A Displacement Field Perception Method for Component Digital Twin in Aircraft Assembly

Abstract

1. Introduction

1.1. Displacement Sensing Technology

1.2. Processing Approaches for Displacement Field

1.3. Displacement Field Perception for Digital Twin

1.4. Motivation of This Work

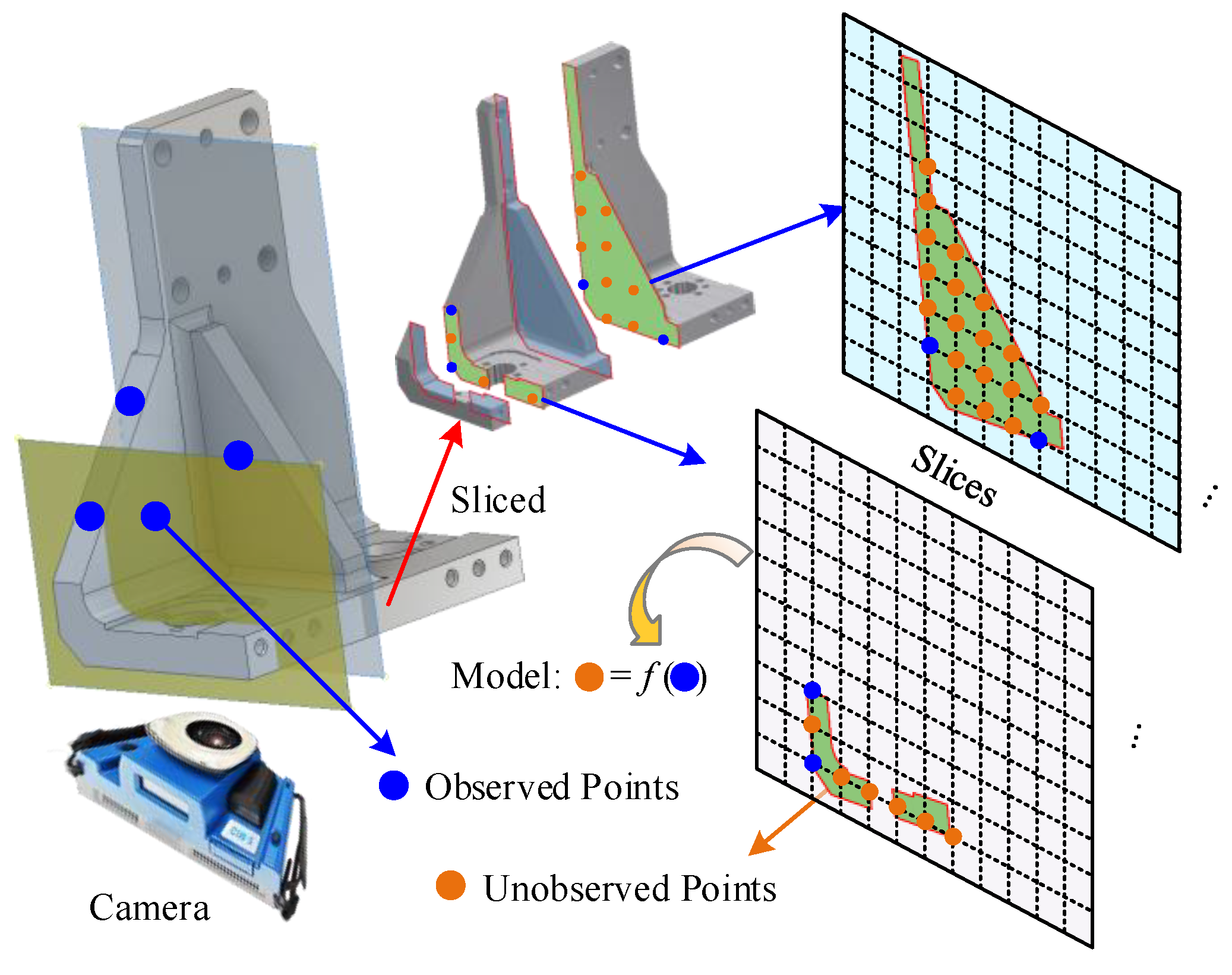

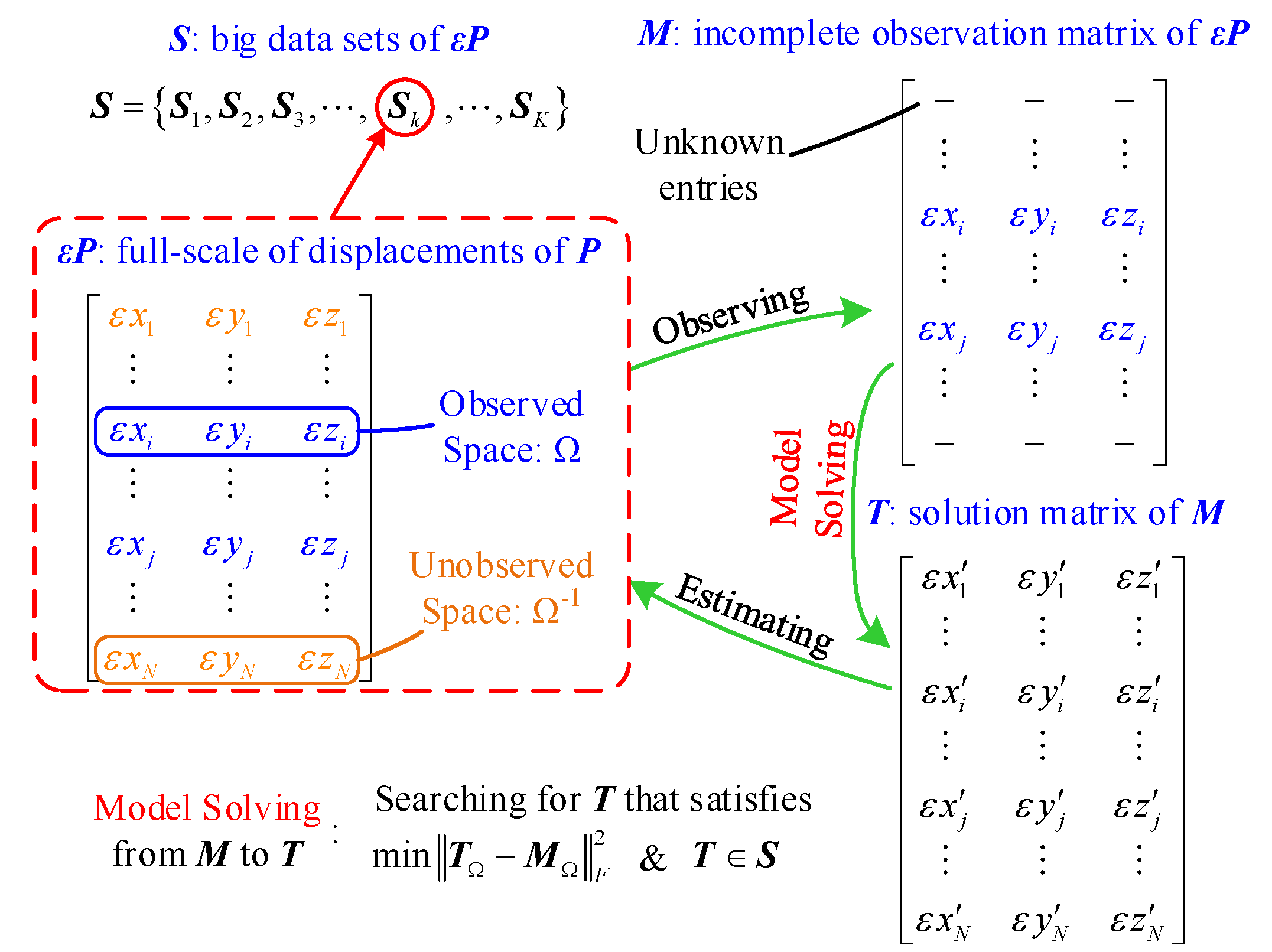

2. Modeling of the Full-Field Displacements

3. Model Solution

3.1. Equivalent Optimization Problem

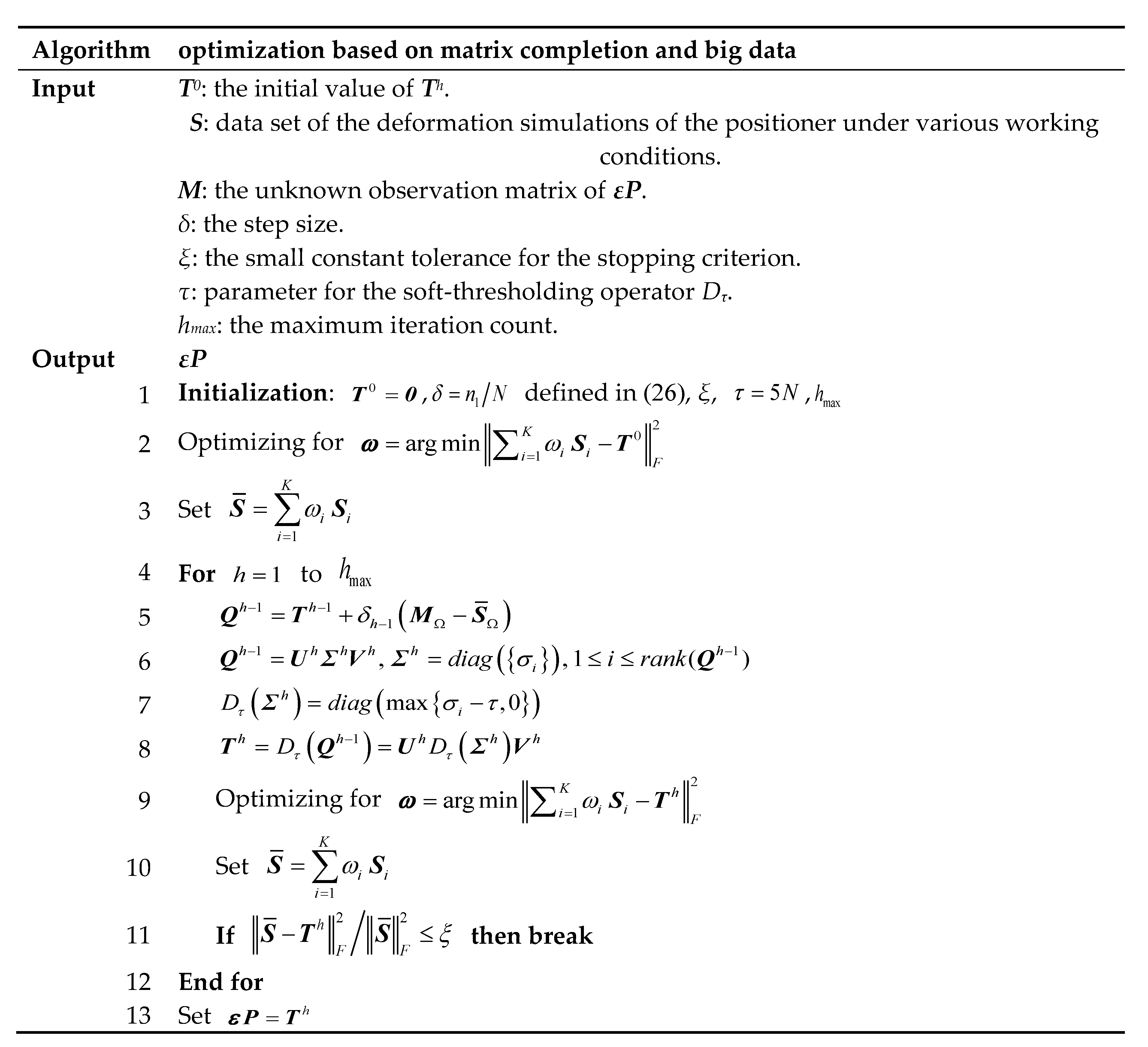

3.2. Solution of the Optimization Problem

3.3. Pseudo-Code

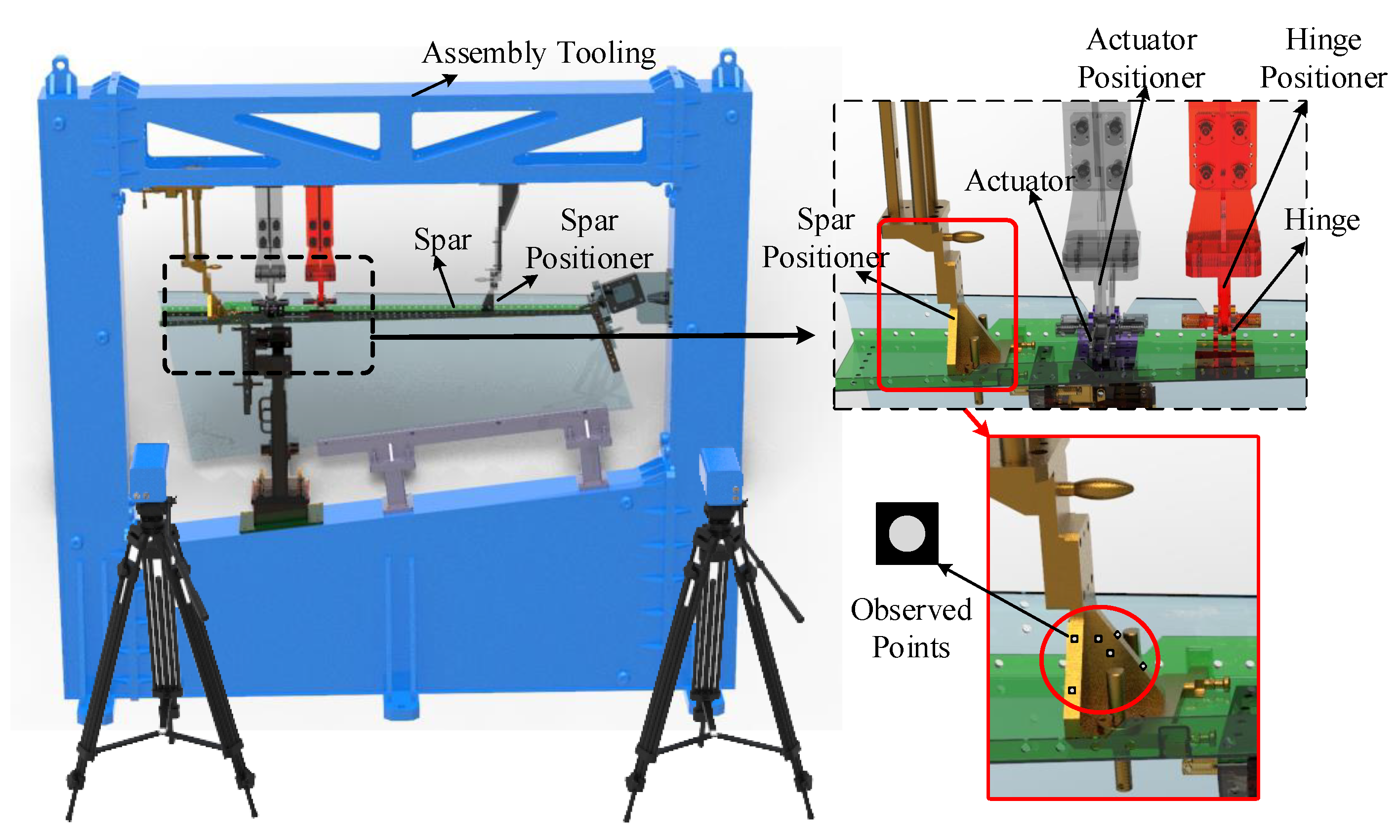

4. Experiments

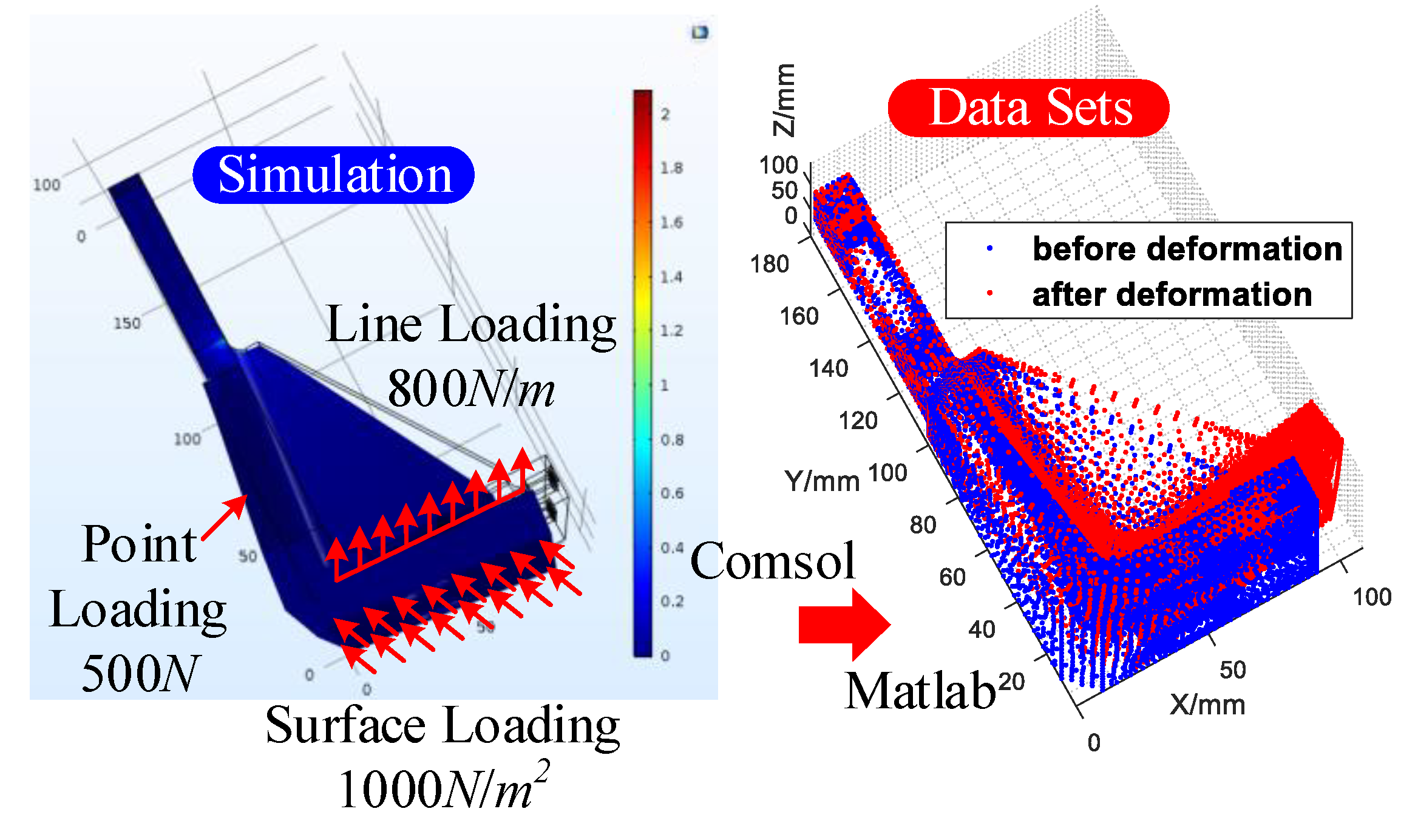

4.1. Simulation for Full-Field Displacement Data Sets

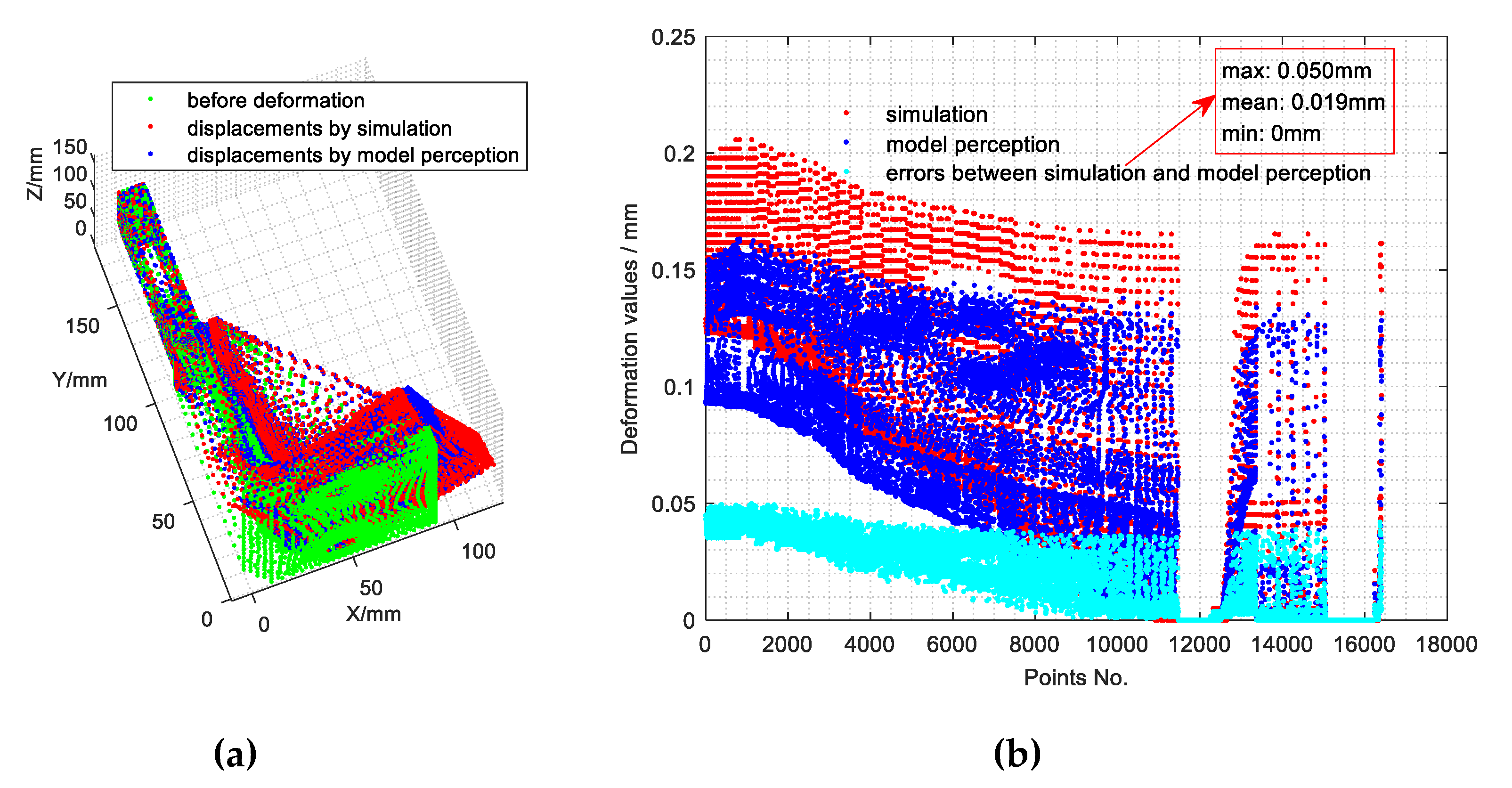

4.2. Accuracy Analysis Based on Simulation Data Sets

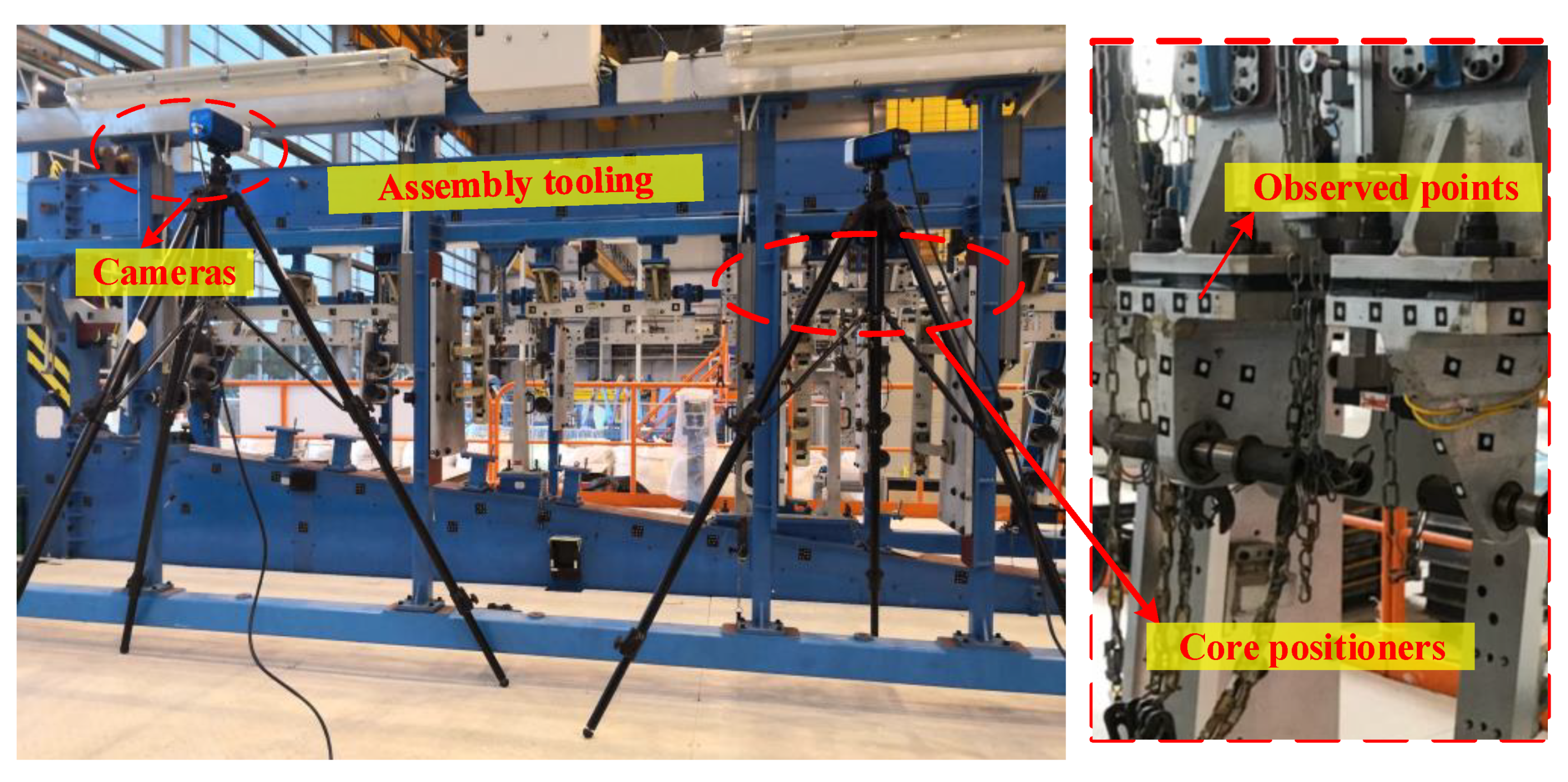

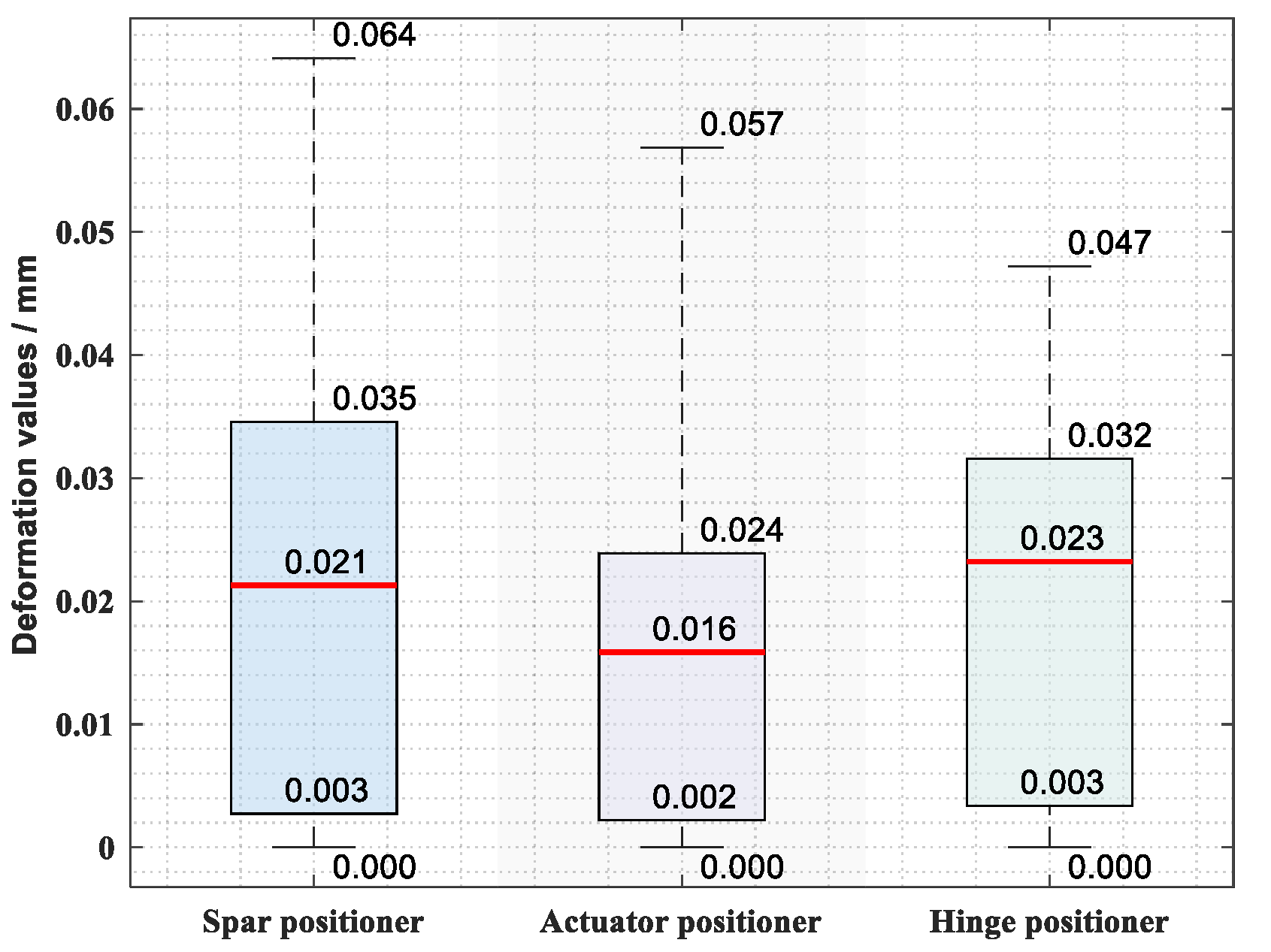

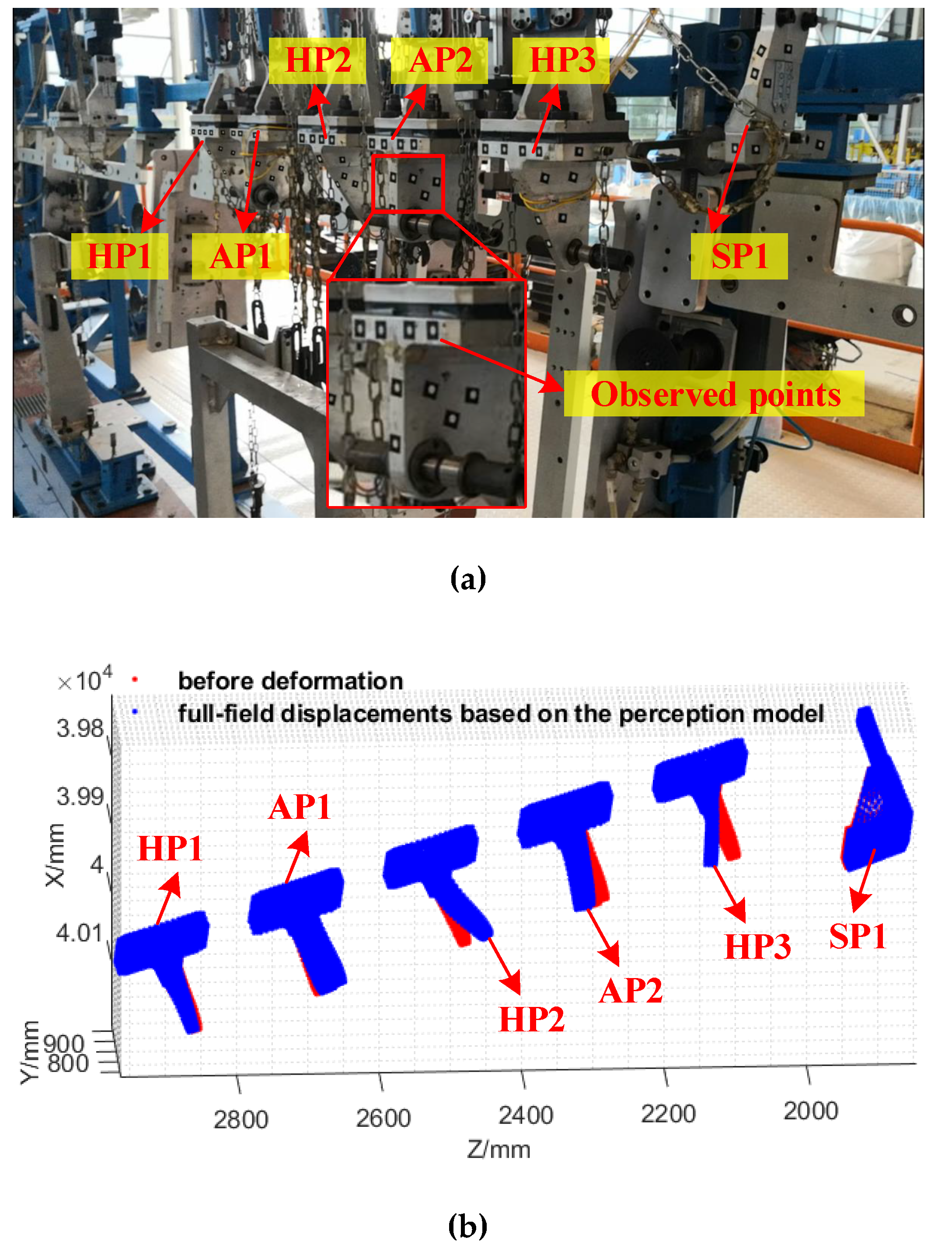

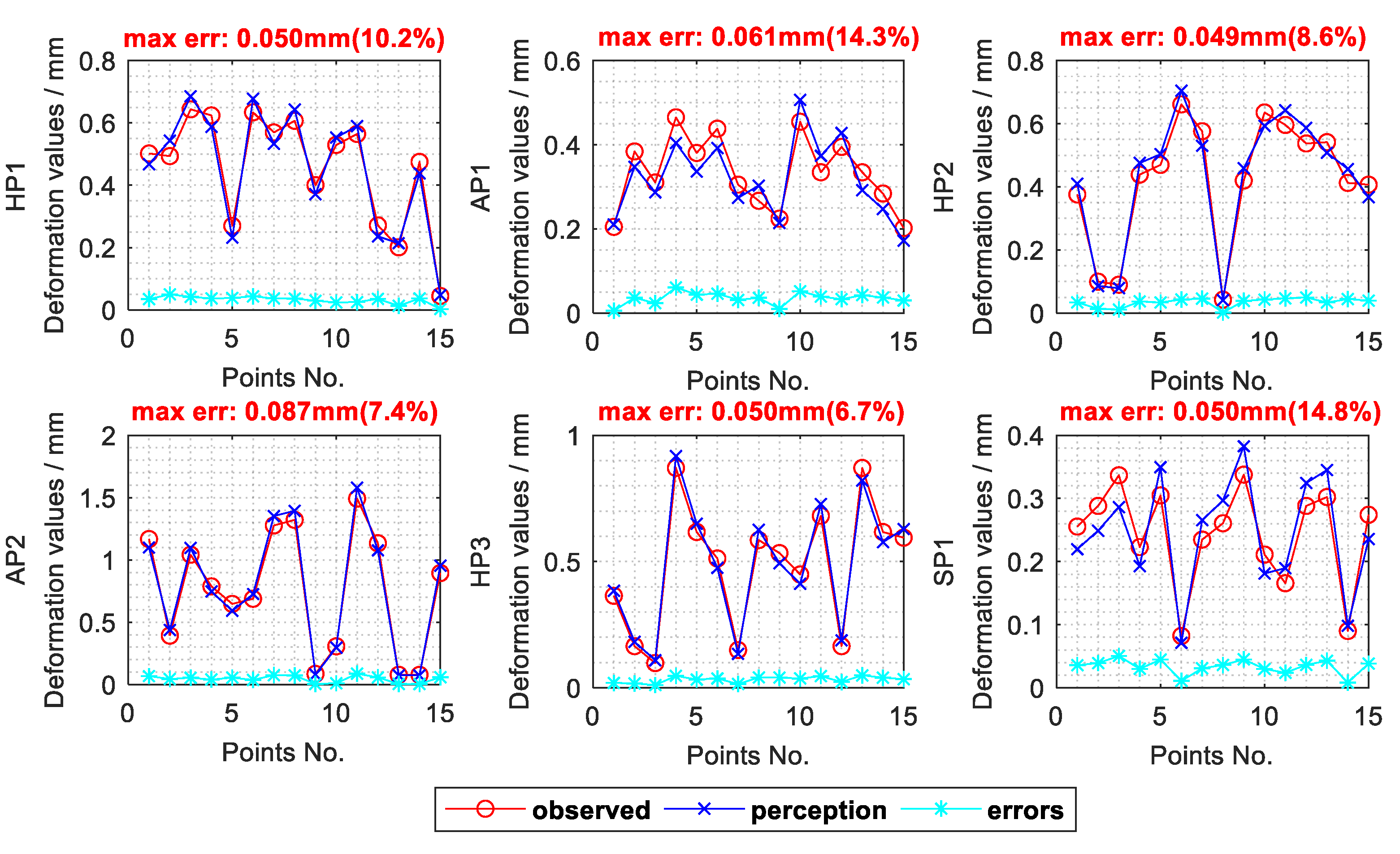

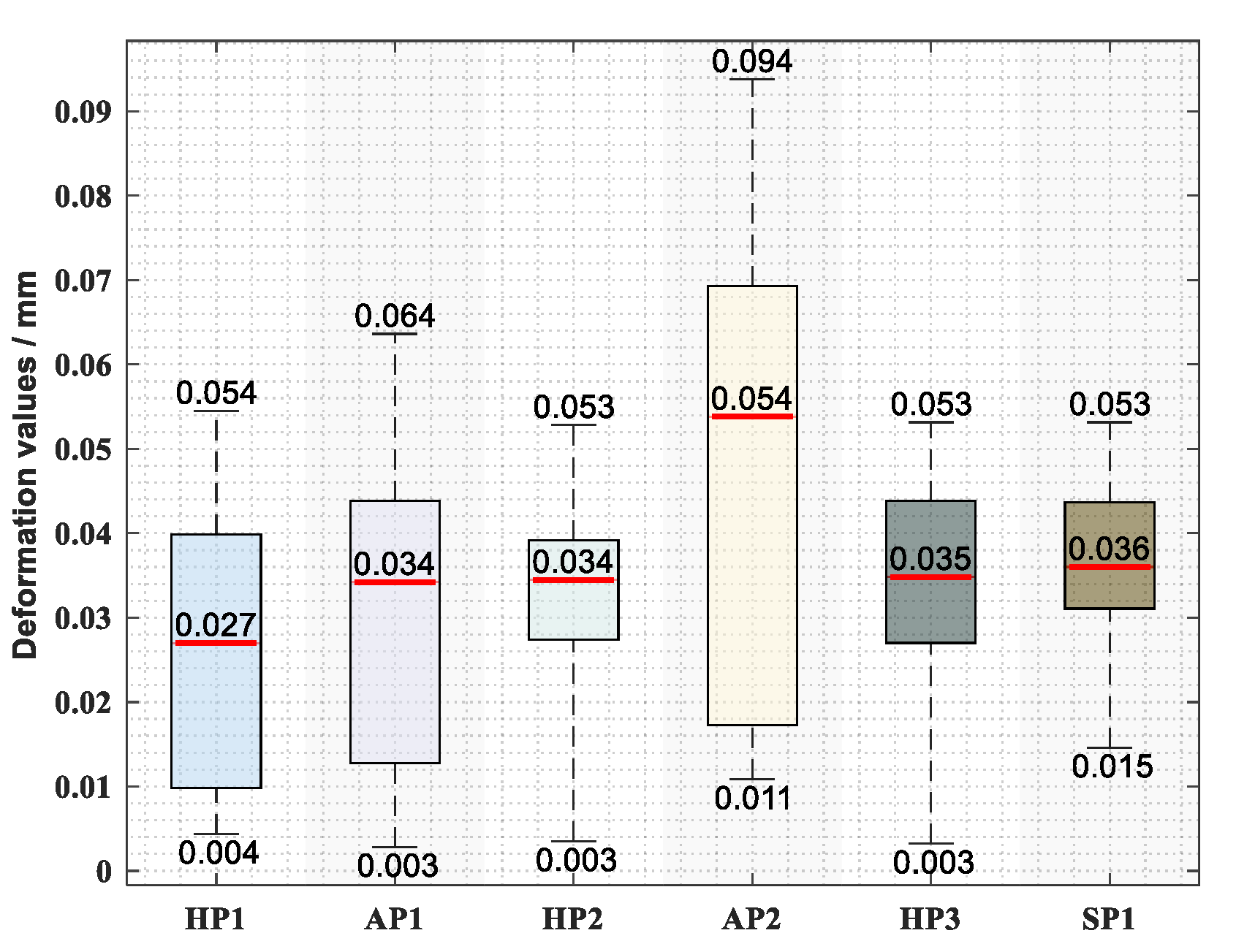

4.3. Digital Twin for the Core Positioners

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Peng, J.; Xu, W.; Liang, B.; Wu, A. Virtual Stereovision Pose Measurement of Noncooperative Space Targets for a Dual-Arm Space Robot. IEEE Trans. Instrum. Meas. 2020, 69, 76–88. [Google Scholar] [CrossRef]

- Lei, P.; Zheng, L. An automated in-situ alignment approach for finish machining assembly interfaces of large-scale components. Robot. Comput. Integr. Manuf. 2017, 46, 130–143. [Google Scholar] [CrossRef]

- Peng, J.; Xu, W.; Liang, B. An Autonomous Pose Measurement Method of Civil Aviation Charging Port Based on Cumulative Natural Feature Data. IEEE Sens. J. 2019, 19, 11646–11655. [Google Scholar] [CrossRef]

- Wu, L.; Xu, S.; Zhong, Z.; Mou, C.; Wang, X. An Inductive Sensor for Two-Dimensional Displacement Measurement. Sensors 2020, 20, 1819. [Google Scholar] [CrossRef]

- Lee, K.; Hao, B.; Li, M.; Bai, K. Multiparameter Eddy-Current Sensor Design for Conductivity Estimation and Simultaneous Distance and Thickness Measurements. IEEE Trans. Ind. Inform. 2019, 15, 1647–1657. [Google Scholar] [CrossRef]

- Liu, W.; Liang, B.; Jia, Z.; Feng, D.; Jiang, X.; Li, X.; Zhou, M. High-Accuracy Calibration Based on Linearity Adjustment for Eddy Current Displacement Sensor. Sensors 2018, 18, 2842. [Google Scholar] [CrossRef]

- Lee, T.; Kim, C.; Cho, D.D. A Monocular Vision Sensor-Based Efficient SLAM Method for Indoor Service Robots. IEEE Trans. Ind. Electron. 2019, 66, 318–328. [Google Scholar] [CrossRef]

- Zhao, Y.; Du, J.; Bao, H.; Xu, Q. Optimal Sensor Placement Based on Eig. Analysis for Sensing Deformation of Wing Frame Using iFEM. Sensors 2018, 18, 2424. [Google Scholar] [CrossRef]

- Liu, Z.; Wu, S.; Wu, Q.; Quan, C.; Ren, Y. A Novel Stereo Vision Measurement System Using Both Line Scan Camera and Frame Camera. IEEE Trans. Instrum. Meas. 2019, 68, 3563–3575. [Google Scholar] [CrossRef]

- An, Y.; Li, B.; Hu, H.; Zhou, X. Building an Omnidirectional 3-D Color Laser Ranging System Through a Novel Calibration Method. IEEE Trans. Ind. Electron. 2019, 66, 8821–8831. [Google Scholar] [CrossRef]

- Kim, Y.; Kim, K.; Kim, S. A Portable and Remote 6-DOF Pose Sensor System With a Long Measurement Range Based on 1-D Laser Sensors. IEEE Trans. Ind. Electron. 2015, 62, 5722–5729. [Google Scholar] [CrossRef]

- Kim, Y.; Kim, Y.; Jung, Y.; Jang, I.; Kim, K.; Kim, S.; Kwak, B. Developing Accurate Long-Distance 6-DOF Motion Detection With One-Dimensional Laser Sensors: Three-Beam Detection System. IEEE Trans. Ind. Electron. 2013, 60, 3386–3395. [Google Scholar]

- Liu, S.; Xu, D.; Zhang, D.; Zhang, Z. High Precision Automatic Assembly Based on Microscopic Vision and Force Information. IEEE Trans. Autom. Sci. Eng. 2016, 13, 382–393. [Google Scholar] [CrossRef]

- Palomer, A.; Ridao, P.; Forest, J.; Ribas, D. Underwater Laser Scanner: Ray-Based Model and Calibration. IEEE/ASME Trans. Mechatron. 2019, 24, 1986–1997. [Google Scholar] [CrossRef]

- Lembono, T.S.; Suarez-Ruiz, F.; Pham, Q. SCALAR: Simultaneous Calibration of 2-D Laser and Robot Kinematic Parameters Using Planarity and Distance Constraints. IEEE Trans. Autom. Sci. Eng. 2019, 16, 1971–1979. [Google Scholar] [CrossRef]

- Uekita, M.; Takaya, Y. On-machine dimensional measurement of large parts by compensating for volumetric errors of machine tools. Precis. Eng. 2016, 43, 200–210. [Google Scholar] [CrossRef]

- Li, S.; Zhang, W.; Cui, Y.; Cheng, H.V.; Yu, W. Joint Design of Measurement Matrix and Sparse Support Recovery Method via Deep Auto-Encoder. IEEE Signal Process. Lett. 2019, 26, 1778–1782. [Google Scholar] [CrossRef]

- Li, C.; Mahadevan, S.; Ling, Y.; Choze, S.; Wang, L. Dynamic Bayesian Network for Aircraft Wing Health Monitoring Digital Twin. AIAA J. 2017, 55, 930–941. [Google Scholar] [CrossRef]

- Knapp, G.L.; Mukherjee, T.; Zuback, J.S.; Wei, H.L.; Palmer, T.A.; De, A.; DebRoy, T. Building blocks for a digital twin of additive manufacturing. Acta Mater. 2017, 135, 390–399. [Google Scholar] [CrossRef]

- Xiong, J.; Zhang, G.; Hu, J.; Wu, L. Bead geometry prediction for robotic GMAW-based rapid manufacturing through a neural network and a second-order regression analysis. J. Intell. Manuf. 2014, 25, 157–163. [Google Scholar] [CrossRef]

- Li, X.; Wang, Z.; Fu, L. A High-speed in Situ Measuring Method for Inner Dimension Inspection. IEEE Trans. Instrum. Meas. 2017, 66, 104–112. [Google Scholar] [CrossRef]

- Zambal, S.; Eitzinger, C.; Clarke, M.; Klintworth, J.; Mechin, P. A digital twin for composite parts manufacturing: Effects of defects analysis based on manufacturing data. In Proceedings of the IEEE 16th International Conference on Industrial Informatics, Porto, Portugal, 18–20 July 2018; pp. 803–808. [Google Scholar]

- Guo, J.; Lee, K.; Liu, W.; Wang, B. Design Criteria Based on Modal Analysis for Vibration Sensing of Thin-Wall Plate Machining. IEEE/ASME Trans. Mechatron. 2015, 20, 1406–1417. [Google Scholar] [CrossRef]

- Guo, J.; Liu, R.; Lee, K. Displacement field sensing and reconstruction for vibration of a thin-wall plate. In Proceedings of the 2015 IEEE International Conference on Advanced Intelligent Mechatronics (AIM), Busan, Korea, 7–11 July 2015; pp. 1350–1355. [Google Scholar]

- Tao, F.; Zhang, H.; Liu, A.; Nee, A.Y.C. Digital Twin in Industry: State-of-the-Art. IEEE Trans. Ind. Inform. 2019, 15, 2405–2415. [Google Scholar] [CrossRef]

- DebRoy, T.; Zhang, W.; Turner, J.; Babu, S.S. Building digital twins of 3D printing machines. Scr. Mater. 2017, 135, 119–124. [Google Scholar] [CrossRef]

- Mandolla, C.; Petruzzelli, A.M.; Percoco, G.; Urbinati, A. Building a digital twin for additive manufacturing through the exploitation of blockchain: A case analysis of the aircraft industry. Comput. Ind. 2019, 109, 134–152. [Google Scholar] [CrossRef]

- Cerrone, A.; Hochhalter, J.; Heber, G.; Ingraffea, A. On the Effects of Modeling As-Manufactured Geometry: Toward Digital Twin. Int. J. Aerospace Eng. 2014, 2014, 439278. [Google Scholar] [CrossRef]

- Tabar, R.S.; Wärmefjord, K.; Söderberg, R. A method for identification and sequence optimisation of geometry spot welds in a digital twin context. Proc. Inst. Mech. Eng. Part C J. Eng. Mech. Eng. Sci. 2019, 233, 5610–5621. [Google Scholar] [CrossRef]

- Rezaei Aderiani, A.; Wärmefjord, K.; Söderberg, R.; Lindkvist, L. Developing a selective assembly technique for sheet metal assemblies. Int J. Prod. Res. 2019, 57, 7174–7188. [Google Scholar] [CrossRef]

- Larsson, V.; Olsson, C.; Bylow, E.; Kahl, F. Rank Minimization with Structured Data Patterns. In Proceedings of the 13th European Conference on Computer Vision (ECCV), Zurich, Switzerland, 6–12 September 2014; pp. 250–265. [Google Scholar]

- Liu, J.; Musialski, P.; Wonka, P.; Ye, J. Tensor Completion for Estimating Missing Values in Visual Data. IEEE Trans Pattern Anal. Mach. Itell. 2013, 35, 208–220. [Google Scholar] [CrossRef]

- Cai, J.; Candes, E.J.; Shen, Z. A Singular Value Thresholding Algorithm for Matrix Completion. SIAM J. Optim. 2010, 20, 1956–1982. [Google Scholar] [CrossRef]

- Bahri, M.; Panagakis, Y.; Zafeiriou, S. Robust Kronecker Component Analysis. IEEE Trans Pattern Anal. Mach. Itell. 2019, 41, 2365–2379. [Google Scholar] [CrossRef] [PubMed]

| Loading Mode | Group Counts |

|---|---|

| point loading | |

| line loading | 10,647 |

| surface loading | 10,647 |

| mixed loading | |

| total | 293,895 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liang, B.; Liu, W.; Liu, K.; Zhou, M.; Zhang, Y.; Jia, Z. A Displacement Field Perception Method for Component Digital Twin in Aircraft Assembly. Sensors 2020, 20, 5161. https://doi.org/10.3390/s20185161

Liang B, Liu W, Liu K, Zhou M, Zhang Y, Jia Z. A Displacement Field Perception Method for Component Digital Twin in Aircraft Assembly. Sensors. 2020; 20(18):5161. https://doi.org/10.3390/s20185161

Chicago/Turabian StyleLiang, Bing, Wei Liu, Kun Liu, Mengde Zhou, Yang Zhang, and Zhenyuan Jia. 2020. "A Displacement Field Perception Method for Component Digital Twin in Aircraft Assembly" Sensors 20, no. 18: 5161. https://doi.org/10.3390/s20185161

APA StyleLiang, B., Liu, W., Liu, K., Zhou, M., Zhang, Y., & Jia, Z. (2020). A Displacement Field Perception Method for Component Digital Twin in Aircraft Assembly. Sensors, 20(18), 5161. https://doi.org/10.3390/s20185161