for the performance on the Day-1 and Day-2 datasets. The random forest classification algorithm showed the best performance on both the datasets. The reliability test on the classification results of both the classifiers confirmed that the classification results are high reliability with minimal change inaccuracies for both the days. The effect of lifting weight on classification performance was assessed, which concluded that the forearm EMG and IMU data could classify three different weights. Further, it was observed that a strong correlation in gyroscope and EMG features exists compared to accelerometer data for three classes. Finally, the comparison of classification performance for different sensor combinations showed that the forearm muscle activity and motion data fusion yield higher classification accuracy for construction activities with various intensities. The armband data is highly reliable, and the scientific evaluation of the armband sensor builds trustworthiness among researchers, policymakers, stakeholders, and customers to use the sensor for various applications. The data quality and reliability assessment of armband sensors show that the quality of muscle and motion-sensing data is sufficient for various construction applications related to construction skill training, safety training, and monitoring. Moreover, the classification results of the study conclude that the forearm-based EMG and IMU data can be used to generate reliable construction activity, recognition models.