1. Introduction

With gradual degradation of many important civil structures (e.g., high-rise buildings and long-span bridges), the safety of these structures becomes a public concern, particularly after these structures are subjected to extreme loads (e.g., earthquakes or strong winds). Structural health monitoring (SHM) systems are an effective measure to detect structural damage in time and ensure the safe operation of these engineering structures [

1,

2,

3]. Structural vibration monitoring is one of core functions of SHM systems. Traditional structural vibration monitoring generally relies on expensive specialized sensors, data transmission and acquisition equipment. Thus, only very important structures are affordable to install a SHM system. However, when an extreme event (e.g., earthquake) occurs, many structures may be damaged. Since it is impractical to install SHM systems on all structures in advance, it will be of great value to develop new affordable and efficient structural vibration monitoring technique, which can be easily available and quickly deployed to assess the structural integrity and safety after the extreme events.

In recent years, smartphone technology has advanced very rapidly. Nowadays, smartphones are not only equipped with powerful data acquisition, processing, storage and transmission capabilities but also integrated with a variety of high-performance vibration sensors (e.g., accelerometers and gyroscopes), which makes it possible to utilize smartphones to carry out the SHM tasks, like structural vibration monitoring.

Compared with the traditional dedicated SHM system, using smartphones for structural vibration monitoring has many attractive advantages: (1) smartphones are very popular and easily available; thus, it is possible to quickly deploy a large number of smartphones as vibration sensors on the structure at relatively low cost, which may be very useful in emergent case, like post-disaster structural evaluation, to quickly access structural integrity condition; (2) smartphones are integrated with a lot of telecommunication technology (e.g., WIFI, Bluetooth, near-field communication and 3G/4G etc.), which provides many flexible ways to build a smartphone-based wireless structural health monitoring network, allowing the smartphones to easily communicate and transmit the monitoring data one other; (3) smartphones also have powerful computing and data storing capacity, which can be used to analyze the monitored structural responses and evaluate structural health status directly on the smartphones, achieving the efficient distributed SHM.

Due to the above attracting features of using smartphones to carry out SHM tasks, many researchers have conducted different research on smartphone-based SHM applications. Kong etc. [

4] verified the possibility of using accelerometers inside smartphones to measure the building accelerations, which were excited by a shake installed on the roof. Feng et al. [

5] proposed to use ubiquitous smartphones to form a low-cost wireless citizen sensor network, measuring structural vibrations during earthquakes to facilitate post-disaster structural evaluation. Ozer et al. [

6] investigated to use heterogeneous sensor data in iPhone to obtain instantaneous phone’s orientation, which can be utilized to correct misaligned sensor signals and improve the efficiency of structural data analysis. Zhao et al. [

7] investigated the possibility of using smartphones to carry out dynamic testing of cable structures. Li et al. [

8] utilized the camera of smartphone to measure the interstory drift of building structures during earthquakes. Xie et al. [

9] conducted an experiment to verify the feasibility of using smartphones to perform structural damage detection of a 3-D steel frame structure. Matarazzo et al. [

10] and Ozer et al. [

11] proposed to use smartphones to identify the bridge’s modal frequencies, which provides a low-cost and efficient method to collect the structural health condition data of the bridges.

Despite a lot of smartphone-based SHM research have been carried out, there are still many challenges for smartphone-based SHM. First, the smartphone-integrated vibration sensor is not of scientific instrument standard and the sensors in different smartphone may have large different accuracy, which greatly affect the quality of the measured data. Second, since smartphones are not initially designed as sensors, they cannot collect signals from integrated sensors according to a strict time schedule as regular sensors do, which poses a difficulty for data analysis. Third, the sampling rate of the smartphone sensors may not be higher enough to measure the vibration of a very stiff structure, which limits the application ranges of the smartphone-based SHM.

Moreover, extensive research of using smartphones for SHM have been conducted, but most of them focus on the utilization of single smartphone. Although there are a few studies [

11,

12,

13] that used multiple smartphones together, the measurement data from these smartphones are not time-synchronized. Therefore, all structural analyses that requires the synchronized measurements cannot be applied. For structural modal parameter identification, many methods (e.g., frequency domain decomposition, Next-ERA, subspace identification, etc.) need the measured structural responses to be synchronized; several researches showed [

14,

15,

16] that large asynchronous error may significantly deteriorate the accuracy of identified structural modal parameters. Hence, developing techniques that can efficiently organize multiple smartphones to work coordinately and simultaneously measure structural responses with high accuracy of time synchronization will be of great value for the SHM applications like structural vibration monitoring.

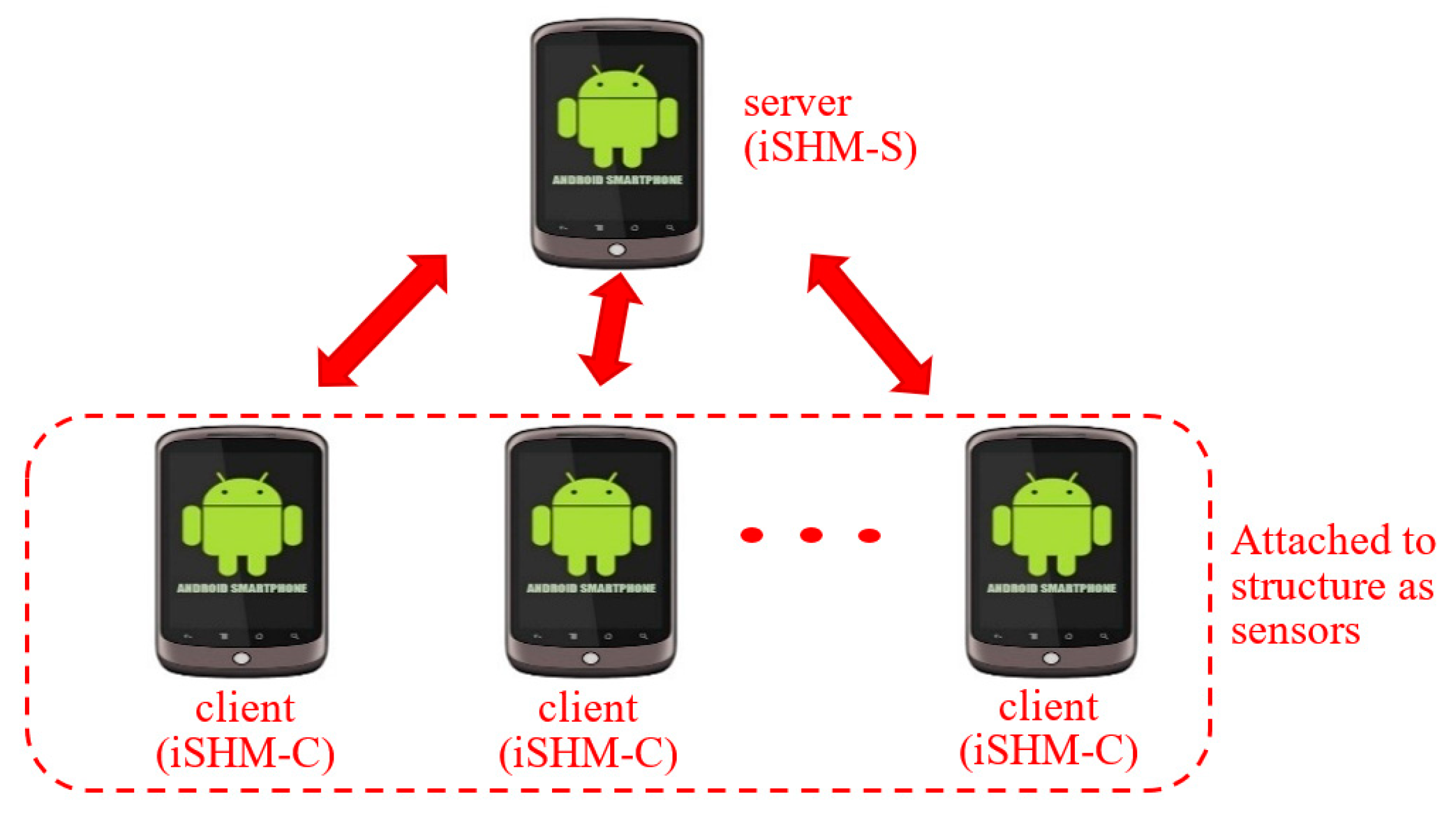

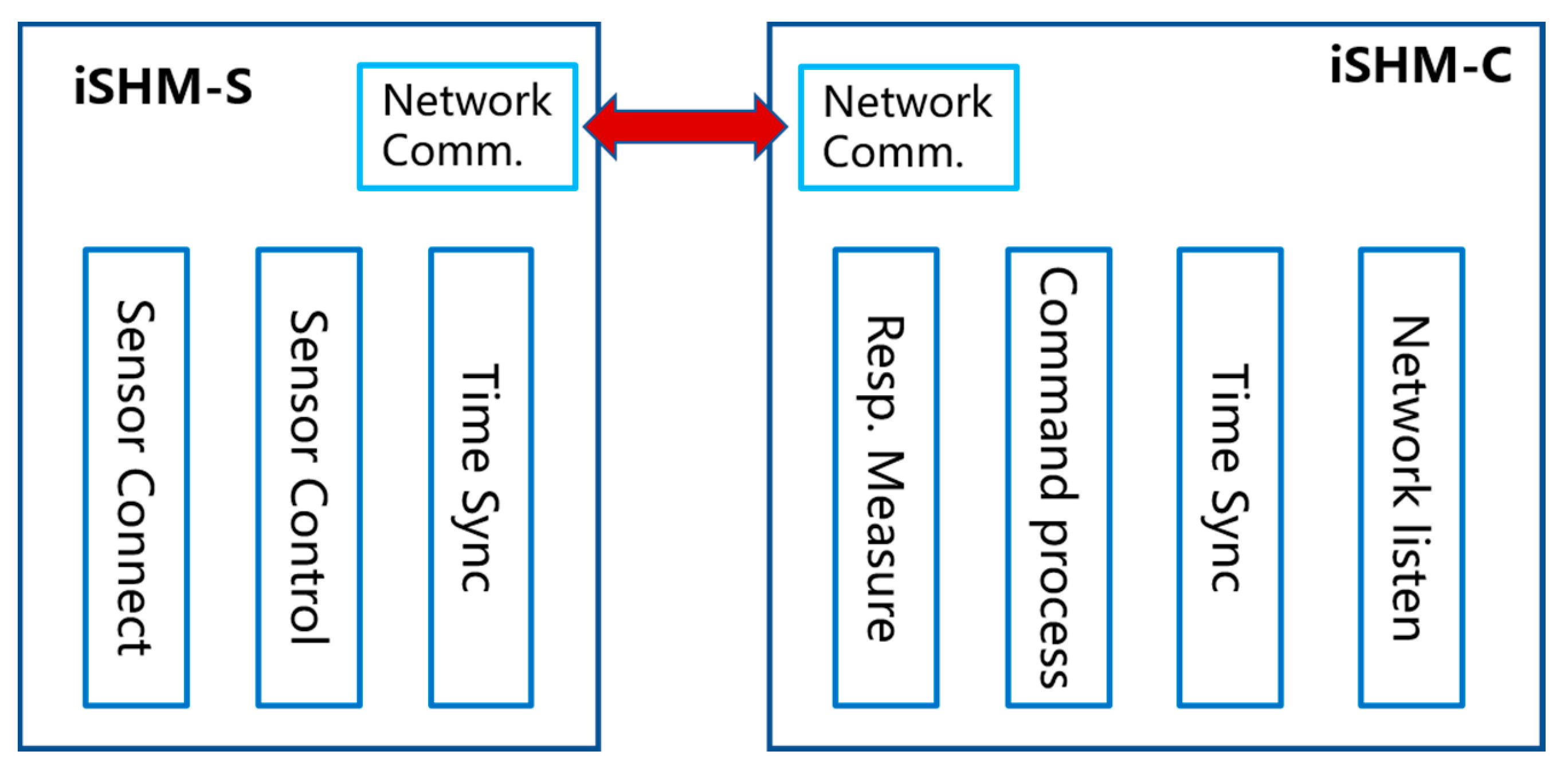

In this paper, an android system-based APP, developed by the authors, is presented, which can easily convert multiple android smartphones into a wireless structural vibration monitoring system, measuring structural vibration with high accuracy of time synchronization. The developed smartphone-based system provides a new and easy way to quickly deploy a wireless structural vibration monitoring network on the structure, which is of great value for the applications like post-disaster structural evaluation.

The organization of the paper is listed as follows. First, the system architecture of the smartphone-based system is introduced in detail, which can efficiently organize multiple smartphones to form a wireless sensor monitoring network. Second, a time synchronizing method is developed for the smartphone-based system, which can synchronize the time clocks of the smartphones with high accuracy for simultaneously structural vibration monitoring. Then, an experiment is designed and conducted to verify the time synchronization accuracy of the designed smartphone-based monitoring system; and a new upsampling-based analysis method is also proposed to improve the resolution of time synchronization accuracy analysis. Finally, shake table tests are conducted on a three-story small-scale structural model to check the performance of the developed smartphone-based monitoring system for structural modal parameter identification, demonstrating that the system can quite accurately identify the structural natural frequencies and mode shapes.

3. Time Synchronization of Smartphone-Based Monitoring System

For a structural vibration measurement system, time synchronization among different sensors is of great importance, because asynchronized structural measurements may lead to large errors of structural modal parameter estimation [

14,

15,

16]. In contrast to the wired SHM system, in which all sensors are securely connected via electrical cables and can synchronously collect data based on the uniform time clock of the data acquisition system, every wireless sensor collect data according to its own local time clock. Therefore, wireless monitoring systems have to adopt some kinds of time synchronization algorithms to keep the local time clocks of all wireless sensors synchronized.

There are many time synchronization algorithms for wireless sensor network [

17]. In this study, according to the characteristics of the designed smartphone-based wireless system, a sender-receiver based time synchronization algorithms is deployed, which is explained thereafter.

Figure 6 shows the process of a message that is sent from the server (i.e., server smartphone) to the client (i.e., sensor smartphone). Then, the time delay

between the time when the message is sent in the server and the time when the message is received by the client can be calculated by Equation (1).

where

is the time delay that the server needs to send out the message,

is the time delay of network communication,

is the time delay that the client needs to process the message,

is the difference of local time clock between the server and the client, which needs determining to synchronize the local time clocks of the server and the client. Since

,

and

in Equation (1) are related to the operation status of the server and client as well as the congestion condition of network communication, which are unknown in advance,

cannot be directly determined by Equation (1).

To obtain the local time difference

, the following operations are carried out. First, the server sends a package with the server’s time stamp, following with a ping command to the client. After the client receives the package, it will calculate the time difference

based on the local time of receiving the message, and send this value back to the server. Simultaneously, the client will automatically reply to the ping command of the server. As shown in

Figure 7, the time difference

between the time when the server sends out ping command and the time when the server receives the reply from the client can be approximated by Equation (2).

Since the client will immediately reply to the ping command from the server, the time delay between the client’s receiving and replying the ping command is ignored herein. Combining Equations (1) and (2), the local time difference

can be estimated as:

However, due to the uncertainties in the wireless communication as well as the operation status of the server and client, the estimated time differences

will be varying in different tests. For example,

Figure 8 demonstrates the distribution of the estimated time differences

of 100 synchronization tests, which has a standard deviation of 3.1 millisecond. To further reduce the uncertainty in the time synchronization, the above message-sending procedure is carried out

n times for each time synchronization operation, and the mean value of all

n estimated time differences

in Equation (3) will be used to synchronize the local time clocks of the server and the client.

The reason that the above averaging operation can reduce the uncertainty of time synchronization is explained as follows. It is assumed herein that all the estimated time differences are statistically independent and identically distributed, which follow a normal probability distribution , where is the mean and assumed to be the true time difference between the server and the client; is the standard deviation of the distribution. Based on the above assumption, it can be easily obtained that the standard deviation of the mean estimate of the n results will reduce to , and the 95% confident range of the mean estimate is . Clearly, increasing the average time n can lead to a more accurate time synchronization result. After considering the trade-off between the synchronization accuracy and the synchronization operation time, the average time n is selected as 30 in the APP design; consequently, the time synchronization accuracy can reach around one millisecond. It is noted that the above time synchronization analysis is conducted based on a very idealistic assumption, which may not be true in real situation. Thus, an experiment will be performed in the next section to verify the effectiveness of the proposed time synchronization method for the developed smartphone-based structural vibration monitoring system.

6. Conclusions

In this study, an android-smartphone based structural vibration system was developed, which can easily convert multiple android smartphones into a wireless sensor network to measure structural vibration. The server/client architecture is adopted for the designed system. One smartphone is selected as the server to remotely control all other smartphones that serves as sensors to measure structural accelerations. A new method is proposed to quickly set up the network communication between the server and sensor smartphones, which facilitates fast deployment of a lot of smartphones as sensors on the structure. Furthermore, to ensure sensor smartphones simultaneously measuring structural responses, a time synchronization method is proposed for the smartphone-based structural vibration monitoring system, which is verified by the experiment to be able to achieve the time synchronization accuracy of millisecond level between sensor smartphones. Finally, a shaking table experiment is conducted, which demonstrates that the designed smartphone-based wireless structural vibration monitoring system can quite accurately identify the modal parameters of the tested structure.

Although the preliminary study in this paper has demonstrated promising potentials for the developed smartphone-based structural vibration monitoring system, more comprehensive tests are still needed to further test the performance of the developed system in more complex working environments. Because the performance of the time synchronization and the structural modal parameter identification of the developed system is affected by many parameters, including the specifications of the smartphone sensors, the electro-magnetic working environment of the system, etc., all of these have not been extensively tested in this paper, which will be an important research direction in future.